Patents

Literature

54results about How to "Guaranteed against damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499AGood car frameFunction increaseLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Technology for dyeing and finishing real silk/corn fabric

ActiveCN101736616AGuaranteed high color fastnessGuaranteed strongBiochemical fibre treatmentDyeing processDisperse dyeEngineering

The invention relates to technology for dyeing and finishing real silk / corn fabric. In order to solve the technical problem, the invention provides the provided technology for dyeing and finishing which can effectively improve the dye uptake of the corn fiber and the color fastness of the fabric, and maximize the strength of the corn fiber and the fabric. The technical scheme of invention is that: the technology for dyeing and finishing the real silk / corn fabric comprises the processes of bleaching, dyeing and heat shaping in turn. The technology for dyeing and finishing the real silk / corn fabric is characterized in that: 1) the bleaching (refining) process comprises steps of pretreating, enzyme scouring, and second scouring; 2) the dyeing process comprises steps of dyeing, reduction clearing, and water washing, wherein staining solution comprises a disperse dye and a reactive dye, or the dyeing process comprises steps of disperse dye dyeing, reduction clearing, water washing, reactive dye dyeing, soap boiling and water washing; and 3) the heat shaping process comprises steps of padding soft solution and heat shaping, wherein the enzyme scouring in the bleaching process adopts neutral enzyme scouring or alkaline enzyme scouring; the staining solution of the disperse dye comprises 0 to 2 g / L of darkening agent DL-6; and the fabric dyed by the disperse dye needs to be washed by adopting acid reduction technology.

Owner:HIGH FASHION CHINA CO LTD

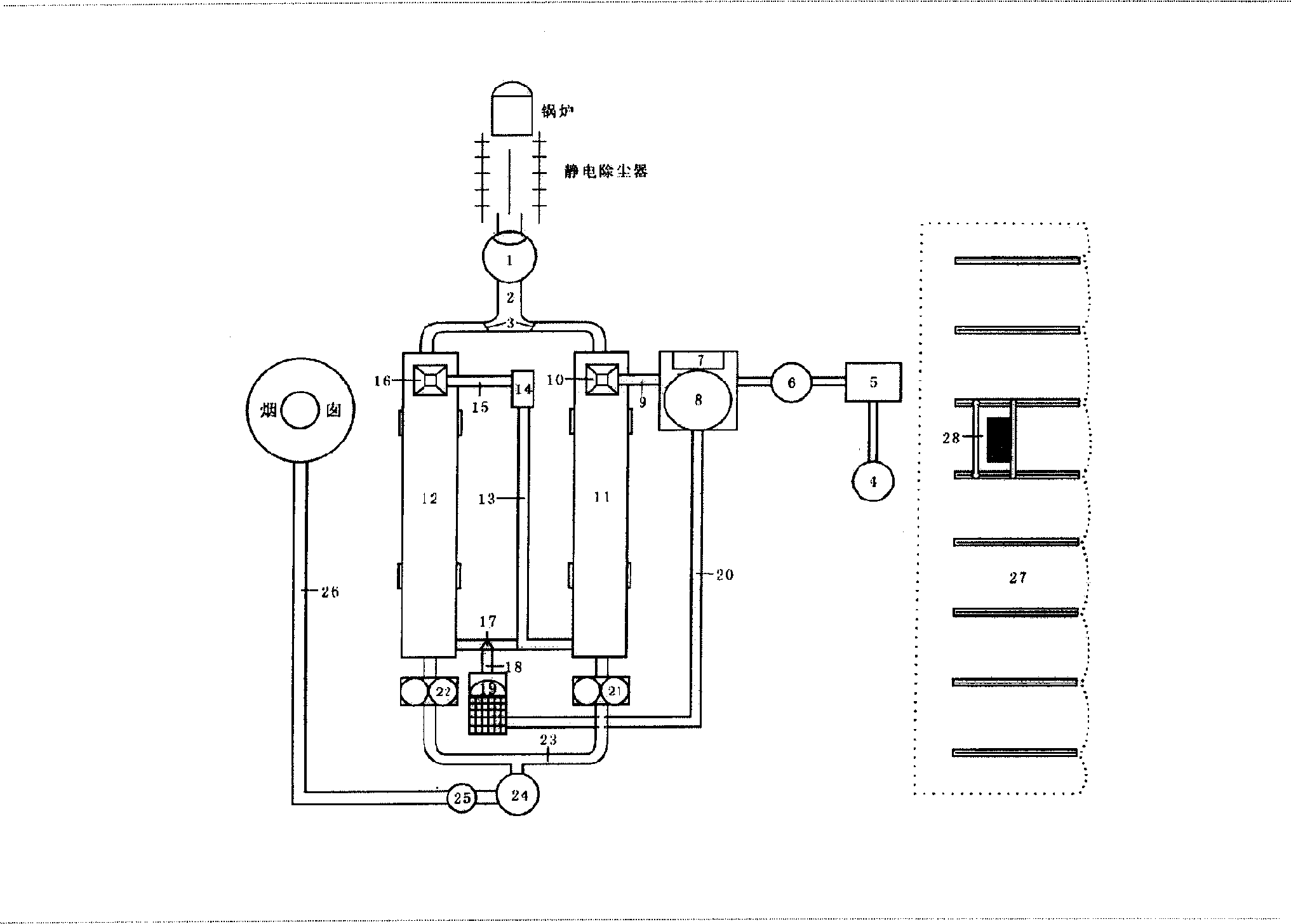

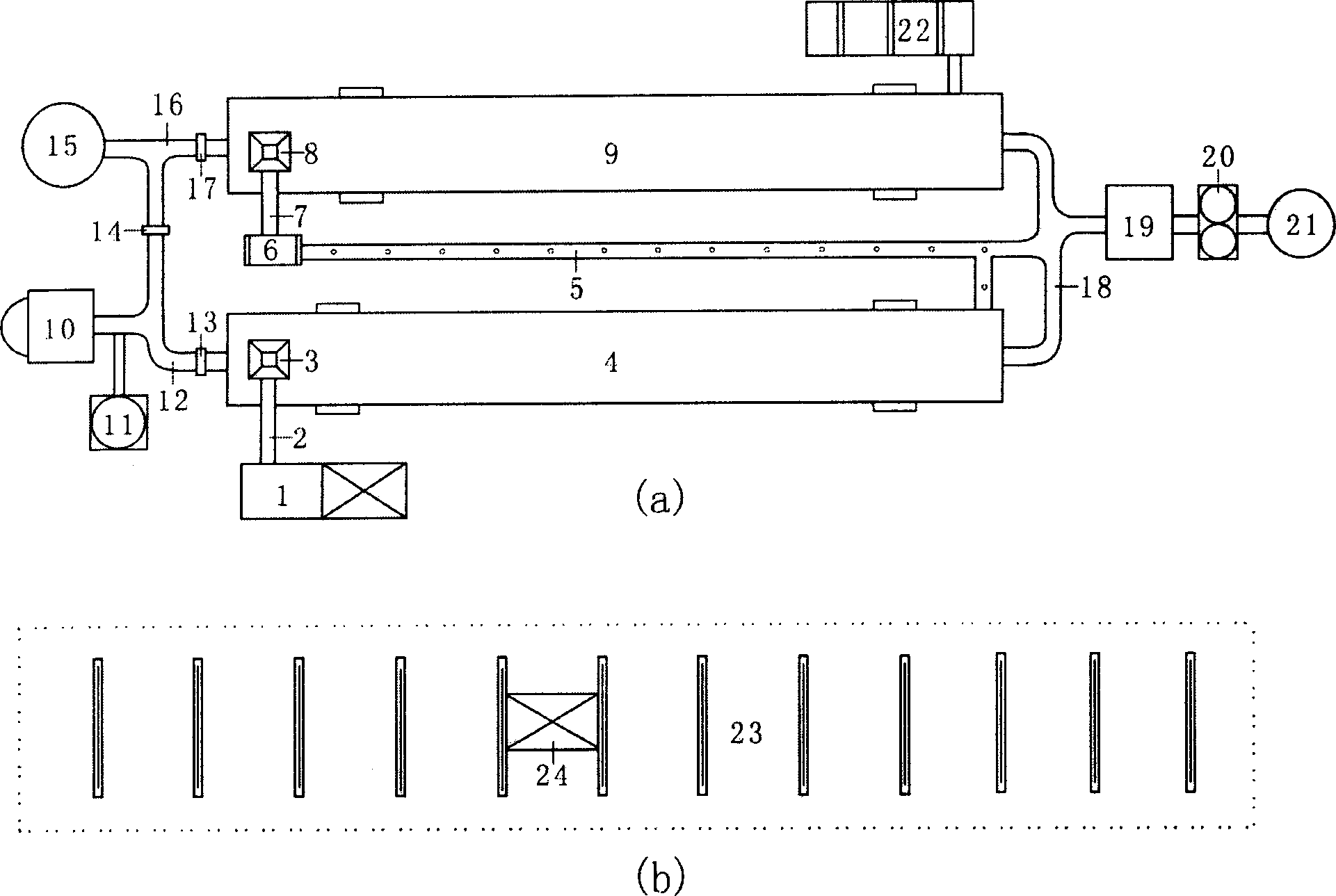

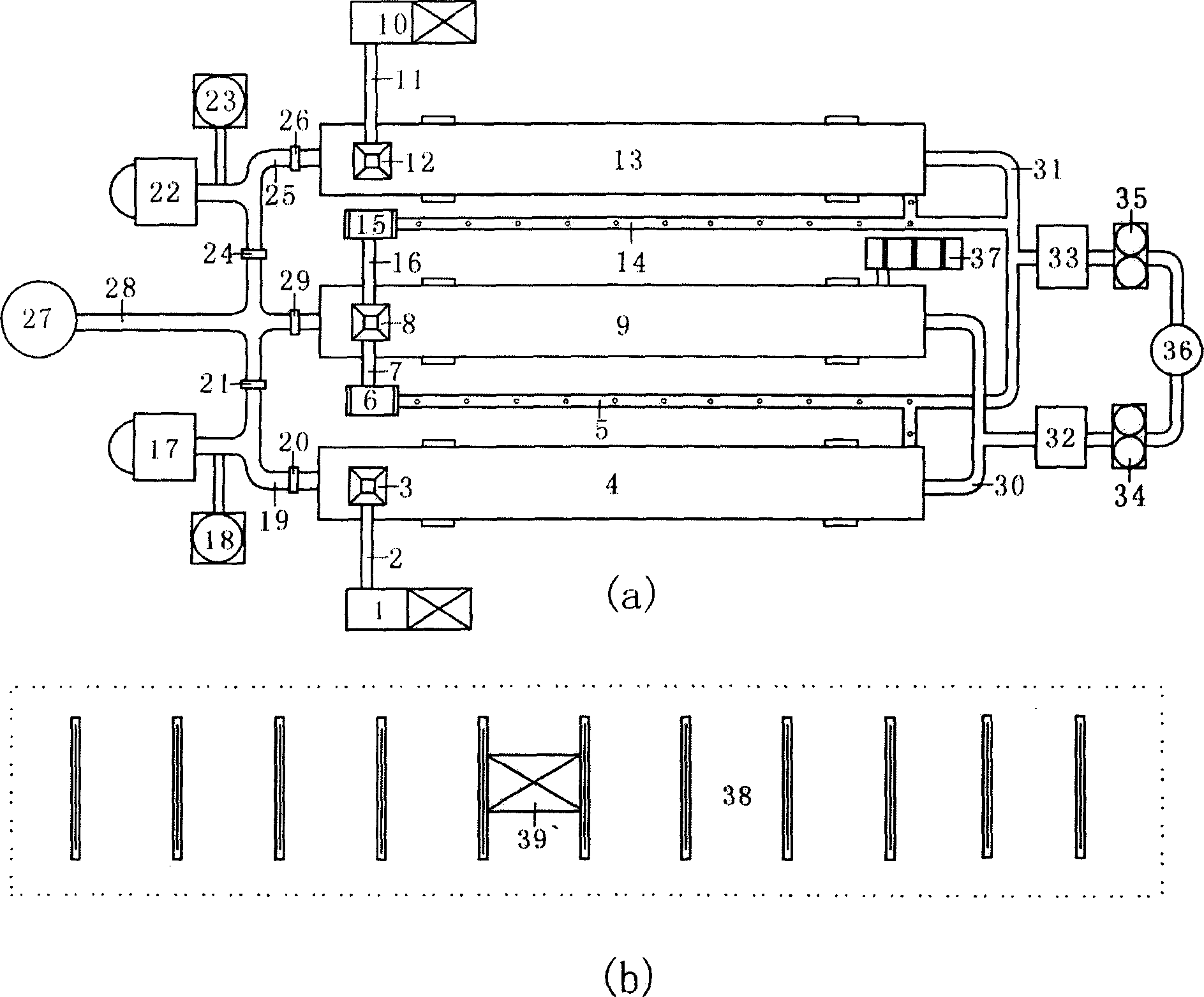

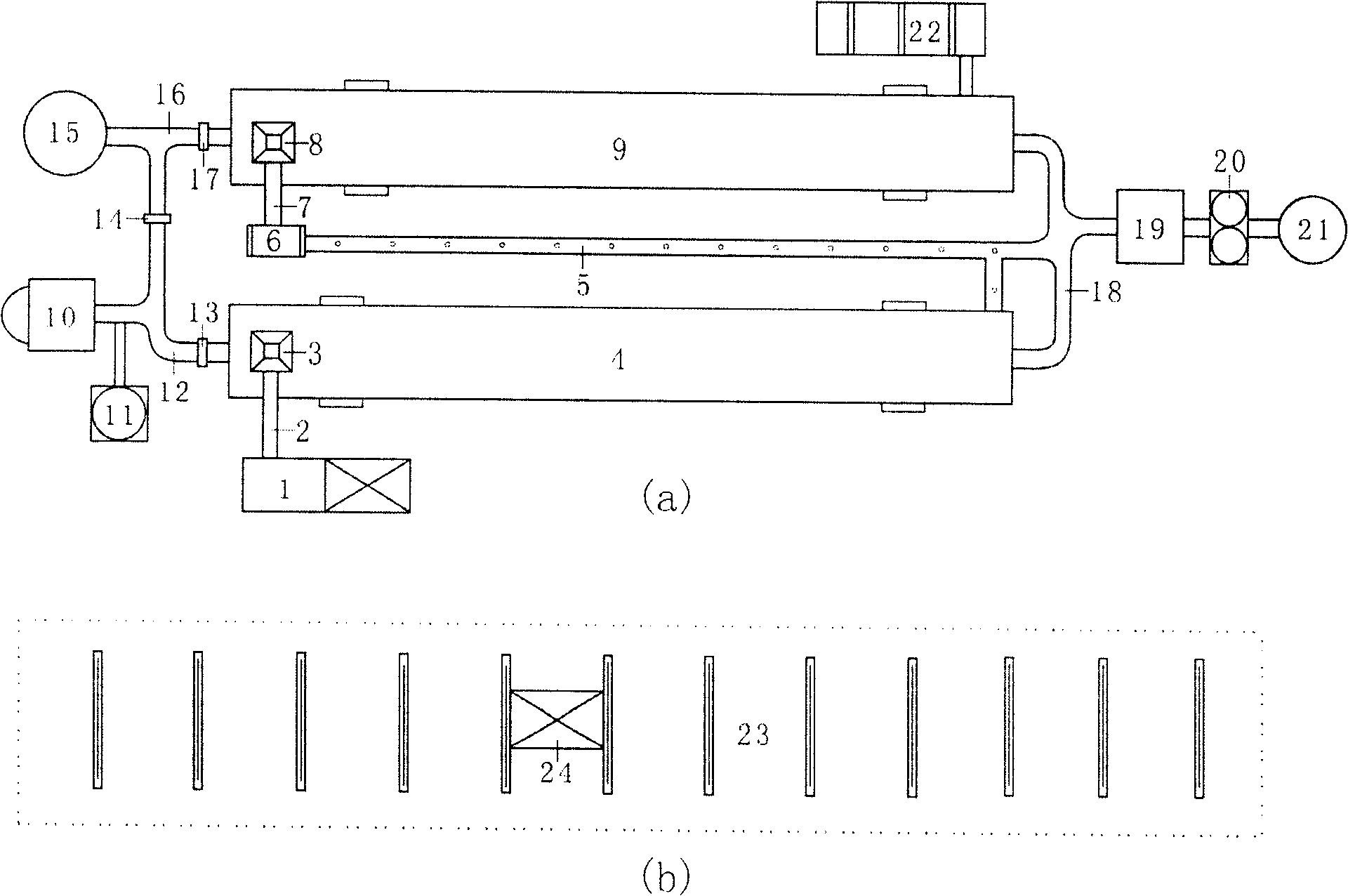

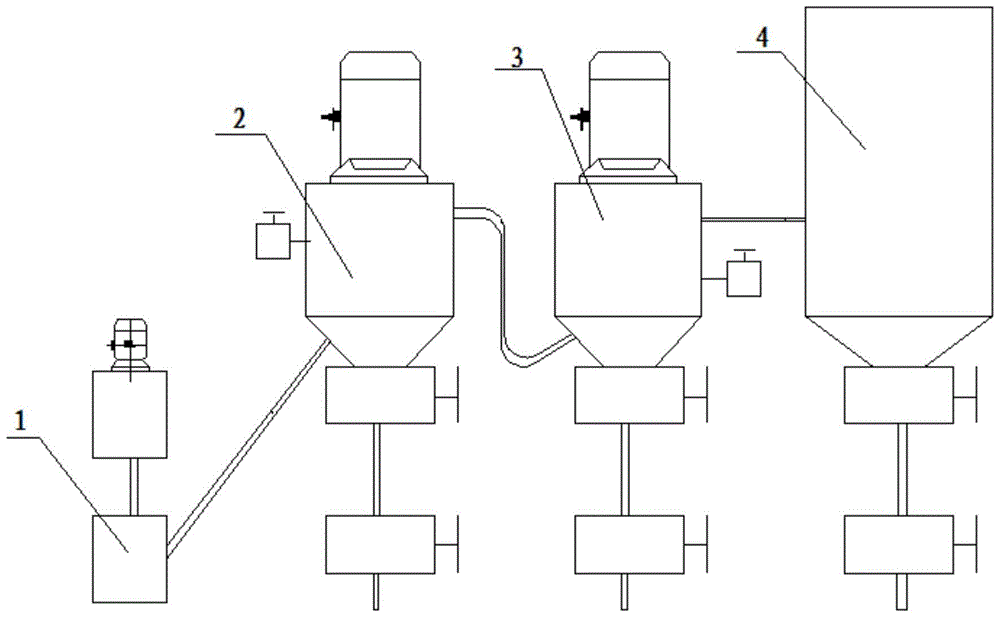

Anhydration system for sludge by using remaining heat of flue gas from steam power plant

ActiveCN1686878AWill not affect normal operationEffective controlSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningFlue gasSludge

The present invention discloses a sludge anhydration system by utilizing waste heat of steam power plant smoke. Said sludge anhydration system includes heat supply system, sludge pretreatment system, feeding system, sludge, anhydration and granulation system and dust-removing and gas-removing system.

