Smoke near-zero-emission system of coal-fired power plant

A near-zero emission, coal-fired power plant technology, applied in gas treatment, separation methods, lighting and heating equipment, etc., can solve problems such as flue gas pollutants, and achieve the goal of reducing flue gas pollution, improving quality of life, and simplifying installation processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

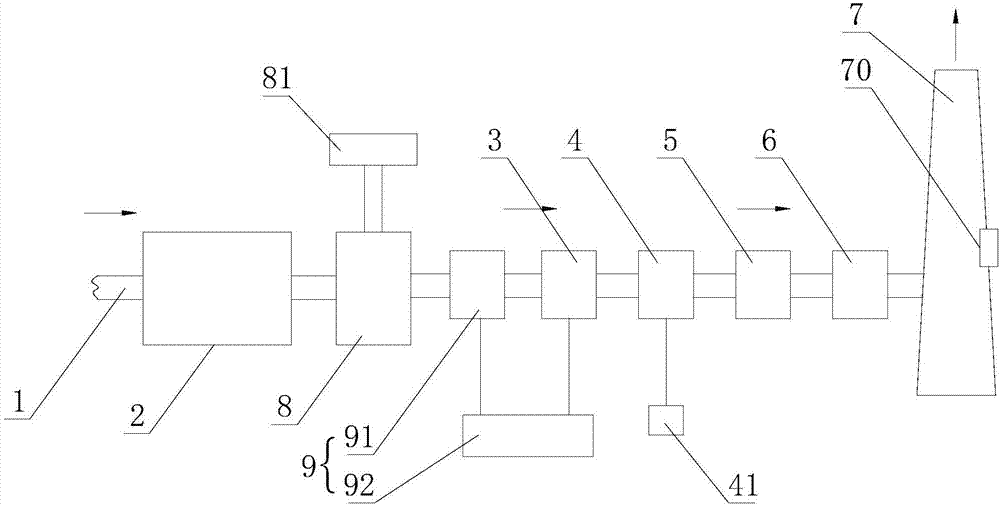

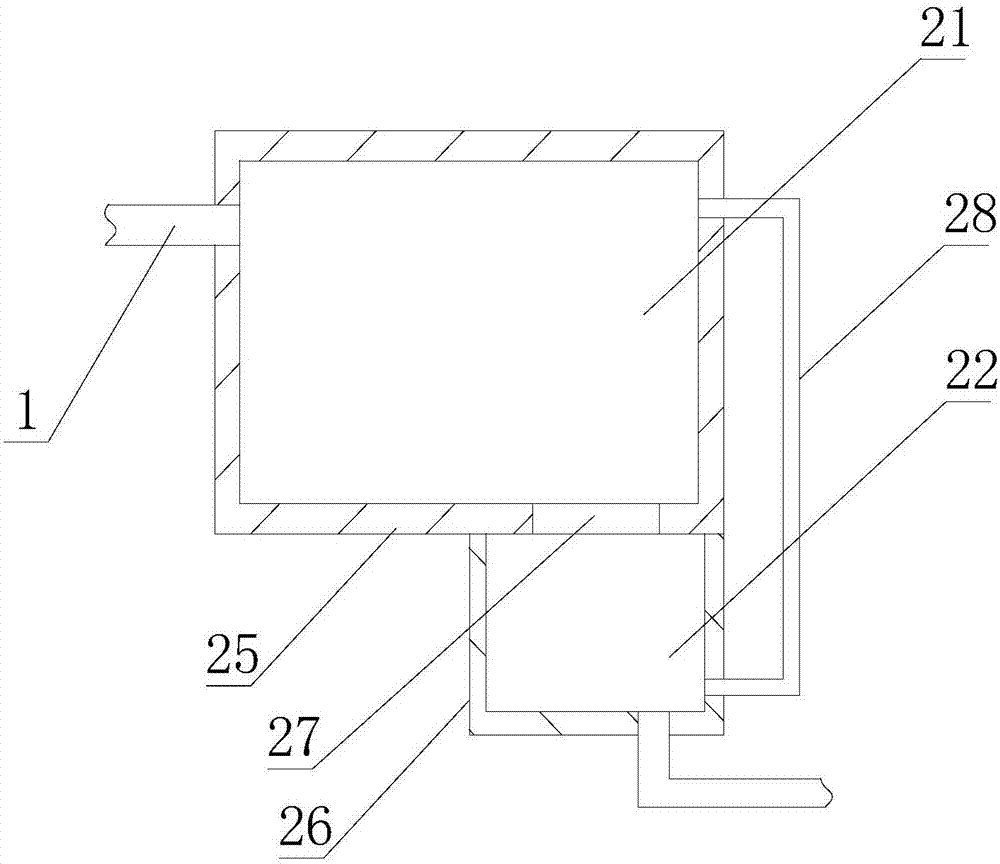

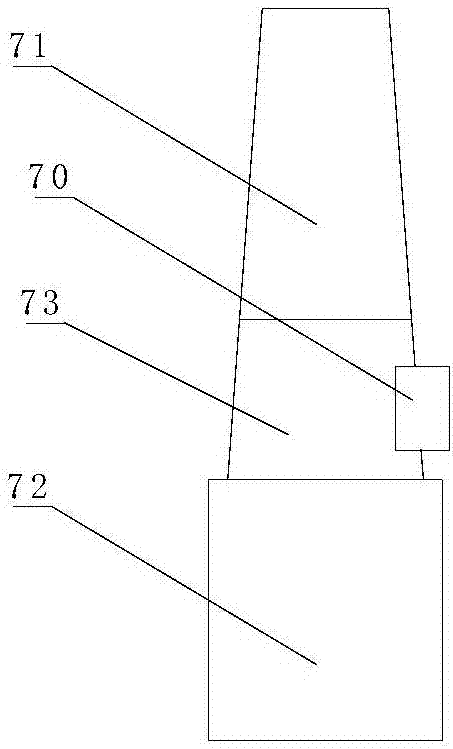

[0021] Such as figure 1 , figure 2 , image 3 As shown, a coal-fired power plant flue gas near-zero emission system includes a discharge pipe 1 for flue gas discharge, and the discharge pipe 1 is sequentially provided with a denitrification device 2 and an electrical discharge pipe 1 along the exhaust direction of the discharge pipe 1. Dust collector 3, wet desulfurization device 4, wet electrostatic precipitator 5, flue gas reheating device 6 and chimney 7; denitrification device 2 is provided with a first processing chamber 21 and a second processing chamber 22, and the first processing chamber 21 is equipped with There is a reducing agent, an oxidation catalyst with Hg is arranged in the second processing chamber 22, and a return pipe 28 is provided on the second processing chamber 22 and the first processing chamber 22; The pipe 1 is provided with a cooling device 8 for reducing the temperature of the flue gas, and the cooling device 8 is connected with a heat exchange ...

Embodiment 2

[0025] A coal-fired power plant flue gas near-zero emission system as described in Embodiment 1, this embodiment has the following differences: Figure 4 As shown, the discharge pipe 1 between the denitrification device 2 and the electrostatic precipitator 3 is provided with a base spraying device 10, and the base spraying device 10 is connected with a supply system 11, and the supply system 11 sprays into the flue gas used to adsorb SO in flue gas 3 base, can effectively remove SO in flue gas 3 , and through the system to realize the feeding treatment of the base spraying device, the continuous spraying of the base to the flue gas is realized.

[0026] When used, such as figure 1 As shown, the direction indicated by the arrow is the direction of flue gas discharge. The flue gas enters the denitrification device 2 through the discharge pipe 1, and the flue gas is sequentially processed by the first processing chamber 21 and the second processing chamber 22, and passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com