Patents

Literature

237results about How to "Avoid bending damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

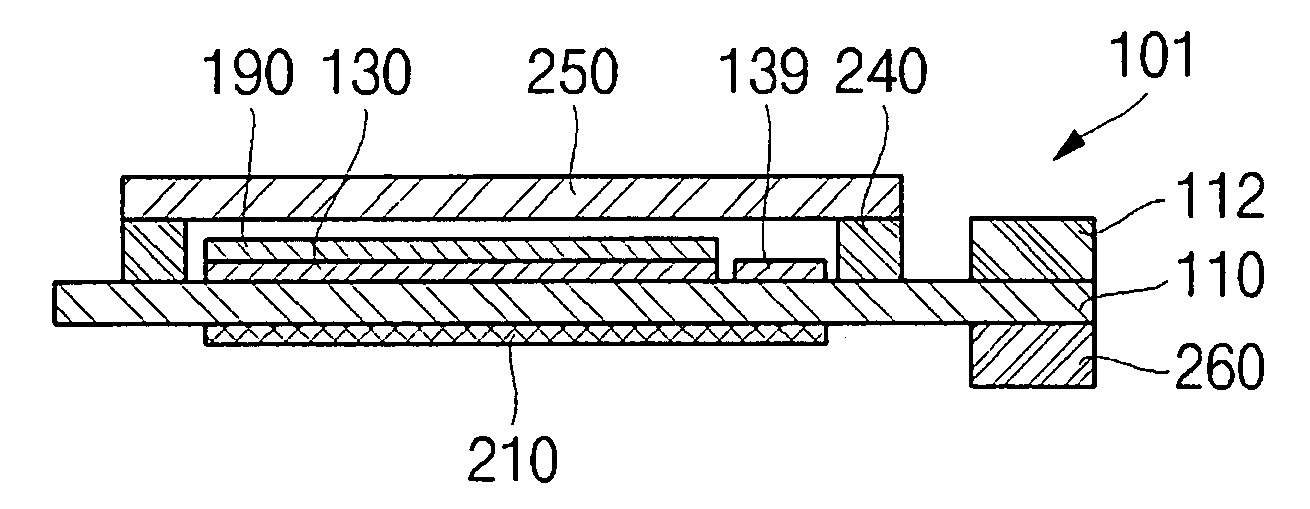

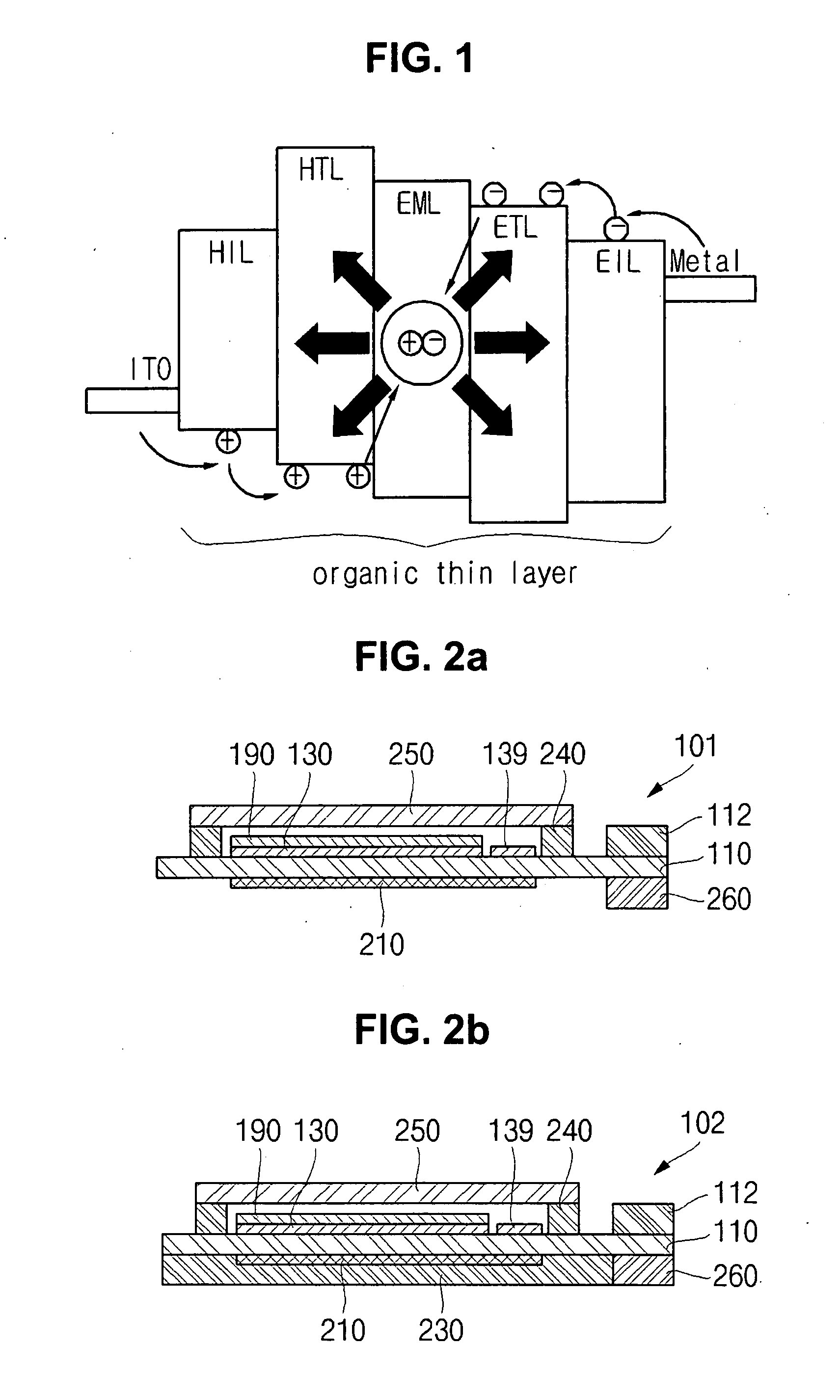

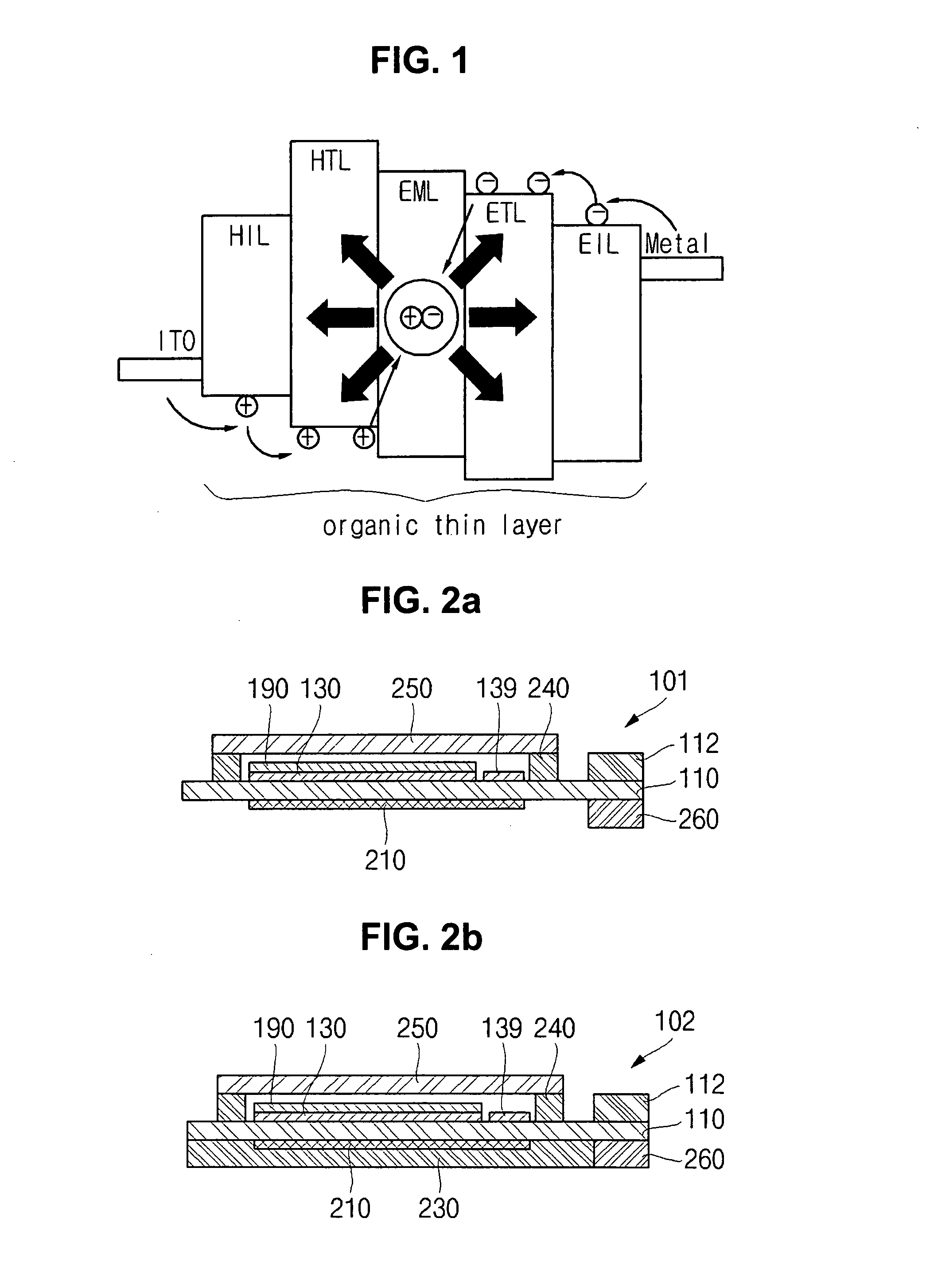

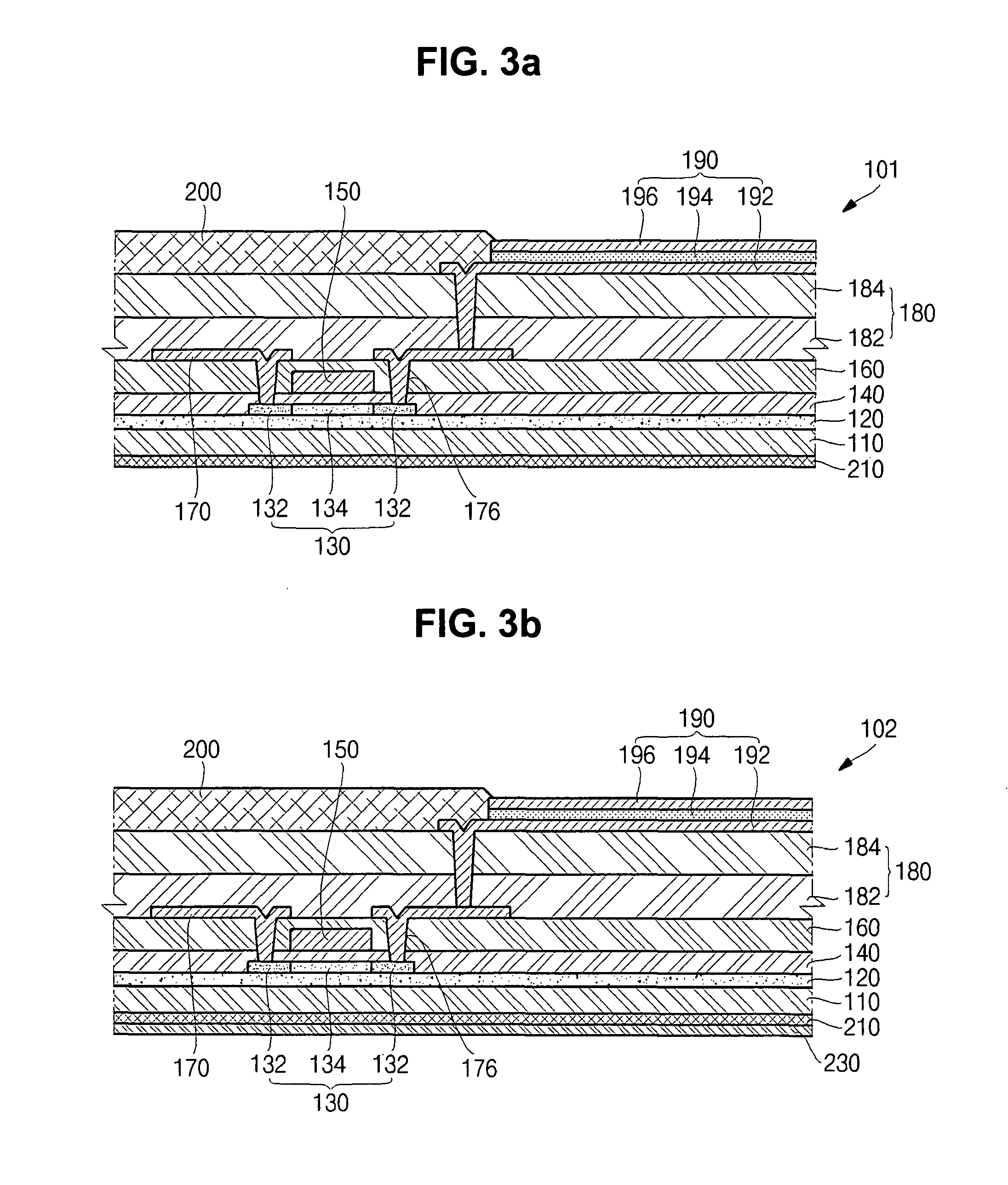

Organic light emitting display and fabricating method thereof

InactiveUS20080142791A1Avoid bending damageAvoid damageElectroluminescent light sourcesSolid-state devicesSealantLight-emitting diode

An organic light emitting display including a substrate, a semiconductor layer formed on the substrate, an organic light emitting diode formed on the semiconductor layer, an encapsulant formed on a periphery of the substrate which is an outer periphery of the organic light emitting diode and the semiconductor layer; and an encapsulation substrate attached to the encapsulant.

