Patents

Literature

105results about How to "More calories" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions and methods for supplementing the diet

InactiveUS20190313682A1Lower sugar contentIncrease in blood sugarAcidic food ingredientsFood ingredient as flavour affecting agentMedicineKetogenic diet

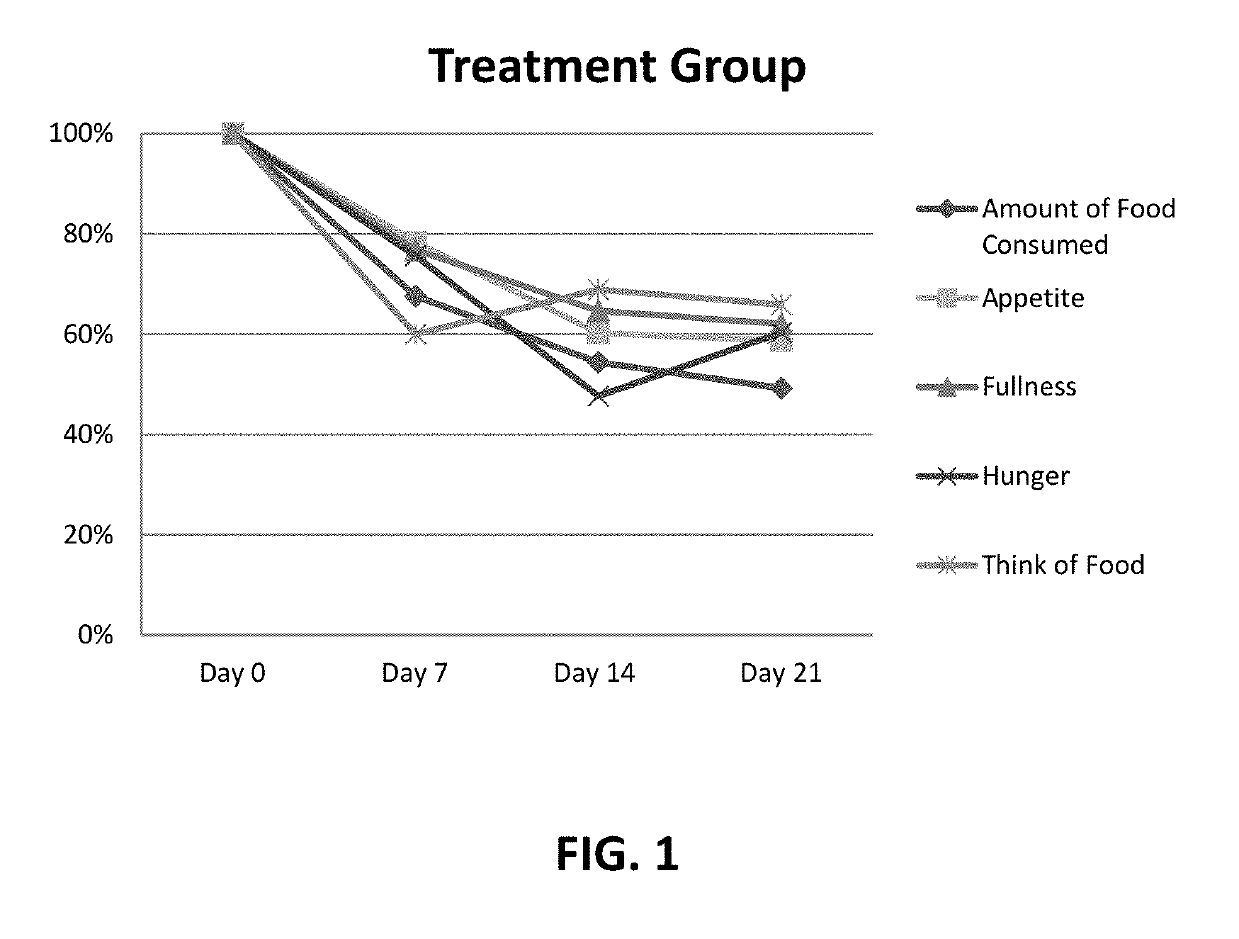

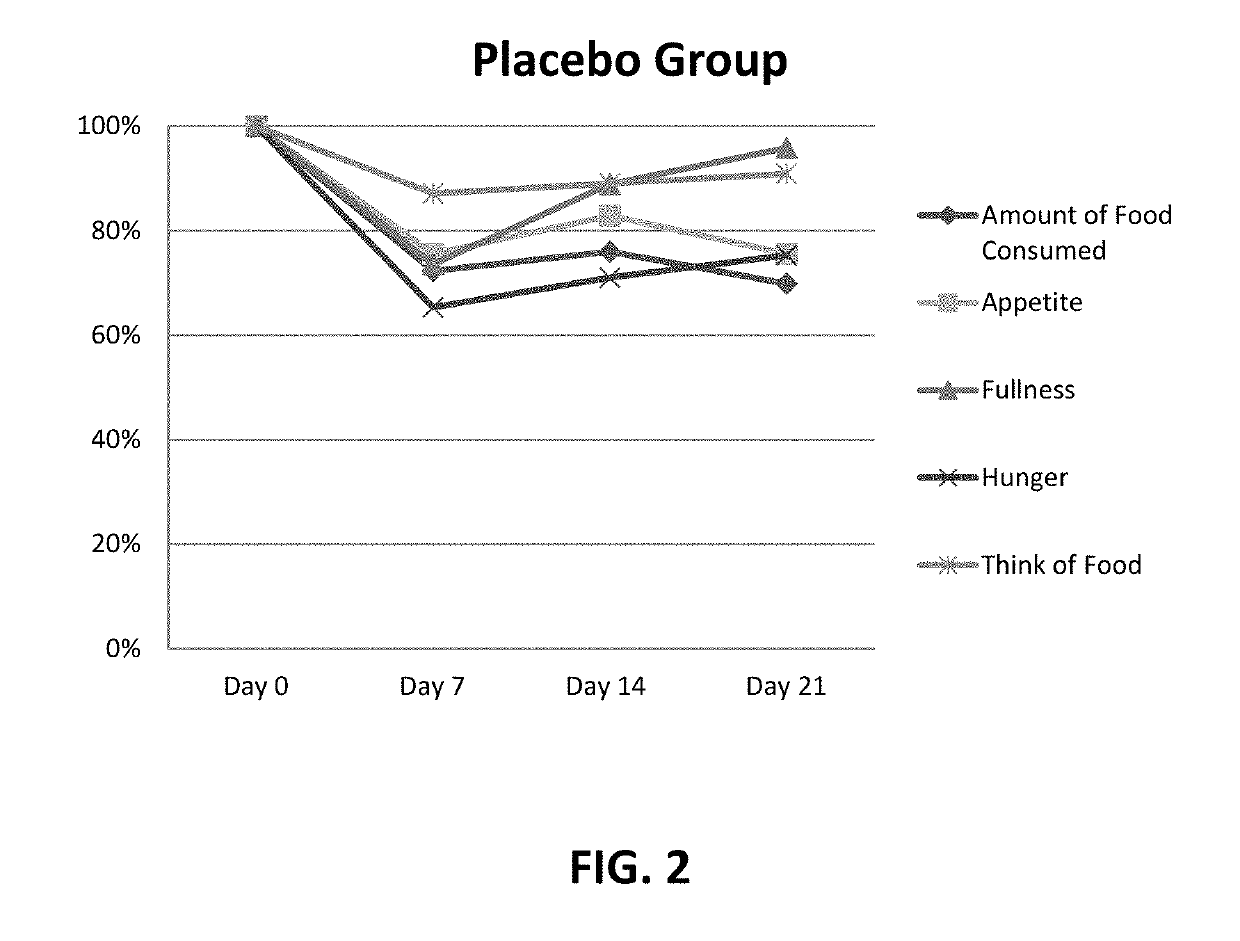

Various aspects and embodiments disclosed herein relate generally to compositions that can be used to increase physical and mental energy, reduce the sensation of hunger. At least some of the composition disclosed herein can be used to obviate or moderate some of the discomfort which may be associated with initiating or maintaining reduced calorie and / or ketogenic diets.

Owner:METABOLIC RECOVERY SYST LLC

High-efficiency coal-saving burning additive

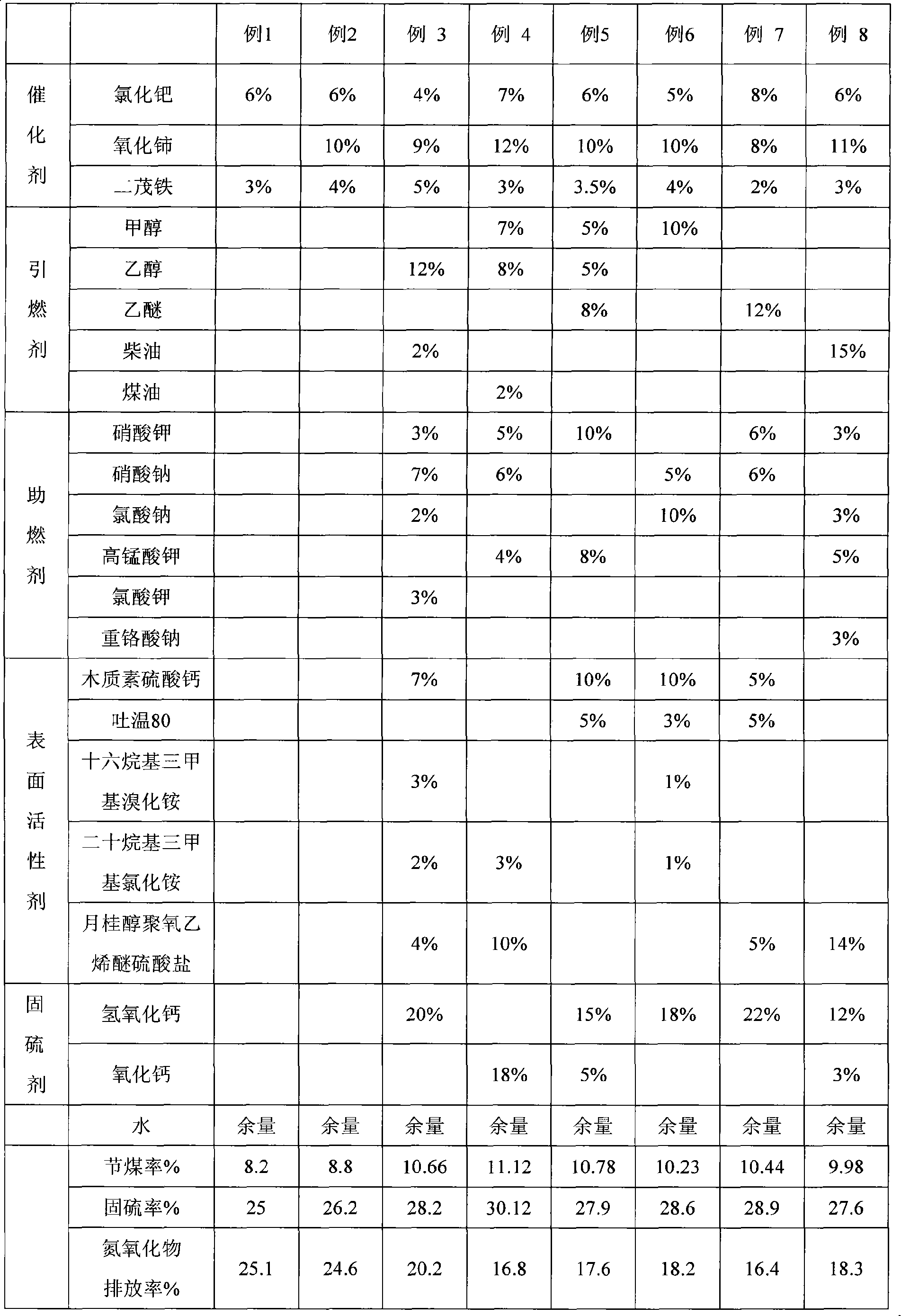

The invention relates to a high-efficiency coal-saving combustion-supporting additive, which comprises the following compositions in weight percentage: 2 to 5 percent of dicyclopentadienyl iron, 4 to 8 percent of palladium chloride, 8 to 12 percent of cerium oxide, 13 to 16 percent of surfactant, 10 to 18 percent of detonator, 12 to 18 percent of combustion promoter, 15 to 22 percent of sulphur-fixing agent, and the balance being water. The method for preparing the high-efficiency coal-saving combustion-supporting additive comprises the steps that: a catalyst, the sulfur-fixing agent, the detonator, the combustion promoter, the surfactant and the water are added according to the proportion and are stirred evenly to obtain the high-efficiency coal-saving combustion-supporting additive. The high-efficiency coal-saving combustion-supporting additive has no corrosiveness, is safe and steady under normal temperature and normal pressure, ensures that bunker coal is completely combusted, improves thermal efficiency, saves energy sources, reduces the emission of harmful gas such as sulfur dioxide and so on simultaneously, has simple preparation technology, and reduces production cost.

Owner:梁宴邱 +1

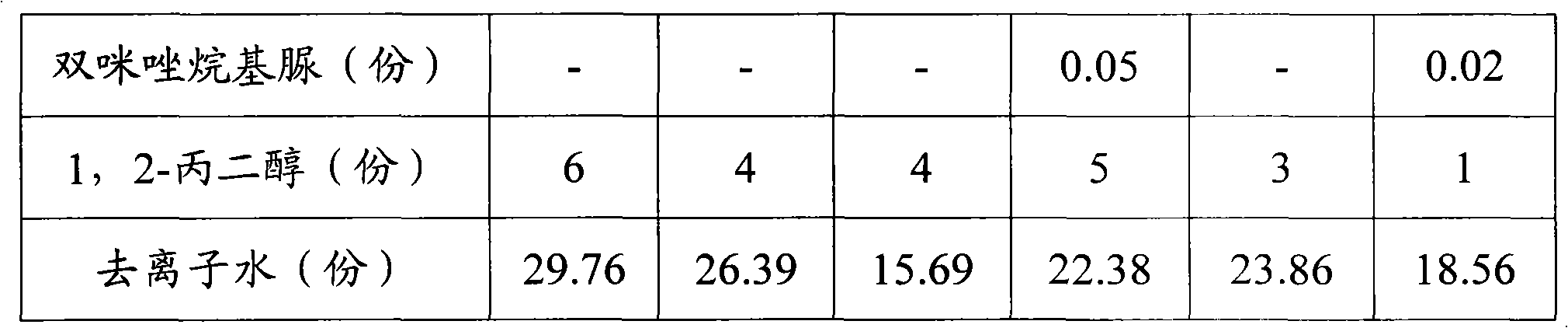

Water-soluble human body lubricants

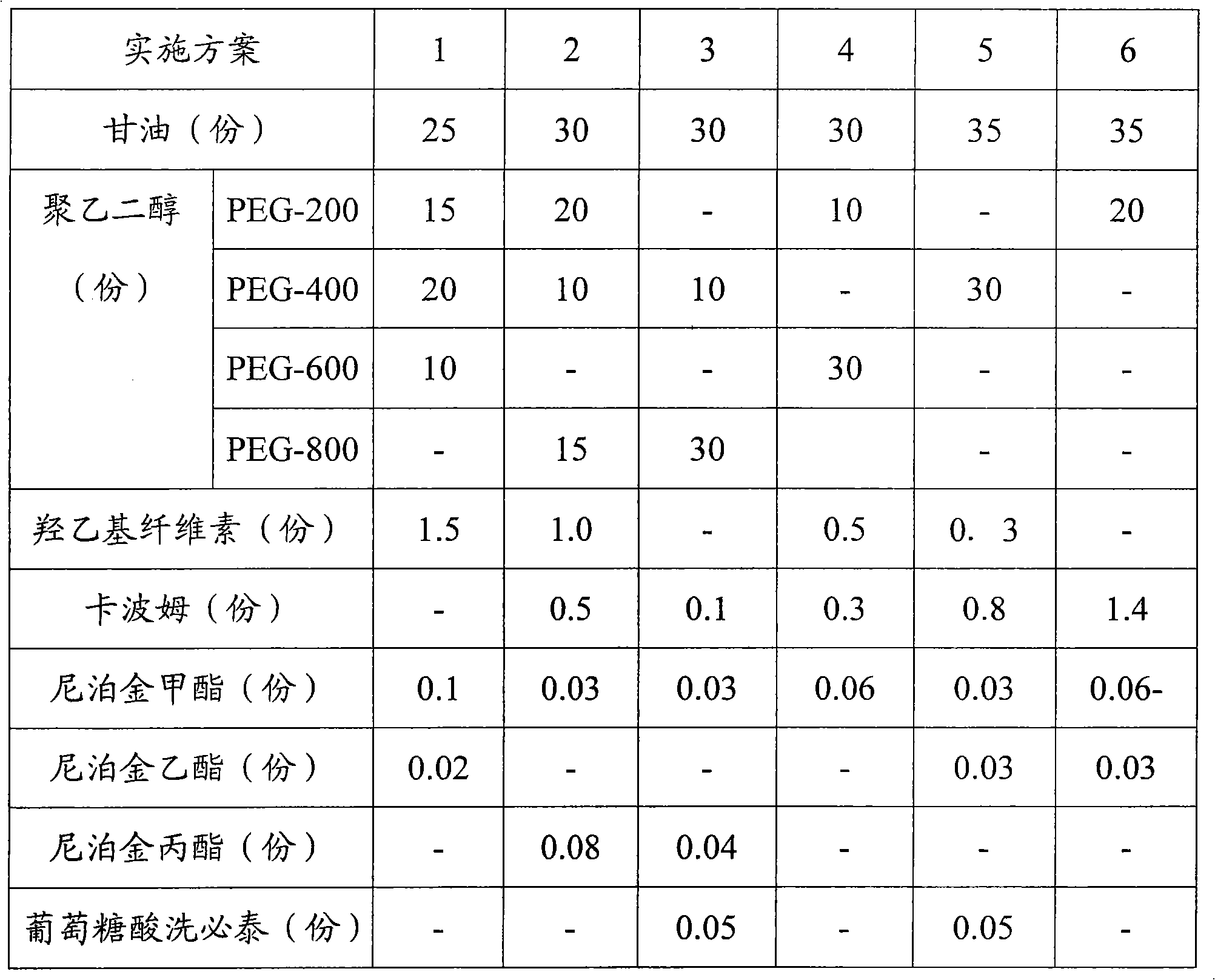

InactiveCN101327346AGood flow regulationGood disinfection and antibacterial effectSurgeryHeat sensationsWater soluble

The invention relates to a water-soluble lubricant for human body, which is characterized in that the water-soluble lubricant comprises 25 portions to 35 portions of glycerol, 20 portions to 45 portions of polyethylene glycol, 0.1 portion to 1.5 portions of tackifier, 0.11 portion to 0.13 portion of preservative, 1 portion to 6 portions of 1,2-propylene glycol, and 15 portions to 30 portions of deionized water. The polyethylene glycol ranges from 200 to 800 in average molecular weight. The water-soluble lubricant not only can be used as a lubricant in sexual life, in massage and on a condom, but also can be used as a lubricant for an instrument to diagnose and examine human cavities. The water-soluble lubricant is nonviscous with moderate characteristics and is mutually soluble with feminine secretion, which is convenient for cleaning, thus ensuring that users have a slight sense of hotness on the coating parts and enhancing the excitement and pleasure for users, providing more fun for the sex life. The sense of hotness is more obvious by tootling the coating parts.

