Patents

Literature

40results about How to "Damage will not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

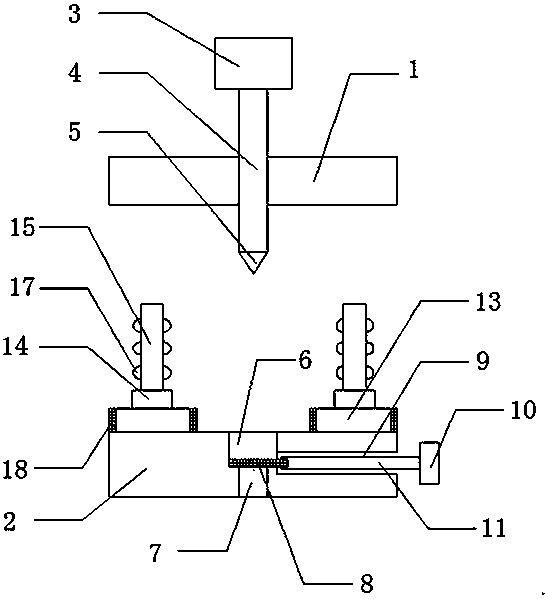

Testing device for resin matrix composite material heat mold pressing curing deformation and manufacturing and using method thereof

ActiveCN104315990AReduce difficultyAvoid damageUsing optical meansSpecial purpose recording/indication apparatusTemperature resistanceStrain sensor

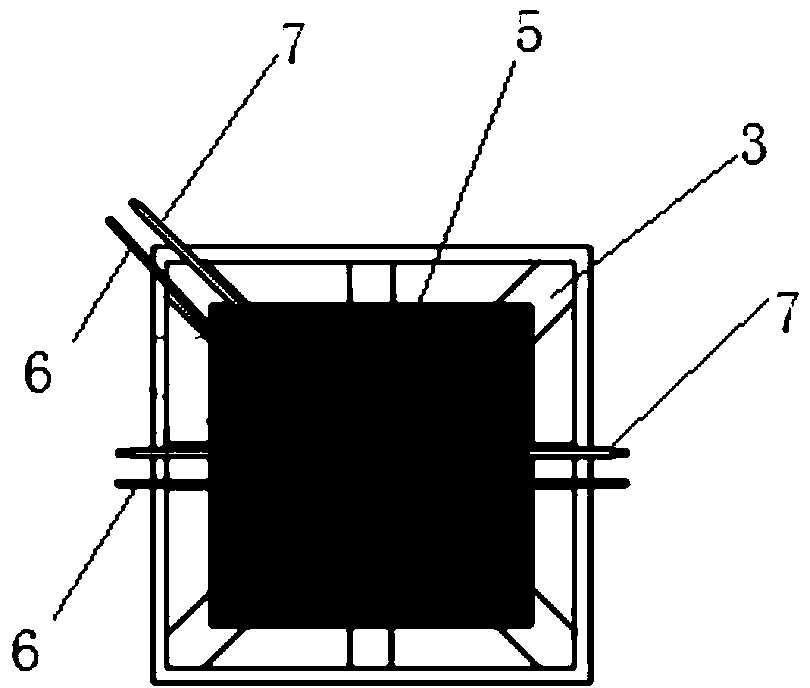

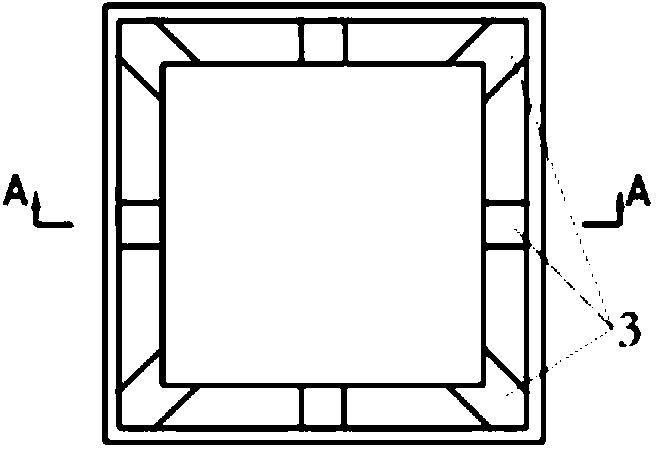

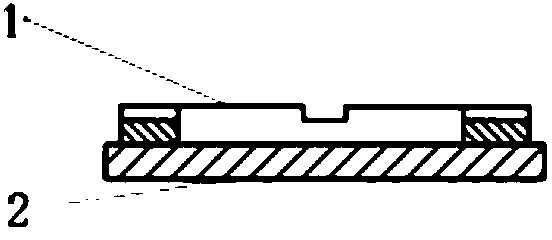

The invention relates to a testing device for resin matrix composite material hot mold pressing curing deformation and a manufacturing and using method thereof. The testing device comprises resin matrix composite material prepreg and FBG sensors arranged in the prepreg. The method comprises the steps that the FBG sensors are laid on the nth layer in the fiber axial direction to be used as strain sensors, reference sensors for temperature compensation are laid on the nth layer or the (n+1)th layer or the (n-1)th layer, lead grooves are formed in a mold side wall frame board, the mold side wall frame board is coated with a high temperature resistance polymer film, leads of the sensors are led out of the lead grooves and connected with a signal receiver, a mold is closed, hot press molding is carried out, and curing forming on-line real-time monitoring is achieved. The problems that during composite material heat mold pressing curing deformation monitoring, grid regions are fragile and prone to breakage, and monitoring signals cannot be effectively transmitted if leading is inappropriate in a closed full-rigid hot mold pressing mold are solved, and meanwhile the problem that a composite material structure part with built-in FBG sensors is hard to break away from the full-rigid mold is solved.

Owner:SHANDONG UNIV

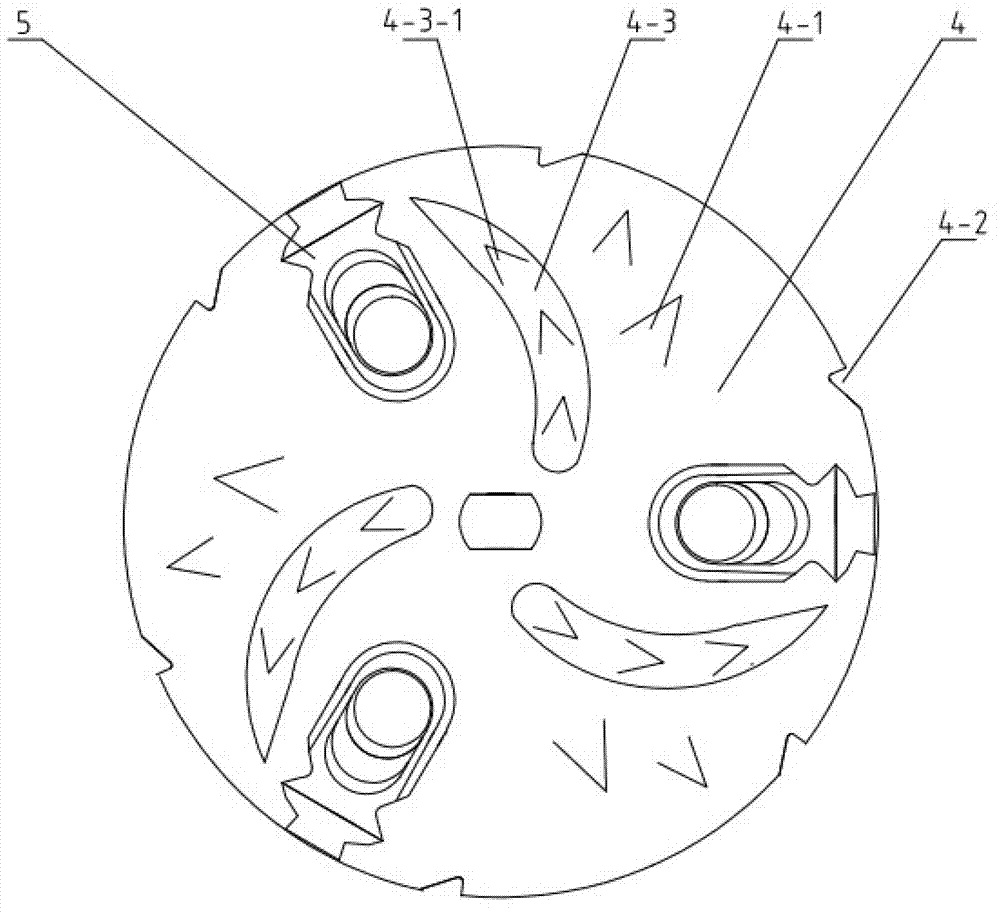

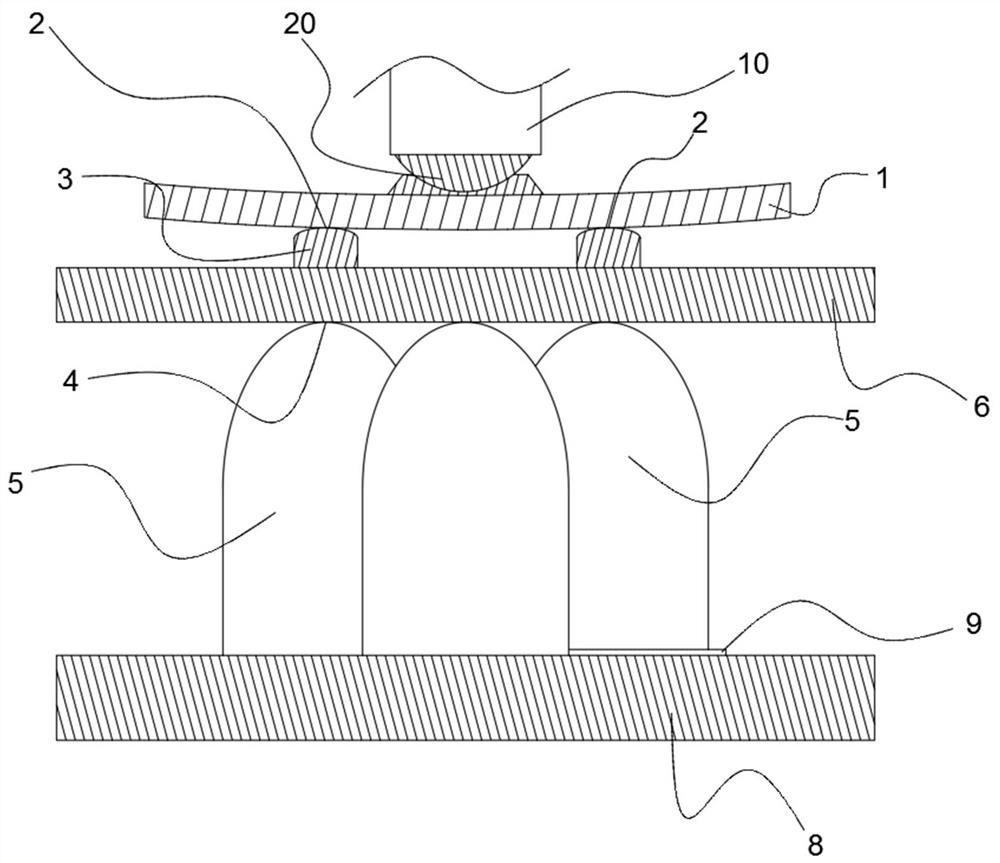

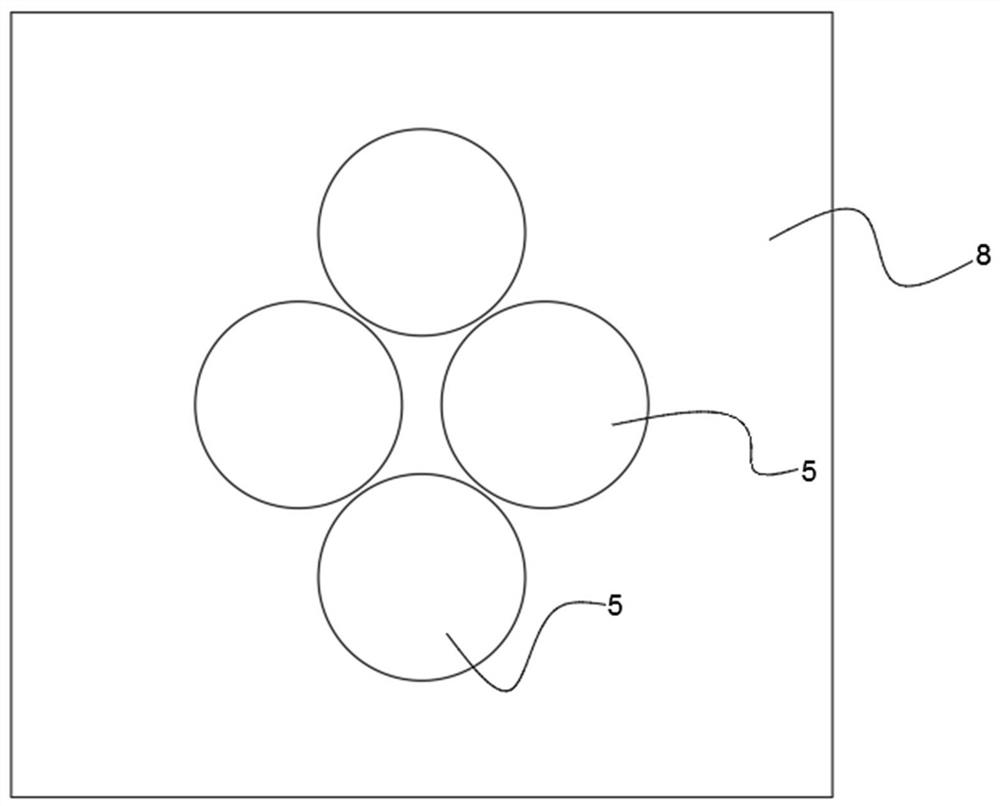

Food waste disposer

InactiveCN102872951AAvoid Risk of Electric ShockDamage will not occurGrain treatmentsLitterWater flow

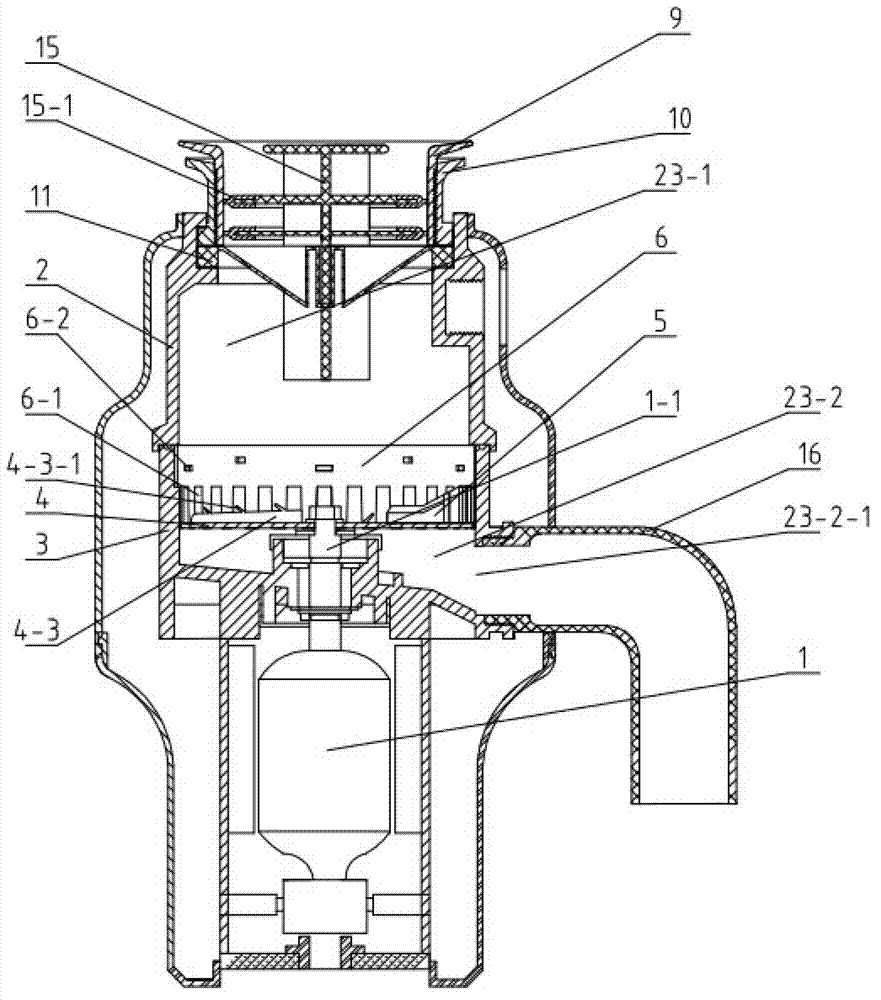

The invention discloses a food waste disposer which comprises a motor, a grinding chamber upper shell and a grinding chamber base. A cutting disk with a crushing cutter is arranged in the grinding chamber base, a plurality of breaking hammers are mounted on the cutting disk, a grinding chamber and a sewage chamber with a sewage outlet are arranged in the grinding chamber upper shell and the grinding chamber base, the grinding chamber is positioned on an upper side of the cutting disk, the sewage chamber is positioned on a lower side of the cutting disk, a grinding ring is fixed on a top inner wall of the grinding chamber base, a clearance is reserved between the grinding ring and the cutting disk, and the grinding ring is provided with a plurality of grinding grooves at intervals. The food waste disposer further comprises a control device for controlling opening and closing of the motor, and the control device is connected with an air pressure switch capable of controlling connection and disconnection through an outside air pressure button and a water flow switch capable of detecting water flow of the grinding chamber. The food waste disposer is good in processing effect on high-tenacity and harder osseous waste, and can open or close a power source by detecting whether the water flow exists or not to avoid damages to the disposer.

