Multi-sensor parallel type force value measuring method

A measurement method and multi-sensor technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problem that the force sensor cannot be guaranteed uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

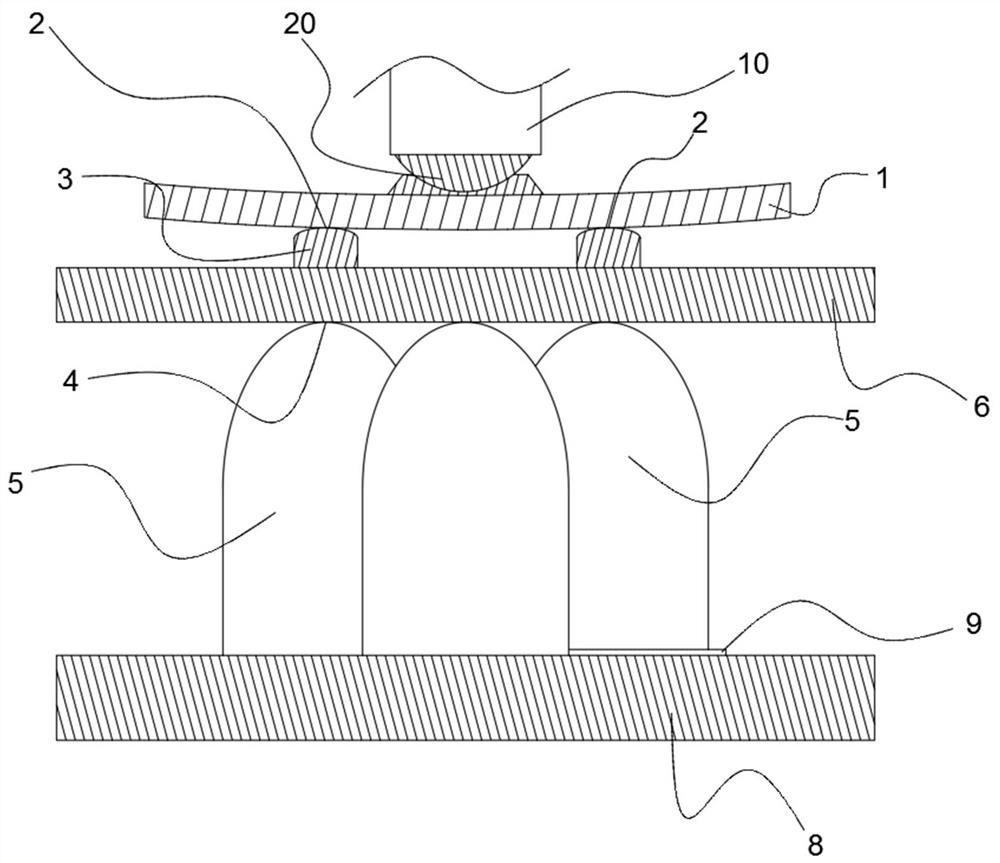

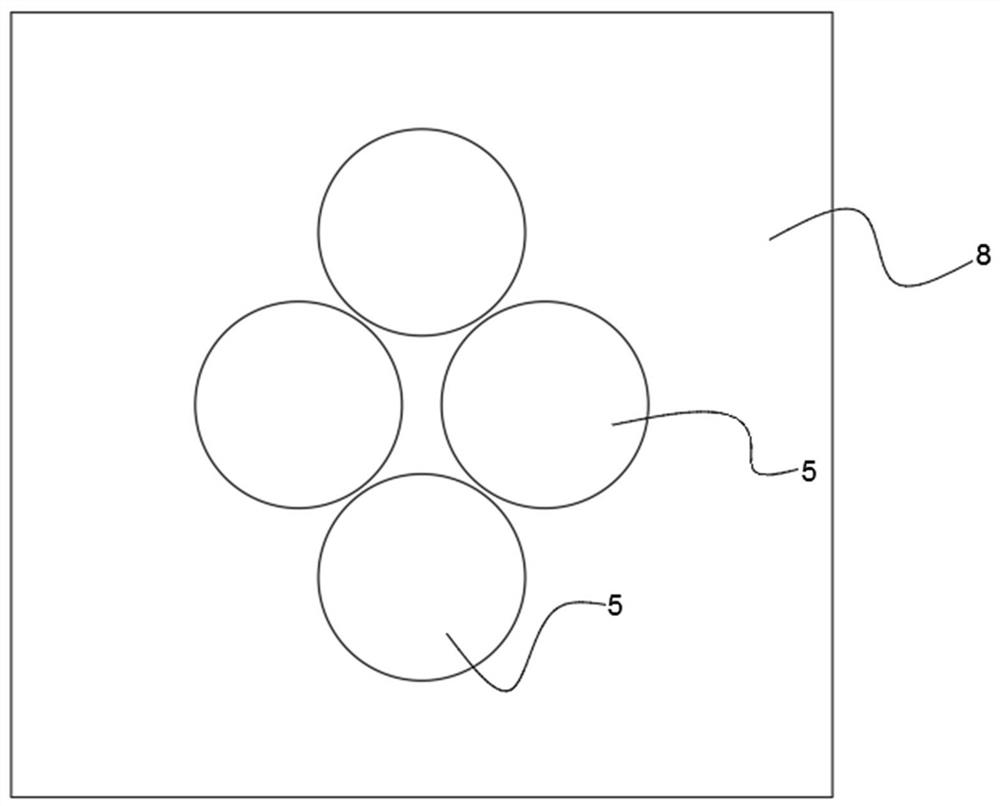

[0016] Embodiments of the multi-sensor parallel force measurement method in the present invention are as follows: Figure 1~2 As shown: the method includes the following steps. In the first step, a test press whose output force value matches the measurement range of a single force sensor 5 is selected to apply pressure to a single force sensor. Calculate the elastic coefficient k of the force sensor under the pressure; the second step, select four force sensors 5 with the same elastic coefficient for pressure detection of the press to be measured, each force sensor 5 is vertically arranged side by side, each force sensor, along the Circumferentially arranged in sequence, adjust the height of the top force point 4 of each force sensor to be consistent. In the third step, the indenter 10 of the press to be measured applies pressure to the top force point 4 of each force sensor through the force transmission plate.

[0017] In the first step above, the matching of the output forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com