Owner:ZHEJIANG UNIV

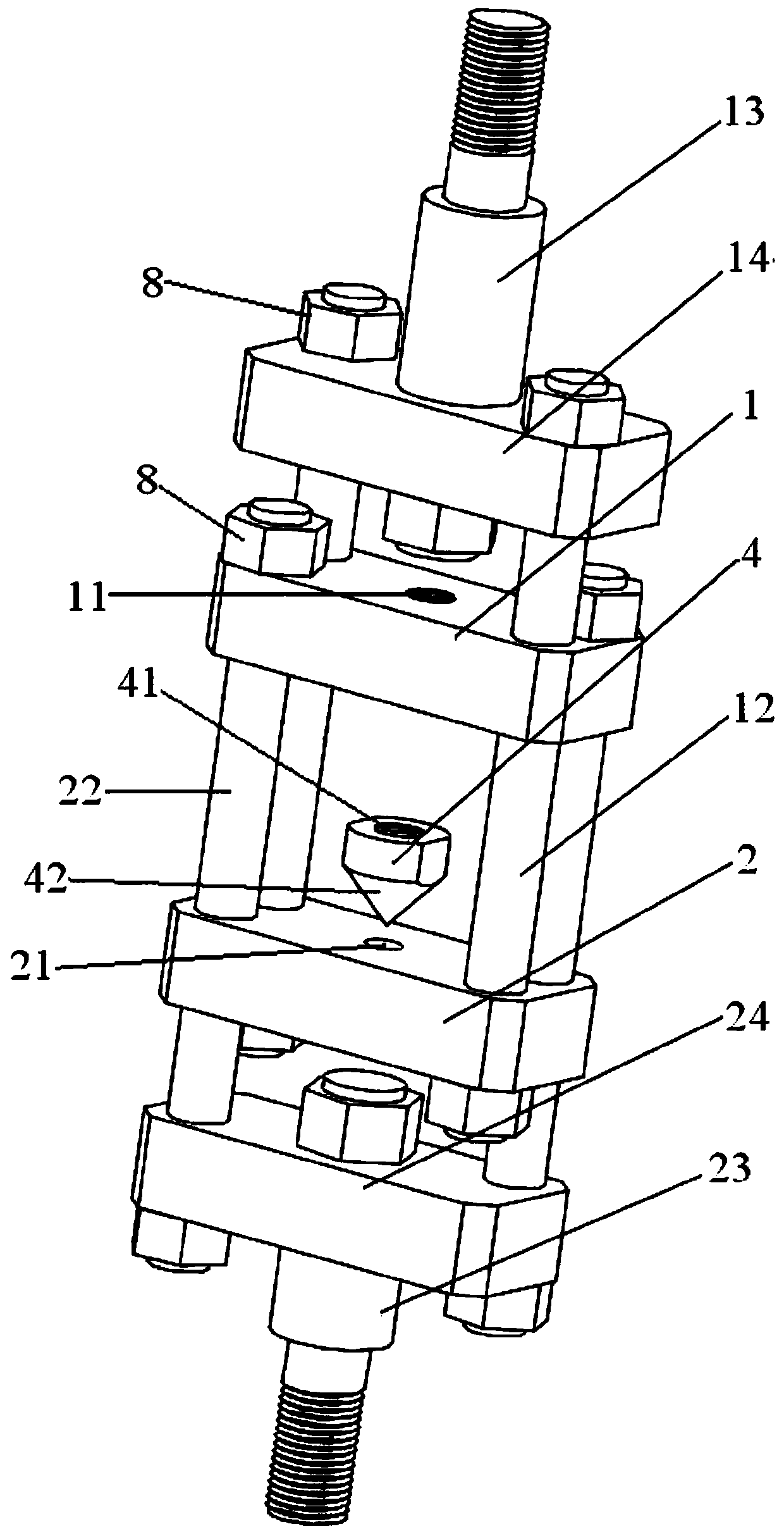

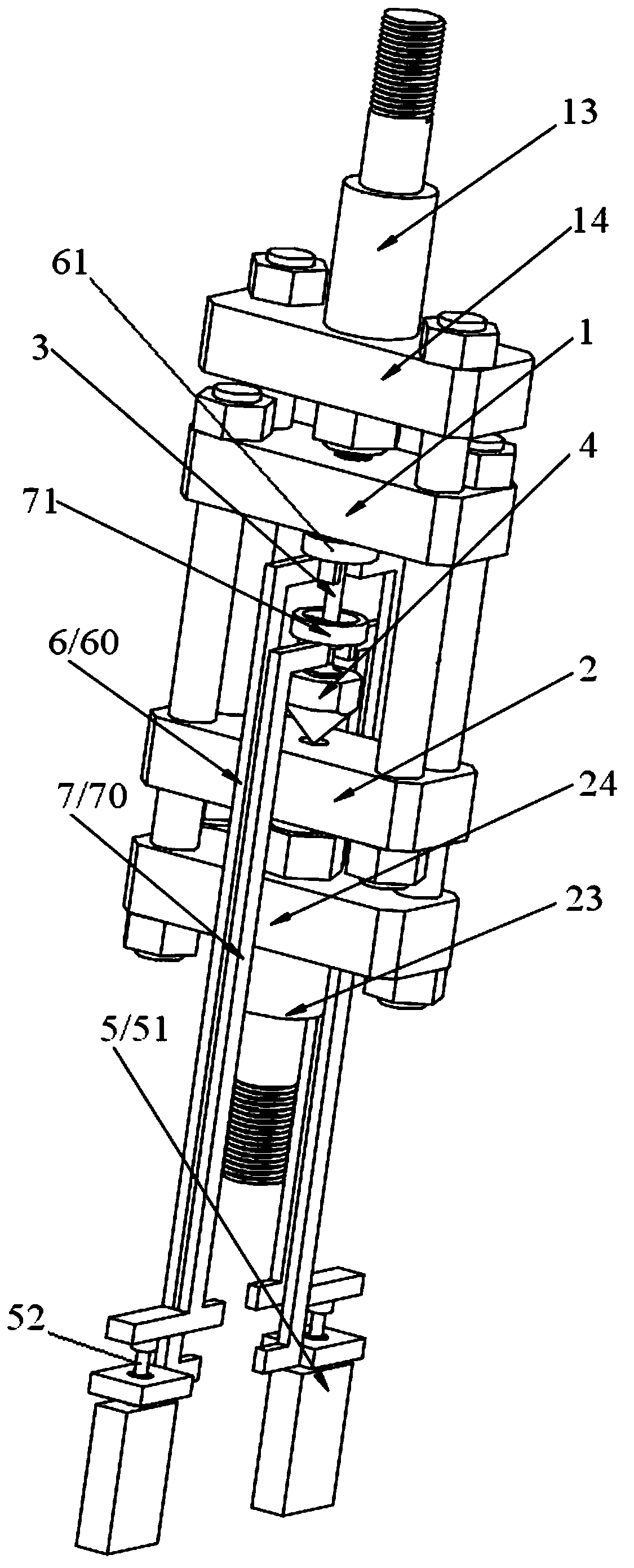

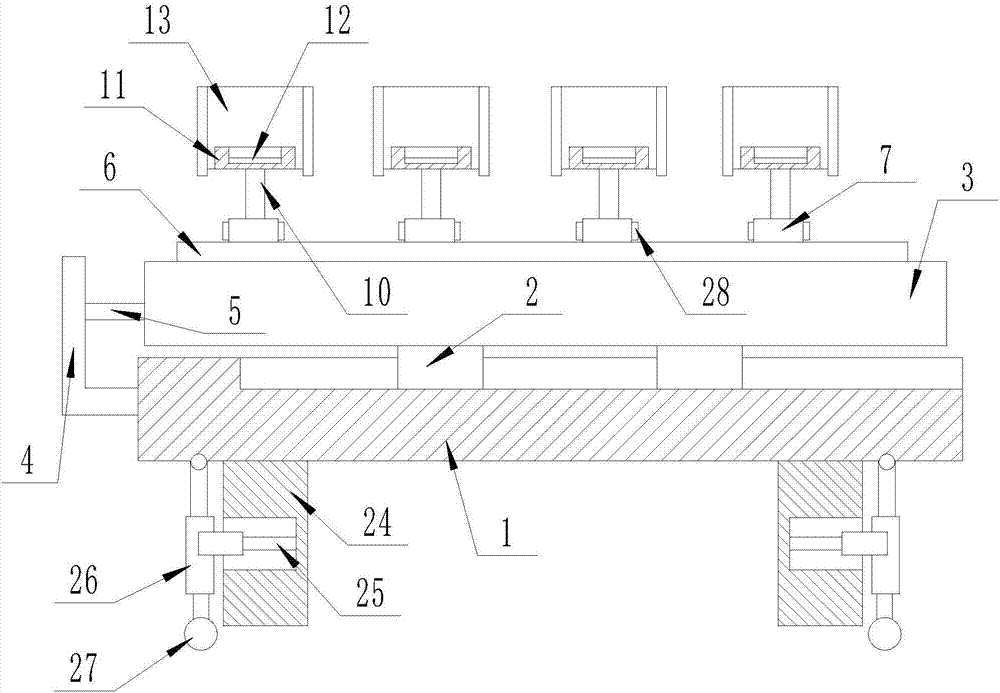

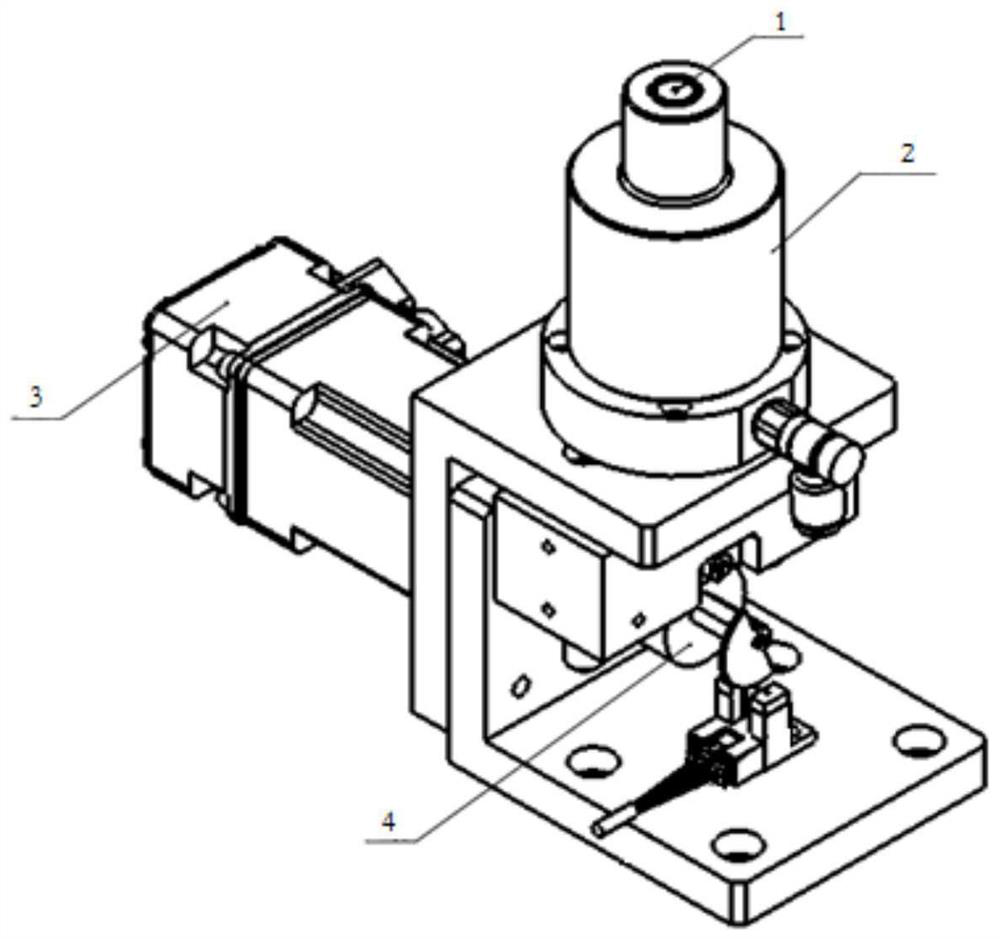

Creep compression experimental apparatus

ActiveCN109870371ANeutral goodReduce risk of damageInvestigating material ductilityNuclear energy generationUniaxial compressionTest sample

The invention provides a creep compression experimental apparatus. The creep compression experimental apparatus comprises an installation frame connected between an upper stretching rod and a lower stretching rod of a creep test machine, wherein the installation frame comprises an upper pressure block and a lower pressure block, the upper pressure block is provided with a threaded hole A, the lower pressure is provided with a conical hole coaxial with the threaded hole A, one end of a test sample is fixed in the threaded hole A, the other end is located in the conical hole by virtue of a conical head of a conical positioning device, and when the conical head is matched with the conical hole, the threaded hole A, the conical head, the conical hole and the test sample are coaxial. The auto-positioning function is realized by virtue of a conical surface contact of the conical positioning device, so that the test sample can be well centralized in the single-axis compression process, and the instability bending possibility of the test sample can be reduced. By virtue of the reversely-arranged extension rod, the rebound displacement of a precompressed sensor measuring head in the reset process is taken as the compression creep deformation of a sample, so that the occurrence of overstroke of the sensor measuring head and damage to the displacement sensor can be effectively avoided.