Owner:LILING SHANGPIN ELECTRICAL APPLIANCE MFG

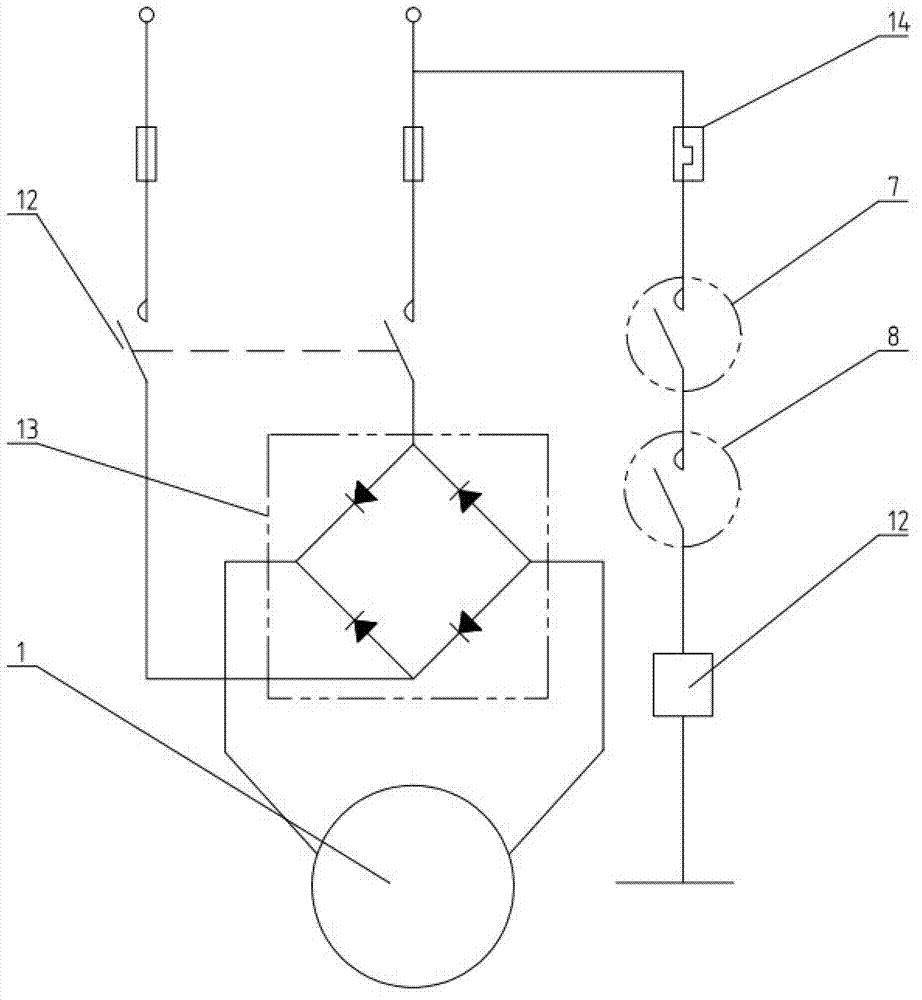

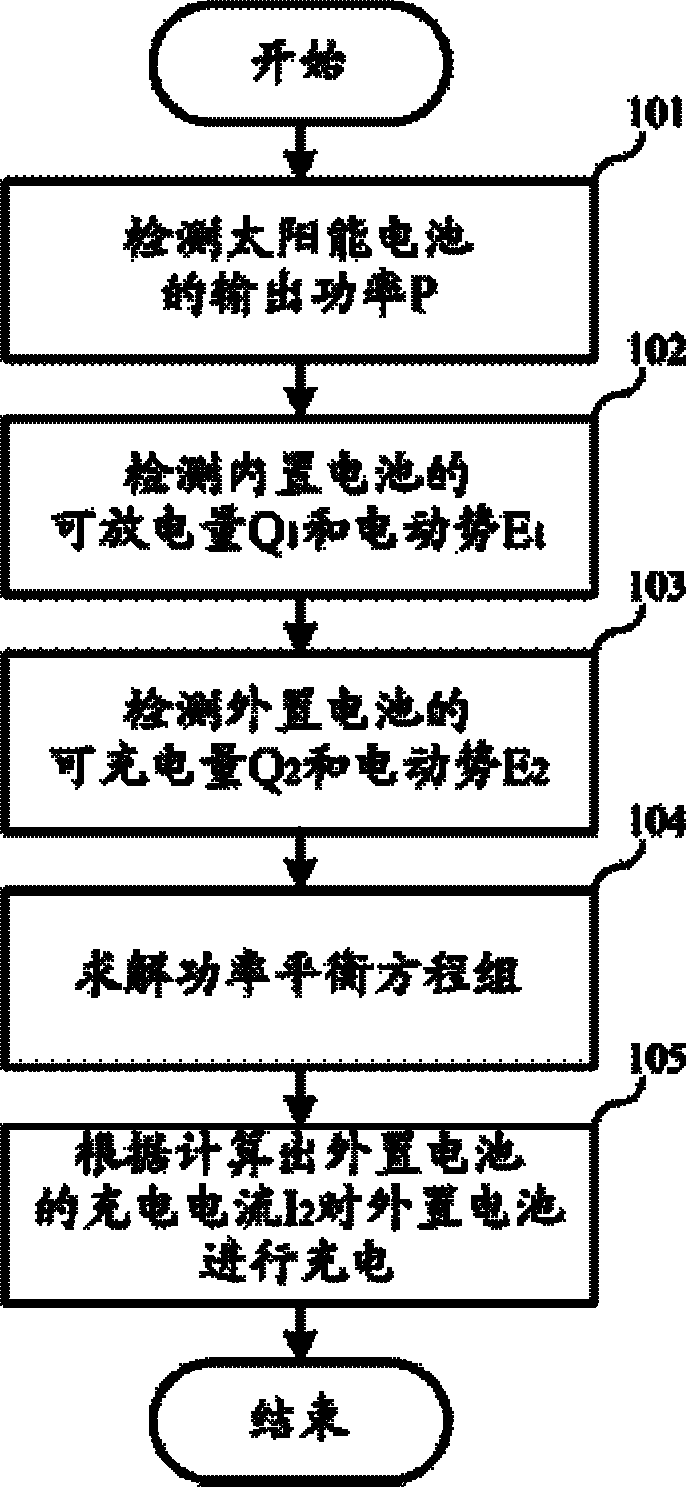

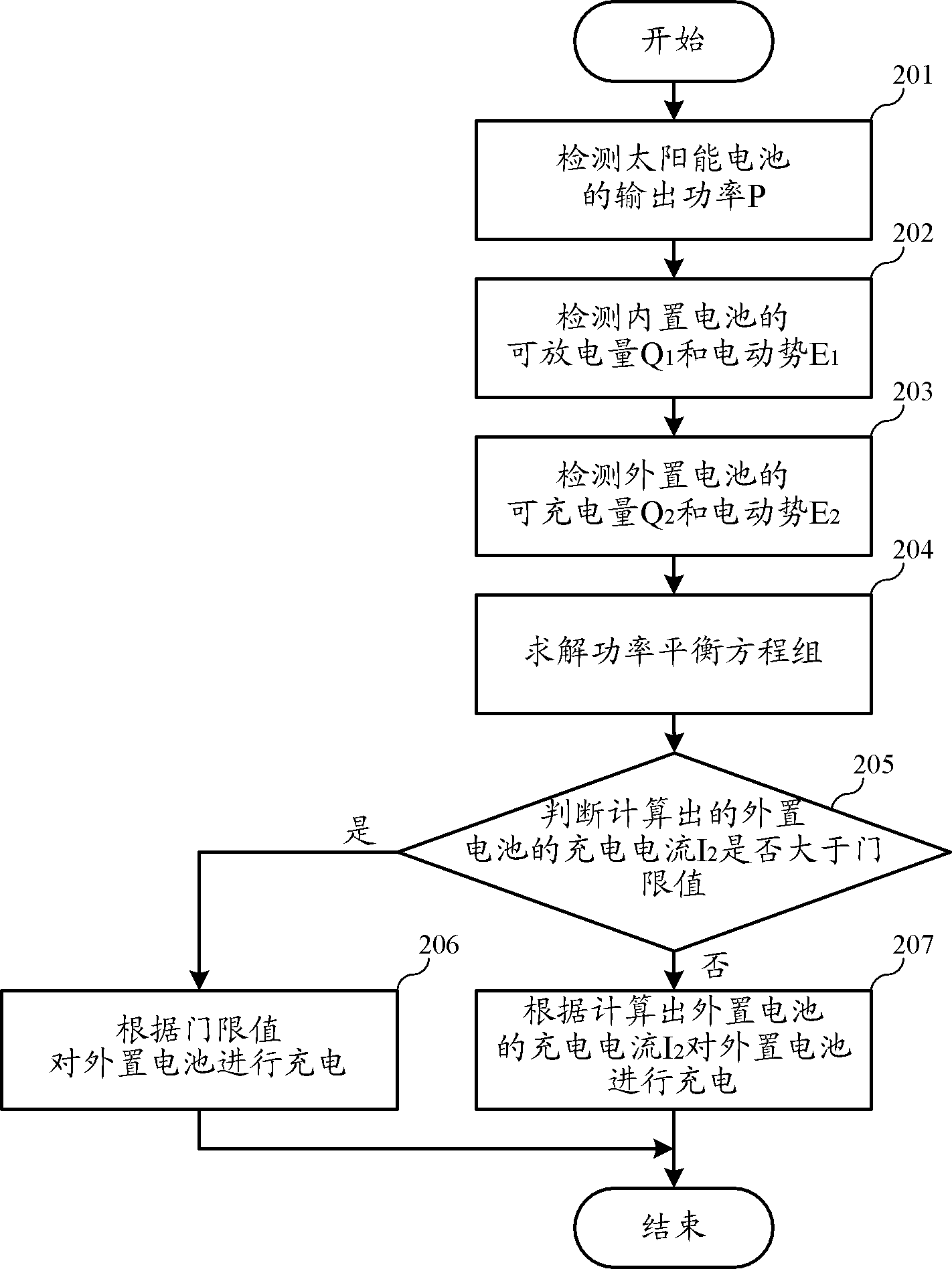

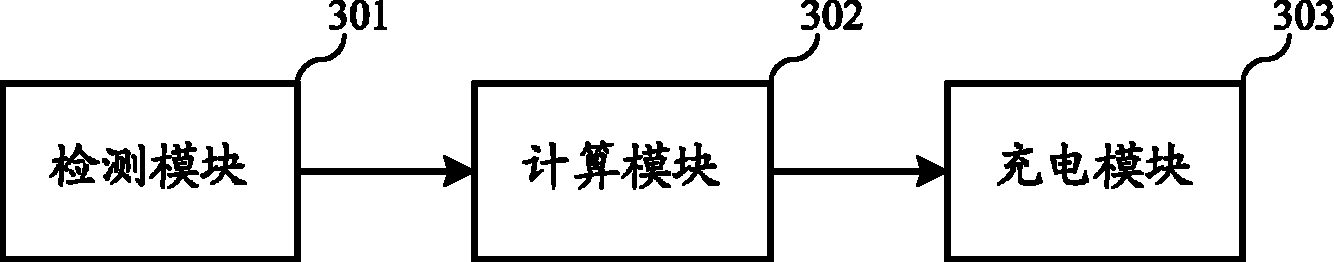

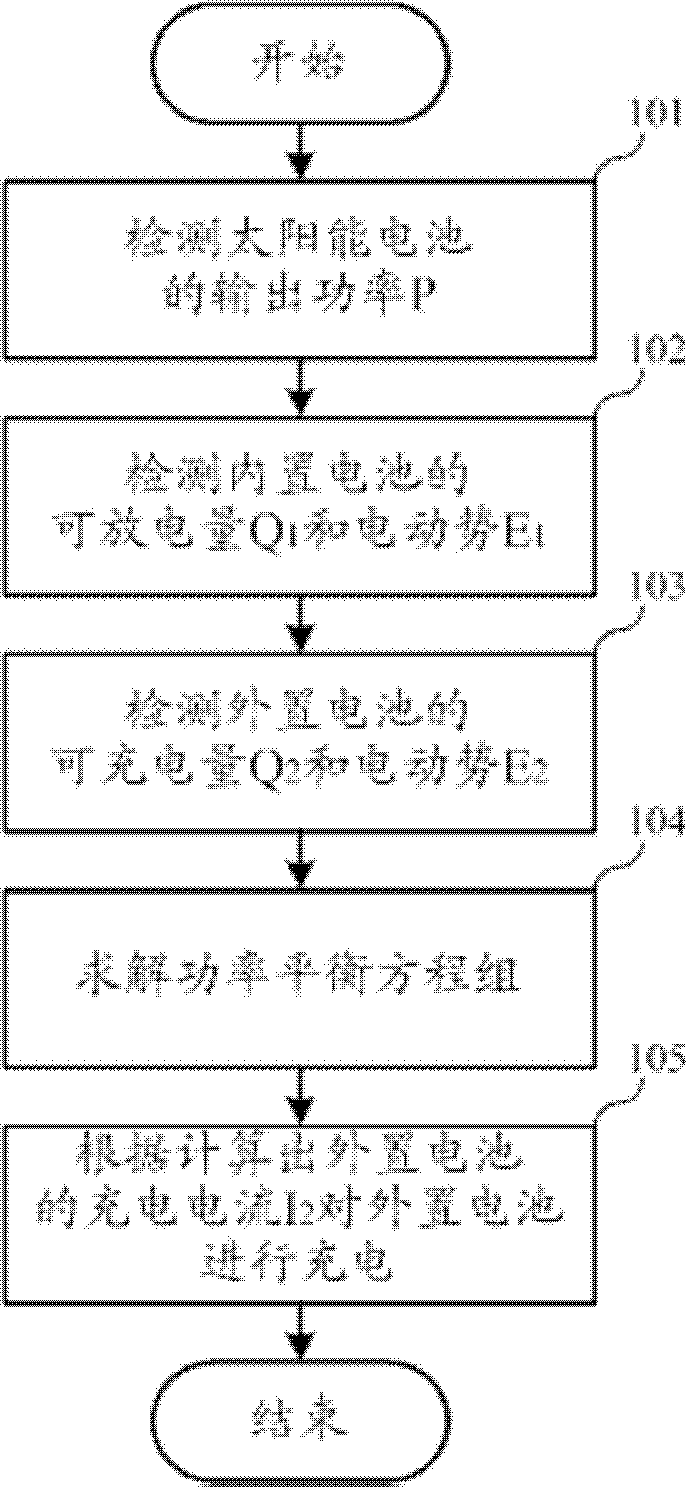

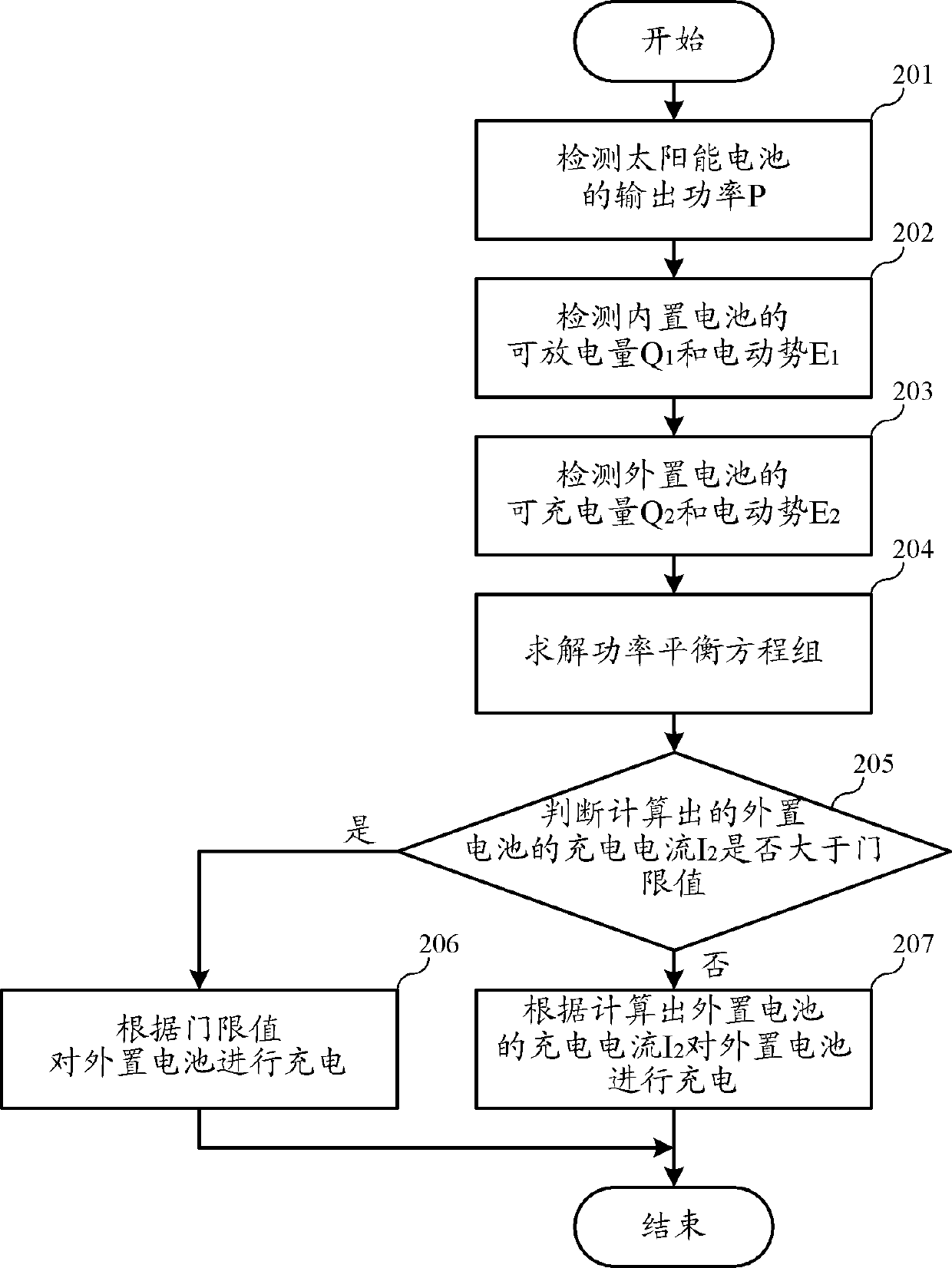

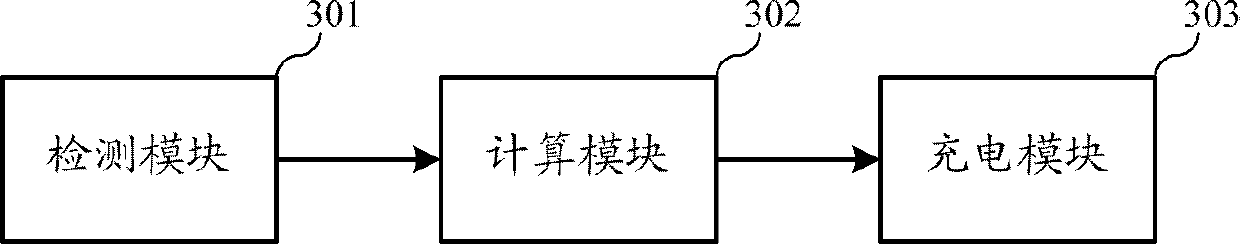

Control method of solar clothes charging current and device

InactiveCN102355019ADamage will not occurBatteries circuit arrangementsElectric powerCharge currentElectromotive force

The invention relates to a control method of solar clothes charging current, which comprises the following steps that: detecting outputted power of a solar battery; detecting dischargeable quantity and electromotive force of a built-in battery; detecting chargeable quantity and electromotive force of an external battery; solving power balance equations set; and charging the external battery according to the calculated charging current of the external battery. The invention also relates to a control device of the solar clothes charging current, which comprises a detection module, a calculation module and a charging module. Due to the adoption of the control method and the control device, the external battery can be charged within a minimal time.

Owner:DONGHUA UNIV

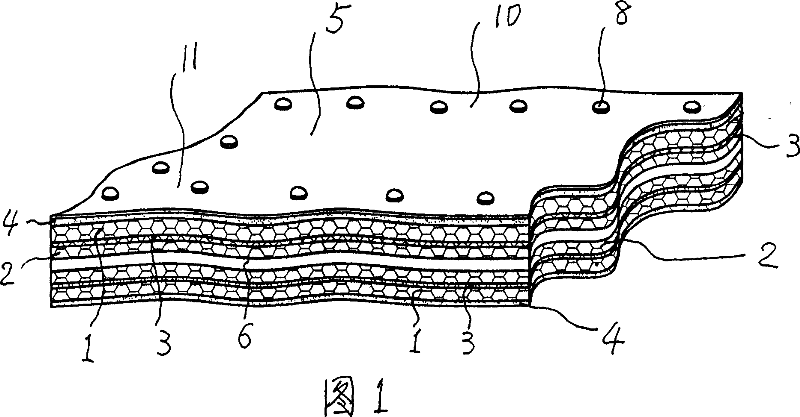

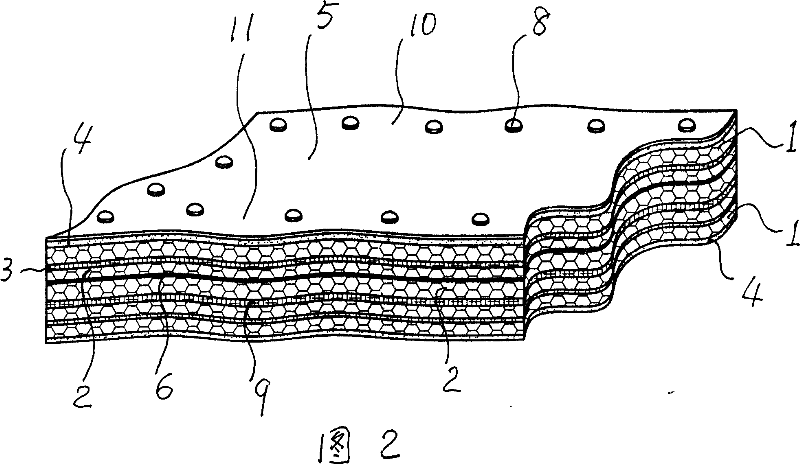

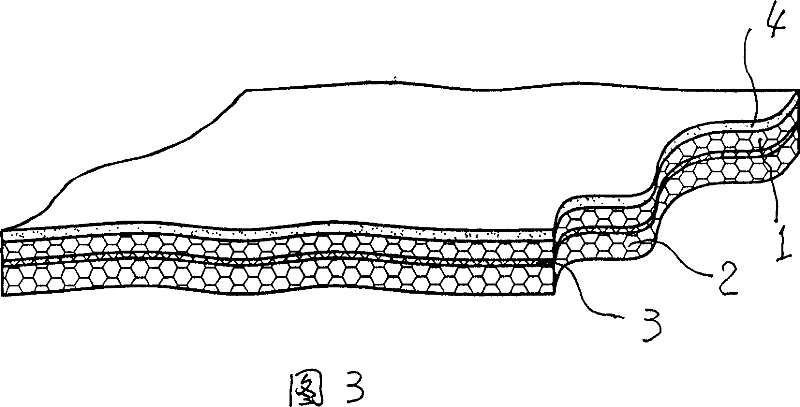

Waterproof and heat preservation quit in greenhouse with sunshine and the technique for producing the same

InactiveCN101040591ABlock heat loss by convectionPrevent rain, snow and windClimate change adaptationSynthetic resin layered productsThermal insulationCorrosion

The invention discloses a waterproof thermal insulated quilt used in light greenhouse booth, belonging to greenhouse booth thermal insulated technique. The invention is characterized in that preparing felt layer, preparing upper and lower thermal insulated layers and fixing the upper and lower thermal insulated layers to obtain a light greenhouse waterproof thermal insulated quilt formed by a waterproof membrane layer, a non-woven cloth layer, upper and lower felt sheets with a strength bar layer between, an air insulated layer, a lower felt sheet, a strength bar layer, an upper felt sheet, and a non-woven cloth layer. The invention can insulate water, seal and confirm transparence, and improve thermal insulation, with low cost, low weight, corrosion resistance, non-pollution and recycle property.

Owner:田金川

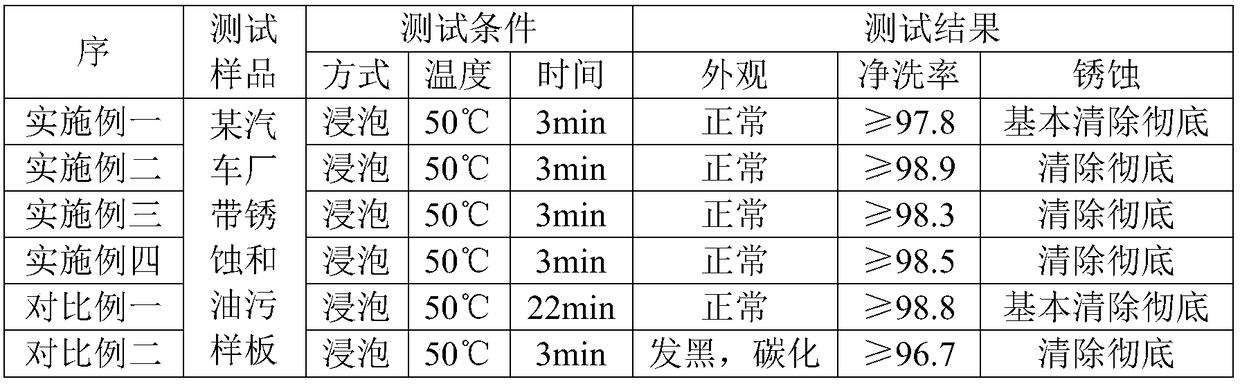

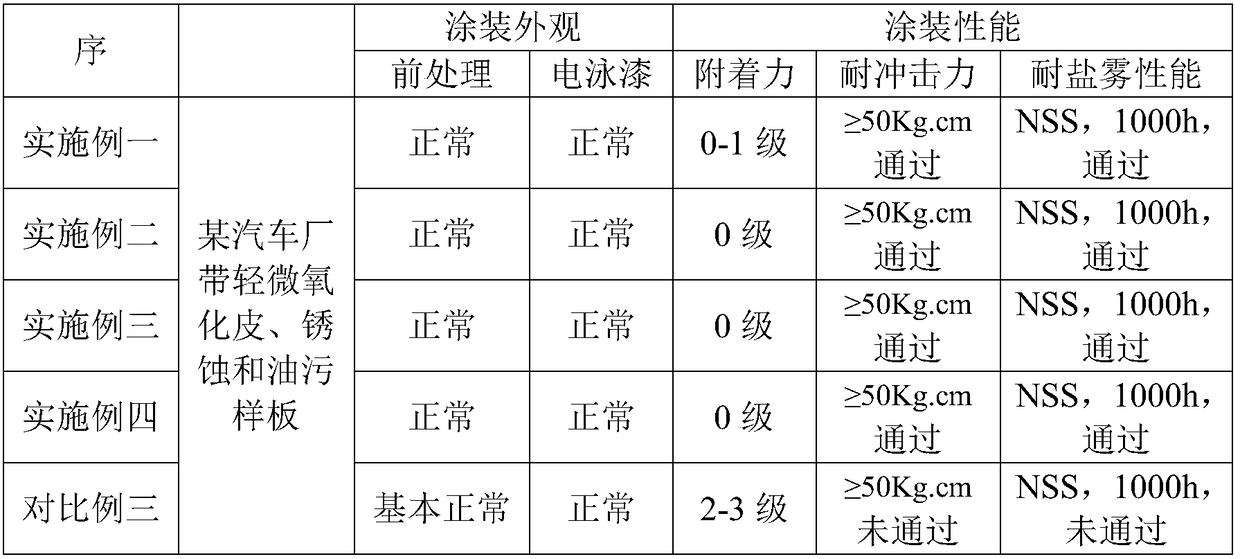

Neutral oil and rust removing detergent used for agreeing with coating pretreatment production takt and preparation method

The invention discloses neutral oil and rust removing detergent used for agreeing with the coating pretreatment production takt and a preparation method and relates to the technical field of metal surface oil and rust removing treatment. The neutral oil and rust removing detergent used for agreeing with the coating pretreatment production takt and the preparation method comprise the following components including, by weight percentage, 5-25% of inorganic salt, 20-40% of organic acid, 5-15% of chelate, 1-5% of surface active agent, 0.5-5% of corrosion inhibitor and the balance water. Accordingto the neutral oil and rust removing detergent, the oil and rust removing speed is high, the existing production takt is not influenced, in the coating application, on the premise of not increasing investment of large equipment or not changing the existing production takt, an original degreasing agent is directly replaced by the neutral oil and rust removing detergent, the existing degreasing working procedure is compatible with the rust removing function, the pretreatment appearance of a metal piece and the appearance of paint films are improved greatly, the adhesive force and the corrosion resisting performance of the paint films are improved remarkably, and the whole coating quality is improved.

