Waste gas treatment device used in kitchen waste biochemical treatment equipment

A waste gas treatment device and biochemical treatment technology, which is applied in the direction of combined devices, gas treatment, and the use of liquid separation agents, can solve the problems of affecting the surrounding environment, unfavorable life of surrounding residents, and high energy loss, and achieve the effect of eliminating visual pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

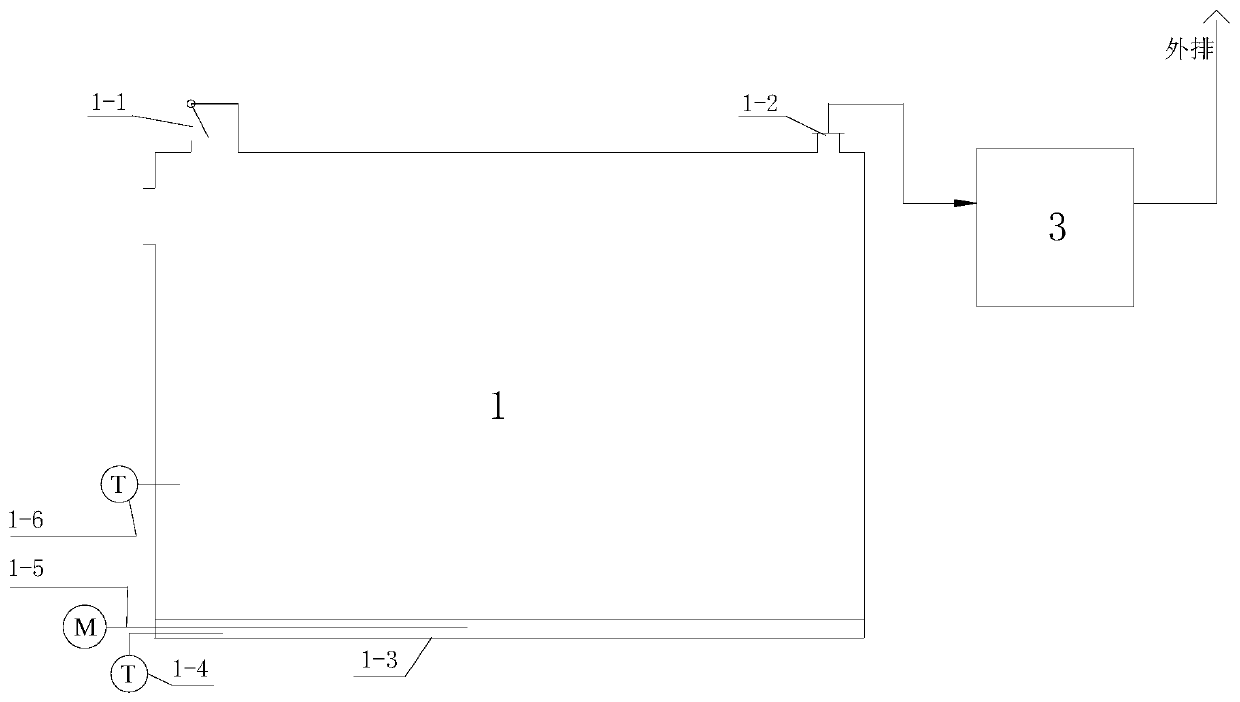

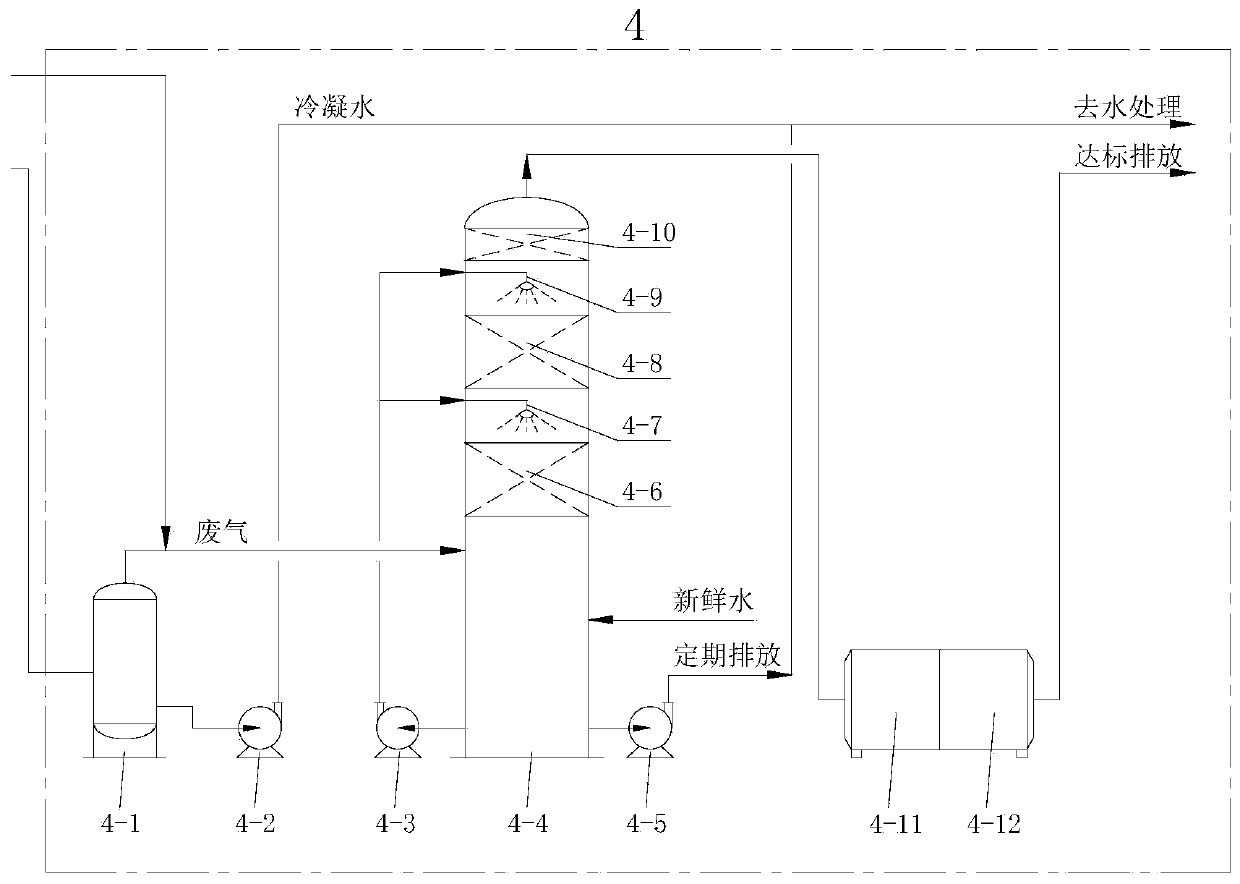

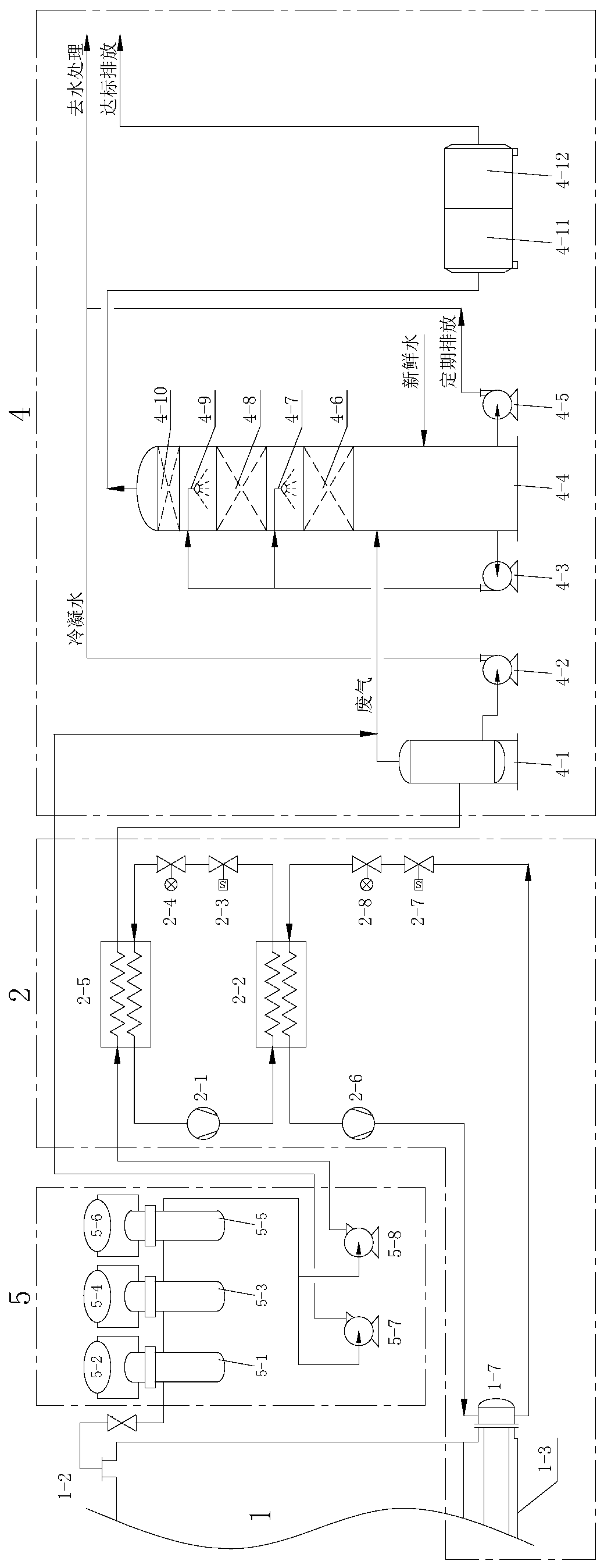

[0033] Such as figure 2 , image 3 As shown, it is an exhaust gas treatment device used in a food waste biochemical treatment equipment in Example 1 of the present invention, including a dust removal unit 5, a waste heat recovery unit 2 and a deodorization unit 4, a dust