Sludge drying system using combination of smoke residual heat and two external heat supply sources

A flue gas waste heat and sludge drying technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of being difficult to be used, unable to meet the energy requirements of dried sludge, scattered and small in quantity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

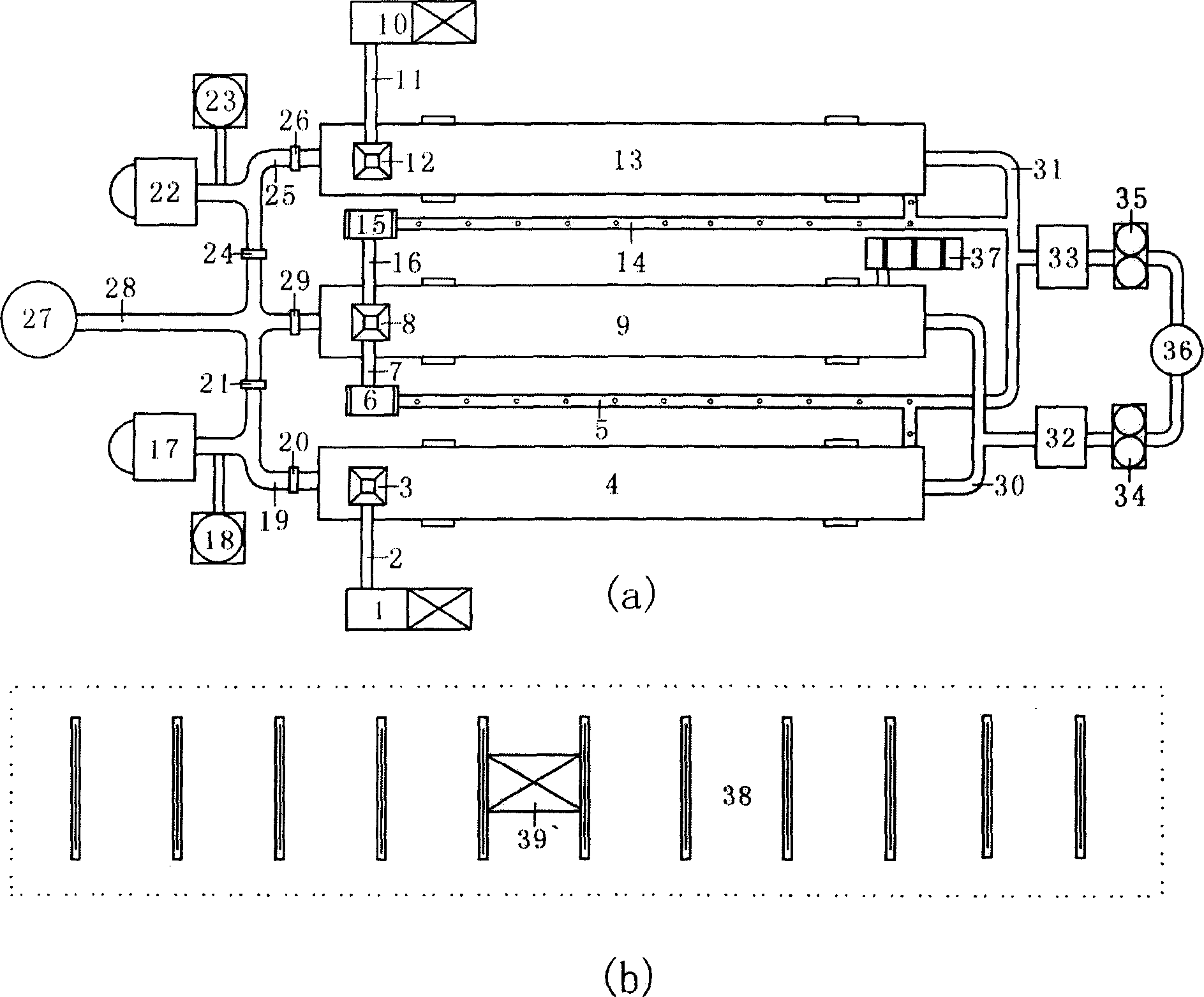

[0015] Such as figure 1 As shown, the sludge drying system using the composite energy of flue gas waste heat and external heating has subsystems such as heating system, sludge pretreatment system, feeding system, sludge drying and granulation system, and dust removal and gas removal.

[0016]The heating system has a first fluidized furnace 17, a second fluidized furnace 22, a first temperature regulator 18, a second temperature regulator 23, a first ventilation duct 19, a second ventilation duct 25, a first damper 20, a second damper 21, The heat energy provided by the third damper 26, the fourth damper 24, the fifth damper 29, the first induced draft fan 27, the flue 28, and the first fluidized fluidized furnace 17 is controlled at 200-400° C. by the first temperature regulator 18, and is controlled by the first temperature regulator 18. The first wind 20 controls the amount of hot air, and sends it into the first rotary drying kiln 4 through the first ventilation duct 19, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com