Owner:湖北博新材料保护有限公司

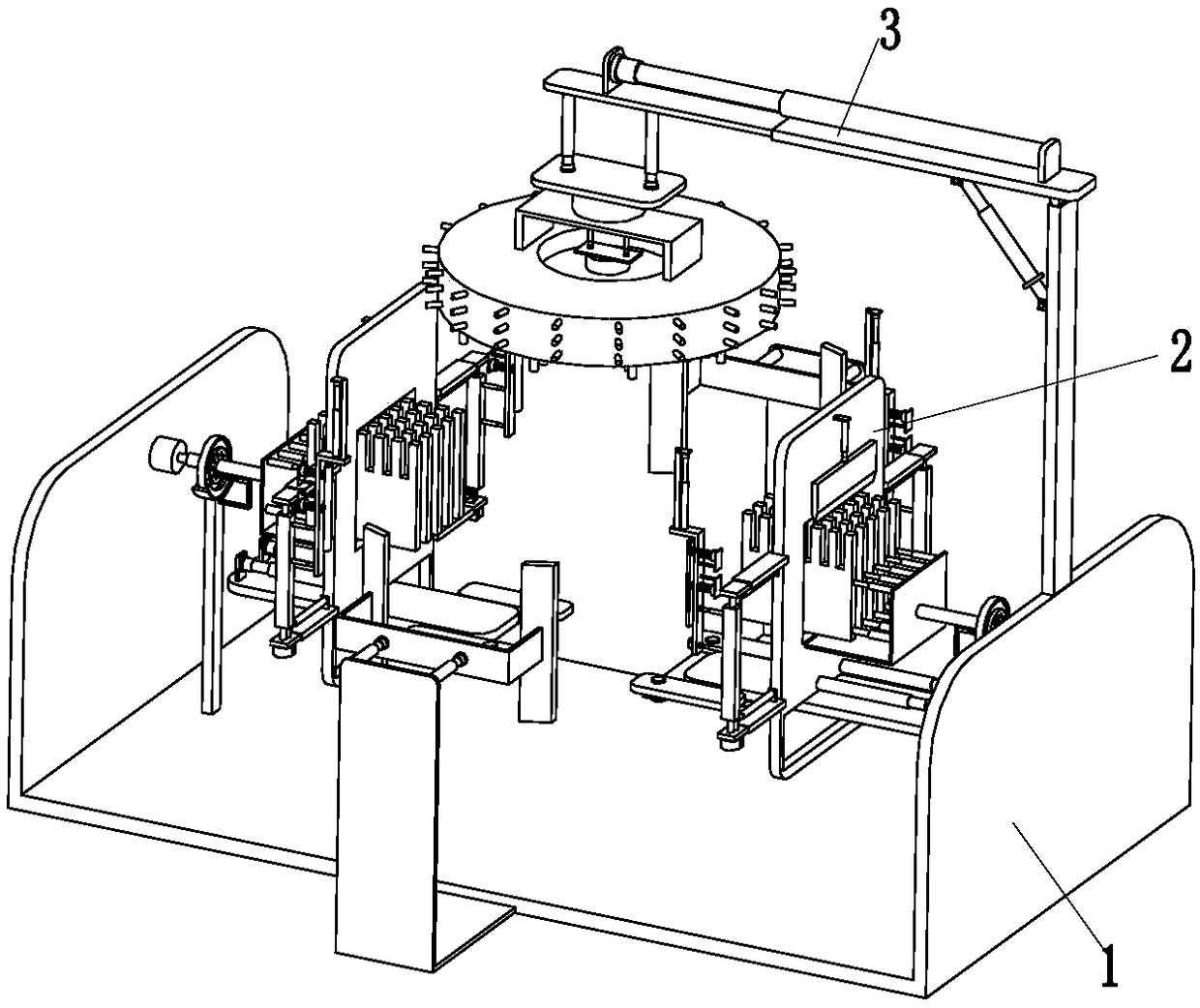

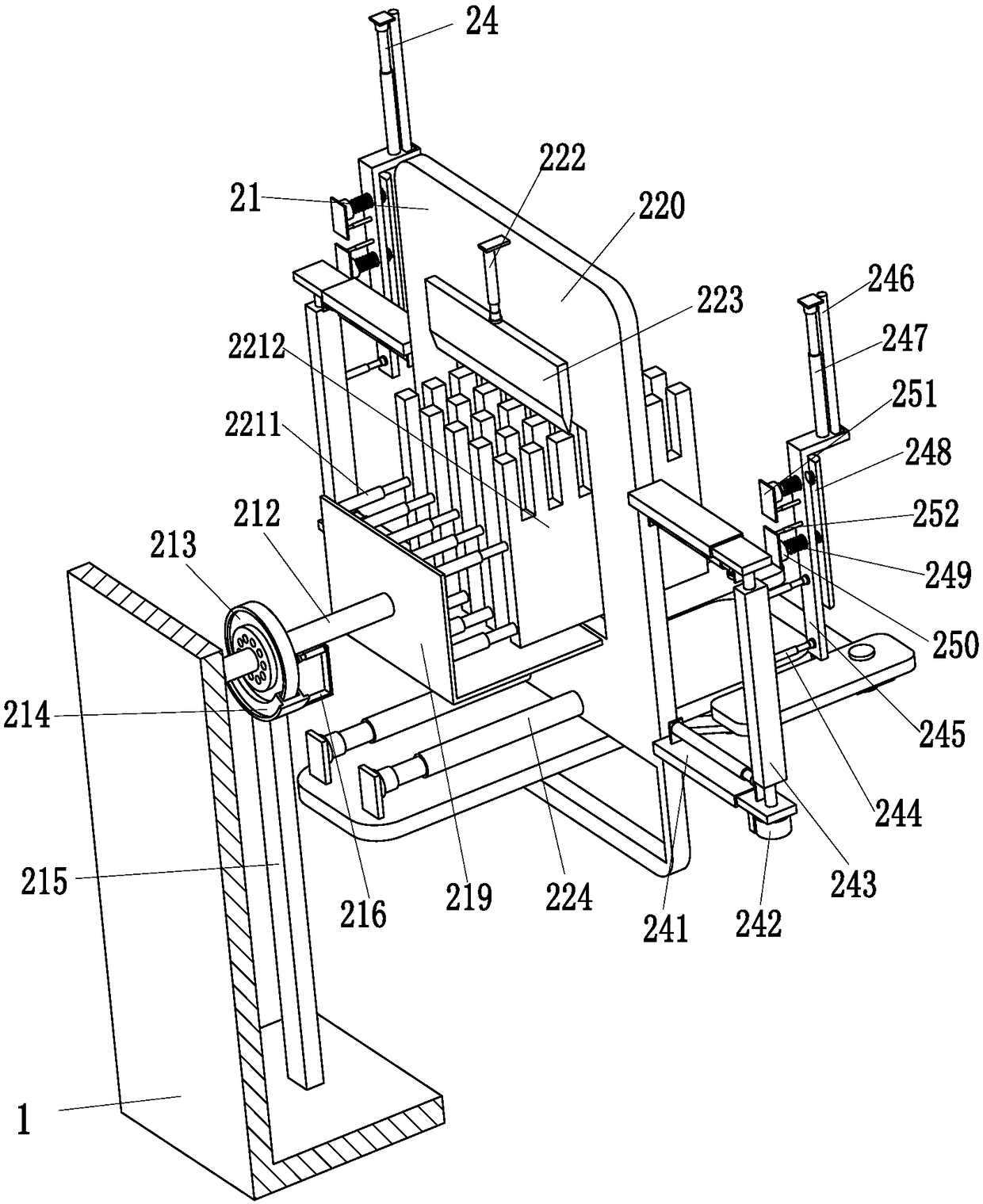

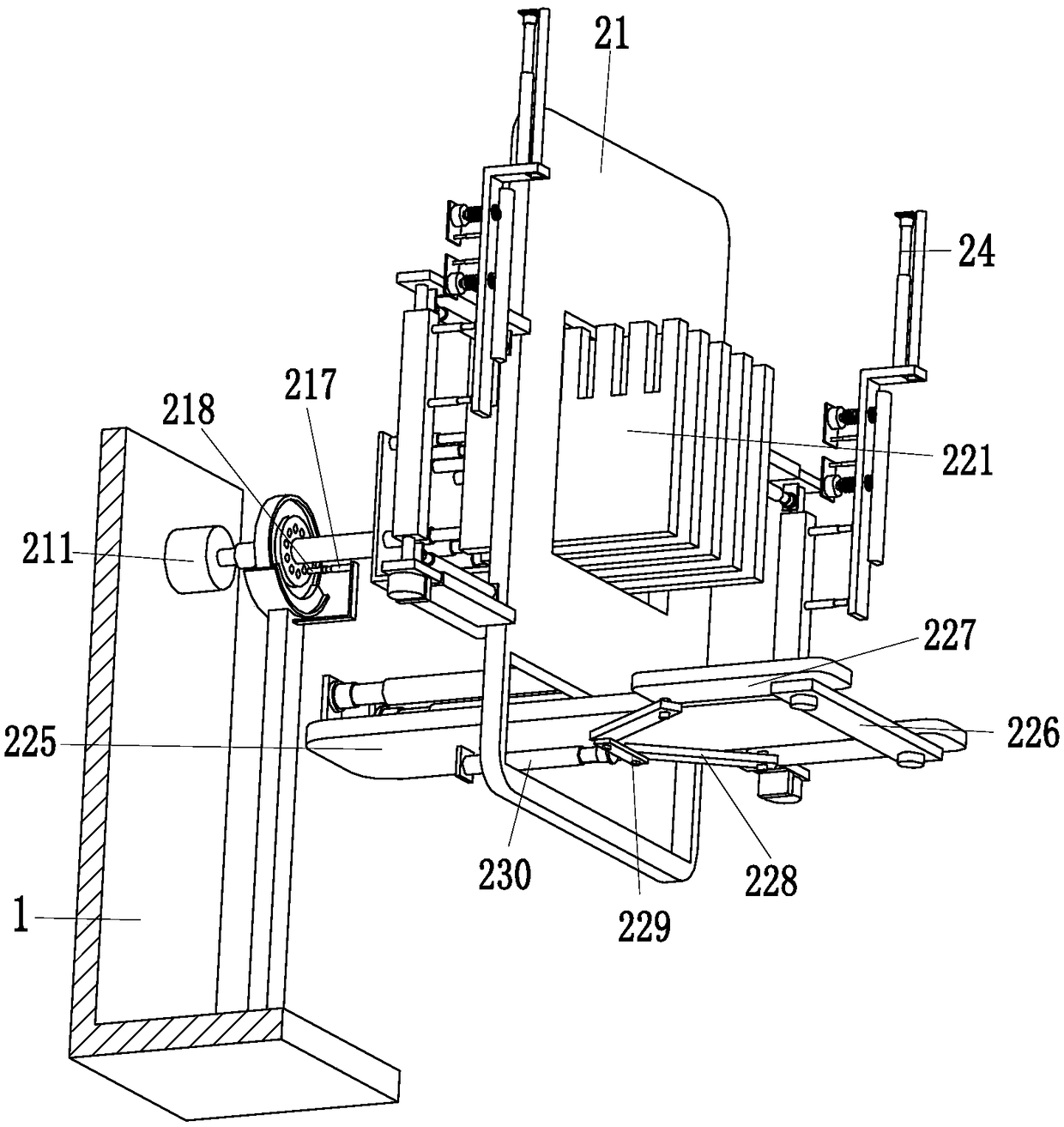

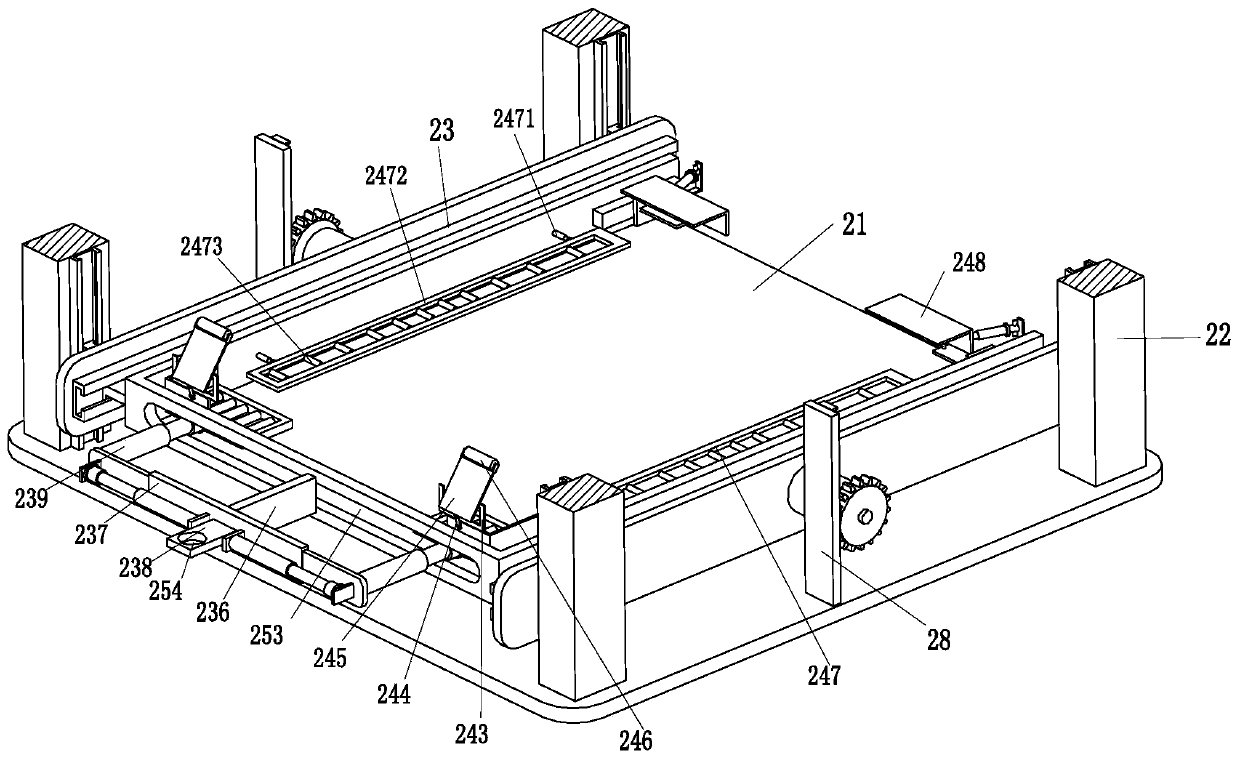

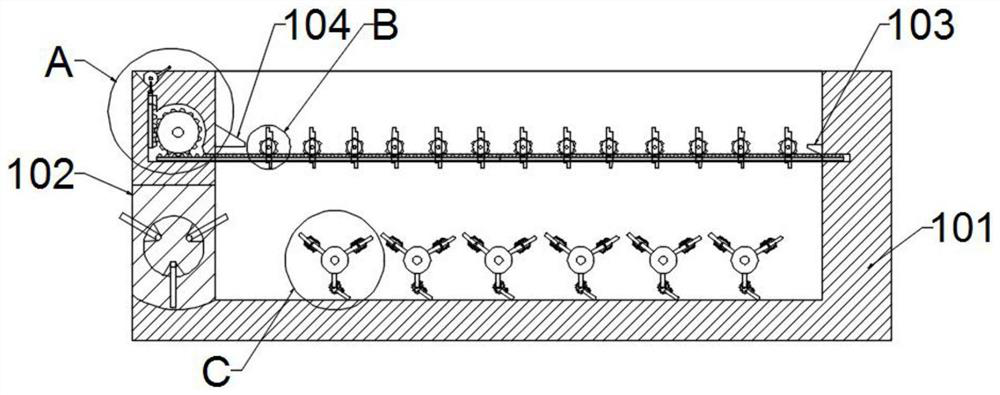

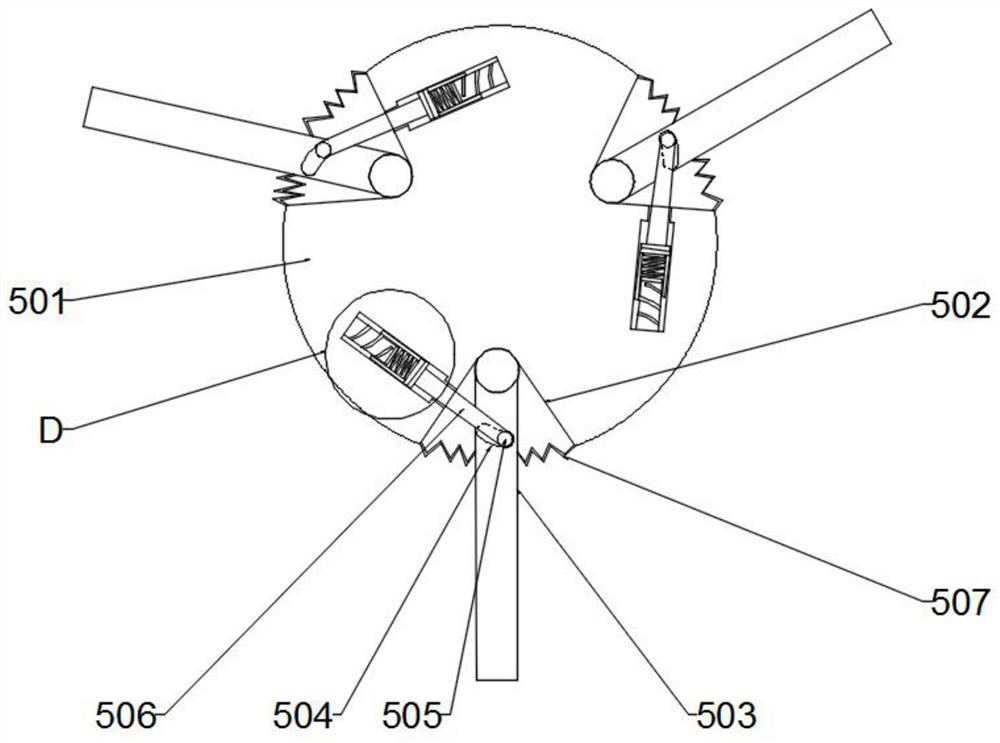

Vehicle fitting flywheel shell automatic treatment equipment and flywheel shell automatic treatment process

ActiveCN109128930AShort timeReduce labor intensityWork clamping meansMetal working apparatusEngineeringFlywheel

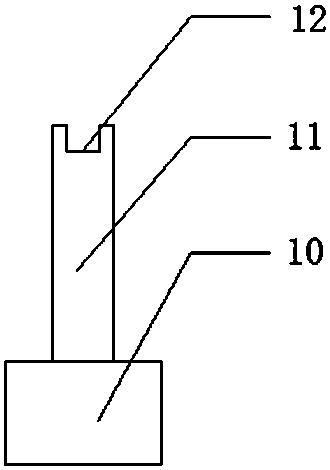

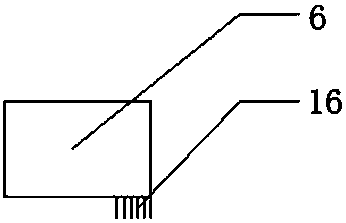

The invention relates to vehicle fitting flywheel shell automatic treatment equipment and a flywheel shell automatic treatment process. The equipment comprises a chassis, a positioning device and a cleaning device; the positioning device is mounted at the upper end of the chassis; and the cleaning device is mounted at the right end of the chassis. The equipment can solve the difficulties of difficult achievement of the positioning precision in traditional clamping of flywheel shells, difficult clamping of the flywheel shells by traditional clamping equipment due to higher weight of the flywheel shells, surface damage of the flywheel shells caused by easy looseness during machining, capability of machining different positions of the flywheel shells through renewed clamping of the flywheel shells by persons, halfway cleaning of iron chips attached in the flywheel shells through a manual mode, long consumed time, high labor intensity and low working efficiency, and can achieve automatic positioning and cleaning functions of the flywheel shells.

Owner:江苏固诺新材料科技有限公司

Hinge for a window or a door

ActiveCN102016211AEasy to manufactureEasy to operateWing accessoriesHingesEngineeringMechanical engineering

Owner:SIEGENIA FRANK

Method for resisting fused zinc corrosion of steel and iron product

InactiveCN1804126AExtended service lifePrevent hard particlesHot-dipping/immersion processesSheet steelZinc

The method to resist Zinc solution corrosion comprises: cover a piece of soft fabric that resists to Zinc solution corrosion and 480-960Deg and composes a plurality of oxides on the steel product surface to insulate the product from Zinc solution. This invention overcomes defects in prior art, reduces difficulty and cost, and benefit to Zn cooker and inner-dip heater.