Owner:武汉杰士邦卫生用品有限公司 +1

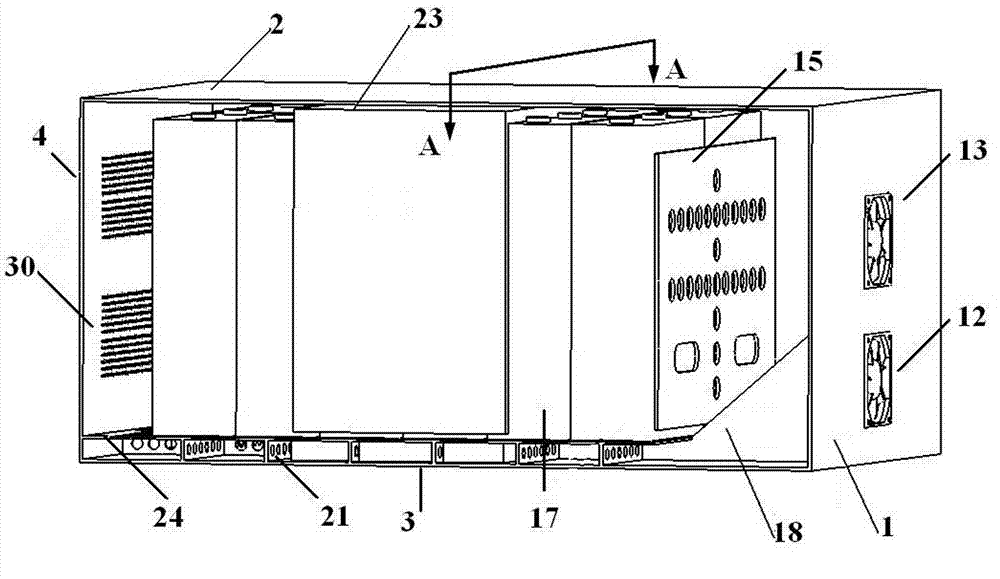

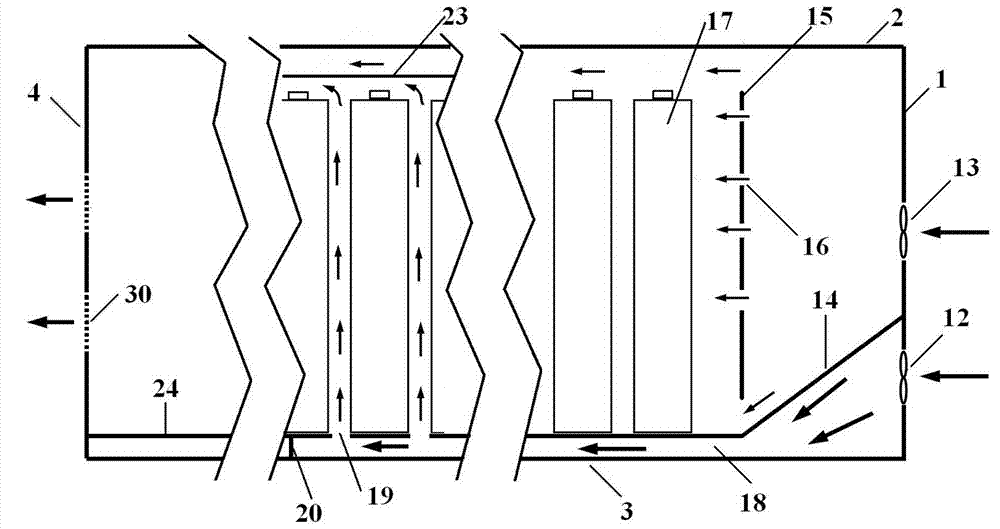

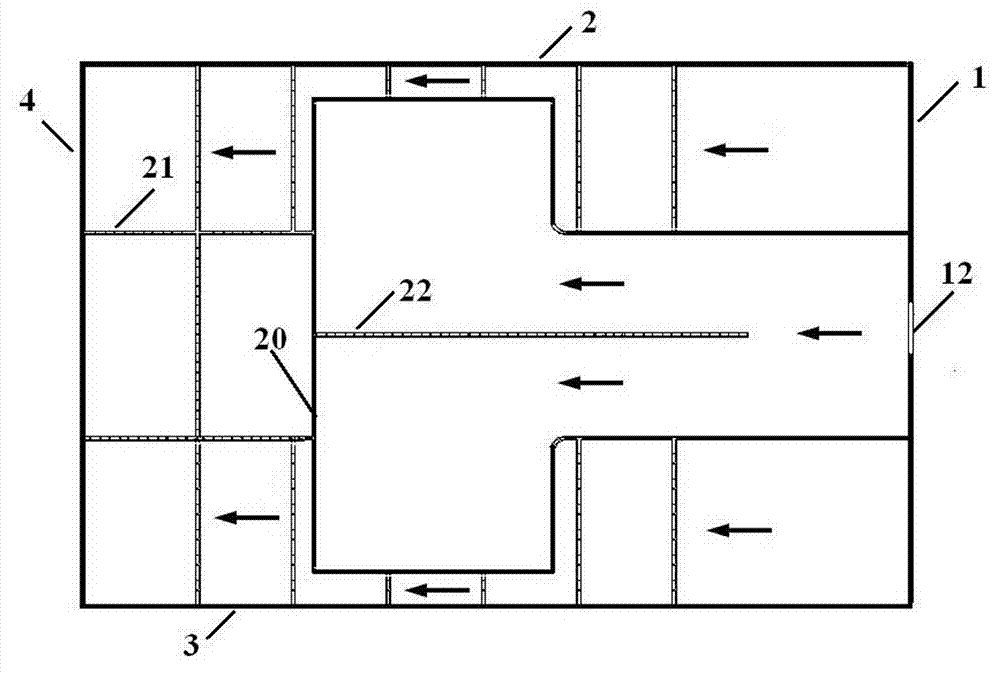

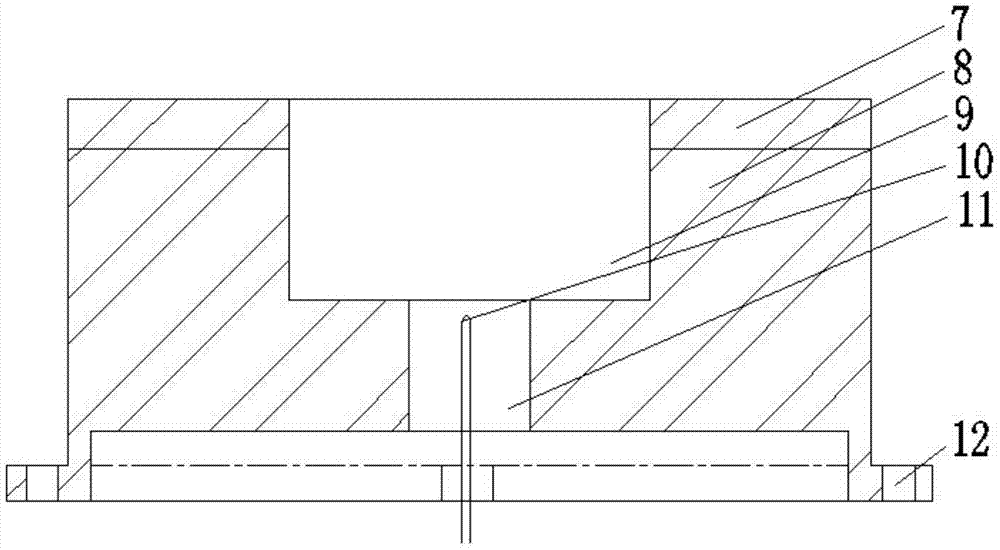

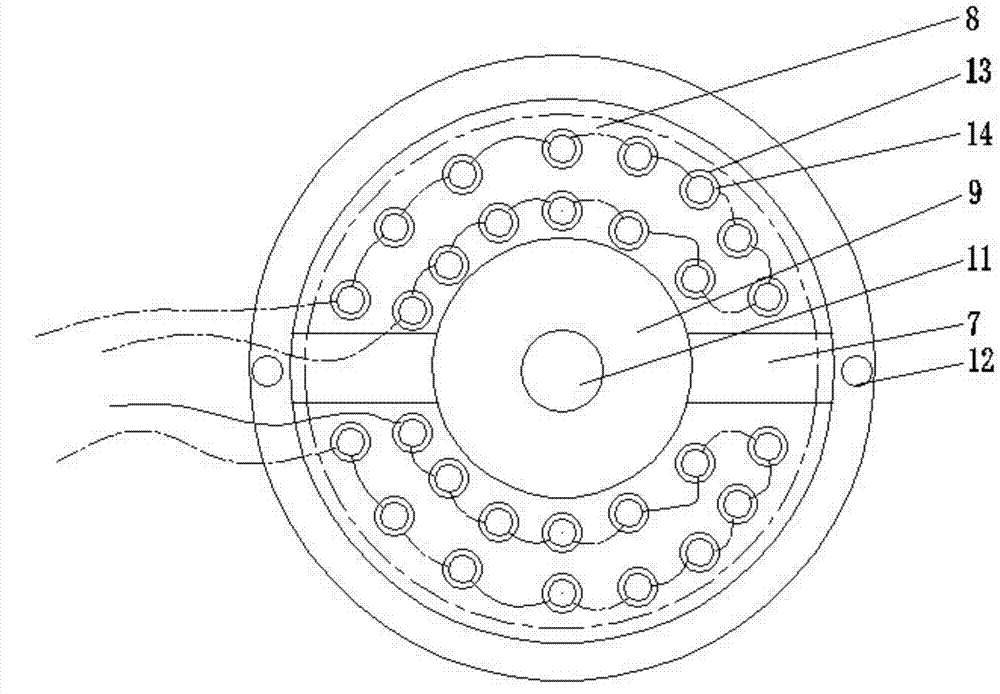

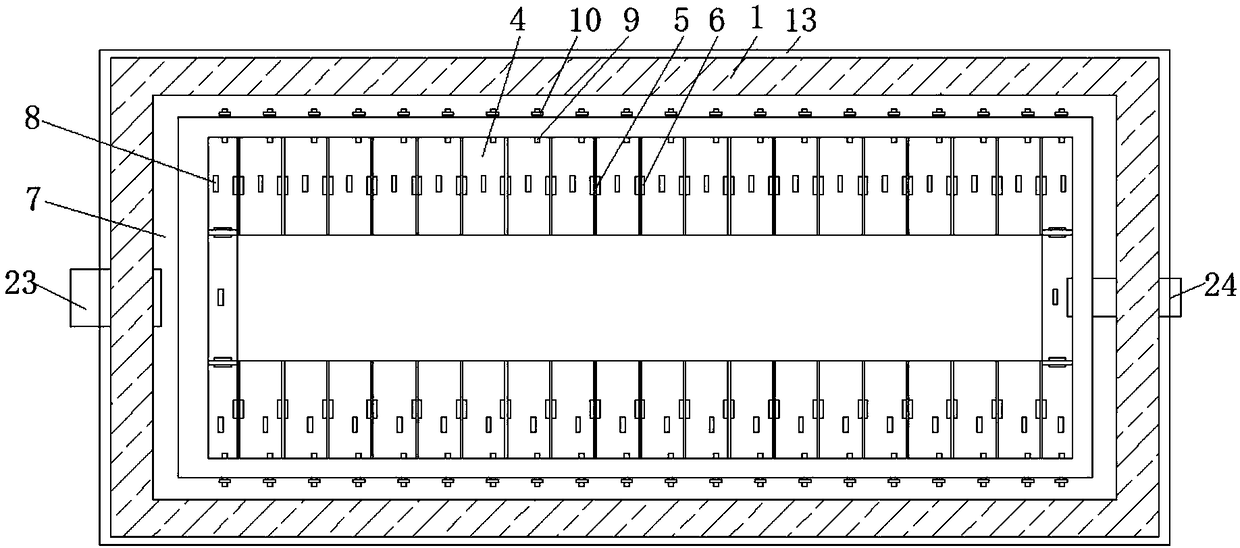

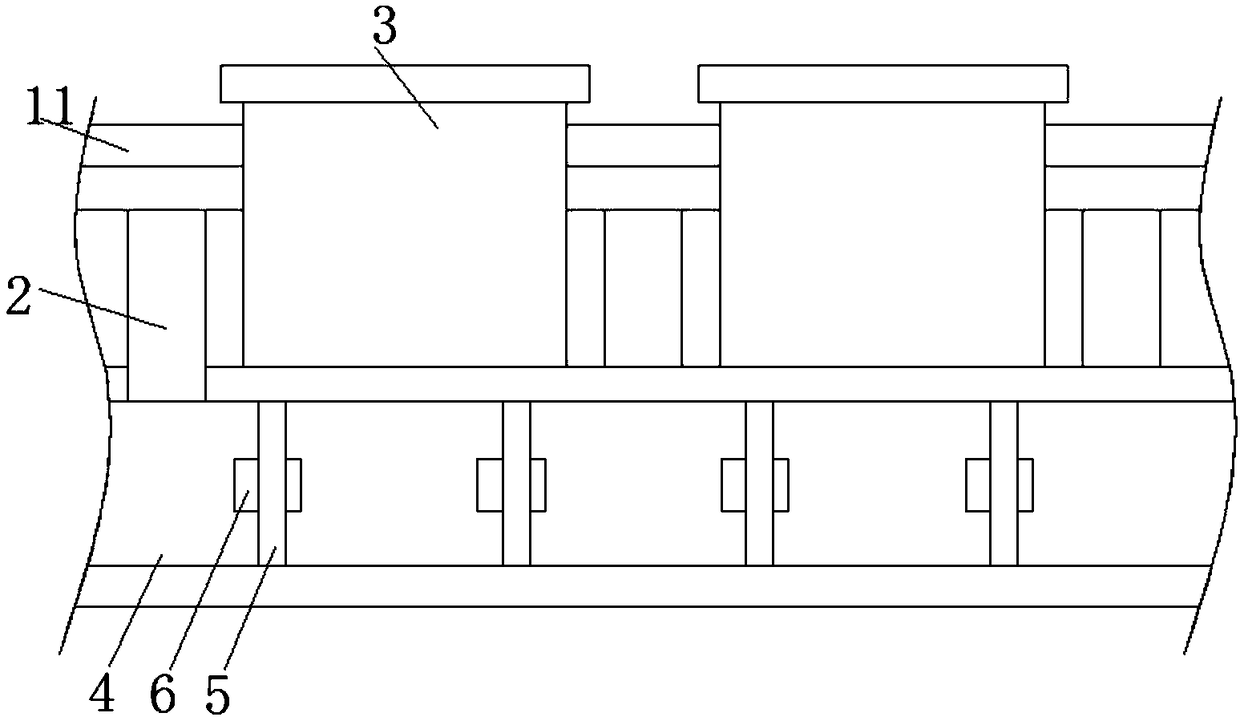

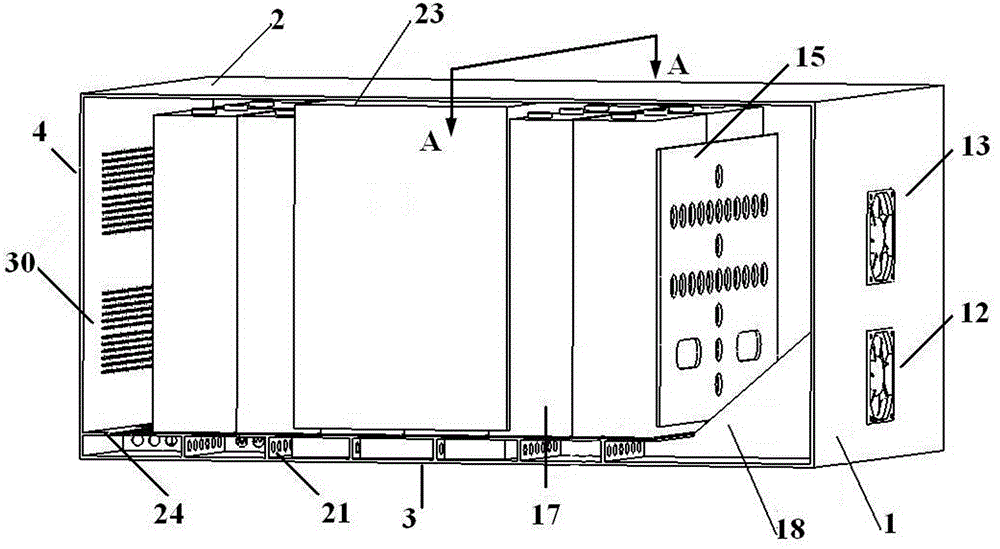

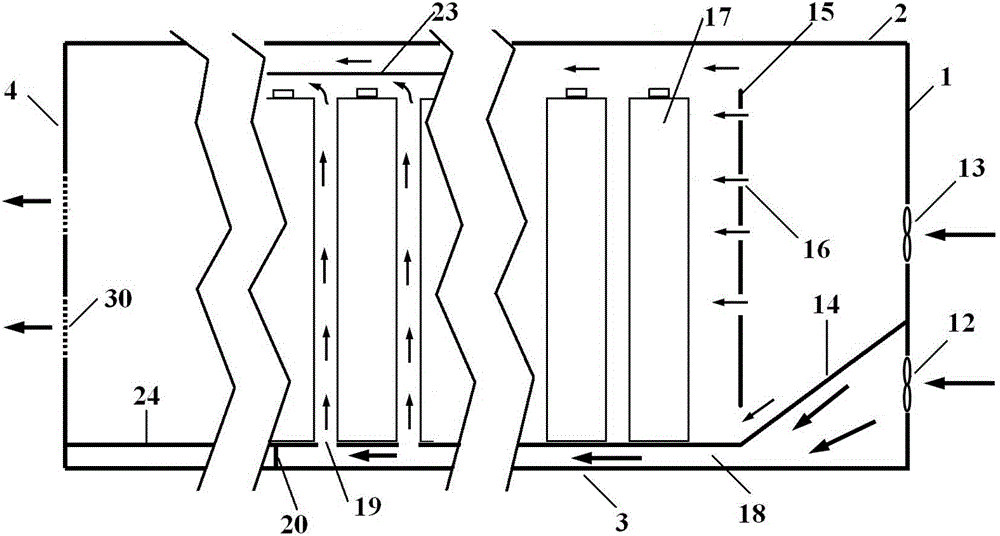

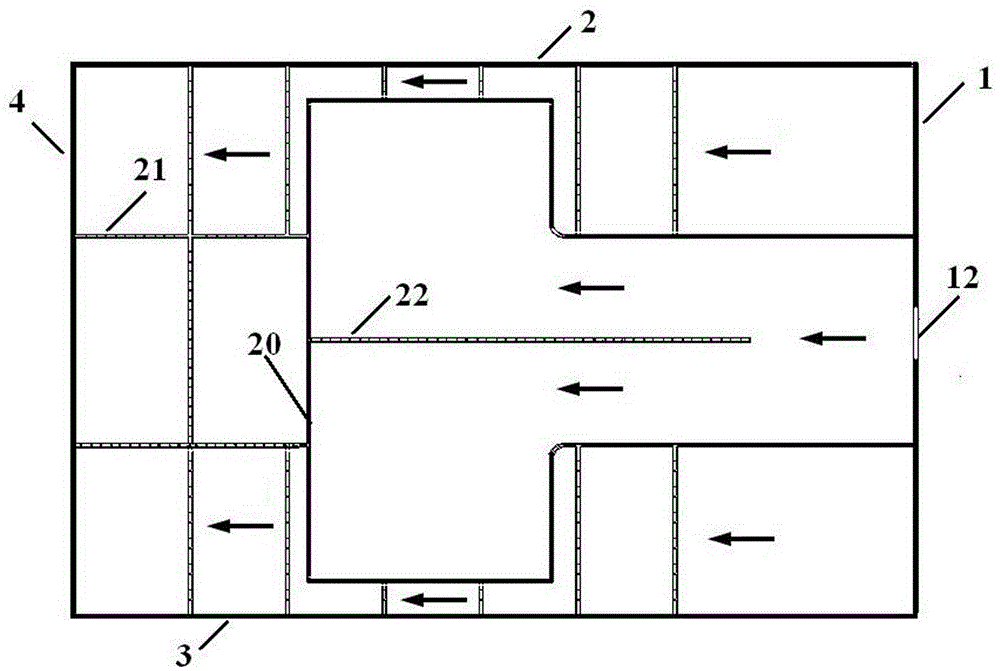

Lithium ion power battery box

ActiveCN103199203ACool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

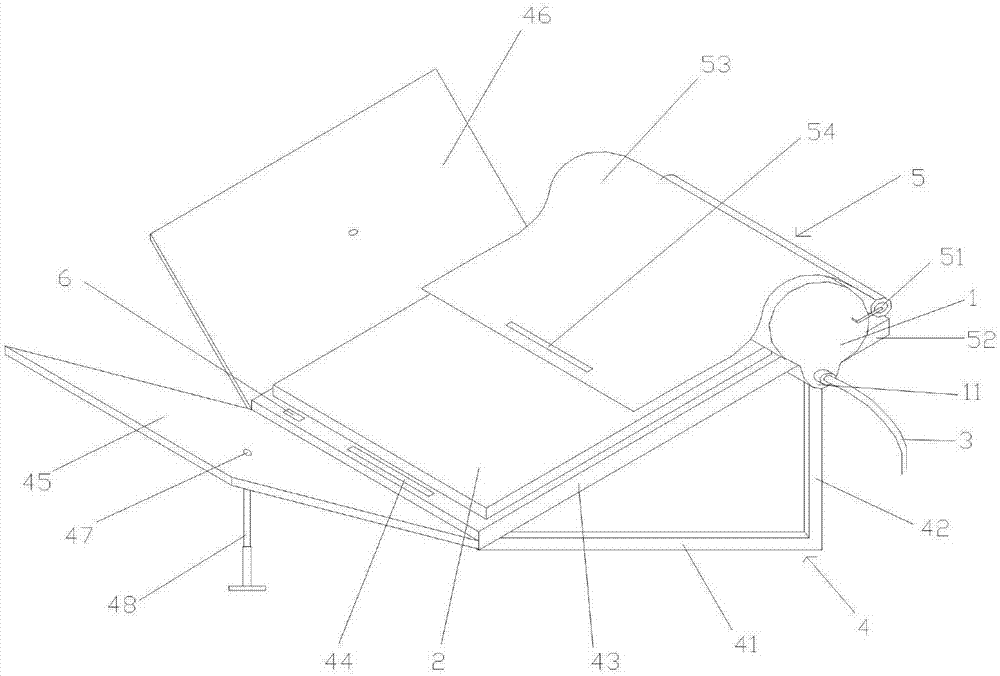

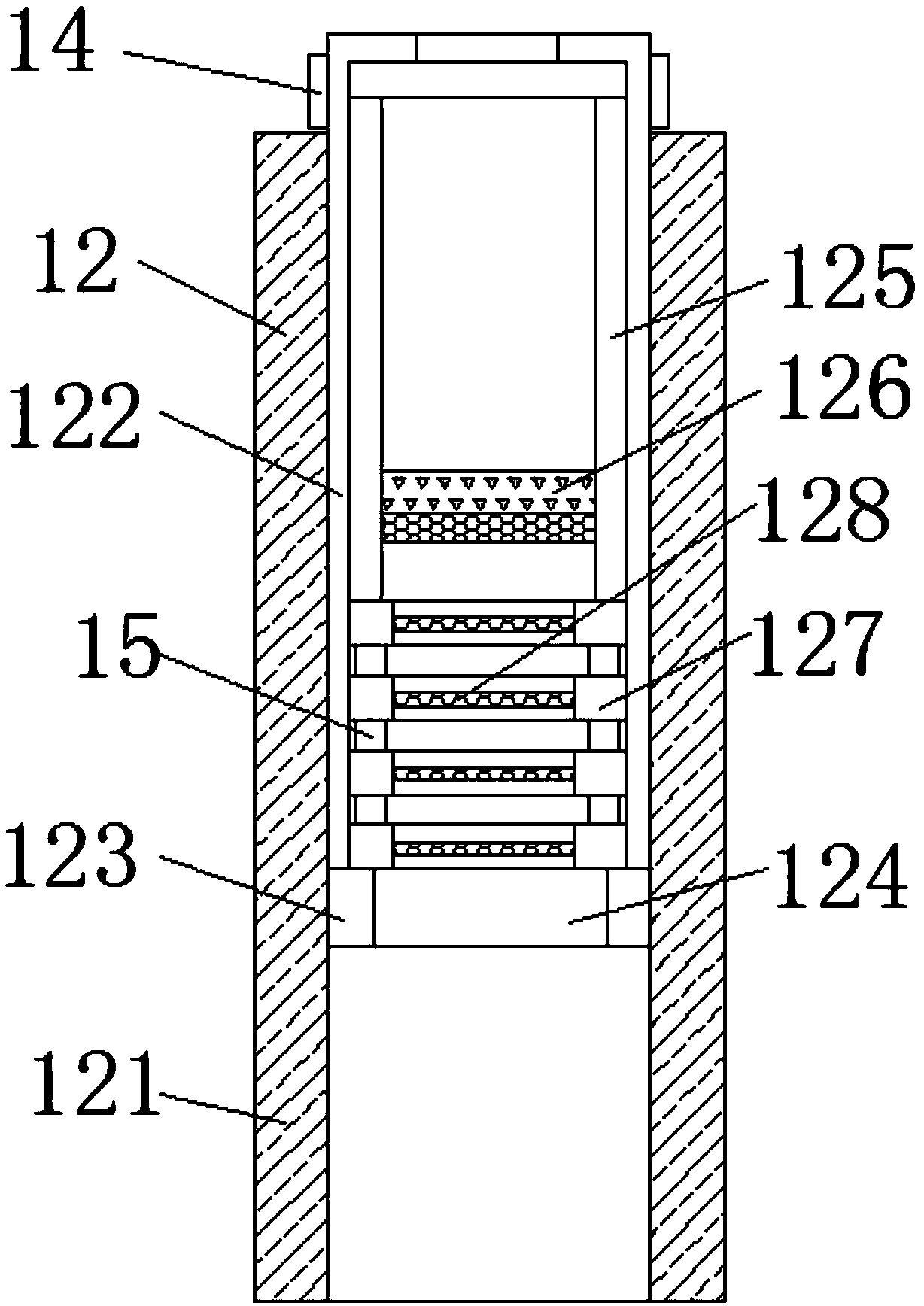

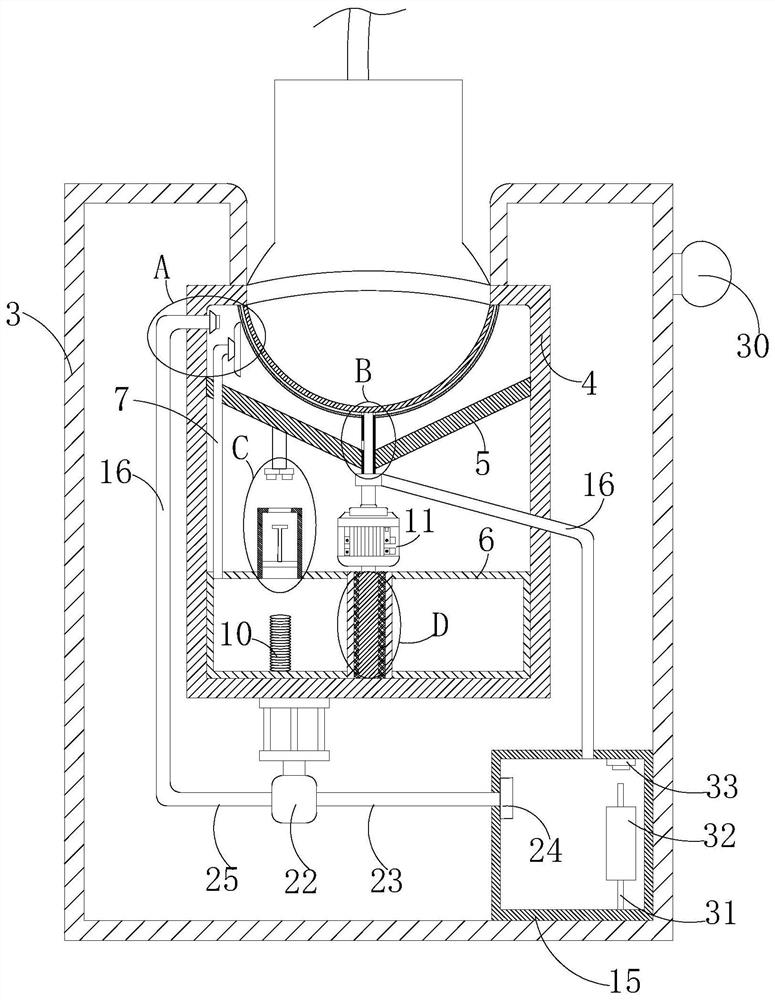

Micro heating platform for measuring molten salt electriochemistry in-situ Raman spectrum and sample cell

The invention discloses a micro heating platform for measuring a molten salt electriochemistry in-situ Raman spectrum and a sample cell, belonging to the technical field of electrochemical analysis. The micro heating platform comprises a heating platform housing, a hearth, a heating platform cover, uprights and a base, wherein a heating platform housing circulating loop water path is arranged inside the heating platform housing, a sample cell arrangement groove is formed in the top of a hearth main body, bar-shaped grooves are symmetrically formed in the left side and the right side of the sample cell arrangement groove, resistance wire mounting holes are formed in the hearth main body at two sides of each of the bar-shaped grooves and the sample cell arrangement groove, spiral resistance wires are arranged in the resistance wire mounting holes, and the resistance wires and the hearth main body are arranged in an insulating manner; a heating platform cover circulating cooling water path is arranged in a heating platform cover main body, and a microscope lens through hole is formed in the middle of the heating platform cover main body. The sample cell has the structure that a quartz cover is arranged at the top of a crucible; through holes are formed in the upper part of the crucible and correspond to the bar-shaped grooves; if the crucible is made of a conductive material, the crucible can be simultaneously used as a counter electrode, or the counter electrode can be singly arranged in the crucible.

Owner:NORTHEASTERN UNIV

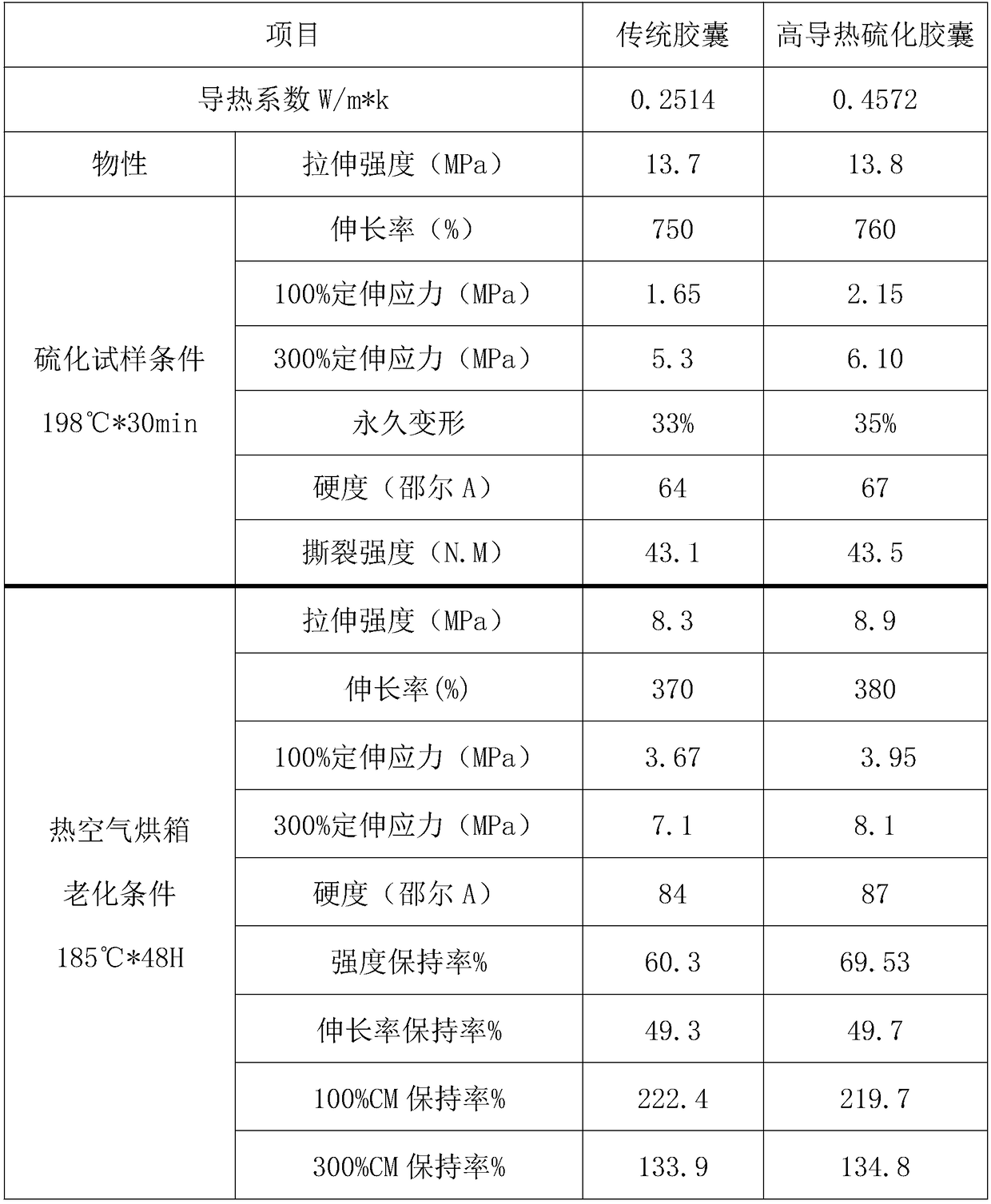

Anthracite carbon casting formed coke

InactiveCN101280203ARealize protection and meet emission standardsHigh carbon contentSpecial form destructive distillationFoundryHigh carbon

Disclosed is anthracite carbon foundry formed coke which solves the disadvantages of uneven granularity, insufficient oxygen-adding, high broken rate and environment pollution found in the formed coke in the prior art; the anthracite carbon foundry formed coke is characterized in that the anthracite or non-coking coal is used to produce the anthracite carbon foundry formed coke; the steps include that the raw coal is conveyed to the factory, crushed and grinded to powder; the binder is added to the grinded powder and the mixture is stirred under the cooling condition, and then stirred evenly after being heated; the mixture is conveyed to the pressing machine for the extruding formation; the formed material is conveyed to the carbonization chamber and then is processed with dry distillation and carbonization under the conditions of air-isolation and the temperature ranging from 950 DEG C-1050 DEG C; finally, the formed material is cooled and the finished product is outputted to be stored in the storehouse for sale; the process of comprehensive utilization of the coke-oven gas generated in the carbonization chamber is set for the lime joint production; the process of dust removal and desulfurization is set for the flue gas and SO2 in the exhausted gas; based on the special binder formula and the special product structure and compared with the traditional coking method, the anthracite carbon foundry formed coke has the advantages of high carbon content, high calorific value, low ash content and sulfur content, crush resistance, abrasion resistance, good intensity, moderate reactivity, high intensity after reaction, good cold and heat intensity, reasonable and simple structure, small investment, low expense and specially being applicable to the coking and the mechanical casting industries.