removal unit 5, a waste heat recovery unit 2 and a deodorization unit. The odor unit 4 is connected in turn through the gas delivery pipeline. The waste gas generated by the fermentation chamber 1 is first introduced into the dust removal unit 5 to filter impurities, then into the waste heat recovery unit 2 to recover waste heat, and then into the deodorization unit 4 to remove odor, and then discharged to the outside.

[0034] The exhaust gas treatment device in this embodiment adopts the process of "dust removal + waste heat recovery + deodorization" to treat the waste gas of the kitchen waste biochemical equipment, which can meet the requirements of emission standards, and at the same time, the waste heat ...

Embodiment 2

[0081] Such as Figure 4 As shown, it is the exhaust gas treatment device used in a kind of food waste biochemical treatment equipment in Example 2 of the present invention, and the difference from Example 1 is:

[0082] The secondary heat recovery unit of the waste heat recovery unit 2 also includes an economizer 2-11, a three-stage switch valve 2-9, and a three-stage expansion valve 2-10; the output port of the heater 1-7 of the fermentation chamber 1 is connected to two cooling refrigerant return path, the first refrigerant return path passes through the economizer 2-11, the secondary on-off valve 2-7, the secondary expansion valve 2-8, and the evaporative condenser 2-2 to return to the secondary compressor 2-6, The second refrigerant return path returns to the secondary compressor 2-6 through the three-stage on-off valve 2-9, the three-stage expansion valve 2-10, and the economizer 2-11.

[0083] The second refrigerant reflux path constitutes an air supplementary enthalpy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com