Owner:ZHEJIANG UNIV

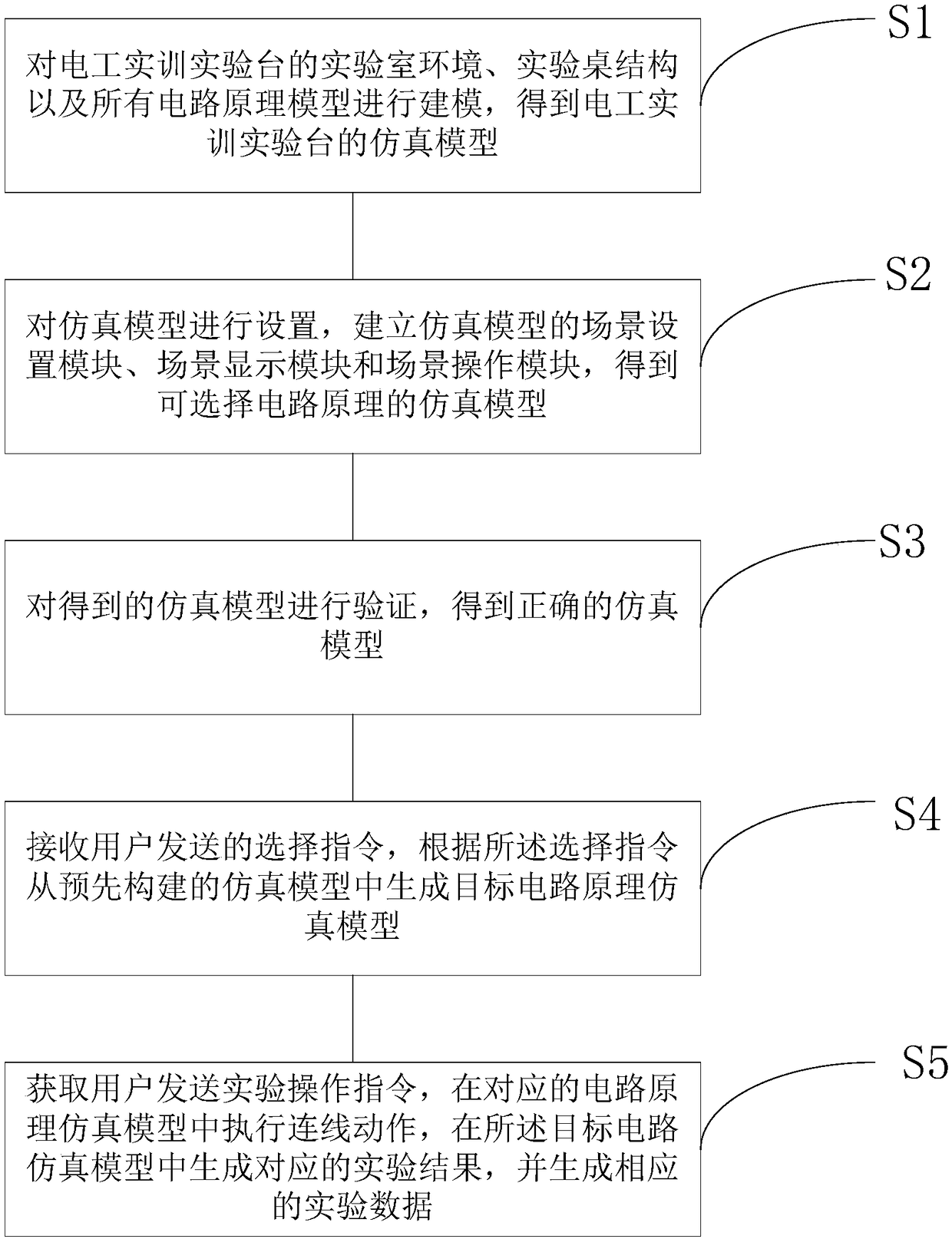

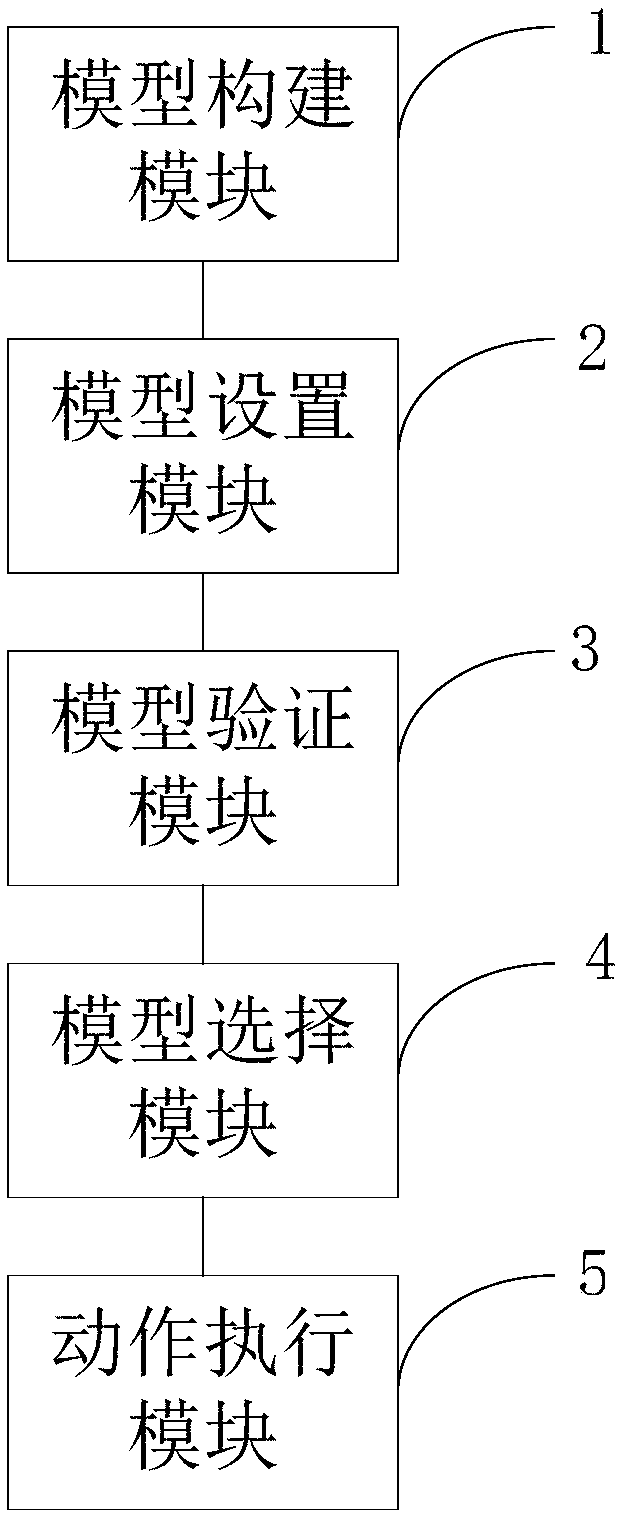

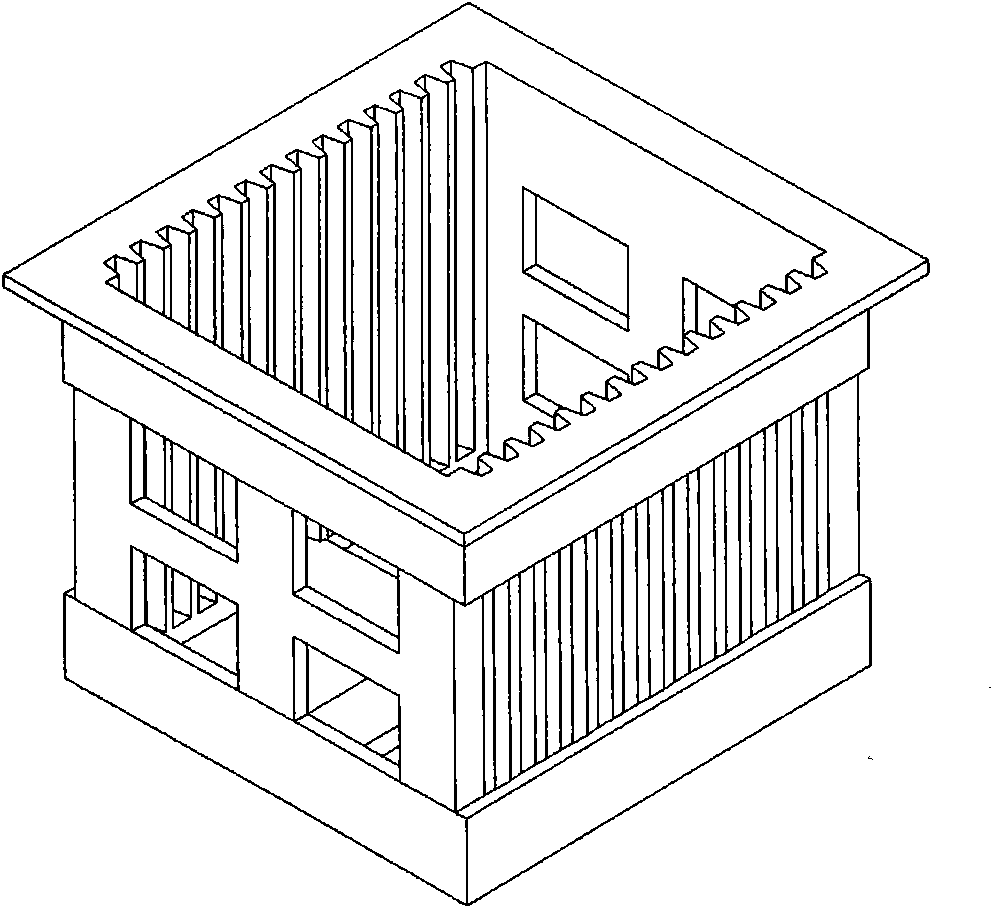

Electrician training testbed simulation method and system

InactiveCN108062446AGood technical effectDamage will not happenCAD circuit designSpecial data processing applicationsSimulationOperational approach

The invention discloses an electrician training testbed simulation method and system. The method comprises the following steps of: modeling a laboratory environment, a test table structure and all thecircuit principal models of an electrician training testbed so as to obtain a simulation model of the electrician training testbed; setting the simulation model, and establishing a scene setting module, a scene display module and a scene operation module of the simulation model so as to obtain a simulation model capable of selecting circuit principles; and verifying the obtained simulation modelto obtain a correct simulation model. The method and system are supplemented with existing entity equipment, do not generate dangerous situations in simulation software, do not cause equipment damagein using processes, and do not need to be arranged and maintained after teaching, and can complete online teaching and management. The method is simple, rapid and convenient to use.

Owner:杭州力控科技有限公司

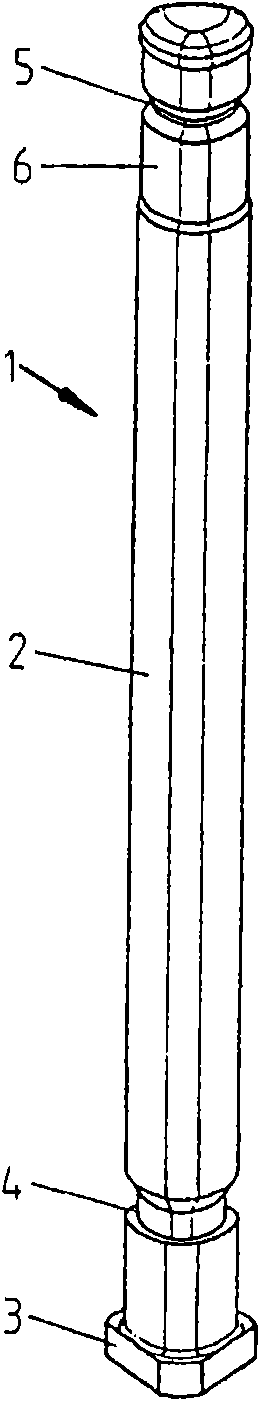

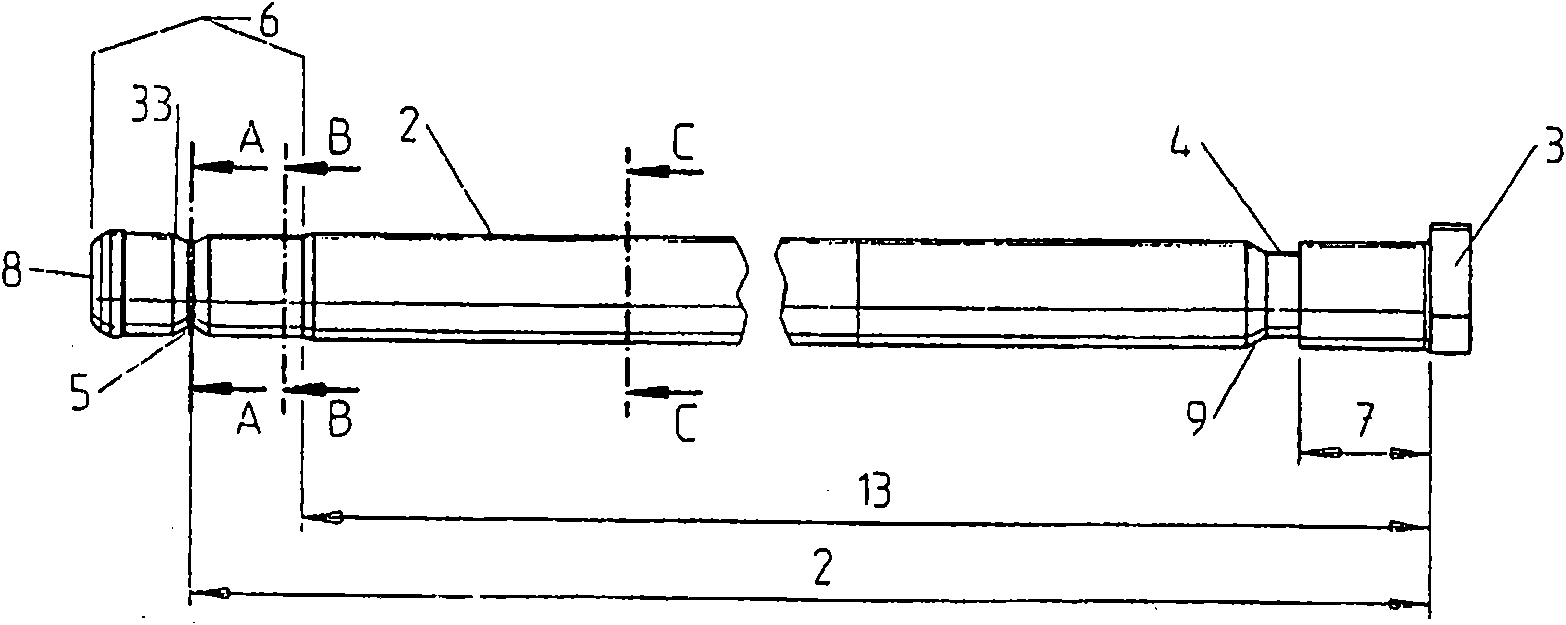

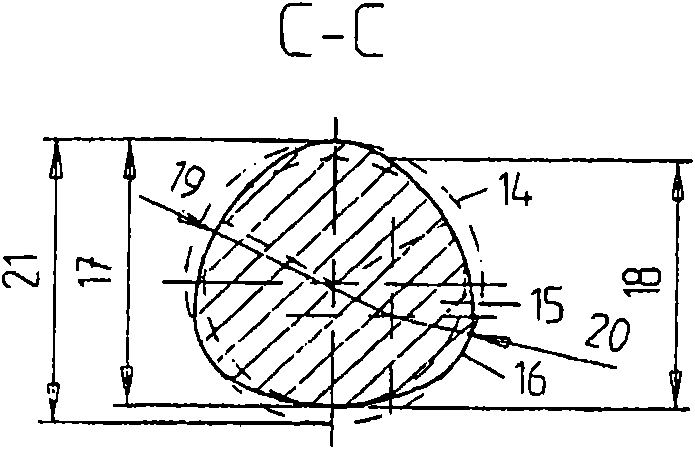

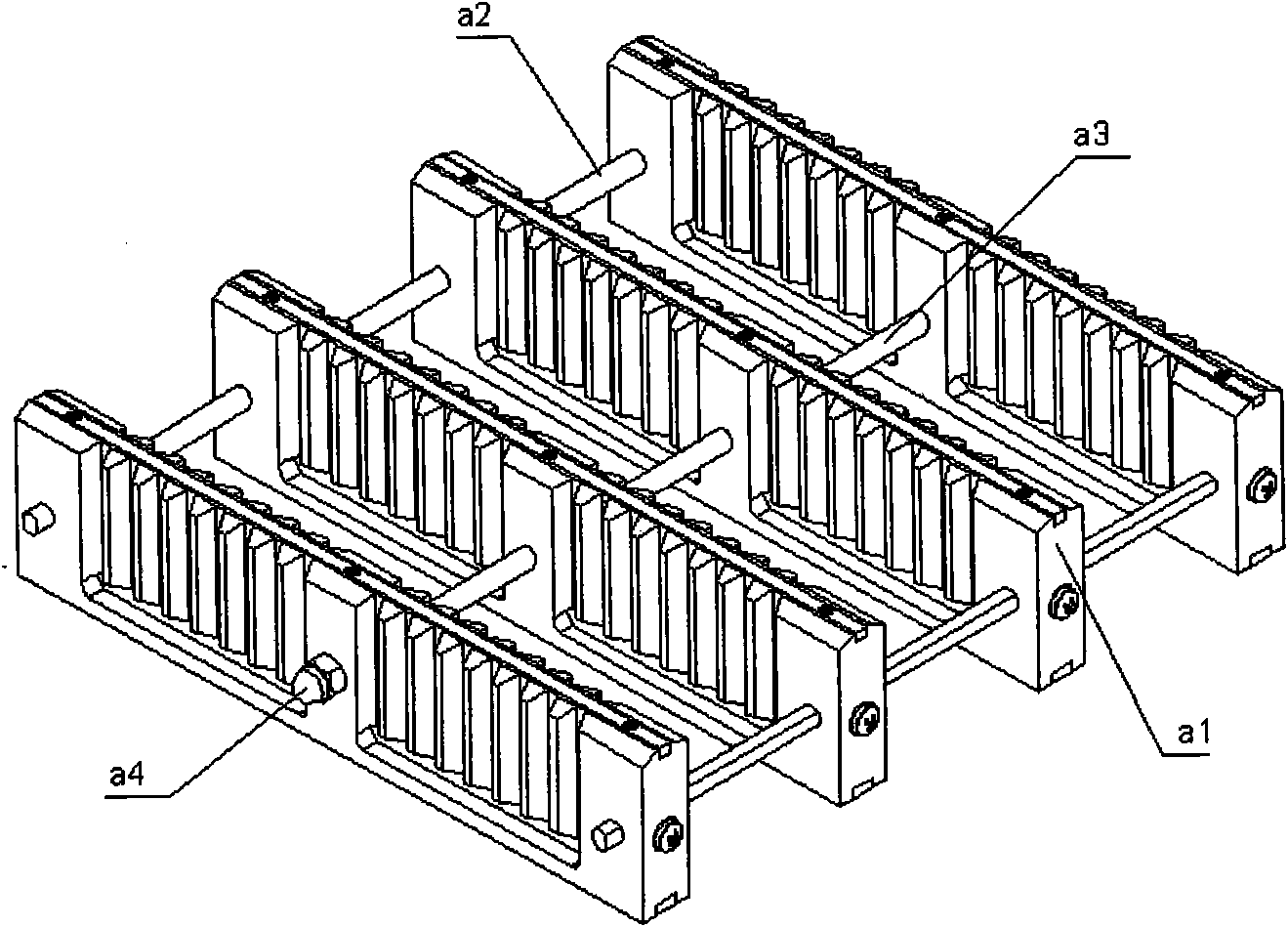

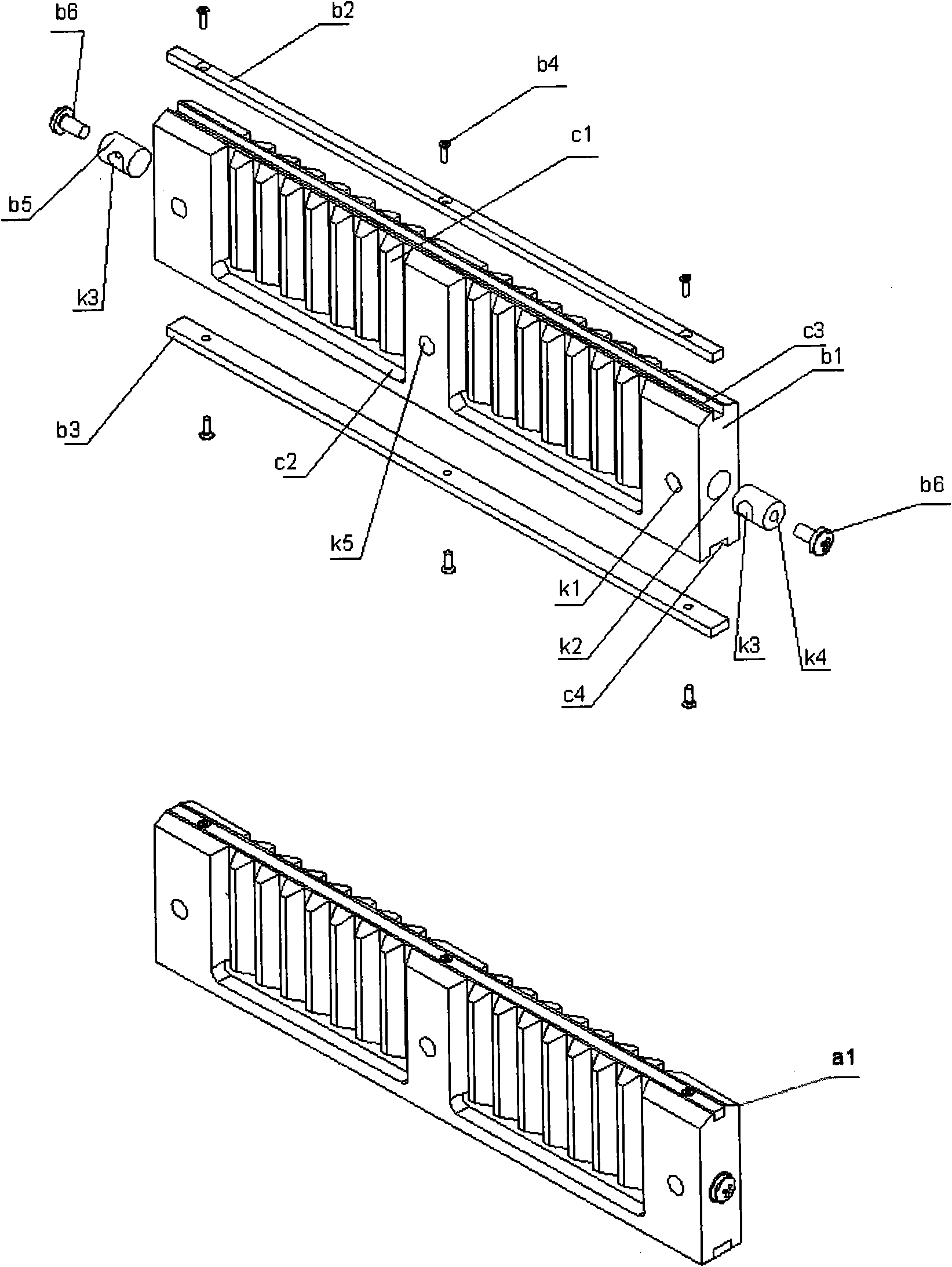

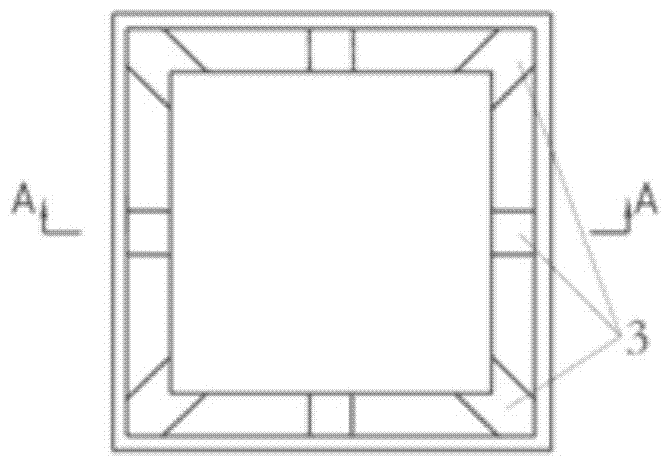

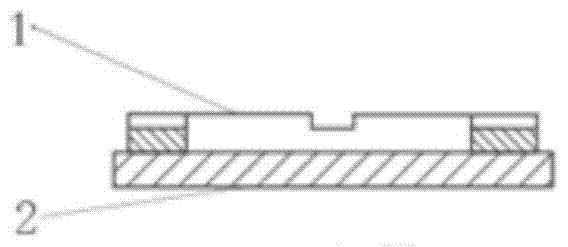

Adjustable bearing cleaning apparatus for processing hard surface photomask base plate and assembling method thereof

InactiveCN101630120ANot easy to insertNot easy to fixGlass reforming apparatusOriginals for photomechanical treatmentWhole bodyWater flow

The invention relates to the field of hard surface photomask base plate manufacture and the field of optical glass finishing, in particular to a bearing cleaning apparatus and an assembling method applied to the process of manufacturing a hard surface photomask base plate. The bearing cleaning apparatus is manufactured by assembling a notch frame (a1) and guiding positioning rods (a2), wherein the notch frame (a1) is formed by positioning and connecting a notch plate (b1) and a rib plate (b3) through a fixing piece, and the left side and the right side of the notch plate (b1) are provided with a mirror symmetrical slot (c1) and a bottom strip slot (c2) vertically running through the symmetrical slot (c1); and the ends of the left side and the right side of the notch plate (b1) are provided with guide holes (k1) for positioning and mounting the guide positioning rods (a2). The bearing cleaning apparatus has good universality and is flexible and convenient, the whole body is difficult to deform, the phenomenon of water flow blockage cannot appear in the cleaning process, and the cleanliness and the operation efficacy of workpieces can be improved effectively.

Owner:华东建筑集团股份有限公司

Preparation method of plywood for full-bamboo or bamboo wood composite container

InactiveCN101508124BAvoid damageDamage will not occurOther plywood/veneer working apparatusPlywood pressesThermal energyEngineering

Owner:杨湘云

Automobile spare part machining mold

InactiveCN108057784ASolve the problem of inconvenient cleaning debrisEasy clampingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an automobile spare part machining mold which comprises a lower mold and an upper mold opposite to the lower mold. A punching air cylinder is arranged above the upper mold. Anoutput shaft of the tail end of the punching air cylinder is arranged in a manner of penetrating the center of the upper mold. A punching head is arranged below the output shaft. A punching groove isformed in the center of the lower mold and located under the punching head. A discharging hole is formed below the punching groove. A baffle is arranged between the punching groove and the discharginghole. A rectangular channel is arranged in the axial direction of the right side of the lower mold. A telescopic air cylinder is arranged on the right side of the lower mold. A telescopic shaft at the tail end of the telescopic air cylinder extends into the channel. A clamp groove with the width matched with that of the baffle is formed in the tail end of the telescopic shaft. The baffle can slide left and right relative to the punching groove. Compared with the prior art, the automobile spare part machining mold of the scheme cannot generate any impact damage, and the problem that chippingsare inconvenient to remove in an existing punching mold is solved; and meanwhile, structure manufacturing is simple, manual machining and assembling are convenient, the production cost is low, and useby operation workers is convenient.