Owner:SAMSUNG DISPLAY CO LTD

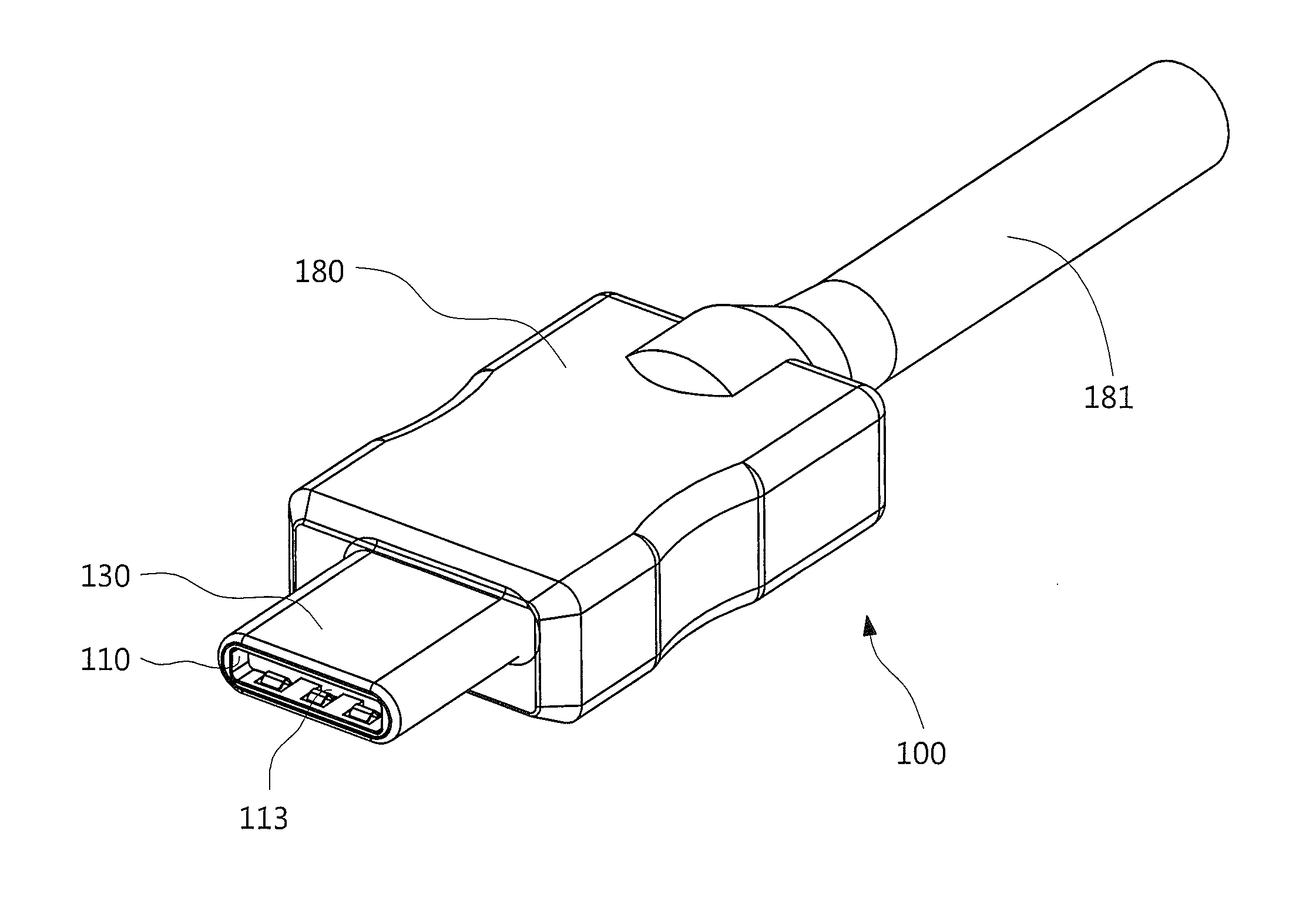

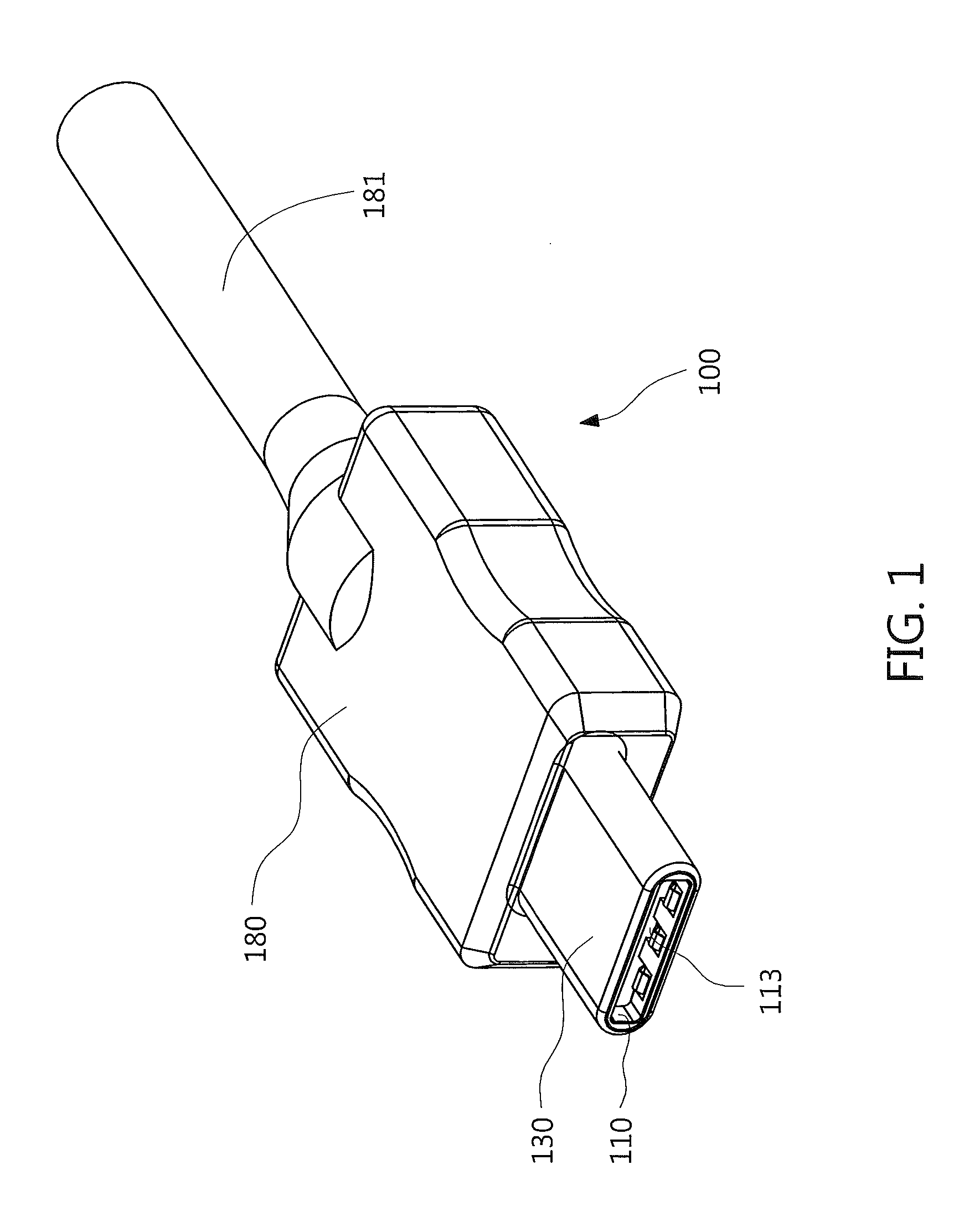

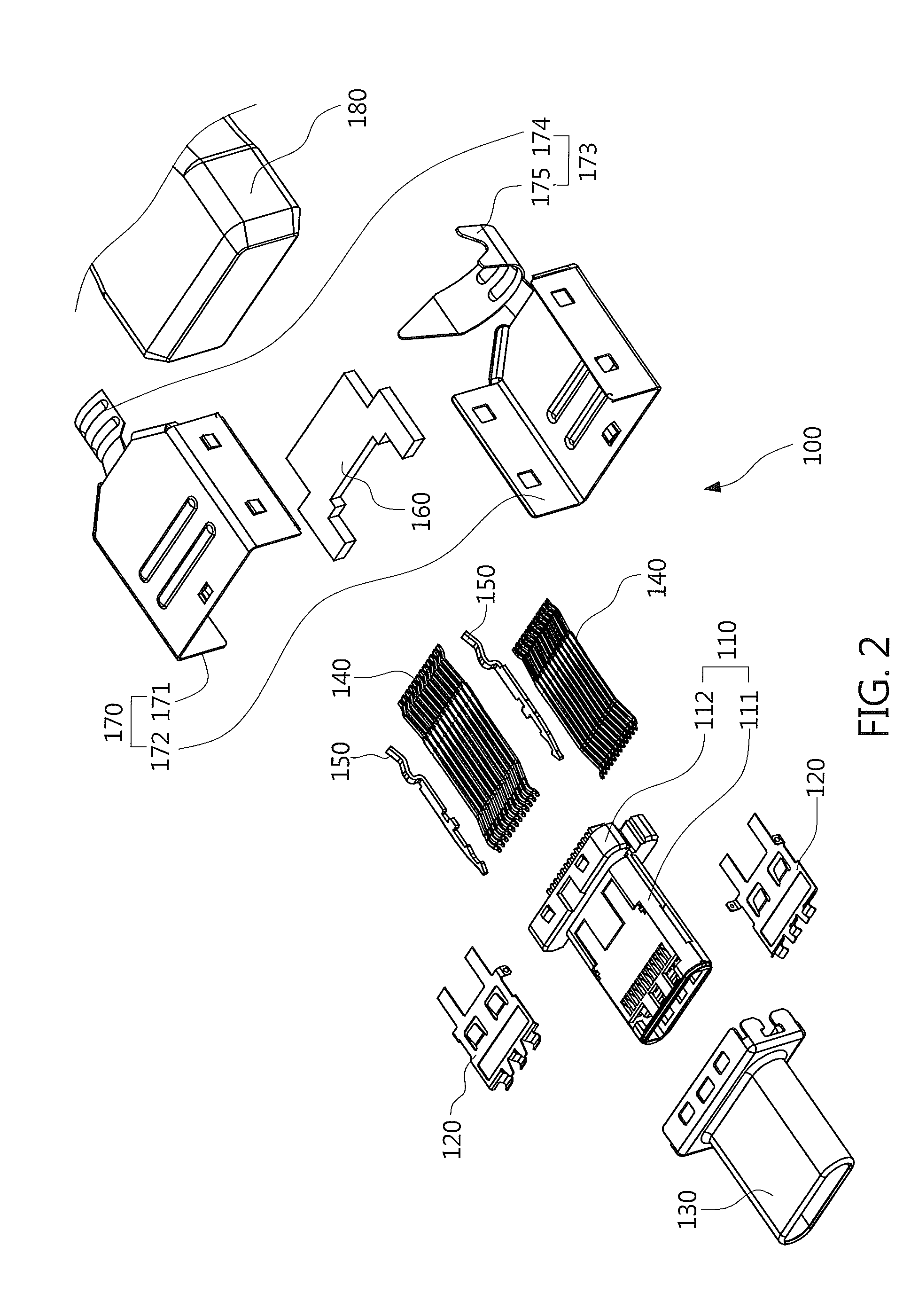

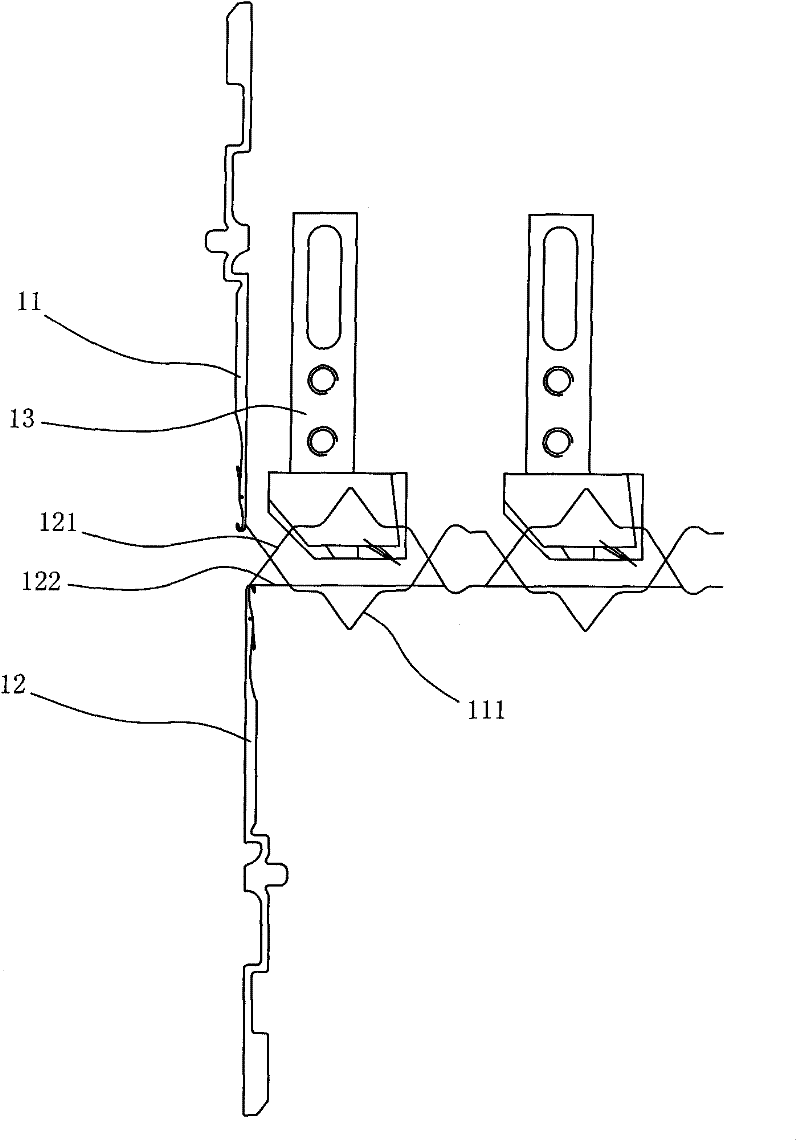

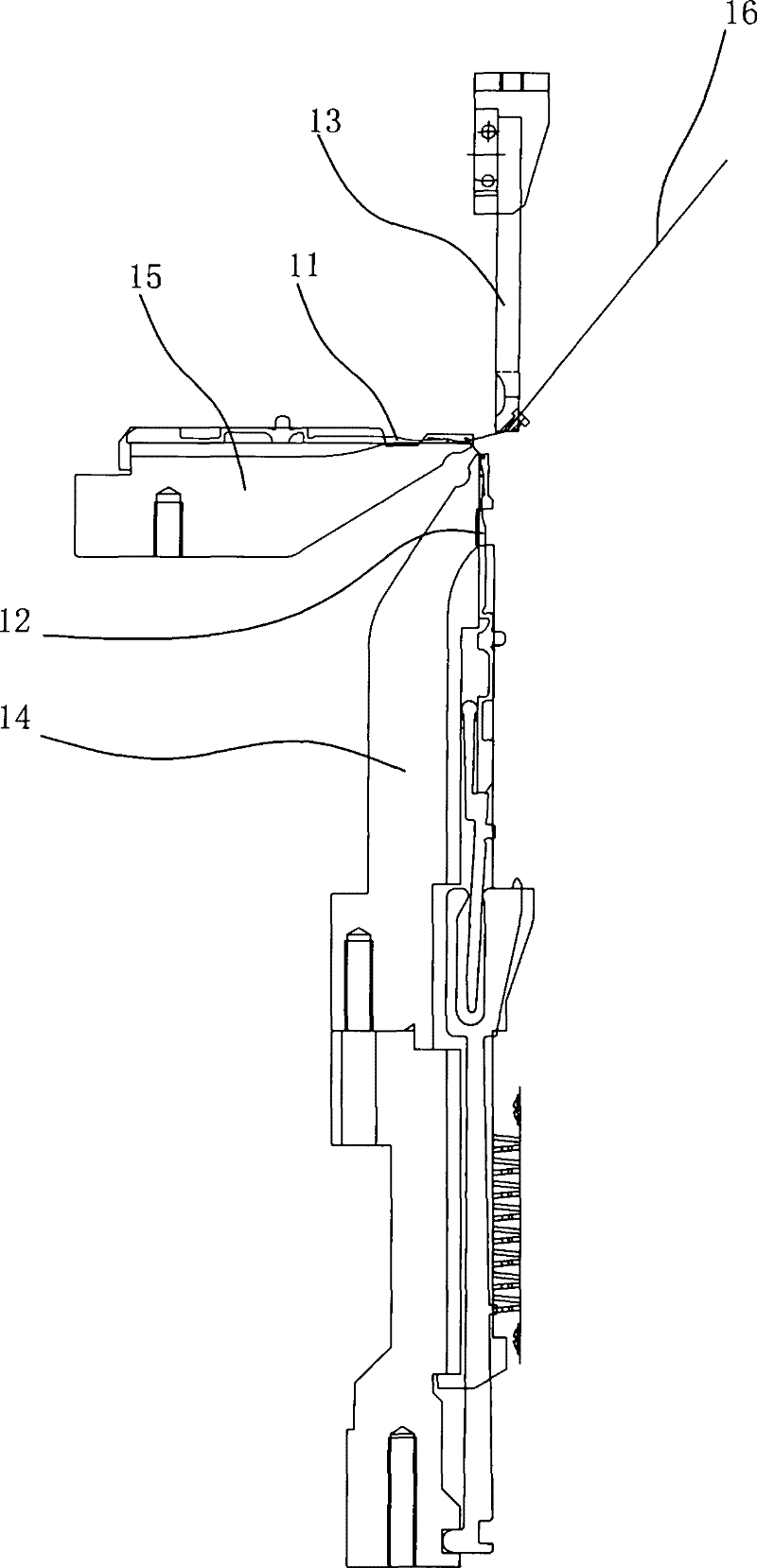

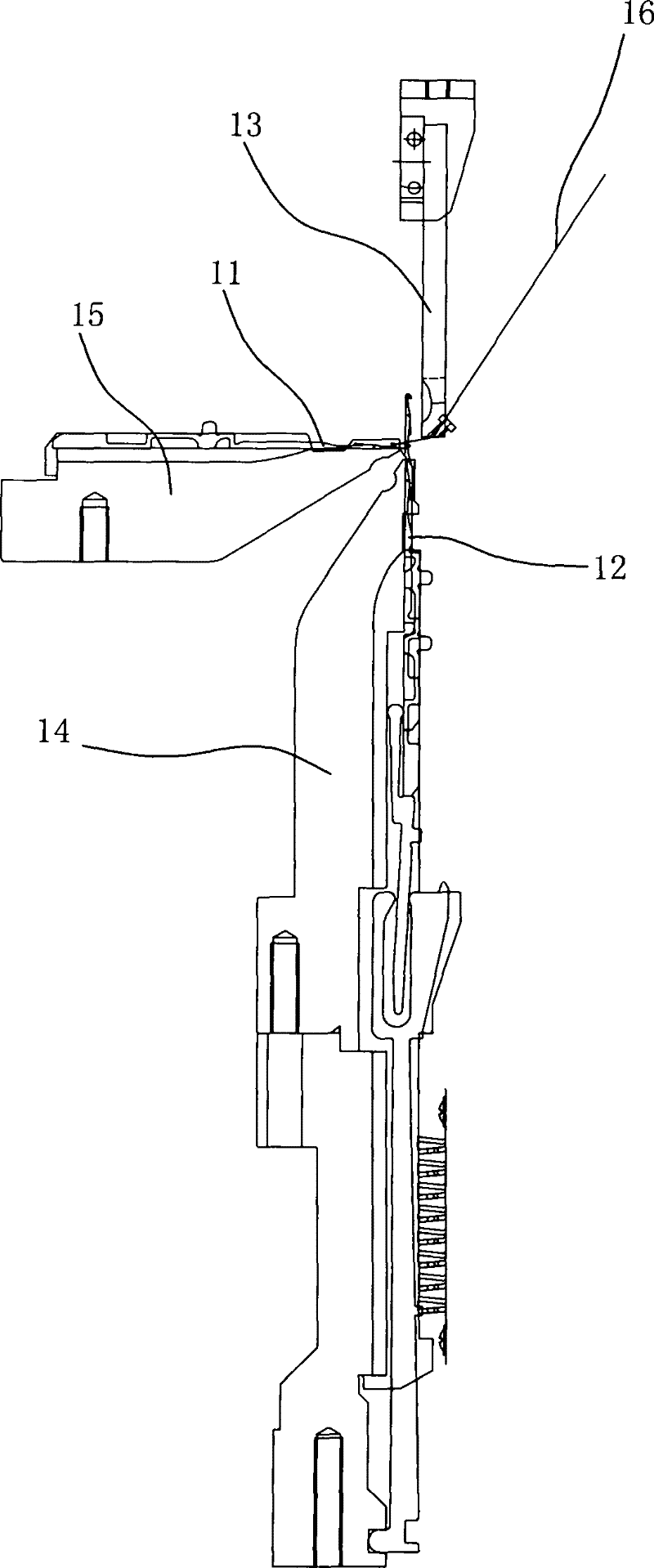

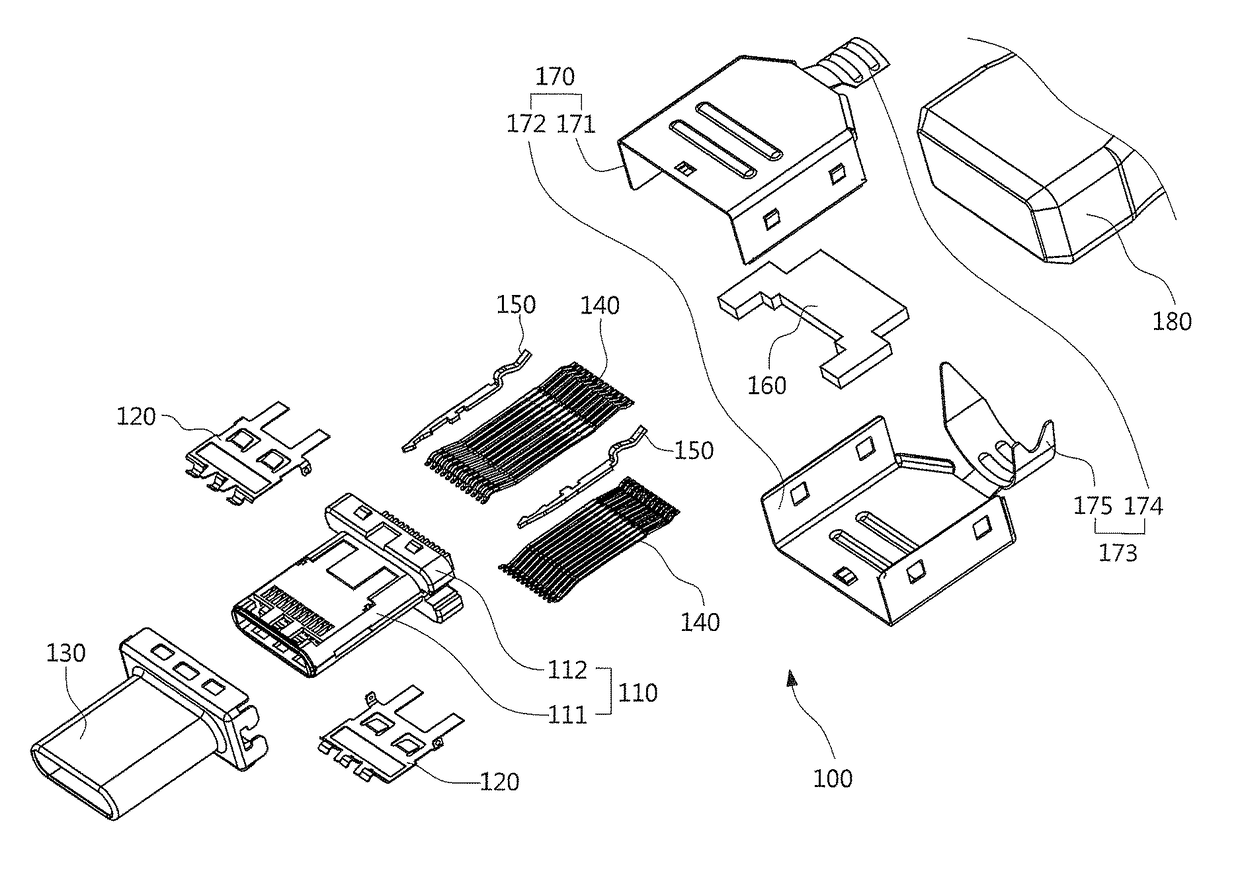

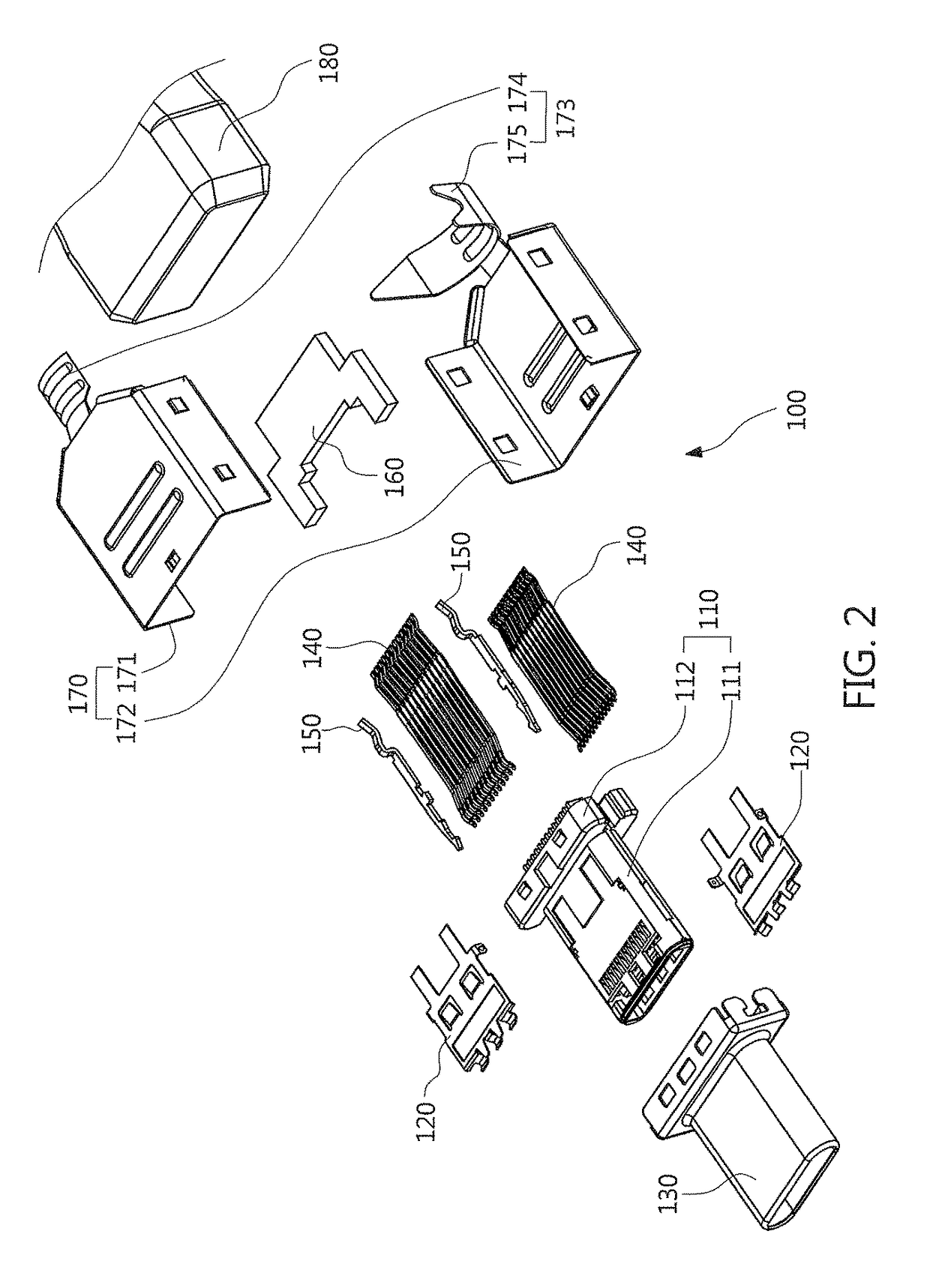

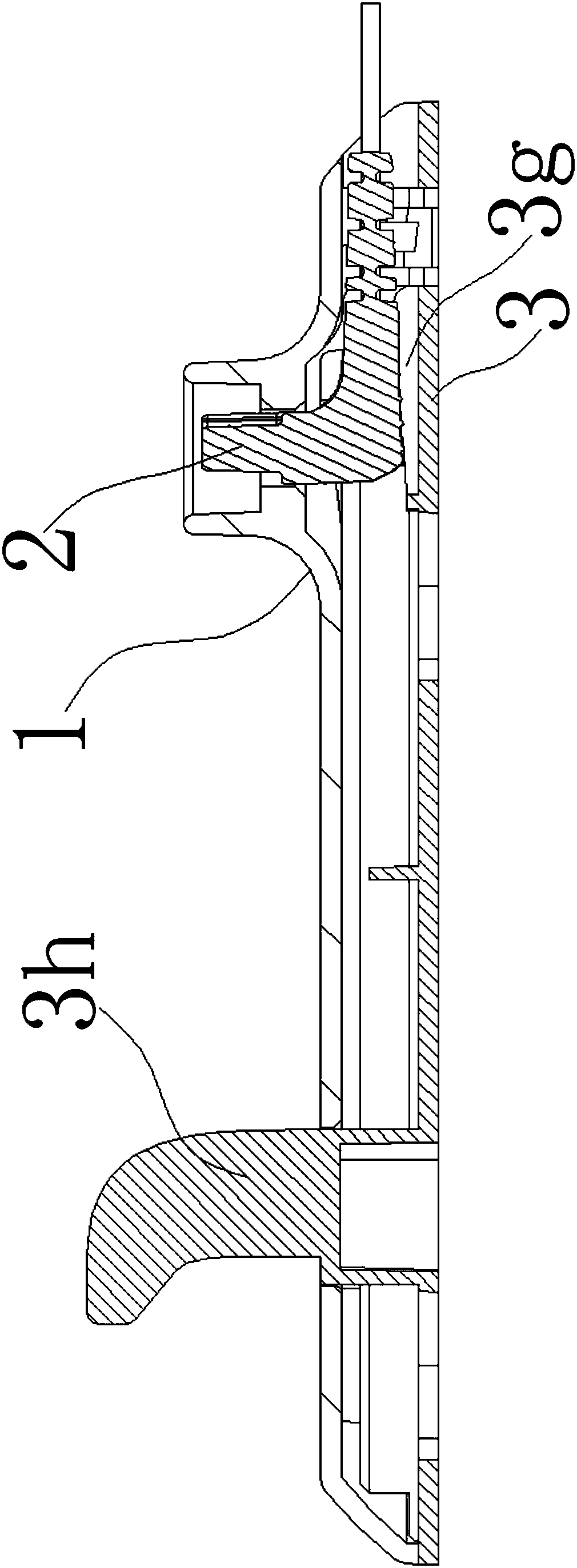

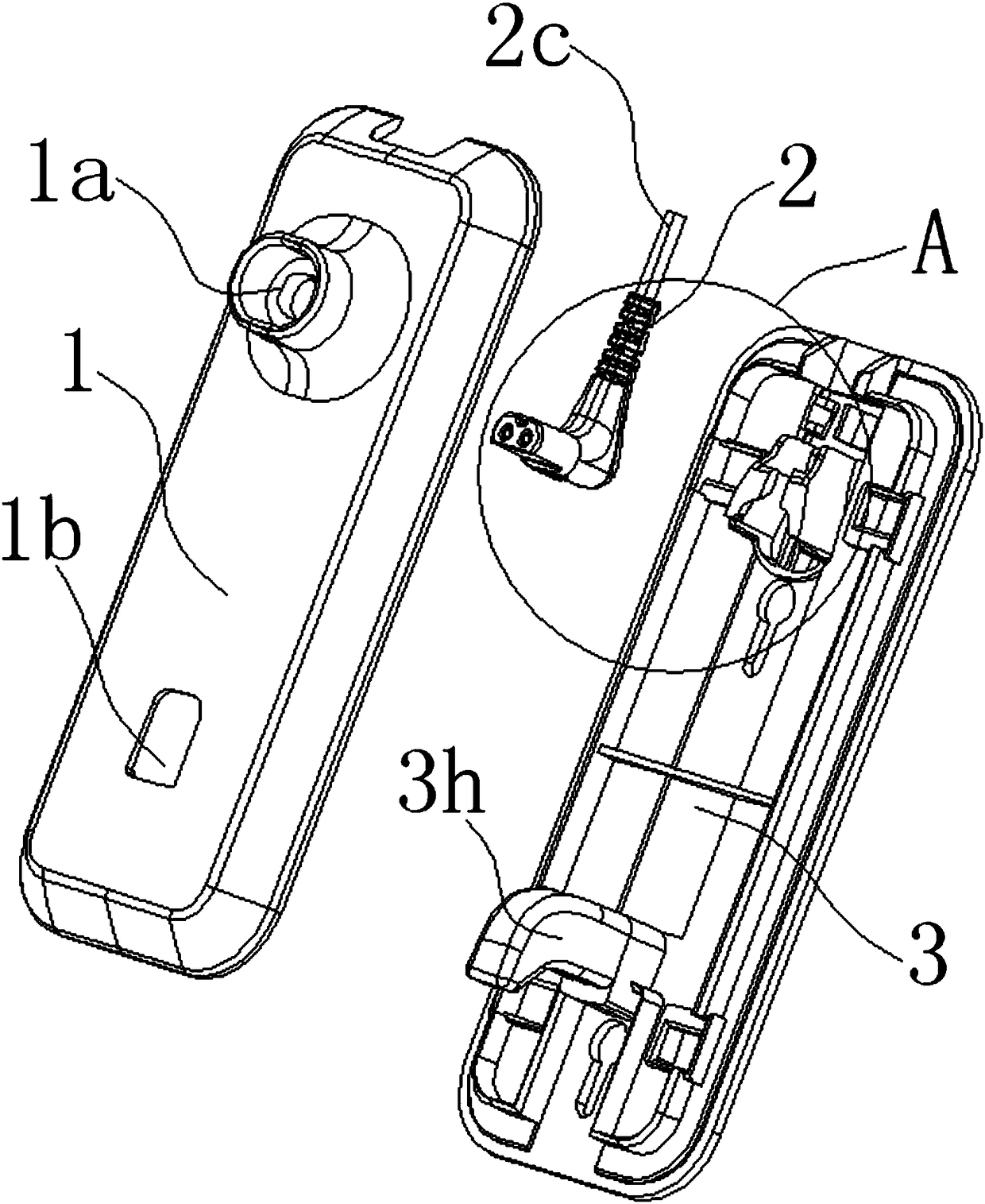

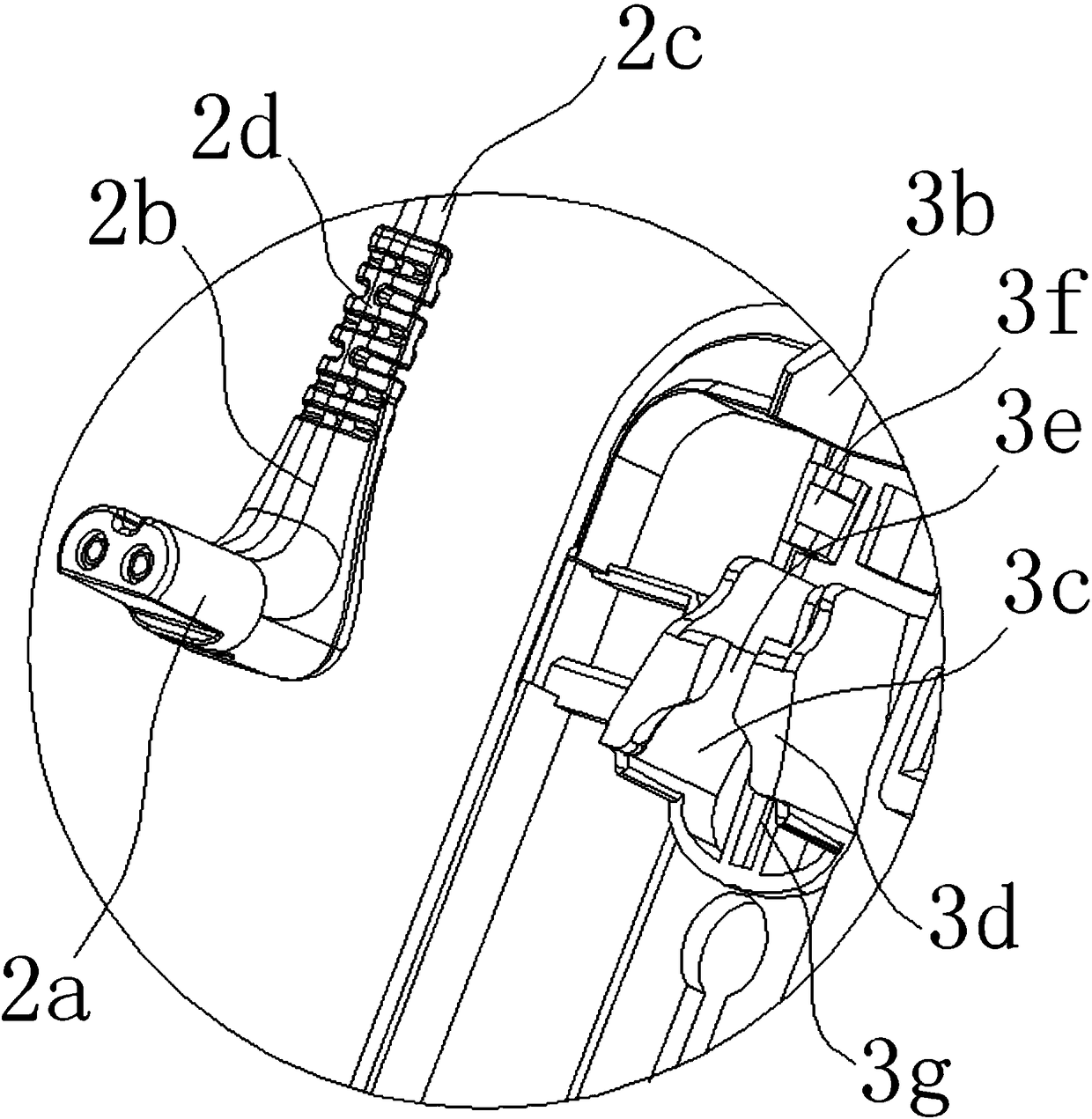

Electrical Plug Connector

ActiveUS20160043512A1Conveniently insertedAvoid bending damageContact member manufacturingCoupling device detailsMetallic enclosureSoldering

The invention relates to an electrical plug connector which comprises an insulated housing, a metallic shell, two terminal sets, and a circuit board. The insulated housing includes a front portion and a rear portion. The front portion extends forwardly from the rear portion and an inside of the front portion forms a receiving cavity. The metallic shell covers the insulated housing. Each terminal set is composed with a plurality of terminals. Each terminal includes a contact portion, a retaining portion, and a soldering portion. The retaining portion is retained in the insulated housing. The soldering portion extends backwardly from the retaining portion. The soldering portions are arranged as a upper row and a lower row in symmetry and the soldering portion is in spring arm type. The circuit board is inserted between the upper row and the lower row of the soldering portions. The upper row and the lower row of the soldering portions clip elastically the circuit board.

Owner:ADVANCED CONNECTEK INC

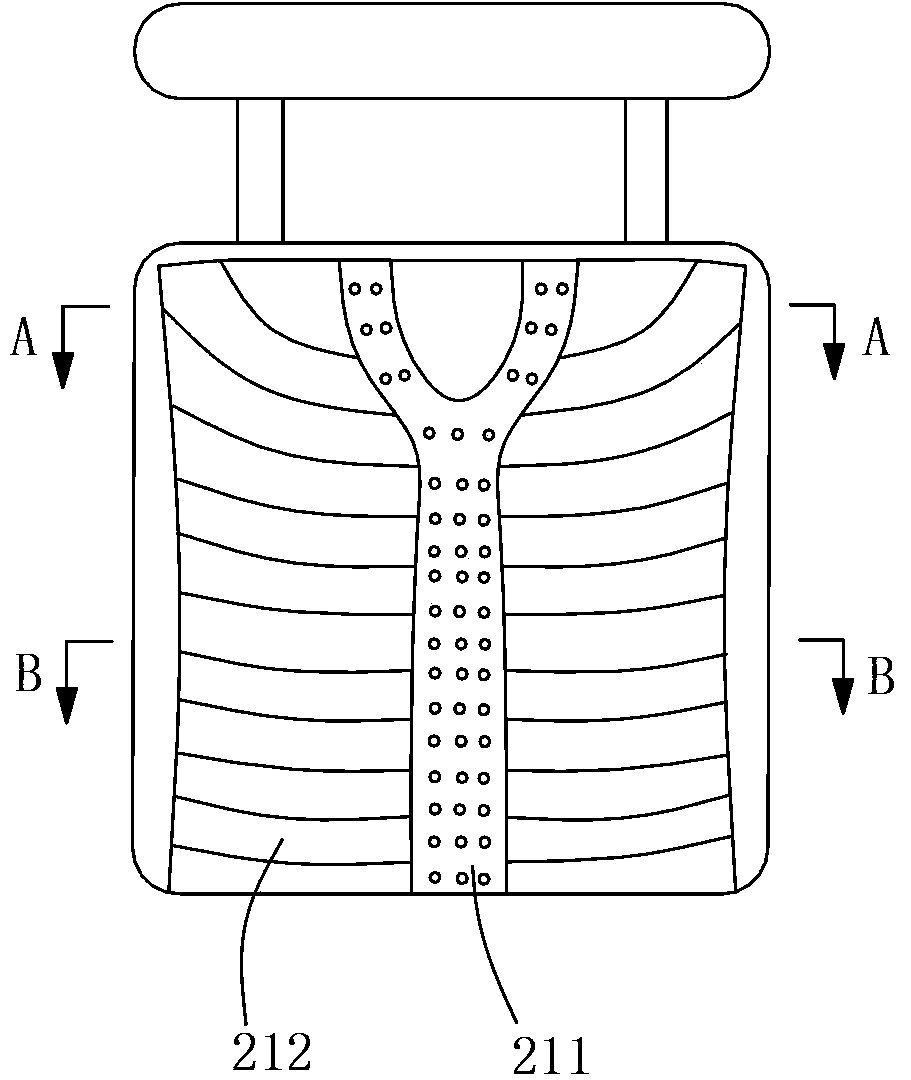

