Dry steam cabinet furnace

A dry steam and steaming cabinet technology, applied in the field of kitchen utensils, can solve the problems of affecting the original taste of food, long heating time, bad taste of food, etc., and achieve the effect of rational use of space, uniform steam, and improvement of space utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

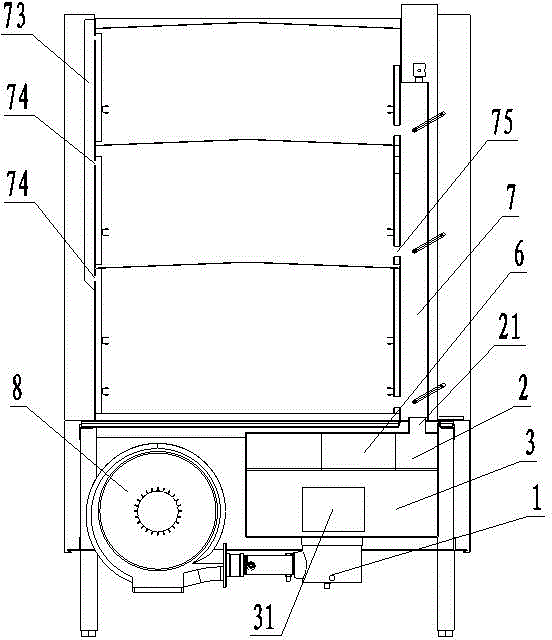

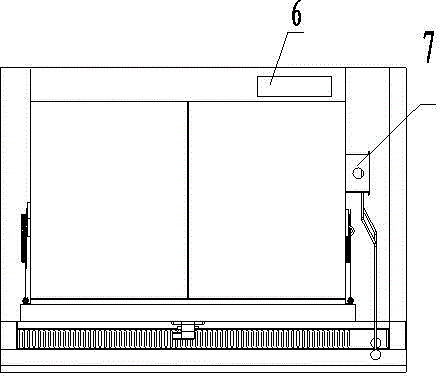

[0038] Example 1, such as Figure 3-8As shown, the present invention is improved on the basis of the existing steaming cabinet furnace, which is the same as the existing steaming cabinet furnace, consisting of a steaming cabinet above and a furnace body below, specifically it also includes a burner 1 , water tank 2, furnace 3, exhaust flue 6, steam cabinet 9, burner head 1 is positioned in the furnace 3, and the front end of furnace 3 has a fire viewing port 31, and the water tank is an airtight water tank, and the difference is that the flue exhaust 6 and the water tank The gas outlets of 2 are combined together, and the flue exhaust duct is changed from the back of the furnace 3 to the side. In the case of the same overall width, the width of the water tank and the furnace 3 can be increased, and the use of space can be effectively and rationally used to improve space utilization. The side edge of the upper surface of the water tank 2 has an opening 26 that can pass through...

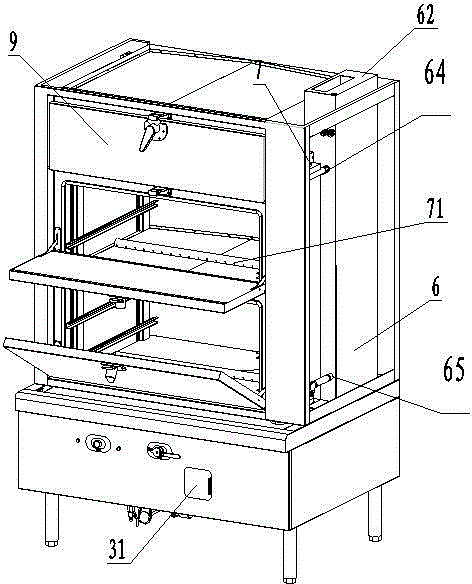

Embodiment 2

[0041] Example 2, such as Figure 9-11 As shown, a further improvement is made on the basis of Embodiment 1. A water inlet chamber 5 is designed below the furnace 3. The upper surface of the water inlet chamber 5 and the lower surface of the water tank 2 form a closed furnace 3, and the mixed gas is blown by the fan. 8 drives into the burner head 1 to burn, the outlet pipe 65 of the flue passage water chamber is connected with the water inlet chamber 5, and the water inlet chamber 5 is replenished by the water outlet pipe 65, and there is a drain valve 51 under the water inlet chamber 5, which can be used for cleaning Or drain water when changing water. A heat absorbing pipe 4 is designed in the furnace 3, and the two ends of the heat absorbing pipe 4 are respectively connected with the water inlet chamber 5 and the water tank 2, and the side wall of the furnace 3 has a water replenishment channel 32 connecting the water tank 2 and the water inlet chamber 5, and the water repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com