Air floating type sheeting and crushing machine for powder coating

A powder coating and air flotation technology, which is used in material forming presses, presses, grain processing, etc., can solve the problems of small storage and transportation space, easy adhesion to conveyor belts, and low bagging costs. The broken particles are small and uniform, suitable for popularization and application, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

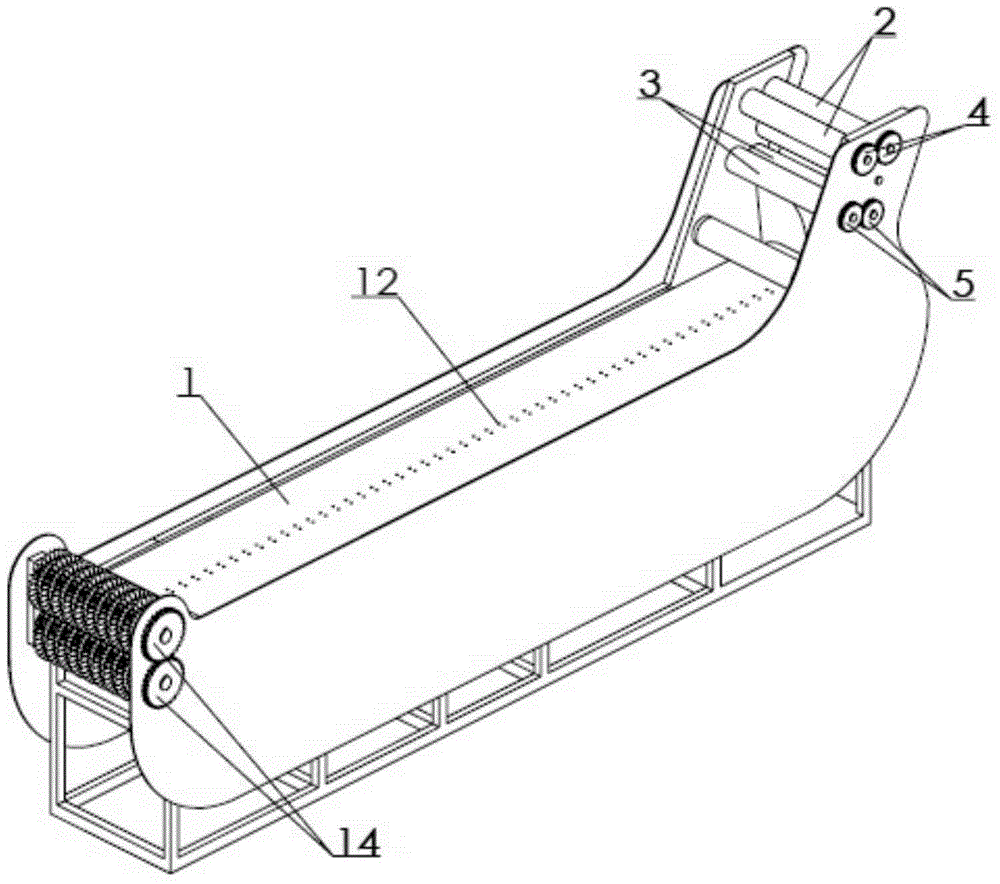

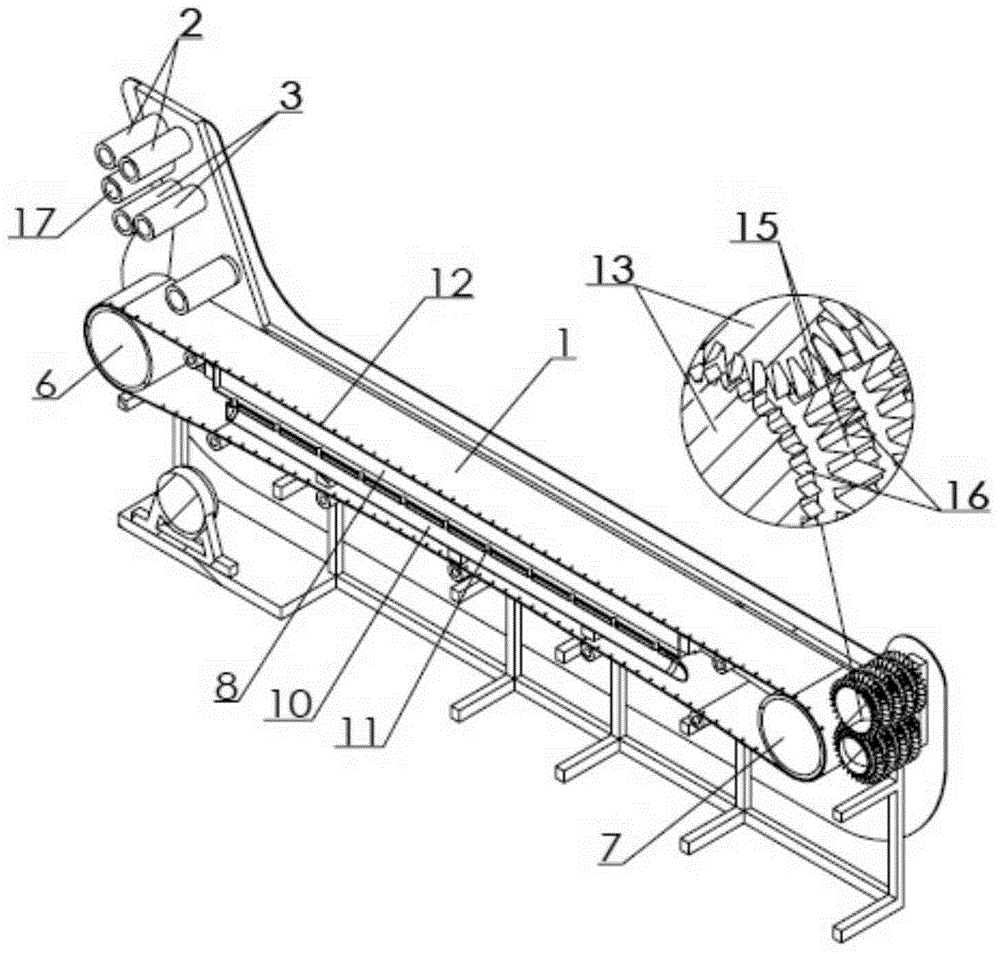

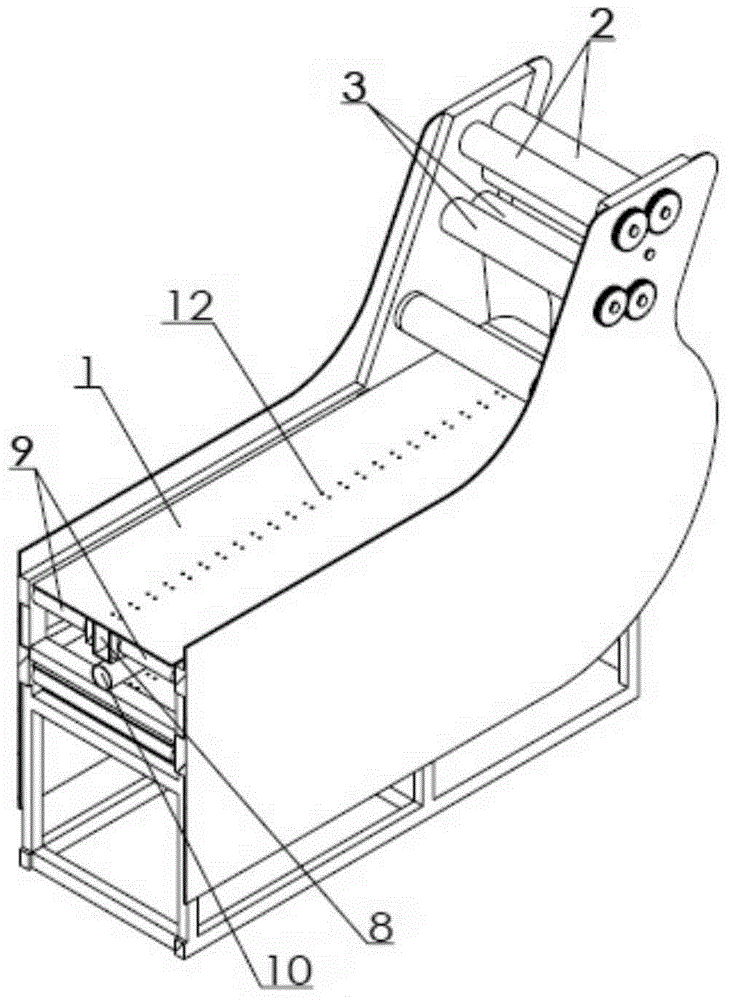

[0013] Examples of the present invention Figures 1 to 3 As shown, the powder coating air-floating tablet crusher includes a tablet pressing part, a conveyor belt 1 and a crushing part. 3. The axes of the primary pressure roller and the secondary pressure roller are perpendicular to the conveying direction of the conveyor belt; the primary pressure roller is a hollow round roller with two shafts parallel to the axis with a gap of 1.5 mm to 2.5 mm connected to the frame The shaft at one end of the primary pressure roller rotates at a constant speed through the first synchronous gear 4; the secondary pressure roller is a hollow circular roller with two shafts parallel to the axis with a gap of 1 mm to 1.5 mm connected to the frame. The shaft at one end of the secondary pressure roller rotates at a constant speed through the second synchronous gear 5, and the molten mixture is pressed into a sheet of 1mm to 1.5mm by the primary and secondary pressure rollers; The moving drum 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com