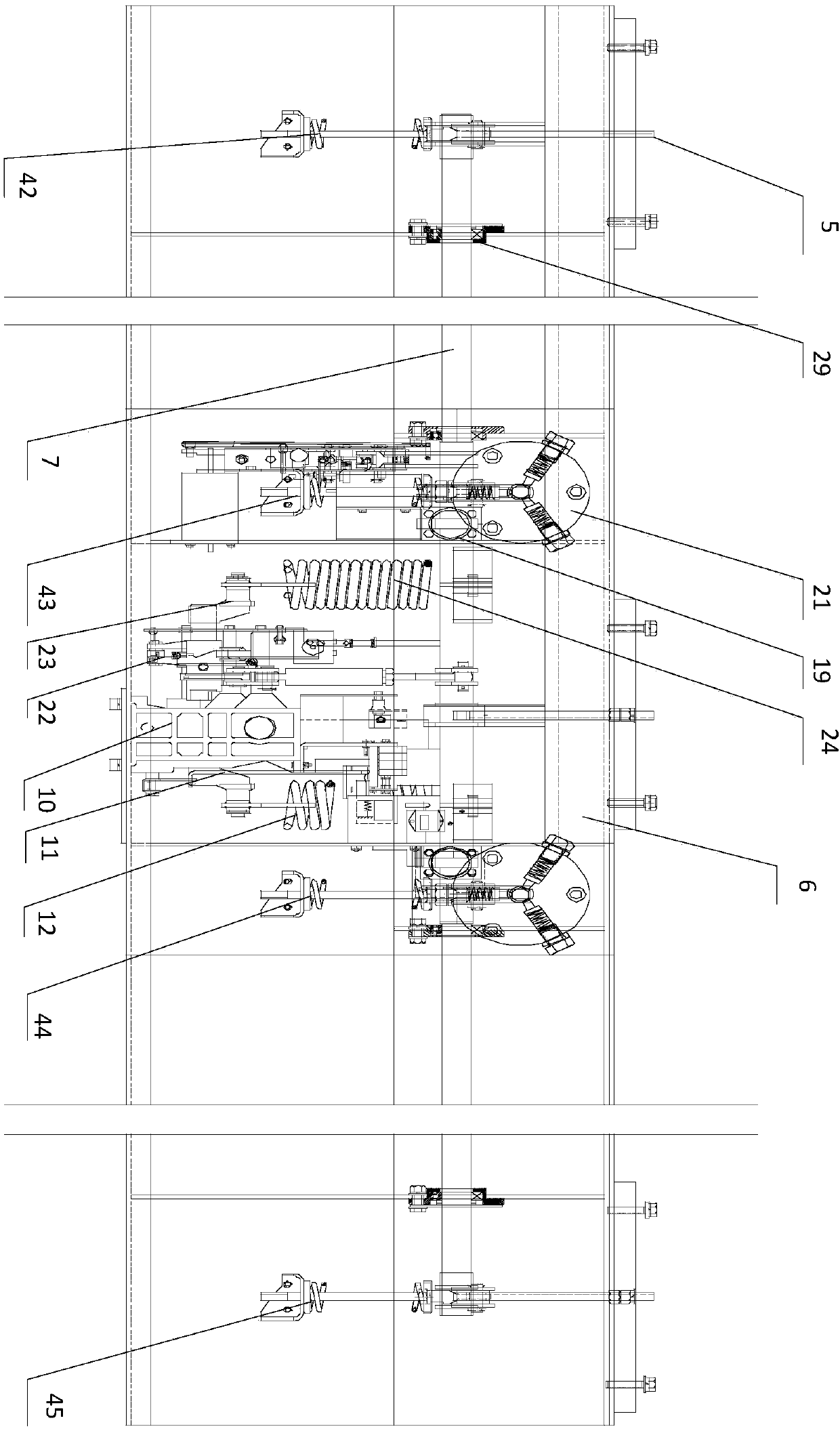

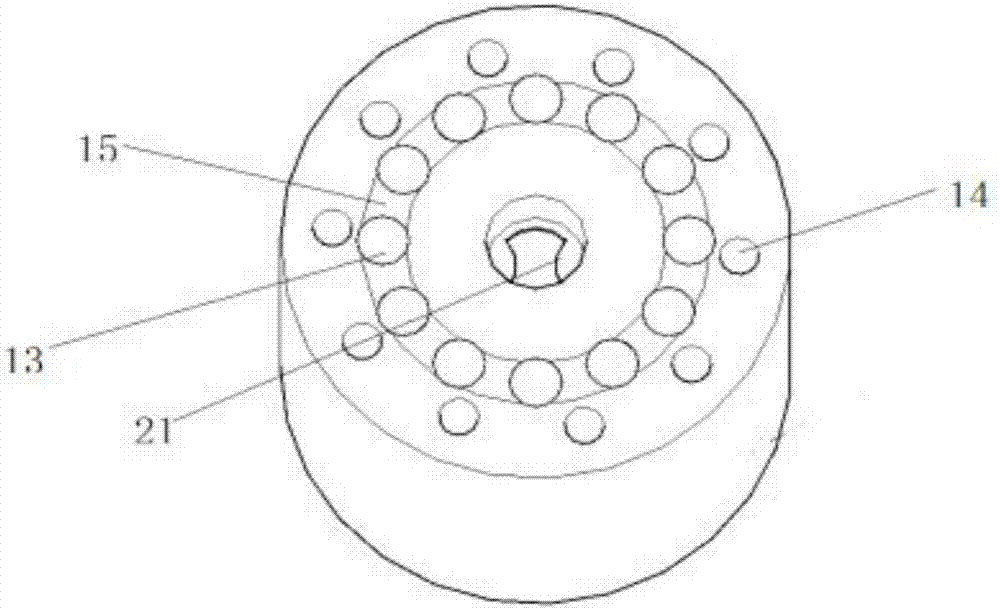

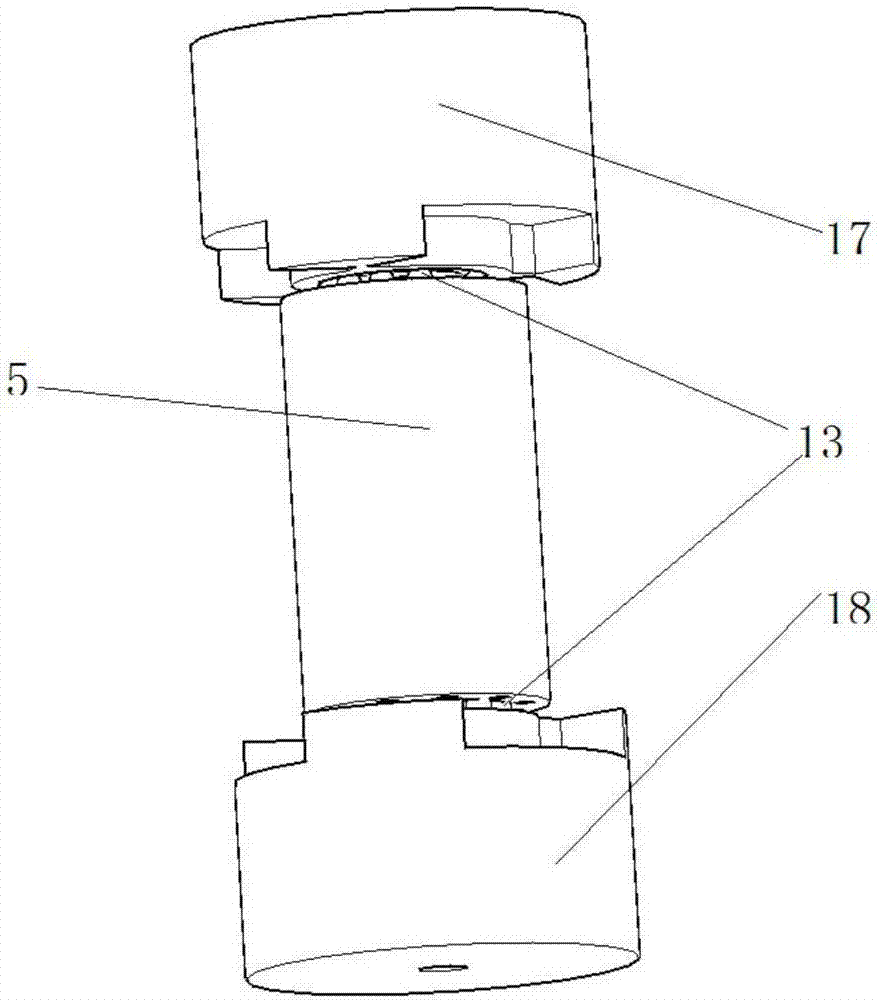

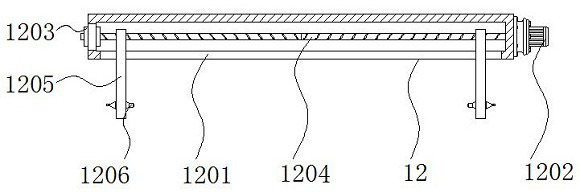

Double-faced jacquard circular knitting machine capable of weaving terry weave

InactiveCN102220669AHas the function of weaving towel tissueAvoid mutual interferenceCircular knitting machinesYarnSelection system

The invention provides a double-faced jacquard circular knitting machine capable of weaving terry weave. The machine comprises a needle cylinder, an upper dial, lower needle grooves which are distributed on the peripheral surface of the needle cylinder and extend vertically, upper needle grooves which are distributed on the upper end face of the upper dial and extend radially, upper and lower needles movably arranged in the upper and lower needle grooves, multiple paths of cam devices for driving the upper and lower needles to coordinate with each other to complete the weaving operation and aneedle selection system, wherein each path of cam device is formed by upper and lower cams for driving the upper and lower needles; the two adjacent paths of cam devices coordinate with each other tocomplete a weaving cycle; a feeding nozzle is arranged on the first path of each weaving cycle; the feeding nozzle is provided with two yarn guide porcelain eyes; and the two yarn guide porcelain eyes are respectively used for guiding the ground yarn from the back of the lower needle and guiding the terry yarn from the front of the lower needle. The machine has the following beneficial effect: bycoordinating with the needle selection system, the machine can weave the cloths with terry weave and jacquard weave.

