Sintering machine head flue gas white smoke removing process

A flue gas and white elimination technology, applied in the field of flue gas white removal system, can solve the problems of white smoke from flue gas and high energy consumption, and achieve the effects of reducing pollutants, low pollutant content in exhaust smoke, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

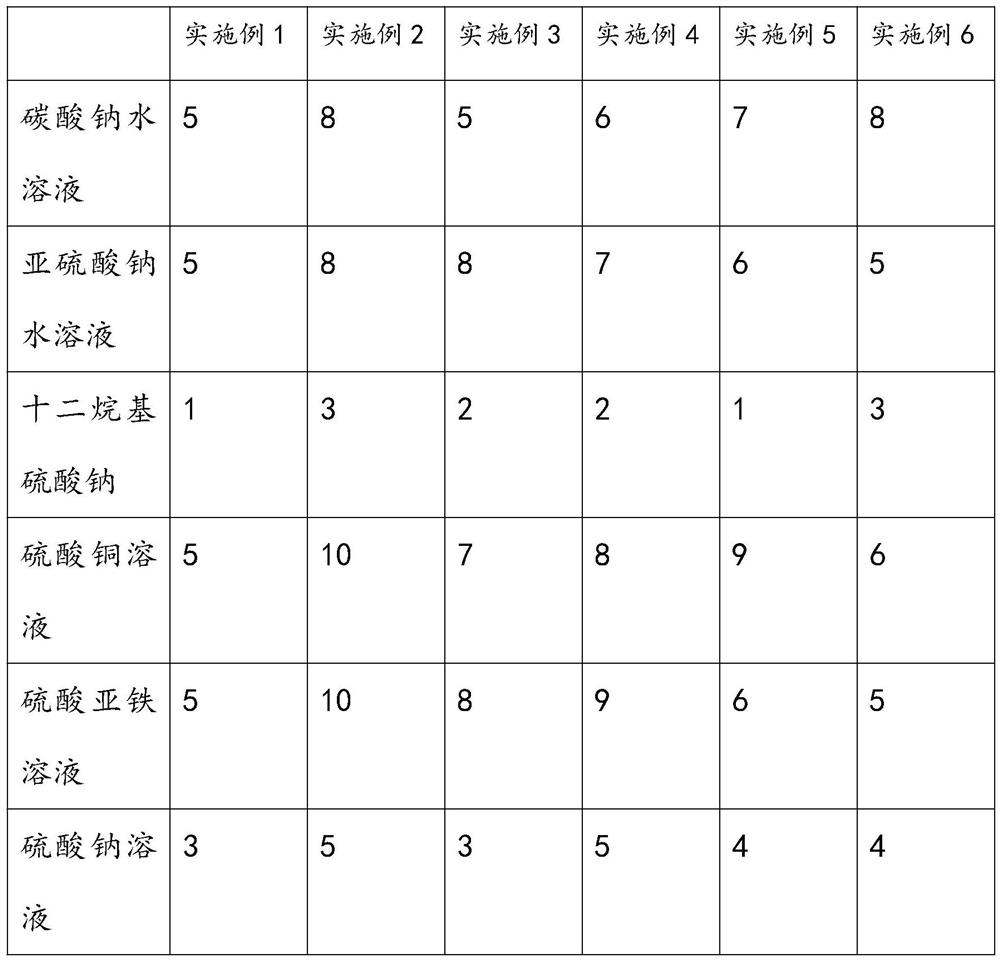

Examples

Embodiment 1

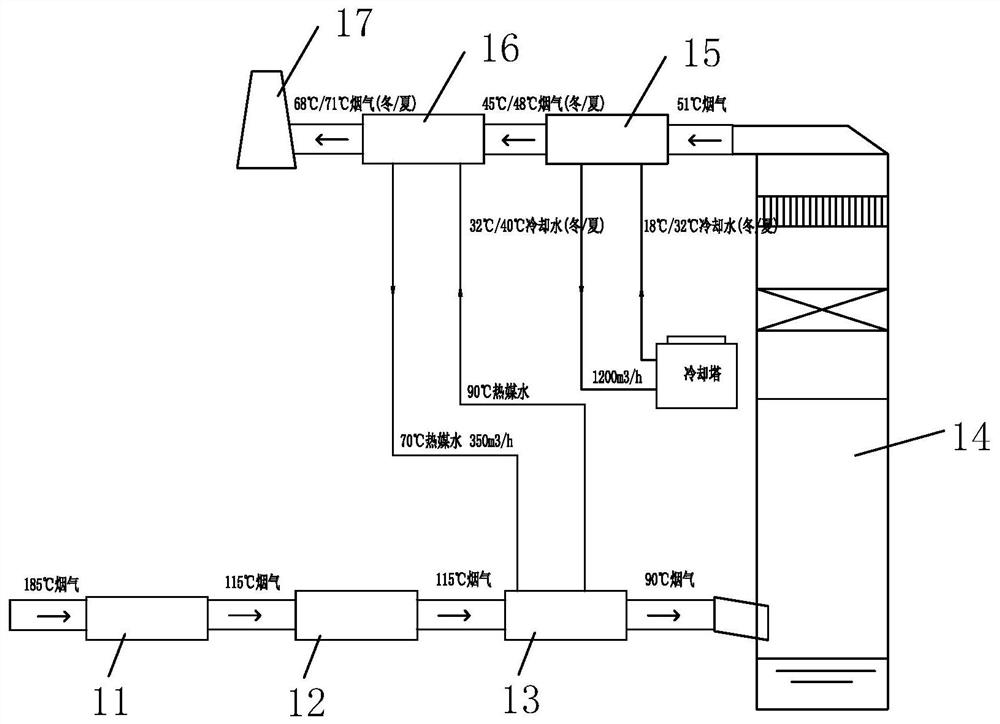

[0026] A sintering head flue gas whitening process, such as figure 1 As shown, it includes the primary cooling tower 11, the booster fan 12, the second cooling tower 13, the desulfurization tower 14, the flue gas condenser 15, the MGGH system 16, the chimney 17, and the flue gas connected to