Compound heat pipe type GGH (Gas-Gas Heater) heat exchanger

A composite heat pipe and heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of air leakage, ash blocking, short life, etc., to eliminate visual pollution, improve lifting force, The effect of improving temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

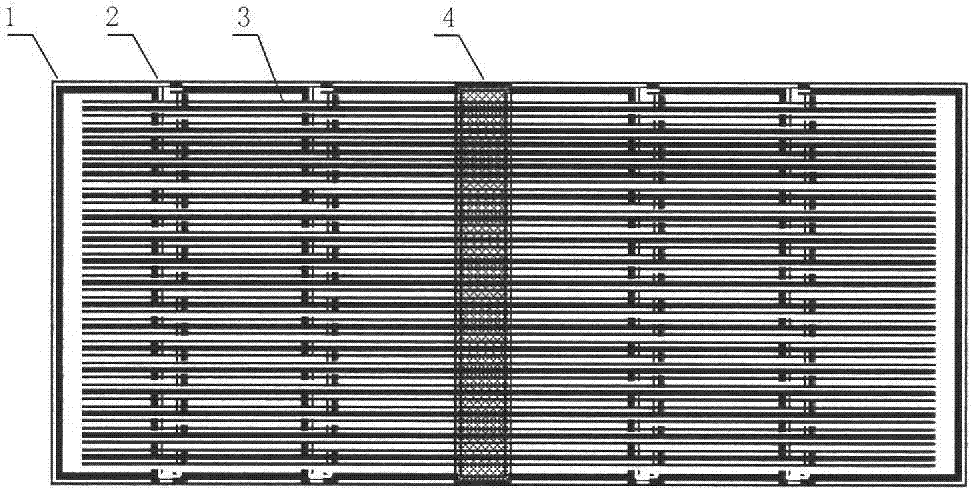

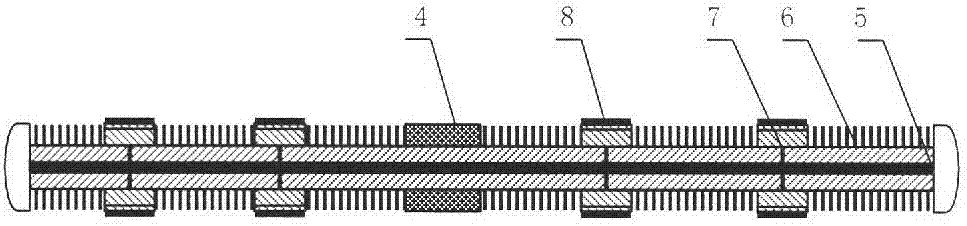

[0016] Reference attached figure 1 , attached figure 2 A composite heat pipe type GGH heat exchanger shown includes a box body 1, a heat pipe support tube plate 2, a composite heat pipe 3, a sandwich partition 4, a pure copper core tube 5, an enameled vertical fin structure carbon steel outer tube 6, The pipe sleeve 7 at the joint of the outer pipe, the shock-absorbing rubber sleeve 8 between the pipe sleeve and the support plate. During assembly and construction, according to the design process, the sandwich partition 4 and the corresponding support tube plate 2 are combined to form a box body 1, the heat pipe core tubes 5, 6 and 7 are combined to form a composite heat pipe 3, and finally the composite heat pipe 2 is assembled into the box body 1 Among them, when assembling the composite heat pipe type, shock-absorbing rubber sleeves 8 are installed in each support tube plate hole, and finally the interlayer partition 4 is filled with sealing material, thus a composite heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com