Owner:广州大汗科技有限公司

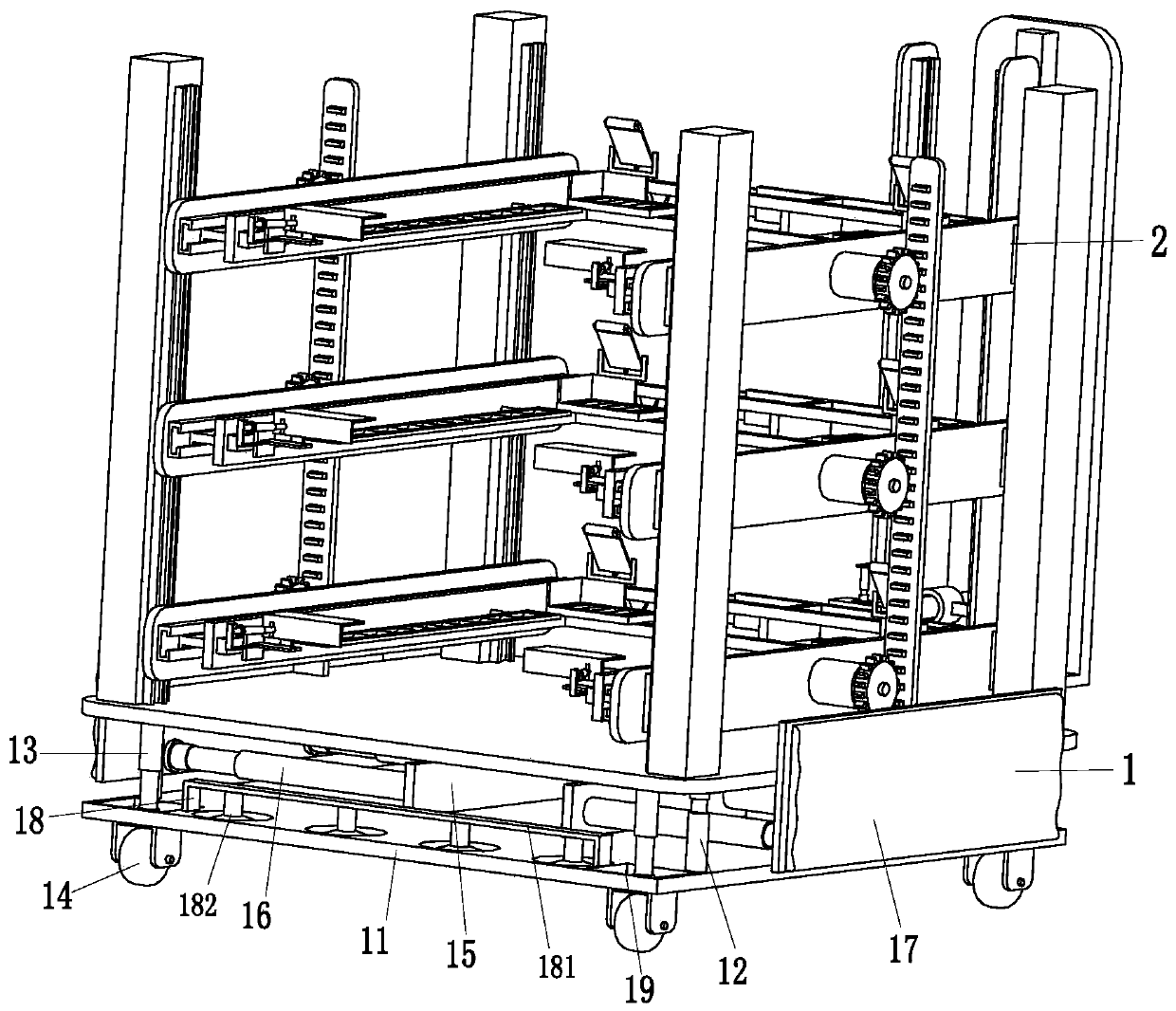

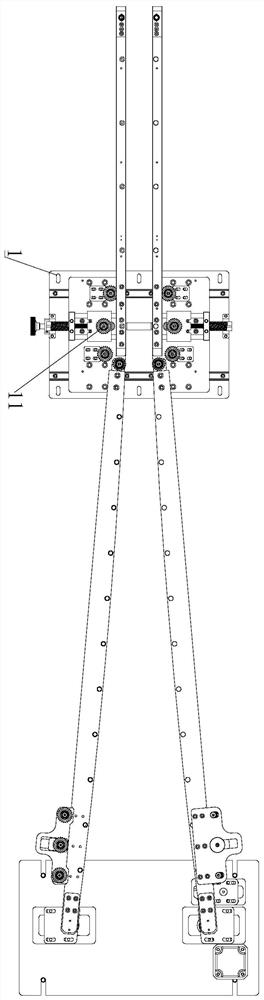

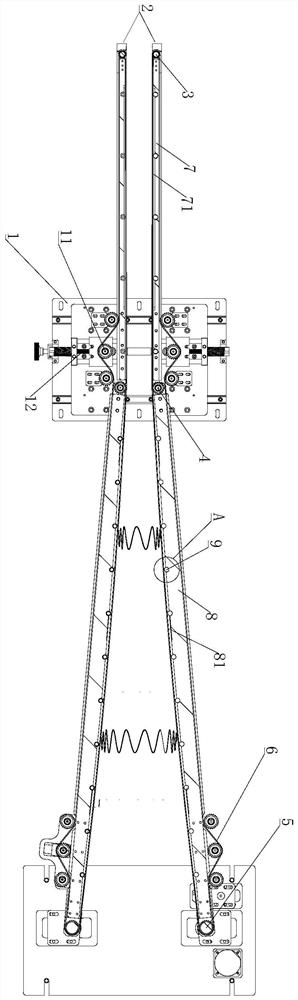

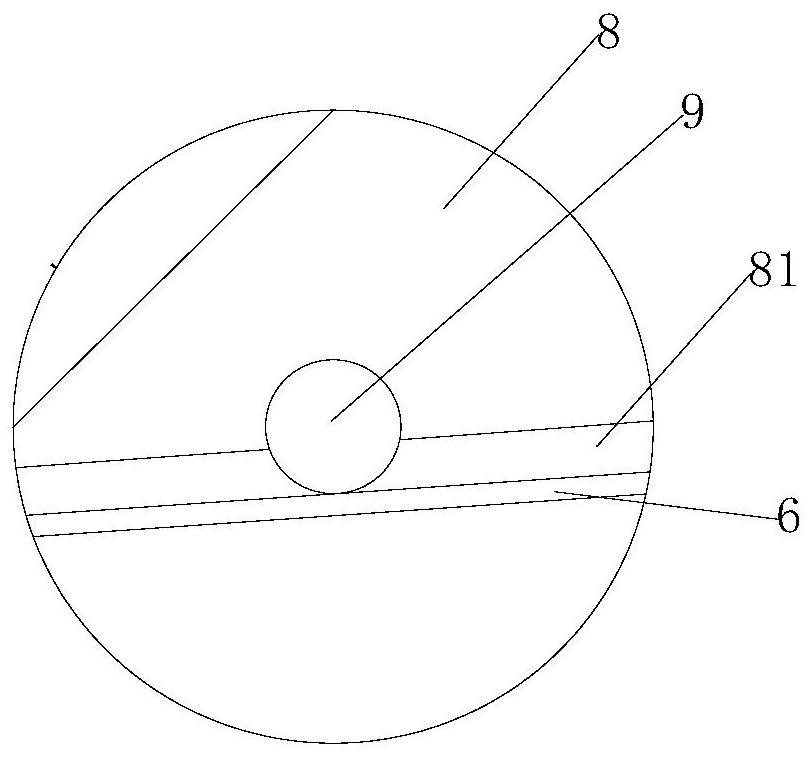

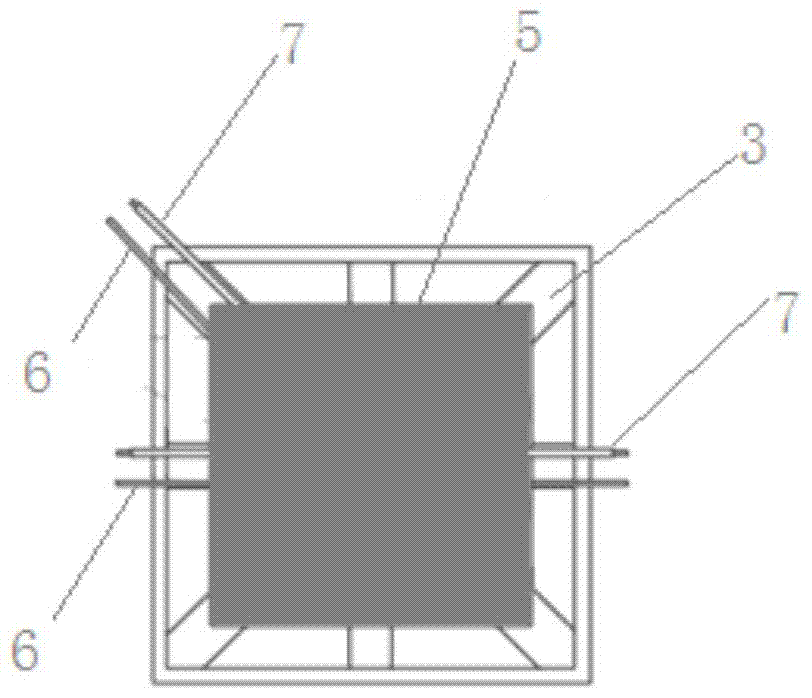

Fixing fixture for aluminum-plastic panel

ActiveCN108860260BDamage will not occurImprove transportation efficiencyHand carts with multiple axesEngineeringAluminium

The invention relates to an aluminium-plastic panel fixing fixture, comprising a fixing device and a clamping device, wherein the clamping device is mounted at the upper end of the fixing device. According to the invention, the aluminium-plastic panel fixing fixture can solve the problems that the existing aluminum-plastic panel need to be transported after the aluminum-plastic panel is mounted onan existing clamping frame in the transportation process, the existing clamping frame cannot clamp the aluminum-plastic panel steadily, an aluminum-plastic panel coating shakes during transportationto form a mark to on the surface of the aluminum-plastic panel, and the spacing adjustment cannot be carried out between panels according to the different thickness of the aluminium-plastic panels, the aluminium-plastic panels enter in and out of the existing clamping frame is not convenient, the existing clamping frame provided with the aluminum-plastic panels cannot be fixed in a container steadily, the existing clamping frame may overturns during transportation to cause the damage of aluminum-plastic panels, and the transportation efficiency is low, and can realize the clamping limiting ofthe aluminum-plastic panels and functions of fixing the aluminum-plastic panels in the container during transportation.

Owner:新沂市马陵山众创科技产业发展有限公司

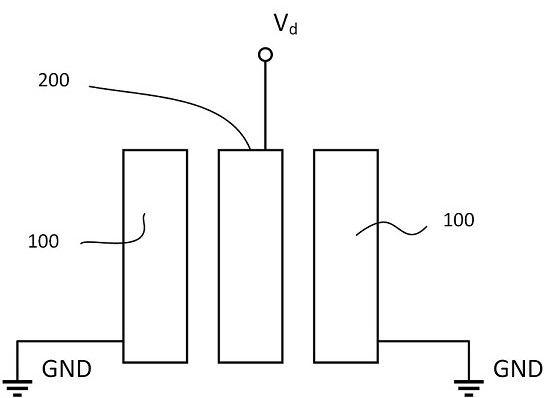

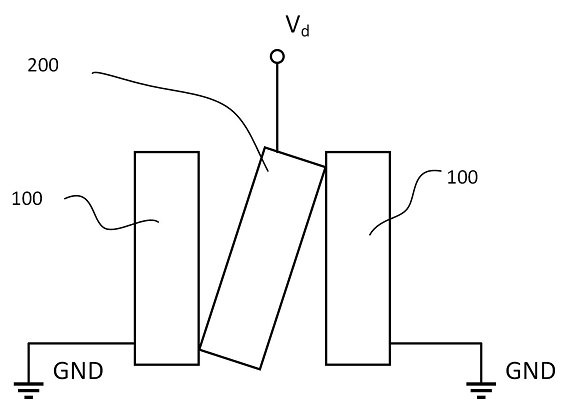

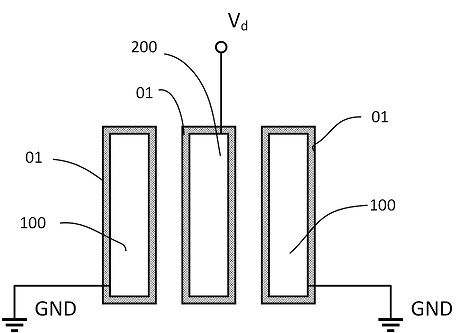

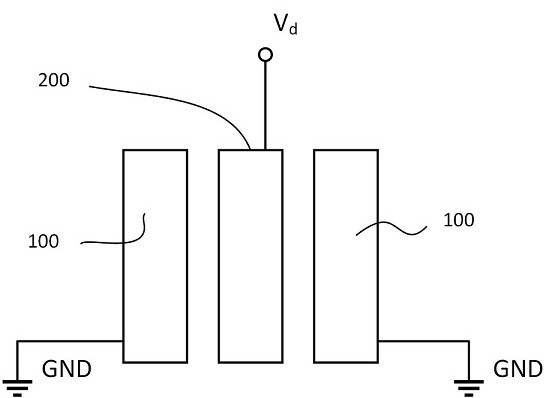

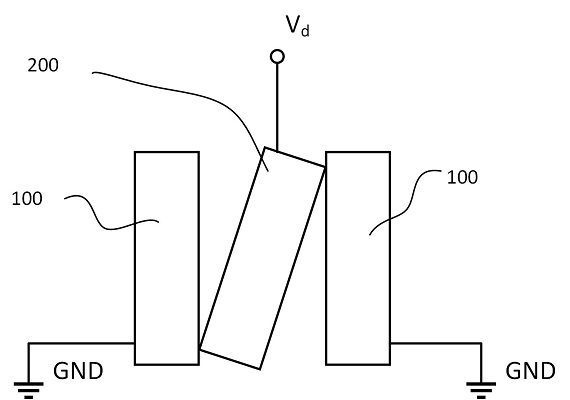

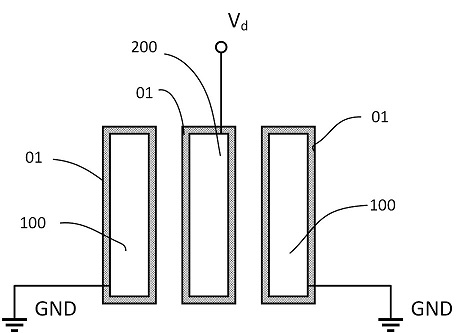

Electrostatically-driven MEMS comb tooth structure, micromirror adopting structure and preparation method of micromirror

ActiveCN114594594ANo damageReduce disturbanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysical chemistryIsolation layer

The invention discloses an electrostatic driving MEMS comb tooth structure, a micromirror adopting the structure and a preparation method of the micromirror. According to the electrostatic driving MEMS comb tooth structure, the surfaces of comb teeth are provided with insulating layers, and the insulating layers on the surfaces of the adjacent comb teeth are the same kind of insulating layers or different insulating layers; the micro-mirror adopting the electrostatic driving MEMS comb tooth structure is sequentially composed of a substrate, an isolation layer and a device layer from bottom to top. According to the manufacturing method of the micromirror, the insulating layer is manufactured by adopting a high-temperature oxidation method, a plasma enhanced chemical vapor deposition method, a low-pressure chemical vapor deposition method, a normal-pressure chemical vapor deposition method, a physical deposition method, an atomic layer deposition method or a step-by-step heterogeneous deposition method; the same or different insulating layers are obtained on the surfaces of the driving comb teeth and the surfaces of the grounding comb teeth; when the driving comb teeth and the grounding comb teeth generate adsorption, insulating layers on the surfaces of the two comb teeth are contacted, short circuit is not formed, and a good insulating effect is achieved. The electrostatic drive type MEMS micromirror capable of preventing adsorption damage is compact in structure and simple in process.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

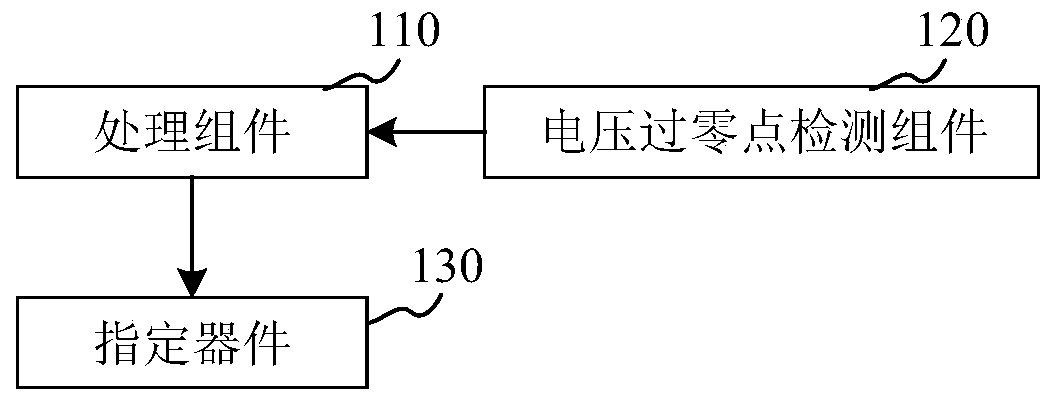

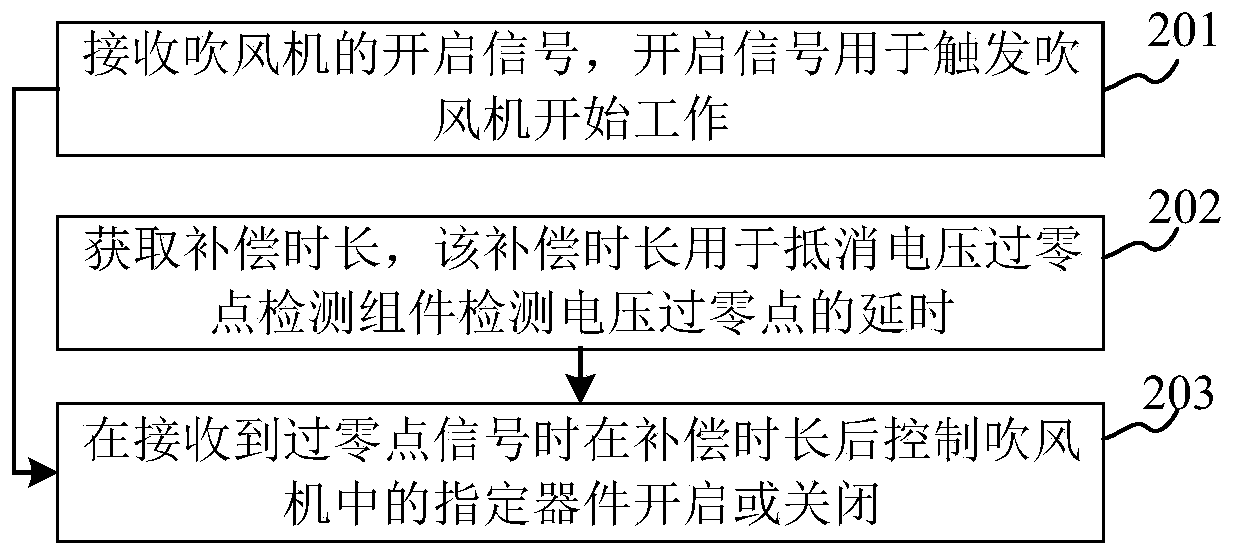

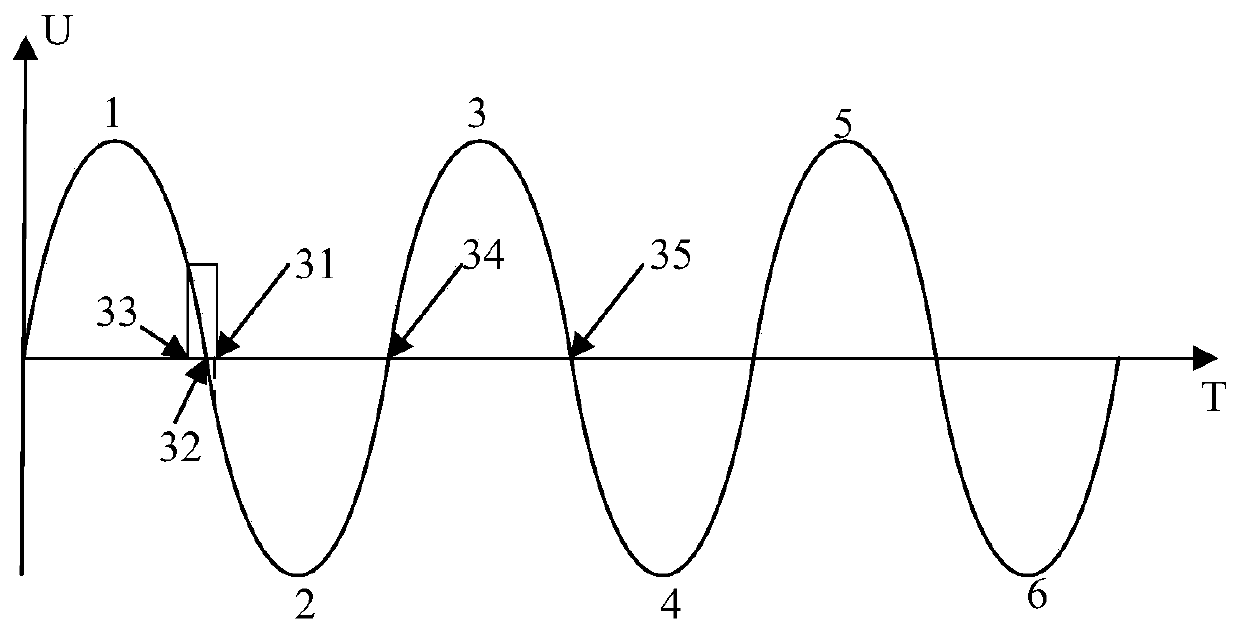

Equipment control method and device and storage medium

ActiveCN111148286ASolve the problem of easily damaged heating elementsSolve the problem of longevityProgramme controlCurrent/voltage measurementControl objectiveControl engineering

The invention relates to an equipment control method and device and a storage medium, and belongs to the technical field of electronics. The method comprises the steps of: receiving starting signals of a target device; obtaining compensation duration, wherein the compensation duration is used for offsetting the delay of a voltage zero crossing point detected by a voltage zero crossing point detection assembly; and when a zero crossing point signal is received, controlling a specified device in the target equipment to be turned on or turned off after the compensation duration, wherein the zerocrossing point signal is a signal sent by the voltage zero crossing point detection assembly when detecting a voltage zero crossing point. The problems that the heating device is easy to damage and the service life of target equipment is shortened when the heating device is controlled to be started at a position far away from a voltage zero-crossing point can be solved; because the actual voltagezero-crossing point can be determined, the specified device is controlled to be turned on or off at the actual voltage zero-crossing point, so that no impact current is generated to damage the specified device; and meanwhile, the precision of controlling the specified device can be improved, and the interference of opening and closing of the specified device on other equipment is reduced.

Owner:DREAME TECH (SHANGHAI) CO LTD

Multi-sensor parallel type force value measuring method

PendingCN113776708AGuaranteed against damageGuaranteed damageApparatus for force/torque/work measurementEngineeringMachine

The invention relates to a multi-sensor parallel type force value measuring method, which comprises the following steps of: 1, selecting a test press machine of which the output force value is matched with the measuring range of a single force sensor to apply pressure to the single force sensor, and calculating an elasticity coefficient k of the force sensor according to the deformation height after the force sensor is pressed and the pressure applied to the force sensor; 2, selecting at least four force sensors with the same elasticity coefficient for pressure detection of a press machine to be tested, vertically arranging the force sensors in parallel, and adjusting the heights of the top force bearing points of the force sensors to be consistent; and 3, applying pressure to the top force bearing points of the force sensors by a pressure head of the press machine to be tested through a force transmission plate. The technical problem that in the prior art, when more than three force sensors are used in parallel, uniform stress of all the force sensors cannot be guaranteed is solved.