Owner:YANGQUAN YANGMEI FORMED COKE TECH DEV CENT

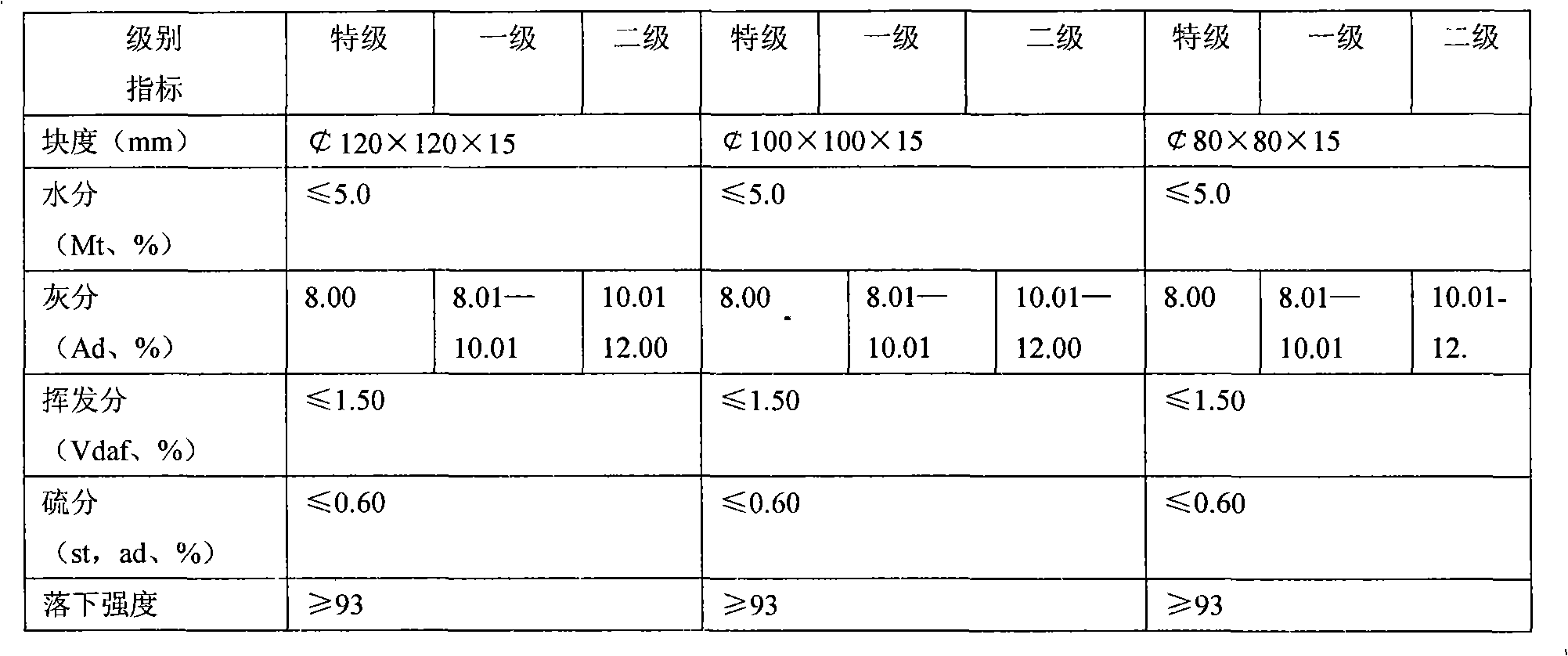

Preparation method of high-heat-conductivity type tire vulcanization capsule

The invention discloses a preparation method of a high-heat-conductivity type tire vulcanization capsule. The preparation method of the high-heat-conductivity type tire vulcanization capsule belongs to the technical field of tires, and comprises the following steps of (1) compounding the components according to the matching ratio: 95 parts of butyl rubber, 4 to 5 parts of chloroprene rubber, 15 to20 parts of N375 carbon black, 35 to 45 parts of acetylene black, 7 to 15 parts of graphene, 7 to 10 parts of alkane oil, 0.5 to 1.5 parts of stearic acid, 5 to 7 parts of zinc oxide, and 8 to 10 parts of resin; (2) primarily mixing; (3) filtering rubber; (4) secondarily mixing; (5) forming; (6) vulcanizing; (7) polishing; and (8) inspecting a finished product. According to the preparation methodof the high-heat-conductivity type tire vulcanization capsule provided by the invention, on the basis of ensuring the stability of various physical and mechanical properties, a heat conductivity coefficient is further improved, so that the aims of saving energy and reducing cost are achieved.

Owner:YONGYI RUBBER CO LTD

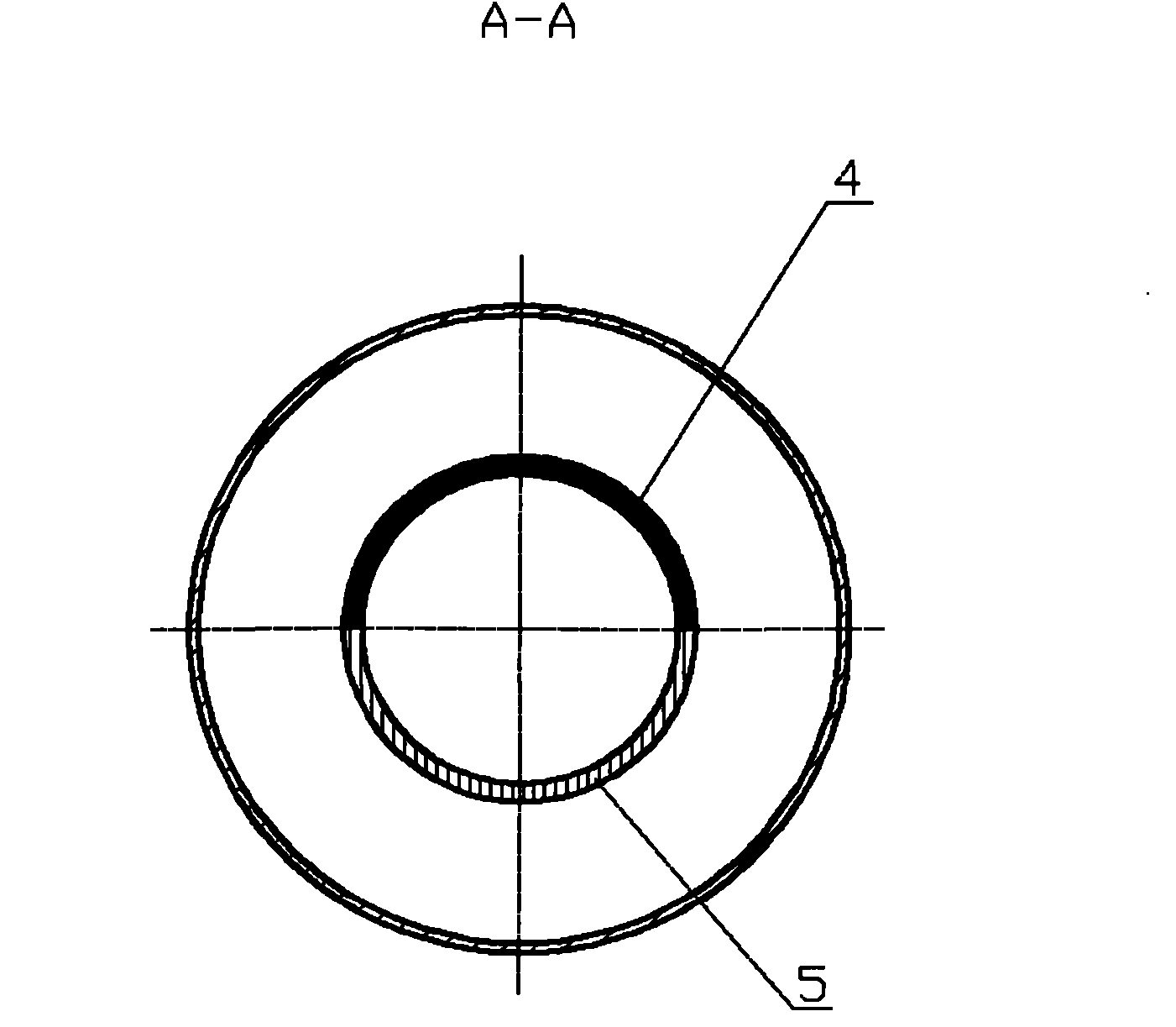

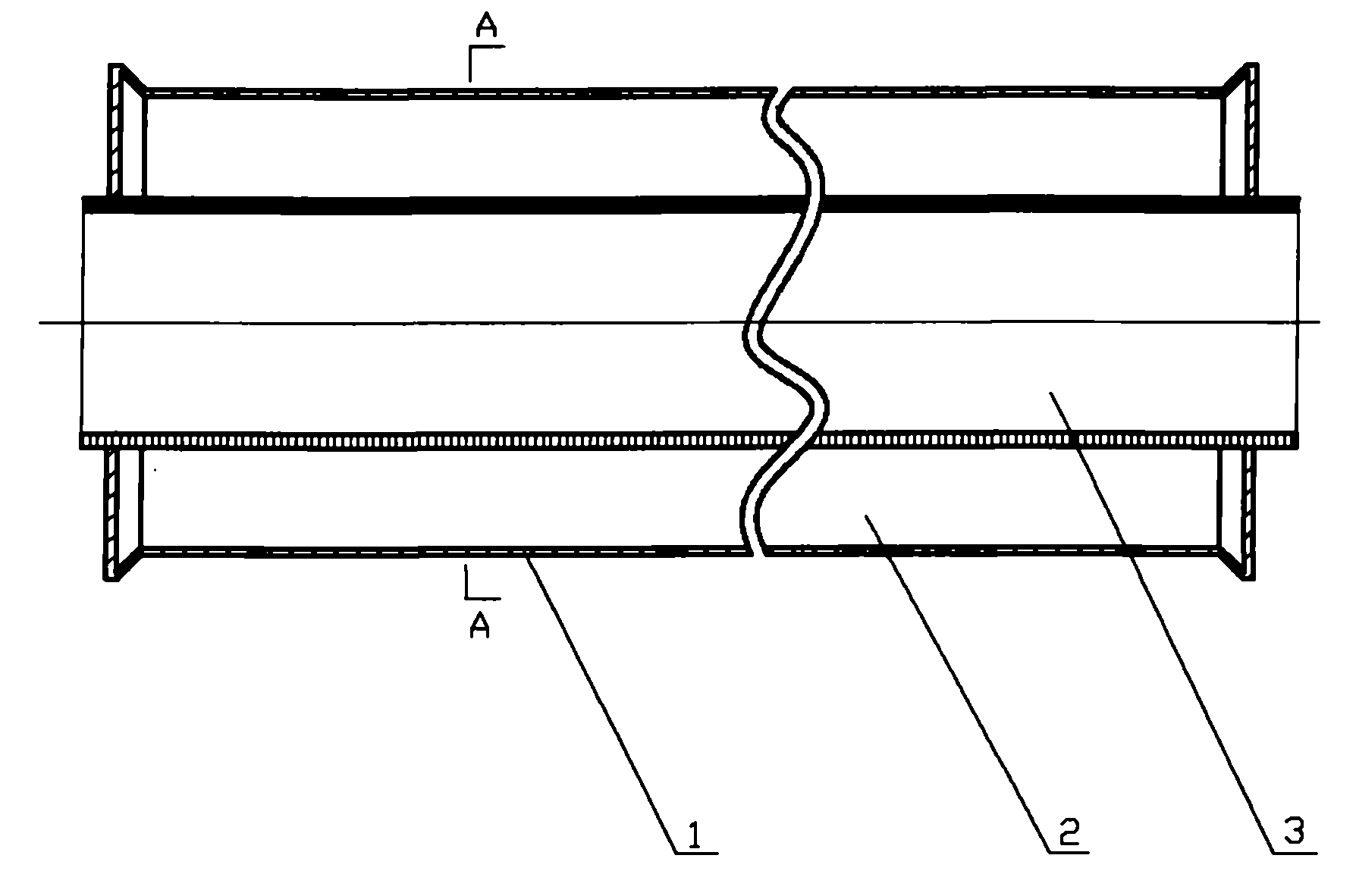

Photoelectric photo-thermal combined vacuum straight-through heat collector for trench light condensing system

InactiveCN101867320AReduce thermal resistanceReduce the temperatureSolar heat devicesPhotovoltaicsWater circulationElectricity

The invention discloses a photoelectric photo-thermal combined vacuum straight-through heat collector for a trench light condensing system. A selective absorption coating is coated on a half cycle of an inner copper pipe of a straight-through pipe, a battery plate is attached to the other half cycle, and the inner and outer pipes are vacuumized, so that heat loss in the pipe due to heat conduction and convection heat transfer is reduced. In a light condensing photovoltaic generating system, one side attached with the battery plate can receive focused light to generate electricity, and one side coated with the selective coating can absorb shielded direct solar energy to reduce the surface temperature of the battery plate through water circulation in the copper pipe; and the generated hot water can be stored in a water tank to be used as domestic hot water. The heat collector has the advantages of simple structure, low production cost, high overall efficiency and the like, and can be widely applied to the light condensing photovoltaic generating system.

Owner:TIANJIN UNIV

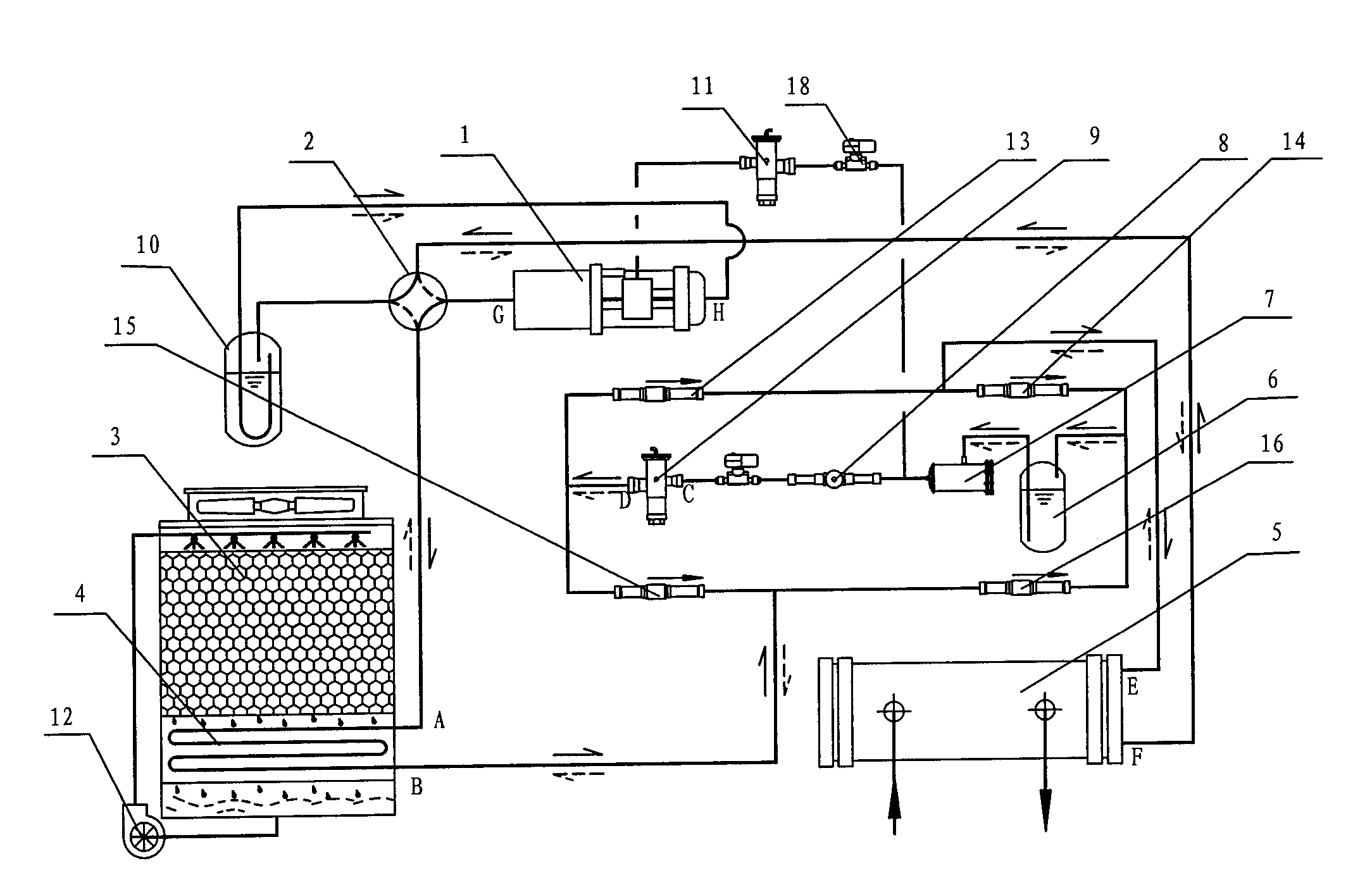

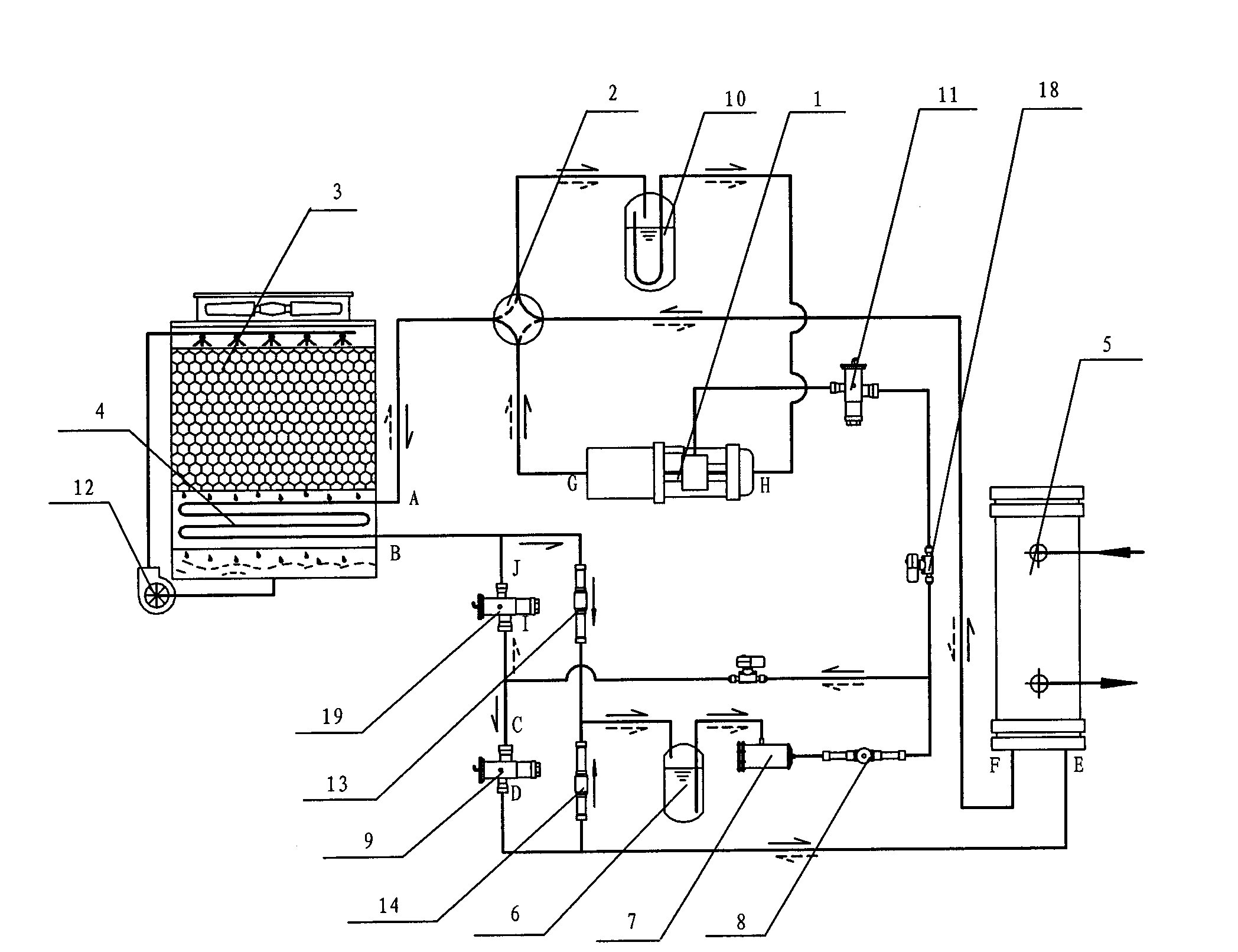

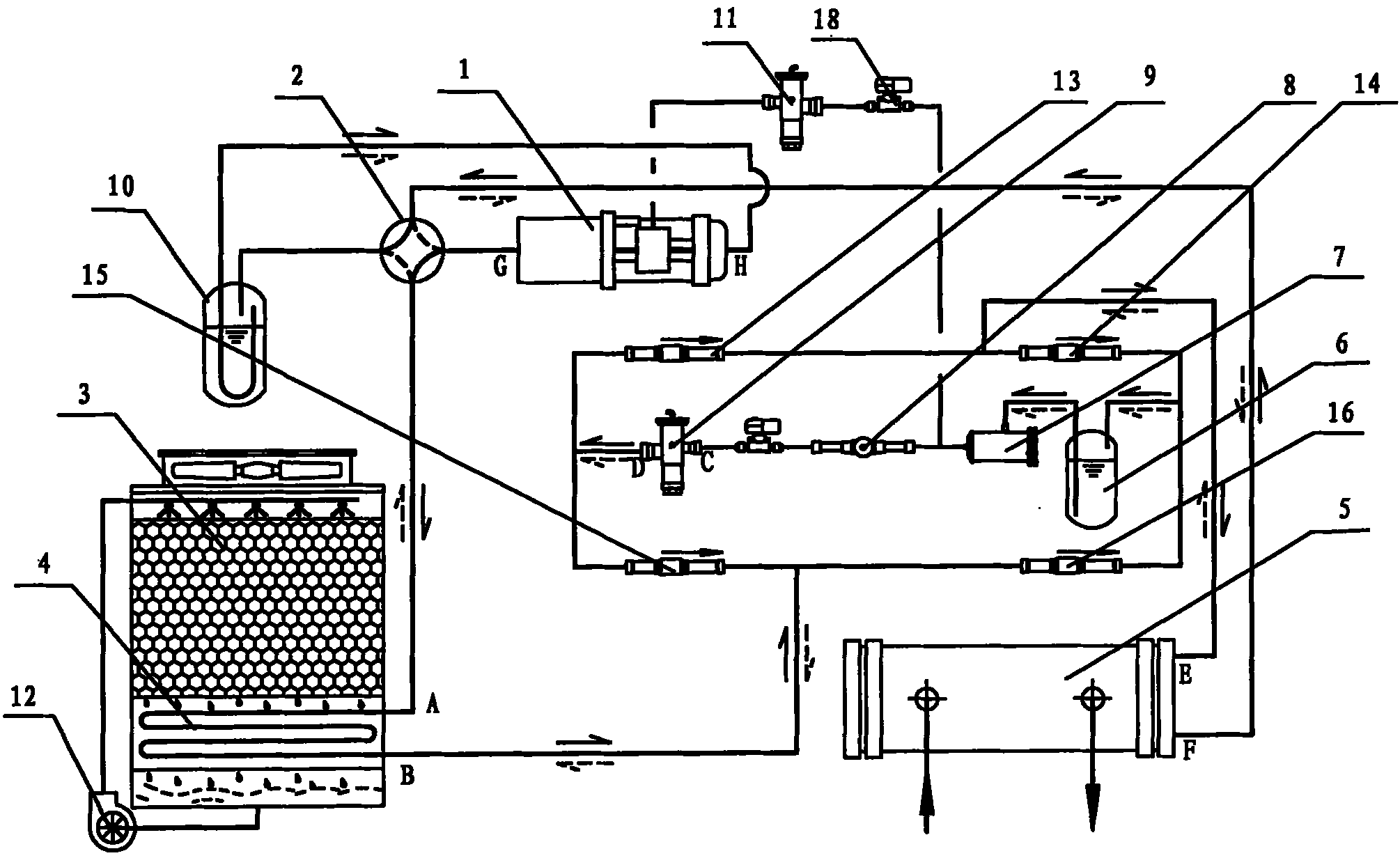

Highly-efficient air energy water source heat pump integrated unit

InactiveCN101788205AStable in natureEasy liquidEvaporators/condensersCompression machines with reversible cycleWater source heat pumpBusiness efficiency

The invention relates to a highly-efficient air energy water source heat pump integrated unit which comprises a compressor, a first heat exchanger, a second heat exchanger, a heat exchange tower, a water pump, an expansion valve and a reversing valve, wherein the first heat exchanger is arranged in the heat exchanger tower; an output of the compressor is connected with an inlet of the first heat exchanger through the reversing valve, an outlet of the first heat exchanger is divided into two paths which are respectively connected with an inlet and an outlet of the expansion valve; the outlet of the expansion valve is connected with an inlet of the second heat exchanger through a one-way valve, an inlet of the second heat exchanger is also connected with the inlet of the expansion valve; the outlet of the second heat exchanger is connected with the inlet of the compressor; and the heat exchanger tower is provided with the water pump for providing cooling media circulating power. The invention has simple structure, small volume, high energy efficiency ratio, lower cost, easy installation and construction, lower cost of the operation and convenient maintenance, thereby being an air conditioner cooling, heating and healthy hot water making mode with development potential, and being suitable for industrialized application. The invention can solve the problems of instability factor of weather with an air source, limitation of ground and water sources, overhigh initial cost and the like.

