Dual-heat exchange structure and heat utilization product thereof

A heat exchange structure, dual technology, applied in the direction of application, household heating, heating methods, etc., can solve the problems of inability to produce hot water, energy consumption, loss, etc., and achieve the effect of increasing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

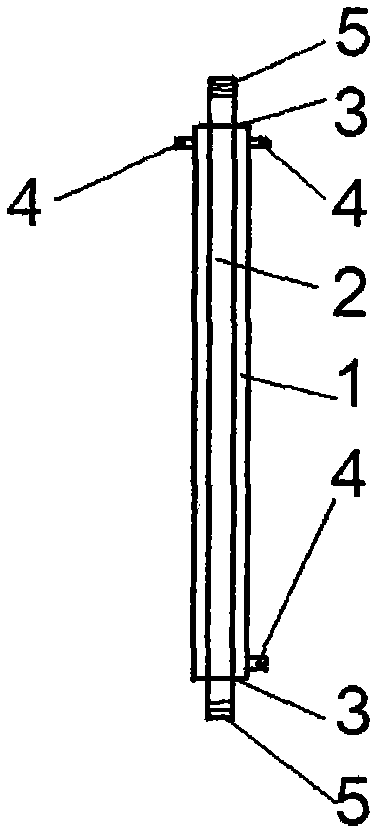

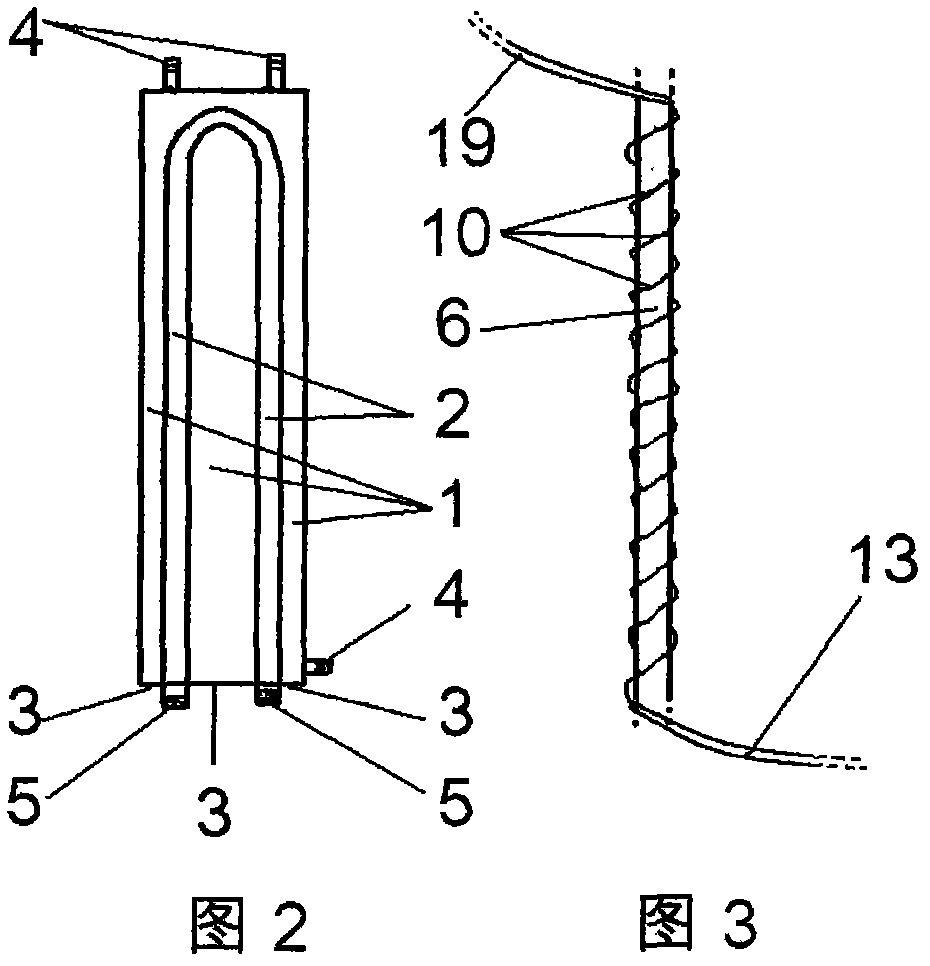

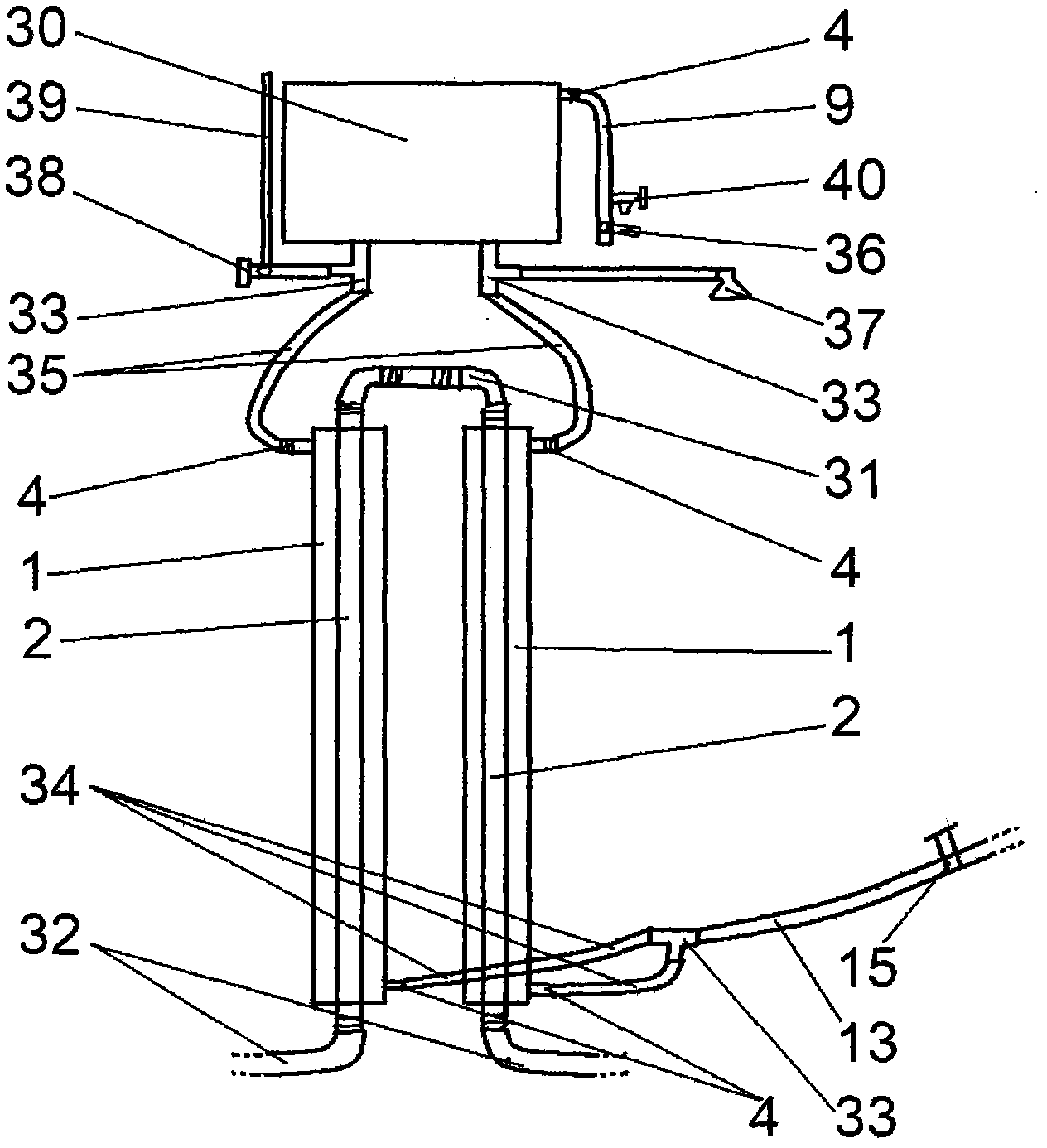

[0031] Example 1: Hot water heat pipe water heater

[0032] Figure 4 The top is a hot water tank (30), and the bottom is a double heat exchange structure of two large tube casing small tubes. The upper ends of the two small pipes (2) of this structure are threaded, so available plumbing fittings (31) (with two elbows and a pair of wires here) can be sealed and connected without water leakage, so that the two small pipes (2) Form an inverted U-shaped tube. The lower ends of the two small pipes (2) also have threads, so water heating pipes can also be used to communicate with existing heat pipes or heating pipes (32) in the room, so that the hot water in the heat pipes or heating pipes (32) can flow through in the inverted U-shaped pipe- --Flow in from one lower end of the two small tubes (2) and flow out from the other lower end.

[0033] Figure 4 Two pairs of wires (4) (one each at the lower ends of the two large pipes (1)) at the lower ends of the two large pipes (1) in...

Embodiment 2

[0048] Example 2: Spiral Hose Water Heater