Owner:JINJIANG HONGJI MACHINERY

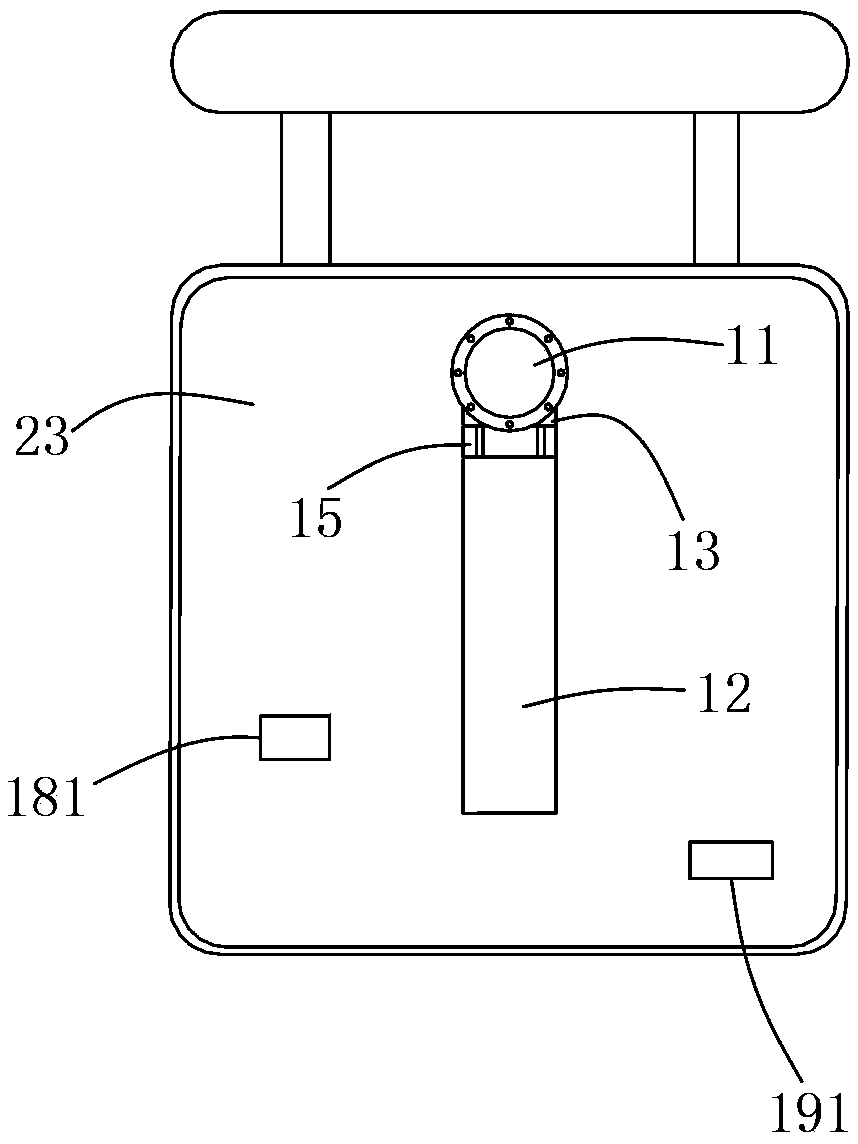

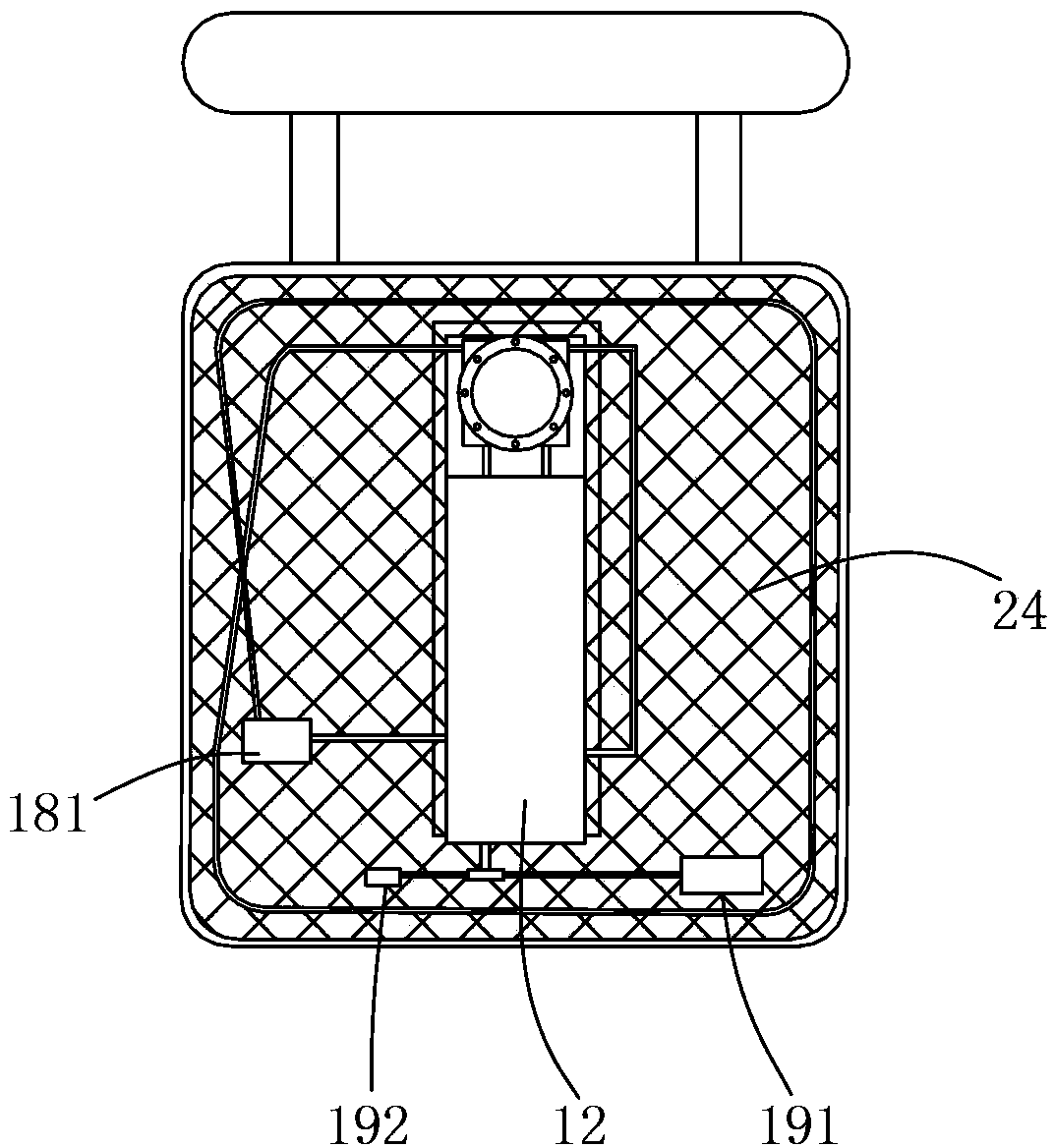

Health care cushion

ActiveCN103405303AAvoid bending damageUniform water temperatureTherapeutic coolingTherapeutic heatingEngineeringSemiconductor

The invention discloses a health care cushion. A transition water bag is arranged in a cushion body, a cold water bag and the transition water bag are vertically stacked, a semiconductor refrigerating sheet is arranged on the adhering portion of the cold water bag and the transition water bag, a refrigerating surface and a heating surface of the semiconductor refrigerating sheet adhere to the cold water bag and the transition water bag respectively, and a water circulating and flowing circulation passage formed by communicating a connection pipe and a pump body is arranged between an inner cavity of the transition water bag and an inner cavity of the hot water bag. The semiconductor refrigerating sheet can be relatively small, the whole refrigerating surface and the heating surface of the semiconductor refrigerating sheet can adhere to the cold water bag and the transition water bag respectively, and the whole semiconductor refrigerating sheet can be stably supported to prevent deformation of the cushion body, so that the semiconductor refrigerating sheet cannot be bent or damaged.

Owner:HANGZHOU TANGCHAO HEALTH TECH

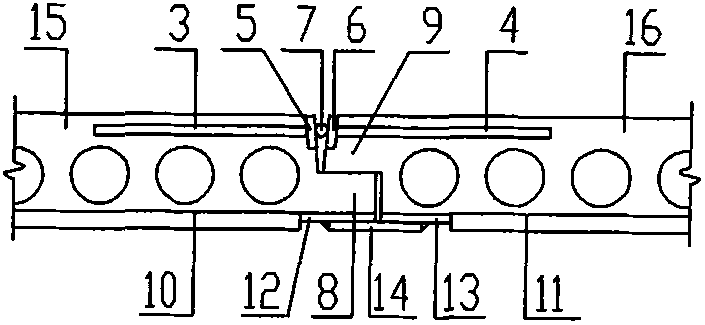

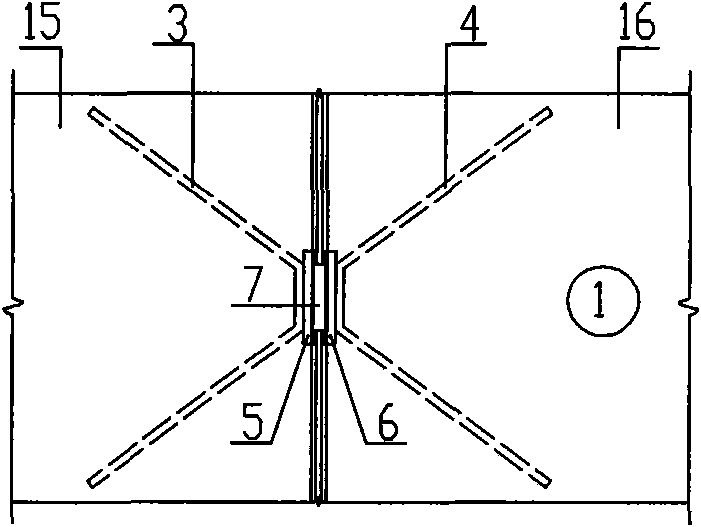

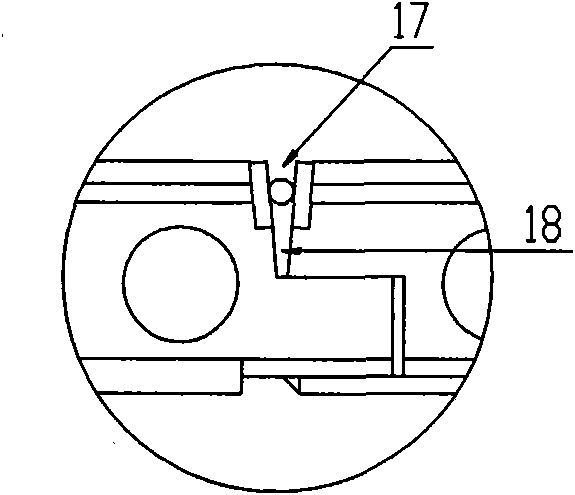

Welding type slab crack joint for precast concrete floor system

The invention discloses a welding type slab crack joint for a precast concrete floor system used in a building. The welding type slab crack joint comprises an X-shaped connection piece, a cover slab type connection piece, a support plate side overhanging platform and a supported plate side overhanging platform, wherein the X-shaped connection piece consists of anchor bars, panels and panel strips; the cover slab type connection piece consists of reinforcing steels arranged at the bottom of a slab, an embedded steel plate and a cover plate; the upper ends of the support plate and supported plate sides are provided with metal embedded pieces which consist of the anchor bars and the panels; the panels of the support plate is fixedly connected with the panels of the supported plate by the panel strips to form the X-shaped connection piece; the lower ends of the support plate and the supported plate sides are embedded with metal plates which are welded with the reinforcing steels at the bottom of a precast slab; the embedded metal plates of the support plate and the supported plate are fixedly connected by a metal cover plate to form a cover plate type connection piece; and after being overlapped with each other, the support plate side overhanging platform and the supported plate side overhanging platform are fixedly connected by the X-shaped connection piece at the top of the slab and the cover plate type connection piece at the bottom of the slab.

