Settling tank sludge treatment plant with ultrasonic depth detection for steelworks

A technology for depth detection and sludge treatment, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, feeding/discharging devices of settling tanks, etc., can solve the impact, can not real-time observation of sludge thickness, sedimentation tank volume and Poor long-term maintenance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

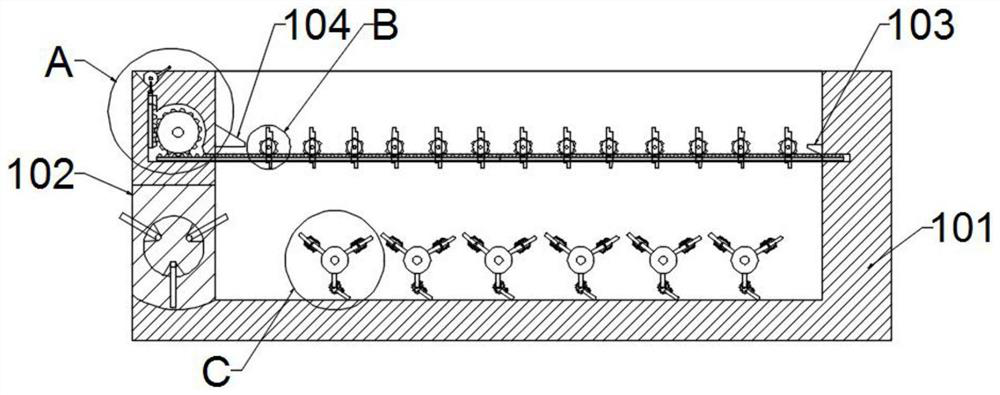

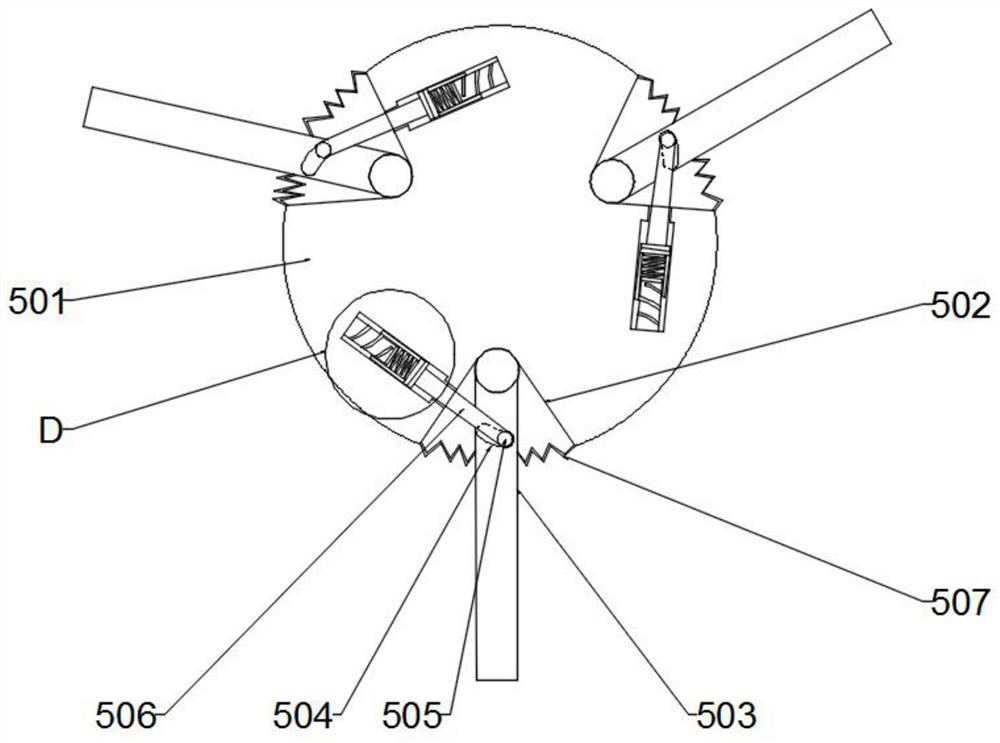

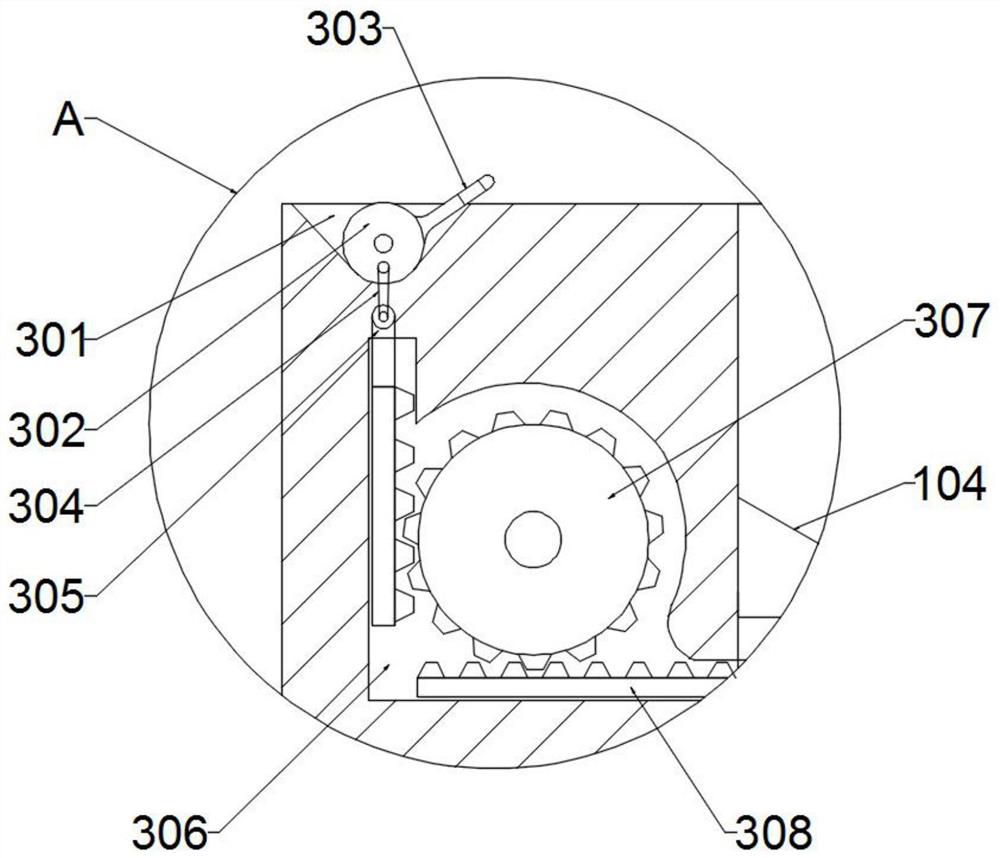

[0028] Example: such as Figure 1-6 As shown, the sedimentation tank sludge treatment device with ultrasonic depth detection used in steelmaking plants includes support components, mud delivery components, transmission components, isolation components, and sludge discharge components. The support components are located on the outside of the entire device to protect and The role of supporting other components, the support component is equipped with a mud delivery component, which plays the role of thoroughly transporting the sludge, the top of the support component is equipped with a transmission component, the transmission component plays the role of controlling the isolation component, and the middle part of the support component is set. An isolation component, the isolation component plays the role of isolating the sludge from the water, and one end of the support component is provided with a mud discharge component, which plays the role of discharging the sludge.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com