Owner:HENAN PROVINCE INST OF METROLOGY

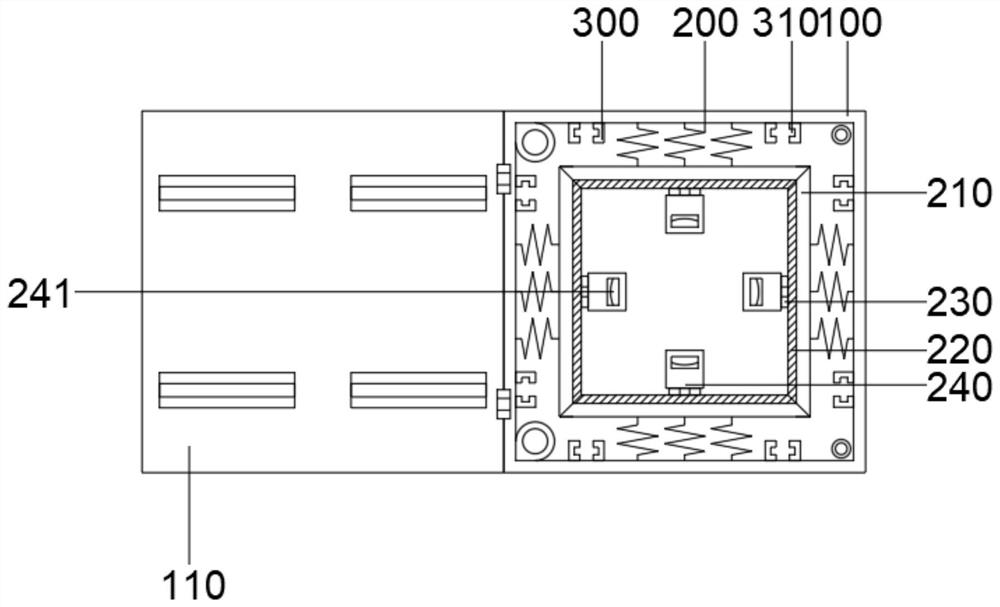

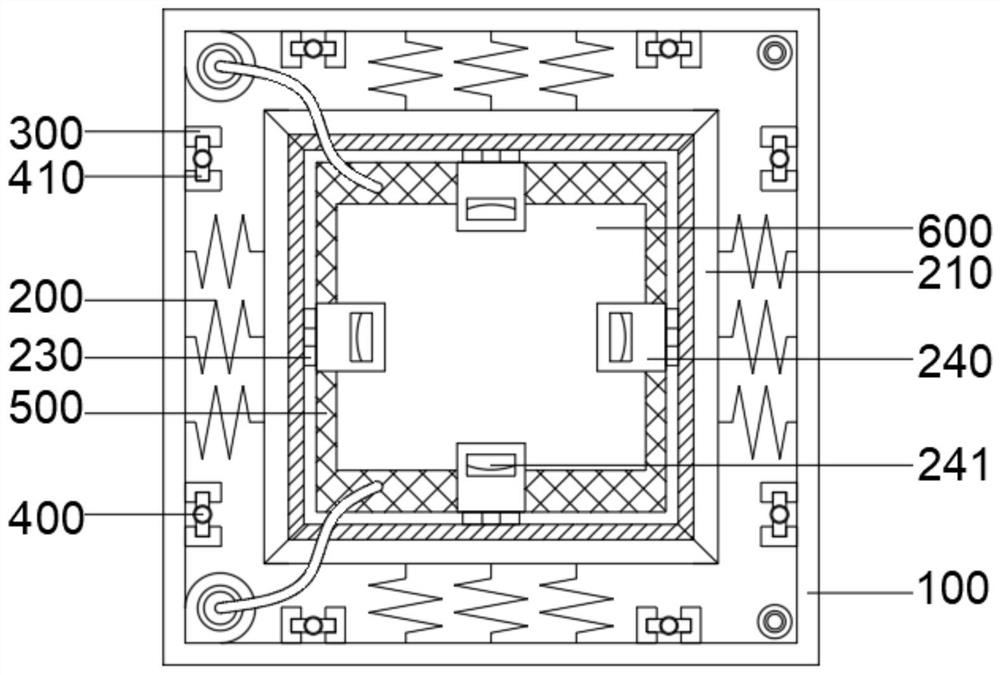

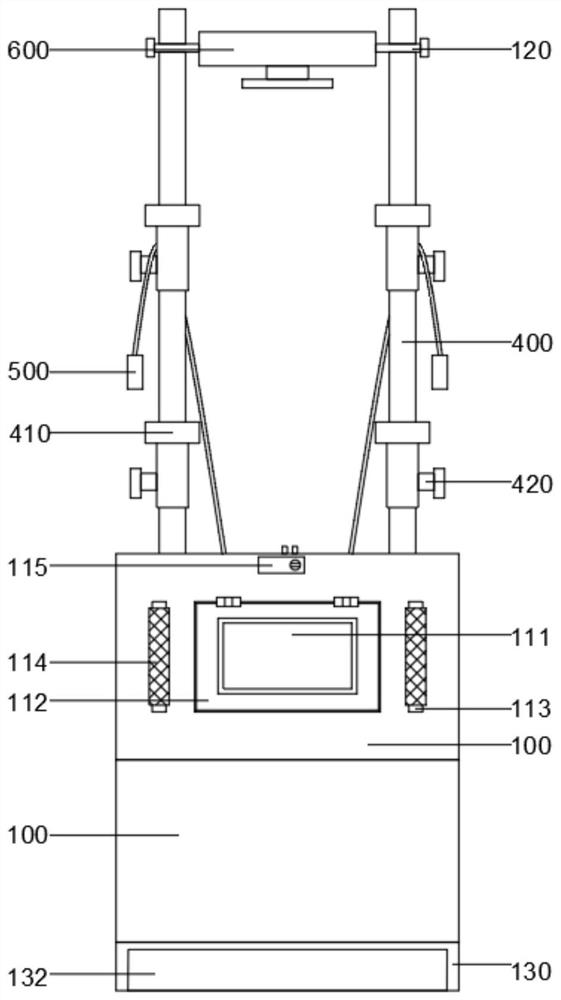

Health examination equipment and classification database thereof

PendingCN112914557AAvoid damageDamage will not occurHealth-index calculationNon-rotating vibration suppressionData transmissionTaxonomic database

The invention belongs to the technical field of health examination, and particularly relates to health examination equipment and a classification database thereof. The health examination equipment comprises a box body, a spring, a buckle block, a supporting pipe, a physical examination module, a height gauge, a data transmission module and a physical examination database; a top plate is mounted at the top end of one side wall of the box body; and a display module is mounted at the top end of the top plate. According to the health examination equipment and the classification database thereof, the health examination equipment not only can be rapidly disassembled, is regulated in mounting height, is suitable for different users and is convenient to carry, cannot be damaged in the carrying process, is wide in application range and convenient to use in various places, but also can upload physical examination information to the network in real time, compare with network information, and obtains an optimal processing scheme through artificial intelligence, so that effective suggestions are provided for improving the body health of detected personnel.

Owner:湖南省山水体检有限公司

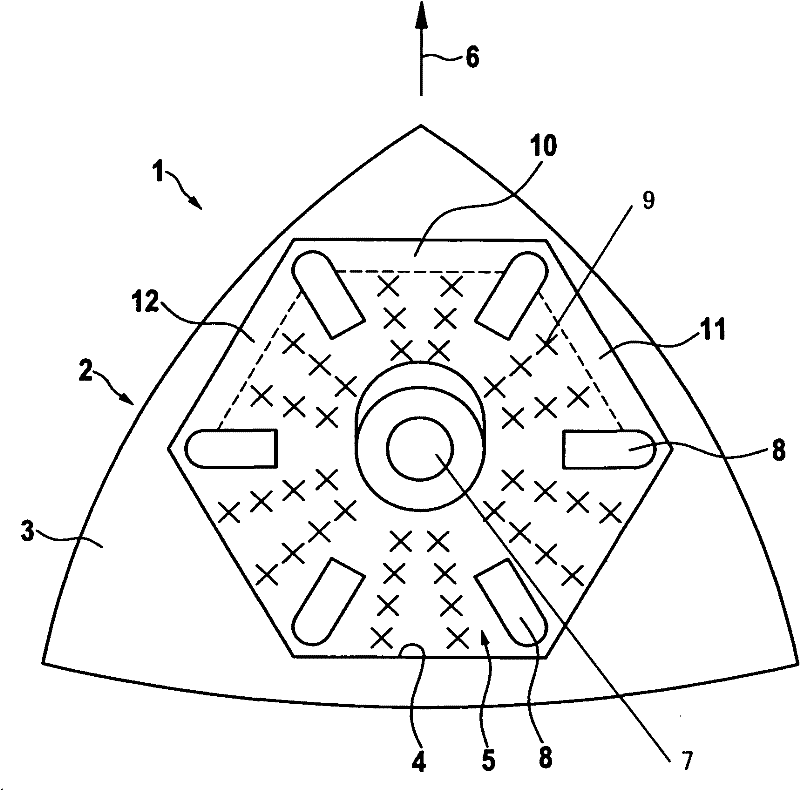

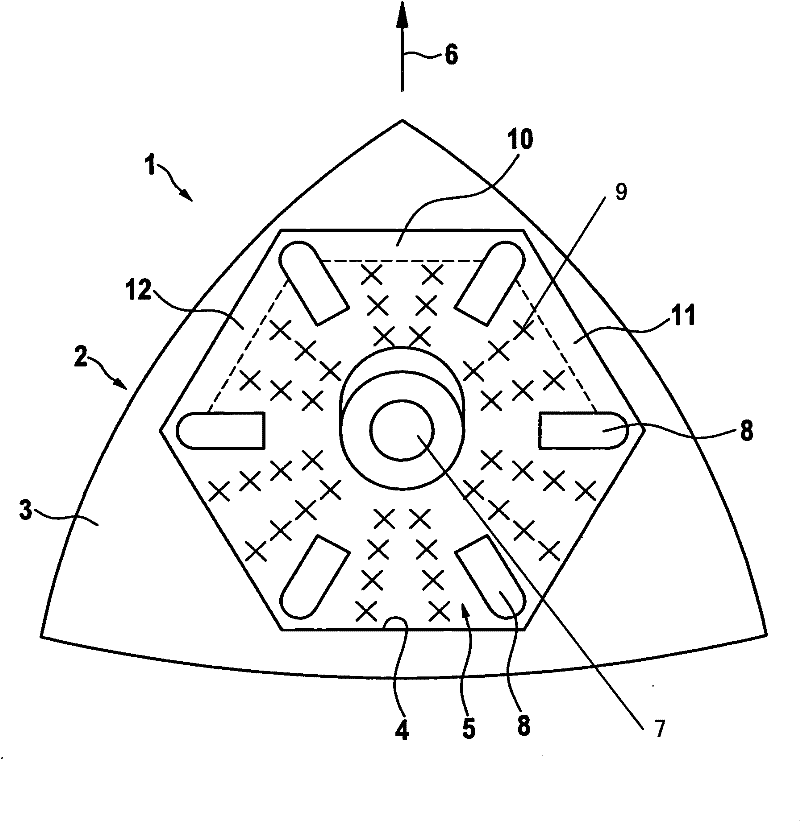

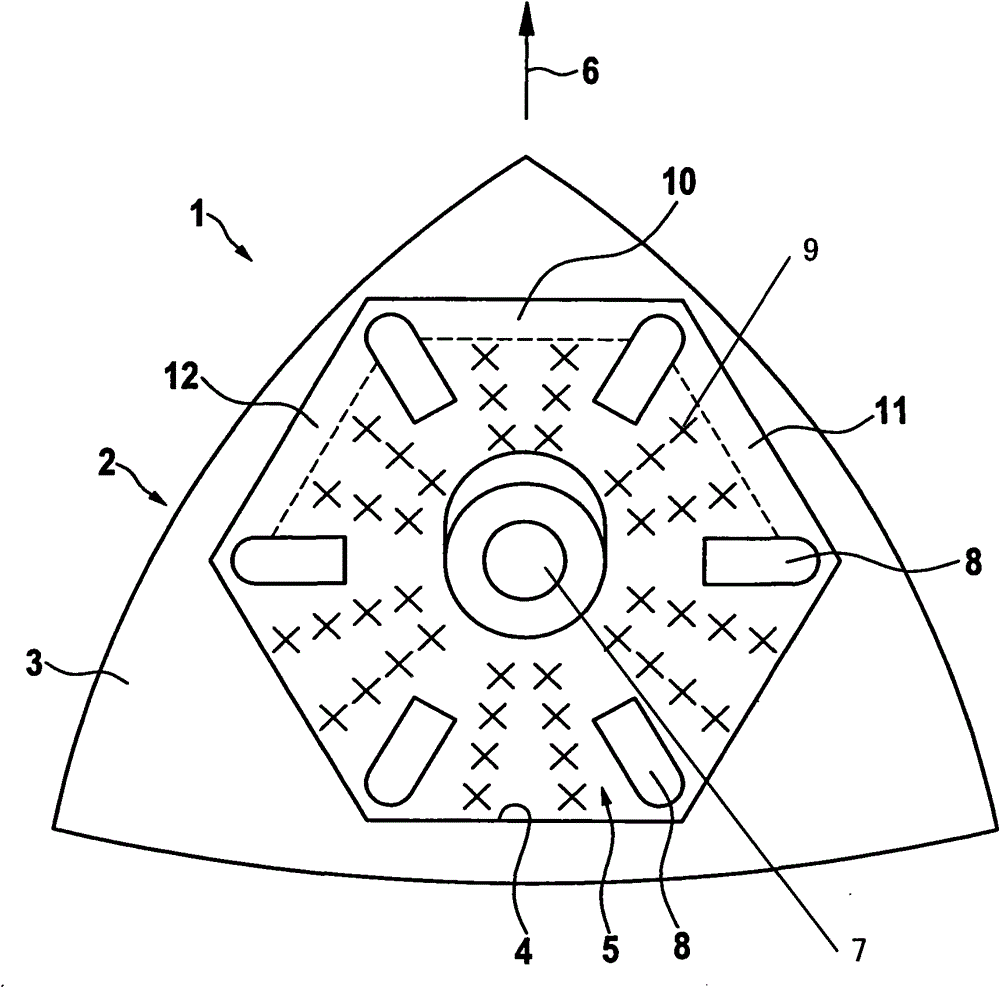

Grinding disc device for grinding apparatus of manual operation

ActiveCN102233538ADamage will not occurWill not harmSupport wheelsPortable grinding machinesEngineeringMechanical engineering

The invention relates to a grinding disc device for a grinding apparatus of manual operation. The grinding disc device comprises a grinding disc. The bottom of the grinding disc is provided with a grinding sheet which is connected to the grinding disc by means of hasps. On the grinding disc, the hasps are locked and only extend on a part of the bottom face contacting with the grinding sheet.

Owner:ROBERT BOSCH GMBH

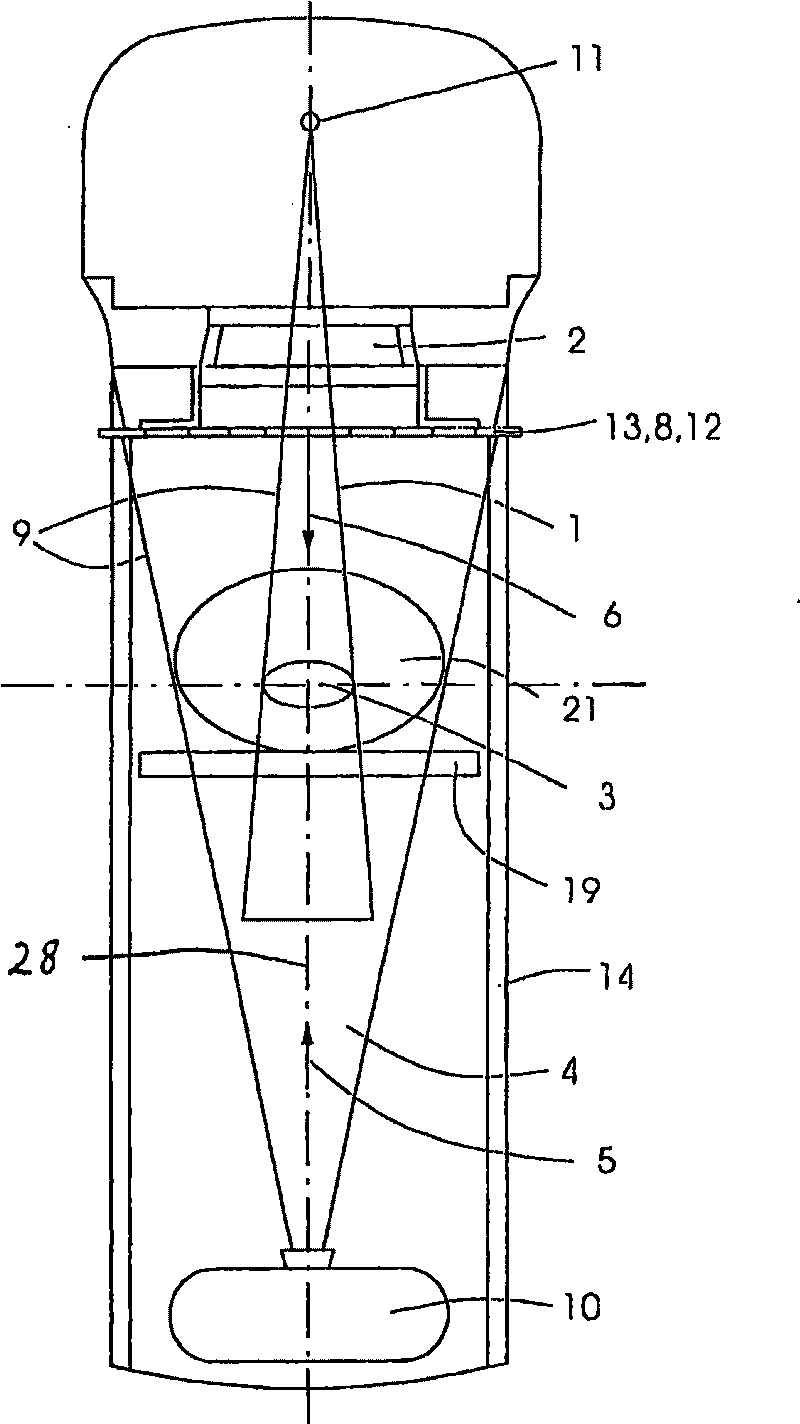

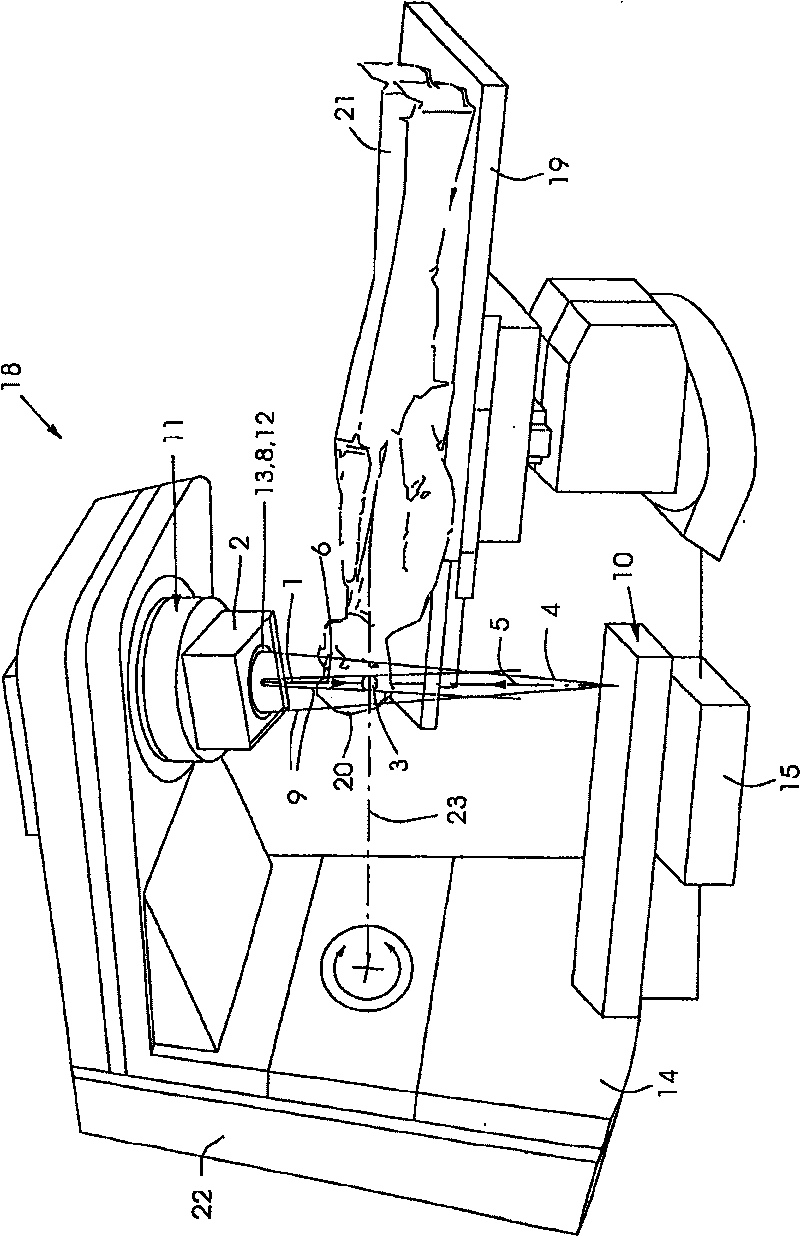

Device for performing and verifying a therapeutic treatment and corresponding controller computer

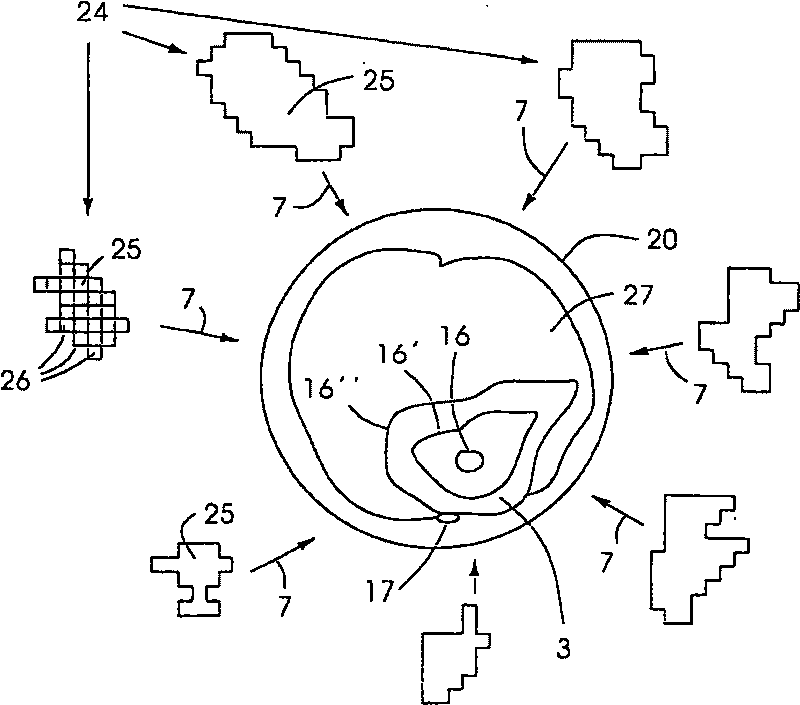

InactiveCN1622843BDamage will not occurLow technical costX-ray/gamma-ray/particle-irradiation therapyBeam sourceTherapeutic treatment

The invention relates to a device for performing and verifying therapeutic radiation. An x-ray (4) is arranged across from a target volume (3) of the beam source (11) for the high-energy beam (1) in such a way that the beams (1, 4) run in essentially opposite directions (5, 6). The invention also relates to a computer program and a control method for operating said device. The inventive device makes it possible to exactly verify areas (16, 16', 16') that are subjected to different levels of radiation, the entire anatomy of the target volume (3), and the surroundings thereof in addition to thecontour of the therapy beam (1). The x-ray (4) detects the anatomy and position of the patient (21) within the range of the target volume (3) before the high-energy beam (1) is applied and then detects the shape of the applied high-energy beam (1) and areas (16, 16', 16') that are subjected to different levels of radiation as well as at least one partial segment of the target volume (3) during theemission breaks of the high-energy beam (1). The detected datan is used for correcting the treatment plan.