Owner:SOUTHEAST UNIV

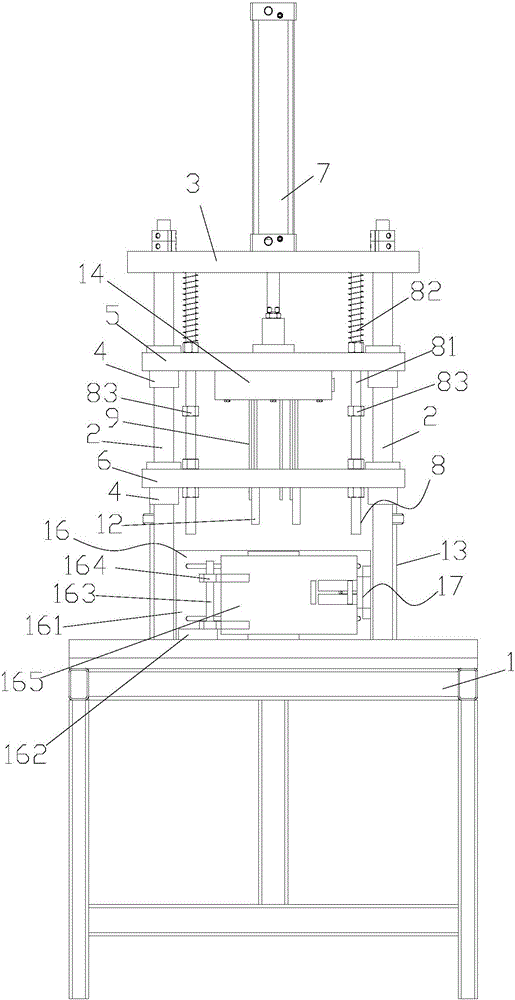

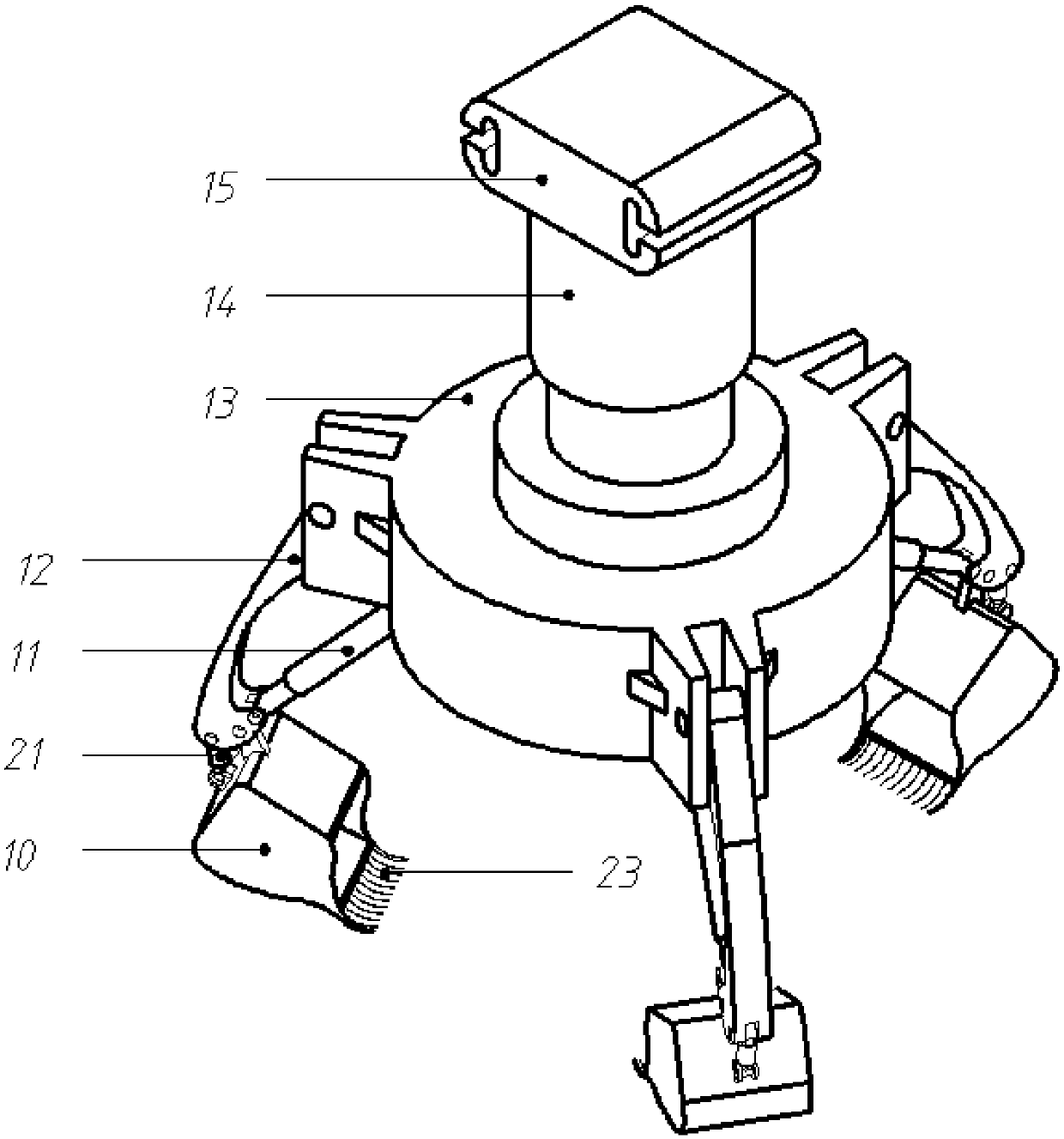

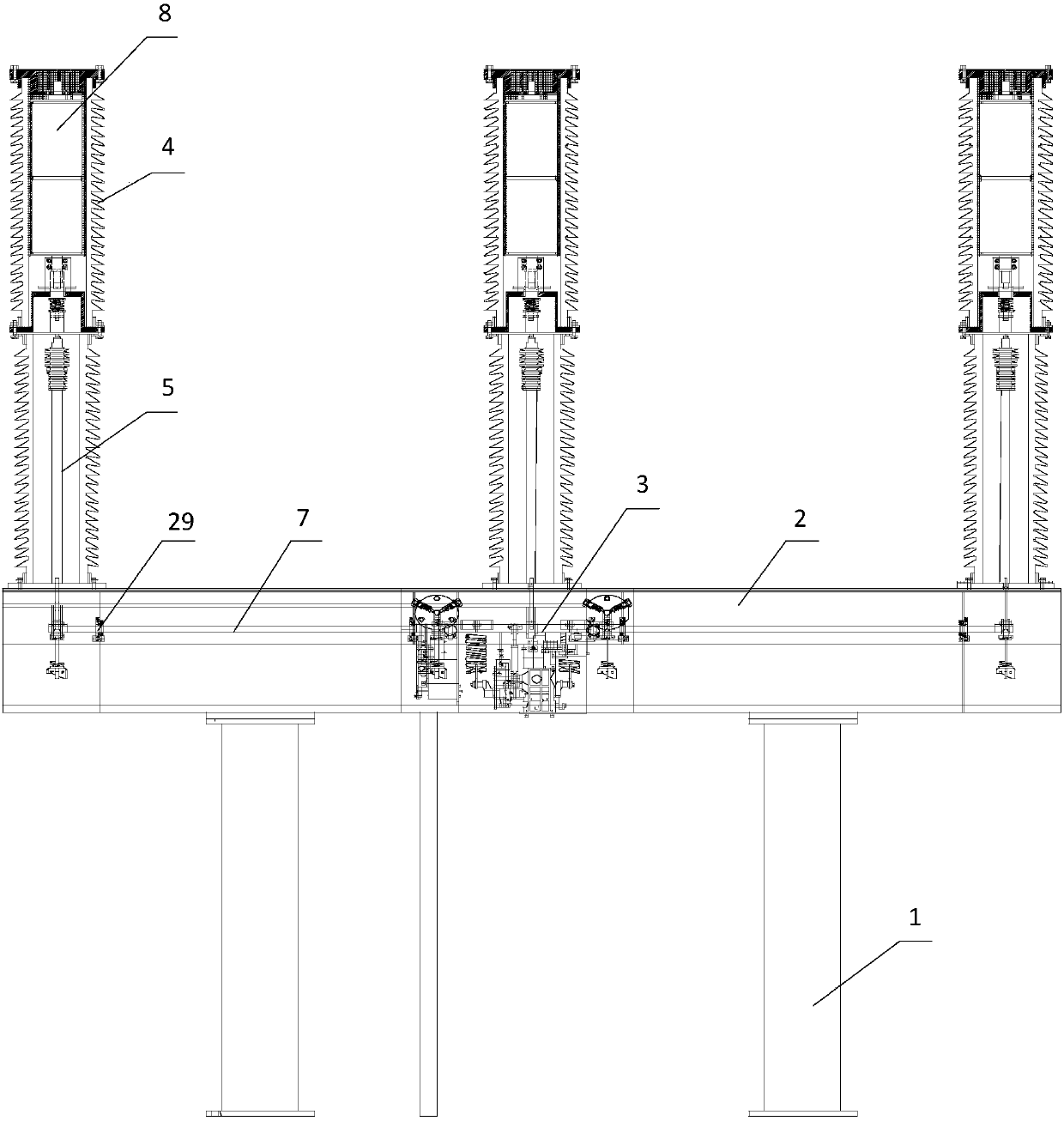

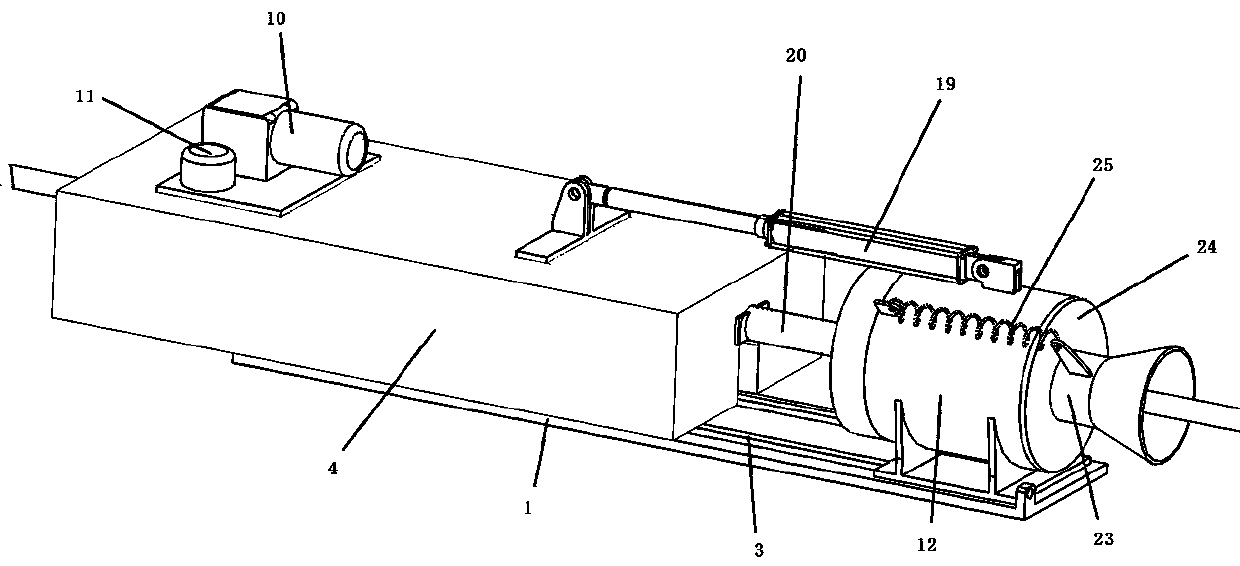

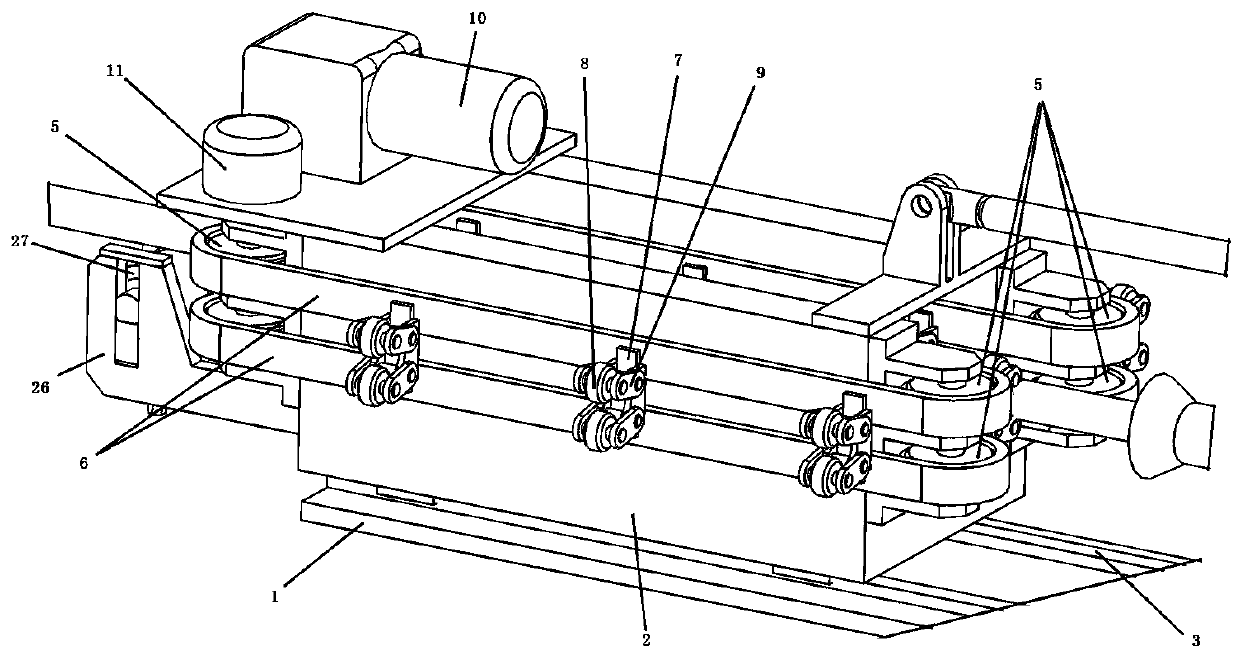

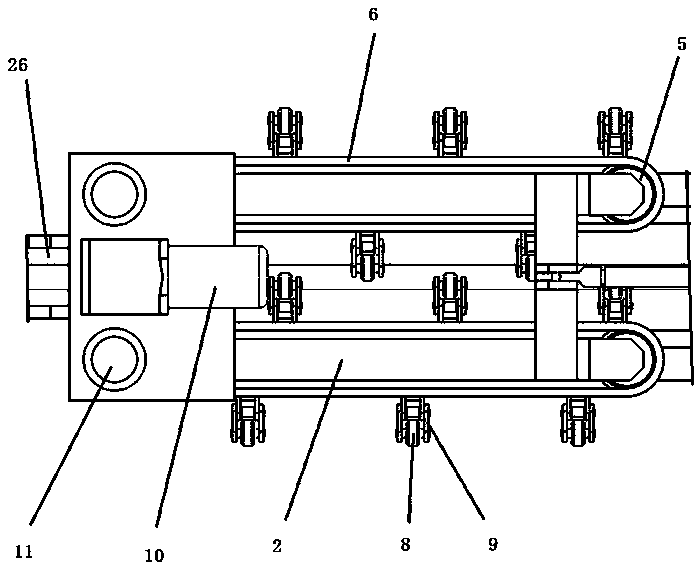

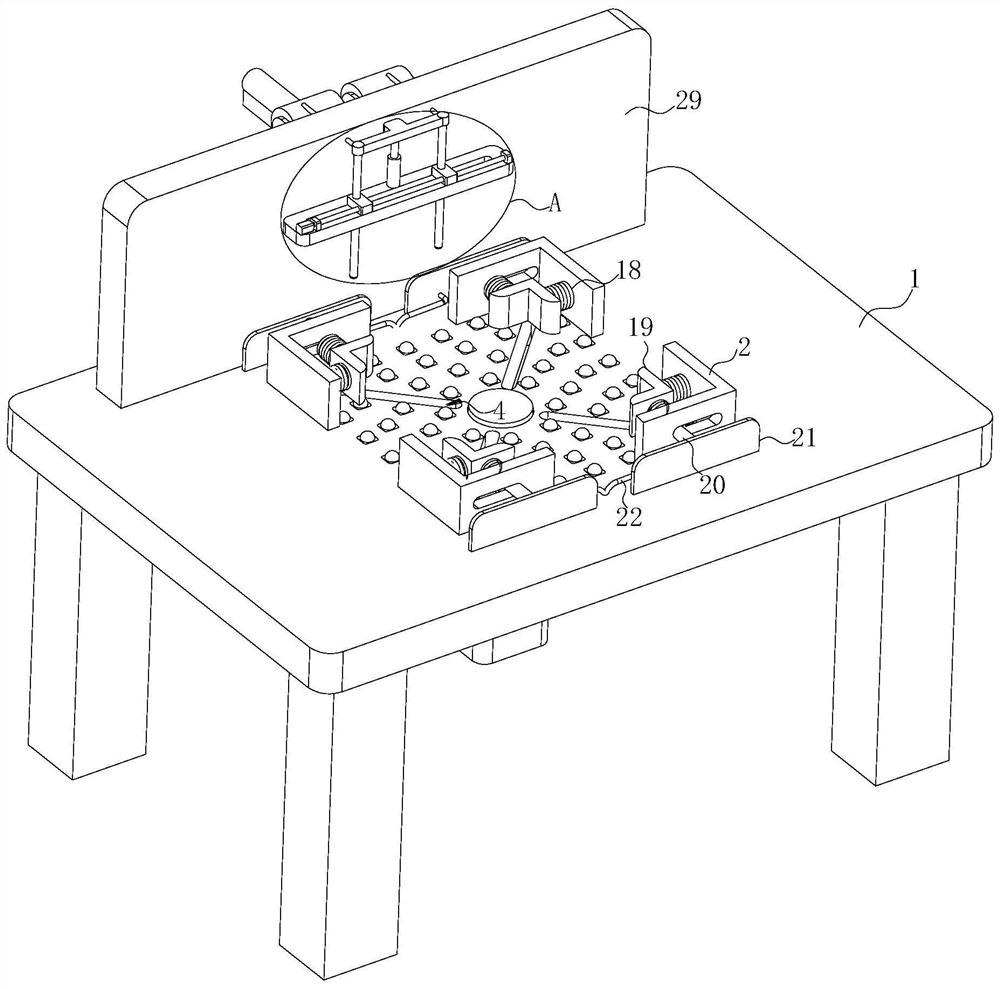

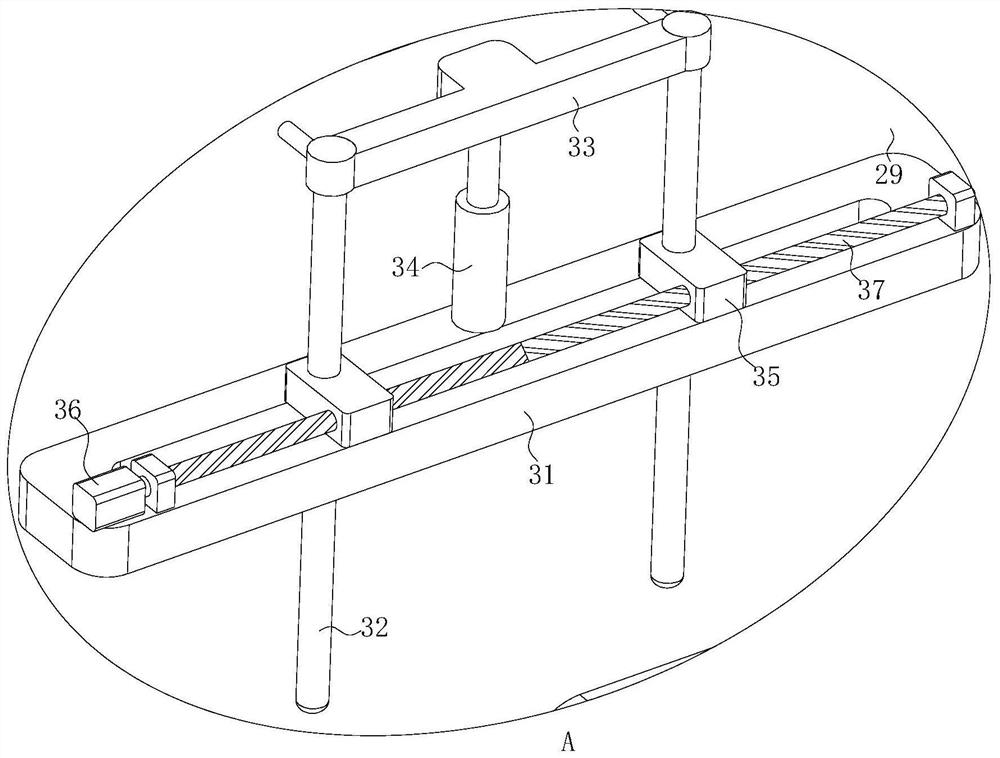

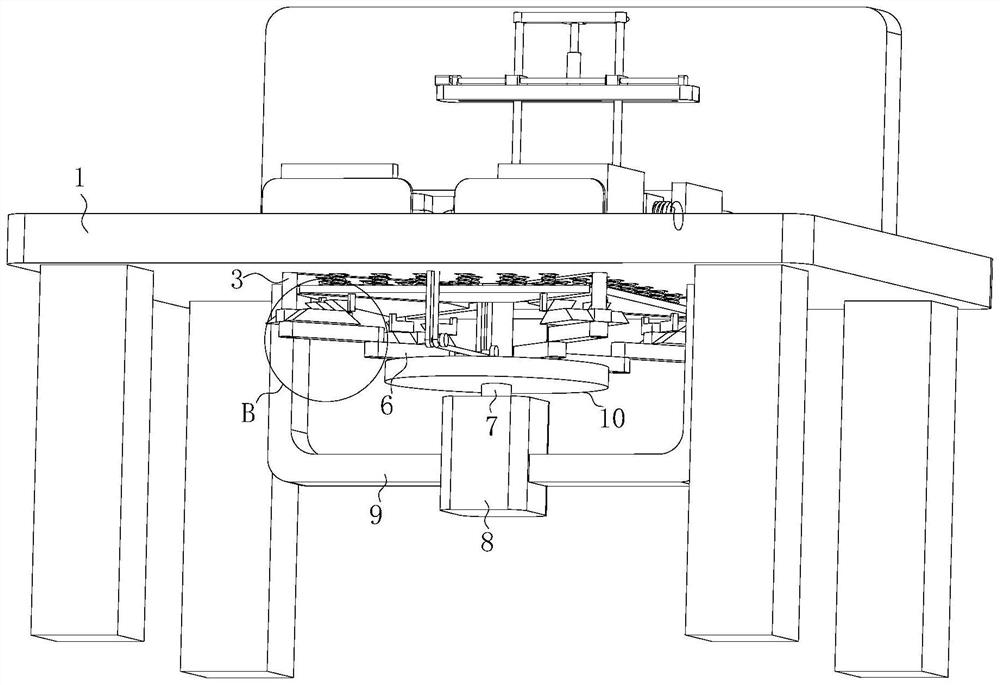

Pipe expander for condenser

ActiveCN105855412ASimple structureHigh precisionMetal-working feeding devicesHeat exchange apparatusEngineeringMechanical engineering

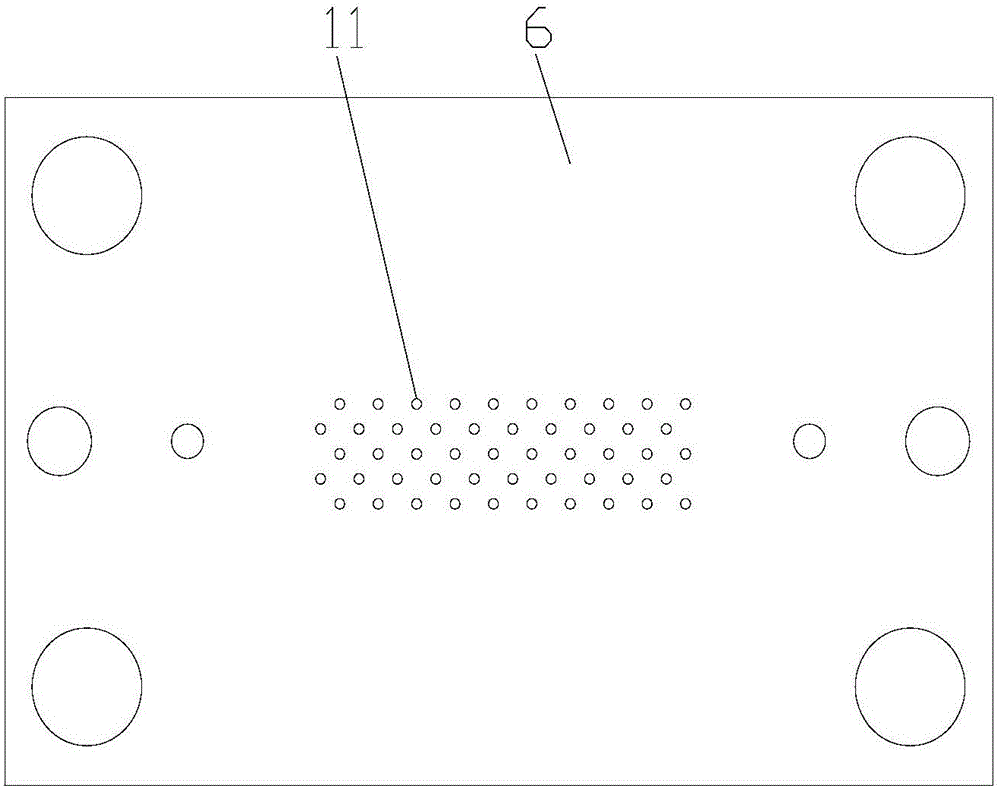

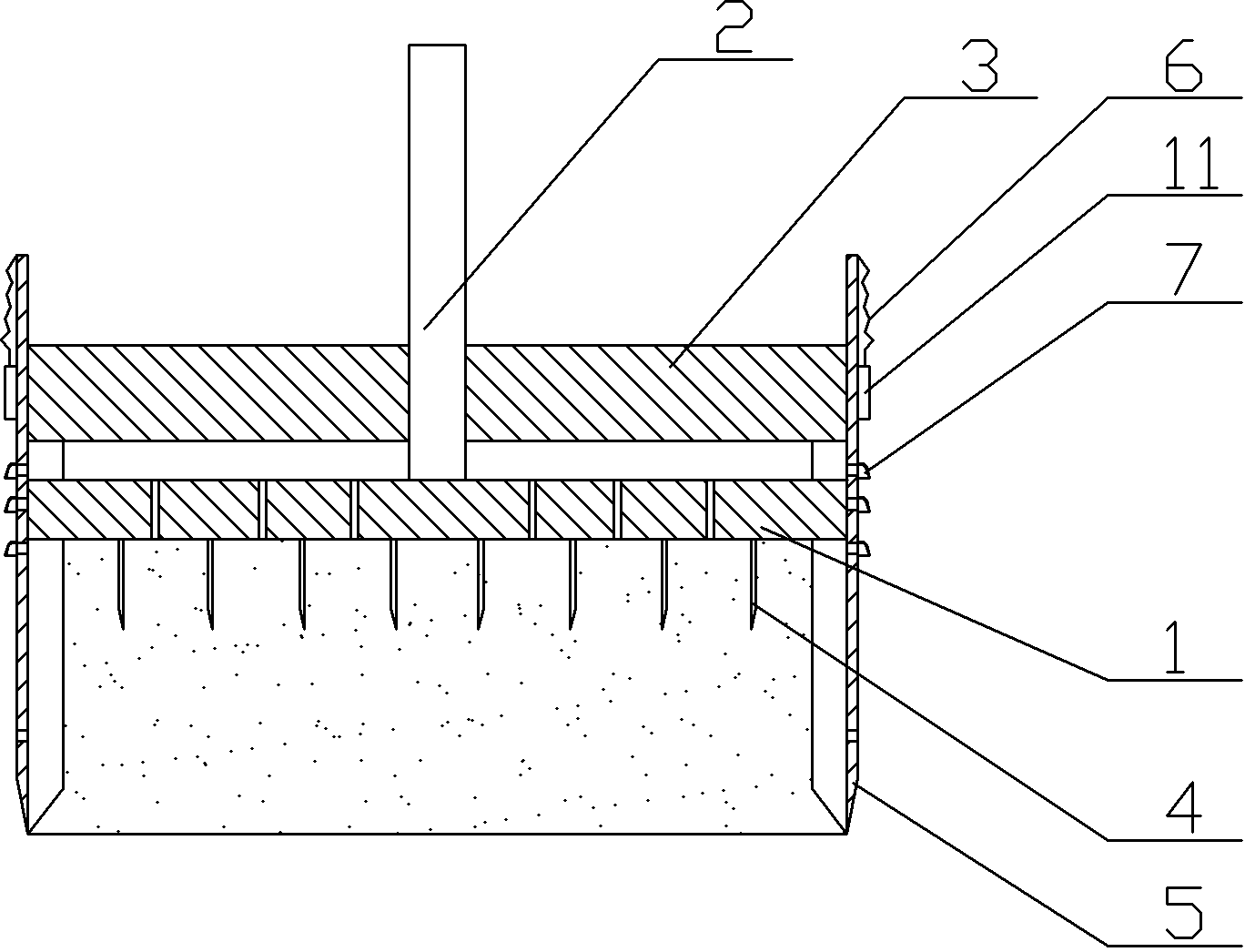

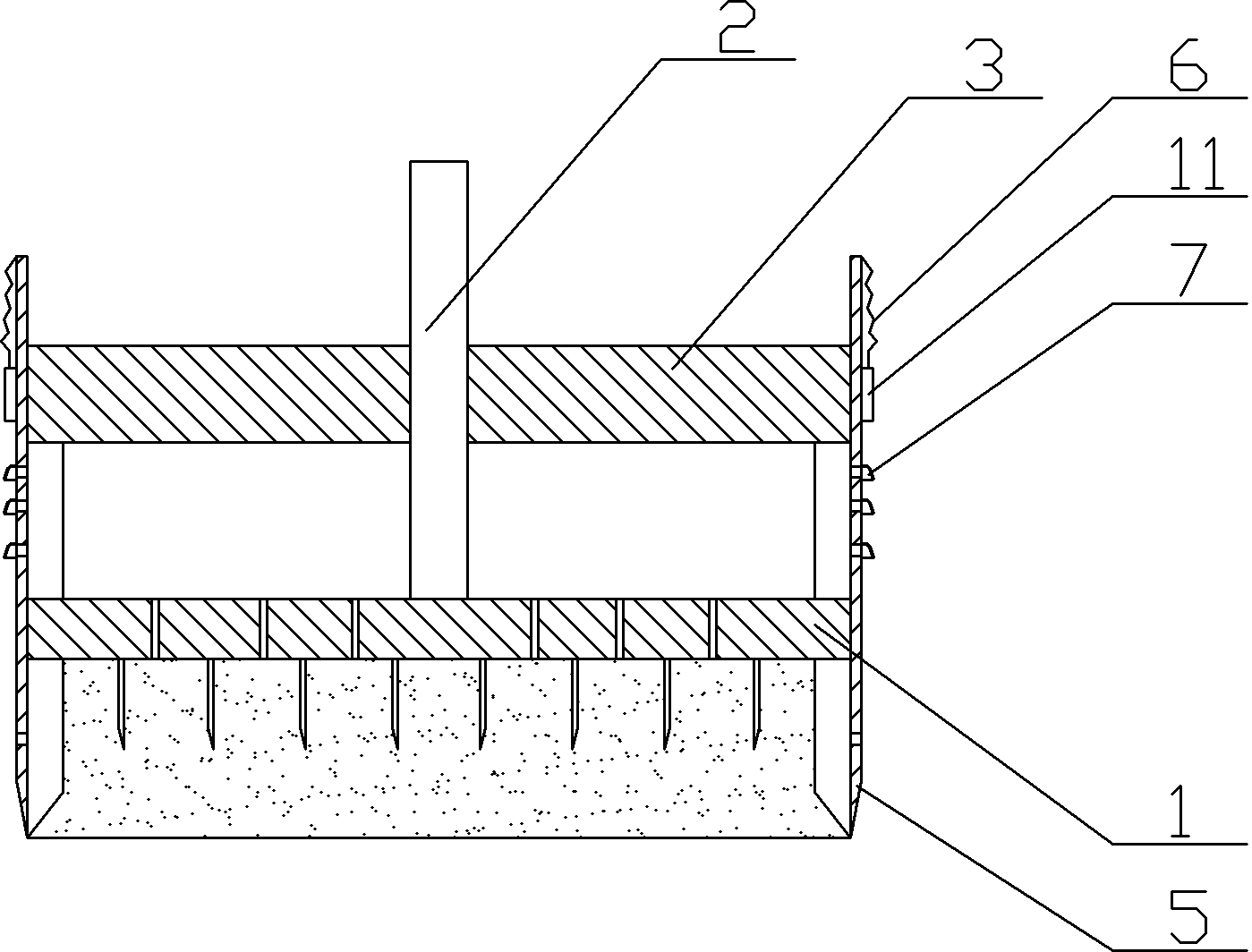

The invention relates to a pipe expander for a condenser. The pipe expander comprises a rack, wherein a fixed rod is mounted on the rack; the upper end of the fixed rod is connected with a mounting plate; a cover plate and a guide plate which are arranged on the fixed rod in a sleeved manner through a guide sleeve are arranged below the mounting plate; a drive mechanism for driving the cover plate to move up and down is arranged on the mounting plate; a plurality of pipe expanding long rods are connected on the lower end surface of the cover plate; a plurality of pressure sleeves are fixedly arranged on the lower end surface of the guide plate; a limiting rod positioned below the guide plate is further arranged on the rack; the pipe expanding long rods are connected with the cover plate through a fixing device; guide holes adaptive to the pipe expanding long rods are formed in the guide plate; a clamping device used for fixing the condenser is arranged on the rack; and the clamping device is positioned below the guide plate. The pipe expander has the characteristics of being simple in structure, suitable for a small condenser, high in precision, high in production efficiency and the like.

