Constant volume chamber and oil atomizer spraying visual test system with same

A test system and constant volume bomb technology, which is applied in the direction of engine test, machine/structural component test, charging system, etc., can solve the problem of disturbing the profile of the oil beam in the later stage, and solve the problem of air leakage or poor sealing of the device, Avoid leakage phenomenon, light path construction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

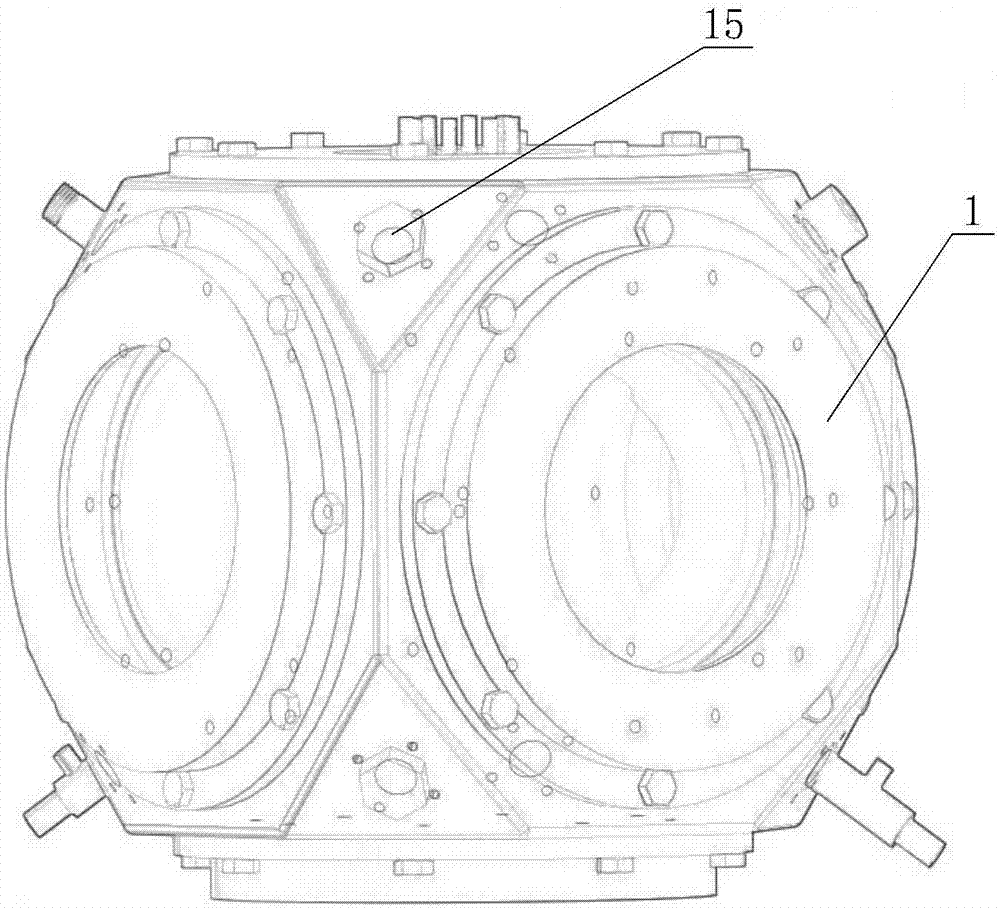

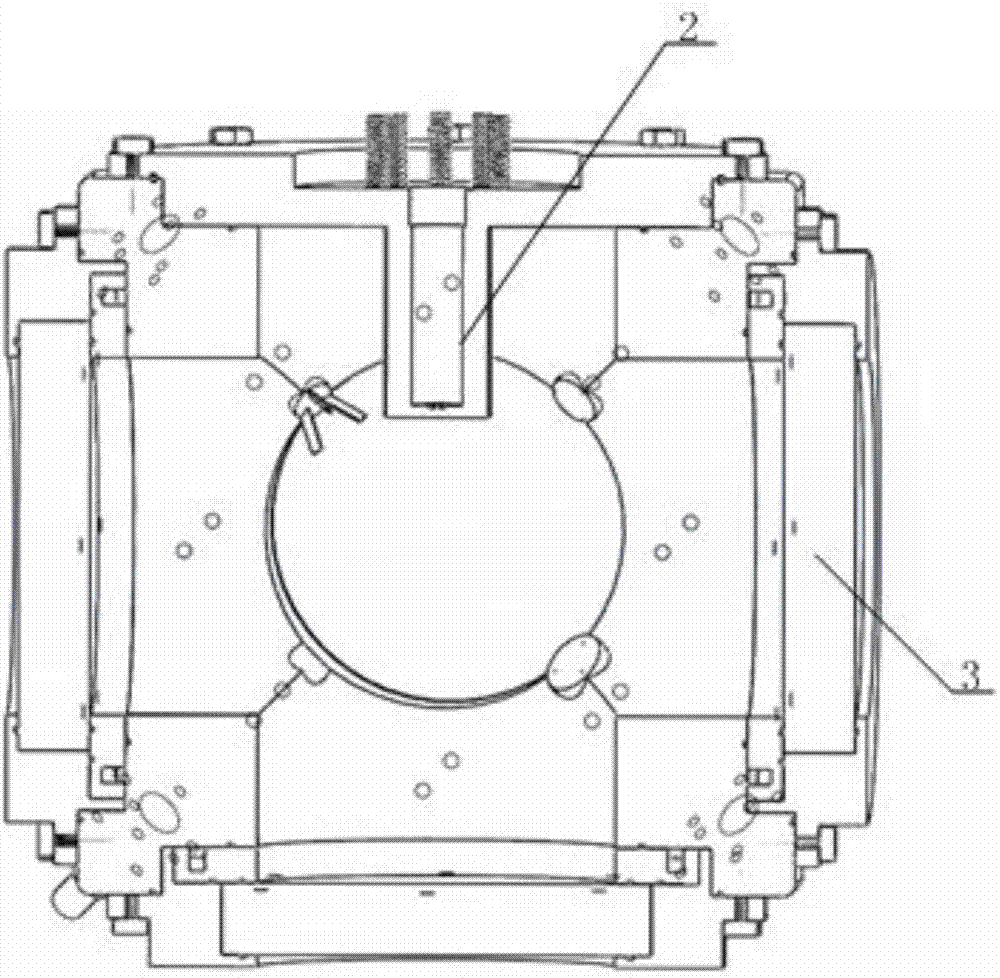

[0029] On the one hand, the present invention provides a constant volume bomb, such as Figure 1 to Figure 5 Shown, comprise constant volume projectile body 1, wherein:

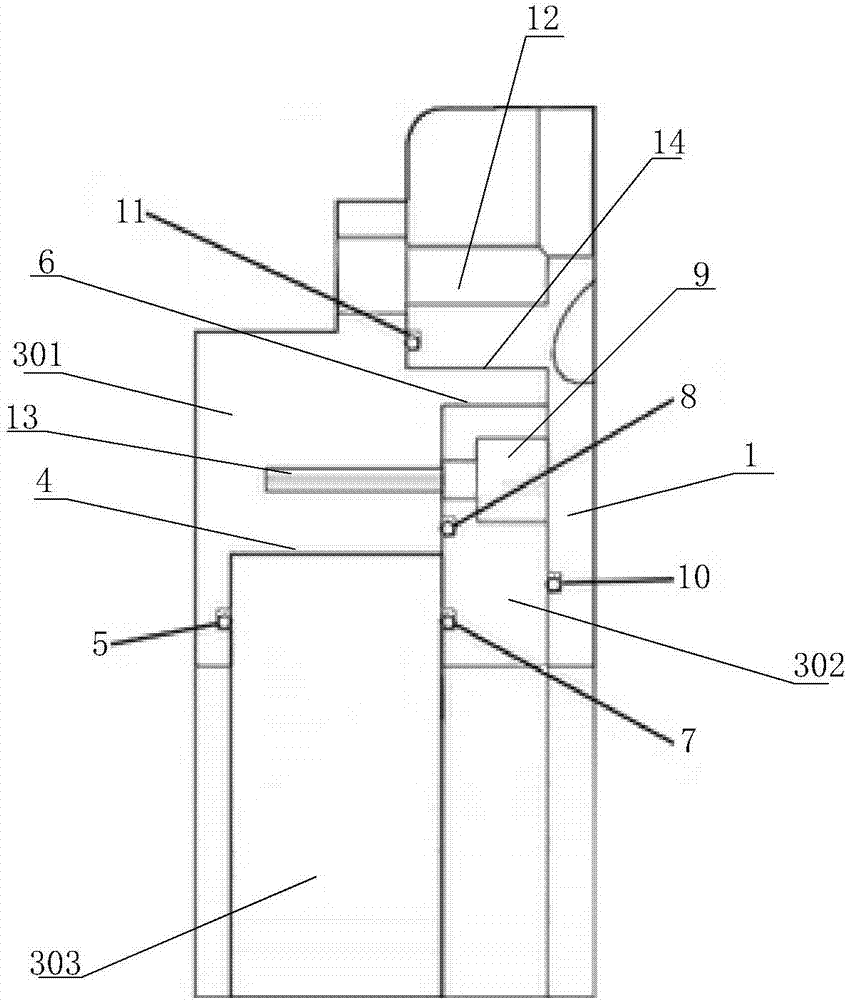

[0030] The constant volume bomb body 1 is a cube, and the constant volume bomb body 1 is provided with vertically intersecting through holes along three axial directions to form an internal cavity. The mouth of the through hole is provided with a fuel injector module 2 and a visualization window module 3 , the visualization window module 3 includes an outer end cover 301, an inner cover plate 302, and a quartz glass 303 between the outer end cover 301 and the inner cover plate 302;

[0031] Both the outer end cover 301 and the inner cover plate 302 are ring-shaped, and the inner middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com