Owner:HUNAN YUANHENG TECH CO LTD

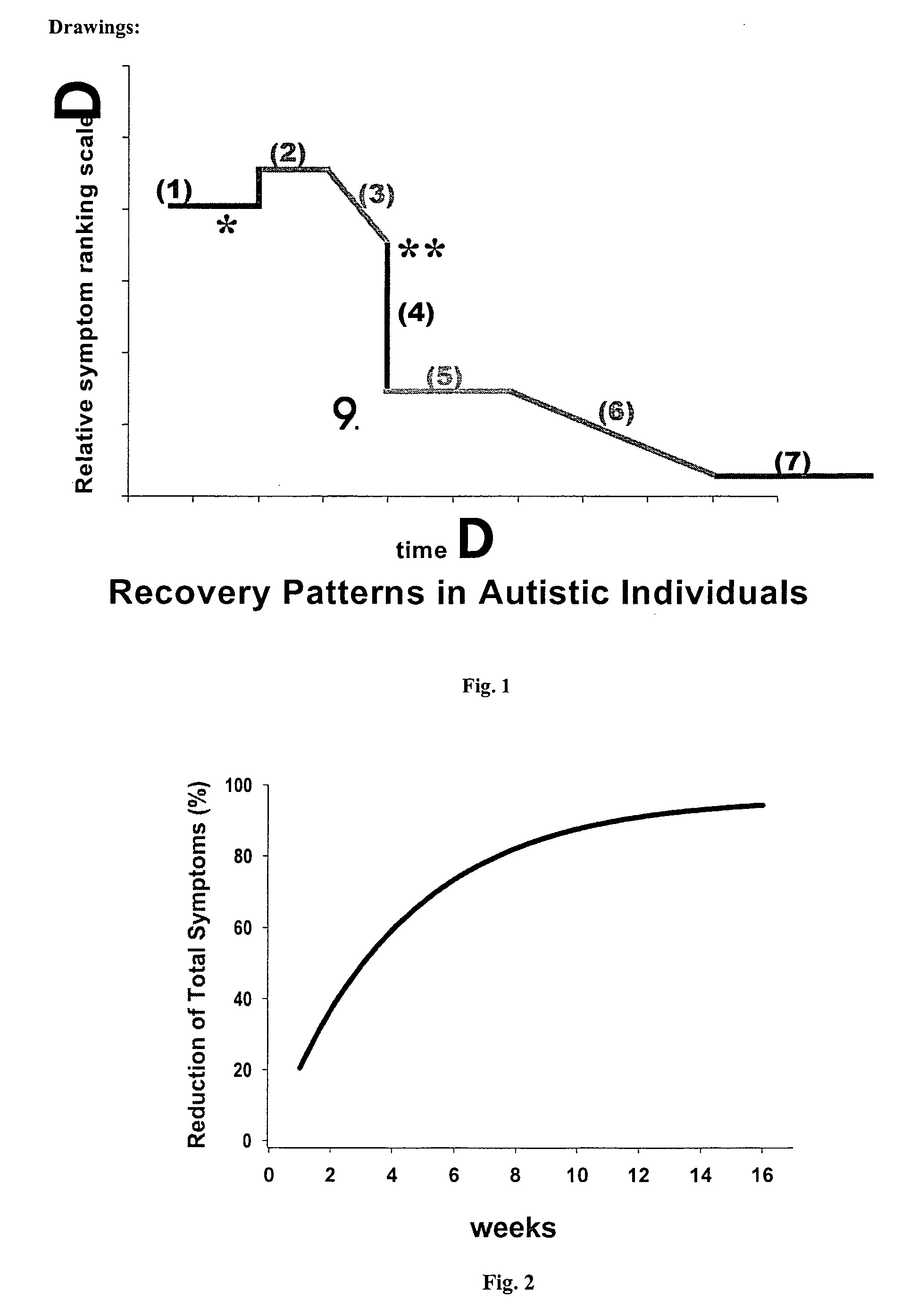

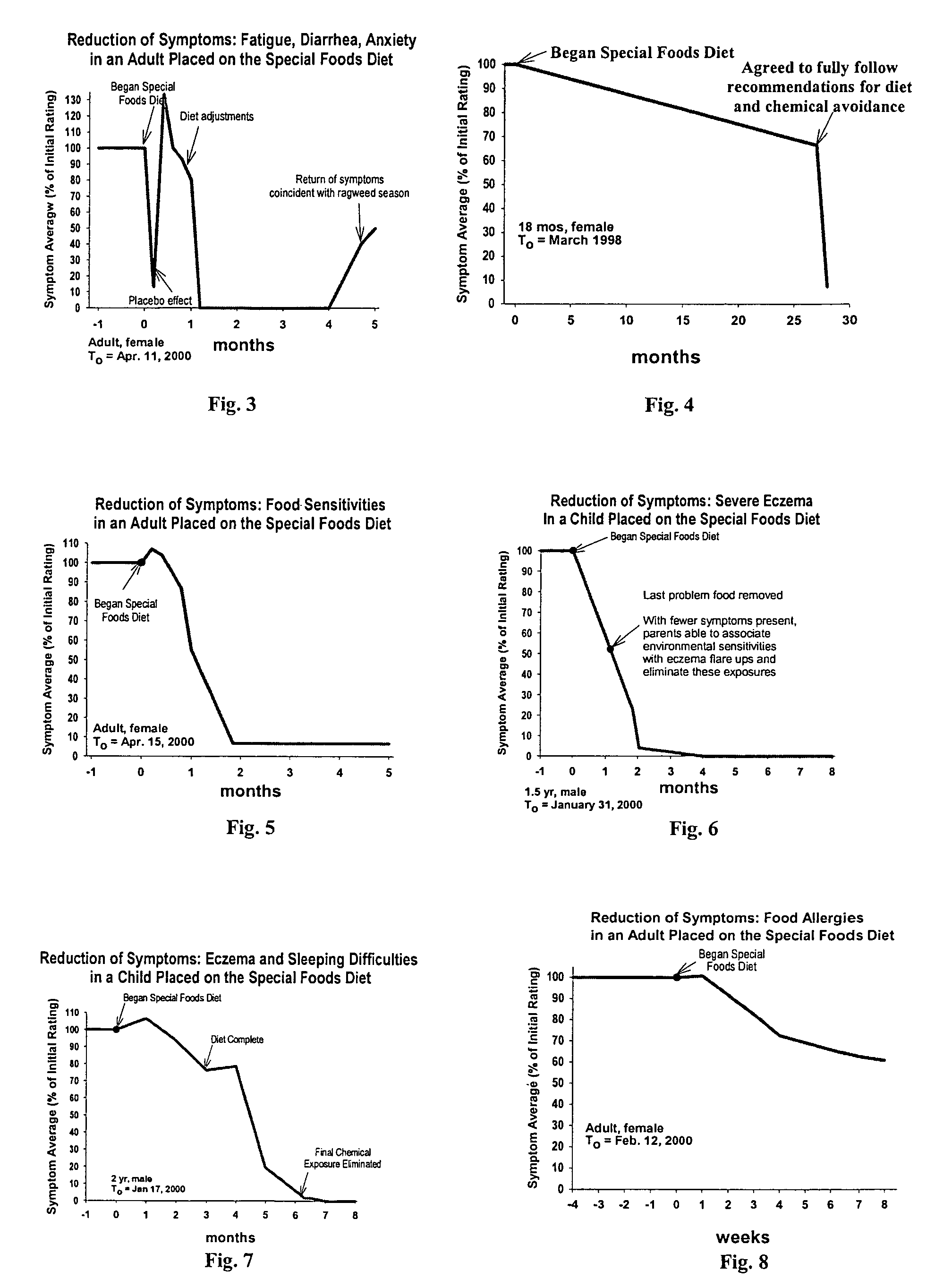

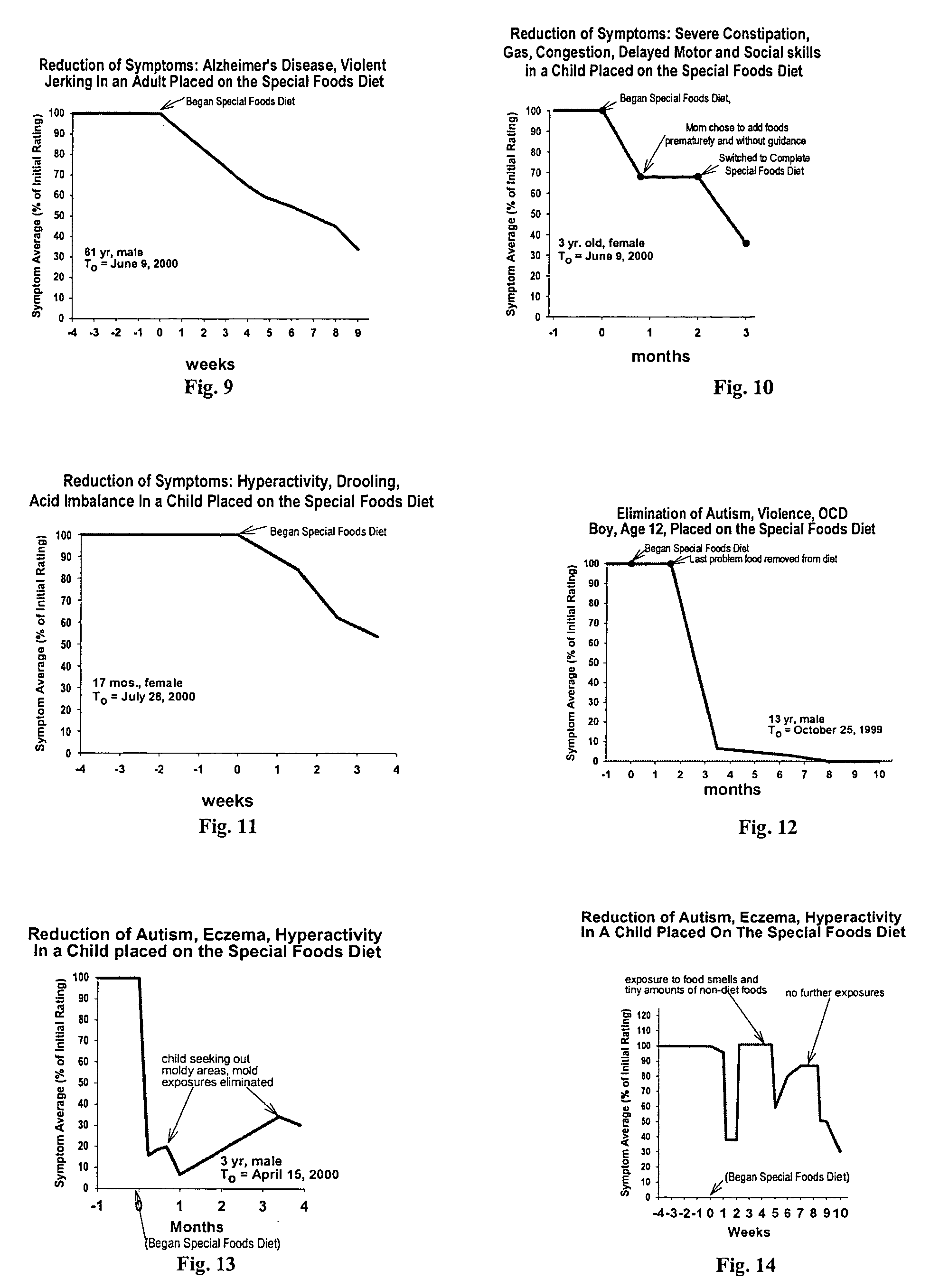

Use of tropical root crops in dietary intervention strategies

InactiveUS7854948B2Nourish wellLarge populationBiocidePharmaceutical delivery mechanismCompulsive disordersPanic

This invention relates to an effective dietary intervention plan. In one aspect all food is withheld for a period of at least 5 days, except for tropical root crops. In another aspect the invention relates to the treatment of various symptoms, conditions or diseases such as Diarrhea, constipation, congestion, eczema, asthma, fatigue, muscle weakness, tension, and spasms, irritable bowel syndrome, swelling, anxiety, multiple chemical sensitivities, moderate to extensive and moderate to severe symptoms due to food allergies, sensitivities, and intolerances, bloating, pain, headaches, leaky gut, hyperactivity, sleeping difficulties, severe underweight, eating disorders, obsessive, compulsive disorders, panic attacks, sensory sensitivities, Alzheimer's disease, acid reflux, irritability, delayed motor skills, delayed social skills, autism, PDD, infantile spasms, seizures by withholding from the patient for a period of at least 5 days all food except for concentrated forms of concentrated tropical root crops. Preferably the patient is also removed from external environmental sources of allergens. After the initial withholding period new foods may be introduced according to a particular selection and schedule.

Owner:SLIMAK K M

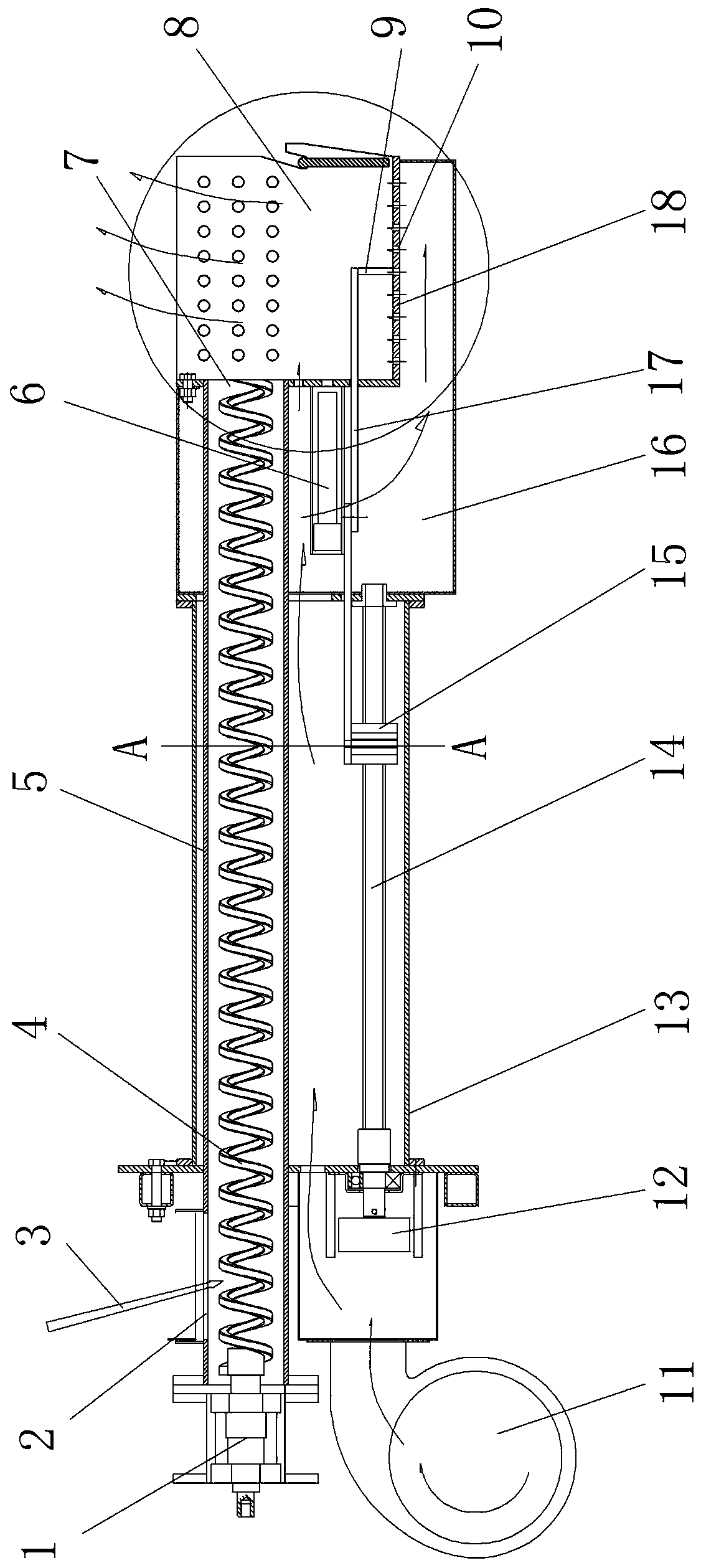

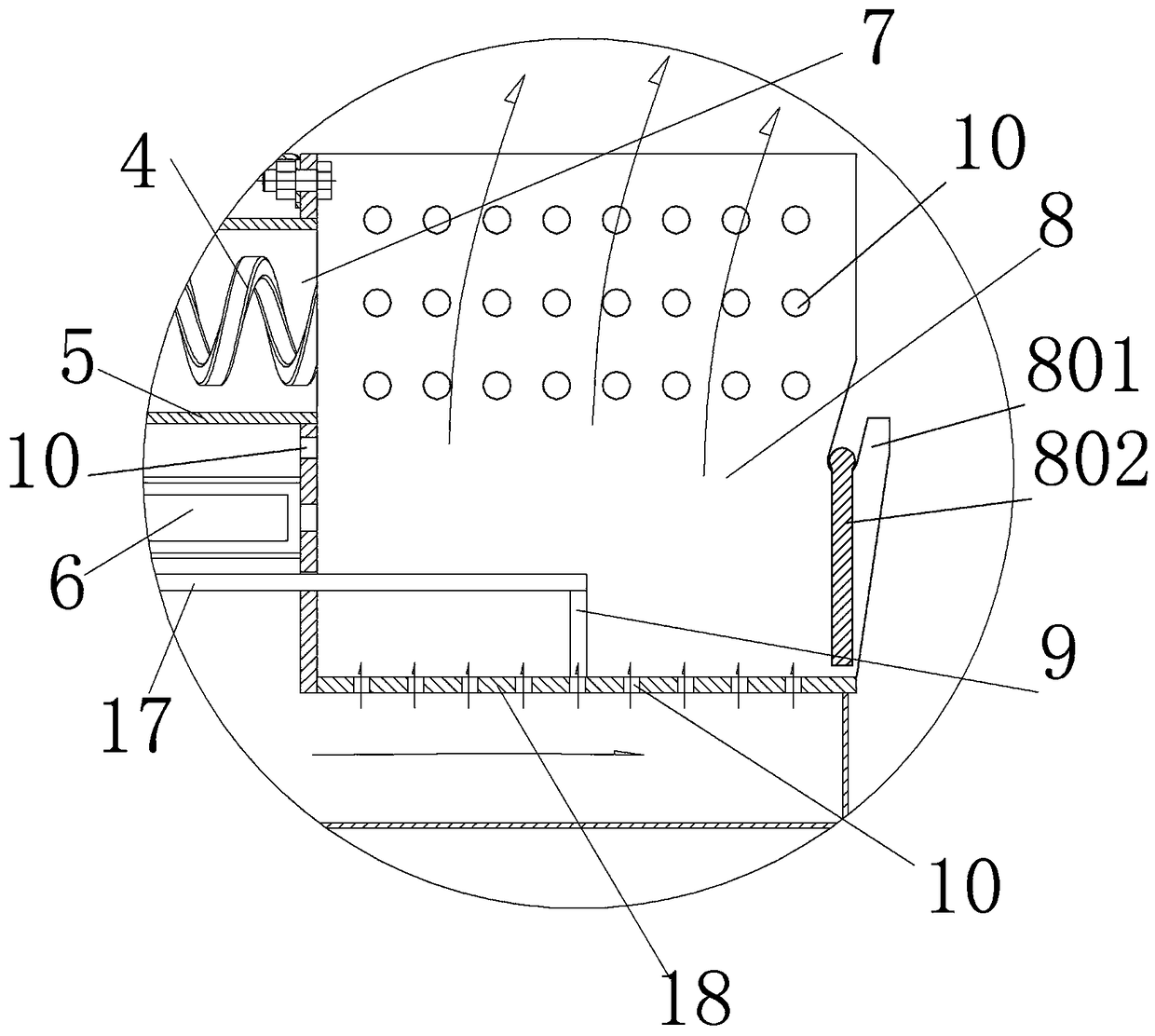

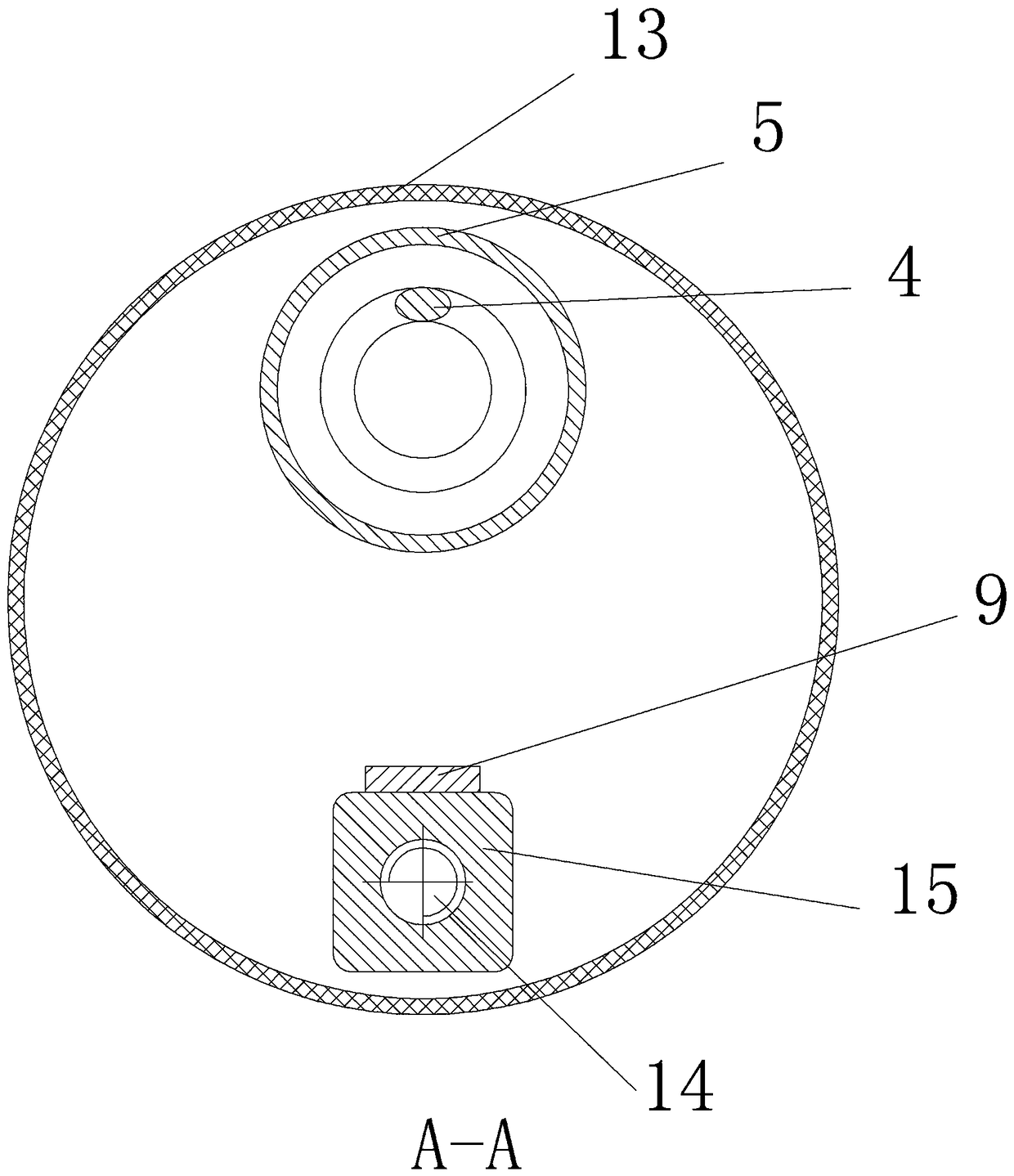

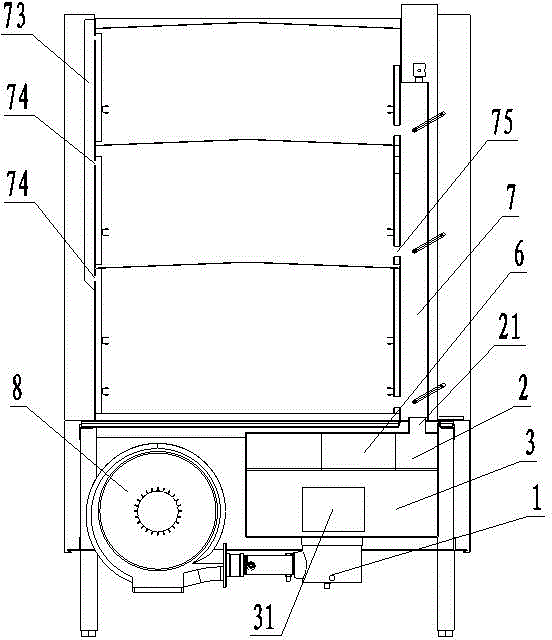

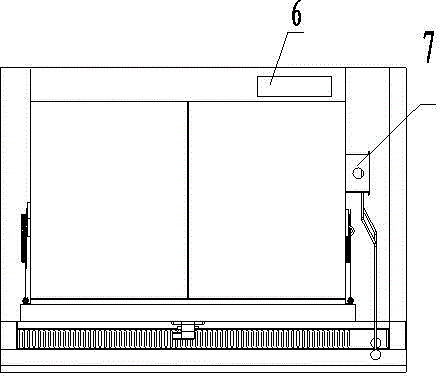

Automatic slag removal biomass combustion device as well as combustion engine and combustion method

PendingCN108397765AExtended service lifeLow costSolid fuel combustionBlast-producing apparatusReciprocating motionAdaptive design

The invention discloses an automatic slag removal biomass combustion device as well as a combustion machine and a combustion method. The automatic slag removal biomass combustion device as well as thecombustion machine and the combustion method have the beneficial effects that the comprehensive optimization design is carried out on the arrangement of a material combustion bin and an air duct, anoriginal combustion mode of transverse fire discharge is changed, and a scraping plate capable of doing reciprocating motion is arranged in the combustion bin, and therefore, the coke slag and the ashin the combustion bin can be cleared in time, then the downward ventilation is not influenced, and the heat conversion rate of biomass fuel can be improved; and the combustion device enables the flame to be directly combusted, the defect that a boiler wall is burnt by the transverse flame is avoided, and therefore the upward combustion enables the heat to be more concentrated, the applicability is wide, the requirements of most existing boiler hearths can be met, the adaptive design is not needed to be carried out on the boiler, the use and popularization cost of the combustion machine is reduced, meanwhile, the service life of the boiler is prolonged, and multiple purposes are achieved.

Owner:河南奥兰斯特新能源技术有限公司

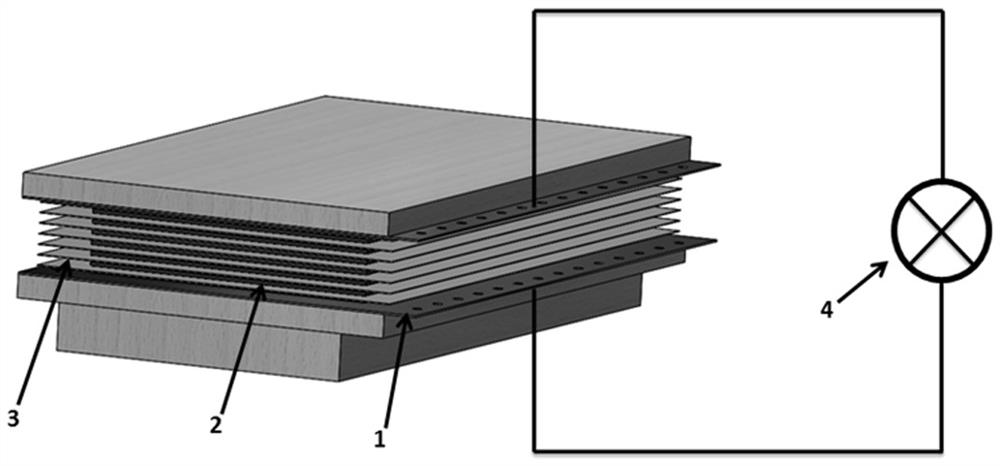

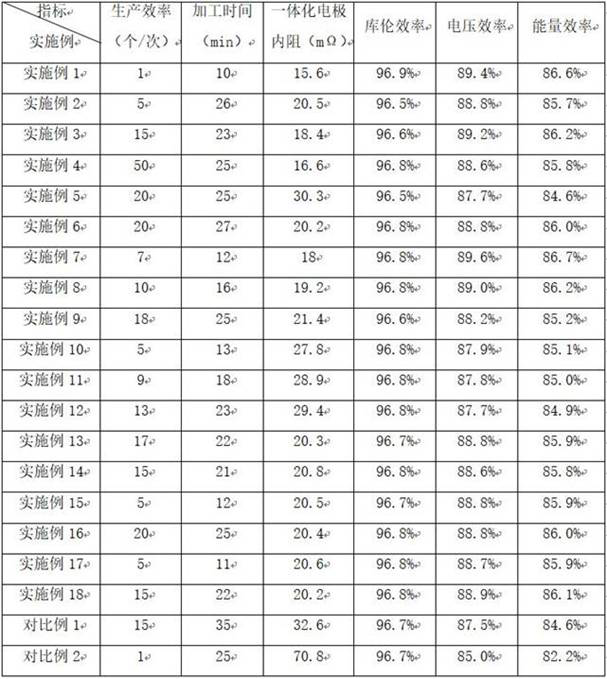

Method for efficiently preparing integrated electrode of flow battery

ActiveCN113809339ASimple methodEasy to mass produceCell electrodesRegenerative fuel cellsCarbon fibersInternal resistance

The invention discloses a method for efficiently preparing an integrated electrode of a flow battery, which comprises the following steps of: S1, well mixing plastic, a conductive auxiliary agent and an auxiliary agent, and processing a bipolar plate from the mixture; S2, pretreating graphite felts; S3, attaching a layer of volatile solvent to the surface of the bipolar plate; S4, tightly attaching the two pretreated graphite felts to the two sides of the bipolar plate with the volatile solvent attached to the surface to form a graphite felt / bipolar plate / graphite felt sandwich structure; and S5, stacking multiple layers of the graphite felt / bipolar plate / graphite felt sandwich structure, tightly laminating the multiple layers through a tablet press, introducing a direct current or an alternating current, and embedding graphite felt carbon fibers into the bipolar plate to form an integrated electrode. The flow battery integrated electrode is prepared in a current mode, the internal resistance in the finished integrated electrode can be remarkably reduced, and the efficiency of the flow battery is improved. The preparation method is simple, multiple integrated electrodes can be produced at a time, the production time is short, the efficiency is high, energy is saved, environment friendliness is achieved, and mass production is facilitated.

