Nodulation-free furnace roller of roller-hearth type thermal treatment furnace

A heat treatment furnace, roller hearth technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems affecting product quality and achieve the effect of increasing furnace energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

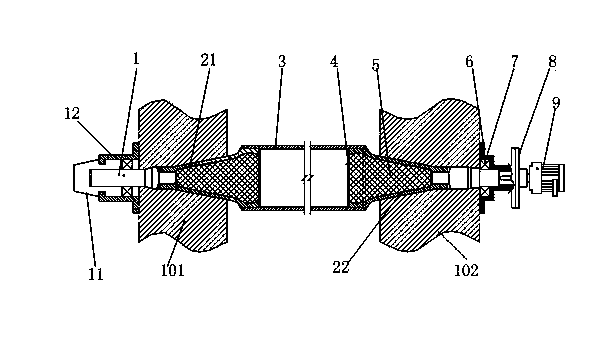

[0011] Such as figure 1 As shown, the nodulation furnace roll of the roller hearth heat treatment furnace of the present invention includes a journal 1, a first journal 21, a second journal 22, a roll body 3, a baffle 4, a heat-resistant material 5, a bearing seat 6, a bearing 7. Coupling 8, motor 9, first slag zone 101, second slag zone 102, end cover 11, first journal 21, second journal 22 respectively fixed to both sides of the roll body 3, a baffle plate 4 are respectively fixed on one end of the first journal 21 and one end of the second journal 22 and are located in the roll body 3, the journal 1 is connected to the other end of the first journal 21, the end cover 11 is set on the journal 1, Both the first journal 21 and the second journal 22 are filled with heat-resistant materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com