Unequal-height variable-speed air distribution particle heat carrier heating furnace for circulating fluidized beds

A circulating fluidized bed and heating furnace technology, which is applied to fluidized bed furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of high energy consumption, low combustion share in the dense phase area, and difficult control, and achieve energy consumption Low, easily controlled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

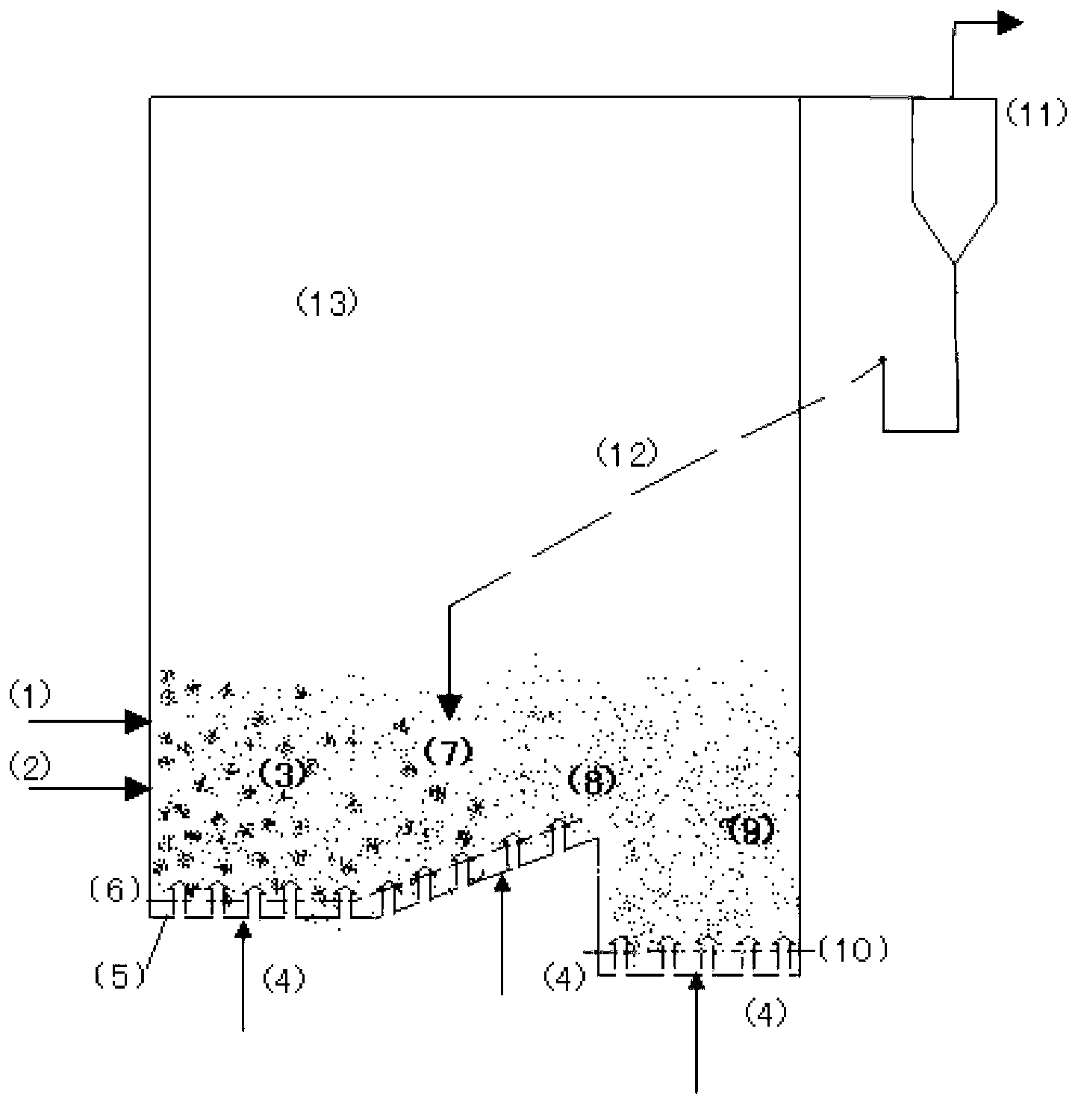

[0020] Such as figure 1 As shown: this air distribution structure divides the fluidized bed dense phase area into three functional areas, according to the flow direction of the particle heat carrier: first, the fuel 1 and the particle heat carrier 2 to be heated are sent to a constant-height, high-speed area 3, where they are burned And the fluidizing air 4 is supplied from the bed bottom hood 5, the hood holes are at the same elevation 6, and the superficial gas velocity is 0.7-1.2m / s, which is suitable for the combustion and good fluidization of large particle fuel; It is a zone of unequal height and low velocity 7. Along the direction of material flow, the elevation of the air supply point rises by 3-10°8, and the superficial air velocity is 0.15-0.3m / s. Many large particles will be brought into this area. In the first area, it is the inclined air distribution that makes the large particles flow back to the high-speed area, forming a circulation of large particles without s...

Embodiment 2

[0022] The third zone and the first and second zones in the first embodiment are turned and arranged in the opposite direction, and the whole bed is U-shaped. This structure avoids the problem of a long bed shape in the first embodiment, and the other parameters are the same as in the first embodiment.

[0023] For example, the furnace type of the present invention can be used to incinerate and dry sludge, and the heated particle heat carrier is used for drying wet sludge. Sludge has the characteristics of dispersed particle size, more fine particles, and high volatile content of combustible base. It is very important to ensure a high combustion share in the dense phase zone. This type of furnace can ensure good fluidization of coarse particle sludge and ensure that fine materials stay in the dense phase area for a long time, and the combustion share in the dense phase area is very high.

[0024] Another example is that the furnace type of the present invention can be used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com