Owner:杭州德海艾科能源科技有限公司

Novel solar water heater

InactiveCN107202439AReasonable convectionUniform water temperaturePhotovoltaic supportsSolar heat devicesMicrocontrollerWater storage tank

The invention discloses a novel solar water heater. The novel solar water heater comprises a cylindrical water storage tank, a solar heat collector, a water inlet and outlet pipe and a supporting frame; the novel solar water heater further comprises a protection roller shutter, a rainwater sensor and an STM8S single-chip microcomputer; the bottom of the water storage tank is provided with protrusions connected with the solar heat collector and air exhaust openings; the cross section of the supporting frame is of an acute triangle structure, and the supporting frame is composed of support front legs, support back legs and a pressing plate; the protection roller shutter comprises a rolling shaft, a driving motor and a protection curtain; the STM8S single-chip microcomputer is arranged outside the water storage tank and is electrically connected with the driving motor, and the rainwater sensor is arranged above the pressing plate and is electrically connected with the STM8S single-chip microcomputer; and when the rainwater sensor senses rainwater, the driving motor is stated by the STM8S single-chip microcomputer, the rolling shaft is driven by the driving motor to roll, and therefore the free end of the protection curtain downwards stretches along the solar heat collector until a first magnet and a second magnet on the protection curtain are attached. The novel solar water heater is simple in structure, reasonable in design and long in service life.

Owner:CHENGDU ANGDIJIA TECH CO LTD

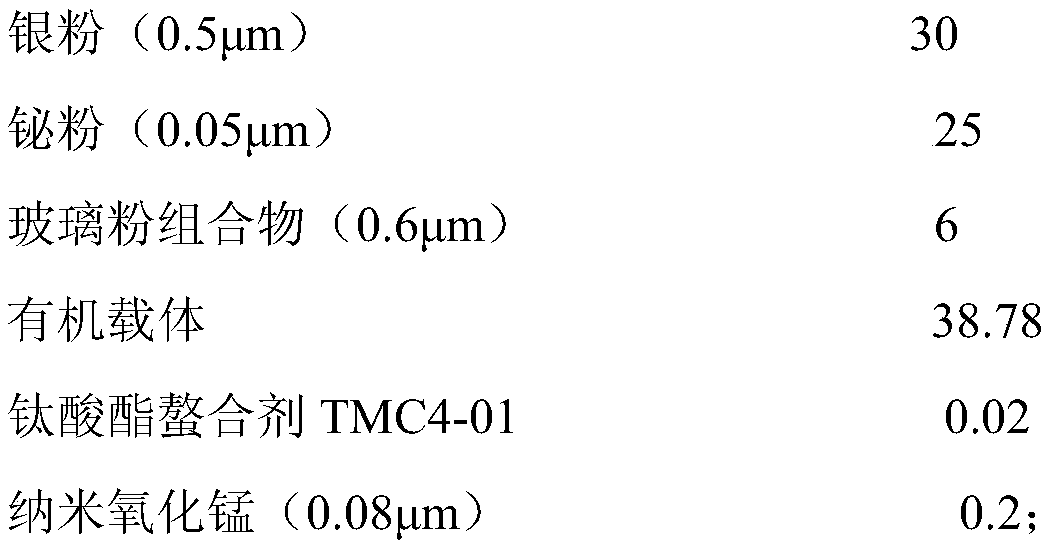

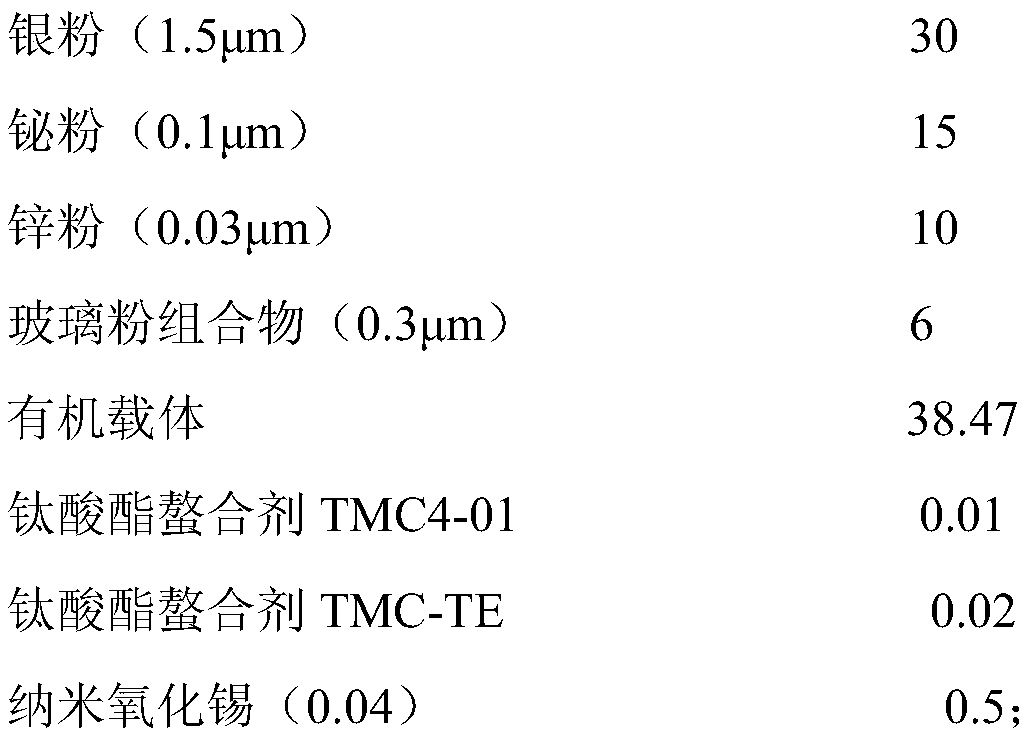

All-aluminum BSF (back surface field) back electrode slurry and preparation method and application thereof

ActiveCN110120274AEvenly sinteredUniform and dense sinteringNon-conductive material with dispersed conductive materialPhotovoltaic energy generationBack surface fieldSlurry

The invention provides all-aluminum BSF (back surface field) back electrode slurry and a preparation method and application thereof. The raw material of the back electrode slurry comprise 20%-60% of back electrode slurry, 1%-40% of nano metal powder, 0.5%-6% of a glass powder composition, 10%-50% of an organic vehicle, 0.01%-0.1% of a dispersant, and 0%-5% of an additive, wherein the total mass ofthe components of the back electrode paste is 100%, and the average particle size of the silver powder is 0.1-3 microns. The invention also provides the preparation method of the back electrode slurry. The back electrode slurry can be fully sintered in an aluminum slurry layer, and the photoelectric conversion efficiency of a solar cell is improved.

Owner:SUZHOU ISILVER MATERIALS

Silicon carbide single crystal growth graphite crucible capable of adjusting ratio of carbon to silicon in growth atmosphere

InactiveCN113249791ARealize SupplementSolve the problem of carbon enrichmentPolycrystalline material growthFrom condensed vaporsCarbide siliconSingle crystal

The invention discloses a silicon carbide single crystal growth graphite crucible capable of adjusting a ratio of carbon to silicon in a growth atmosphere. According to the invention, a cavity of the graphite crucible comprises a crucible raw material cavity and a crucible growth cavity, and the thickness of the graphite wall of the crucible raw material cavity is greater than the thickness of the graphite wall of the crucible growth cavity; the crucible raw material cavity comprises a silicon carbide powder cavity and at least two silicon powder cavities; and the top of the silicon powder cavity is connected with a silicon powder conveying pipe, and the silicon powder conveying pipe is also connected with a silicon powder bin outside the graphite crucible. According to the invention, the growth atmosphere can be adjusted by consuming certain gas-phase silicon in the growth process of a silicon carbide single crystal, and the ratio of carbon to silicon in the growth process of the silicon carbide single crystal is kept in an optimal range, so silicon liquid drops are prevented from appearing on the growth surface of the silicon carbide single crystal, and the growth quality of the silicon carbide single crystal is further improved.

Owner:中科汇通(内蒙古)投资控股有限公司

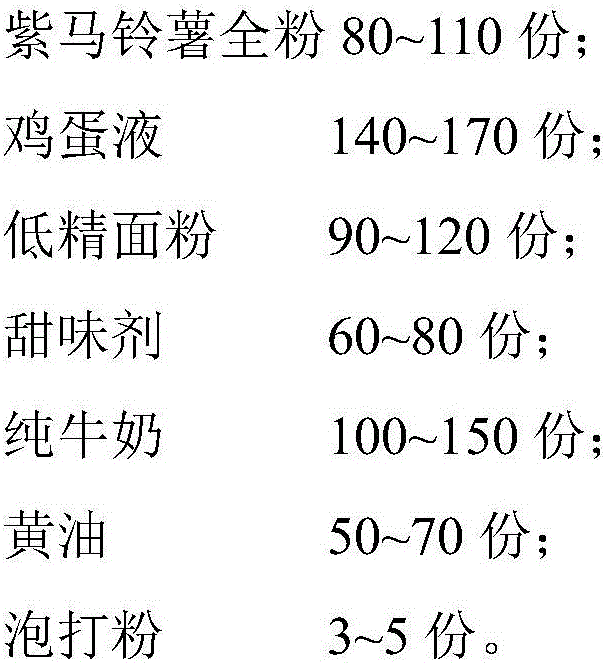

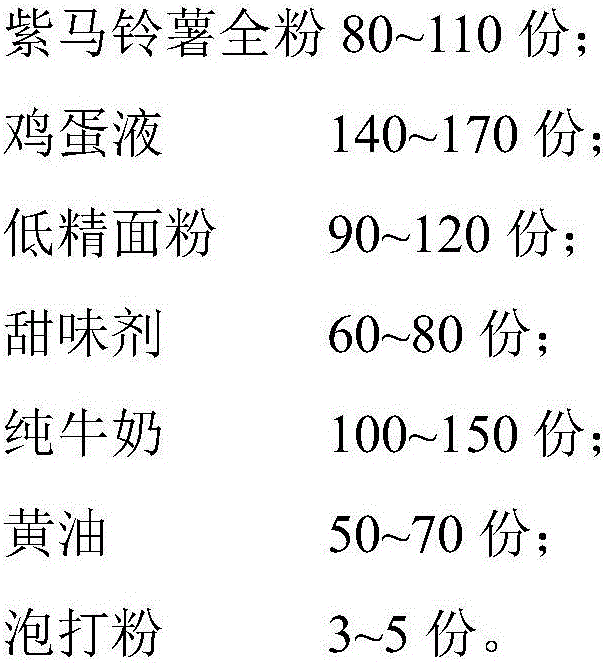

Low-sugar purple potato waffle and making method thereof

The invention provides a low-sugar purple potato waffle which is baked by mixing the following materials in parts by weight: 80-110 parts of purple potato flakes, 140-170 parts of egg liquid, 90-120 parts of low-gluten flour, 60-80 parts of a sweetening agent, 100-150 parts of pure milk, 50-70 parts of butter, and 3-5 parts of baking powder. Compared with a traditional waffle, the content of sucrose in the low-sugar purple potato waffle is greatly reduced, the calories of a finished product is low, and sugar alcohol used in the making process integrates nutrition, health care and dietary therapy into a whole body, so that the original sweet taste of the product is guaranteed, and the calories are not excessive. In addition, a making method is simple and convenient, the operation is simple, no large machine is needed, and the production is easy to carry out.

Owner:SHANGHAI JIAO TONG UNIV

Oxygen-rich lost foam bubble garage kit

InactiveCN107175313AMake up for endothermic coolingIncrease the degree of lysisFoundry moulding apparatusOxygen enrichmentPyrolysis

The invention discloses an oxygen-enriched lost foam foam white mold, which belongs to the technical field of lost foam casting. In the foam structure of the foam white mold, the foam cavity gas is oxygen-enriched air or pure oxygen with an oxygen volume content of not less than 21%. Oxygen, the foam structure material includes EPS beads, EPMMA beads, STMMA beads and other commonly used expandable resin beads. The preparation method includes at least one of the oxygen-enriching method in the pre-foaming stage, the oxygen-enriching method in the drying and aging stage, and the oxygen-enriching method in the molding and foaming stage. On the one hand, the oxygen-enriched gas in the cavity can promote the combustion and gasification of carbon atoms in the white mold, and reduce the residual solid products produced by foam pyrolysis; The endothermic cooling of the white mold pyrolysis process; and more active oxygen atoms can promote the cracking degree and cracking speed of the white mold.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

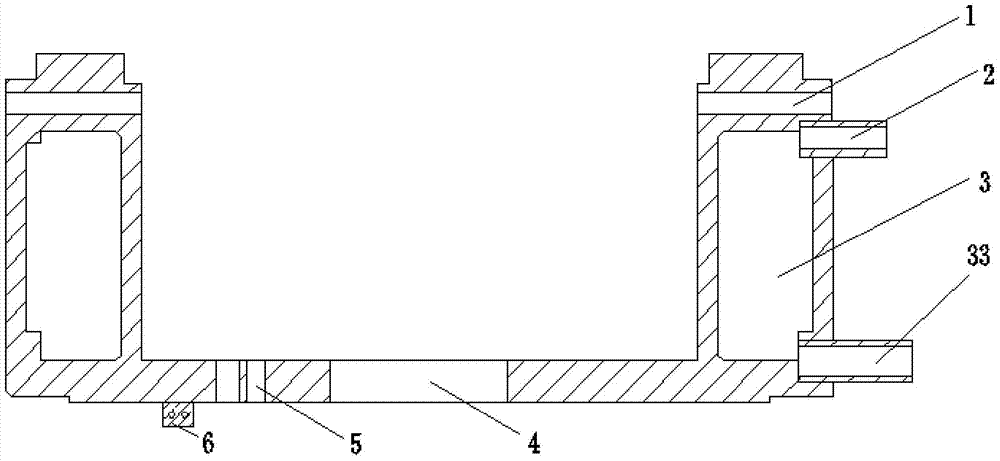

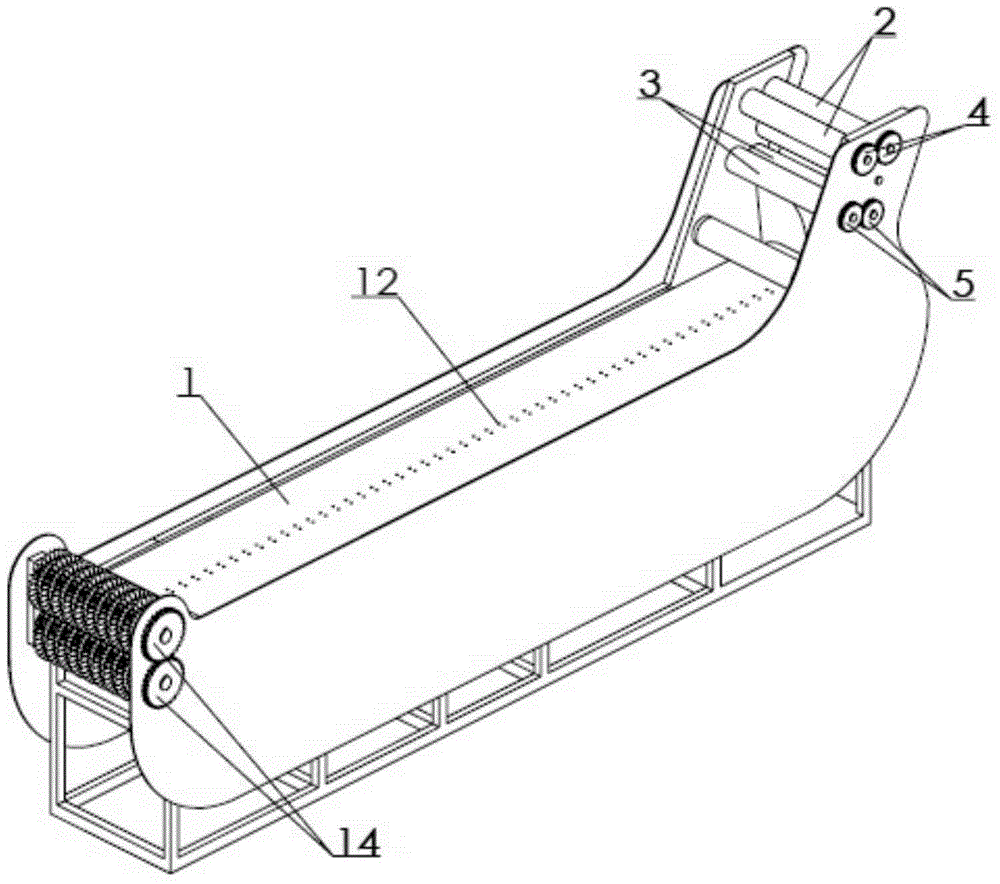

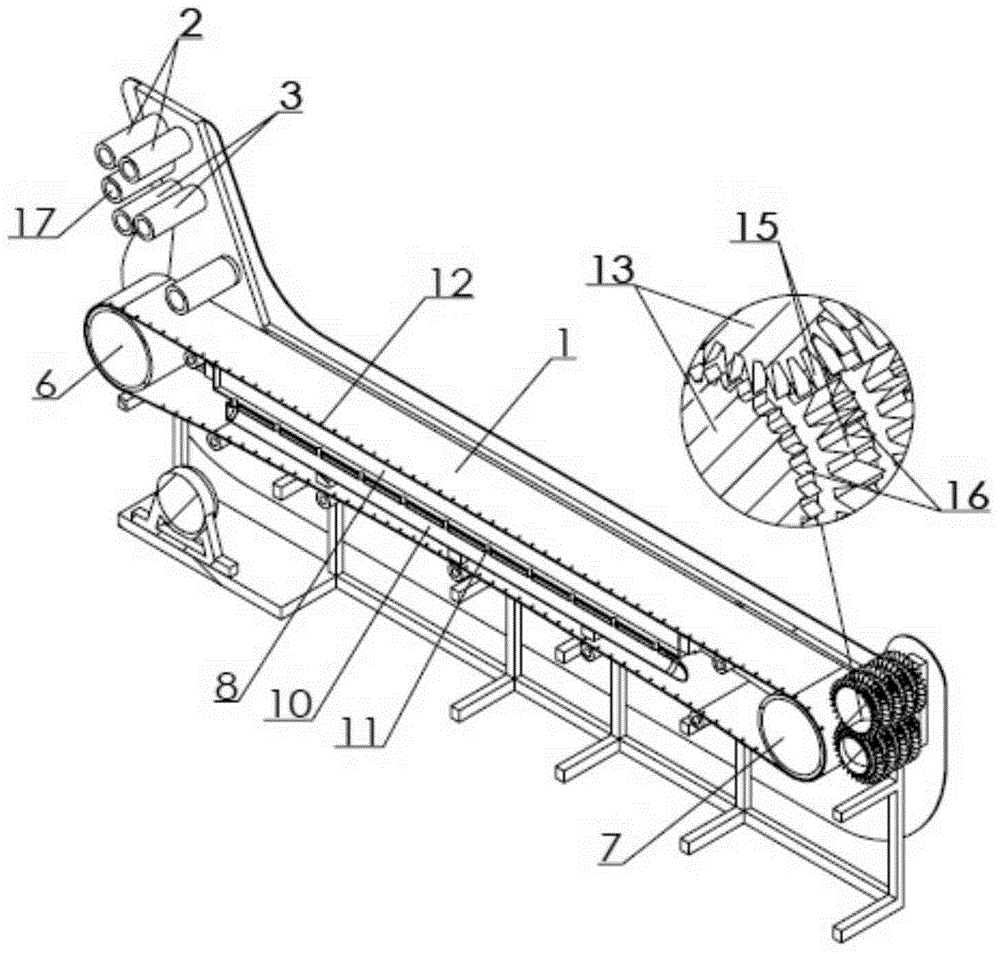

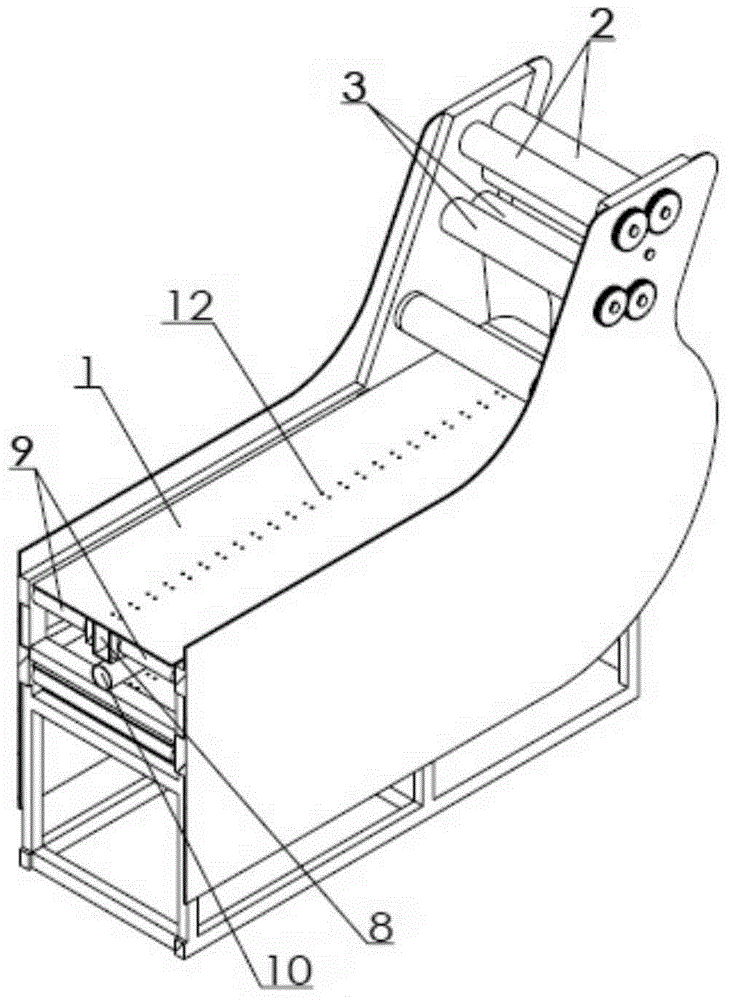

Air floating type sheeting and crushing machine for powder coating

ActiveCN105665068AMore caloriesImprove efficiencyGrain treatmentsShaping pressEngineeringLeather belt

The invention discloses an air floating type sheeting and crushing machine for powder coating. The air floating type sheeting and crushing machine comprises a sheeting part, a conveyer belt and a crushing part. The conveyer belt is unfolded through a driven roller and a driving roller which are arranged at the two ends of a rack. A longitudinal groove is formed in the position of the longitudinal center line under the upper belt. Carrier rollers are arranged on the two sides of the longitudinal groove. An upper opening of the longitudinal groove is flush with the upper edges of the carrier rollers and is attached to the lower face of the upper belt. An air pipe introduced through a side plate is arranged below the longitudinal groove and communicates with the longitudinal groove through at least one vertical pipe. Air holes are formed in the positions, within the width range of the longitudinal groove, of the longitudinal center line of the conveyer belt. Shaft rods at one ends of two crushing rollers are connected through third synchronous gears so that the crushing rollers can rotate at an equal speed. Long teeth and short teeth are axially arrayed on the surface of each crushing roller at intervals, and the long teeth and the short teeth are distributed in the circumferential direction. The radius of a circle where the outer edges of the long teeth are located is greater than the radius of a circle where the outer edges of the short teeth are located. The radiating efficiency is high, sheeted pieces cannot adhere to the conveyer belt under the action of an air cushion, and the machine is simple in structure, easy to implement and suitable for application and popularization.