Owner:CHANGZHOU CHANGZHENG HEAT EXCHANGER TECH

Extruding-dewatering dried tofu shaping device

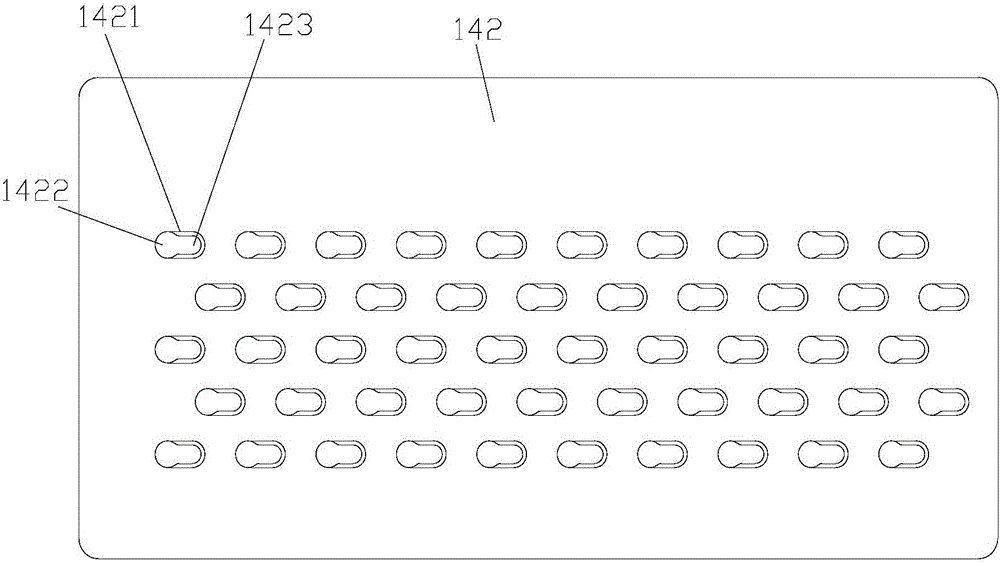

The invention relates to a tofu processing device, in particular to an extruding-dewatering dried tofu shaping device. The device comprises an extruding plate, a push rod arranged above the extruding plate, and a supporting plate for the passing of the push plate, and is characterized in that the extruding plate is in a rectangle shape; knife blades are perpendicularly arranged below the extruding plate; the circumferential side faces of the extruding plate are respectively in sliding connection with retaining sheets which are respectively in a rectangular cylinder shape; the edges of the lower parts of the retaining sheets are respectively provided with a cutting edge; the retaining sheets are respectively and vertically provided with a guide groove; the side faces of the extruding plate are respectively provided with a bump embedded into the guide groove; the outer edges of the bumps are respectively connected with the top parts of the retaining sheets through returning tension springs; extruding water-discharging holes are formed in each of the retaining sheets and the extruding plate. By applying the extruding-dewatering dried tofu shaping device provided by the invention, tofu can be extruded into block-like dried tofu, and moreover, incisions are formed in the surface of the dried tofu.

Owner:CHONGQING HEDELONG FOOD

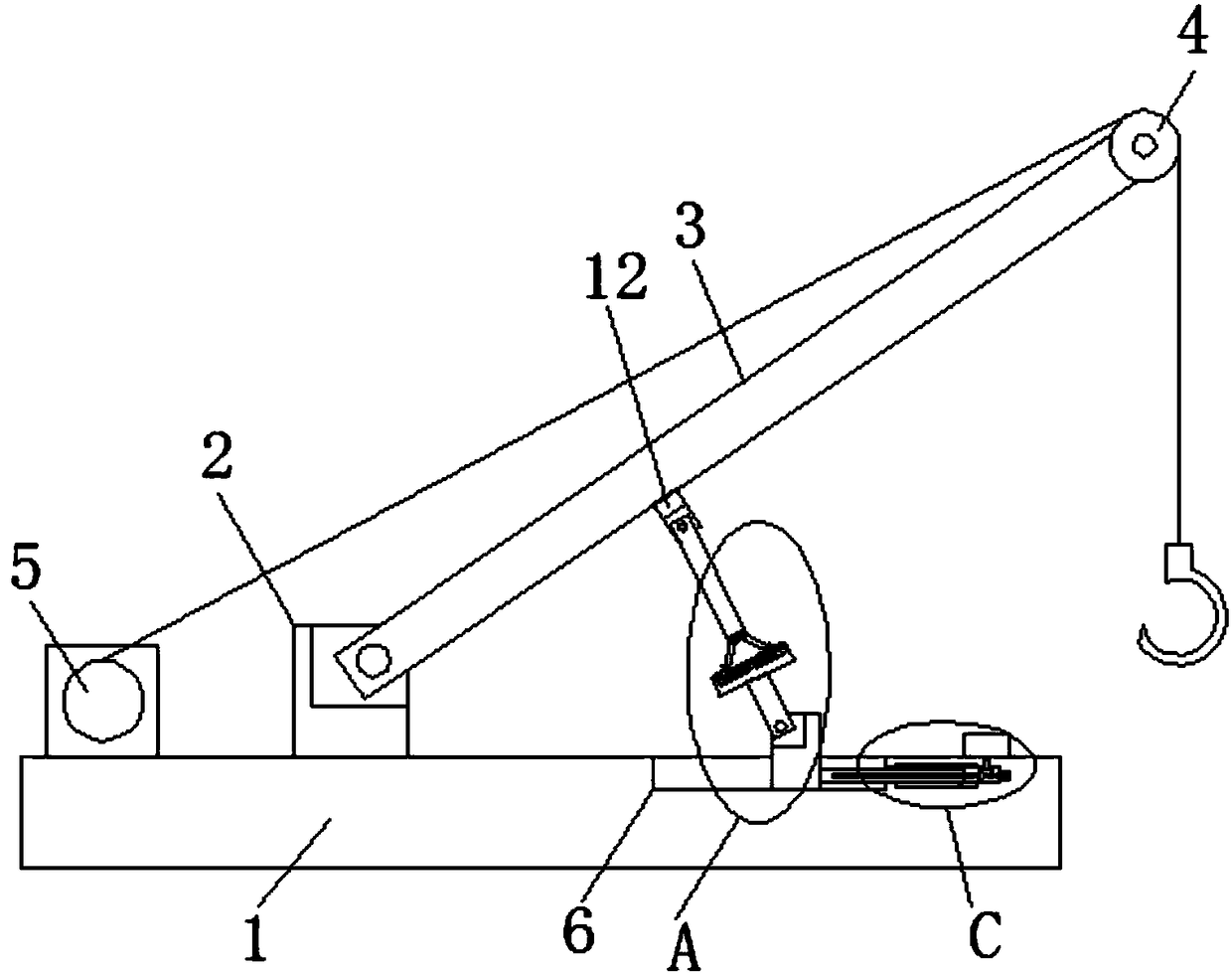

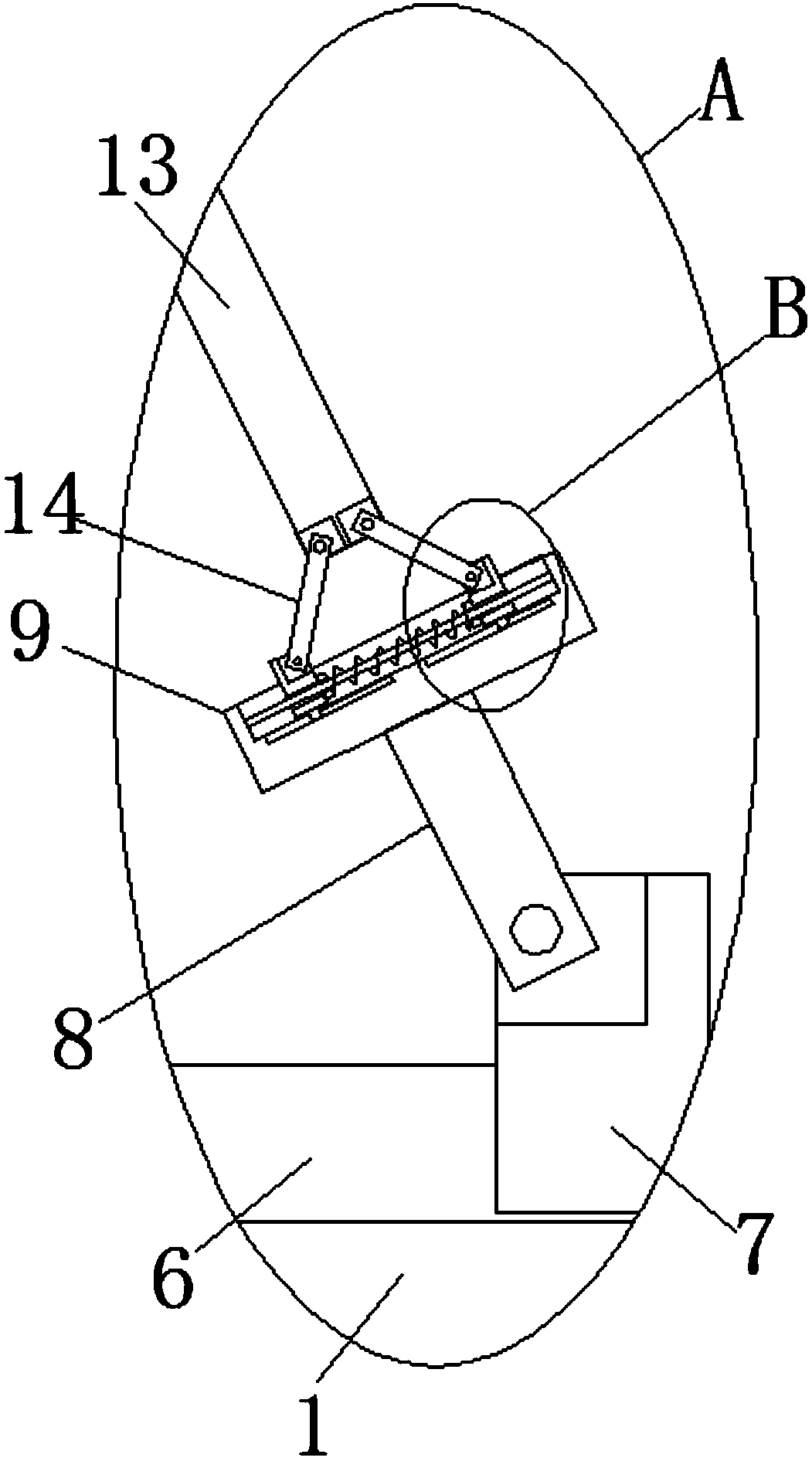

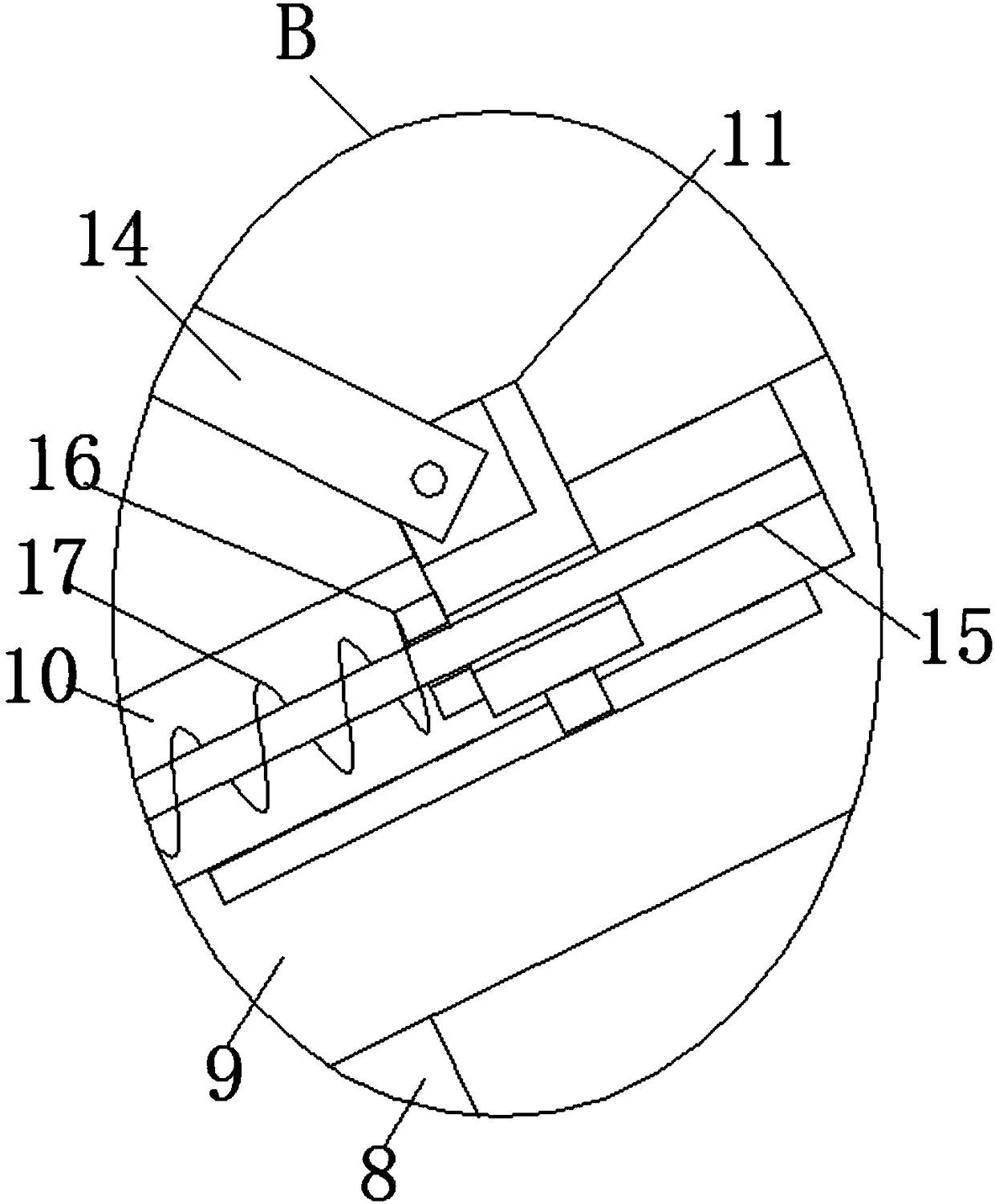

Crane with dual-drive structure

The invention discloses a crane with a dual-drive structure. The crane with the dual-drive structure comprises a base. A first fixed base is fixedly installed on the top of the base. A crane boom is rotationally installed on the top of the first fixed base. A pulley is rotationally installed at the end, away from the first fixed base, of the crane boom. A winch fixedly installed on the top of thebase is arranged on one side of the first fixed base. A first sliding groove is formed in the top of the base. A first sliding block located on the side, away from the winch, of the first fixed base is installed in the first sliding groove in a sliding manner. The top of the first sliding block extends out of the first sliding groove and is rotationally provided with a first connecting rod. The first connecting rod is arranged in an inclined manner. A buffer base is fixedly installed at the end, away from the first sliding block, of the first connecting rod. According to the crane with the dual-drive structure, because dual-drive hoisting can be realized with the winch and a motor, the stability of hoisted articles can be improved, the first connecting rod, a second connecting rod and a third connecting rod are prevented from bending, and the later maintenance cost is reduced.

