RFID-based rapid automated weighing system

A weighing system and fast technology, applied in the field of RFID, can solve the problems of high degree of equipment customization, affecting system response time, large error, etc., to achieve the effect of automatic management, high system compatibility, and fast weighing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

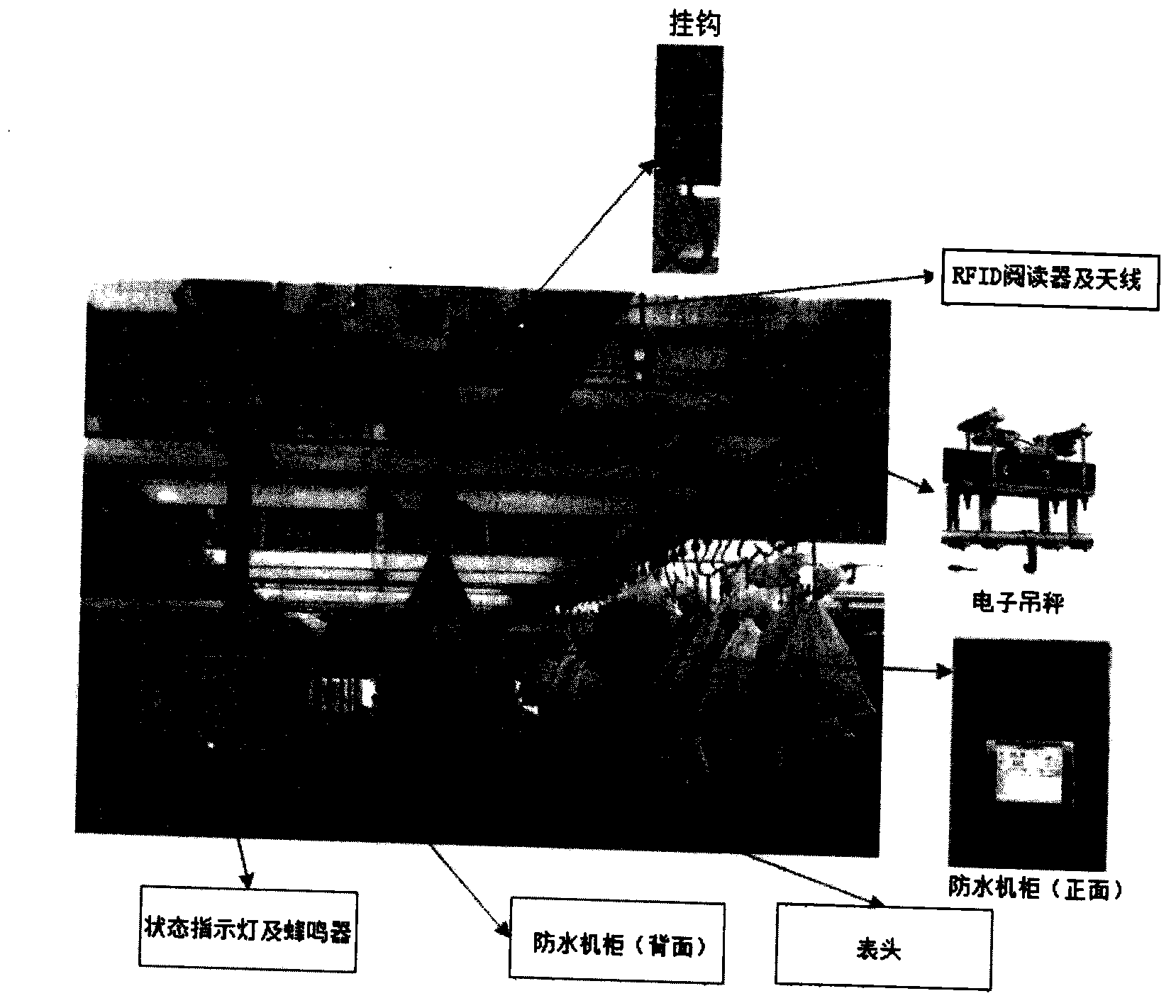

[0031] Example 1: Pork weighing system of Shanghai Xijiao International Agricultural Trade Center.

[0032] Such as figure 2 As shown, in this case, a complete set of automatic weighing system based on RFID is used to carry out weighing and storage management of fresh white striped pigs. The white-striped pig is in a suspended state, and the scale adopts a monorail electronic hanging scale, and RFID is bound to the pork hook. The picture shows the system is in trial operation.