Owner:江苏彩奇新材料科技有限公司

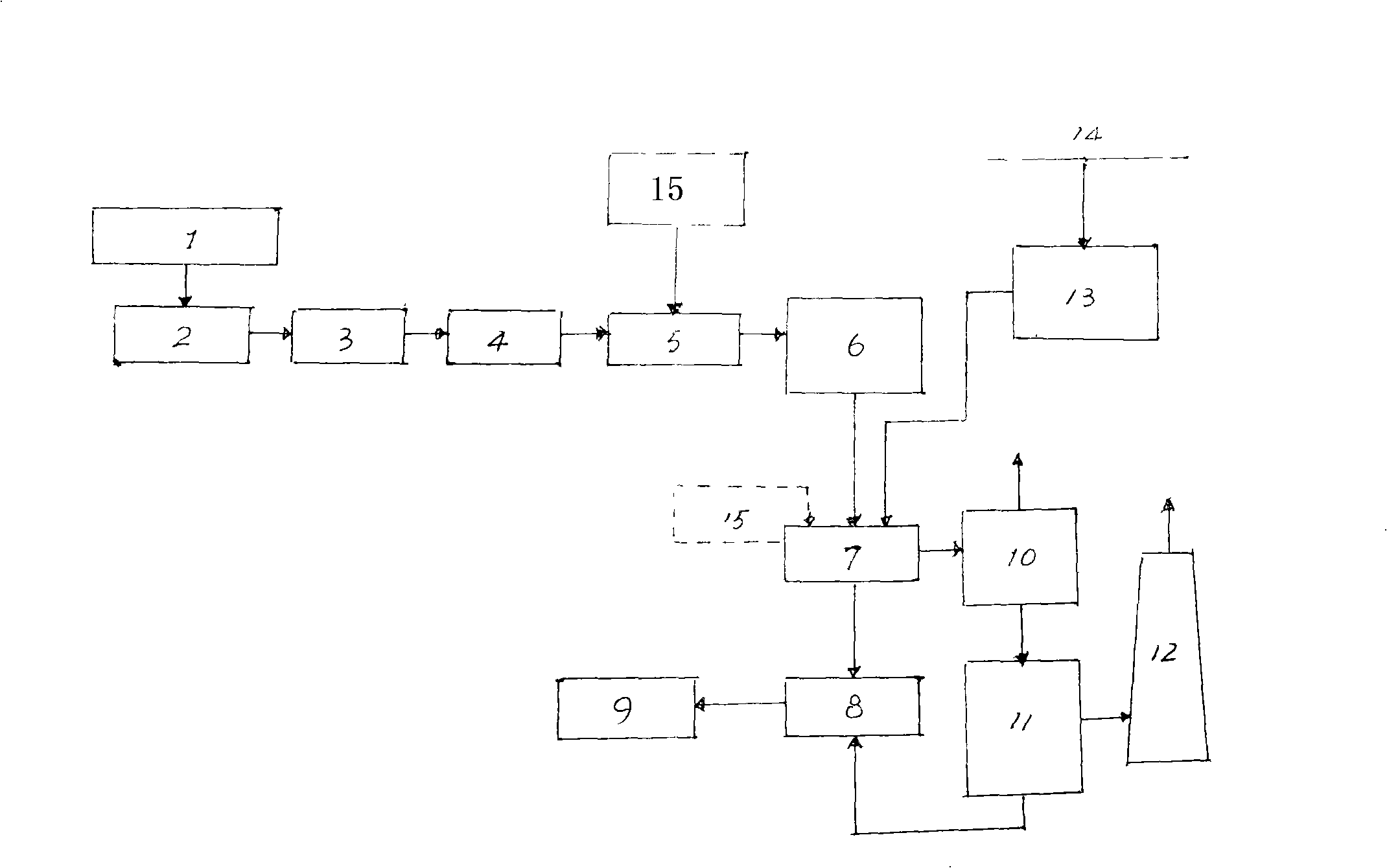

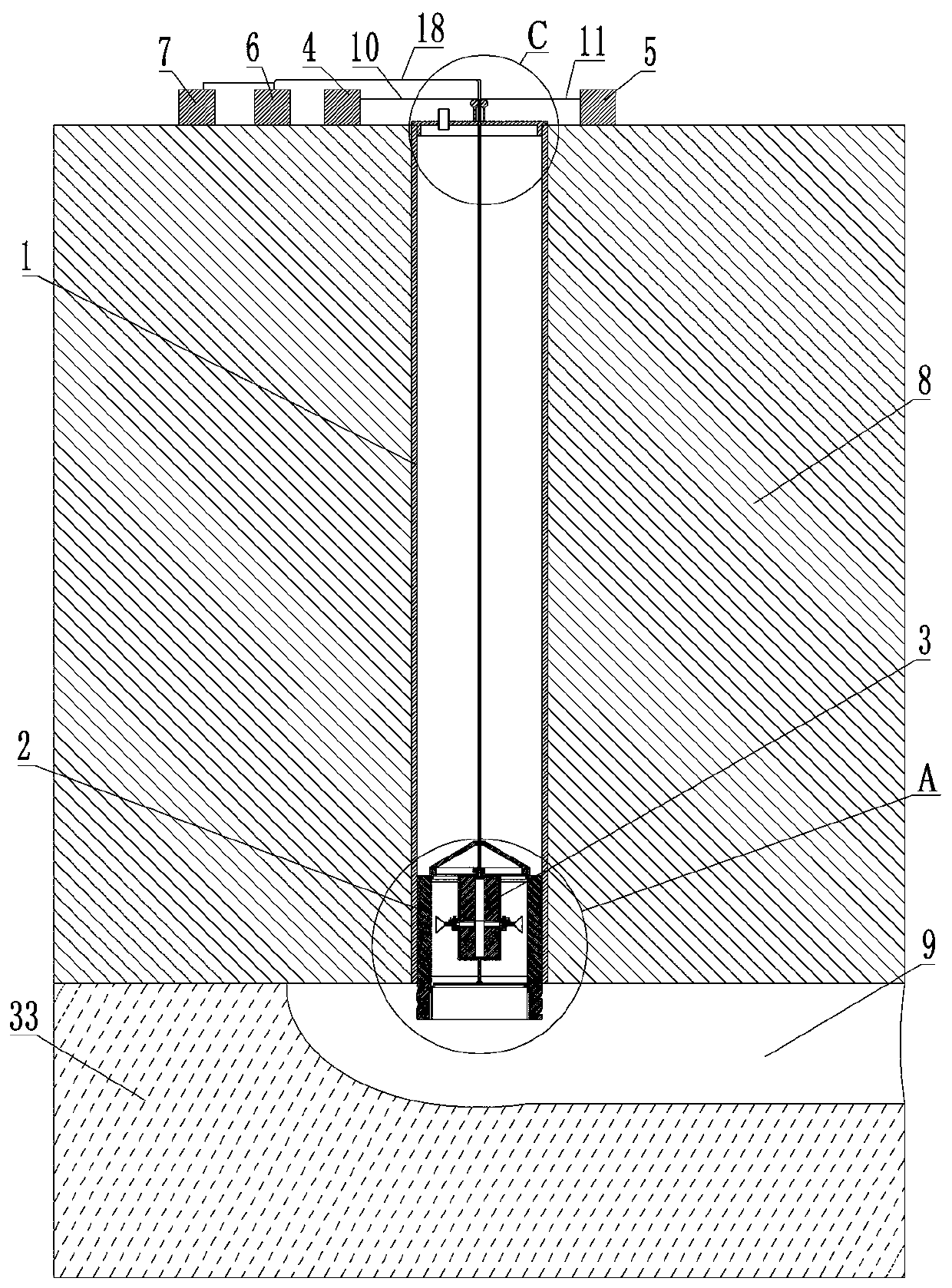

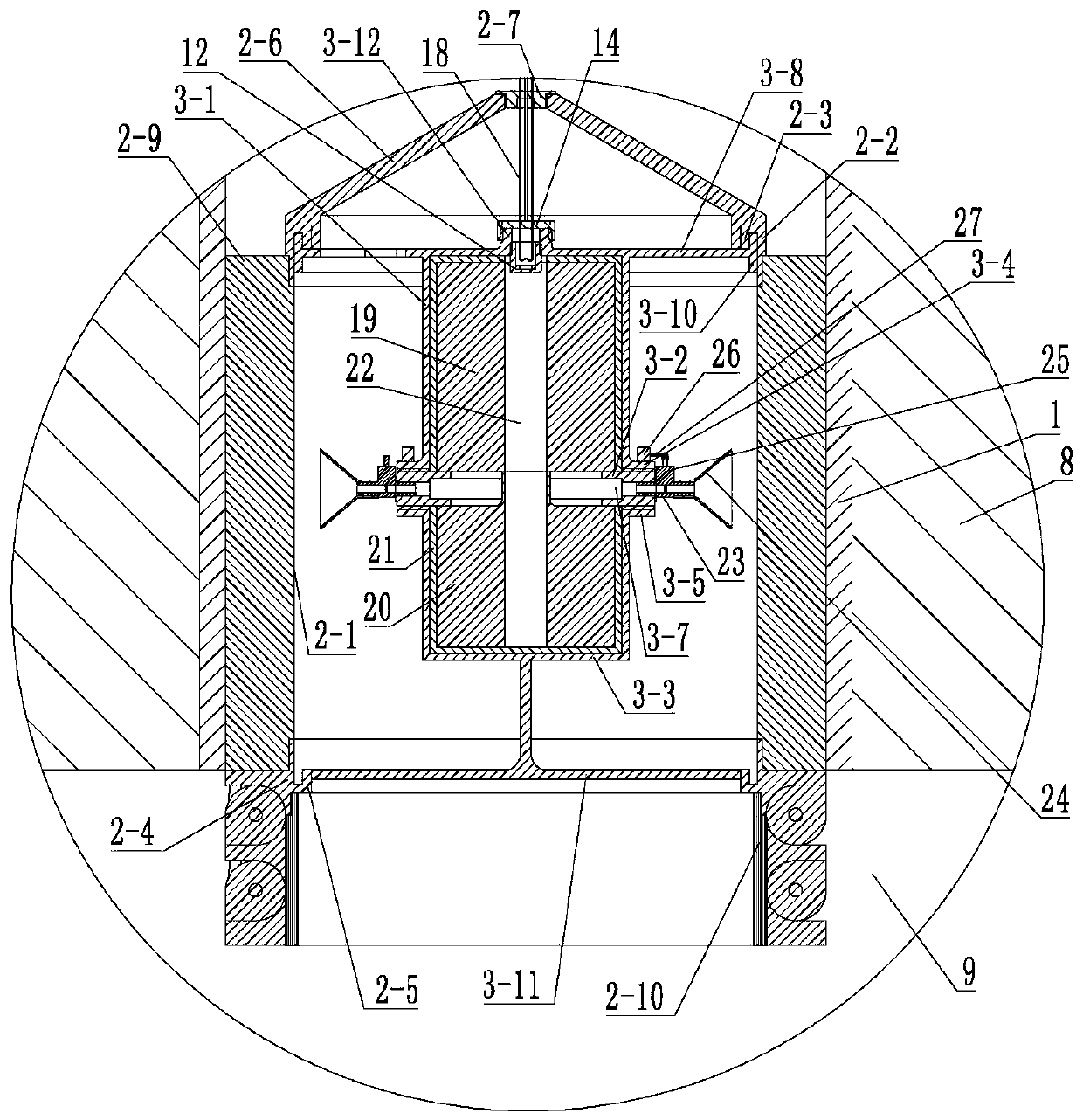

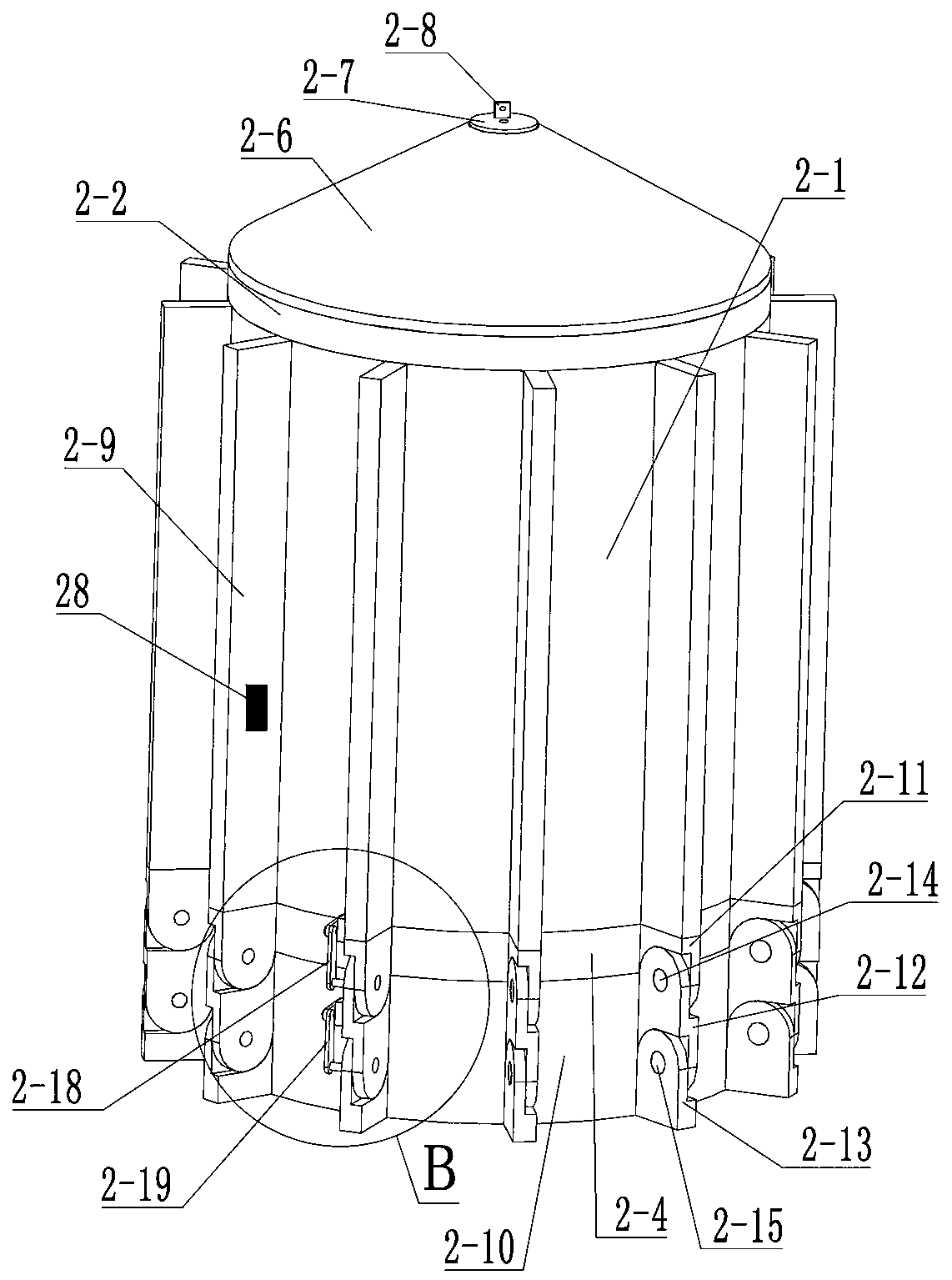

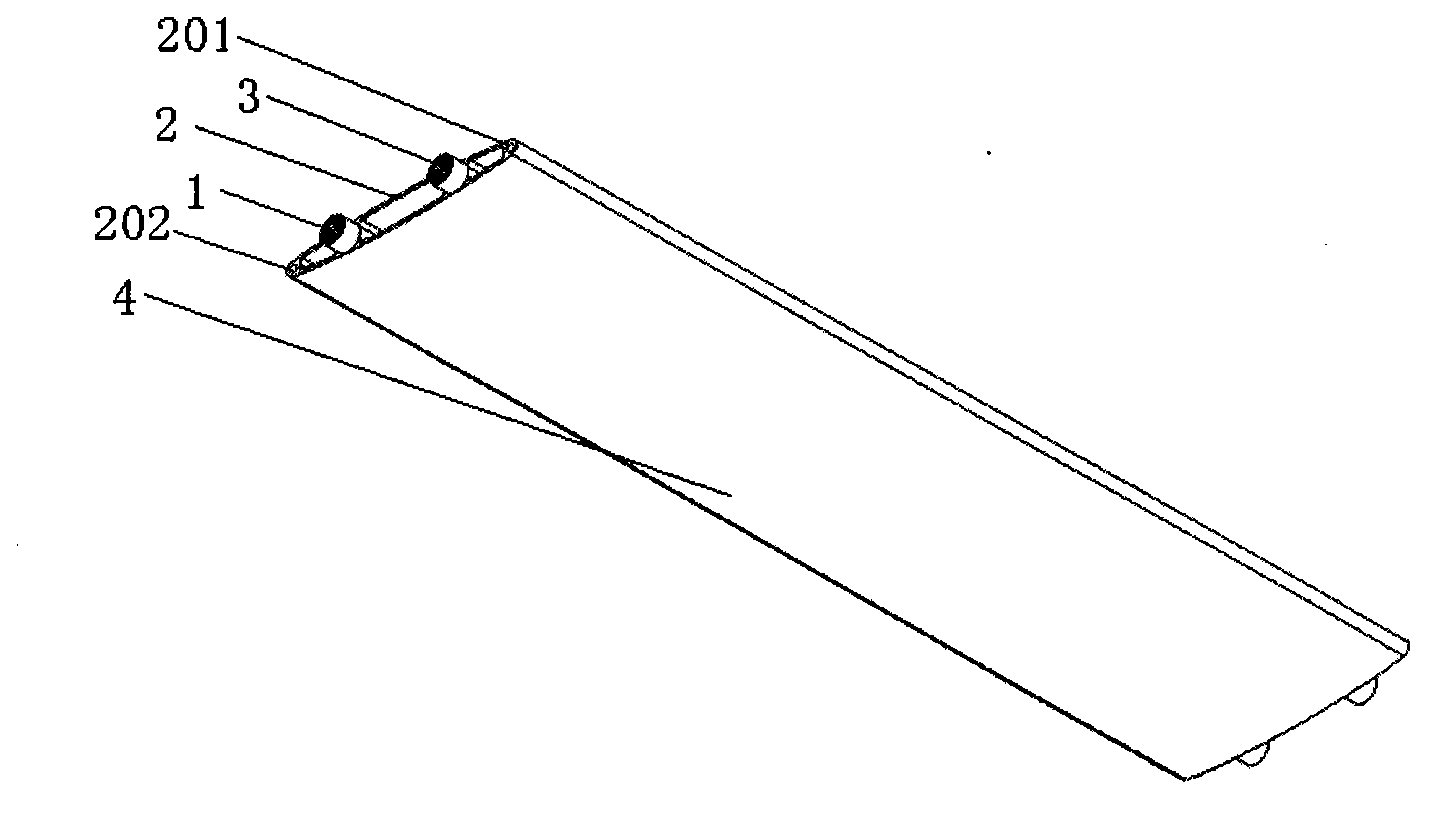

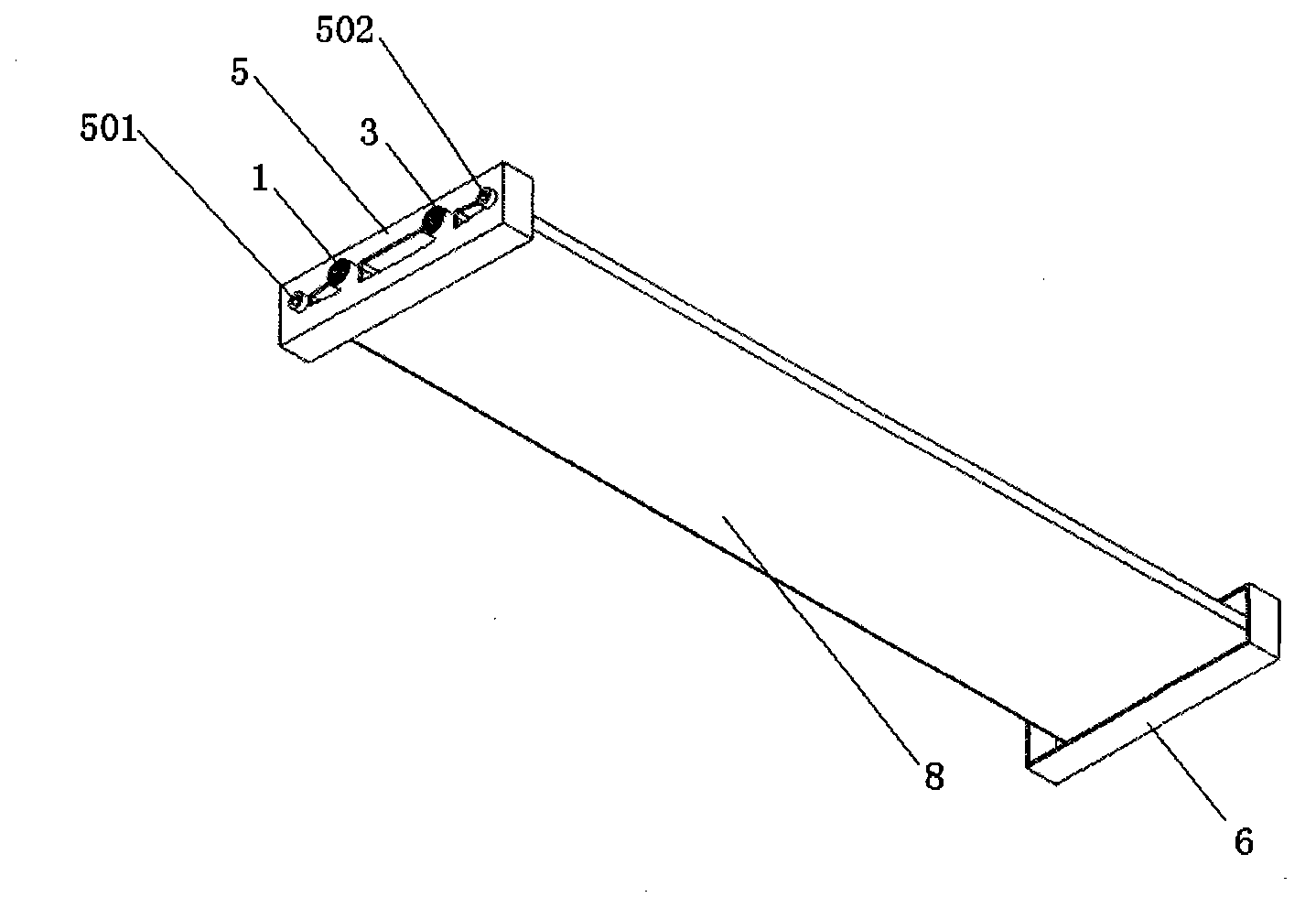

Non-well underground coal gasification ignition device

InactiveCN111101920AIncrease success rateImprove ignition success rateConstructionsCoal gasificationDrill holeEnvironmental geology

The invention relates to a non-well underground coal gasification ignition device. The non-well underground coal gasification ignition device comprises a gas conveying pipeline, a gas guiding barrel,a combustion barrel, a first winch, a second winch, a power supply and a controller. The gas conveying pipeline is fixedly supported in a gas inlet drilling hole. The gas guiding barrel ascends, descends and slides in the gas conveying pipeline. The combustion barrel ascends, descends and slides in the gas guiding barrel. A first steel wire rope is wound on the first winch and is fixedly connectedwith the top of the gas guiding barrel. The second steel wire rope is wound on the second winch and is fixedly connected with the top of the combustion barrel. An electric spark system and solid fuelare arranged in the combustion barrel. A plurality of fire spraying assemblies are arranged on the circumference of the outer circumferential side wall of the combustion barrel in an array mode. Thepower supply is respectively and electrically connected with the controller, the electric spark system and the fire spraying assemblies. The controller is in respective signal connection with the electric spark system and the fire spraying assemblies. Combustion-supporting gas is conveyed to a coal seam roadway, a coal seam is ignited by means of the solid fuel, the ignition success rate is high,the flow direction of the combustion-supporting gas can be controlled, and the coal seam burning efficiency is higher.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