Owner:唐志赏

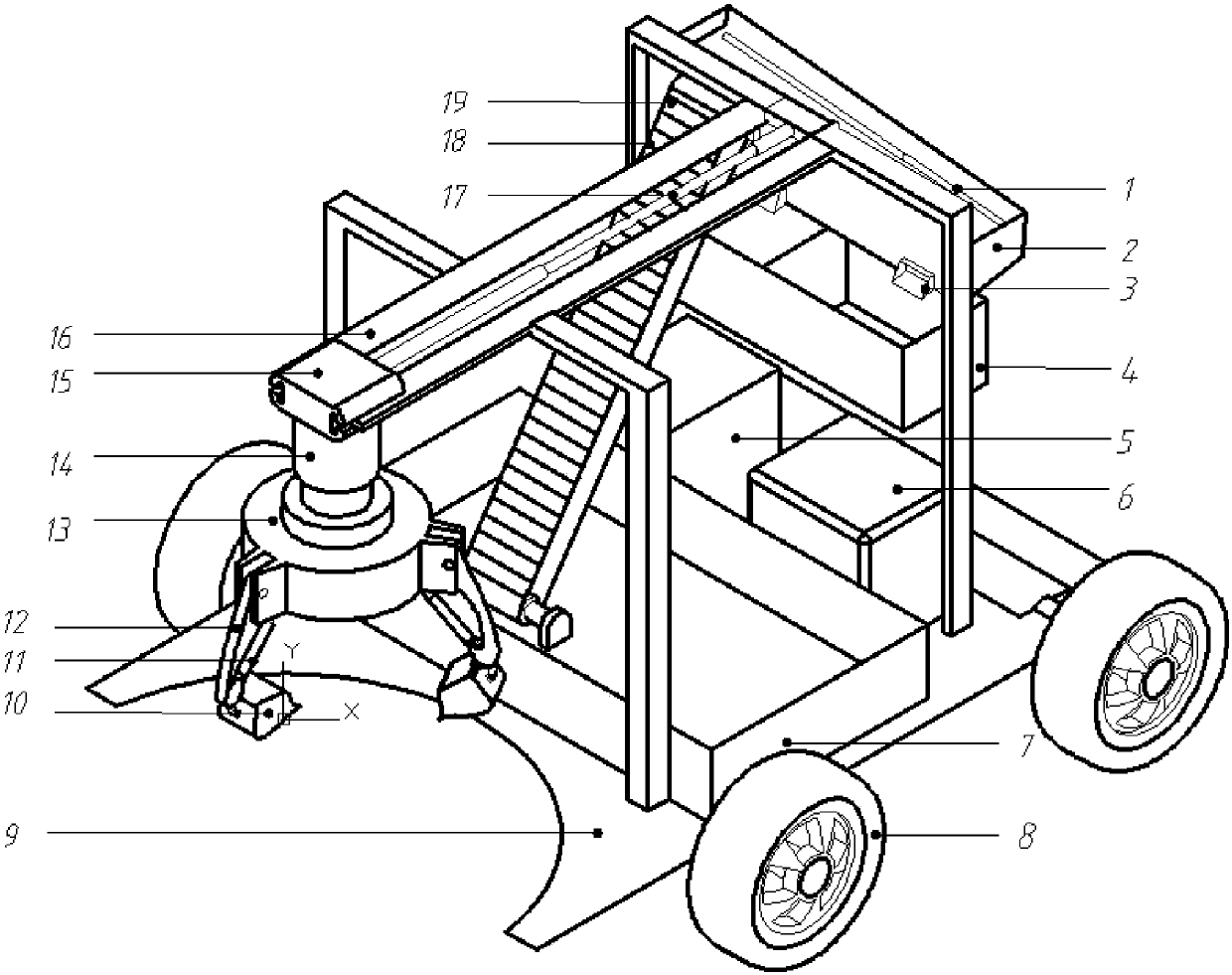

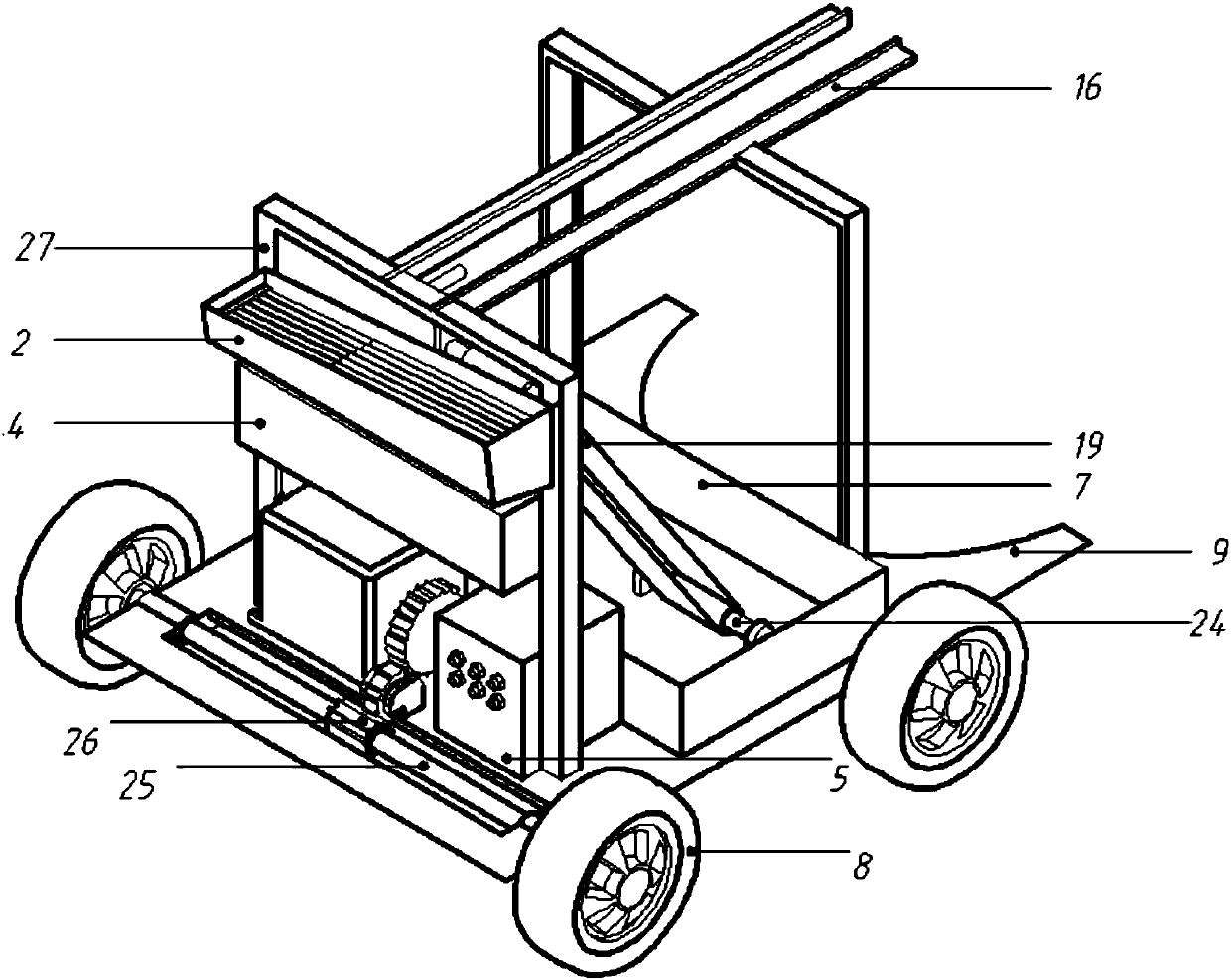

Blueberry picking and sorting apparatus and working method

PendingCN107820849AImprove work efficiencyReduce manual labor intensitySievingScreeningAgricultural engineeringVine

The invention relates to a blueberry picking and sorting apparatus and a working method, and belongs to the technical field of planting machinery and equipment. The blueberry picking and sorting apparatus and the working method are in particular applicable to picking and preliminary sorting of dwarf blueberries in mountains. The apparatus includes a bottom frame and a machine frame arranged on thebottom frame. The machine frame is equipped with a picking device and a sorting device. The picking device is used for picking fruits. A collection bin is arranged on the bottom frame. The picked fruits are placed in the collection bin, and then sent to the sorting device by a conveyor belt for multi-level sorting. With the apparatus of the invention, the efficiency of blueberry picking operationcan be improved, the artificial labor intensity can be reduced, and multiple damage to blueberry vines can be reduced.

Owner:SHANDONG UNIV OF SCI & TECH

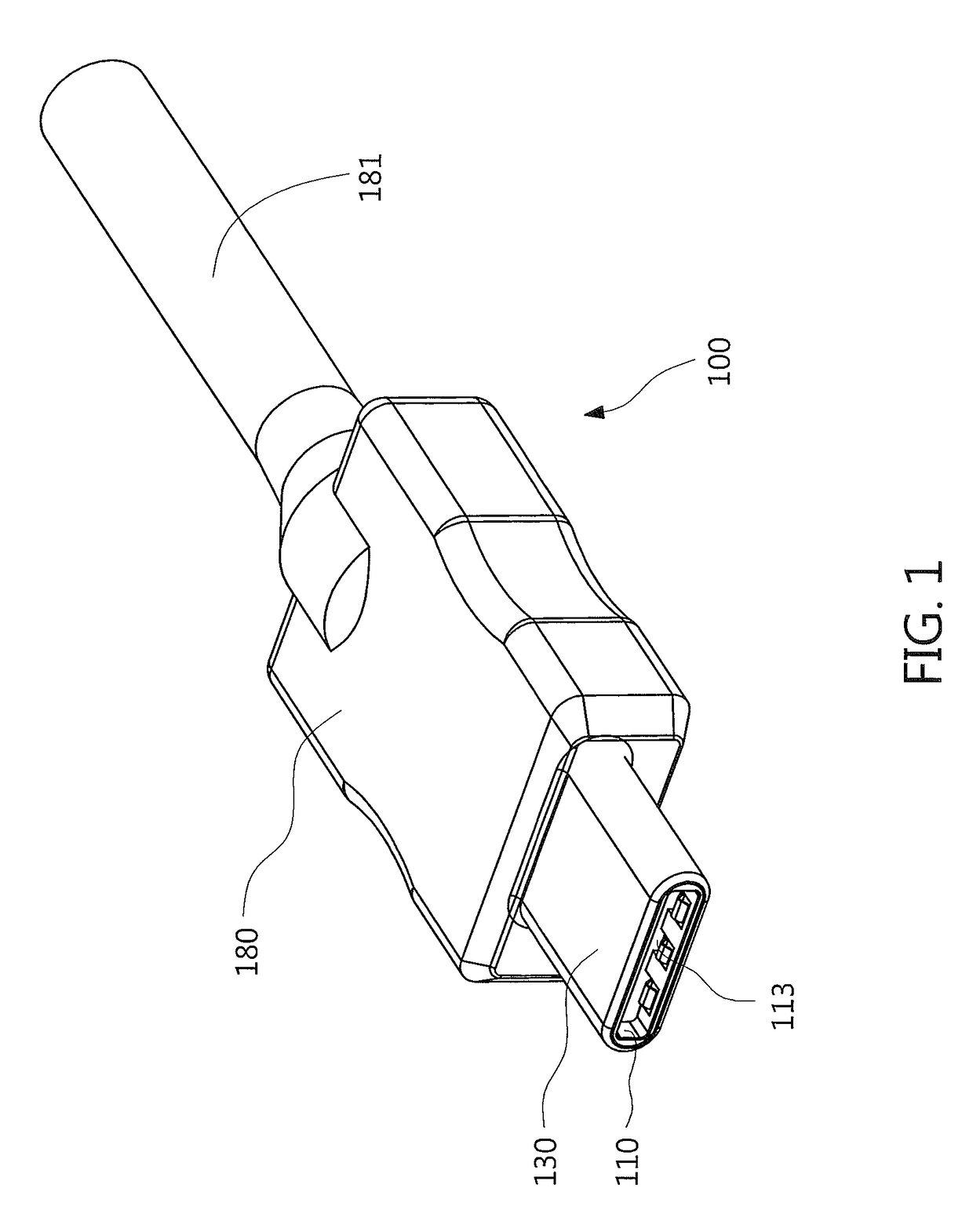

Electrical plug connector

ActiveUS9780500B2Avoid collisionConveniently insertedContact member manufacturingCoupling device detailsMetallic enclosureSoldering

An electrical plug connector includes an insulated housing, a metallic shell, two terminal sets, and a circuit board. The insulated housing includes a front portion and a rear portion. The front portion extends forwardly from the rear portion, and an inside of the front portion forms a receiving cavity. The metallic shell covers the insulated housing. Each terminal set is composed with a plurality of terminals. Each terminal includes a contact portion, a retaining portion, and a soldering portion. The retaining portion is retained in the insulated housing. The soldering portion extends backwardly from the retaining portion. The soldering portions are arranged as an upper row and a lower row in symmetry, and the soldering portion is of the spring arm type. The circuit board is inserted between the upper row and the lower row of the soldering portions. The upper row and the lower row of the soldering portions clip elastically the circuit board.

Owner:ADVANCED CONNECTEK INC

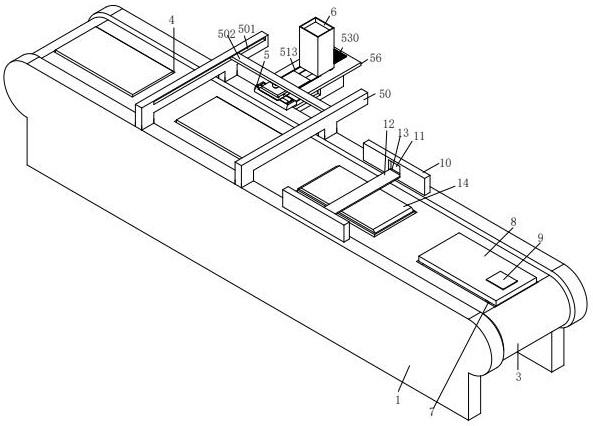

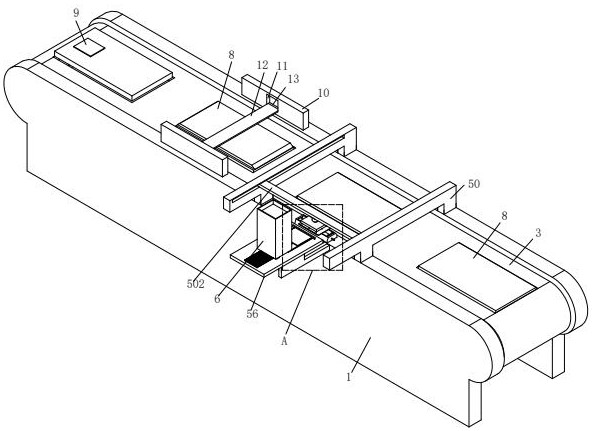

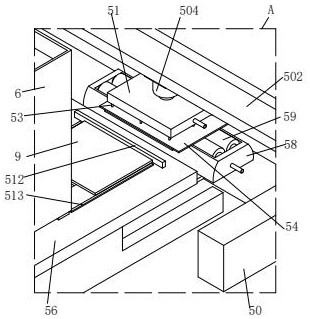

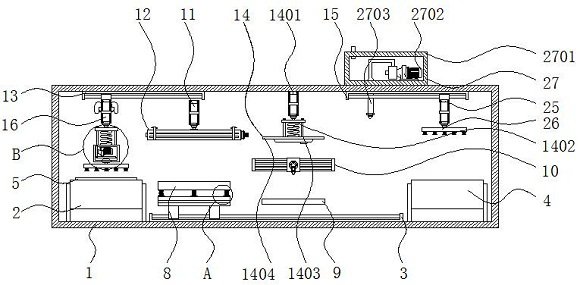

Automatic surface mounting equipment for electronic components

ActiveCN114501847ACause more or less problemsAvoid cumbersomePrinted circuit assemblingElectrical componentsSurface mountingEngineering

The invention relates to the technical field of electronic component surface mounting, in particular to electronic component automatic surface mounting equipment which comprises a supporting and fixing frame, a rotating shaft, a conveying belt and a fixing groove. According to the automatic surface mounting equipment for the electronic component, the surface mounting mechanism is adopted to coat the surface mounting component with the solder paste, and then the surface mounting component is mounted on a circuit board by adjusting the position of the surface mounting component; the problem that the solder paste on the circuit board is too much or little due to the fact that the solder paste coated on the circuit board is difficult to accurately coat according to the size of the patch component is solved, meanwhile, the solder paste is directly coated on the patch component, only the patch position of the patch component needs to be adjusted, and the production efficiency is improved. And the problem that the surface mounting of the electronic component is relatively tedious due to the fact that the tin paste coating position and the surface mounting component position are all adjusted is avoided.

Owner:华研电子科技(徐州)有限公司

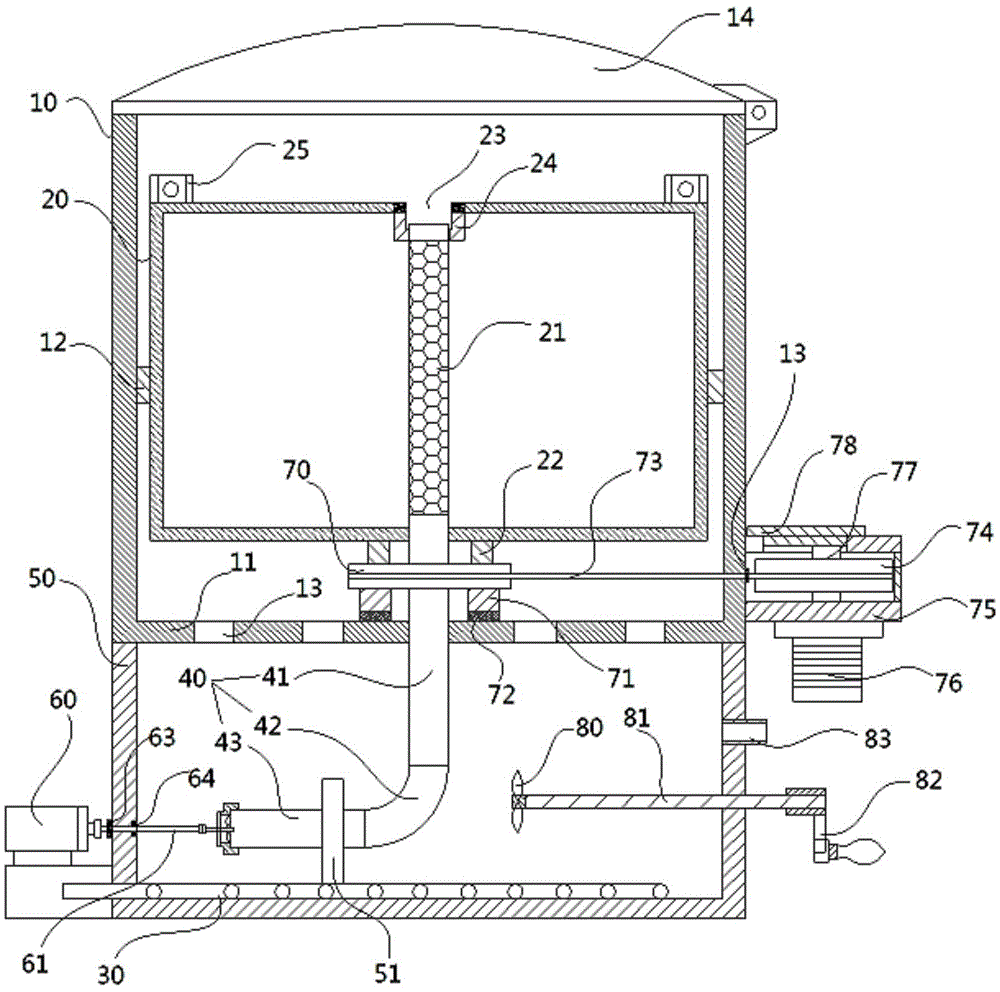

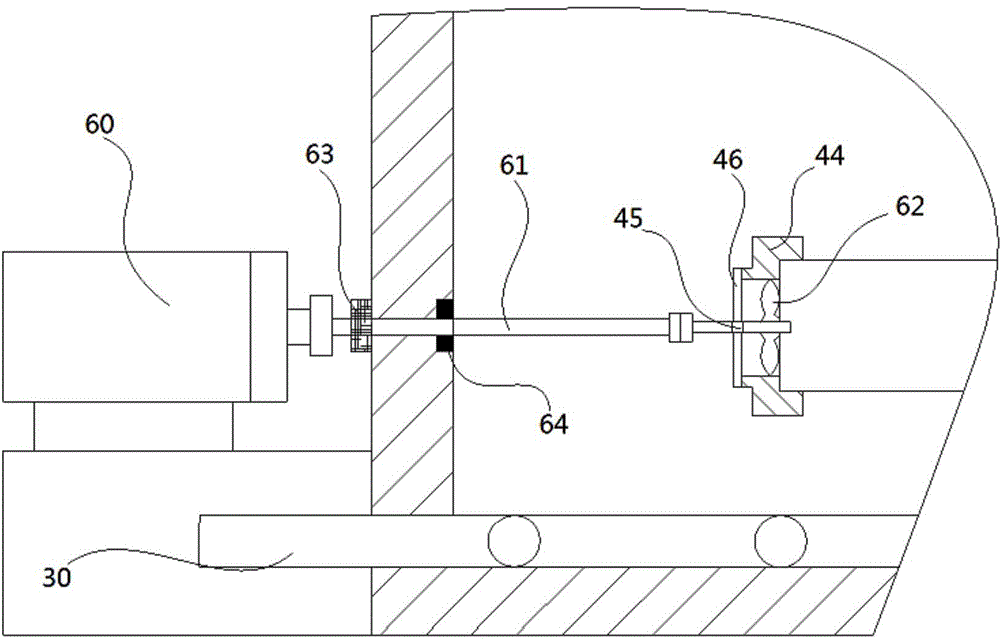

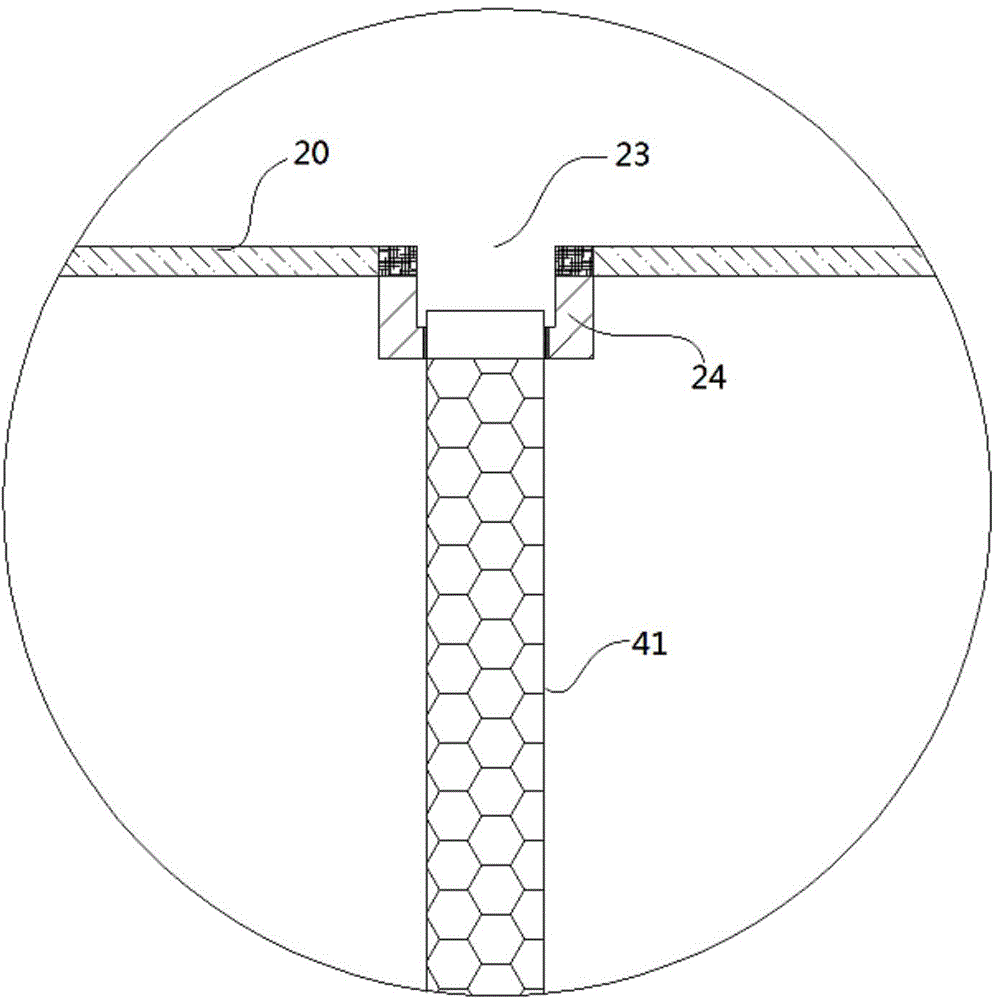

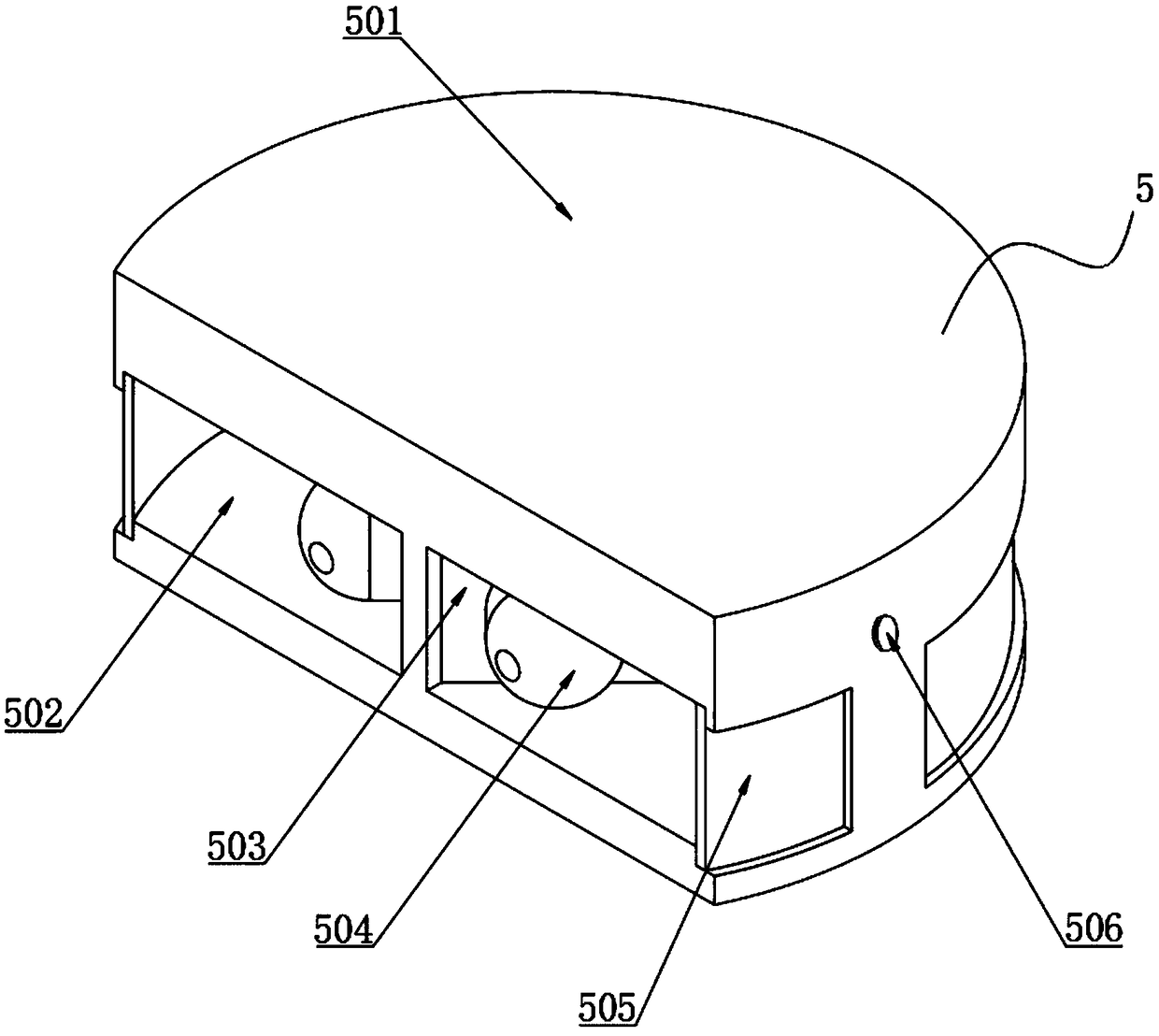

Loose stock dyeing device with rotatable fiber cage

InactiveCN104790145AStir wellPromote circulationTextile treatment machine arrangementsTextile treatment with treating outlet contectImpellerFiber