Owner:CENT SOUTH UNIV

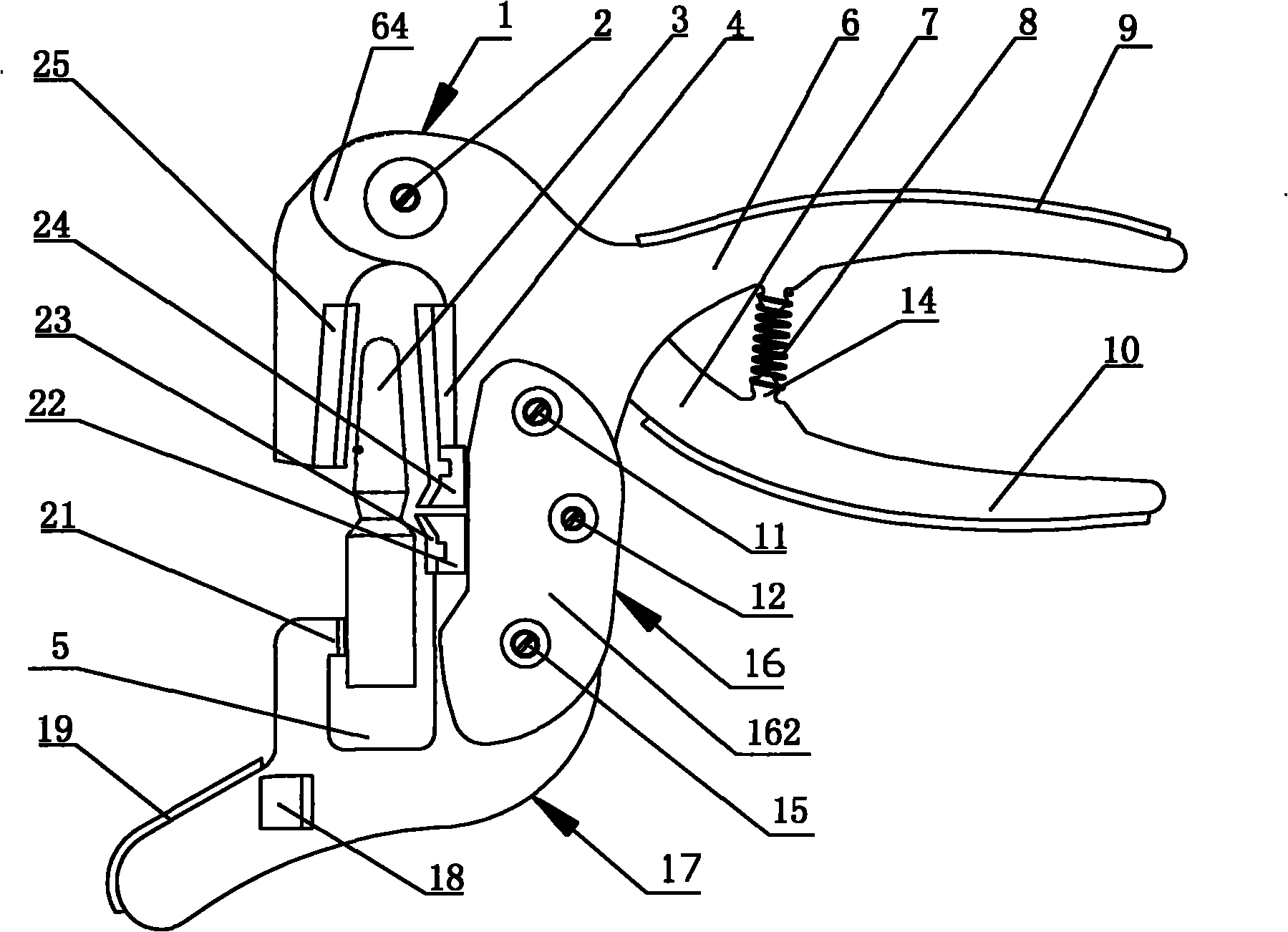

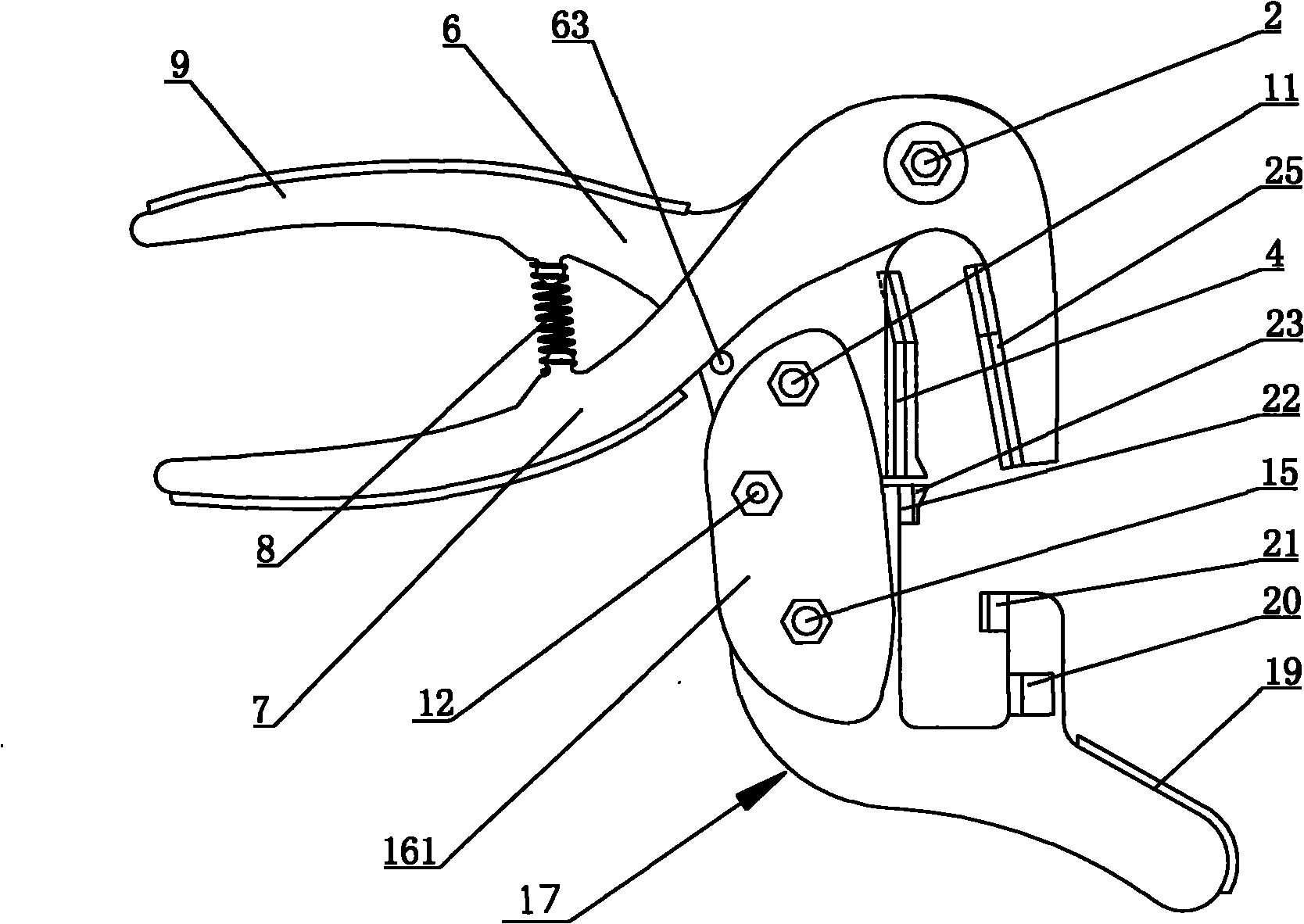

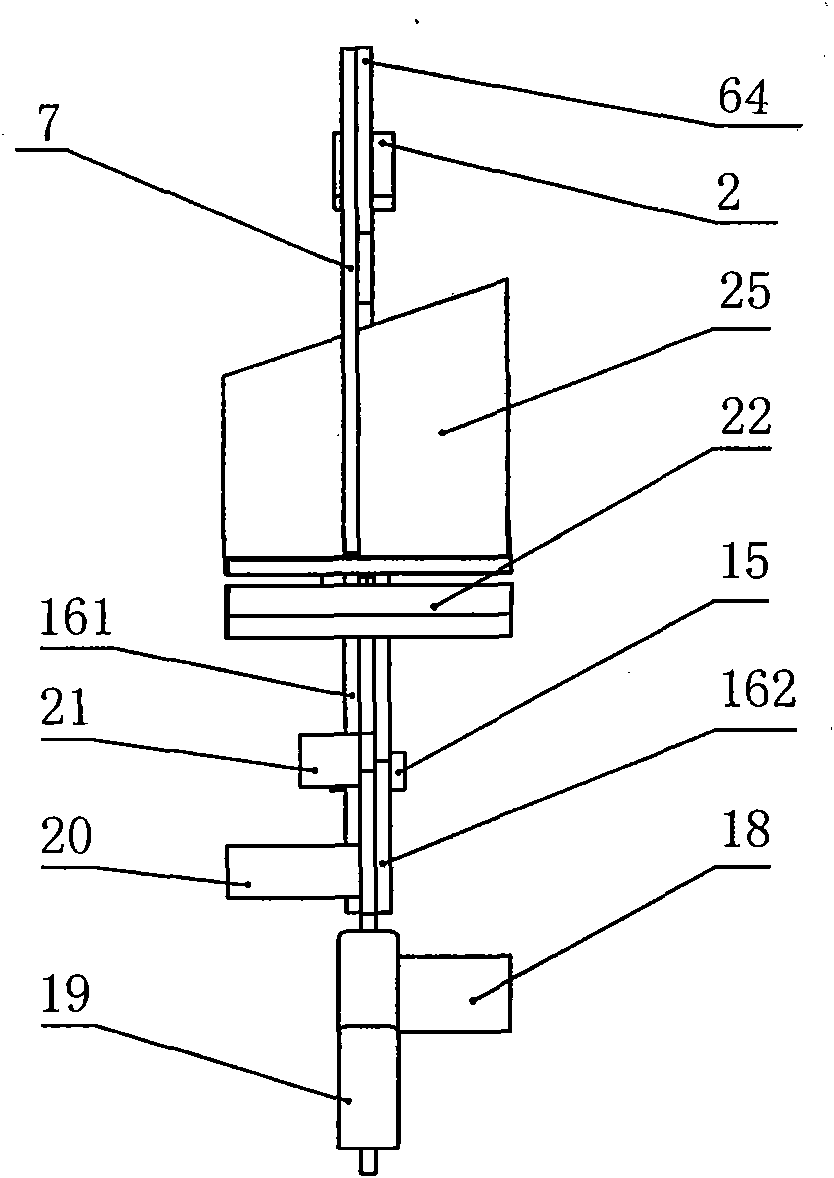

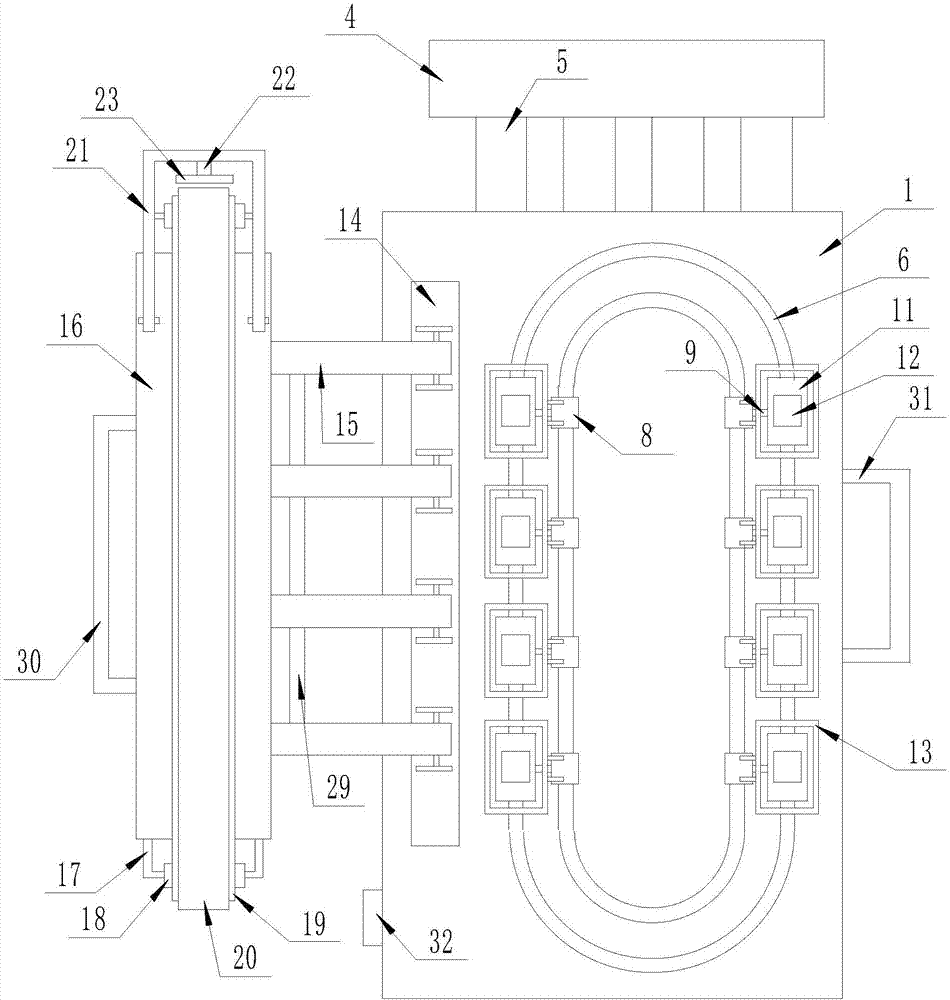

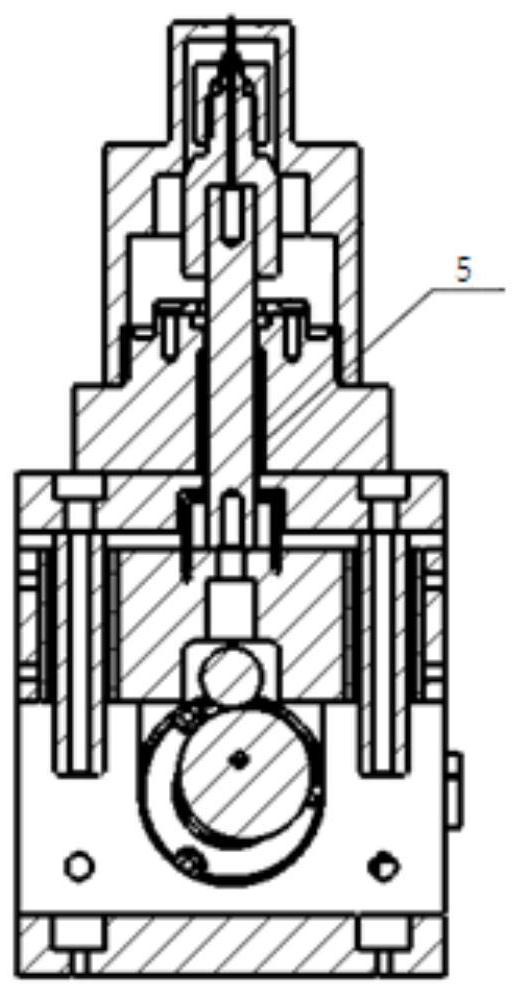

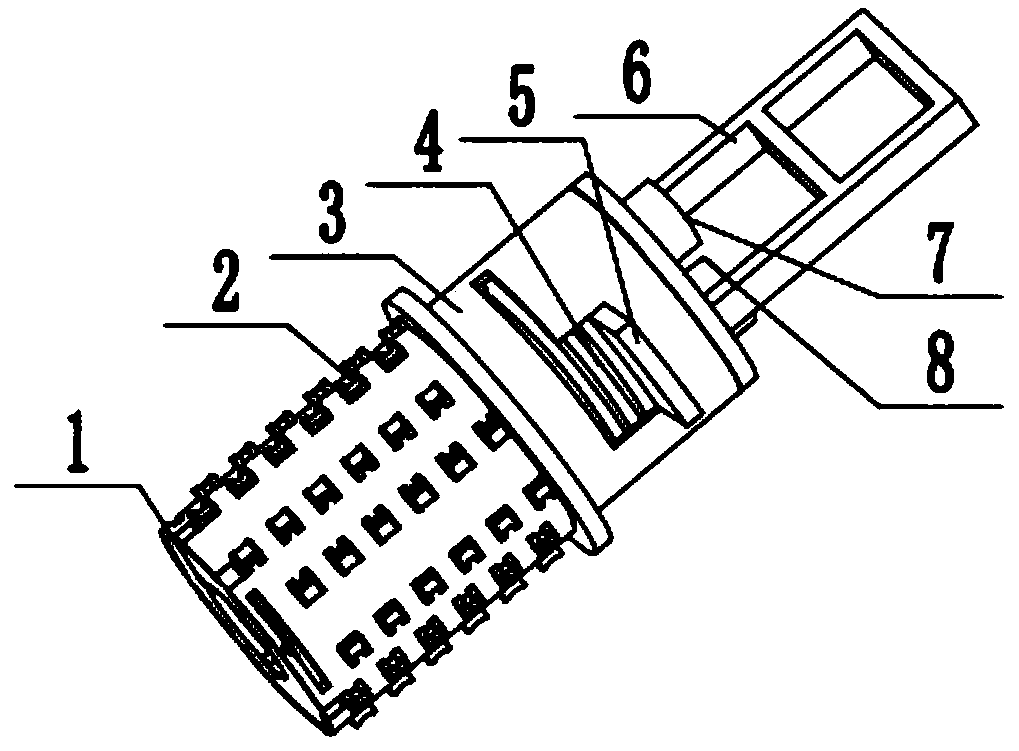

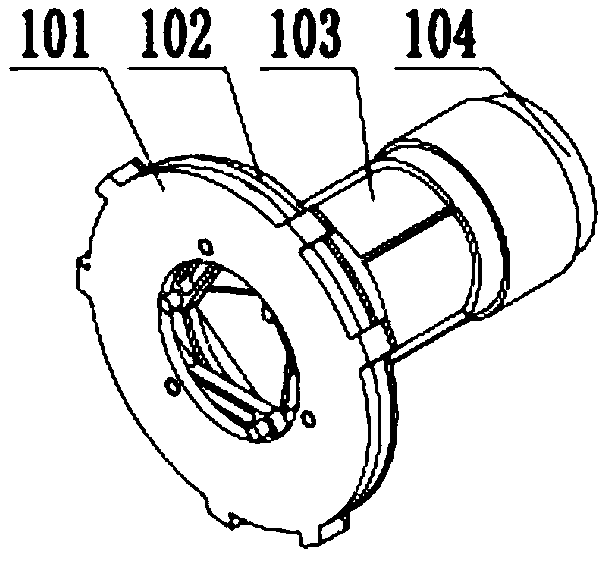

Ampoule splitter

InactiveCN101973505AHigh breaking forceGuaranteed against damageOpening closed containersBottle/container closureEngineeringBottle neck

The invention discloses an ampoule splitter which is a manual-operation type or full-automatic type ampoule splitter. The ampoule splitter comprises a bottle bubble clamp, a positioning frame and a bottle body frame and is characterized in that the upper part of the positioning frame is provided with the bottle bubble clamp used for clamping an ampoule bottle bubble and splitting the ampoule bottle bubble through a lever, and the bottle bubble clamp is formed by crosswise and movably connecting an upper clamp body and a lower clamp body through a clamp pin shaft. The lower part of the positioning frame is provided with the bottle body frame used for positioning and clamping the ampoule bottle body, and the bottle body frame comprise a connecting plate, a bottle neck lower force arm and a bottle body force arm. The positioning frame is formed by assembling the bottle bubble clamp and the bottle body frame together through double shafts in a linkage way, and the bottle bubble clamp is movably connected with the bottle body frame through the positioning frame. By using the ampoule splitter of the invention, fine glass fragments cannot be generated, the phenomena of hands injuring and medicinal liquid spilling are prevented, the table type or full-automatic type ampoule splitter can be used for splitting two or three ampoule bottles at the same time. The ampoule splitter has the advantages of convenient and rapid operation and meets the professional requirements of medical treatment.

Owner:向永川

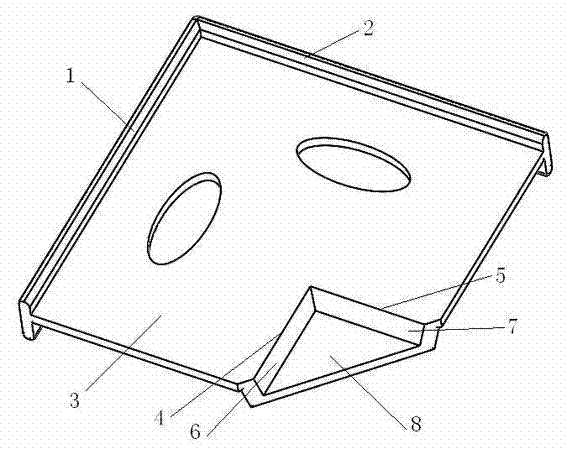

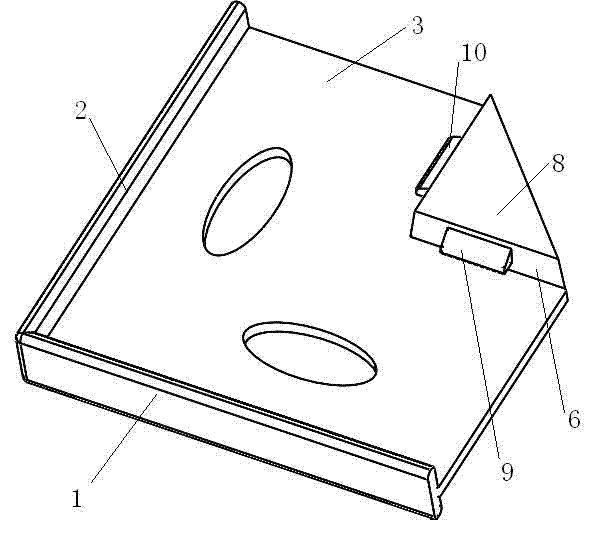

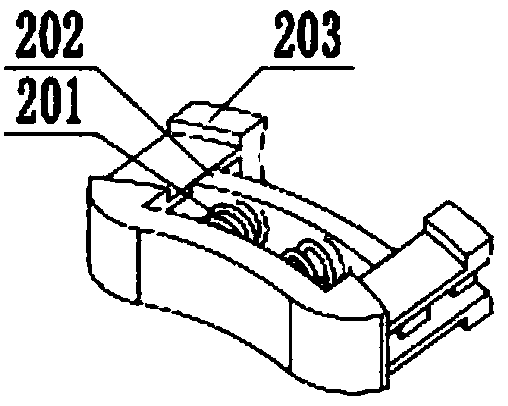

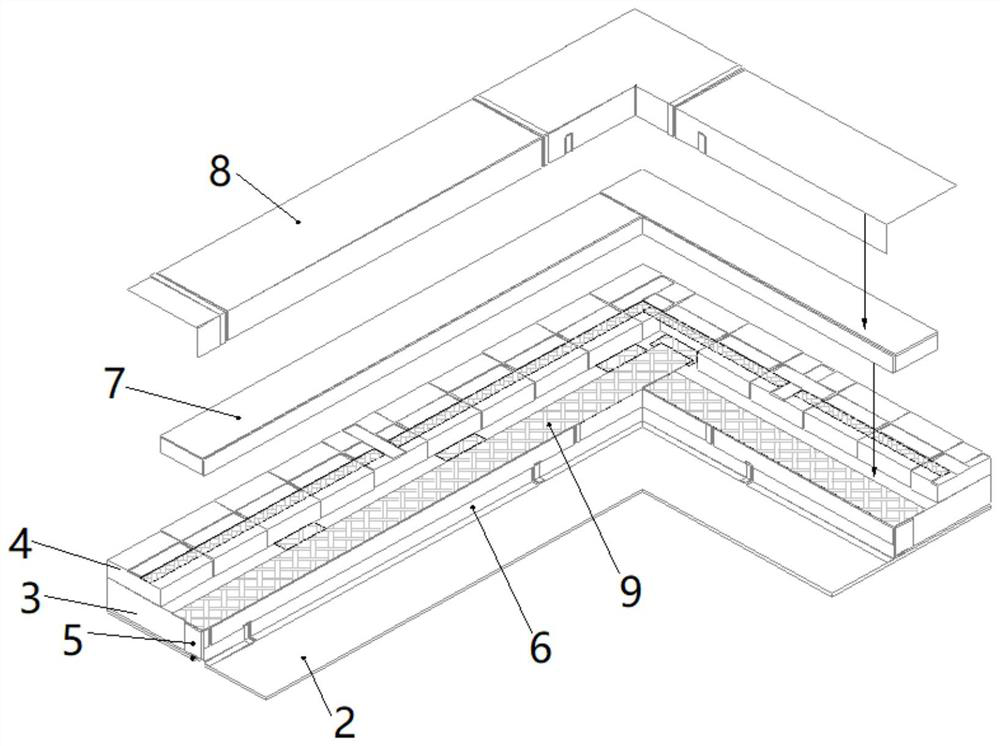

Corner protection structure for solar battery component

InactiveCN102820354AGuaranteed against damagePrevent slipping outClosuresPhotovoltaicsElectrical batteryEngineering

The invention relates to a corner protection structure for a solar battery component, for protecting the corners of the solar battery component. The corner protection structure comprises a corner protecting plate which is arranged at the tops of adjacent first and second frames of the solar battery component; a first outer protecting plate which is arranged on an outer side wall of the first frame and a second outer protecting plate which is arranged on the outer side wall of the second frame are arranged on the corner protecting plate; a first lateral edge which is parallel to the first outer protecting plate and a second lateral edge which is parallel to the second outer protecting plate are arranged on the corner protecting plate; a first inner protecting plate is arranged at the bottom of the first lateral edge; the bottom end of the first inner protecting plate is inclined along a direction away from the first outer protecting plate; a second inner protecting plate is arranged at the bottom of the second lateral edge; and the bottom end of the second inner protecting plate is inclined along the direction away from the second outer protecting plate. The corner protection structure for the solar battery component provided by the invention is used for preventing the corners of the solar battery component from being scratched, ensuring that the relative sliding among various solar battery components is avoided, and ensuring that the solar battery components are not damaged.

Owner:湖南红太阳新能源科技有限公司

Equipment for automatic boxing of LED lamps

Owner:江苏靓艾斯光电科技有限公司

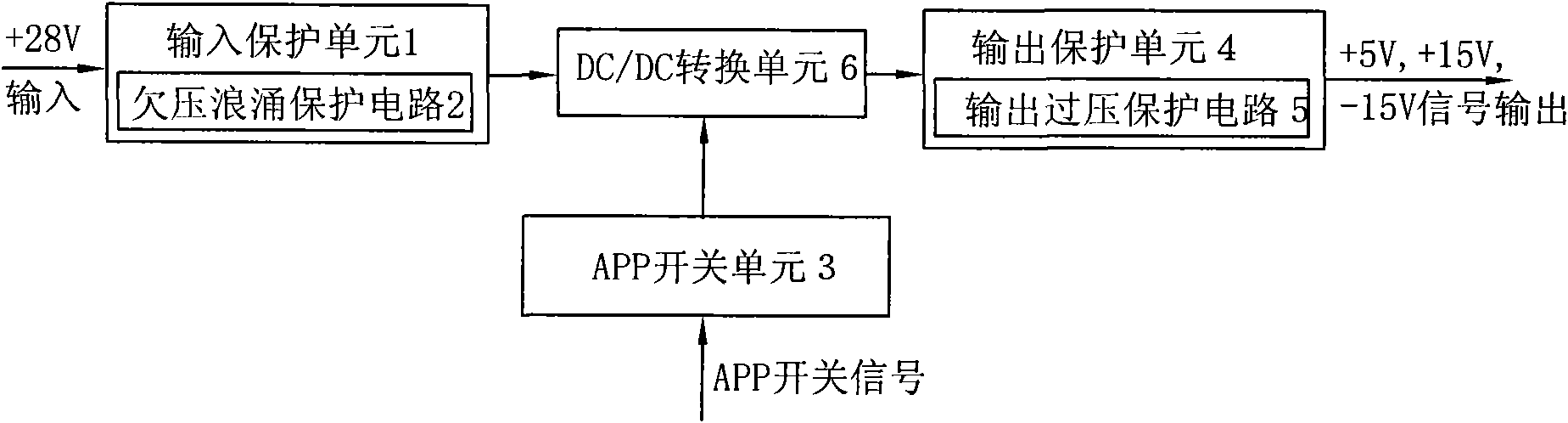

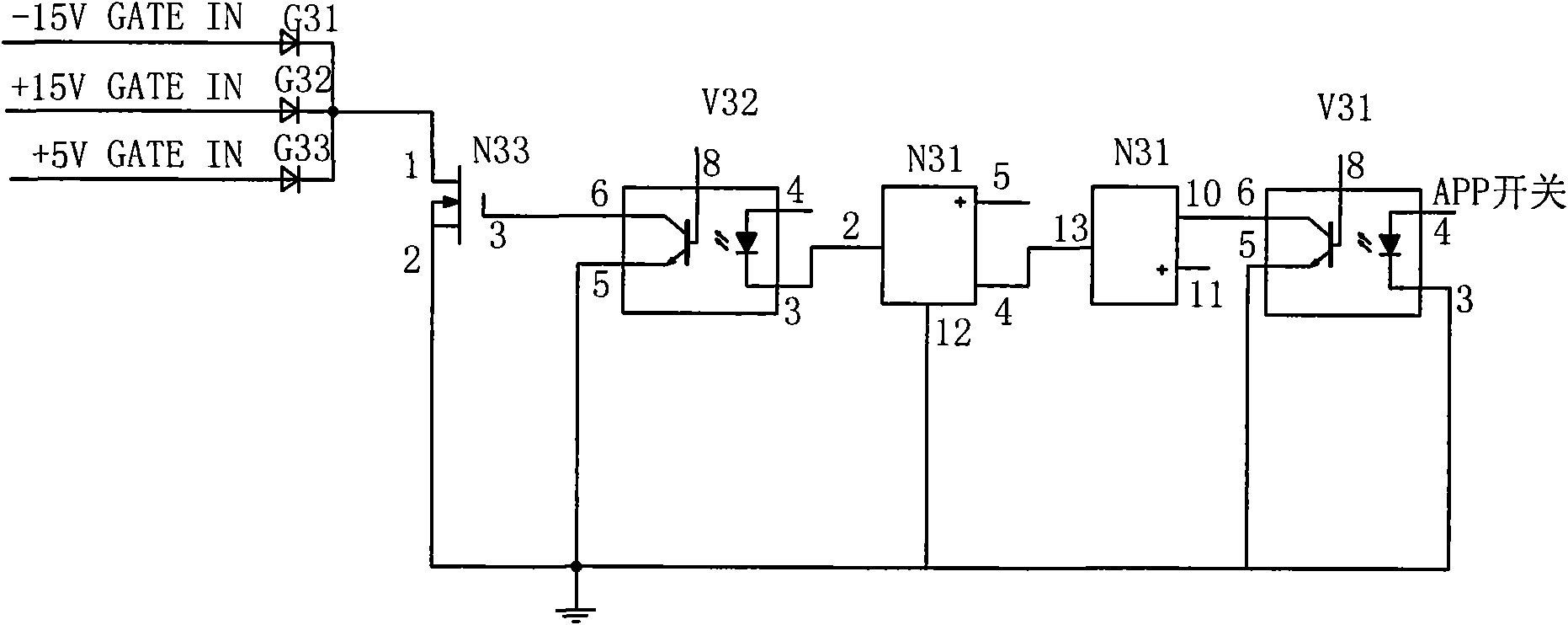

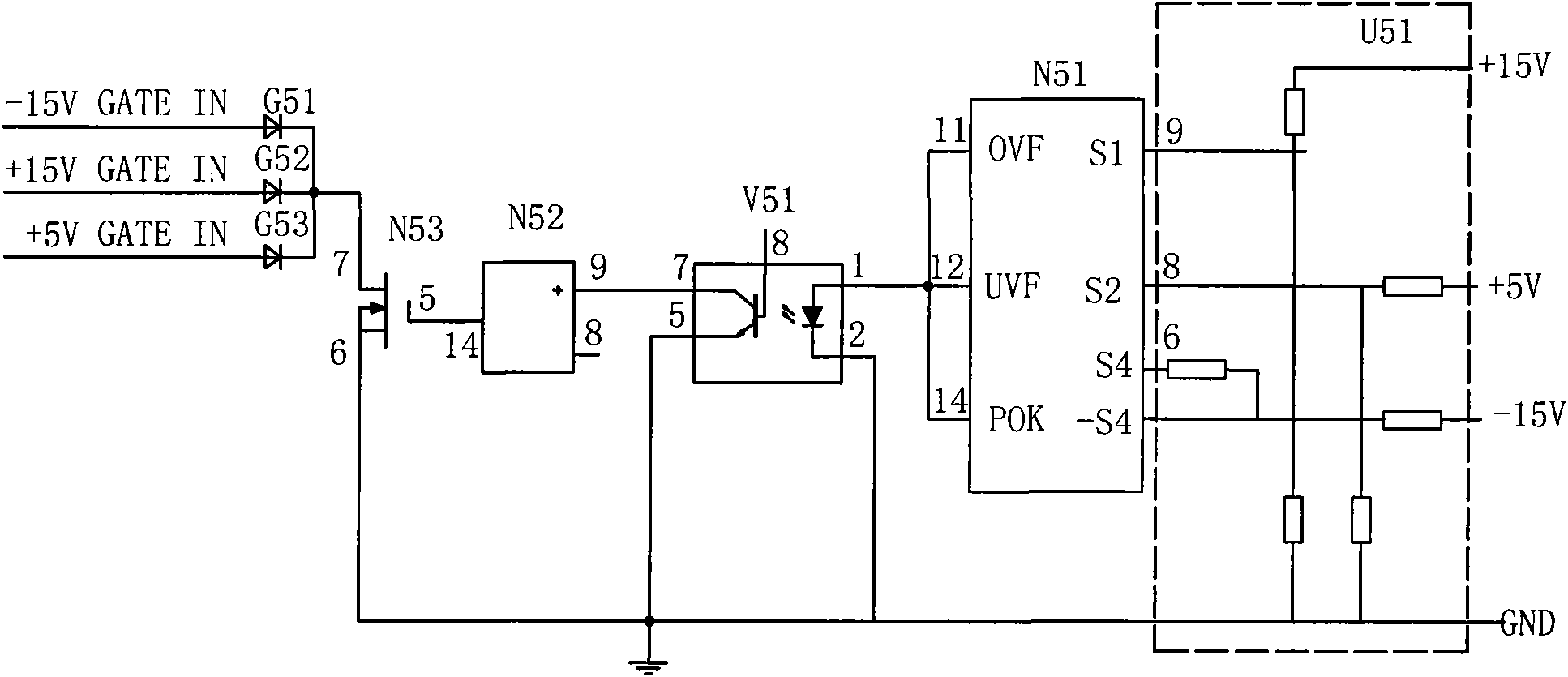

Switching power supply module with high reliability and low power consumption

ActiveCN101771338AReduce energy consumptionEasy to debugApparatus without intermediate ac conversionHigh energyEngineering

The invention relates to a switching power supply module with high reliability and low power consumption, comprising a DC / DC converting unit, an input protection unit arranged at the input end of the DC-DC converting unit, an output protection unit arranged at the output end of the DC-DC converting unit, and an AAP switching unit. The power-up enable control switch signal of the module is selected from a voltage signal based on an input wire or a voltage signal based on any output wire, and the output end thereof is connected with each output enable control end of the DC-DC converting unit. The invention solves the shortcomings of unreasonable design, high energy consumption, poor reliability, low stability, inconvenient debugging existing in auxiliary and protective circuits inside the switching power supply module in the prior art, and has the advantages of low energy consumption, simple design, reliability, stability and the like.