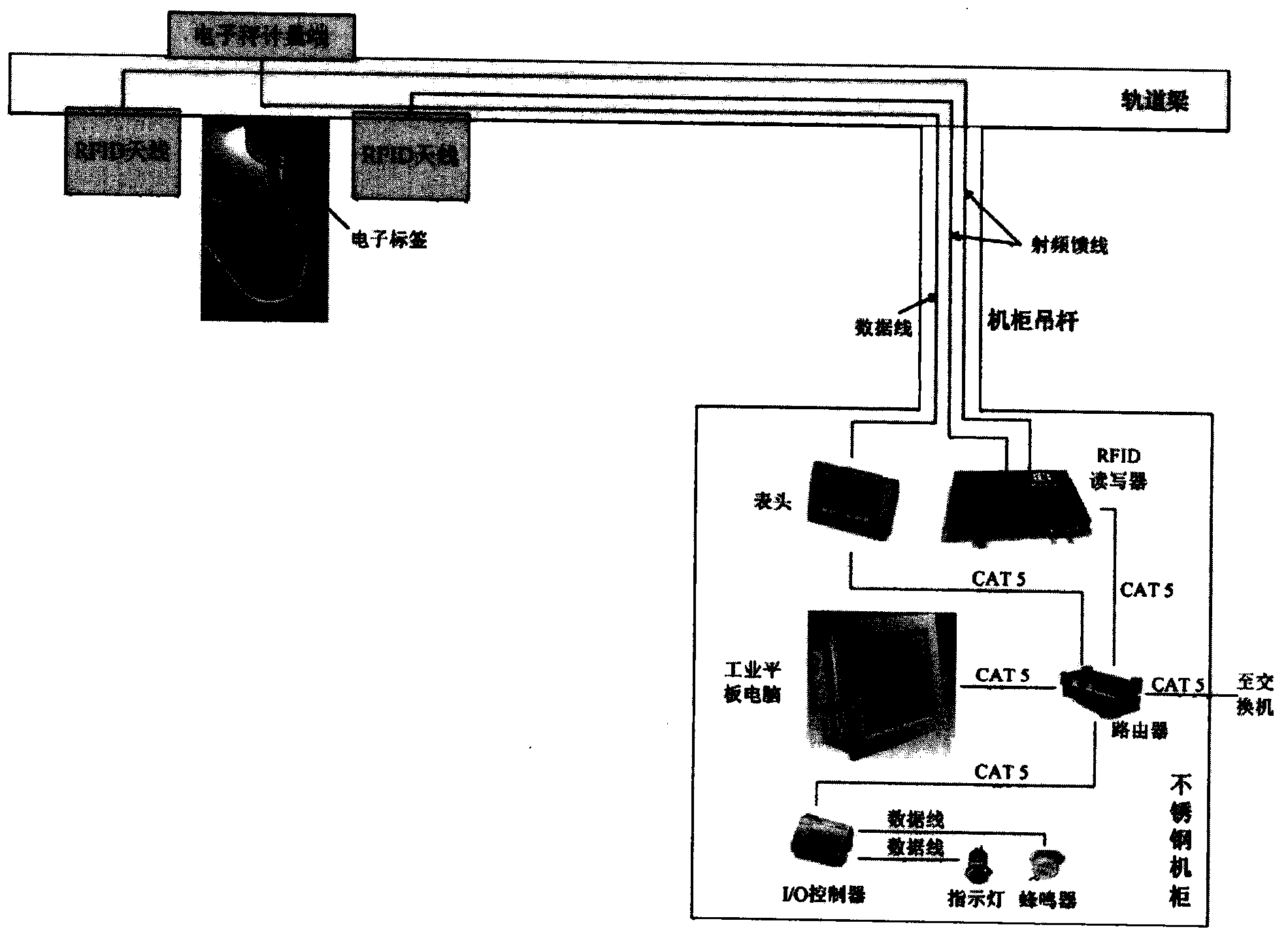

[0033] The pig automatic weighing system includes a data acquisition module, a mechanical module, an information processing module and an information output module, wherein:

[0034] The data acquisition module includes an electronic scale and an RFID device, which are used to collect weight and hook label information respectively. The electronic scale is composed of a meter head and a sensor, and the RFID device is composed of a reader and an antenna;

[0035] The mechanical module includes a guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com