the flue gas condenser 15. The condensation tower 18 also includes a circulation system arranged between the MGGH system 16 and the second cooling tower 13 , and the circulation system communicates the second cooling tower 13 with the MGGH system 16 .

[0027] Such as figure 1 As shown, the primary cooling tower 11 adopts ND steel, and the second cooling tower 13 adopts fluoroplastics.

[0028] Such as figure 1 As shown, the circulation system is made of fluoroplastic.

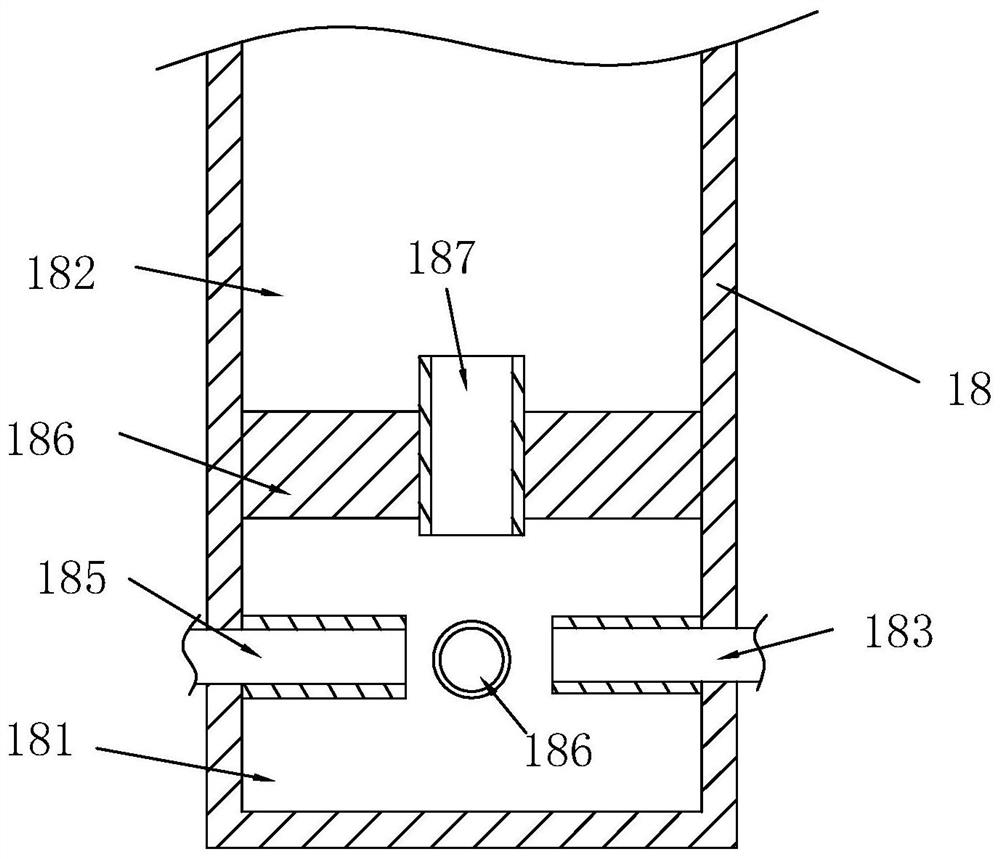

[0029] Such as figure 1 , 2 As shown, the desulfurization tower 18 includes a desulfurization and denitrification pipe 181 arranged at the bottom and a redox chamber 182 arranged at the top, and the desulfurization an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com