Owner:中国航空工业第一集团公司第六三一研究所

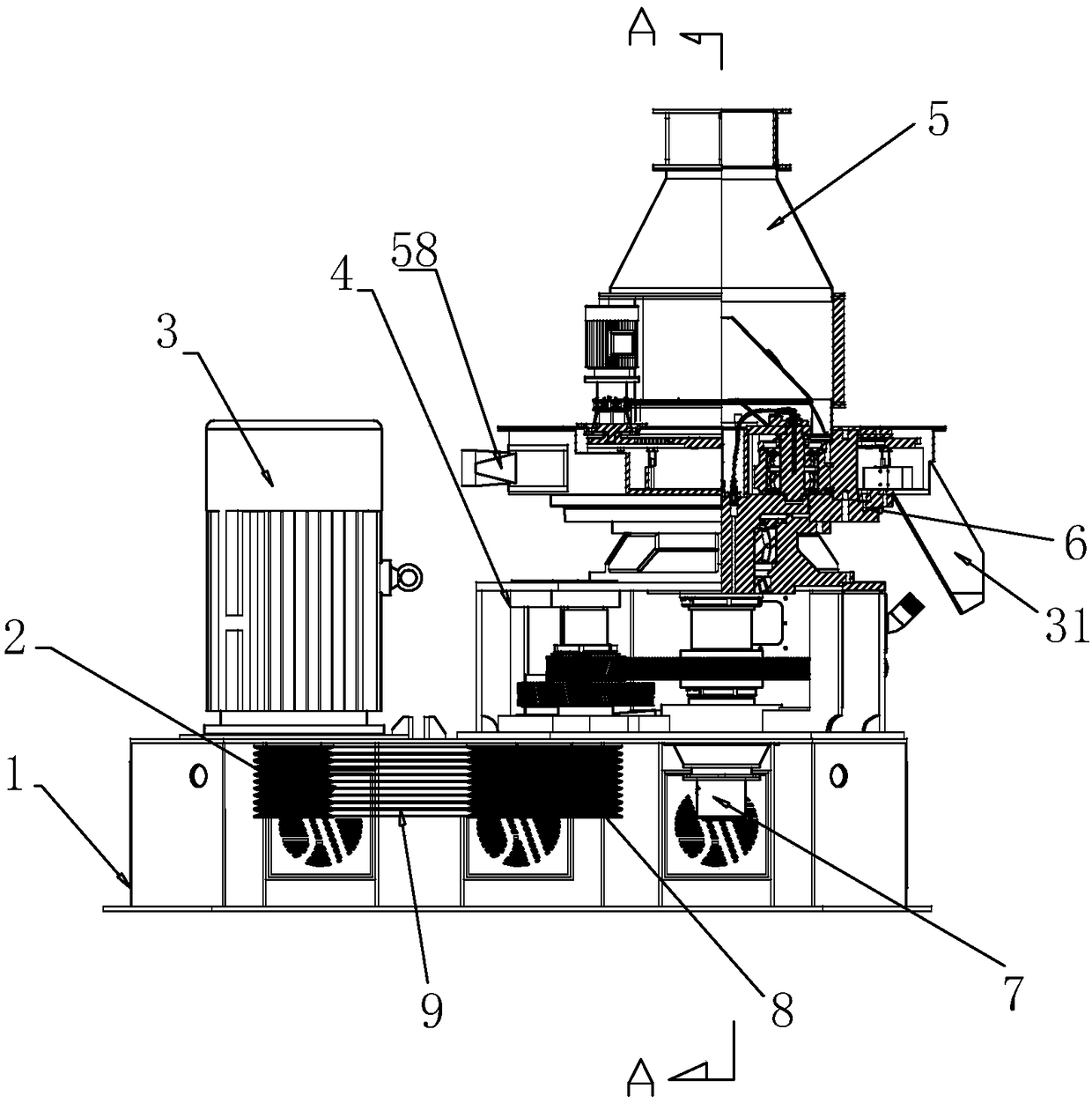

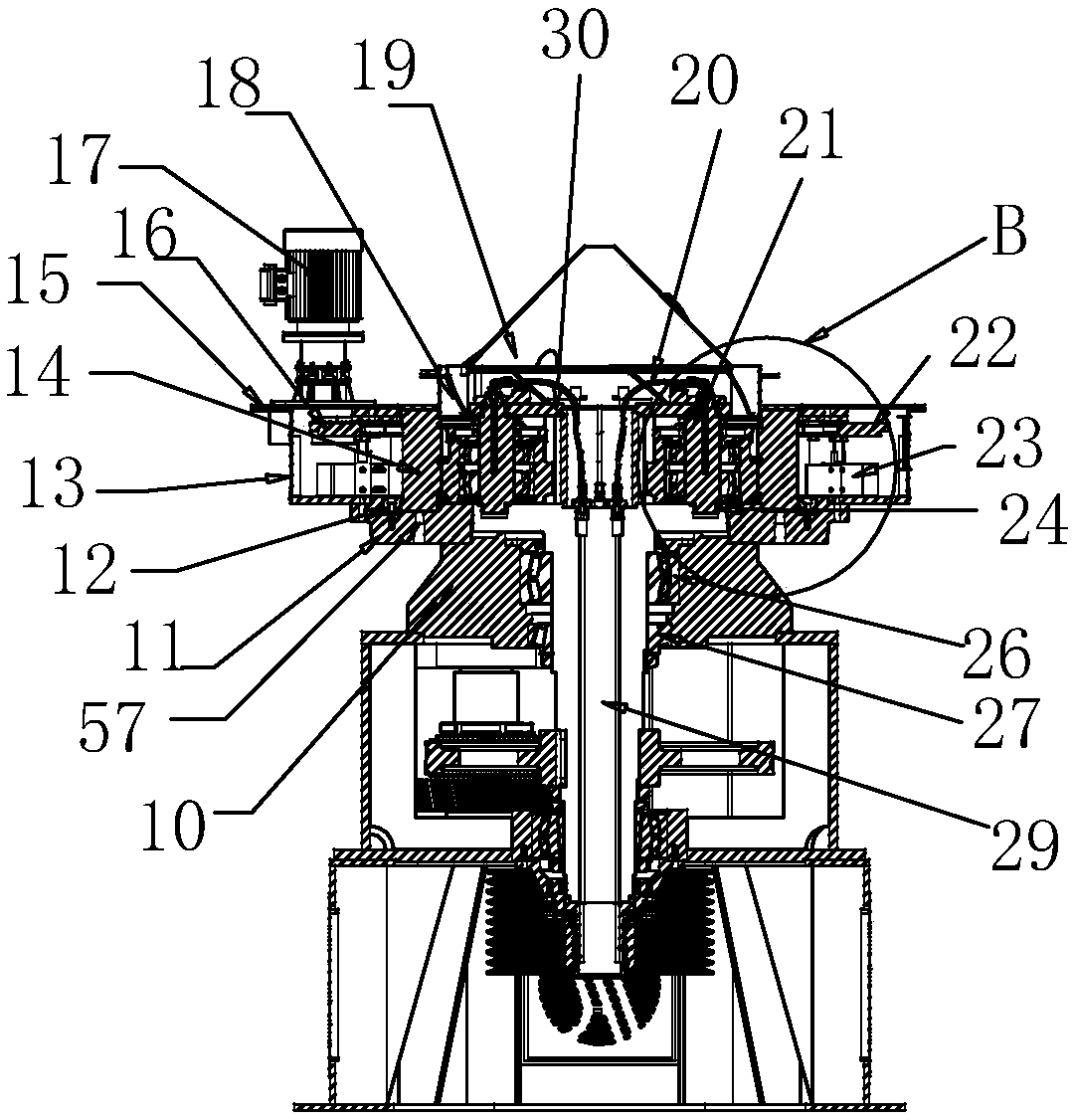

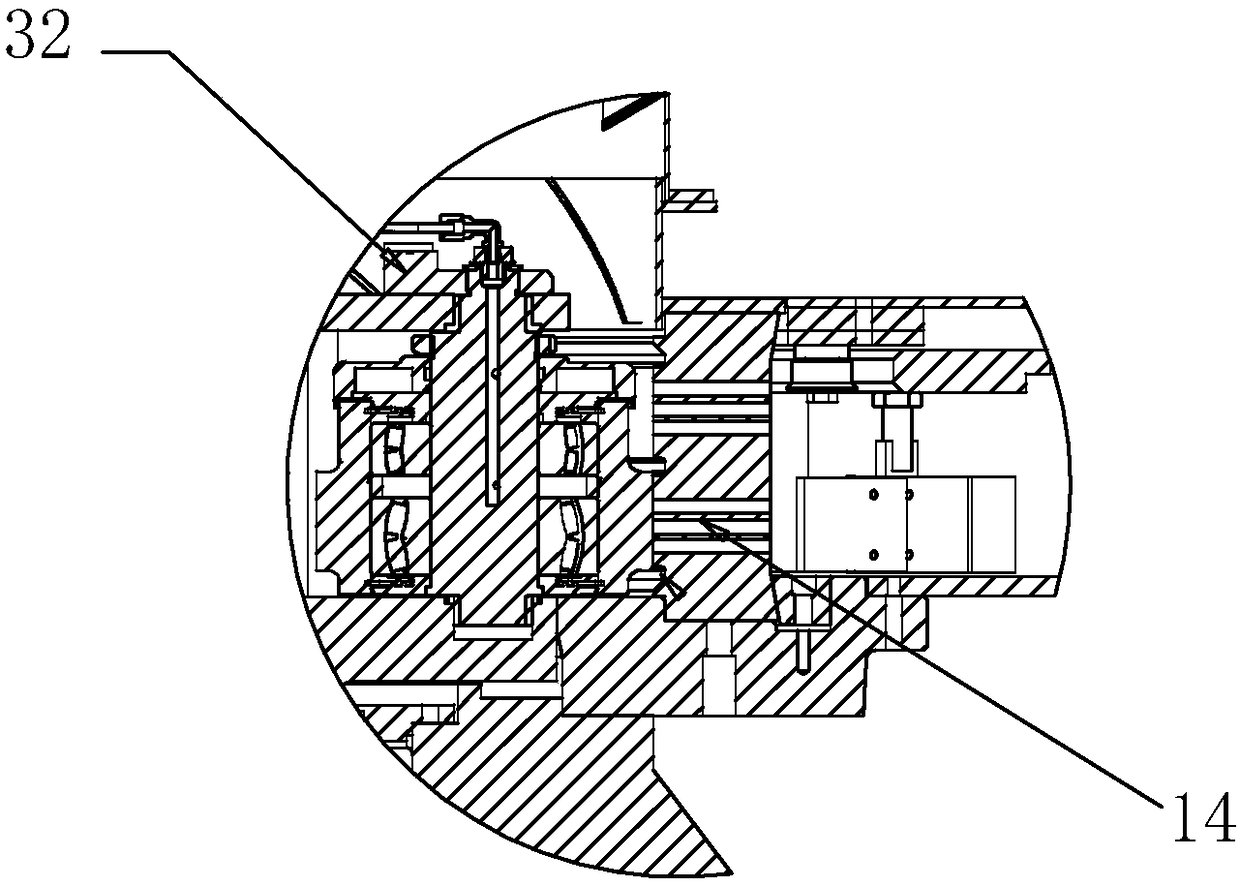

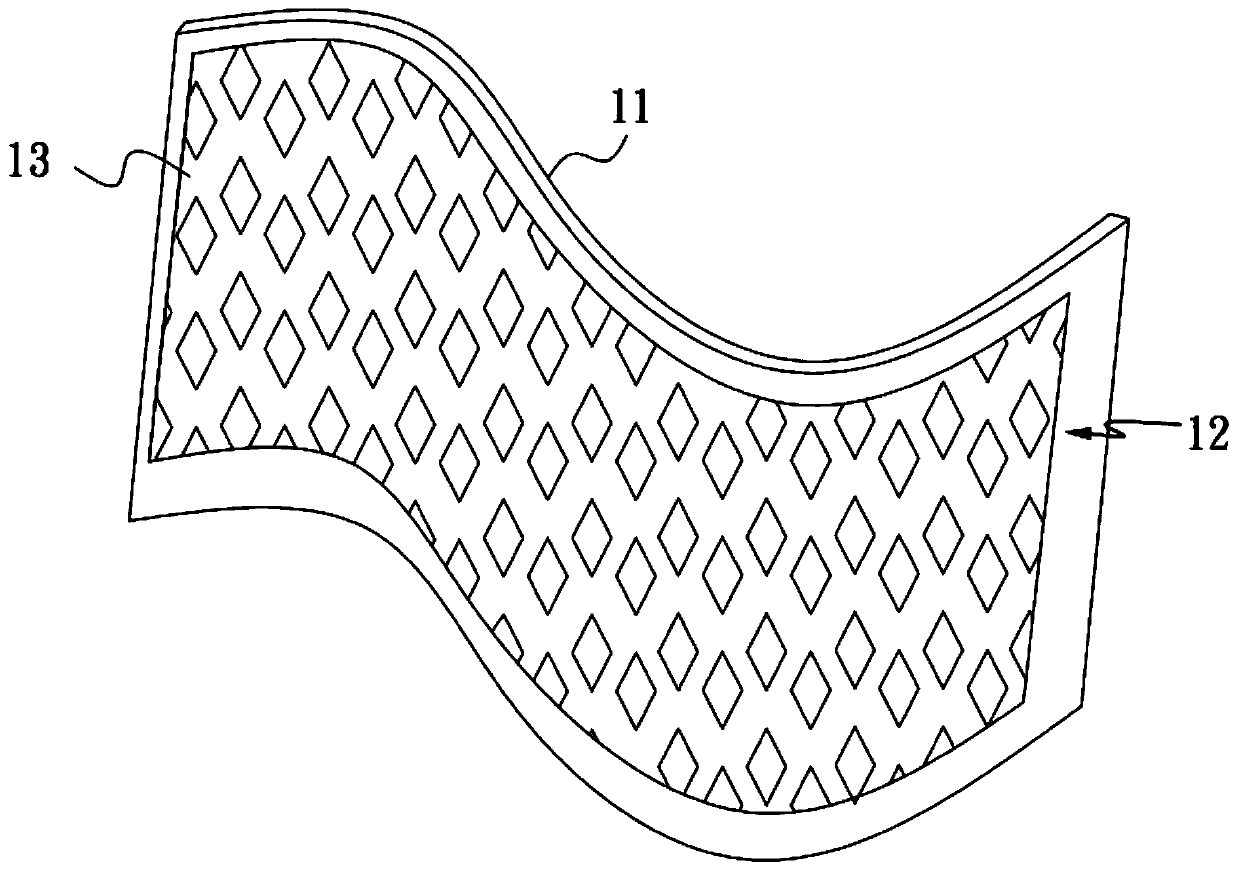

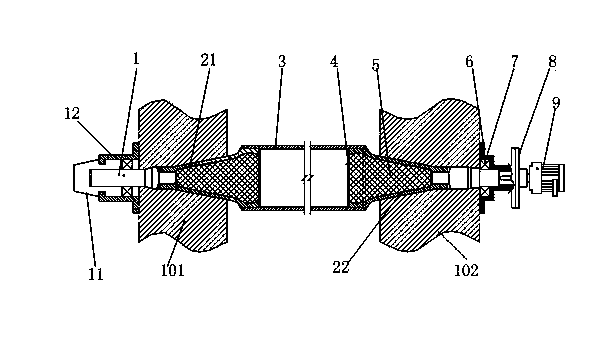

Vertical ring die pelleter

PendingCN108246203ADissipate heat in timeImprove efficiencyBiofuelsSolid fuelsMotor driveAgricultural engineering

The invention relates to a vertical ring die pelleter, which comprises a main machine (6), wherein the main machine comprises a bracket (10), a ring die seat (11), a connection seat (18), a main machine shell (13), an upper cover (15), a ring die (14), a pressure roller assembly (21) and a main shaft (29), the main shaft (29) and the power output shaft of a speed reduction box share a shaft, the pressure roller assembly (21) is fixed on the upper portion of the main shaft, the ring die and the pressure roller assembly (21) are matched, the outer side of the ring die is provided with the main machine shell (13), the upper cover (15) is fixed on the main machine shell (13), a speed reduction motor (17) is fixed on the upper cover (15), a material scraping plate and a cutter are fixedly connected on a tooth disc (22), and the speed reduction motor drives the tooth disc to move. With the technical scheme of the present invention, the vertical ring die pelleter is reliable and safe.

Owner:JIANGSU YONGLI MACHINERY

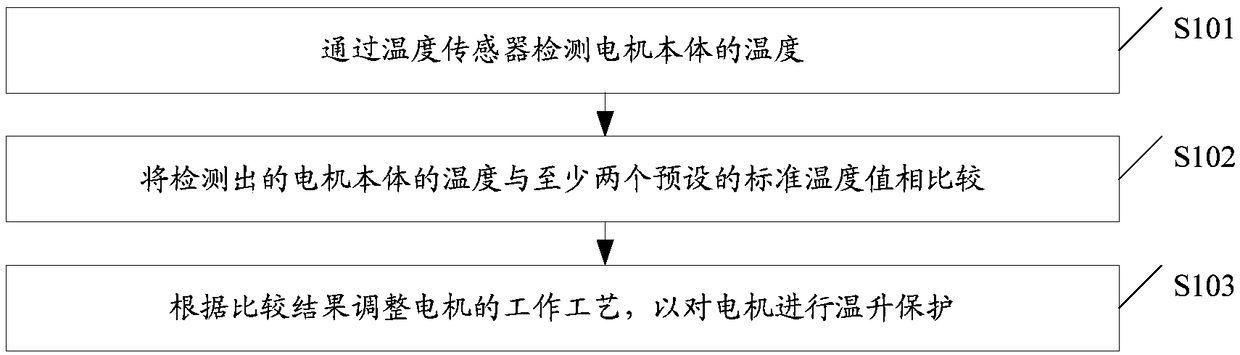

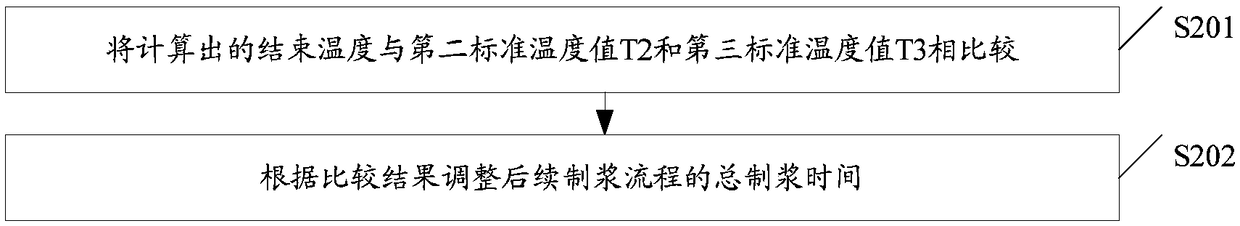

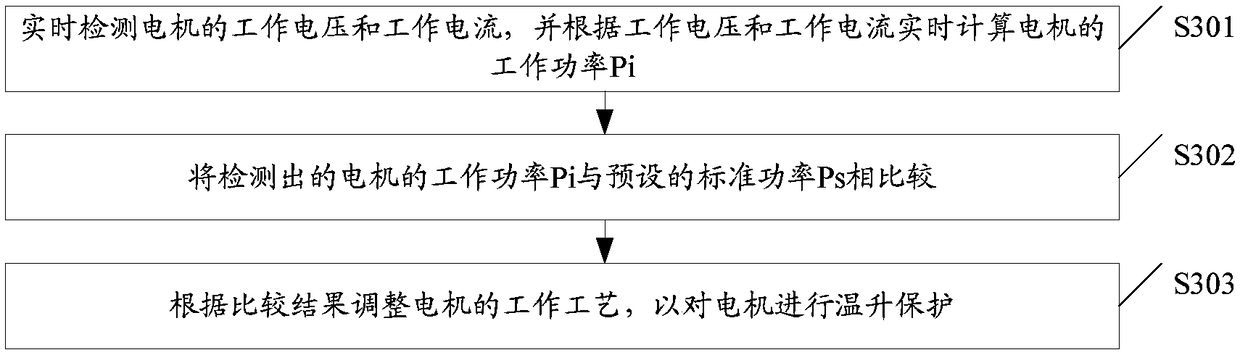

Motor protecting method of food processing machine

ActiveCN108836138AReliable productReal time monitoringKitchen equipmentMotor protectionFood processing

The embodiment of the invention discloses a motor protecting method of a food processing machine. A temperature sensor and a motor can be included in the food processing machine. The method comprisesthe steps that the temperature of a motor body is detected through the temperature sensor; detected temperature of the motor body is compared with at least two preset standard temperature values; theoperating process of the motor is adjusted according to comparison results to perform protection of the motor. By means of the method, real-time monitoring and protecting are conducted on the motor without the constraint of various specific conditions, and a product is more reliable.