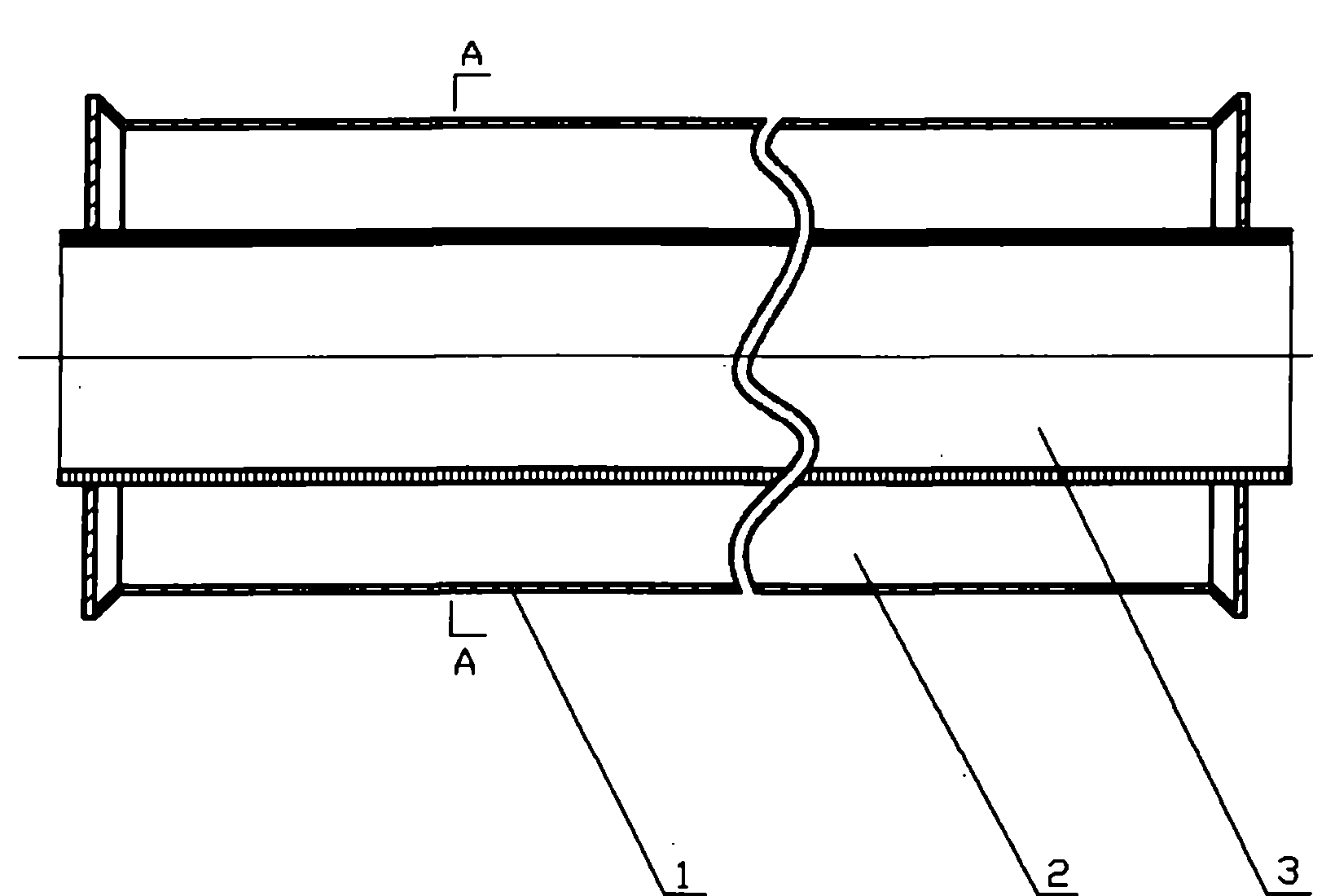

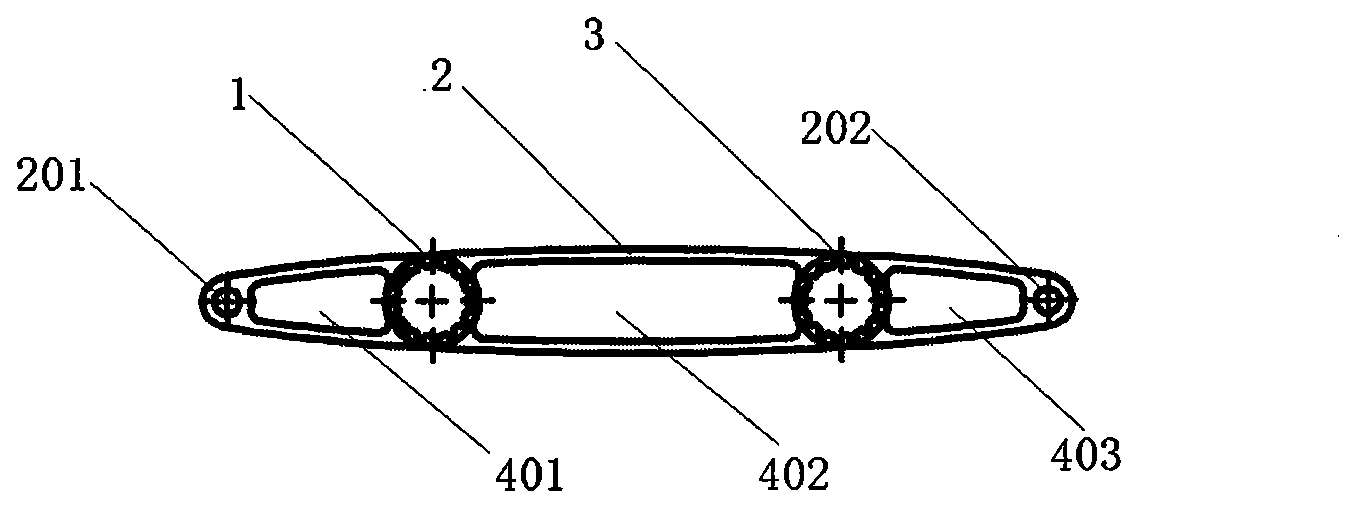

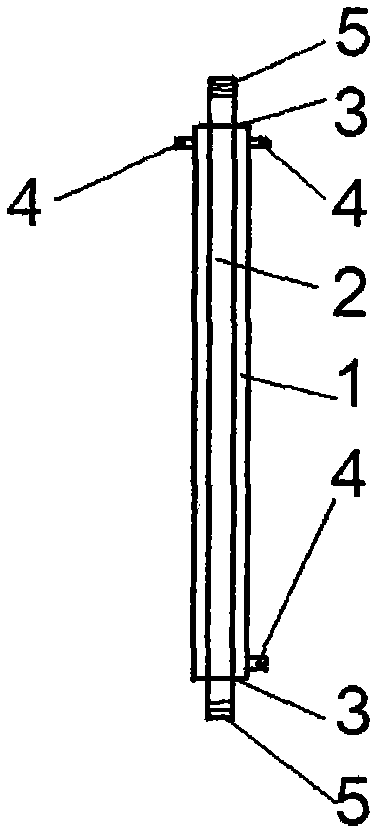

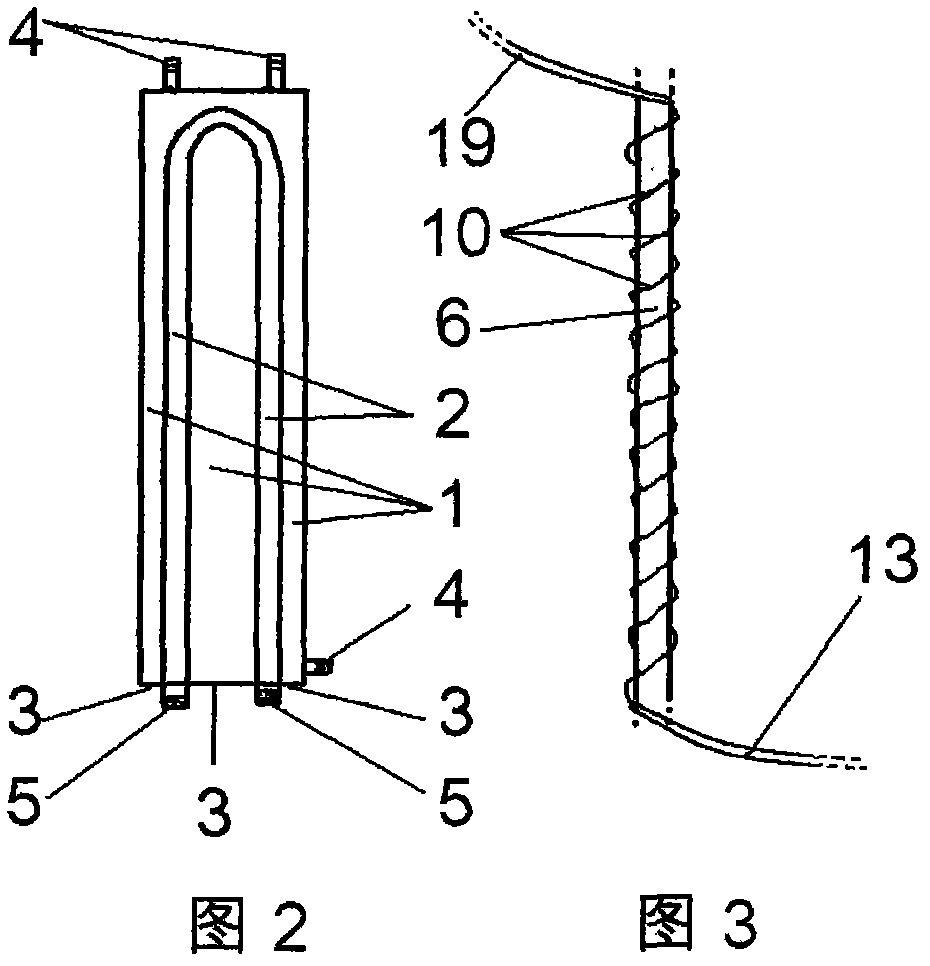

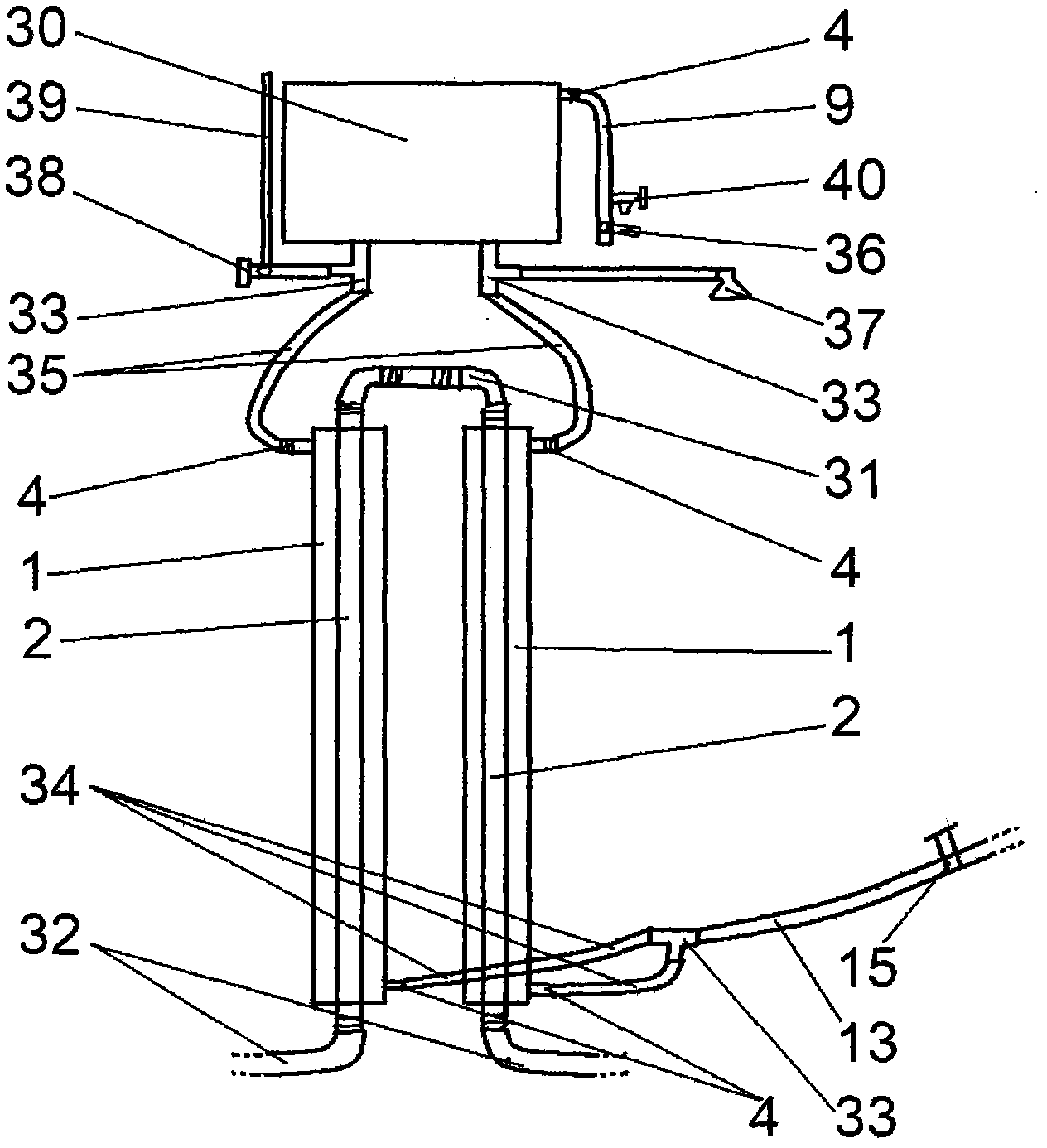

Flue gas waste heat recovery element and device capable of breaking through low temperature dew point

InactiveCN103245227AFully contactedImprove heat transfer efficiencyStationary tubular conduit assembliesCoatingsTemperature resistanceMaterials science

The invention relates to a flue gas waste heat recovery element and device capable of breaking through the low temperature dew point. The flue gas waste heat recovery element and device is characterized in that a heat exchange element is formed by an aluminum flat-oval-tube-shaped fin and aluminum fluid tubes; corrosion resistant, abrasion resistant and high temperature resistant ceramic glaze materials are composited on the surface of the heat exchange element; and an unsaturated contraction high polymer heat-shrink tube is wrapped on the outer surfaces of the ceramic glaze materials. The heat exchange element is fixed through an enameled steel plate to form a single module, a plurality of the single modules are combined in parallel connection mode to form a heat exchanger assembly, and all the fluid tubes of the heat exchange element are welded in series connection mode through bends. Liquid cold fluid is filled into the fluid tubes of the heat exchange element, three air cold fluid channels are arranged between the flat-oval-tube-shaped fin and the aluminum fluid tubes, and air hot fluid flows through the outer side of the flat-oval-tube-shaped fin. The flue gas waste heat recovery element and device has the advantages that a heat exchange tube is formed in once extruding mode, the fin is sufficiently contacted with the fluid tubes, accordingly heat exchange efficiency is improved and a large amount of labor work is reduced; the inner walls of the fluid tubes are designed to be tooth-shaped, the internal surface heat exchange areas of the fluid tubes are increased, and the heat exchange efficiency is led to be high; the heat exchange channels are additionally arranged so that use functions of a heat exchanger are increased; the surface is subjected to enameling processing and high polymer heat-shrink tube processing so that corrosion resistance, abrasion resistance and high temperature resistance are greatly improved; and the self-cleaning purpose is achieved, and normal and efficient heat exchange is ensured.

Owner:HANGZHOU YUANYUAN ENVIRONMENT TECH

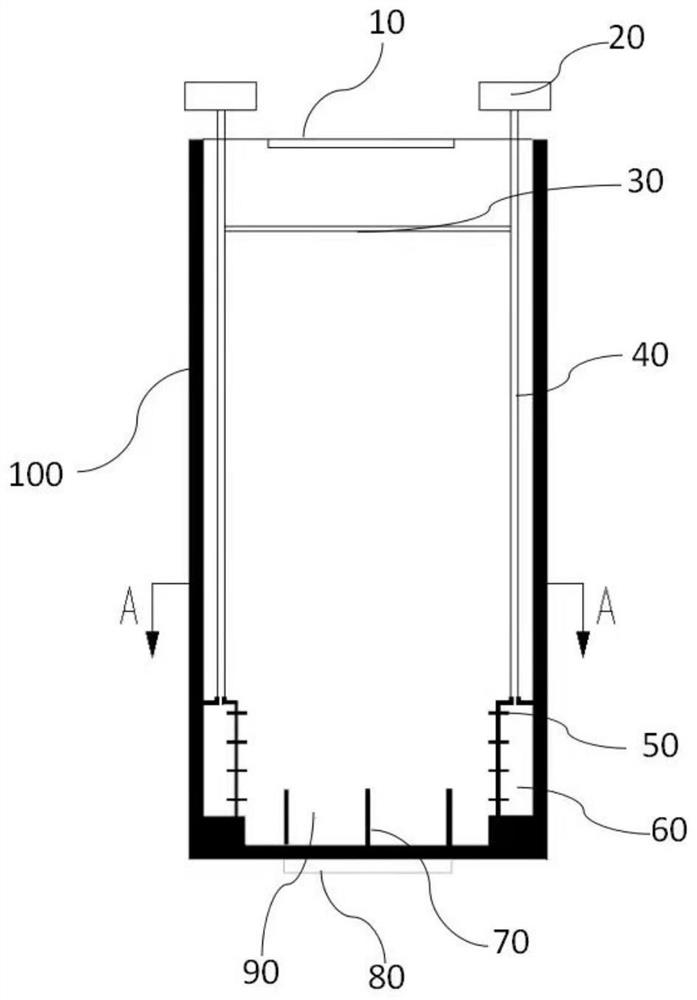

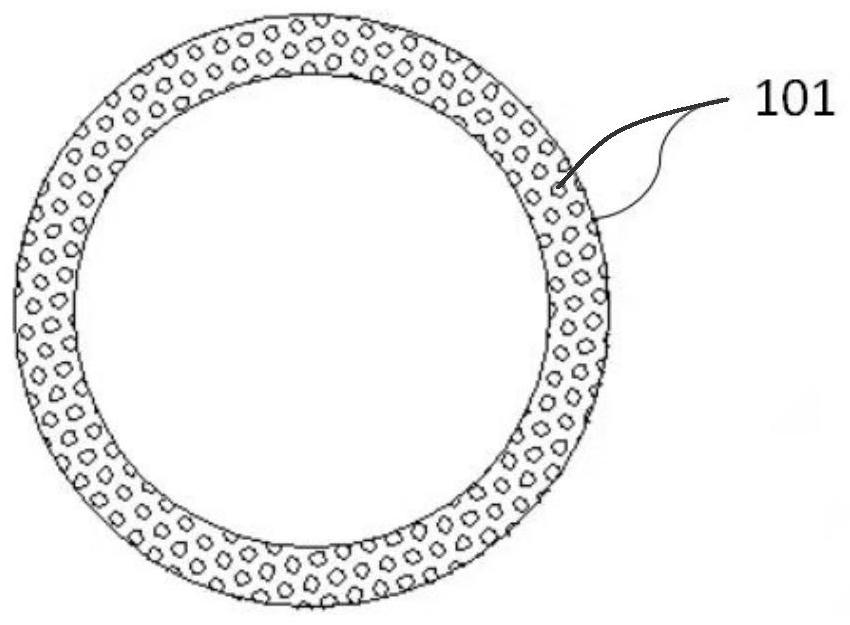

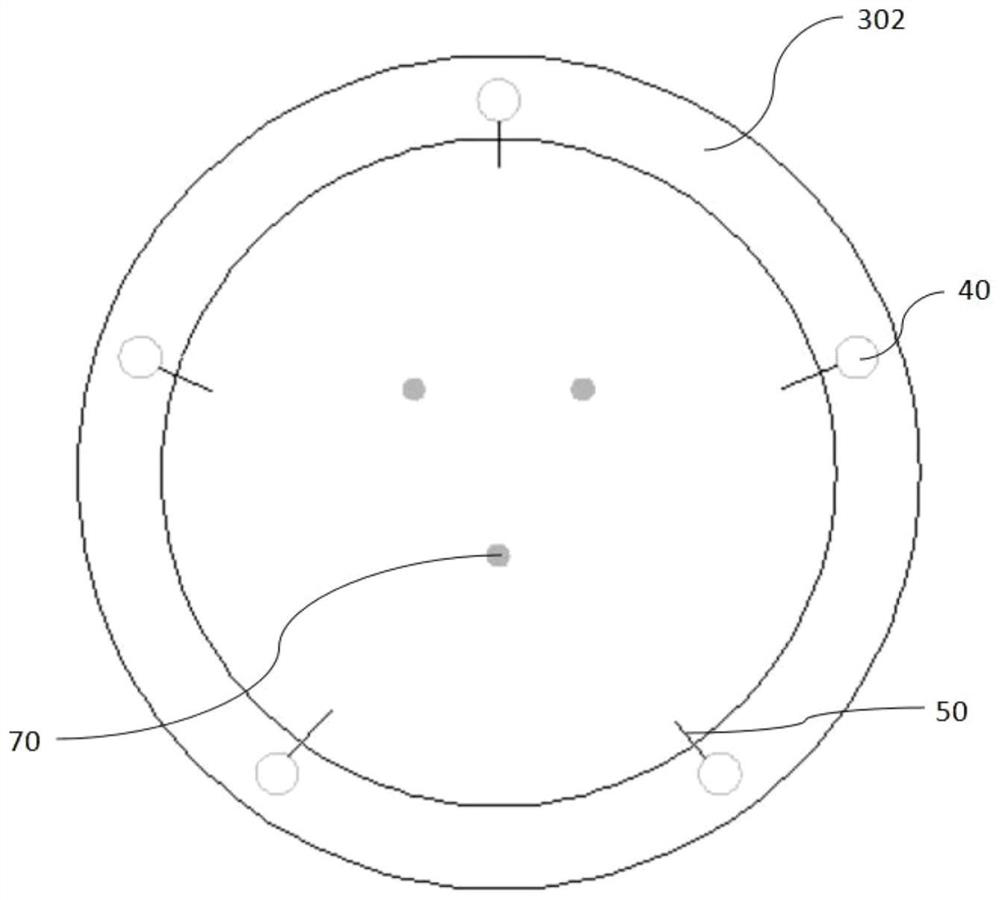

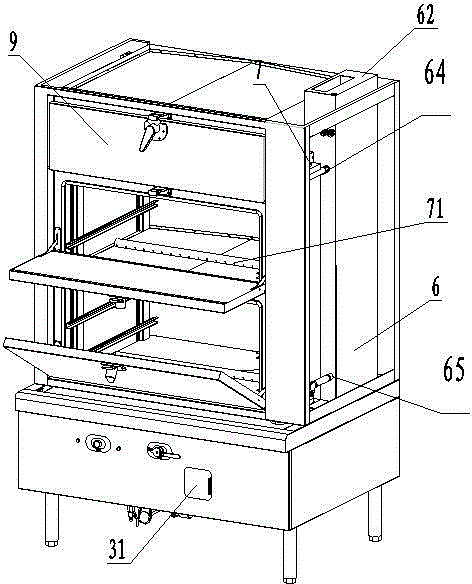

Dry steam cabinet furnace

The invention belongs to cooking utensils especially steam cabinet furnaces and particularly relates to a dry steam cabinet furnace. The dry steam cabinet furnace comprises a furnace end, a water tank, a hearth, a discharge flue and a steam cabinet, wherein the furnace end is located in the hearth, a fire observation opening is formed in the front end of the hearth, and the water tank is airtight. The dry steam cabinet furnace is characterized in that the side edge of the upper surface of the water tank is provided with an opening allowing the discharge flue to penetrate, an interval is formed between the outer wall of the discharge flue and the opening of the water tank and is a steam outlet of the water tank, baffles are arranged on the periphery of the interval to form a steam chamber, and a steam outlet is formed in the surface of the steam chamber and is connected with a steam pipe. The dry steam cabinet furnace has the advantages that generated steam is high in temperature and dry and contains a large amount of heat, the heating time of food is shortened, and the original flavor of the food can be kept at the same time; heat absorption area is large, heat efficiency is high, steam amount is stable and continuous, the temperature of exhausted smoke is low, the taste of the cooked food is good, and the original flavor of the food is kept more easily.

Owner:FUZHOU RONGKUN KITCHEN EQUIP

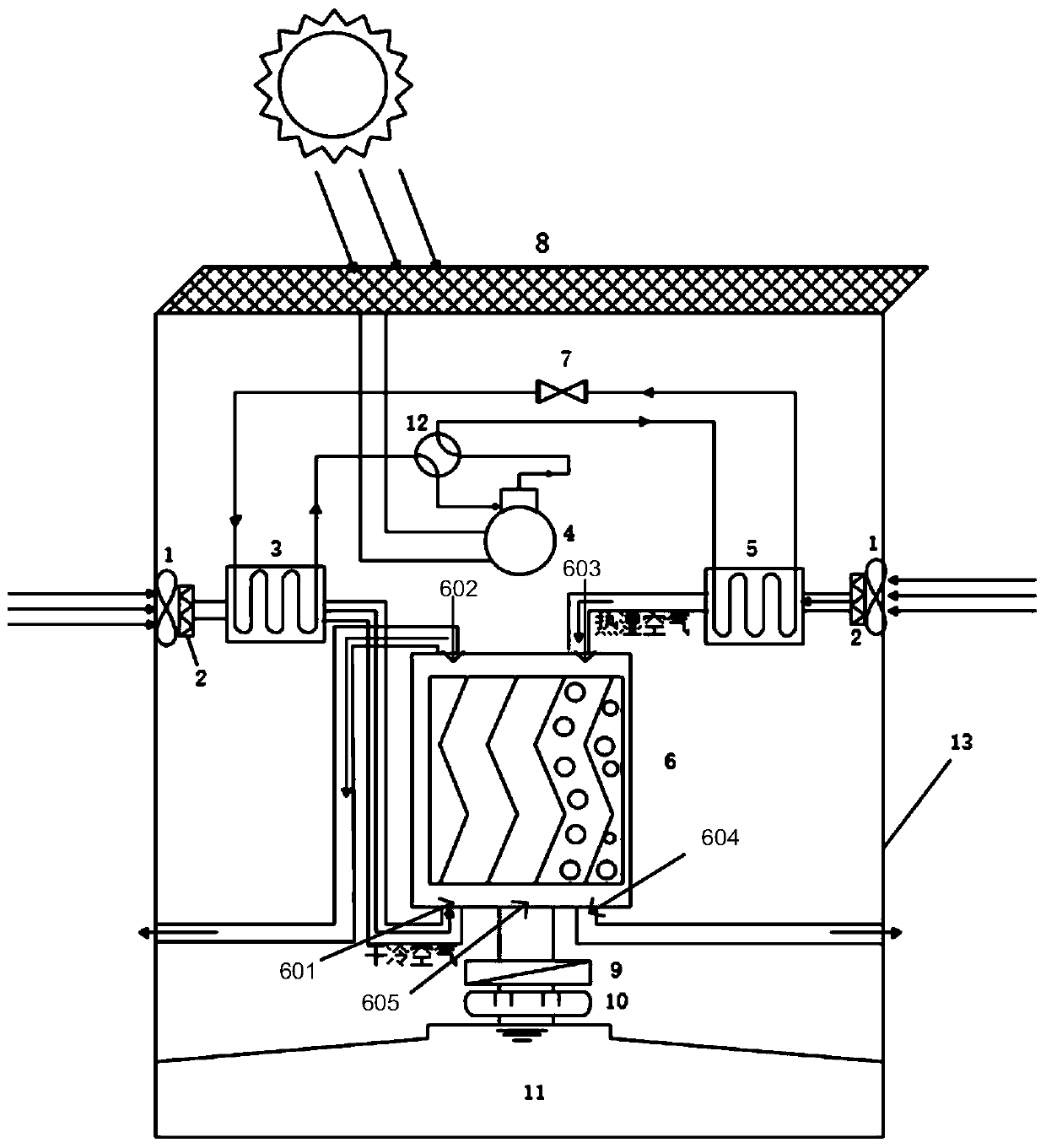

Solar powered compression typewater collection device

InactiveCN110130440AReduce energy consumptionImprove cooling efficiencyDrinking water installationElectric energyEvaporator

The invention provides a solar powered compression typewater collection device. The solar powered compression type water collection device comprises an evaporator (3), a compressor (4), a condenser (5), a regenerative condenser device (6), a solar panel (8),and a casing (13); air outside the casing (13) passes through the evaporator (3) to form dry and cold air; the air outside the casing (13) passes through the condenser (5) to form damp and hot air; the dry and cold air and the damp and hot air pass through the regenerative condenser device (6) to obtain condensate water; the evaporator (3)and the condenser (5) are cooled through the compressor (4); the solar panel (8) supplies electric energy to the compressor (4); the evaporator (3), the compressor (4), the condenser (5), and the regenerative condenser device (6) are located inside the casing (13); and the solar panel (8) is arranged outside the casing (13). The whole solar powered compression typewater collection deviceis free from dependence on electric energy, the structure is simple, operation is simple, and safety and high efficiency are achieved.

Owner:SHANGHAI JIAO TONG UNIV

Ring type roasting furnace

The invention discloses a ring type roasting furnace, and relates to the field of roasting furnaces. The ring type roasting furnace comprises a furnace shell; flame paths and furnace chambers communicating with the flame paths are formed in the furnace shell; material boxes are further embedded in the furnace shell; one material box is arranged between every two flame paths; the furnace chambers are formed in the positions, located below the flame paths, inside the furnace shell and communicate with the flame paths; the furnace chambers are partitioned through partition plates; an ignition device is arranged in each furnace chamber; a guide pipe is arranged on each partition plate in a penetrating mode; a fuel cavity is formed in the position, surrounding the furnace chambers, inside the furnace shell in a ring shape; and a fuel gas inlet pipe communicating with the fuel cavity is arranged on one side of the furnace shell in a penetrating mode. The ring type roasting furnace has the advantages that a flue gas filtering device is arranged, exhausted hot gas can be filtered by the flue gas filtering device, so that the hot gas and waste gas in a furnace body can be sufficiently filtered in the emission process so as to filter out particulate impurities in flue gas and toxic and harmful gas in the flue gas, and therefore the flue gas can accord with the emission standard, and thering type roasting furnace can be more environmentally-friendly.

Owner:山东齐明炭素有限公司

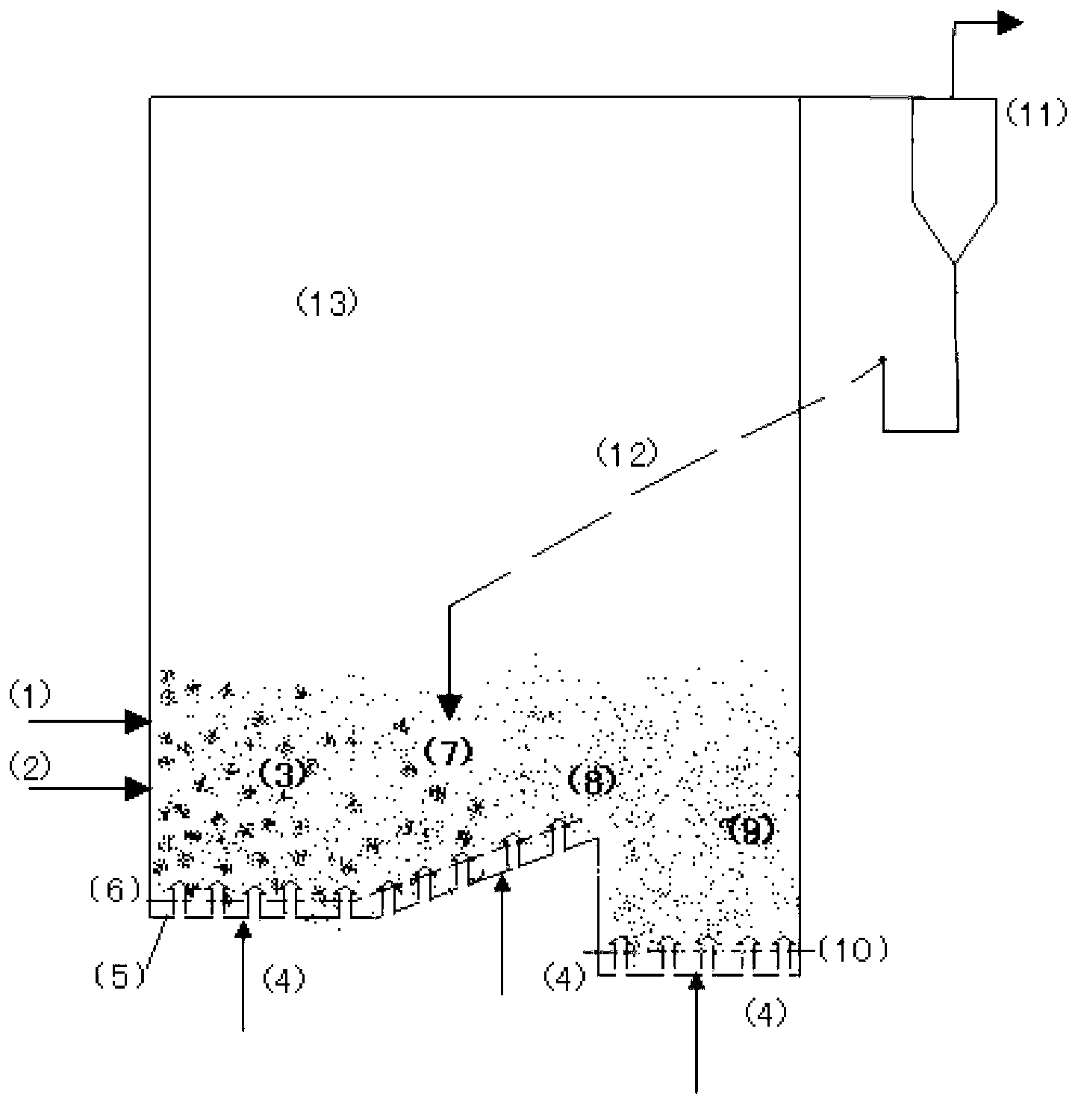

Unequal-height variable-speed air distribution particle heat carrier heating furnace for circulating fluidized beds

ActiveCN103196293AMore caloriesReduce energy consumptionFluidised-bed furnacesHeat carrierProcess engineering

The invention provides an unequal-height variable-speed air distribution particle heat carrier heating furnace for circulating fluidized beds and mainly solves the problems of low burning shares, high energy consumption and difficulty in regulation in dense-phase zones in the prior art. The unequal-height variable-speed air distribution particle heat carrier heating furnace for circulating fluidized beds comprise fluidized bed dense-phase zones arranged in the furnace body. An equal-height high-speed zone, an unequal-height low-speed zone and an equal-height low-speed zone are sequentially arranged in the fluidized bed dense-phase zones from a material inlet to a material outlet. By the aid of the special air distribution structure, particle heat carriers are completed in a group of fluidized bed dense-phase zones which are communicated to each other and different in functions from entering to discharging, no high height difference is caused, and the unequal-height variable-speed air distribution particle heat carrier heating furnace is low in energy consumption and easy to control.