Owner:DEUTES KREBSFORSCHUNGSZENT STIFTUNG DES OFFENTLICHEN RECHTS

Electrostatically driven mems comb-tooth structure, micromirror using the structure and preparation method thereof

ActiveCN114594594BNo damageReduce disturbanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesPhysical chemistryIsolation layer

Electrostatically driven MEMS comb-tooth structure, micromirror using the same, and preparation method thereof; electrostatically driven MEMS comb-tooth structure, the surface of the comb-tooth has an insulating layer, and the insulating layers on the surfaces of adjacent comb-tooths are the same insulating layer or different insulating layers The micromirror using the electrostatically driven MEMS comb-tooth structure is composed of a substrate, an isolation layer and a device layer from bottom to top; the fabrication method of the micromirror adopts high temperature oxidation, plasma enhanced chemical vapor deposition, low pressure chemical vapor deposition, atmospheric pressure chemical vapor deposition Deposition, physical deposition, atomic layer deposition or step-by-step heterogeneous deposition to make insulating layers; that is, the same or different insulating layers are obtained on the surfaces of the driving comb teeth and the grounding comb teeth; when the driving comb teeth and the grounding comb teeth are adsorbed, then The insulating layers on the surfaces of the two are in contact without forming a short circuit and have good insulating effect; the electrostatically driven MEMS micromirror for preventing adsorption damage of the present invention has a compact structure and a simple process.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

Spring compression conveying device

The invention discloses a spring compression conveying device. The spring compression conveying device comprises a bottom frame and conveying mechanisms, wherein the two conveying mechanisms are oppositely arranged, each conveying mechanism is composed of a flat conveying section and an arc section which are not provided with baffles, and a plurality of stand columns are arranged in each flat conveying sections and each arc section. According to the spring compression conveying device, firstly, the stand columns are arranged to replace original baffles, and the conveying belts / conveying chains are in point contact with the stand columns, so that the friction resistance generated in the moving process of the conveying belts / conveying chains is reduced, and the conveying belts / conveying chains are prevented from being damaged due to excessive friction; secondly, the stand columns are arranged to replace original belt wheels / chain wheels, so that the structure is simplified, no corresponding matching relation exists, and the situation that the conveying belts / conveying chains are stuck is avoided; and finally, the stand columns are arranged along arcs, the compression distance is obviously reduced compared with inclined straight edge compression, the length of a compression section is reduced, meanwhile, the tensioning effect of the stand columns on the conveying belts / conveying chains can be effectively improved, the possibility that the conveying belts / conveying chains fall off from the stand columns can be reduced, and the stability is improved.

Owner:FOSHAN QILIN MATTRESS MACHINERY CO LTD

A test device for thermal molding and curing deformation of resin-based composite materials and the preparation and use method of the device

ActiveCN104315990BReduce difficultyImprove survival rateUsing optical meansSpecial purpose recording/indication apparatusPolymer scienceResin matrix

The invention relates to a testing device for resin matrix composite material hot mold pressing curing deformation and a manufacturing and using method thereof. The testing device comprises resin matrix composite material prepreg and FBG sensors arranged in the prepreg. The method comprises the steps that the FBG sensors are laid on the nth layer in the fiber axial direction to be used as strain sensors, reference sensors for temperature compensation are laid on the nth layer or the (n+1)th layer or the (n-1)th layer, lead grooves are formed in a mold side wall frame board, the mold side wall frame board is coated with a high temperature resistance polymer film, leads of the sensors are led out of the lead grooves and connected with a signal receiver, a mold is closed, hot press molding is carried out, and curing forming on-line real-time monitoring is achieved. The problems that during composite material heat mold pressing curing deformation monitoring, grid regions are fragile and prone to breakage, and monitoring signals cannot be effectively transmitted if leading is inappropriate in a closed full-rigid hot mold pressing mold are solved, and meanwhile the problem that a composite material structure part with built-in FBG sensors is hard to break away from the full-rigid mold is solved.

Owner:SHANDONG UNIV

Settling tank sludge treatment plant with ultrasonic depth detection for steelworks

ActiveCN111686484BConducive to scientific distributionGuaranteed cleanlinessSettling tanks feed/dischargeUsing subsonic/sonic/ultrasonic vibration meansSteelmakingHigh density

The invention discloses a sedimentation tank sludge treatment device with ultrasonic depth detection for a steelmaking plant, which belongs to the technical field of sludge treatment and includes a support component, a mud delivery component, and a transmission component. The support component is located outside the entire set of devices. The support assembly is provided with a mud delivery assembly, and the top of the support assembly is provided with a transmission assembly. The present invention is scientific and reasonable, and safe and convenient to use. The device can observe the amount of sludge in real time through an ultrasonic distance sensor, which is beneficial to sludge treatment. The frequency is scientifically allocated, and the sludge and water can be separated by pushing and pulling the switch, so that the upper layer of water will not be affected when the sludge is discharged, and the upper layer of water is still kept clean. This device makes the shallow layer The mixing of sludge and water is conducive to the efficient discharge of sludge, and when the movable mud scraper rotates to the bottom of the shell, the movable mud scraper will bend and scrape the high-density sludge deposited on the bottom of the shell , so that sludge cleaning is more thorough.

Owner:赤峰远联钢铁有限责任公司

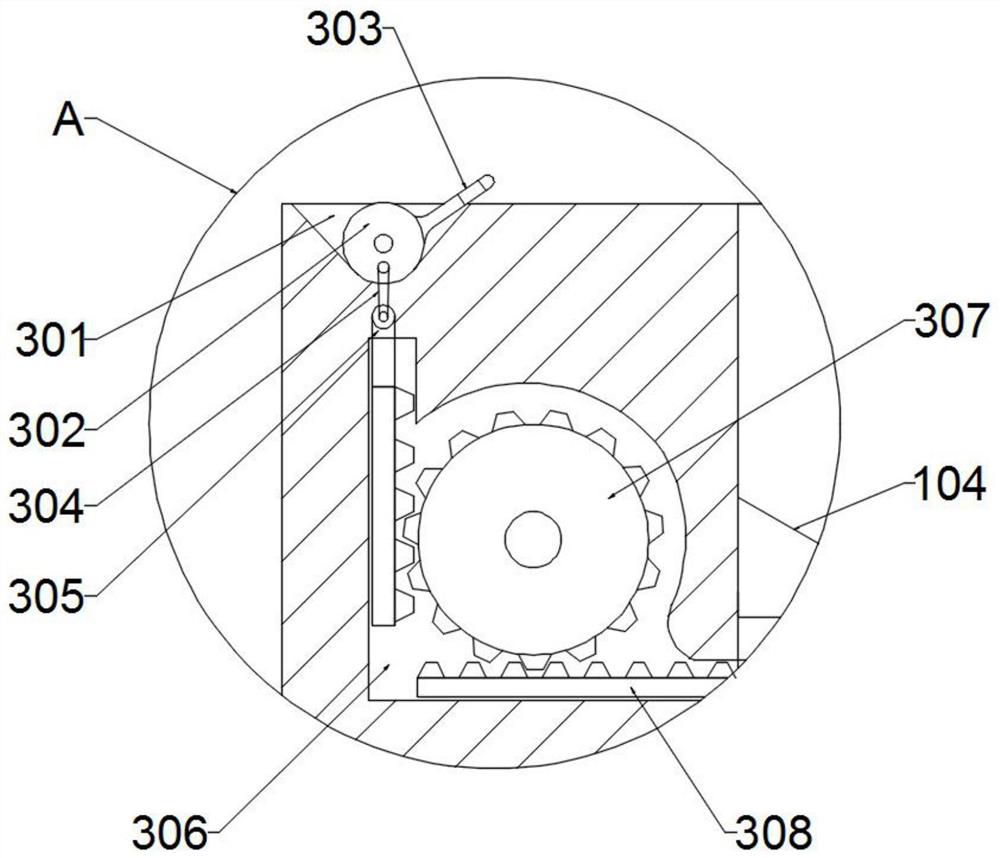

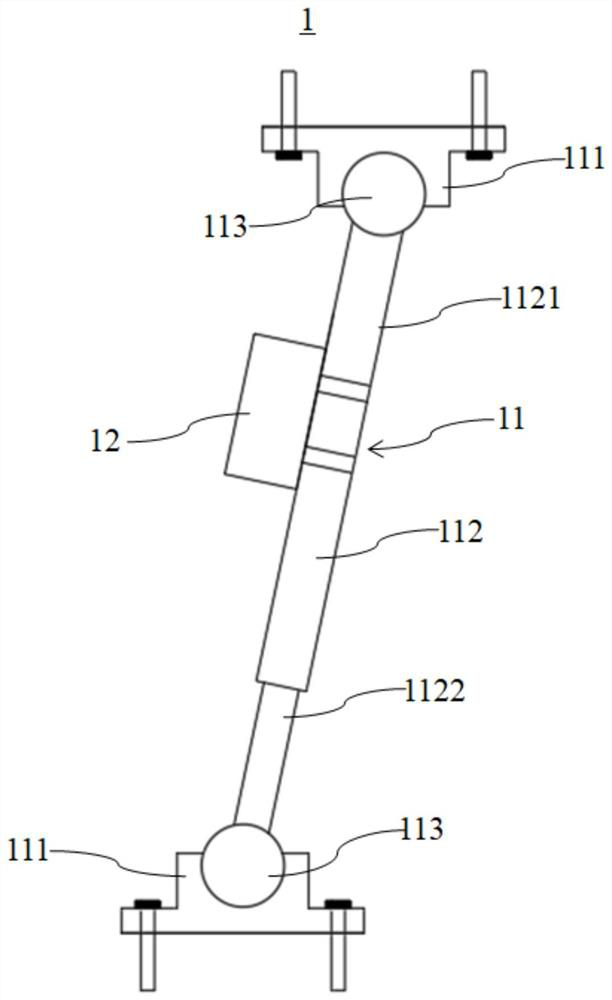

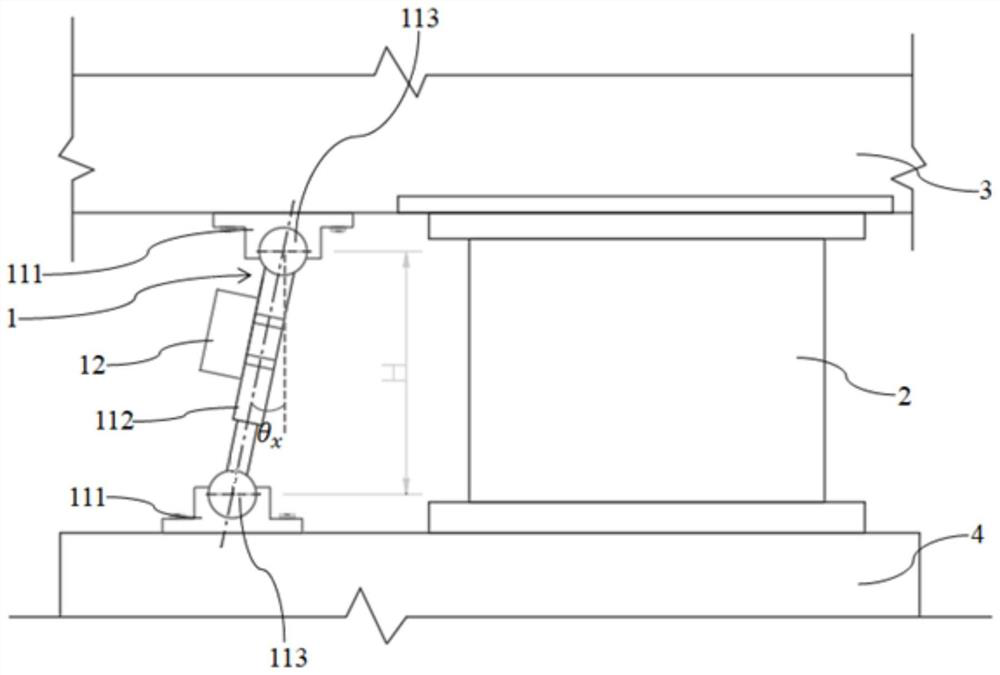

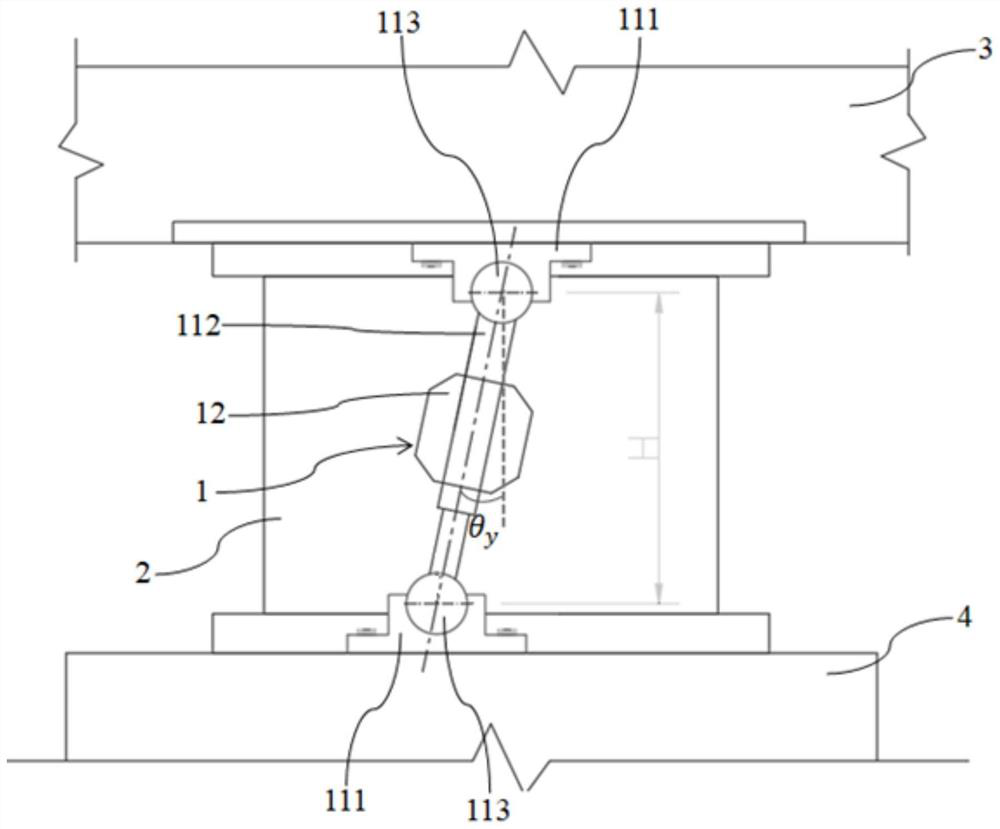

Displacement monitoring device and displacement monitoring method for bridge support

PendingCN114322880ALow installation requirementsAvoid damageIncline measurementStructural engineeringControl theory

The invention discloses a displacement monitoring device and a displacement monitoring method for a bridge support, the displacement monitoring device comprises a supporting assembly and a tilt angle sensor, the supporting assembly is telescopic and can be rotatably connected between the bottom of a bridge body and the top of a bridge pier in multiple directions; the tilt angle sensor is fixedly arranged on the supporting assembly and used for measuring the tilt angle of the supporting assembly in the bridge direction and the tilt angle of the supporting assembly in the transverse bridge direction so as to monitor the displacement of the support in the bridge direction and the displacement of the support in the transverse bridge direction. According to the embodiment of the invention, the supporting assembly which is telescopic and can rotate in multiple directions and the tilt angle sensor are adopted, so that the measurement precision is improved and the service life of the sensor is prolonged.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

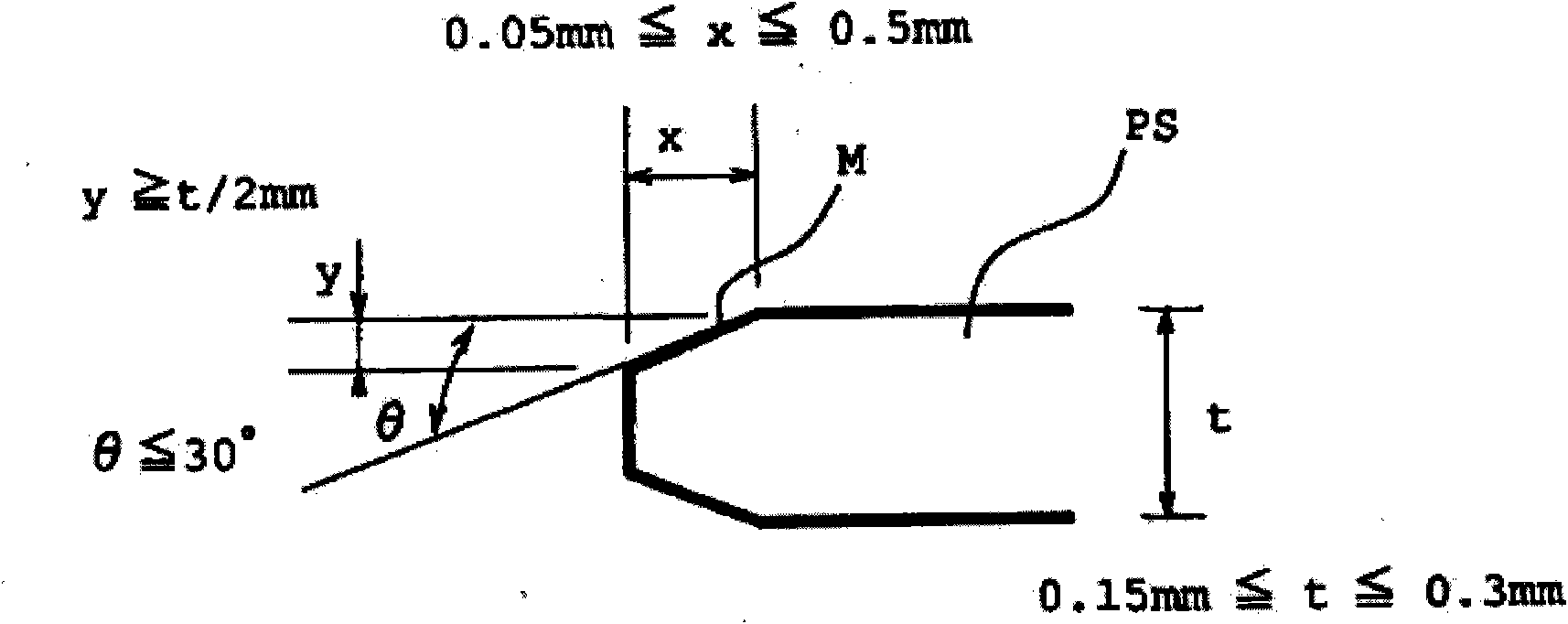

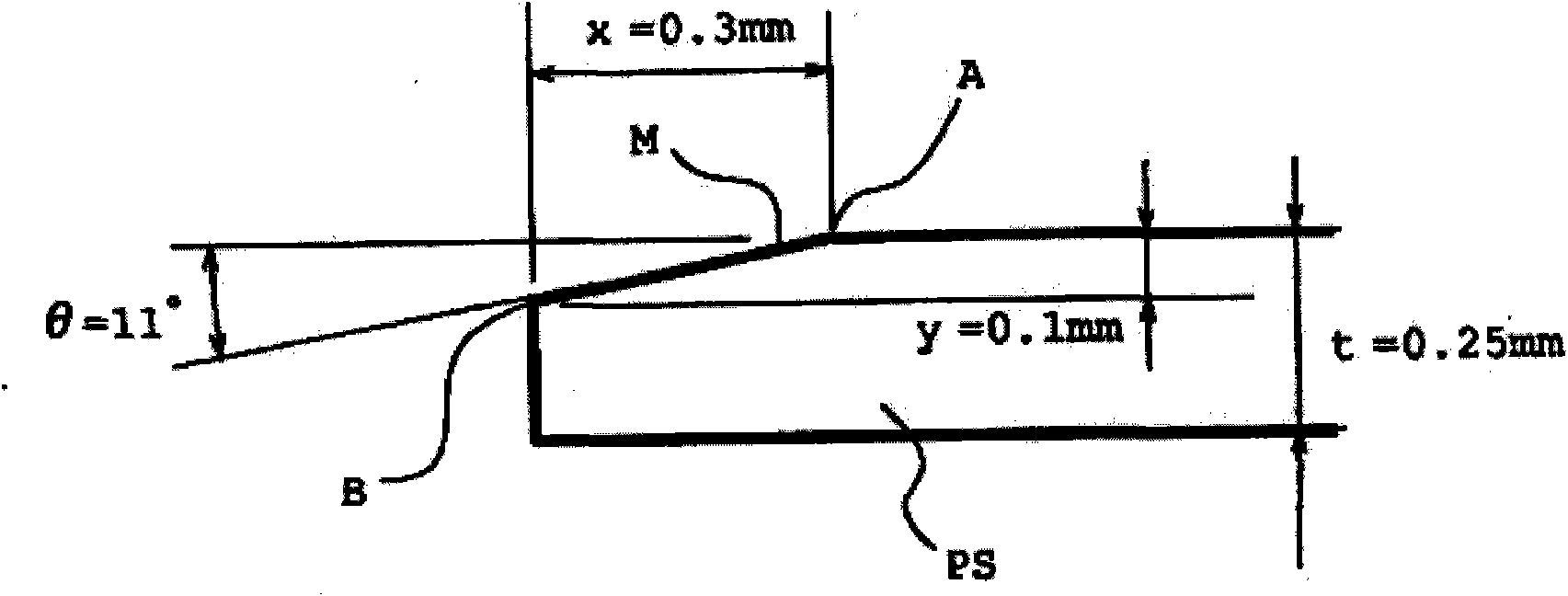

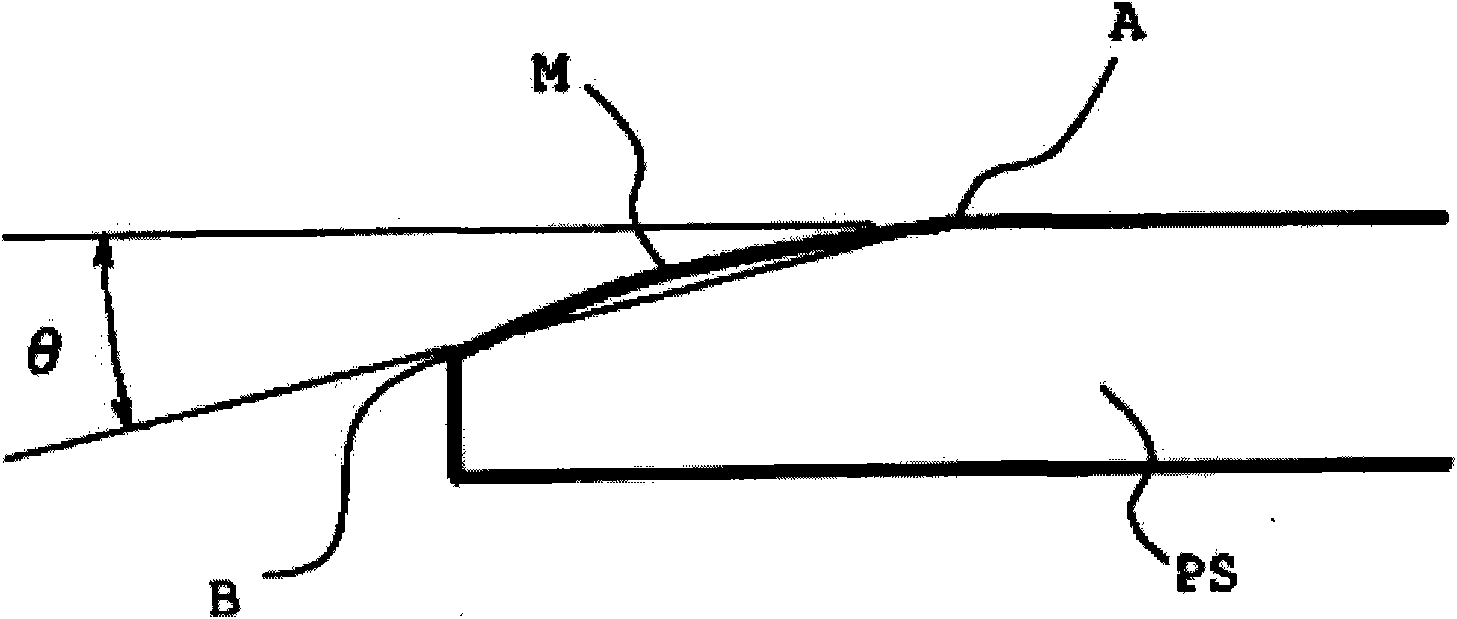

Print sheet

InactiveCN101624802AReduce the force of entrySmooth entrySpecial paperPaper/cardboardHeat sensitivePaper sheet

The invention provides a printing sheet, it is desirable that a print sheet be provided which can be smoothly inserted between a thermal head and a platen which are in contact with or almost in contact with each other. A print sheet which is transported by transporting means and inserted between a thermal head and a platen which are disposed to oppose to each other in a printing unit of a printer, which is to be used for printing, includes: a chamfered portion to decrease the sheet thickness of at least one surface of the front and rear surfaces and which is formed at the end portion in the supply direction of the printing unit. The chamfered portion forms tape shape, which has a dimension in a thickness direction y equal to or less than t / 2 mm in the case where the sheet thickness is t and a dimension x in a longitudinal direction in the range of 0.05 to 0.5 mm from the end in the feeding direction, and an inclination angle [theta] of a cut-off imaginary line is equal to or less than 30[deg.].