Owner:JOYOUNG CO LTD

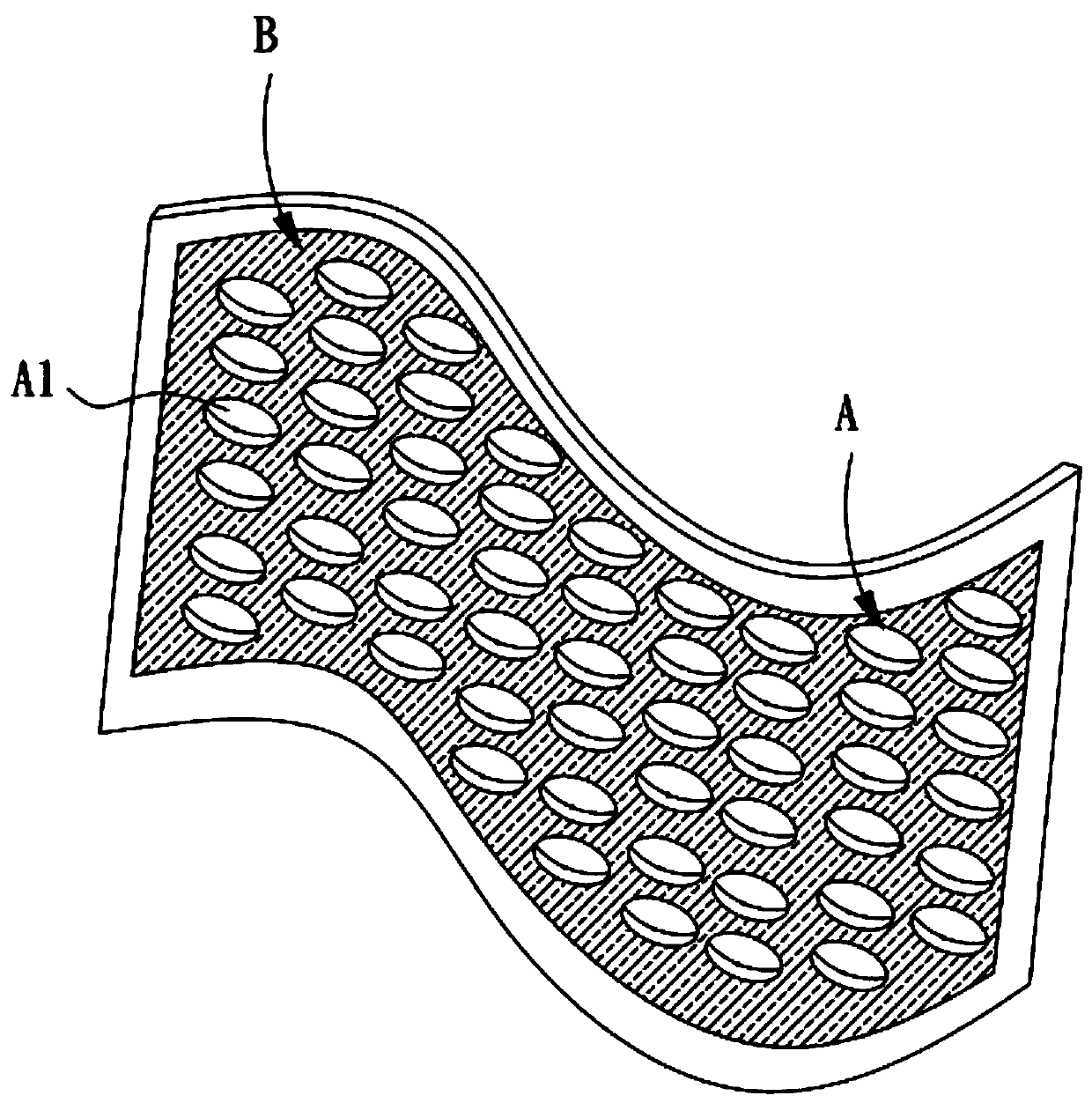

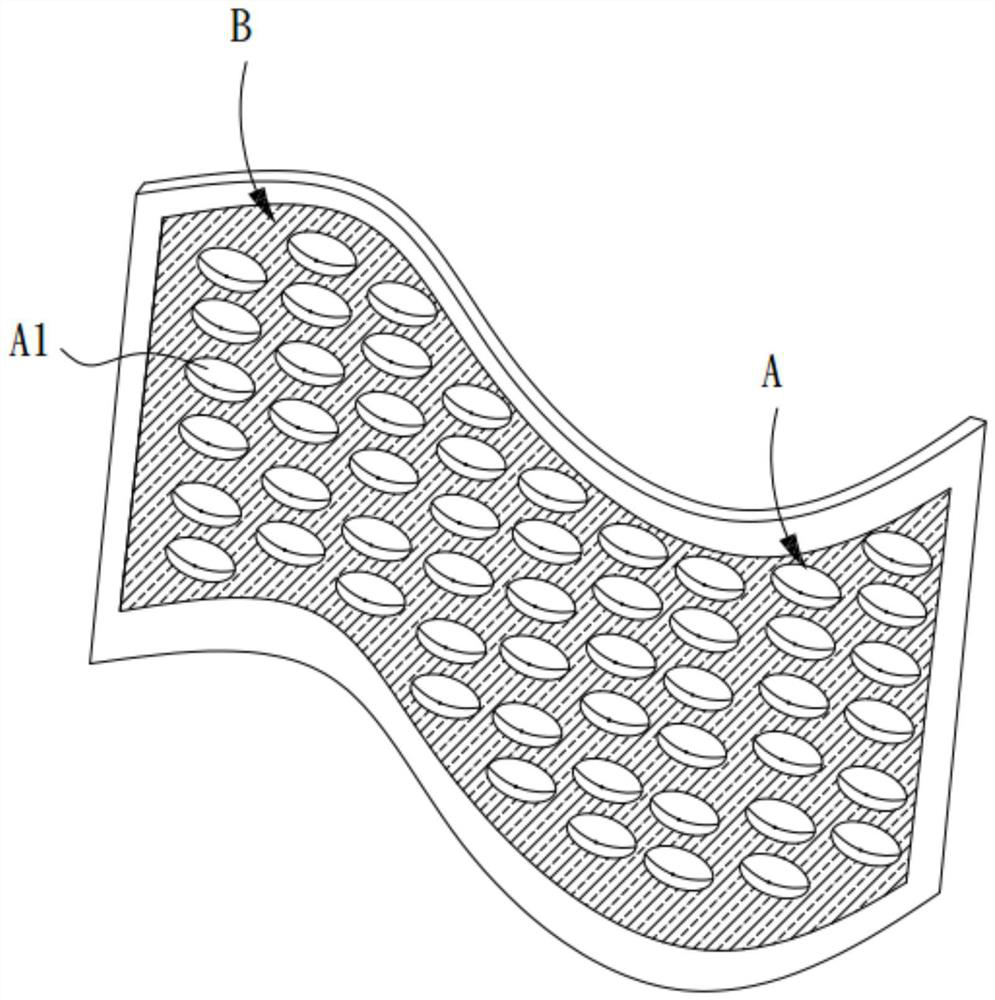

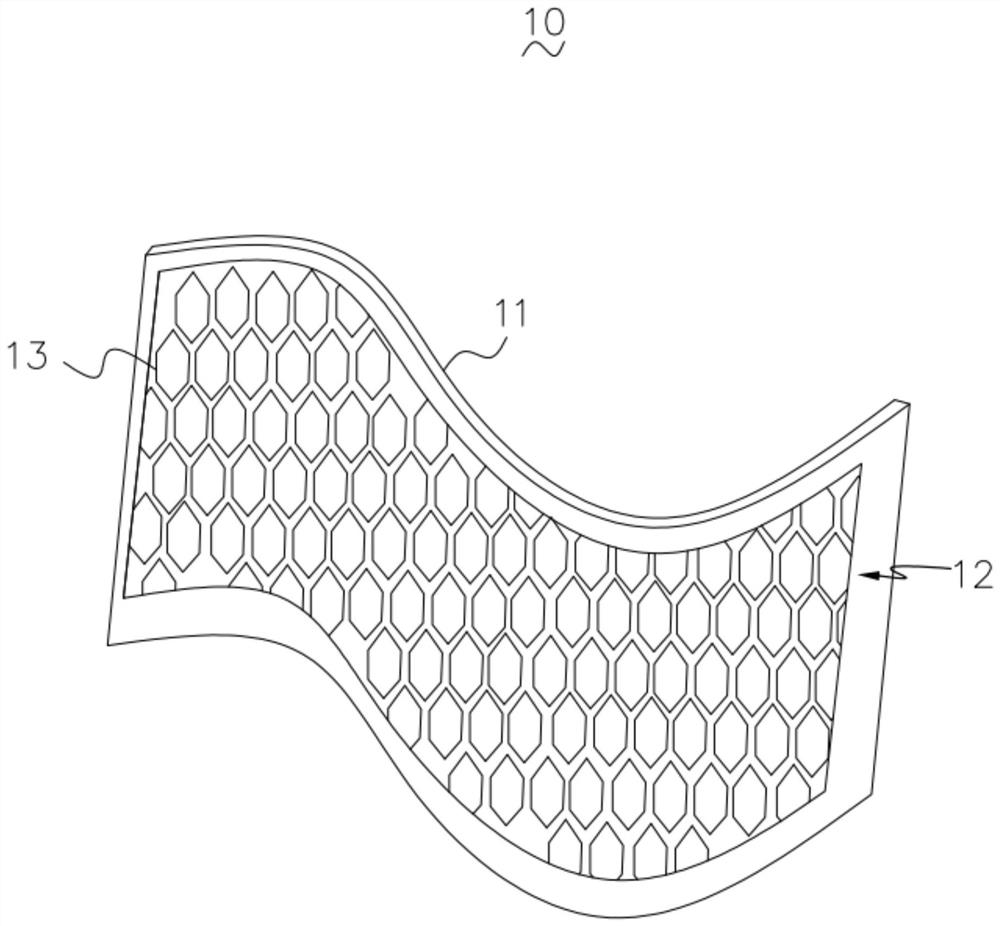

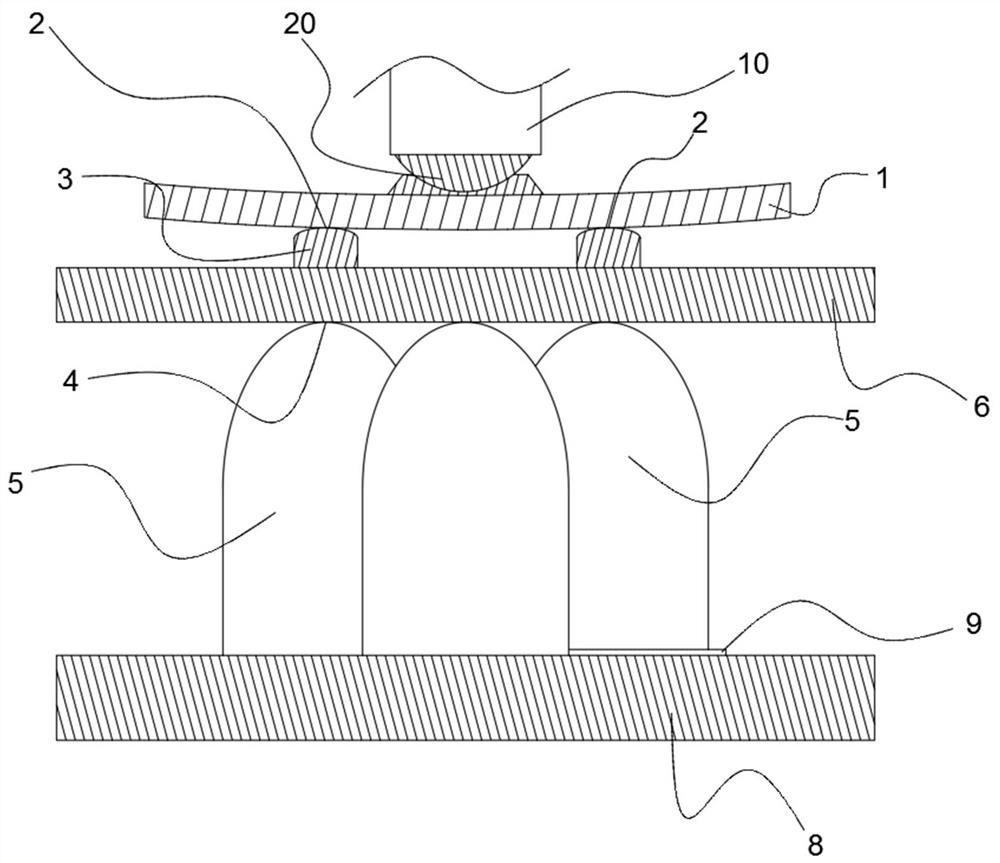

Full-recovery environment-friendly packaging structure and manufacturing method thereof

PendingCN110435219AAct as a protective bufferOvercoming problems that require separationPackage recyclingWrappersFull recoveryEngineering

The invention discloses a full-recovery environment-friendly packaging structure and a manufacturing method thereof. The packaging structure is applied to the packaging of express delivery, postal service and logistics and is composed of a paper plane structure, the plane structure comprises a first surface and a protective layer which is overlapped on the first surface, the protective layer comprises at least one layer of liner, and the liner is of a net structure formed by stretching paper materials after die cutting. The packaging structure provided by the invention overcomes the problems that in the prior art, for kraft paper bubble bags or envelopes, paper and plastic cannot be separated and recycled, and the environment is polluted. Meanwhile, the technical problems of environmentaldust pollution and poor air quality caused by adopting a powdery and granular soft structure as a buffer liner in the prior art are solved.

Owner:BETA SHENZHEN PACKAGE PRODS +1

Thread passing self-lubricating device capable of ensuring undamage of threads for knitting machine for textiles

InactiveCN112853600AGuaranteed lubrication effectBroaden applicationKnittingCircular discEngineering

The invention relates to the technical field of thread passing of textile machines, and discloses a thread passing self-lubricating device capable of ensuring undamage of threads for a knitting machine for textiles. The thread passing self-lubricating device comprises a fixed disc, wherein an air guide pipe is fixedly connected to the outer wall of a thread passing hole, a rotating plate is movably mounted on the inner wall of the air guide pipe, a baffle is fixedly mounted on the inner wall of the air guide pipe, an air bag is fixedly mounted at the top of the air guide pipe, a heating bin is fixedly mounted in the air bag, and an air outlet pipeline is fixedly mounted at the top of the air bag. After a thread control plate moves towards the inner side of a circle center, a through hole is conducted, air heated by the heating bin is discharged from the air outlet pipeline at the top, an air hole is formed in the air bag, and the air guide pipe faces dust in the thread passing hole to pump away the dust along with the air; sticky grease in an oil tank needs a certain time to drop, so that cleaning time is given, and the effect of automatically cleaning the dust in the thread control plate when the thread control plate is not clean is achieved.

Owner:杭州红玺科技有限公司

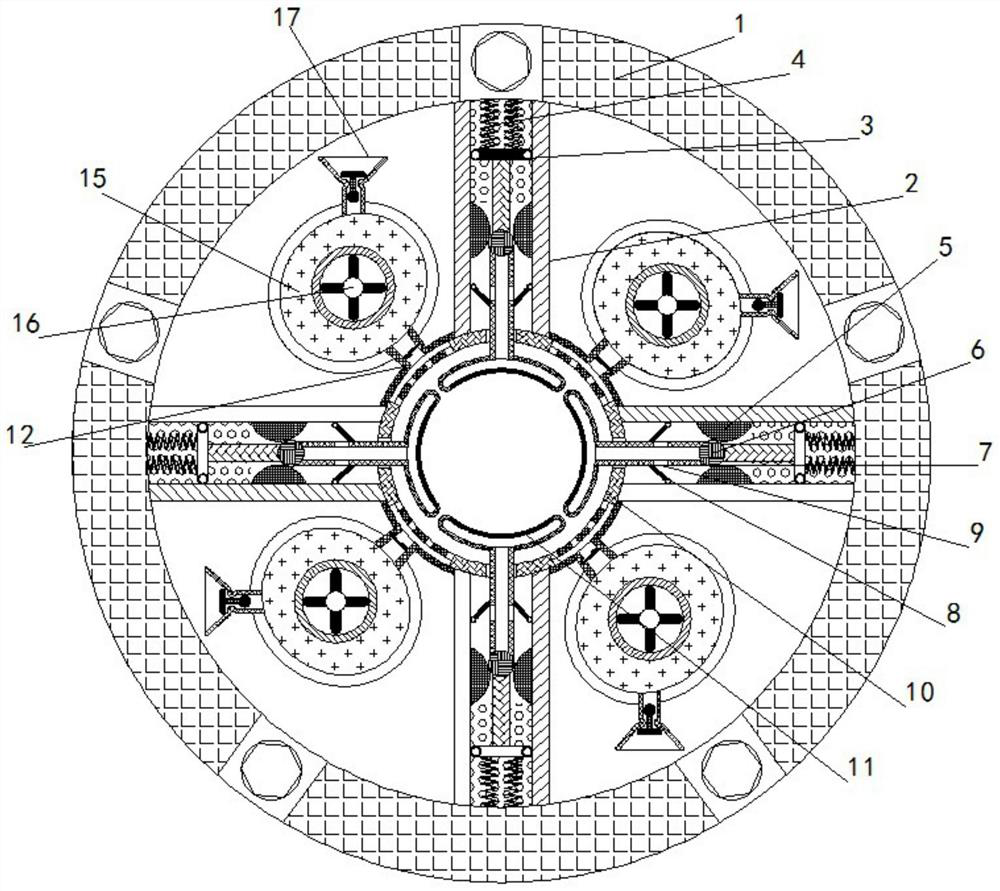

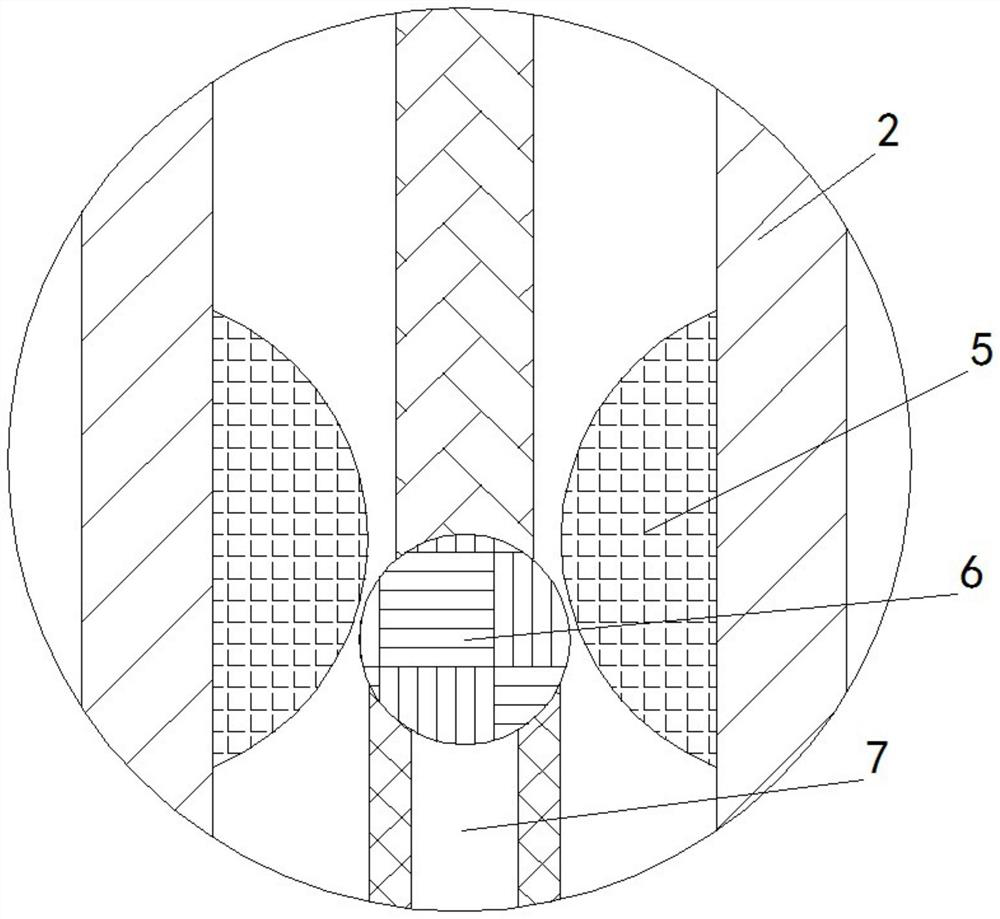

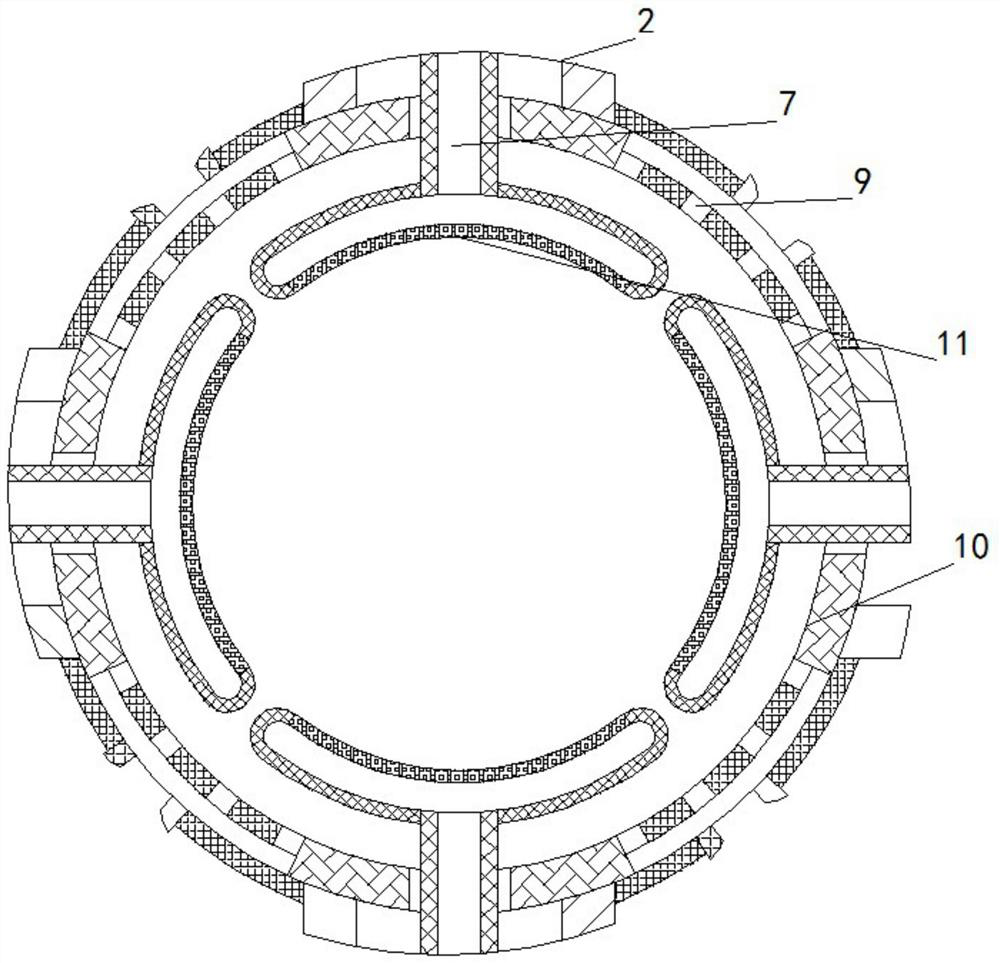

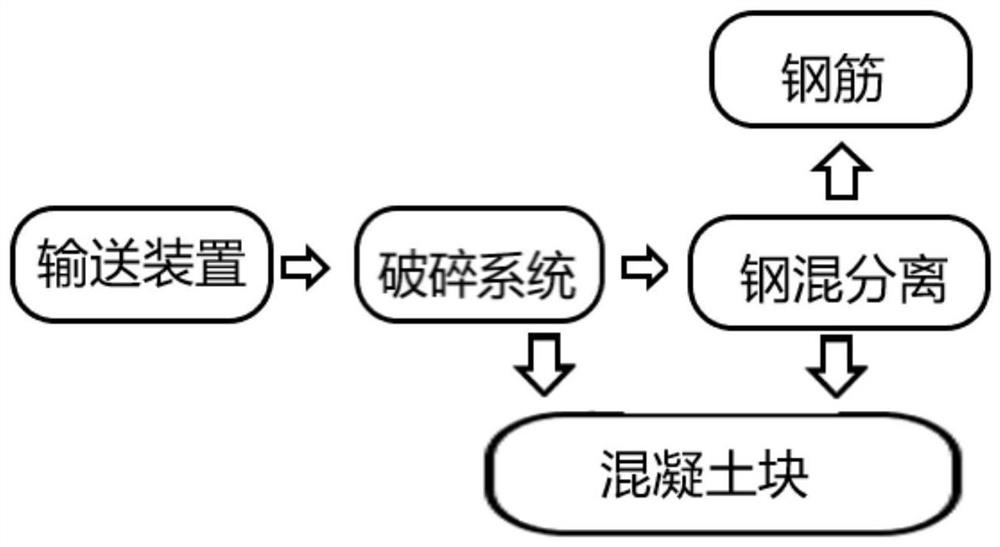

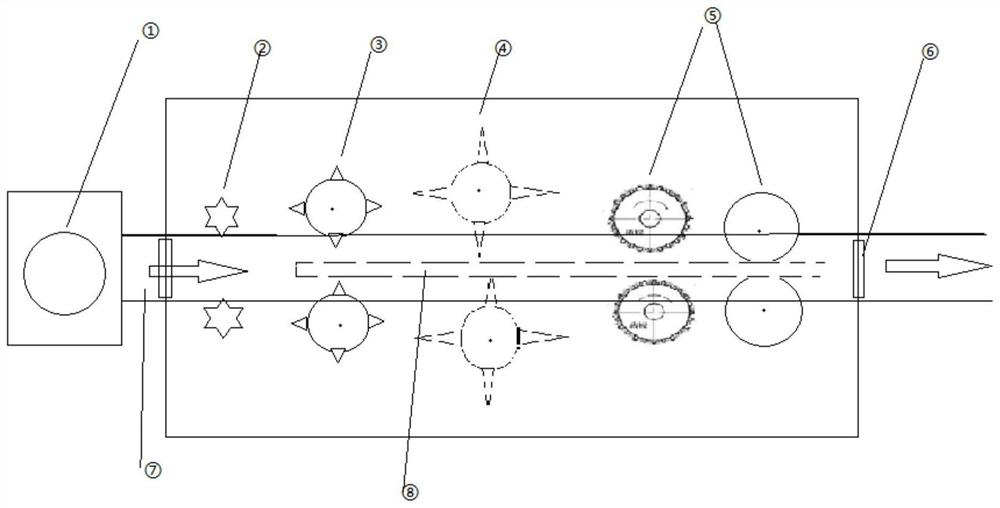

Efficient environment-friendly reinforced concrete beam column automatic crushing treatment process

ActiveCN113275115AEasy to separateGuaranteed against damageSolid waste managementGrain treatmentsConcrete beamsArchitectural engineering

The invention provides an efficient and environment-friendly reinforced concrete beam column automatic crushing treatment process which comprises the following steps that firstly, a reinforced concrete beam column is unloaded to the position of an unloading port and conveyed to an occlusion material conveying mechanism by an upper-layer conveying belt; secondly, the occlusion material conveying mechanism drives the reinforced concrete beam column to move front and back at a certain speed; thirdly, a surface layer crushing mechanism automatically shears stirrups in the reinforced concrete beam column and surface layer concrete; fourthly, an internal crushing mechanism automatically crushes deep concrete in the reinforced concrete beam column; and fifthly, steel bars and the concrete are separated through a separating mechanism. By designing conveying, crushing, vibrating and rolling, a reinforced concrete structure can be automatically crushed, the steel bars and the concrete can be fully separated, it is guaranteed that main bars in the reinforced concrete structure are not damaged, and the steel bar and concrete separation efficiency can be effectively improved by means of layered crushing and the like.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +1

Aqueous automobile framework and automobile motorcycle wheel surface protection coating

ActiveCN101139499BAvoid scratchesImprove aging resistanceLiquid surface applicatorsPolyester coatingsPolyesterEthyleneglycol monobutyl ether

The invention discloses a water protection coating for automobile skeletons and automobile and motorcycles wheels, which essentially comprises by weight the following components: acrylic acid modified polyester 20-55 portions, methylated amino resin 4-20 portions, colorant 2.5-30 portions, dispersing agent 1-9 portions, flatting agent 0.2-1 portions, defoaming agent 0.01-0.5 portions, solving assistant 1-5 portions, pure water 10-30 portions, ethyleneglycol monobutyl ether 5-12 portions, and thixotropic agent 1-3 portions. The film of the coating is of excellent weatherability, resistance to salt fog, resistance to acid and alkaline, resistance to water, resistance to scrubbing by solvent, excellent stiffness, high hardness and resistance to scratching, is of excellent protective and decorative role for automobile skeletons and automobile and motorcycles wheels.