Owner:陕西德源建设开发有限公司

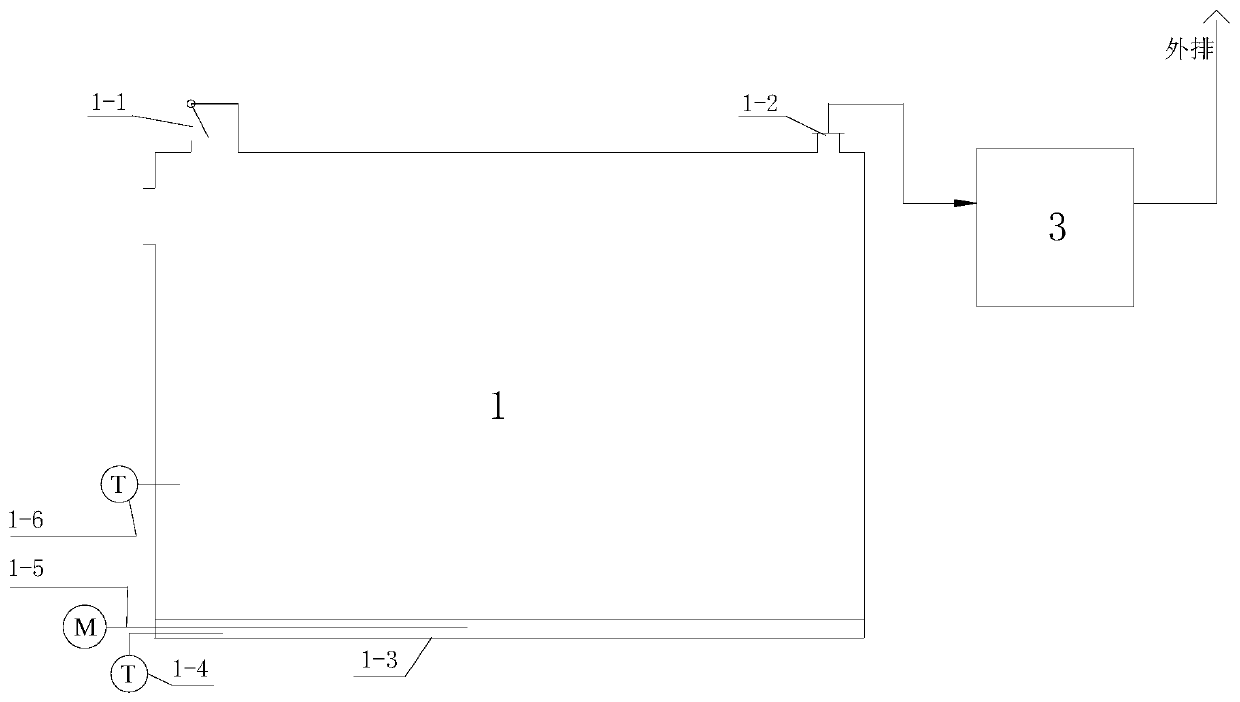

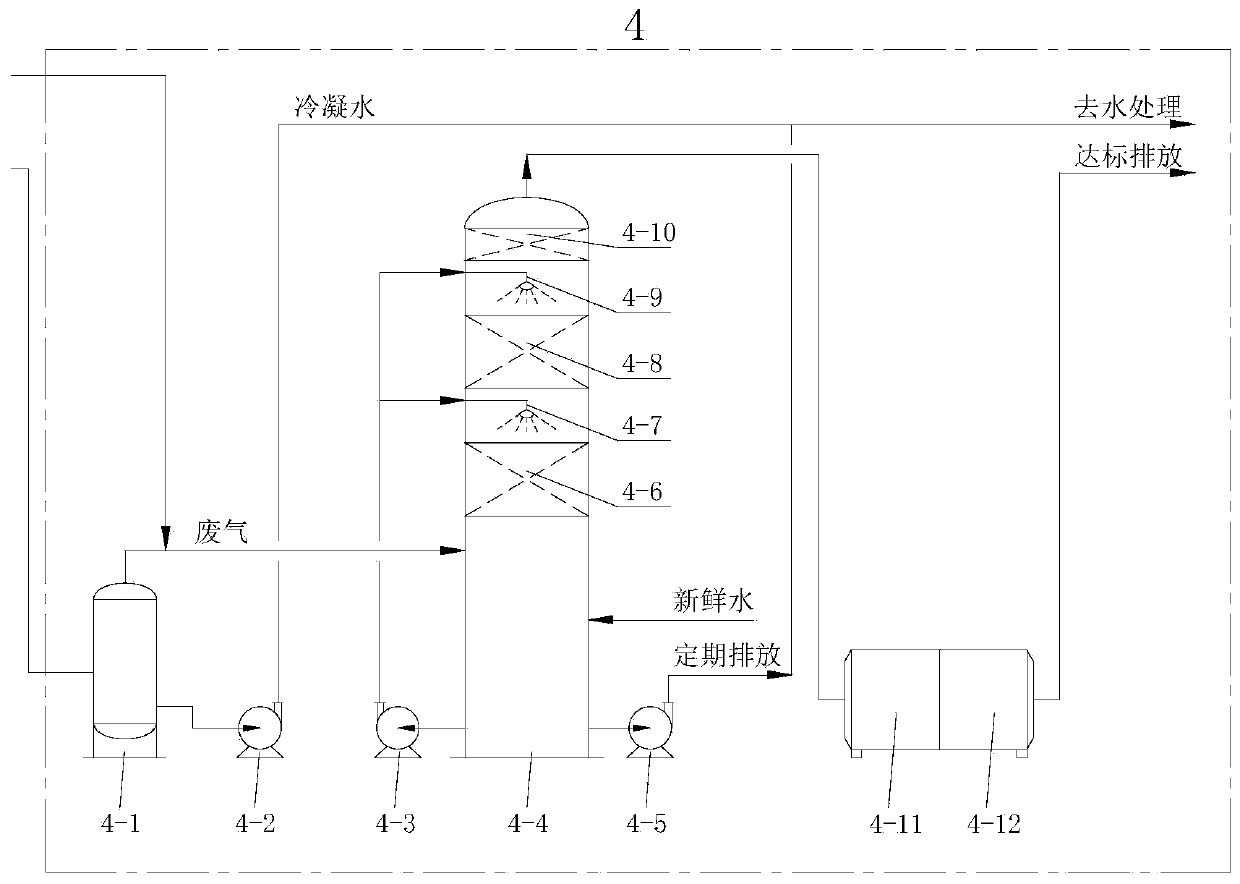

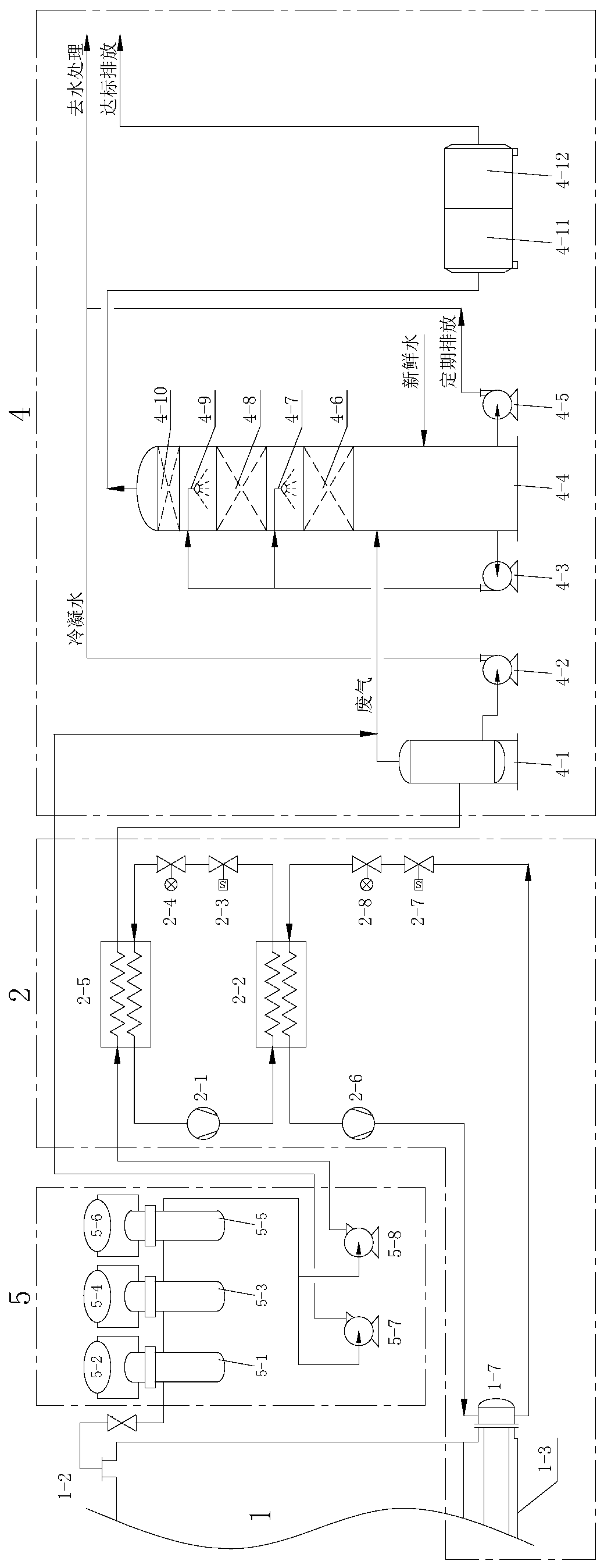

Waste gas treatment device used in kitchen waste biochemical treatment equipment

PendingCN111408200AEliminate Visual PollutionRequirements to meet emission standardsCombination devicesGas treatmentProcess engineeringWaste heat recovery unit

The invention relates to a waste gas treatment device used in kitchen waste biochemical treatment equipment. The device comprises a dust removal unit, a waste heat recovery unit and a deodorization unit, wherein the dust removal unit, the waste heat recovery unit and the deodorization unit are sequentially connected through a gas conveying pipeline, waste gas generated by a fermentation bin is firstly guided into the dust removal unit to filter impurities, then is guided into the waste heat recovery unit to recover waste heat, then is guided into the deodorization unit to remove odor, and thenis discharged outwards. According to the technical scheme provided by the invention, the waste gas of the kitchen waste biochemical equipment is treated by adopting a process of dust removal, waste heat recovery and deodorization, impurities and odor in the waste gas can be removed, and the waste heat of the waste gas is recovered, so that the effects of reducing environmental pollution, saving energy and reducing emission are achieved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

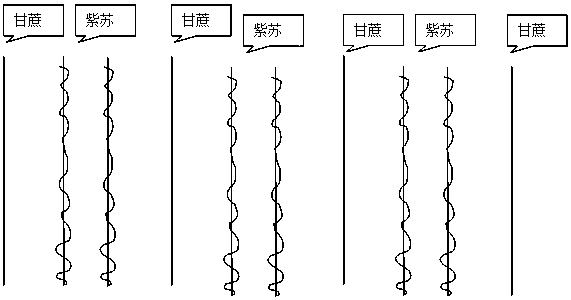

Method for interplanting perilla with sugarcane

InactiveCN108739100AImprove land utilizationIncrease profitSugarcane cultivationCultivating equipmentsDiseaseInsect pest

The invention discloses a method for interplanting perilla with sugarcane, including the following steps: (1) sugarcane seed selection; (2) land preparation; (3) planting; (4) management; (5) perillaharvest; (6) sugarcane collection. The method for interplanting perilla with sugarcane in the invention is a new planting method according to the local characteristics of Guangxi Zhuang Autonomous Region, which provides a new thought for the culture technique of perilla. The method for interplanting perilla with sugarcane has improved the utilization of rural land to some extent, increased crop yield per unit of land area, realized sugarcane and perilla double harvest, and thereby increased the income of farmers. The sugar content of sugarcane is high, the quality of perilla is good, and the disease and insect pest is very rare, thereby increasing the per unit area yield.

Owner:XIANGZHOU COUNTY INST OF SCI & TECHN INFORMATION

Dual-heat exchange structure and heat utilization product thereof

InactiveCN101922867AIncrease the lengthIncrease surface areaSpace heating and ventilation detailsStationary tubular conduit assembliesWater sourceHeat losses

Owner:王海昆

Lithium ion power battery box

ActiveCN103199203BCool evenlyObvious temperature differenceSecondary cellsCell component detailsLithiumPower battery

The invention relates to a lithium ion power battery box, which comprises a battery box body for alternately arranging batteries inside the body along a set arrangement direction, and a base air channel arranged in the battery box body, wherein the flow direction of the base air channel is consistent with the set arrangement direction; the battery box is also provided with a reinforced cooling air channel for delivering cooling air separated from the base air channel; the reinforced cooling air channel is provided with jet holes for directing the cooling air into a set cooling area in the battery box body; and the cooling area is a gap between front and back adjacent batteries along the battery arrangement direction in set positions or batteries in the set positions. By adopting the lithium ion power battery box, the problem in the prior art that cooling capacity distribution in various parts in the battery box body is non-uniform because the batteries are successively cooled along a single base air channel is solved; and the lithium ion power battery box of the invention can uniformly cool the batteries and improve the overall discharge performance and the service life of the batteries in the battery box.

Owner:CALB CO LTD

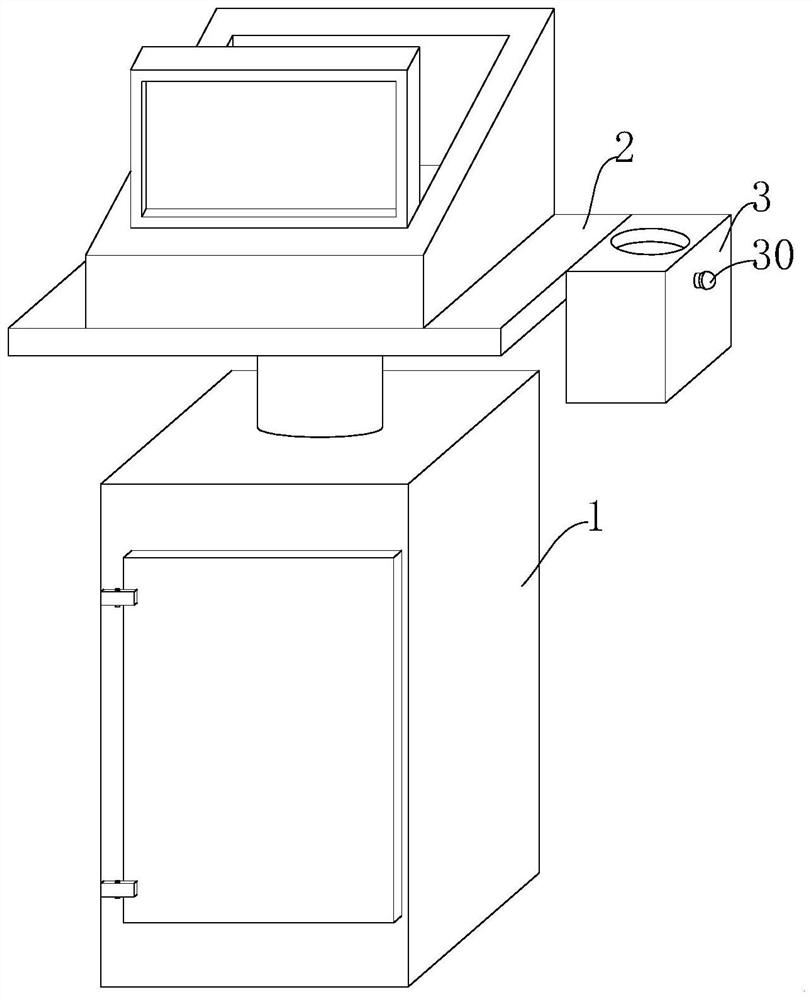

Ultrasonic medical equipment

PendingCN113827272AIncrease flow rateIncrease frictionLavatory sanitoryCleaning using toolsMedical equipmentMedicine

The invention relates to the technical field of medical equipment, in particular to ultrasonic medical equipment. The ultrasonic medical equipment comprises a case, wherein a support is mounted on the side wall of the case, a storage box is fixedly mounted on the support, an insertion opening is formed in the top wall of the storage box, a disinfection box is fixedly mounted on the bottom wall of the insertion opening, a partition plate is fixedly mounted in the disinfection box, and a medicine box is fixedly mounted on the inner bottom wall of the disinfection box. According to the ultrasonic medical equipment, an electric heating wire is used for heating a disinfectant in the medicine box, so that the disinfectant which is rapidly evaporated due to heating flows along a first flow guide pipe, the disinfectant in the first flow guide pipe penetrates through a first one-way valve and flows out of a spray head, the flow speed of steam is increased under the action of the spray head, therefore, the steam can be quickly diffused in the space, above the partition plate, in the disinfection box, the disinfectant diffused in the space is in contact with a probe, and thus, bacteria on the surface of the probe can be killed.

Owner:杨梦婷

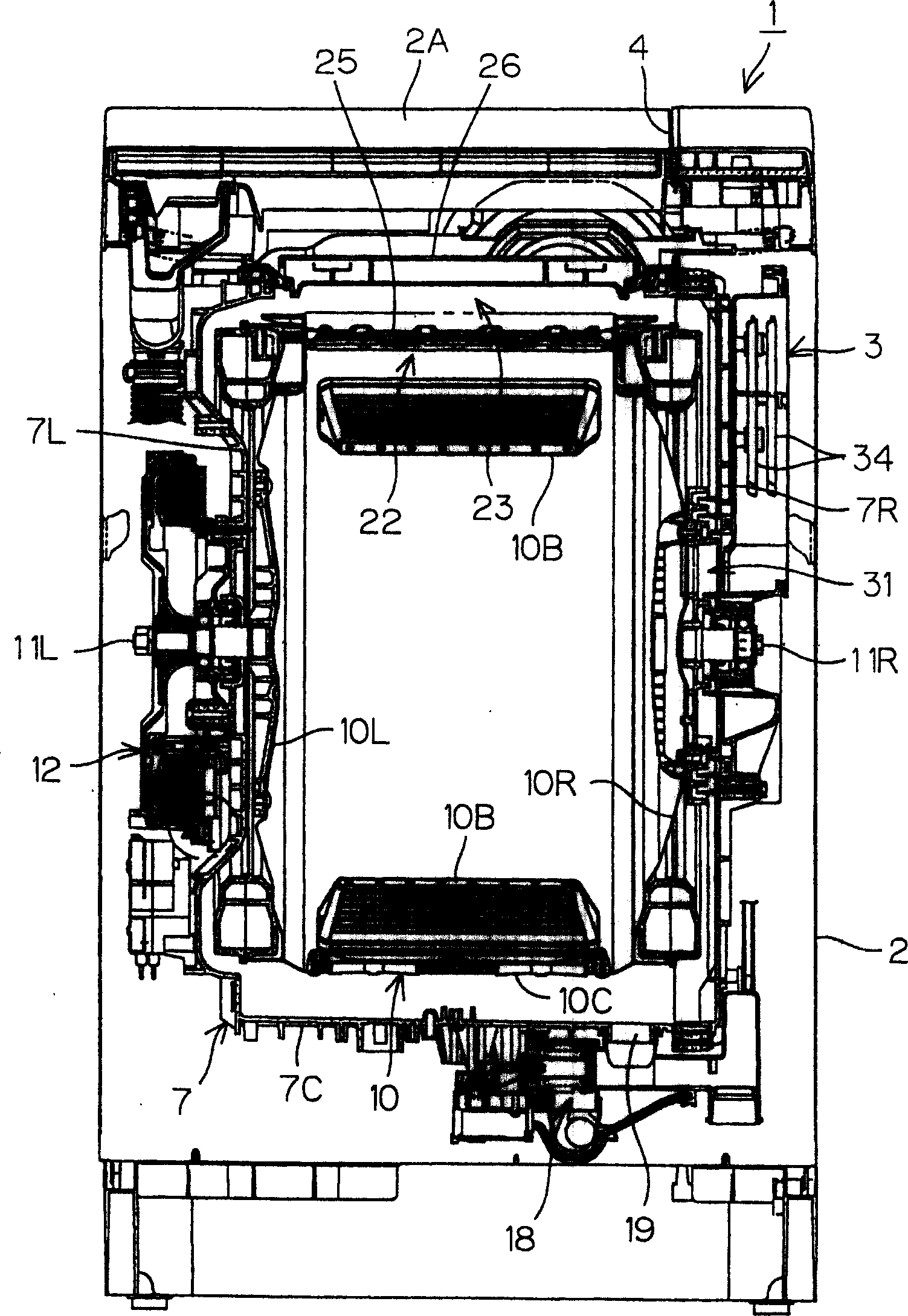

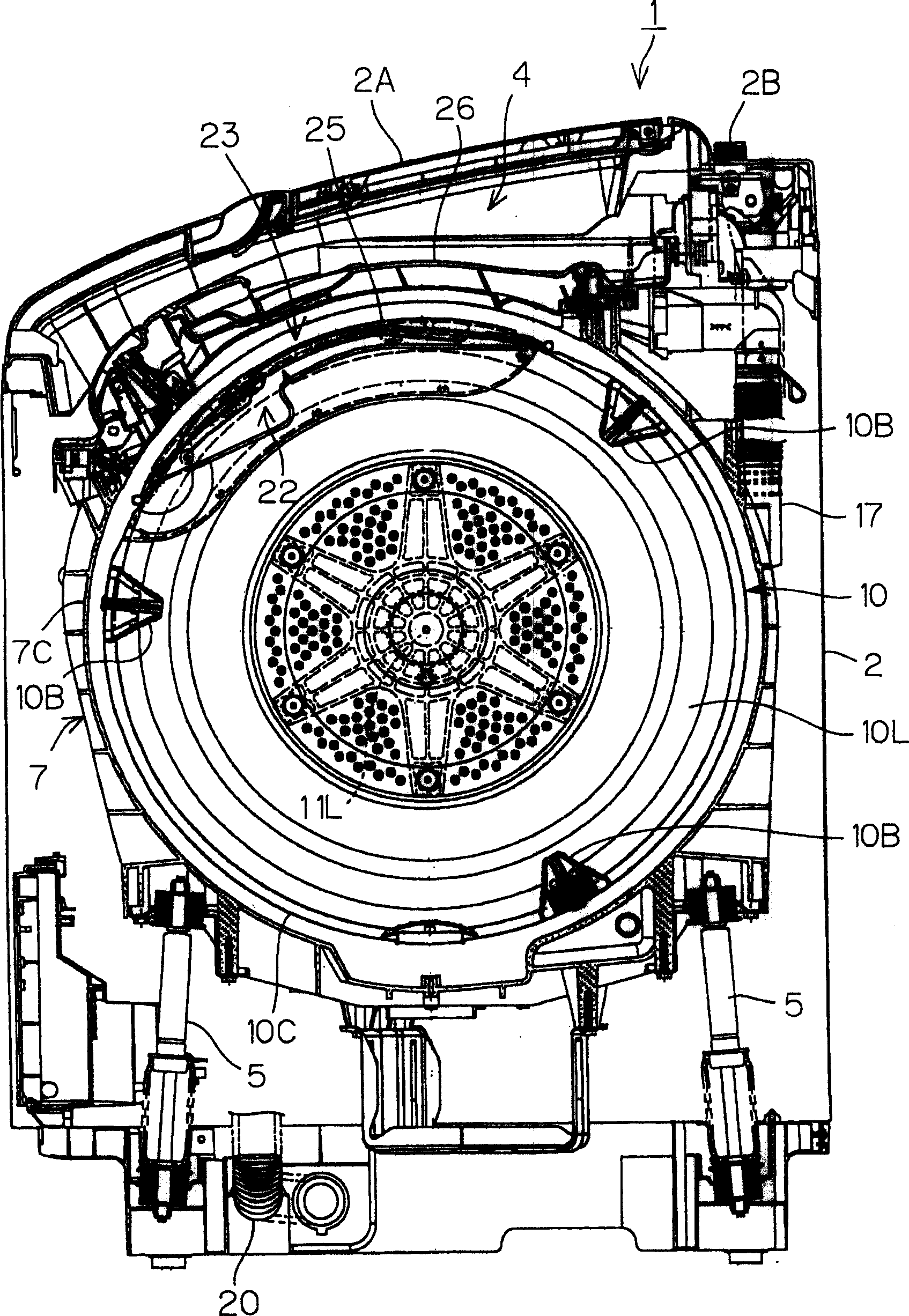

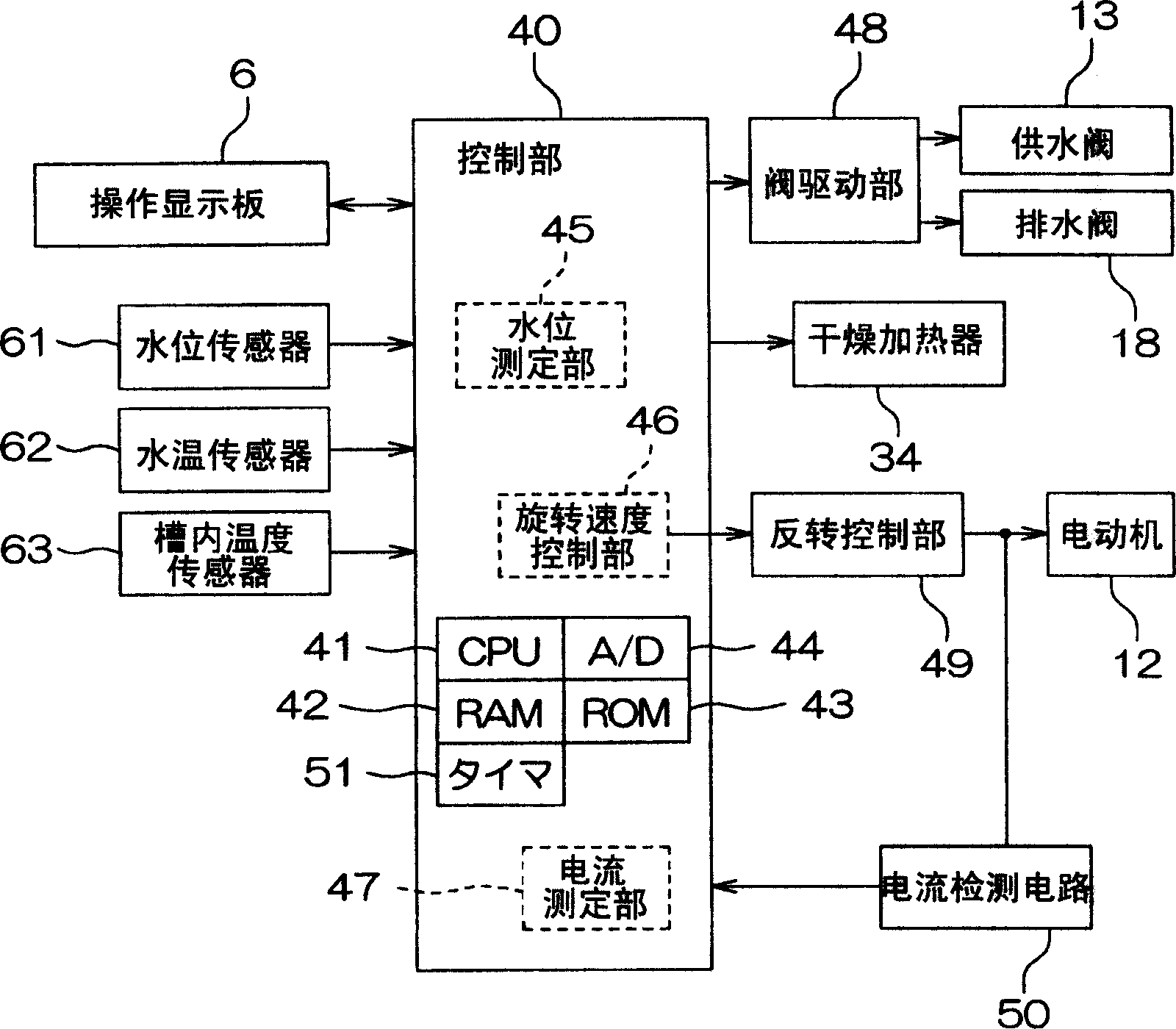

Drum washing machine

ActiveCN1667176AImprove cleanlinessSave electricityOther washing machinesControl devices for washing apparatusWater dischargeWarm water

This inventon provides a drum type washing machine for improving washing power with less electric power. After a washing process (step S2) is ended and water inside an outer tub is discharged (step S3) and before a spin-drying process (step S5) is started, by rotating a drum while supplying warm air into the outer tub by a drying unit, a warm air washing process is executed (step S4). In the warm air washing process, water contained in laundry after water discharge is warmed by the warm air supplied from the drying unit into the outer tub. Then, since the laundry containing the warmed water is rubbed with other laundry and the inner surface of the drum and hit to the inner surface of the drum accompanying the rotation of the drum, washing by the warm water is achieved. A relatively small amount of the water contained in the laundry after draining is warmed in a short time and washing (warm water washing) is performed.

Owner:HAIER GRP CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com