[0049] Such as Figure 5 , use a single hose (10) to be wound on the heat pipe (6) (such as an indoor heating pipe) in turn, and each turn of the hose is next to each other, but does not overlap each other, forming a shape such as image 3 The solenoid shown. Its water inlet end is connected with water inlet pipe (13), water source switch (15), electric switch (14), flow meter (25) successively. The water outlet is communicated with the water outlet (17), the water outlet pipe (19), the hot water tank (30) or the water place. Probe (18) sealing wears in the water inlet and outlet (17), and the control wire (21) that connects probe (18) is connected with temperature controller (16) and electric switch (14).

[0050] Above structure is exactly full-automatic hose winding heat pipe water heater or helical hose water heater, and its working principle is as follows: flow into cold water from water inlet pipe (13), be full of the solen...

Embodiment 3

[0058] Example 3: Heat pipe water heater wrapped with metal film plate

[0059] The meaning of the metal membrane plate in this embodiment:

[0060] Metal film ----- refers to semi-soft metal foil, about 0.1mm thick, which can be easily bent by hand, but also has a certain hardness, which can withstand the weight and low pressure of tens of centimeters of water. Metal plate ----- refers to a relatively hard and not very hard metal sheet, with a thickness of about 0.3-1mm, which can withstand water pressure several meters deep, but is also relatively easy to process. The metal film plate refers to this kind of metal foil or a metal plate that is not very hard.

[0061] Wrapping the heat pipe with this metal film plate is easy to process, and it is easy to connect with the heat pipe in the following two ways without changing the metal structure of the original heat pipe:

[0062] 1) Water heater with metal film plate wrapped horizontal heat pipe: such as Image 6 , a kind of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com