Owner:仙居县鸿润涂料有限公司

Planting method of celery

InactiveCN107241987AEfficient killingInhibition of reproductionBiocidePlant growth regulatorsEconomic benefitsEntry time

The invention relates to a planting method of celery. The planting method includes the steps of firstly, preparing soil and furrowing; secondly, processing seeds; thirdly, sowing; fourthly, performing daily management. Experiments show that when the method is used for planting the celery, the germination rate and the seedling emergence time of the celery are increased greatly. In the prior art, the germination rate of the celery is 88.5%, the average seedling emergence time of the celery is 11 days; when the method is used for planting the celery, the germination rate of celery seeds reaches up to more than 95.8%, the average seedling emergence time of the celery is lowered to 6 days, the market entry time of the celery can be advanced greatly, and huge economic benefits are brought to farmers.

Owner:界首市民杰种植专业合作社

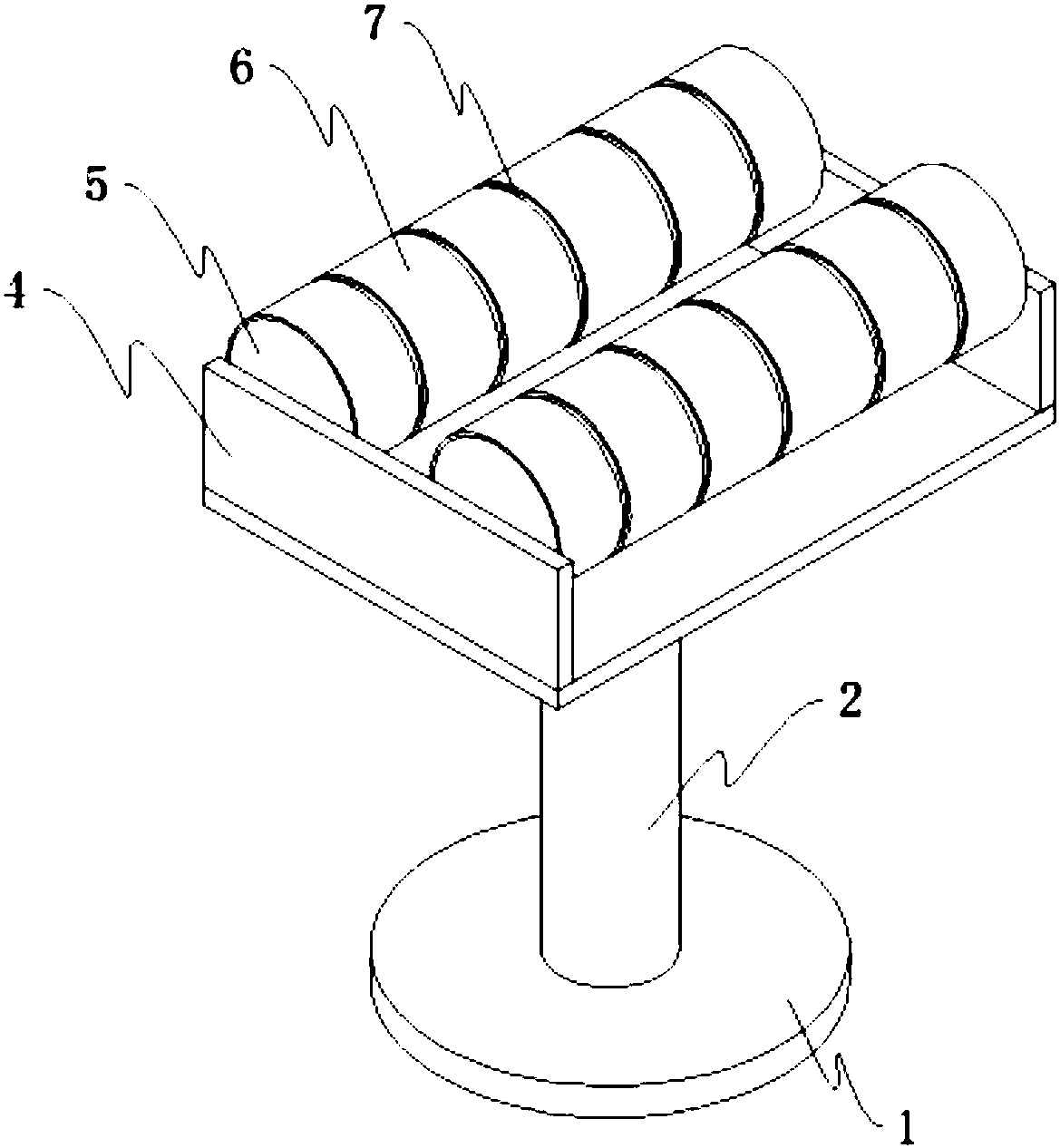

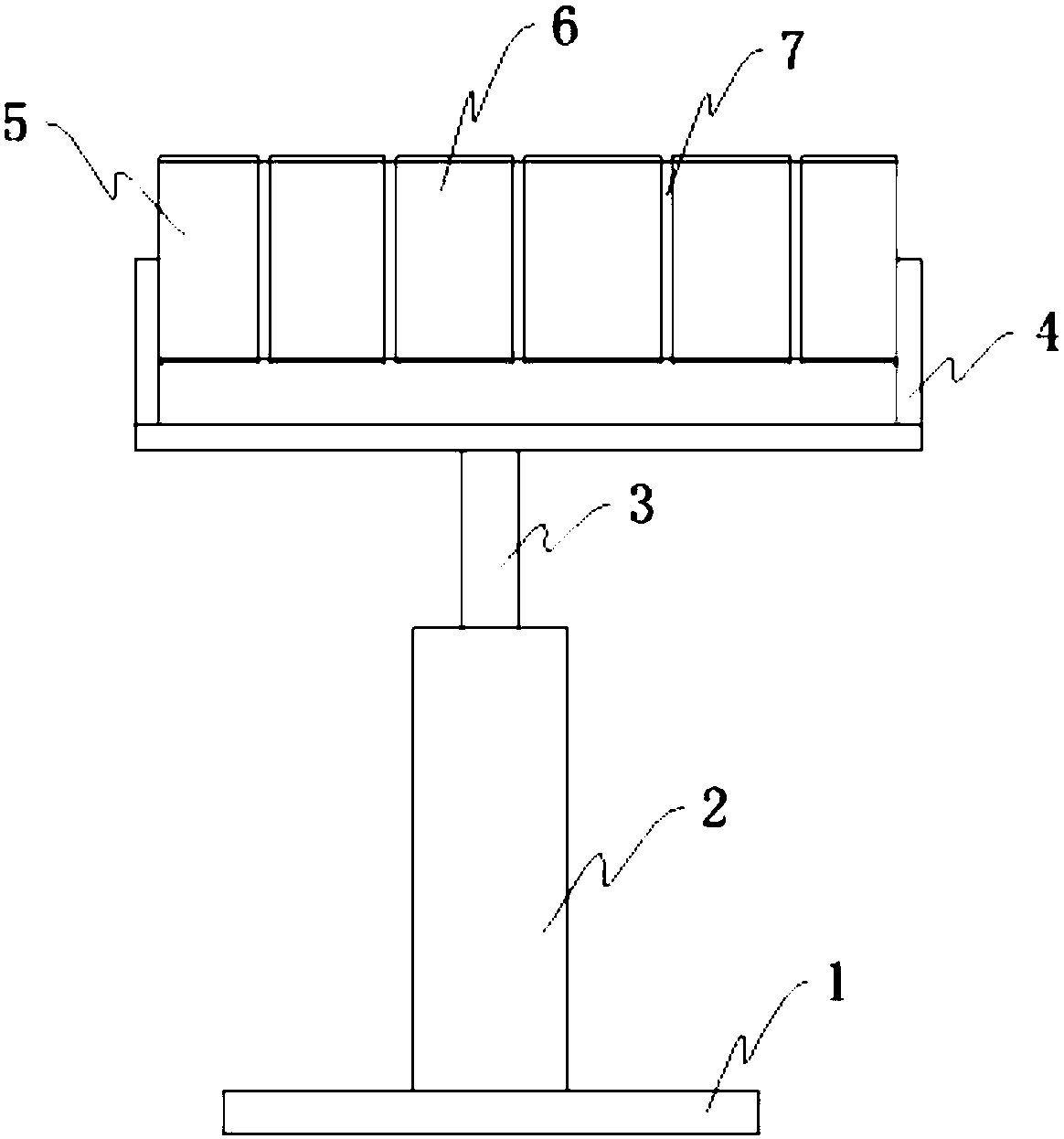

Wire bracket

InactiveCN108257776APrevent slippingAvoid entanglementInductances/transformers/magnets manufactureTransformerFixed frame

The invention discloses a wire bracket, which comprises a base, wherein the base is fixedly connected with a sleeve; a support column is arranged at the top end of the sleeve; an adjusting bolt used for adjusting the height of the support column is arranged at the connected part of the sleeve and the support column; the top end of the support column is fixedly connected with a fixing frame; the fixing frame is hinged with two wire rotating rods for cross winding of wires; a plurality of evenly distributed wire distribution devices sleeve the outer surface of each wire rotating rod; and a wireduct is formed between two adjacent wire distribution devices. Through the improvement, the wires can be prevented from sliding from a wire support shaft and a plurality of different wires can be separated to be prevented from being wound; and the height of the bracket can also be adjusted according to the change of a winding position, so that the condition that the wires are not damaged is ensured and the work efficiency is also improved. According to the wire bracket, the strength of a bracket body is high, a base is firm, the wire support shaft is smooth to run and the winding operation ofa transformer coil is greatly facilitated.

Owner:天津市纳斯特科技有限公司

Sludge drying system using combination of smoke residual heat and external heat supply source

InactiveCN1868936AReduce the temperatureEffective controlSludge treatment by de-watering/drying/thickeningBrickSludge

Owner:ZHEJIANG UNIV

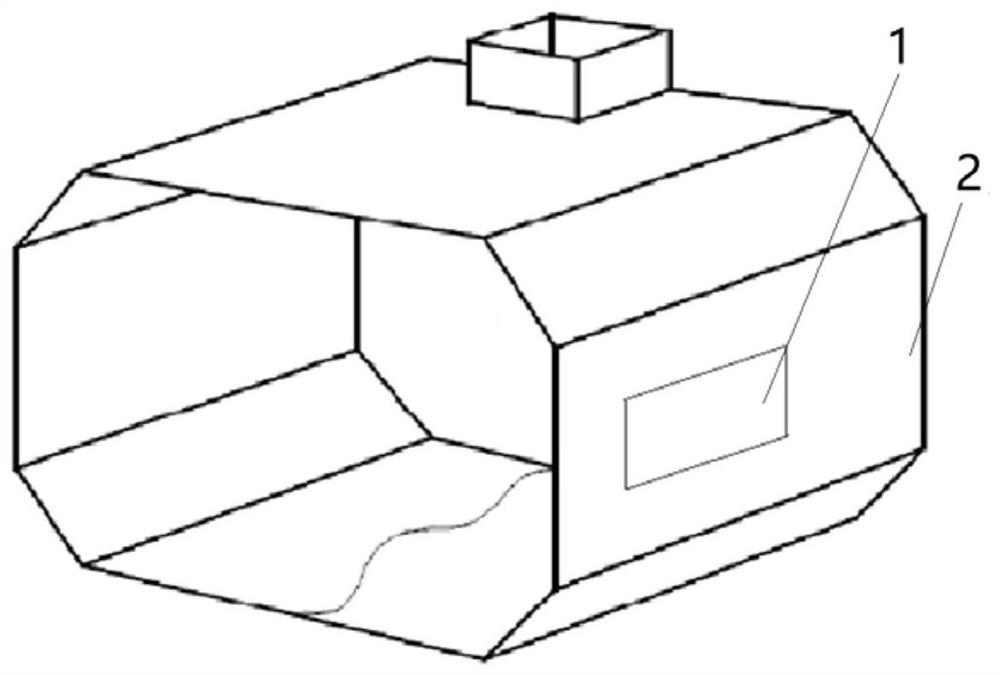

Fully recycled environment-friendly packaging structure

PendingCN113104398AAct as a protective bufferOvercoming problems that require separationFlexible coversWrappersLogistics managementProcess engineering

The invention discloses a fully recycled environment-friendly packaging structure. The packaging structure is applied to packaging of express delivery, postal service and logistics. The packaging structure is composed of a paper plane structure, wherein the plane structure comprises a first surface and a protective layer overlapped on the first surface; the protective layer comprises at least one layer of gasket; and the gasket is of a three-dimensional net structure. According to the packaging structure, the problem that in kraft paper bubble bags or envelopes in the prior art, paper and plastic cannot be separated and recycled, so that the environment is polluted is solved; and meanwhile, the technical problems of environmental dust pollution and poor air quality caused by the adoption of a powdery and granular soft structure as a buffer gasket in the prior art are solved.

Owner:BETA SHENZHEN PACKAGE PRODS +1

Sludge drying system using combination of smoke residual heat and two external heat supply sources

InactiveCN1868937AEffective controlReduce the temperatureSludge treatment by de-watering/drying/thickeningBrickSludge

Owner:ZHEJIANG UNIV

Sludge drying system using combination of smoke residual heat and external heat supply source

InactiveCN100429166CReduce the temperatureEffective controlSludge treatment by de-watering/drying/thickeningBrickSludge

Owner:ZHEJIANG UNIV

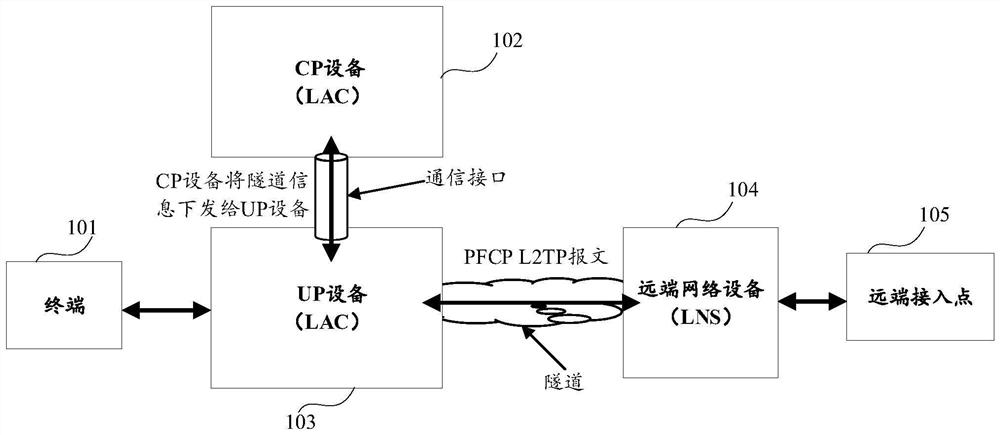

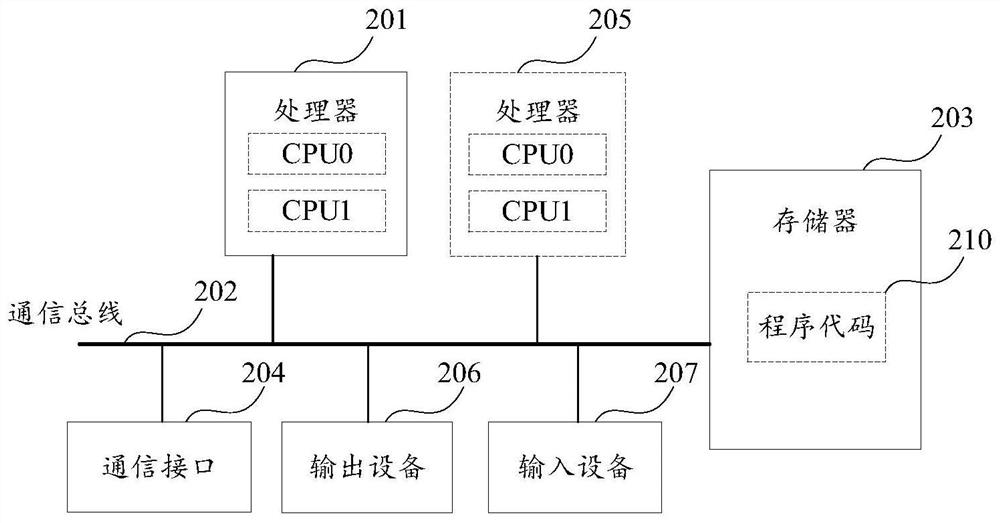

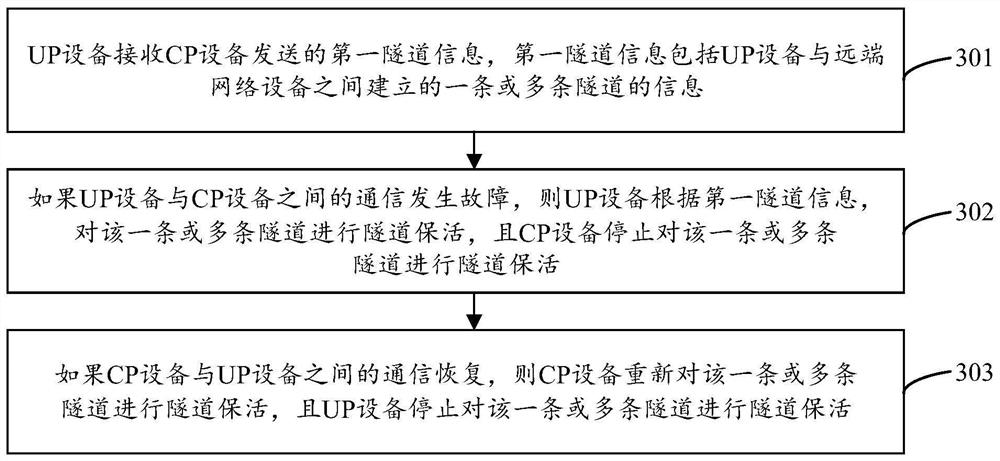

Tunnel keep-alive method, network equipment, system and storage medium

PendingCN114125910AGuaranteed against damageNo connection interruptionConnection managementBroadband local area networksReal-time computingElectrical and Electronics engineering

The embodiment of the invention discloses a tunnel keep-alive method, network equipment, a system and a storage medium, and belongs to the technical field of communication. In the embodiment of the invention, before the communication between the UP equipment and the CP equipment fails, the UP equipment receives the tunnel information synchronized by the CP equipment, and after the communication between the UP equipment and the CP equipment fails, the UP equipment performs tunnel keep-alive according to the tunnel information, namely, the UP equipment maintains the tunnel between the UP equipment and the remote network equipment. In this way, it is avoided that tunnel dismantling is triggered due to communication faults between the CP device and the UP device, it can be guaranteed that network connection between the terminal and the remote end is not interrupted, and it is also guaranteed that user services are not damaged.

Owner:HUAWEI TECH CO LTD

Nodulation-free furnace roller of roller-hearth type thermal treatment furnace

InactiveCN103667670AGuaranteed against damageGuaranteed DimensionsCharge manipulationFurnace typesFiberSlag

The invention discloses a nodulation-free furnace roller of a roller-hearth type thermal treatment furnace. The nodulation-free furnace roller comprises shaft necks, wherein the first and second shaft necks are respectively fixed on both sides of a roller body, a baffle is respectively fixed at one end of the first shaft neck and one end of the second shaft neck, and is located in the roller body, the shaft necks are connected with the other end of the first shaft neck, end caps are sleeved on the shaft necks, heat-resisting materials are filled in the first and second shaft necks, a first slag area is located outside the first shaft neck, a second slag area is located outside the second shaft neck, a bearing pedestal is located on one side of the second slag area and fixed together with a bearing, a coupler is connected with the bearing, and a motor is connected with the coupler. The roller body is made from ceramic fibers. The nodulation-free furnace roller disclosed by the invention can be used for solving the technical problem that the product quality is affected due to scratching of a heat treatment panel caused by swelling of the furnace roller and nodulation, and the surface of the heat treatment panel is not damaged.

