Liquid phase intermediate medium heat exchanging type heat exchanger

A technology of heat exchange and heat exchanger, which is applied in the direction of feed water heater, preheating, waste heat treatment, etc. It can solve the problems of limited space and layout range, and achieve the effect of increasing flexibility, reasonable heat exchange, and eliminating air leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

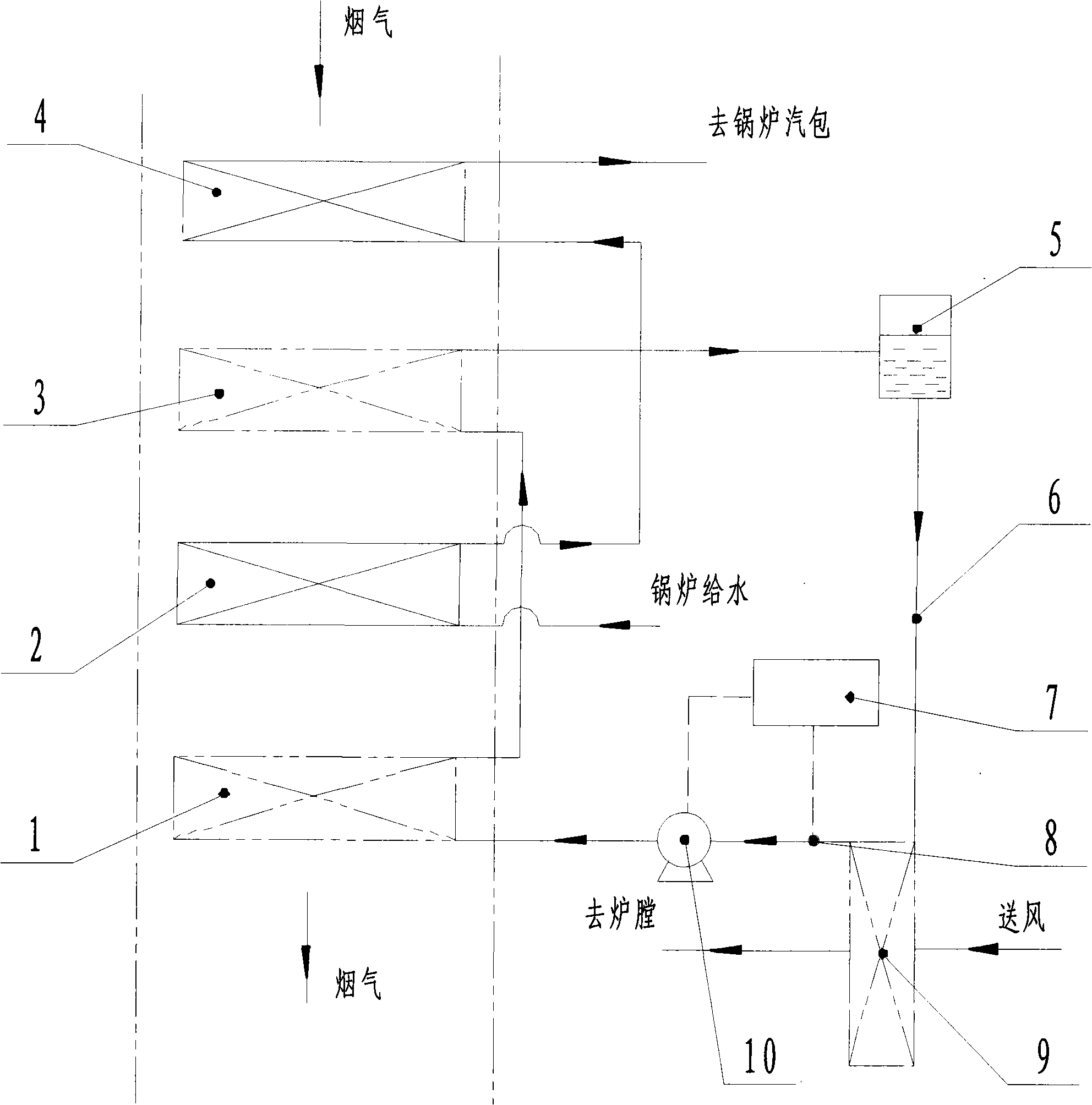

[0012] Such as figure 1 As shown, the present invention includes a circulation pipeline 6, a medium circulation pump 10 with a frequency converter arranged on the circulation pipeline 6, a medium heating section is also arranged on the circulation pipeline 6 located in the flue gas channel, and a medium heating section is arranged on the circulation pipeline 6 at the same time A medium heat releasing section 9 is also arranged on the road 6 .

[0013] The medium heating section set on the circulation pipeline 6 in the flue gas channel is the medium heating section 3 and the medium heating section 1 successively connected in series on the circulation pipeline 6, and the medium heating section 3 and the medium heating section 1 1 is provided with an economizer low-temperature section 2 connected to the heating boiler feed water pipe, and in front of the medium heating II section 3 is also provided with an economizer high-temperature section 4 connected with the economizer low-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com