A process and device for nitrogen-enriched bog liquefaction

A nitrogen-enriched and technological technology, applied in liquefaction, refrigeration and liquefaction, solidification and other directions, can solve the problems of combustible gas combustion, greenhouse effect, affecting the stability of natural gas-refrigerant heat exchange system, and achieve reasonable heat exchange with little impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention proposes a nitrogen-enriched BOG liquefaction process.

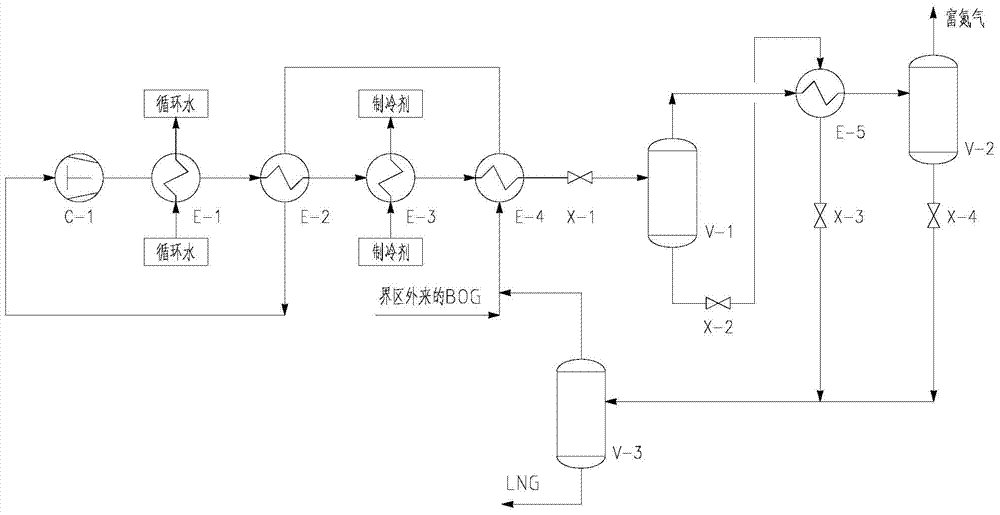

[0027] Refer to attached figure 1 , technique of the present invention realizes by following technical scheme:

[0028] The low-temperature and atmospheric-pressure BOG rich in nitrogen from the LNG storage tank or LNG loading and unloading system first enters the BOG low-temperature heat exchanger E-4 to recover cold energy, and is exchanged with the high-pressure BOG pressurized by the BOG compressor C-1. Reheat to -20~-45°C (eg -35°C), and then optionally enter the BOG normal temperature heat exchanger E-2 to reheat to 15~25°C (eg 20°C);

[0029] The reheated BOG is pressurized to 10-25MPaA (such as 20MPaA) by BOG compressor C-1, then cooled to 30-45°C, such as about 40-45°C, in the compressor aftercooler E-1, and then passed through Optional BOG normal temperature heat exchanger E-2, refrigerator E-3 and BOG low temperature heat exchanger E-4 are pre-cooled to about -85~-150°C (preferably -85~-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com