Owner:浦杰

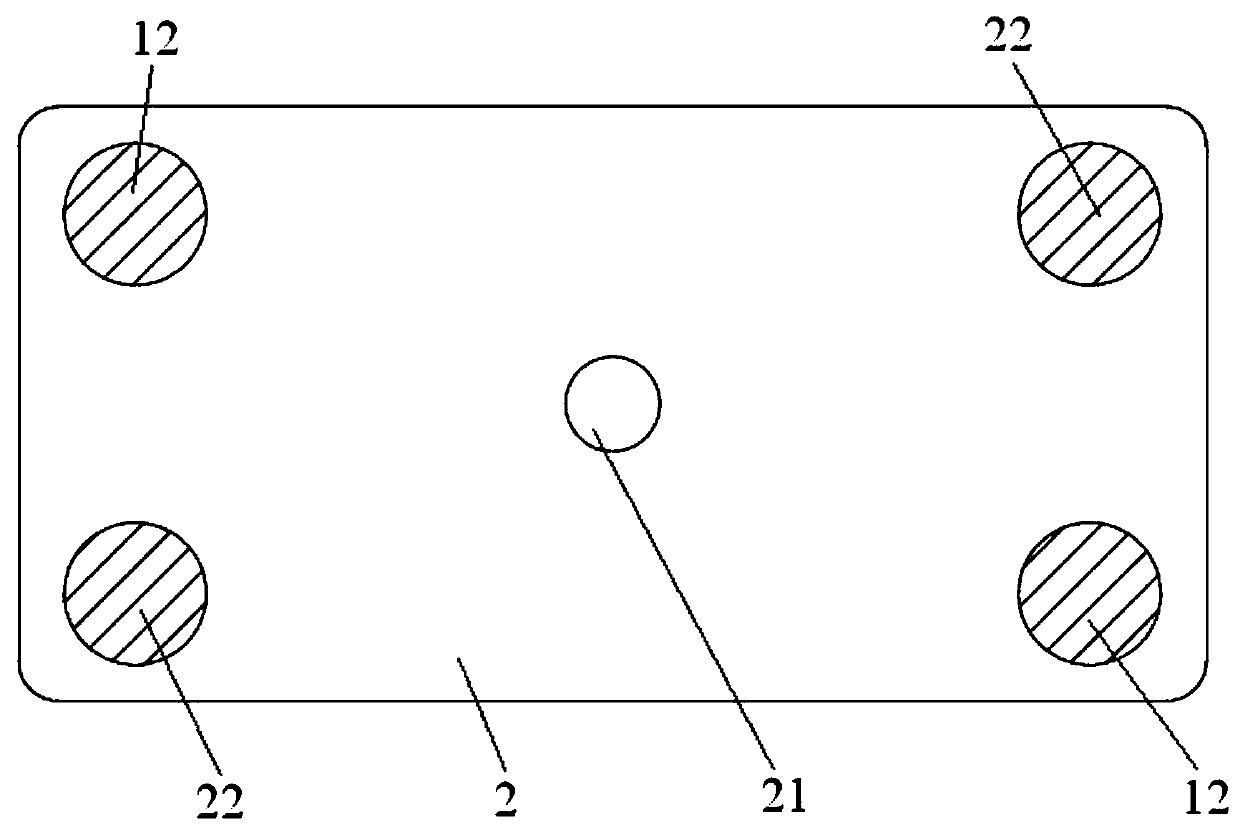

Multi-sensor parallel type force value measuring method

PendingCN113776708AGuaranteed against damageGuaranteed damageApparatus for force/torque/work measurementEngineeringMachine

The invention relates to a multi-sensor parallel type force value measuring method, which comprises the following steps of: 1, selecting a test press machine of which the output force value is matched with the measuring range of a single force sensor to apply pressure to the single force sensor, and calculating an elasticity coefficient k of the force sensor according to the deformation height after the force sensor is pressed and the pressure applied to the force sensor; 2, selecting at least four force sensors with the same elasticity coefficient for pressure detection of a press machine to be tested, vertically arranging the force sensors in parallel, and adjusting the heights of the top force bearing points of the force sensors to be consistent; and 3, applying pressure to the top force bearing points of the force sensors by a pressure head of the press machine to be tested through a force transmission plate. The technical problem that in the prior art, when more than three force sensors are used in parallel, uniform stress of all the force sensors cannot be guaranteed is solved.

Owner:HENAN PROVINCE INST OF METROLOGY

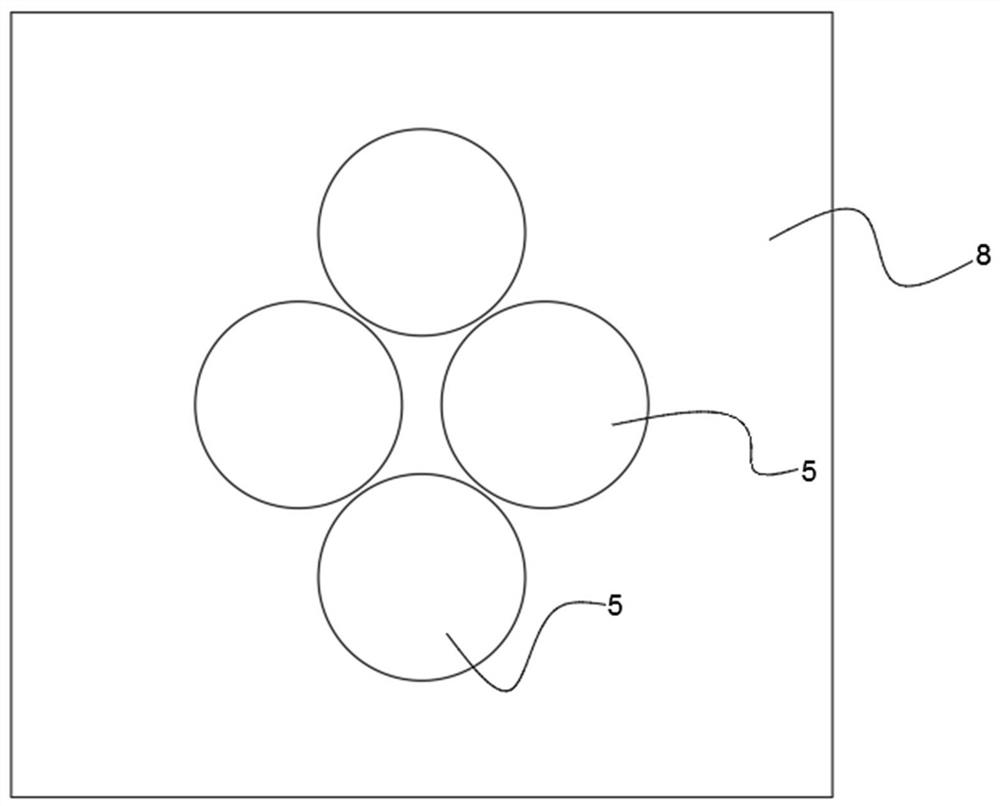

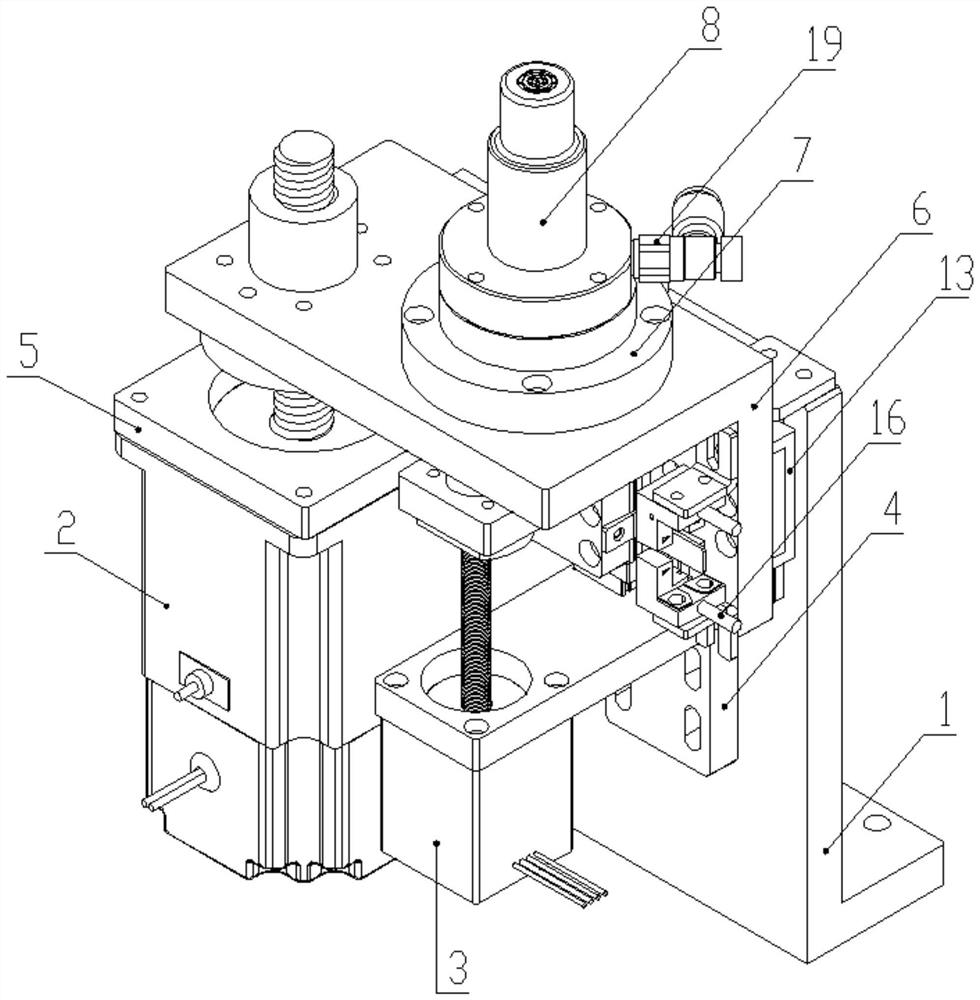

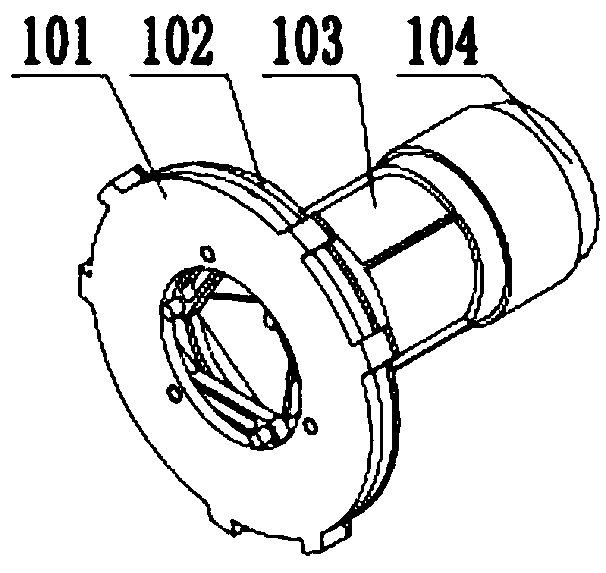

Blue film chip ejection device

PendingCN112885766AGuaranteed stabilityGuaranteed against damageSemiconductor/solid-state device manufacturingPhysicsElectric machinery

A blue film chip ejection device belongs to the technical field of chip assembly and comprises a mounting bottom plate, wherein a vacuum cover lifting plate capable of moving up and down is mounted on the mounting bottom plate, a vacuum cover is arranged on the vacuum cover lifting plate, an ejector pin is arranged at the top part of the vacuum cover, a vacuum cover lifting lead screw motor for driving the vacuum cover lifting plate to move up and down is further installed on the installation bottom plate, an ejector pin lifting lead screw motor for driving the ejector pin to move up and down is further installed on the installation bottom plate, the ejector pin is inserted into an ejector pin lifting rod, the ejector pin lifting rod is installed on an ejector pin installation plate, and a screw rod of the ejector pin lifting screw rod motor penetrates through the ejector rod mounting plate and then is connected through a nut. According to the blue film chip ejection device, the vacuum cover sucks a blue film and pulls down to drive a chip to move down to contact the ejector pin to eject the chip, and the vacuum cover sucks the blue film around the chip and pulls down to separate the chip from the blue film, so that the risk of crushing the chip is eliminated, and meanwhile, the risk of chip damage caused by overshoot due to the fact that the chip suction nozzle lags behind the ejector pin at the moment when the ejector pin ejects the chip is further eliminated.

Owner:CHENGDU TSUHAN SCI & TECH

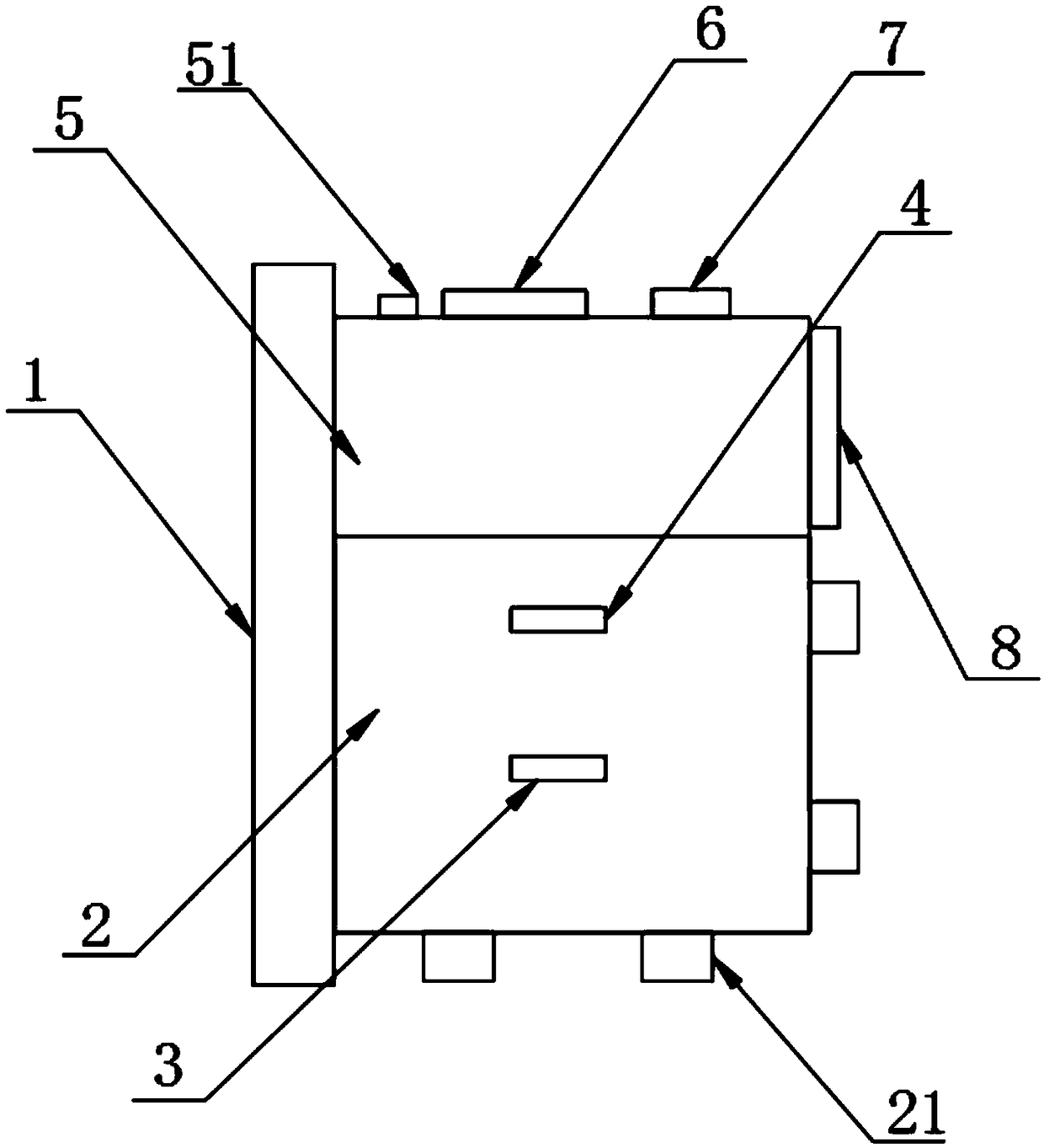

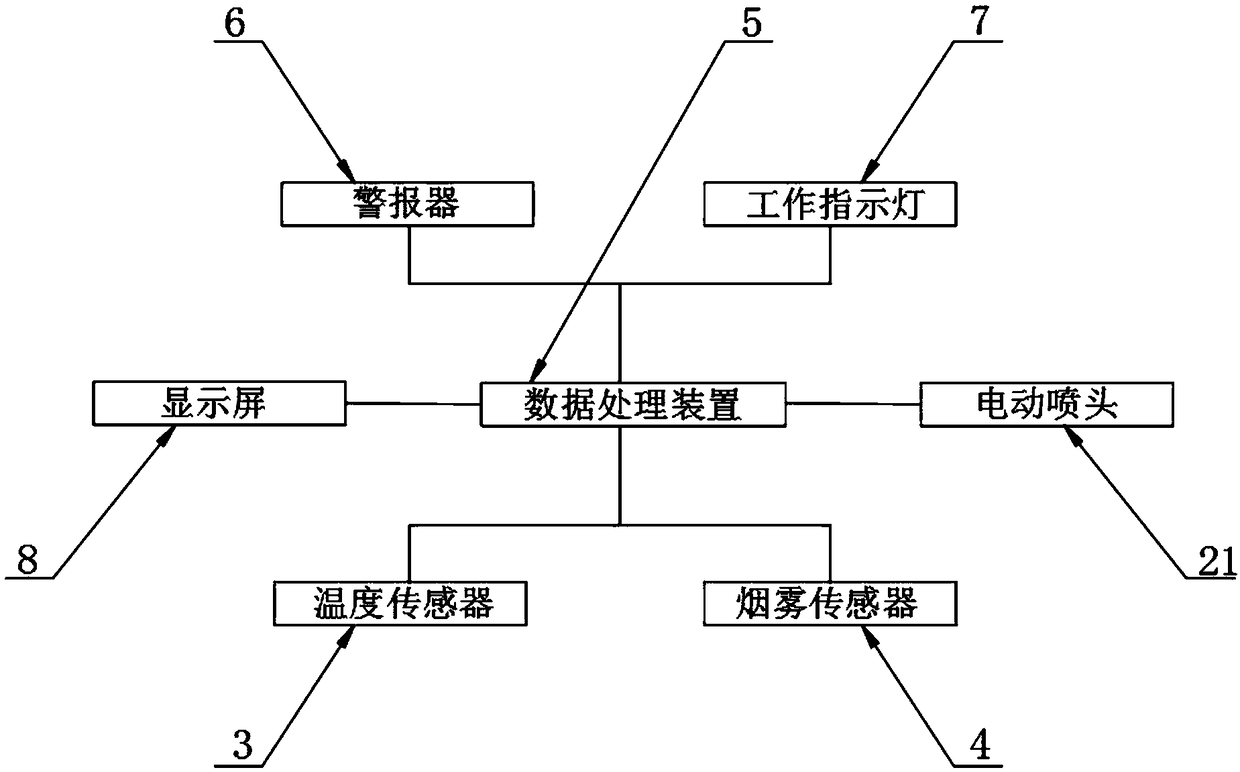

In-kitchen early warning device

InactiveCN108648404AGuaranteed against damageAvoid accidentsFire alarm electric actuationFire alarm smoke/gas actuationEmergency treatmentEngineering

The invention discloses an in-kitchen early warning device. The device comprises a mounting plate, wherein a water storage chamber is formed in one side of the mounting plate, the front side and backside surfaces of the water storage chamber are both provided with temperature sensors, the top of each temperature sensor is provided with a smoke sensor, the top of the water storage chamber is provided with a data processing device, the top of the data processing device is provided with an alarm device, one side of the alarm device is provided with a working indicator light, and one side of thedata processing device is provided with a display screen. The in-kitchen early warning device has the advantages that the temperature sensors and the smoke sensors are arranged to detect the temperature in a kitchen respectively and whether or not a large amount of smoke appears, and transmit detection data to the data processing device in real time, and when the temperature is too high or a largeamount of smoke occurs, the data processing device controls the alarm device to sound to remind a user to perform emergency treatment to avoid accidents.

Owner:安徽西曲智能科技有限公司

An optical disc inner hole pickup device

ActiveCN107591169BGuaranteed against damagePrevent fallingRecord information storageRecord carrier contruction detailsEngineeringAirbag

Owner:BEIJING ZHONGKE KAIDI SOFTWARE CO LTD

A method for separating rare earth phosphor from electronic waste powder

ActiveCN104673270BEasy to separateSimple and fast operationRecycling and recovery technologiesLuminescent compositionsRare-earth elementPhosphor

The invention discloses a method for separating rare-earth fluorescent powder from electronic waste powder. The method comprises the following steps: 1, screening the electronic waste powder, thereby obtaining fine electronic waste particles; 2, conveying the fine electronic waste particles into a fine particle separation device for performing secondary separation, thereby obtaining the materials subjected to secondary separation; 3, performing powder slurry treatment on the materials subjected to secondary separation, allowing the materials to pass through a water sieve, and taking the screen underflow, thereby obtaining wet materials; and 4, sequentially carrying out washing, suction filtration, drying, grinding and screening the wet materials, thereby obtaining the rare-earth fluorescent powder of which the quality purity is not less than 98 percent. According to the method disclosed by the invention, the rare-earth fluorescent powder of which the quality purity is not less than 98 percent can be separated, the mass content of rare earth oxides in the rare-earth fluorescent powder of which the quality purity is not less than 98 percent is not less than 28 percent, the rare earth elements in the rare-earth fluorescent powder can be further conveniently separated by rare-earth purification enterprises, and the method is environmentally friendly, easy and convenient to operate and suitable for popularization and application.