Owner:ALPS ALPINE CO LTD

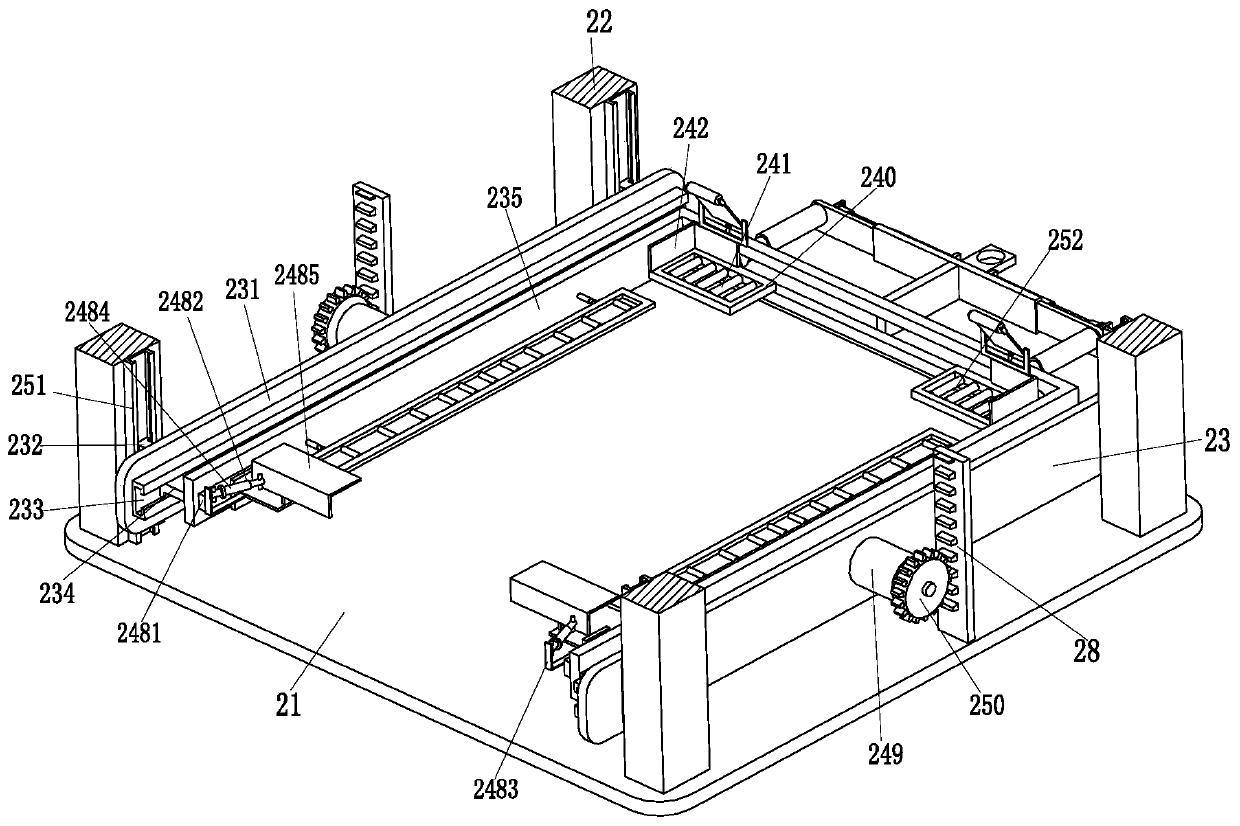

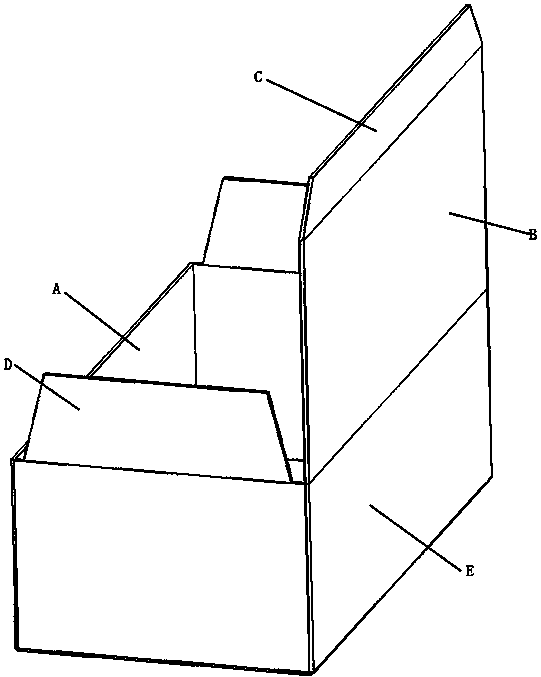

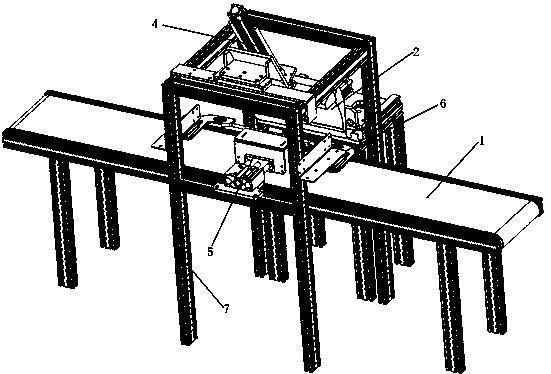

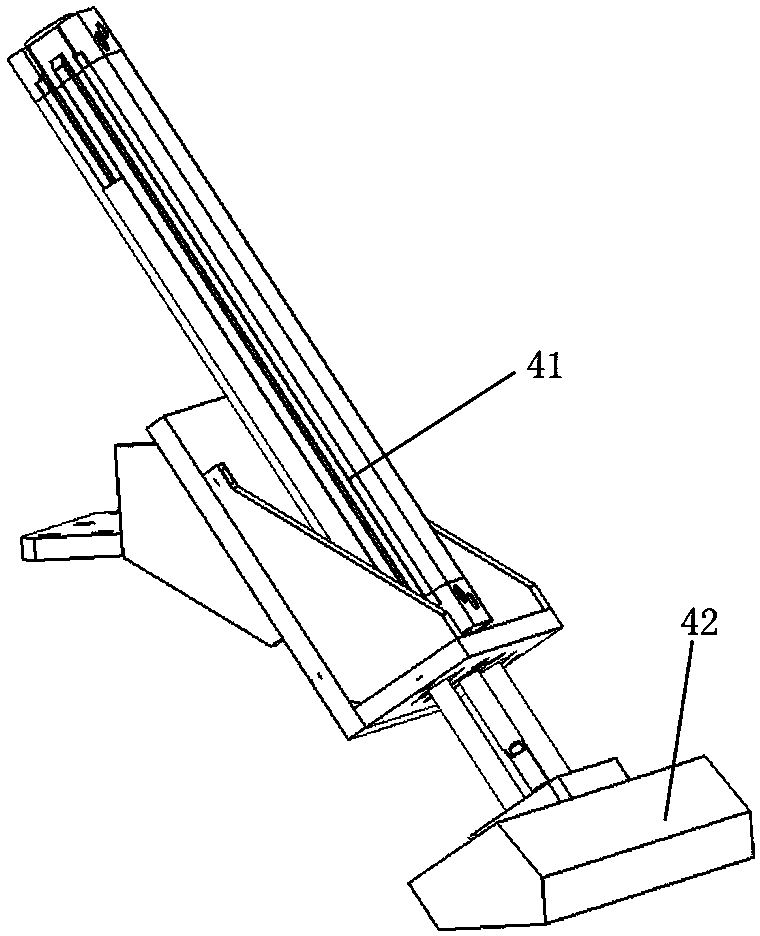

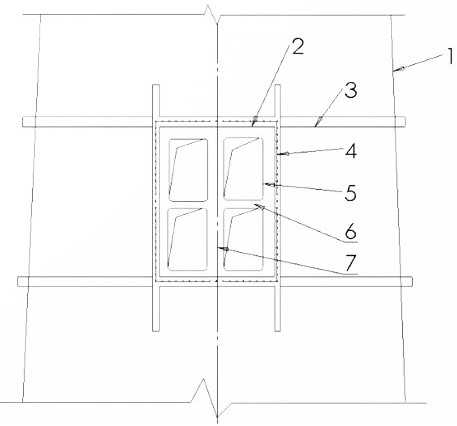

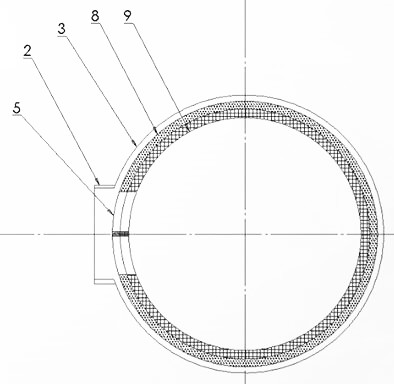

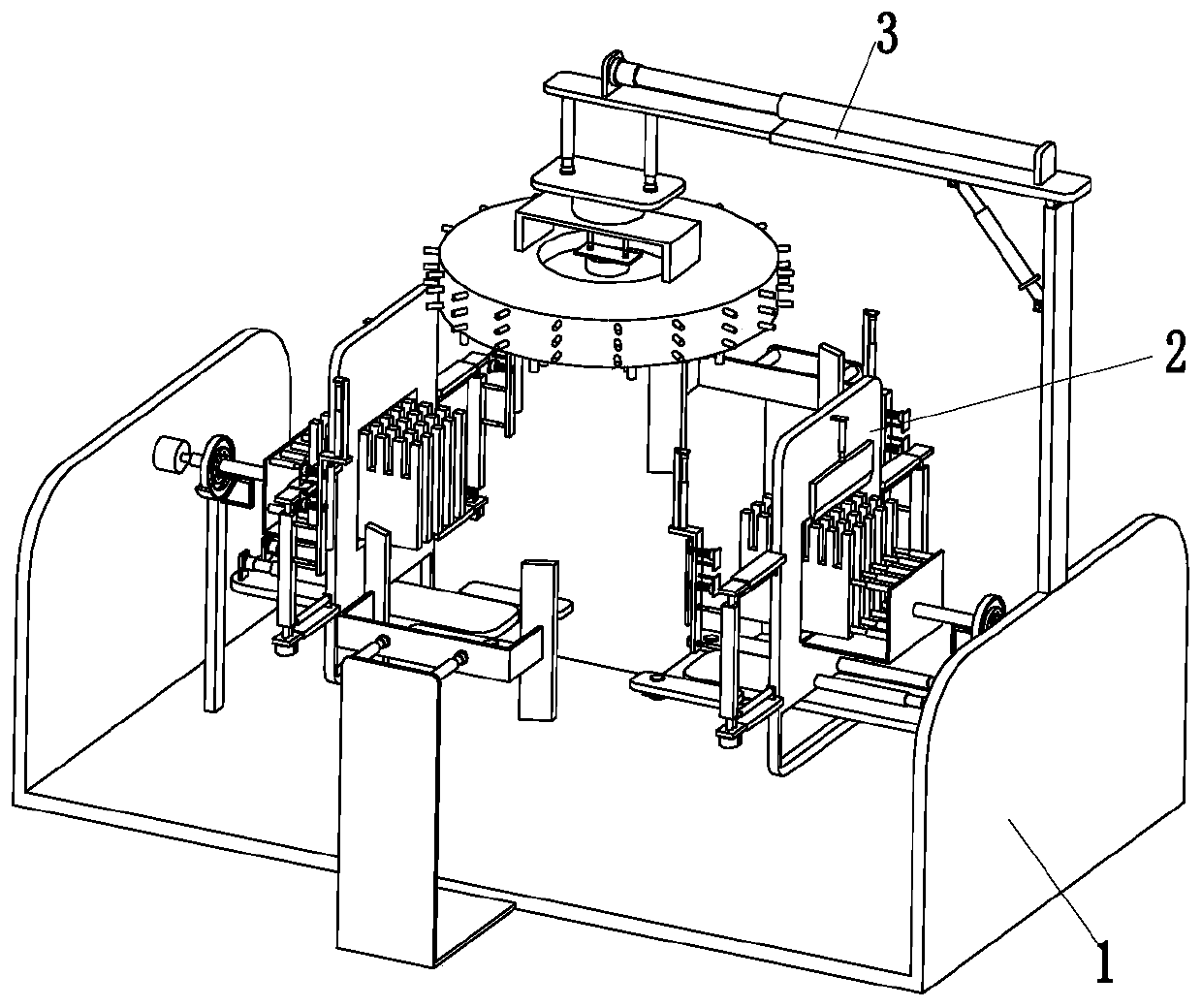

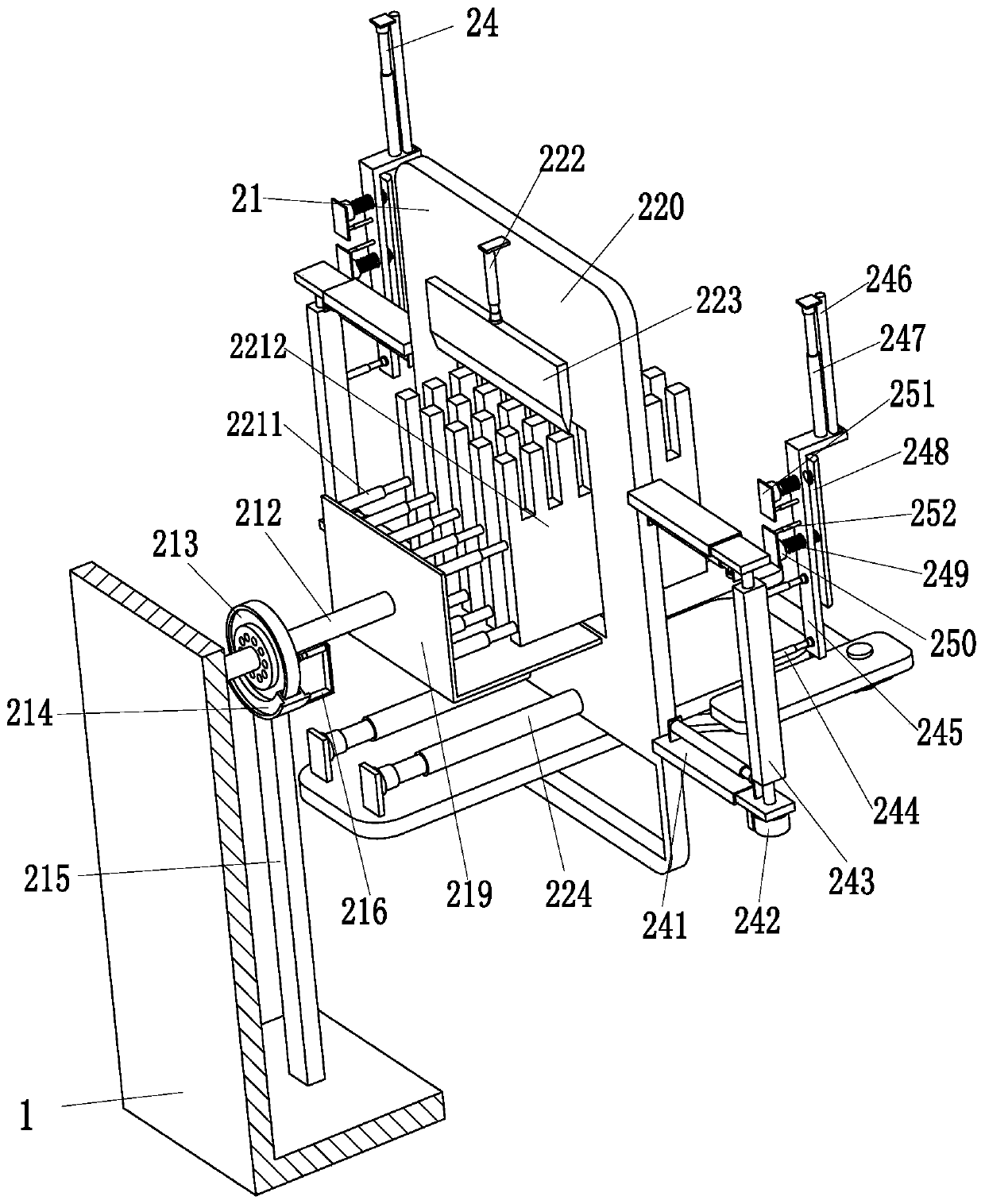

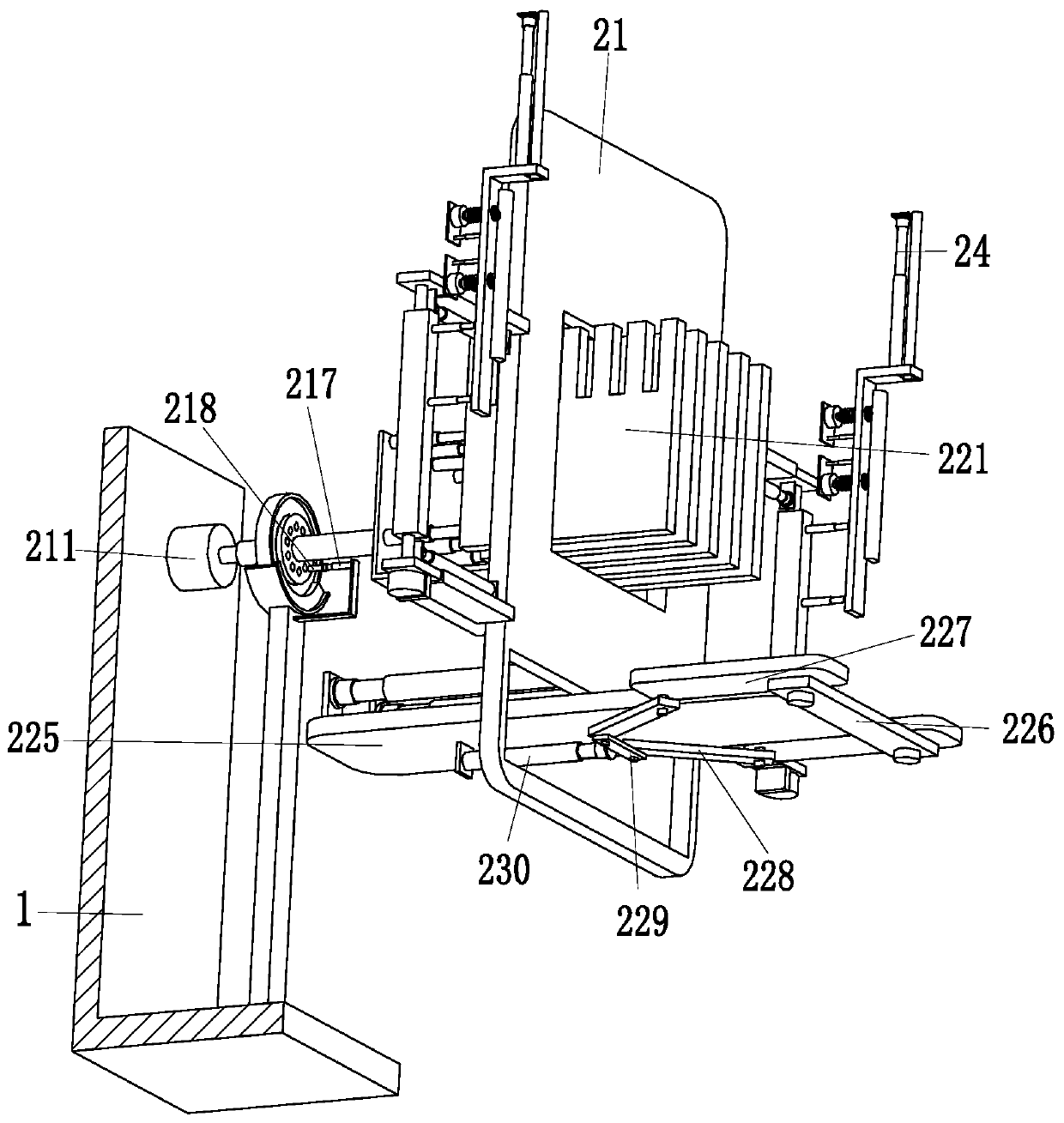

A type 02 corrugated carton packaging machine with duck tongue

Owner:ROBOT PHOENIX

An online method for opening holes in a coke oven brick-concrete chimney

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Auto parts flywheel shell automatic processing equipment and flywheel shell automatic processing process

ActiveCN109128930BRealize the positioning functionDamage will not occurWork clamping meansMetal working apparatusFlywheelMachining

The invention relates to vehicle fitting flywheel shell automatic treatment equipment and a flywheel shell automatic treatment process. The equipment comprises a chassis, a positioning device and a cleaning device; the positioning device is mounted at the upper end of the chassis; and the cleaning device is mounted at the right end of the chassis. The equipment can solve the difficulties of difficult achievement of the positioning precision in traditional clamping of flywheel shells, difficult clamping of the flywheel shells by traditional clamping equipment due to higher weight of the flywheel shells, surface damage of the flywheel shells caused by easy looseness during machining, capability of machining different positions of the flywheel shells through renewed clamping of the flywheel shells by persons, halfway cleaning of iron chips attached in the flywheel shells through a manual mode, long consumed time, high labor intensity and low working efficiency, and can achieve automatic positioning and cleaning functions of the flywheel shells.

Owner:江苏固诺新材料科技有限公司

Grinding disc devices for hand-operated grinding instruments

ActiveCN102233538BDamage will not occurWill not harmSupport wheelsPortable grinding machinesEngineeringSand-paper

Owner:ROBERT BOSCH GMBH

Control method of solar clothes charging current and device

InactiveCN102355019BDamage will not occurBatteries circuit arrangementsElectric powerCharge currentElectrical battery

The invention relates to a control method of solar clothes charging current, which comprises the following steps that: detecting outputted power of a solar battery; detecting dischargeable quantity and electromotive force of a built-in battery; detecting chargeable quantity and electromotive force of an external battery; solving power balance equations set; and charging the external battery according to the calculated charging current of the external battery. The invention also relates to a control device of the solar clothes charging current, which comprises a detection module, a calculation module and a charging module. Due to the adoption of the control method and the control device, the external battery can be charged within a minimal time.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com