Anhydration system for sludge by using remaining heat of flue gas from steam power plant

A technology of sludge drying and flue gas waste heat, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, etc., which can solve the problems of large energy consumption, high cost of sludge drying, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

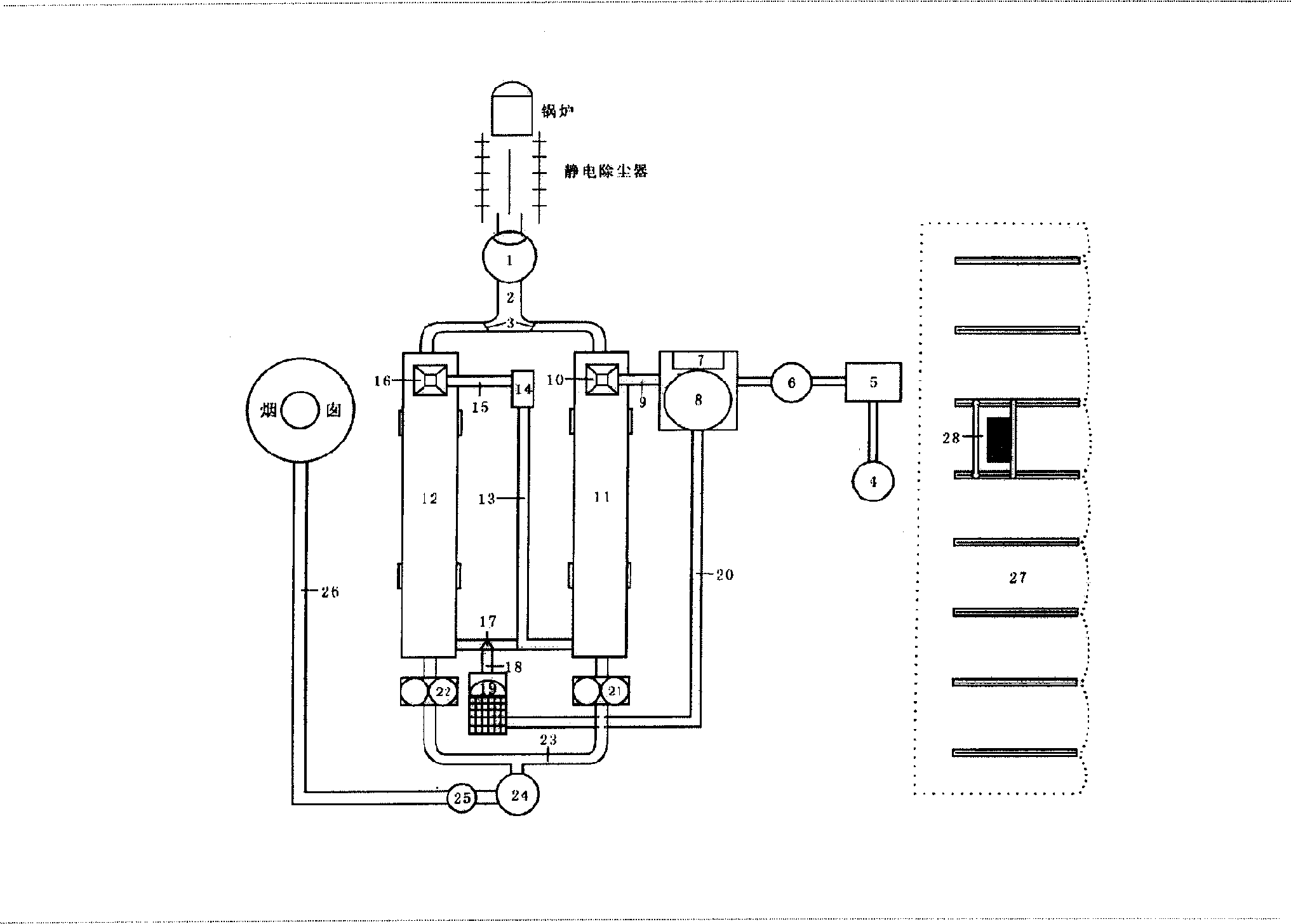

[0010] The sludge drying system using the waste heat of flue gas in thermal power plants has a heating system, a sludge pretreatment system, a feeding system, a sludge drying and granulation system, and a dust removal and gas removal system. The heating system has a first induced draft fan 1, which sends the flue gas that passes through the electrostatic precipitator at 100-150°C through the flue 2, and the flue gas volume is controlled by the damper 3, and is sent to the first rotary drying kiln 11 and the second rotary drying kiln respectively. Drying kiln 12; The sludge pretreatment system has a trough-type sludge dump 27, and a mixer 28 is provided on the trough-type sludge dump; the feeding system has a mobile pressure pump 4, which is sequentially connected with the homogenizer machine 5, fixed pressure pump 6, extruder 7, powder coating machine 8, the first bucket belt elevator 9 and the first feed port 10 are connected; the sludge drying and granulation system has the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com