Owner:SHAANXI ANXIN KINESCOPE CIRCULATION PROCESSING APPL

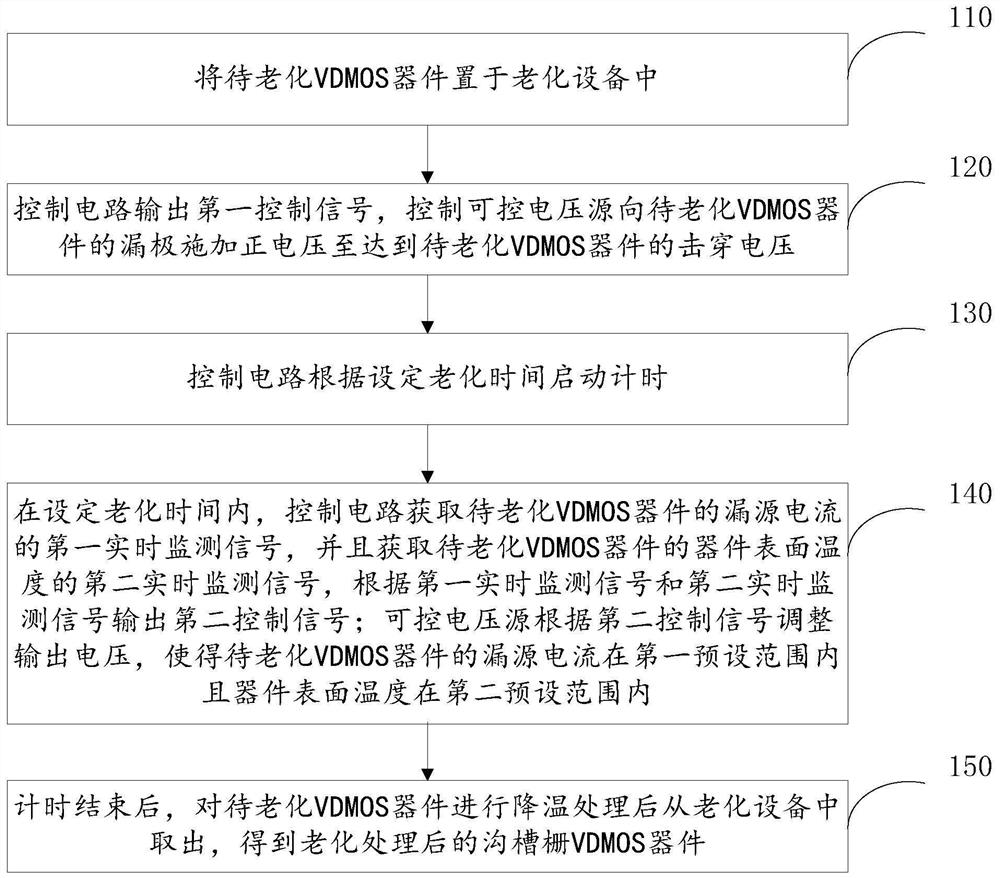

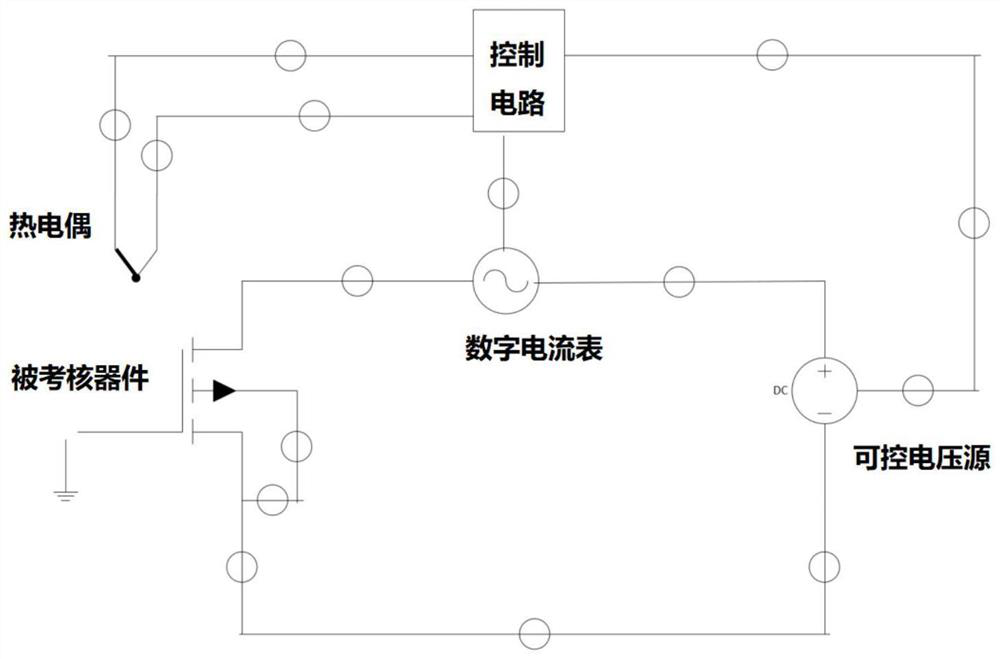

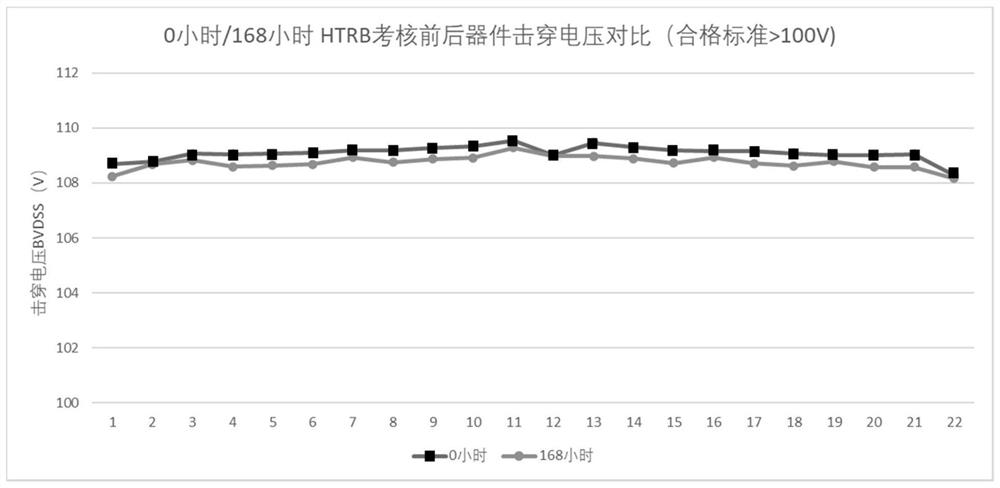

Method for aging trench gate VDMOS device and aging equipment

PendingCN111983416ARealize aging assessment screeningControl the actual breakdown voltageSemiconductor operation lifetime testingControl signalVoltage source

The embodiment of the invention relates to a method for aging a trench gate VDMOS device and aging equipment. The method comprises the following steps: enabling a control circuit to output a first control signal, and controlling a controllable voltage source to apply a positive voltage to a drain electrode of a to-be-aged VDMOS device till the positive voltage reaches a breakdown voltage of the to-be-aged VDMOS device; within the set aging time, enabling the control circuit to acquire a first real-time monitoring signal of the drain-source current of the to-be-aged VDMOS device, acquiring a second real-time monitoring signal of the device surface temperature of the to-be-aged VDMOS device, and outputting a second control signal according to the first real-time monitoring signal and the second real-time monitoring signal; enabling the controllable voltage source to adjust the output voltage according to the second control signal to enable the drain-source current of the to-be-aged VDMOSdevice to be within a first preset range and the surface temperature of the device to be within a second preset range; and after timing is finished, cooling the to-be-aged VDMOS device, and taking out the to-be-aged VDMOS device from the aging equipment to obtain the aged trench gate VDMOS device.

Owner:无锡摩斯法特电子有限公司

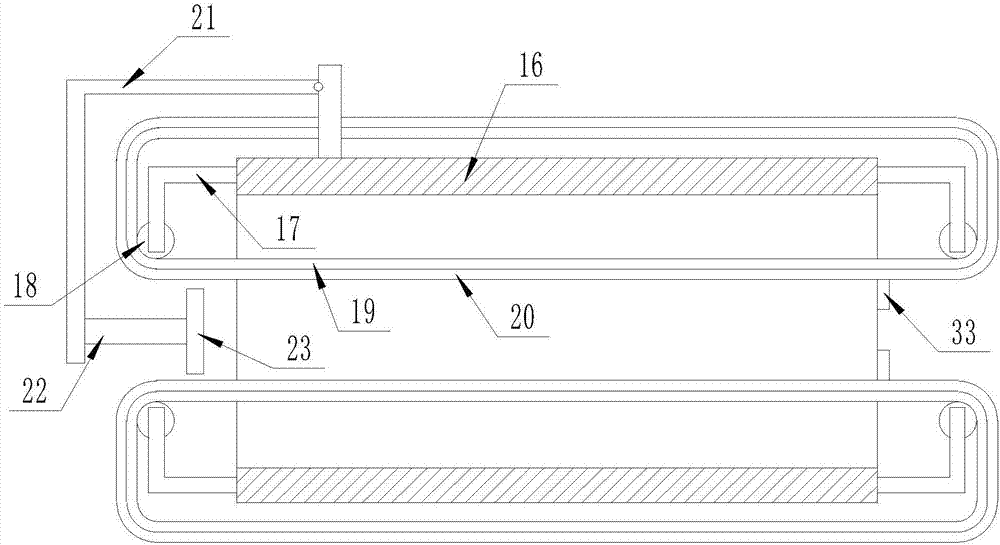

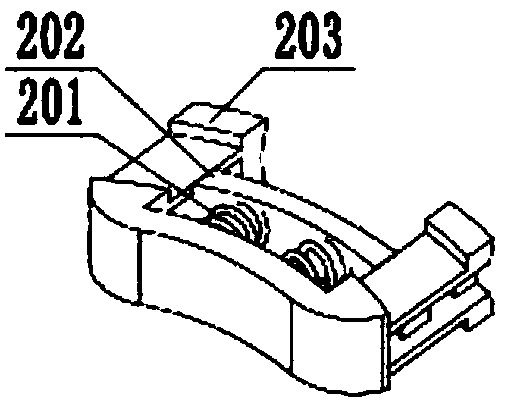

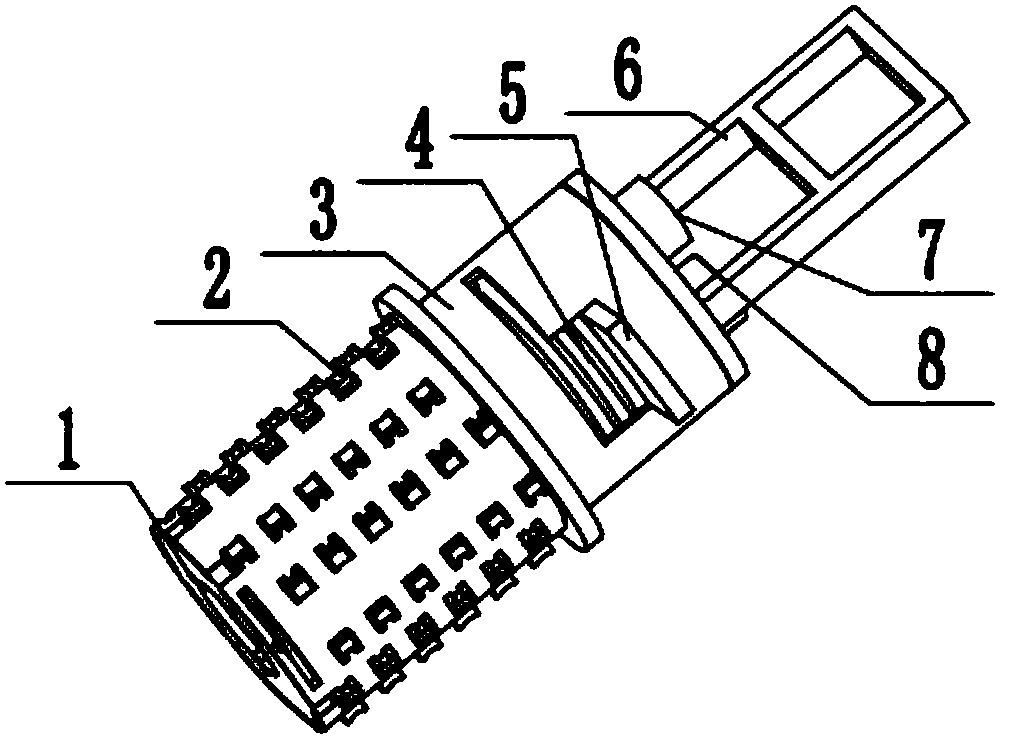

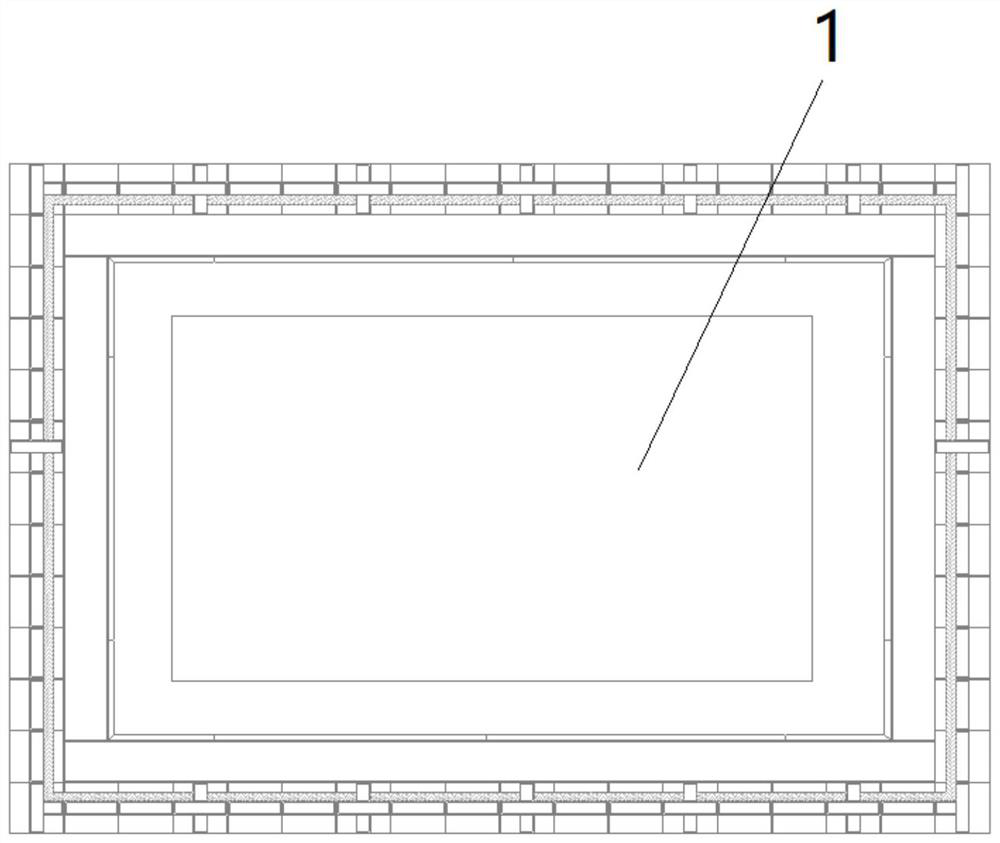

Disk inner hole pickup device

ActiveCN107591169AGuaranteed against damagePrevent fallingRecord information storageRecord carrier contruction detailsEngineeringAirbag

A disk inner hole pickup device belongs to the field of daily necessities. The disk inner hole pickup device includes a protection device, elastic ejector blocks, an outer pipe, an airbag expansion device, a handle, a pressure plate, an opening button, and a closing button. The protection device is fixed inside the lower end of the outer pipe. The elastic ejector blocks are arranged in three columns, and are distributed in a circumferential array on the cylindrical surface of the lower end of the outer pipe. The airbag expansion device is placed inside the outer pipe. The lower end of the pressure plate is connected with the airbag expansion device, and the upper end of the pressure plate is connected with the outer pipe. The handle is fixed to the upper end of the outer pipe. The openingbutton and the closing button are symmetrically distributed at the upper end of the handle. A disk can be picked up quickly by supporting the inner hole without contacting the surface of the disk, and12 disks can be picked up at a time. The device has the advantages of simple structure, low cost, and less space occupation. The device is not in contact with a disk except the inner hole, and ensures that disks are not damaged.

Owner:BEIJING ZHONGKE KAIDI SOFTWARE CO LTD

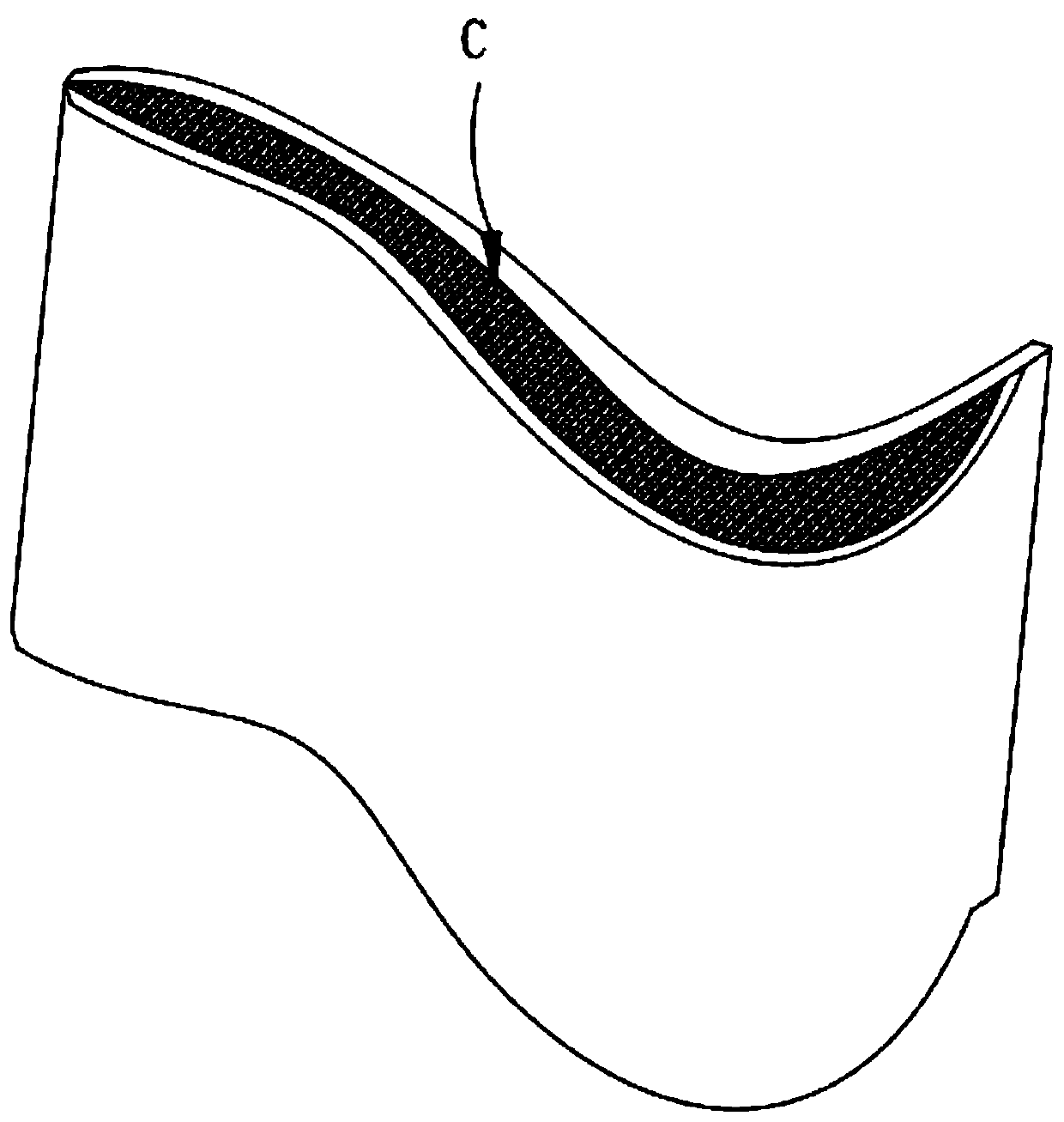

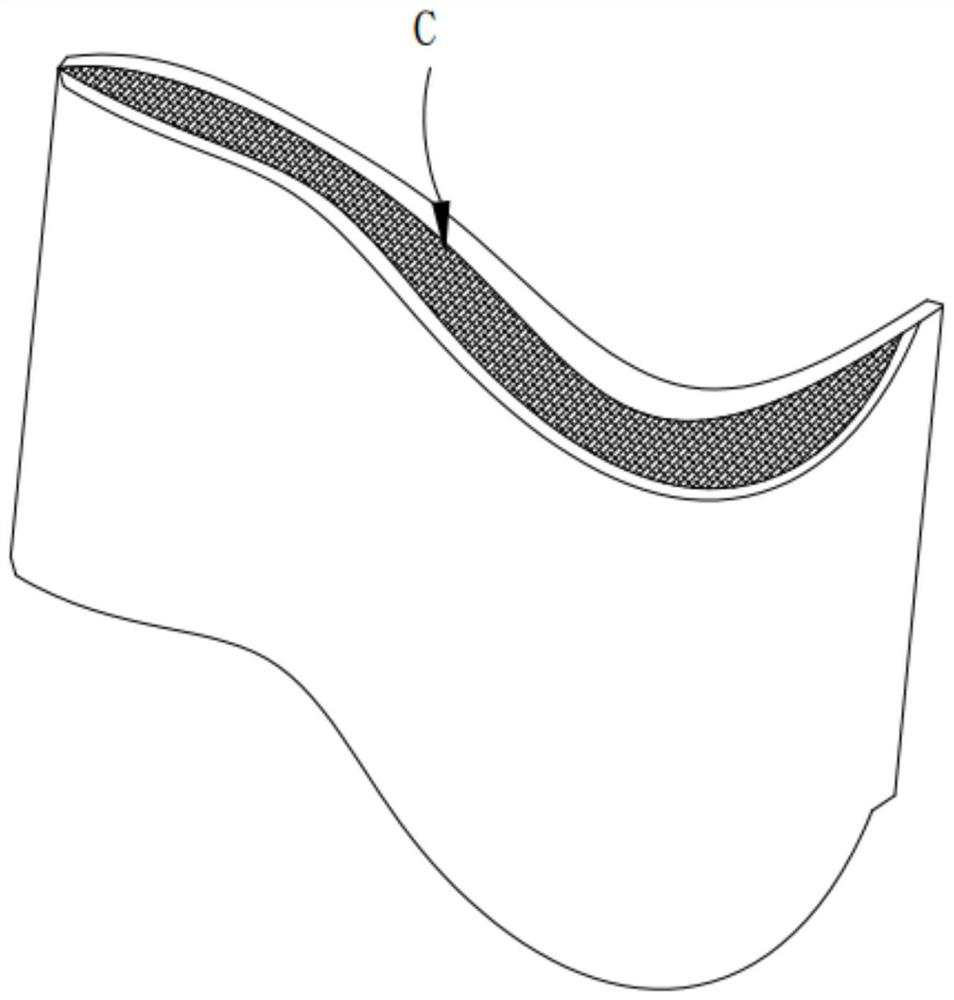

Installation process of liquid cargo tank broadside temporary insulation module

PendingCN112173036AEasy to installGuaranteed against damageWaterborne vesselsClear adhesive tapeAdhesive glue

The invention provides an installation process of a liquid cargo tank broadside temporary insulation module. The liquid cargo tank broadside temporary insulation module is installed at the end part ofa conventional insulation module, and the end part of the conventional insulation module is of a big-end-down stepped structure. The installation process comprises the following steps: 1, installinga temporary sub-layer insulation module along the periphery of a broadside opening; 2, installing a secondary-layer apron board along the periphery of the broadside opening, wherein the upper end surface of the secondary-layer apron board is as high as the conventional secondary-layer insulation module; 3, mounting temporary main layer insulation modules along the periphery of the broadside opening; and 4, mounting a main-layer apron board along the periphery of the broadside opening, wherein the upper end surface of the main-layer apron board is as high as the conventional main-layer insulation module. During installation, smeared resin and glue do not make direct contact with the temporary secondary-layer insulation module and the temporary main-layer insulation module and are mixed withtransparent adhesive tape or kraft paper, so that disassembly is convenient, damage to the temporary secondary-layer insulation module and the temporary main-layer insulation module is avoided, and the temporary secondary-layer insulation module and the temporary main-layer insulation module can be repeatedly used.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com