Print sheet

A technology of printing paper and printing section, applied in the directions of printing device, printing, paper, etc., can solve the problems of not getting good printing results, wrinkling of printing paper, etc., achieving good printing results, not easy to jam, and preventing paper feeding The effect of speed changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

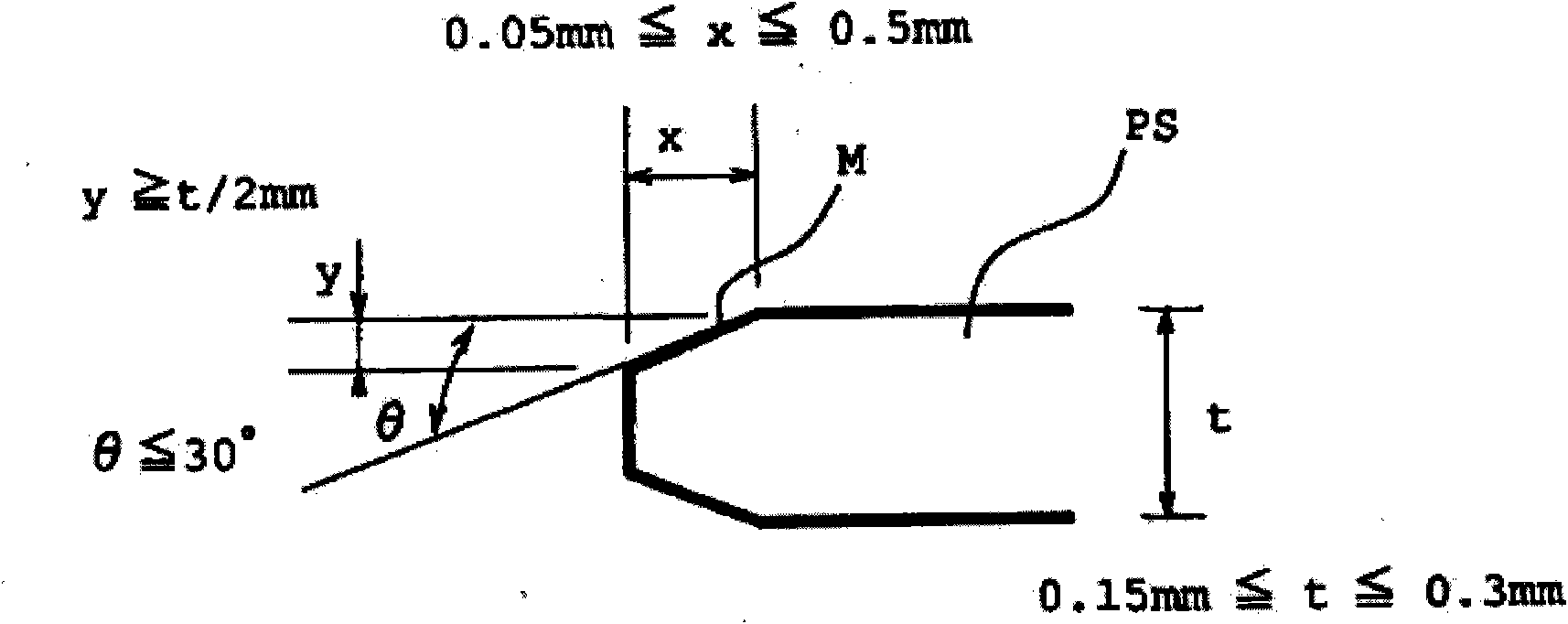

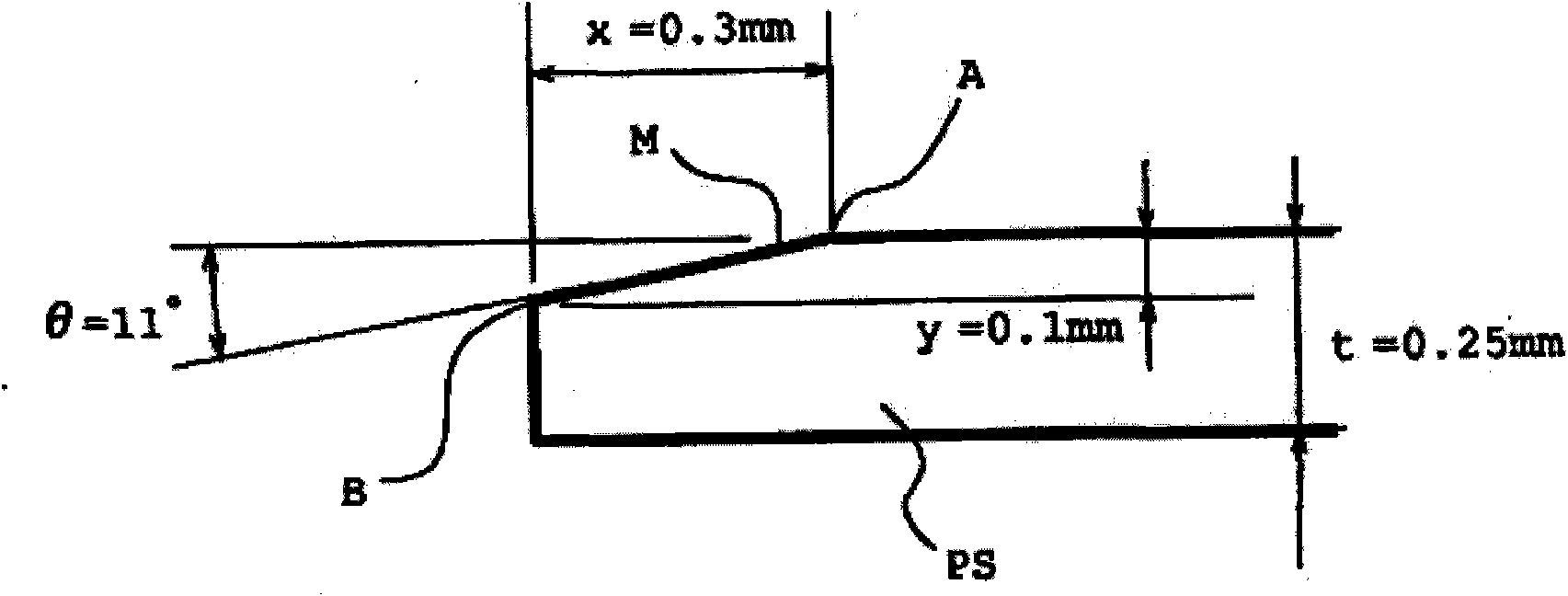

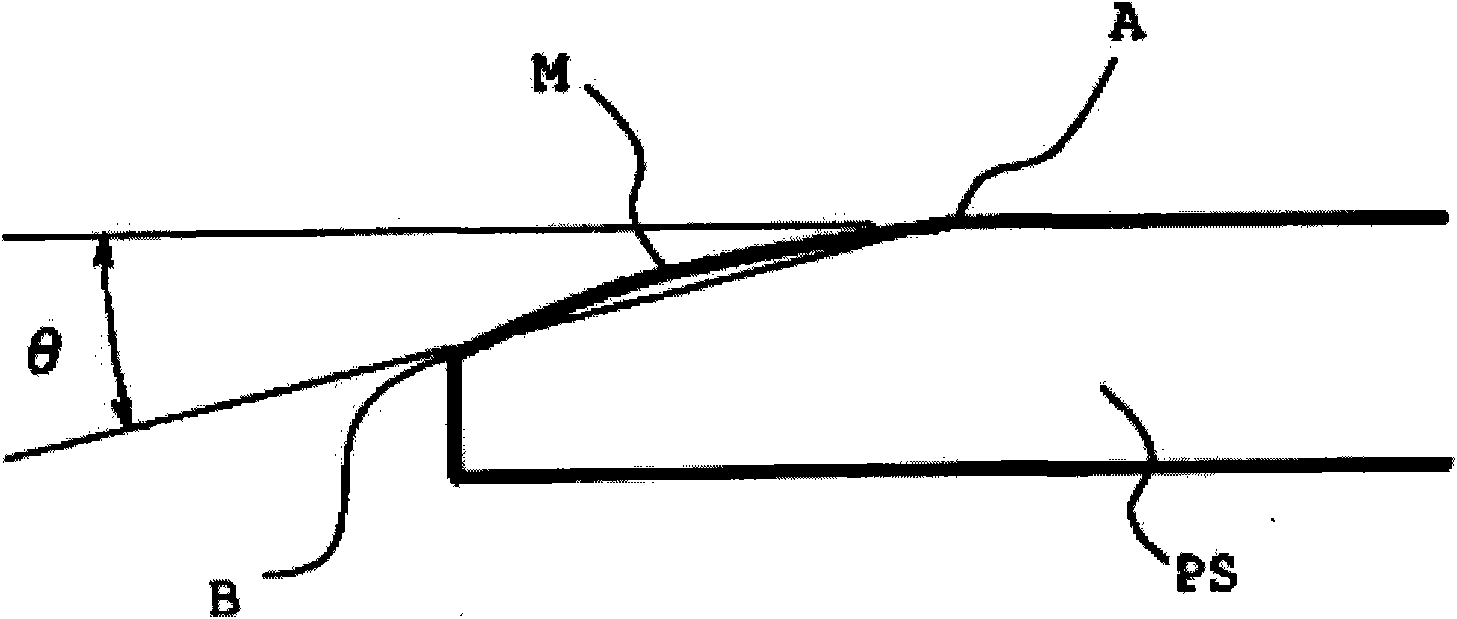

[0029] Below will be used Figure 1 to Figure 5 The printing paper of the present invention will be described. figure 1 It is a model diagram representing the structure of the main part of the printing paper of the present invention; figure 2 It is a schematic diagram showing the structure of the printing paper of this embodiment; image 3 It is a schematic diagram showing other structures. Figure 4 It is a coordinate diagram representing the inclination angle of the chamfering portion of the printing paper of the present invention and the entering force between the thermal head and the platen; Figure 5 It is a schematic diagram showing the entry state of the printing paper between the thermal head and the platen according to this embodiment.

[0030] The printing paper PS according to the present embodiment is conveyed by driving a pair of conveying rollers arranged on a conveyance path in the printer and rotatable while sandwiching the printing paper PS. In the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com