The invention discloses a loose stock dyeing device with a rotatable fiber cage. The loose stock dyeing device comprises a dyeing vat, the fiber cage, a heating coil pipe and a central spraying pipe, a dye tank is fixed to the bottom of the dyeing vat, a rotary wheel is arranged between the fiber cage and a bottom plate of the dyeing vat, and the rotary wheel is connected with a driving wheel through a driving belt. A mounting hole is formed in the upper end face of the rotary wheel, a mounting shaft corresponding to the mounting hole is arranged at the bottom end of the fiber cage, a locating hole is formed in the top of the fiber cage, locating blocks are arranged on the two sides of the locating hole, the upper side of the central spraying pipe is clamped by the locating blocks, and dye through holes communicated with the dye tank are evenly formed in the bottom plate of the dyeing vat. A stirring impeller is arranged in the dye tank, the stirring impeller is arranged on a lead screw, the end of the part, stretching out of the dye tank, of the lead screw is in pivot joint with a stirring handle, and a dye adding opening is formed in the position, on one side of the lead screw, of the side wall of the dye tank. When the fiber cage is hoisted down into the dyeing vat, the fiber cage does not rigidly collide with the dyeing vat, dye is not likely to be caked when added, the fiber cage rotates, and therefore dyeing is more even.

Owner:湖州市菱湖东方丝织厂

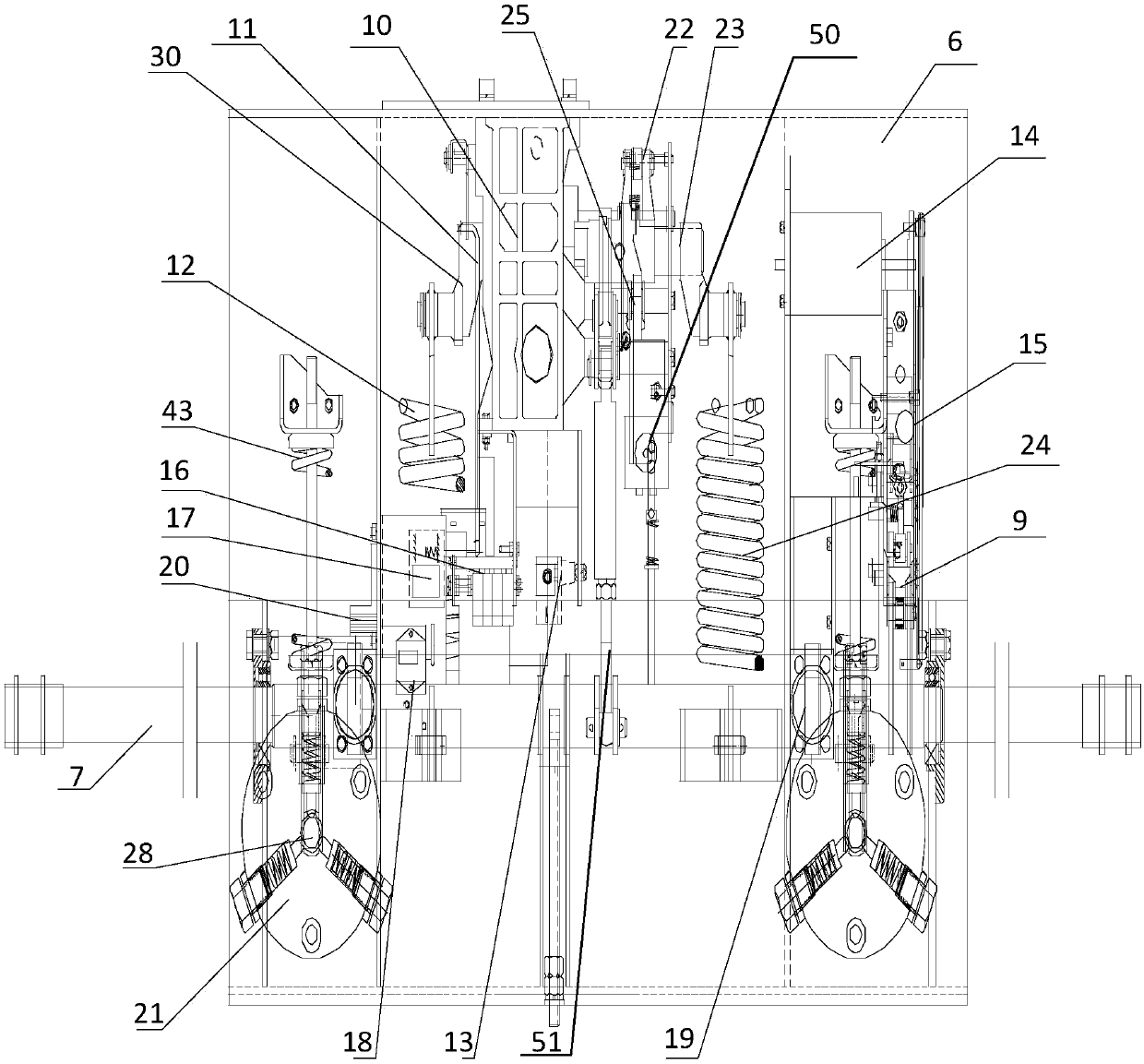

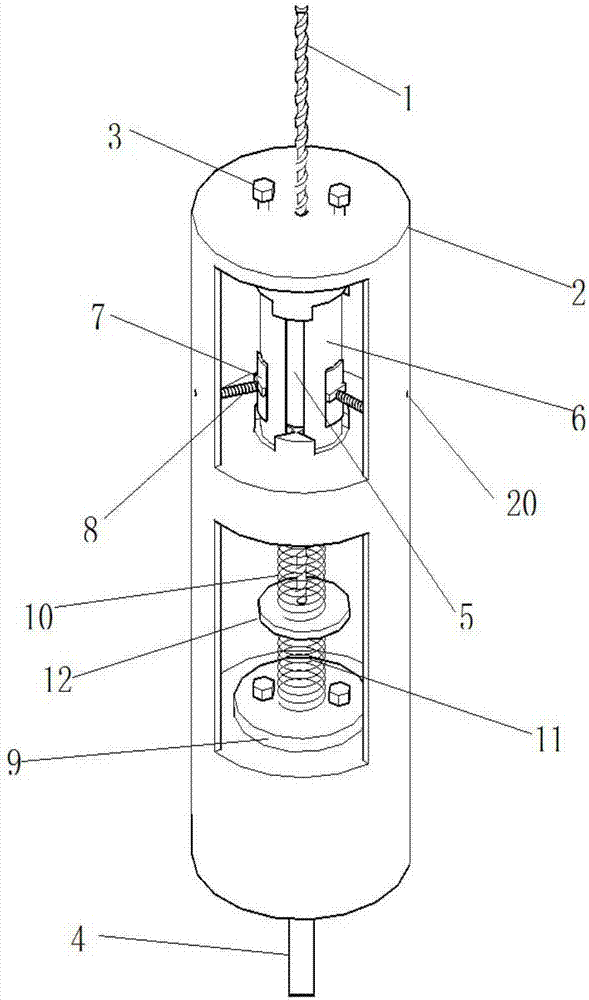

High-voltage no-reignition vacuum circuit breaker

ActiveCN107749369AReliable arc extinguishingSolve the problem of slow closingHigh-tension/heavy-dress switchesAir-break switchesEnergy absorptionEngineering

The present invention discloses a high-voltage no-reignition vacuum circuit breaker which mainly solves the problems in the prior art that the time corresponding to an optimal arc extinguishing open distance at opening cannot be prolonged, the opening and closing output power is low, a main shaft swings and bends during a rotation process, etc. The vacuum circuit breaker comprises a supporting rack, an installing pedestal, an operating mechanism, a magnetic sleeve, a contact, an insulating pull rod and a vacuum arc-extinguishing chamber, wherein the operating mechanism also comprises an operating mechanism box, the main shaft, a reduction gearbox, an energy storage motor, an opening spring, a closing energy storage rod, a first closing spring, an auxiliary switch, an opening button, a closing button, an energy storage indicating part, a movable energy absorption limiting device, an overshoot adjusting pad, an energy storage limiting arm, an opening measure, a closing measure, a first closing energy storage connecting lever, a closing coil, an opening coil, a speed regulation device, a supporting bearing, a second closing energy storage connecting lever and a second closing spring.The high-voltage no-reignition vacuum circuit breaker of the present invention has the advantages of being simple in structure, large in output power, reliable in speed reduction and excellent in arcextinguishing performance, etc.

Owner:四川奇通电气成套设备有限公司

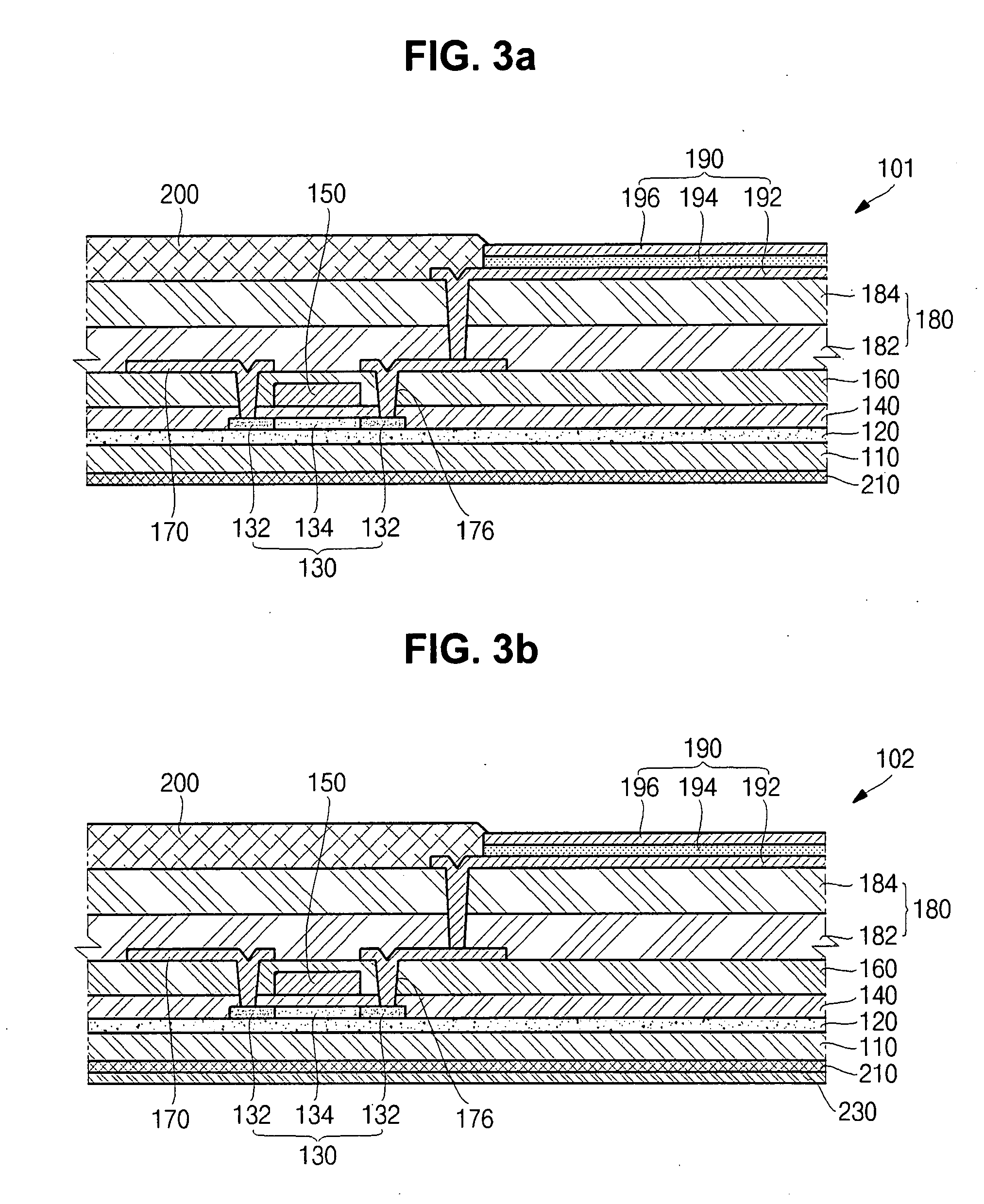

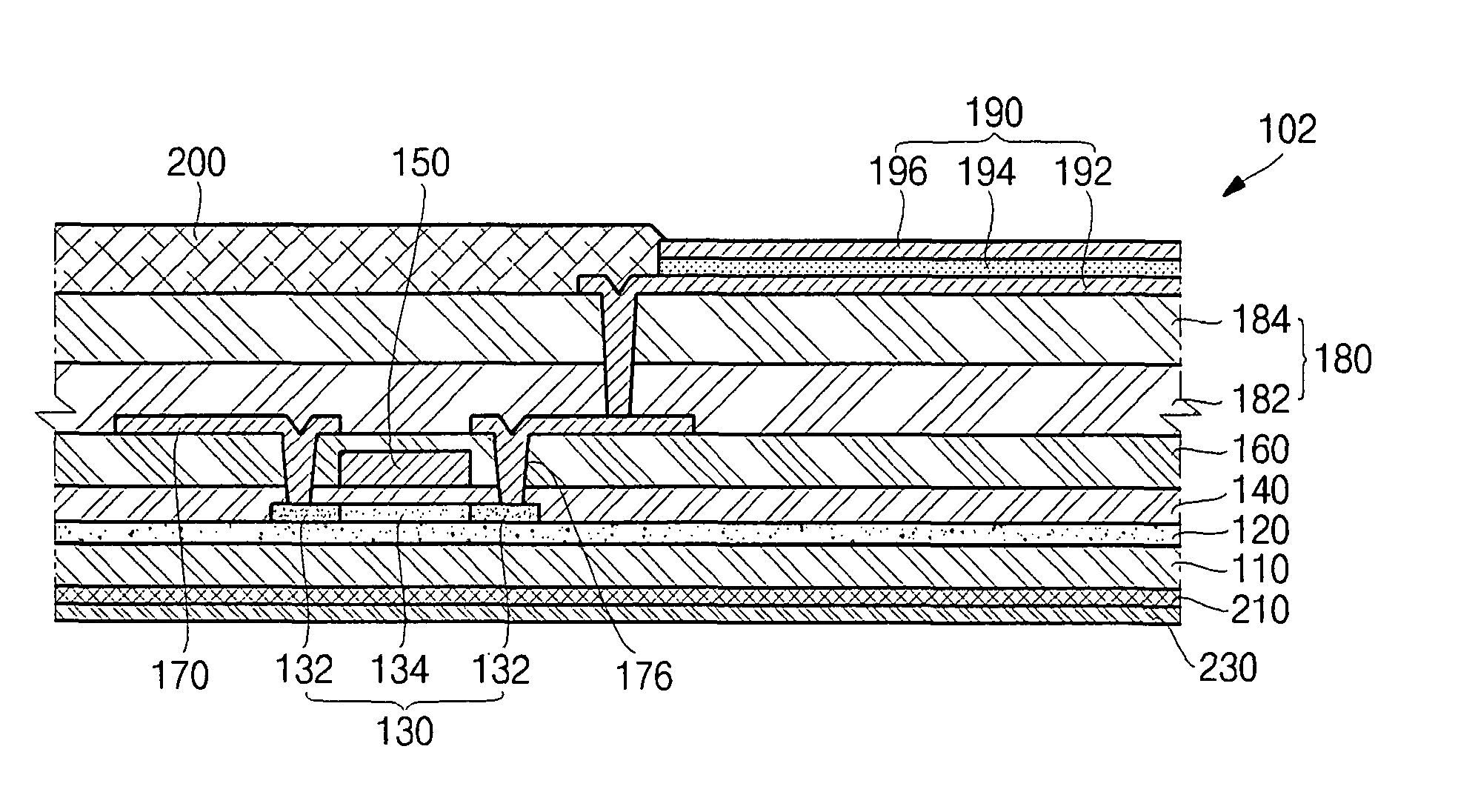

Organic light emitting display having a substrate support structure and fabricating method thereof

InactiveUS8916852B2Avoid bending damageAvoid damageDischarge tube luminescnet screensElectroluminescent light sourcesLight-emitting diodeOLED

An organic light emitting display including a substrate, a semiconductor layer formed on the substrate, an organic light emitting diode formed on the semiconductor layer, an encapsulant formed on a periphery of the substrate which is an outer periphery of the organic light emitting diode and the semiconductor layer; and an encapsulation substrate attached to the encapsulant.

Owner:SAMSUNG DISPLAY CO LTD

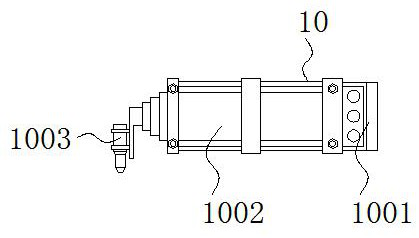

Thin-walled tube penetrating and conveying device

PendingCN109665254AAvoid damageTo achieve continuous inputConveyorsRoller-waysWorking environmentEngineering

Owner:郑州科慧科技股份有限公司

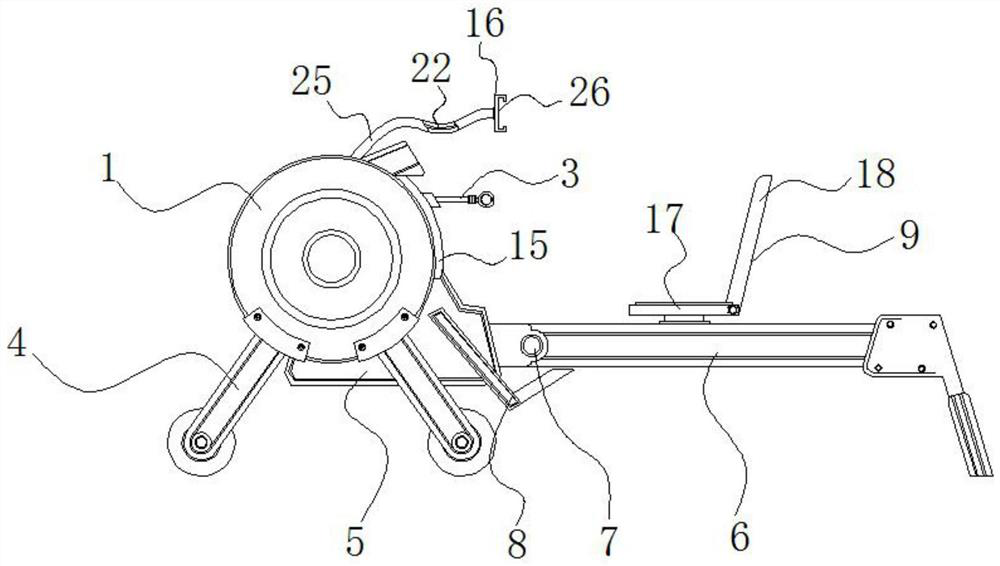

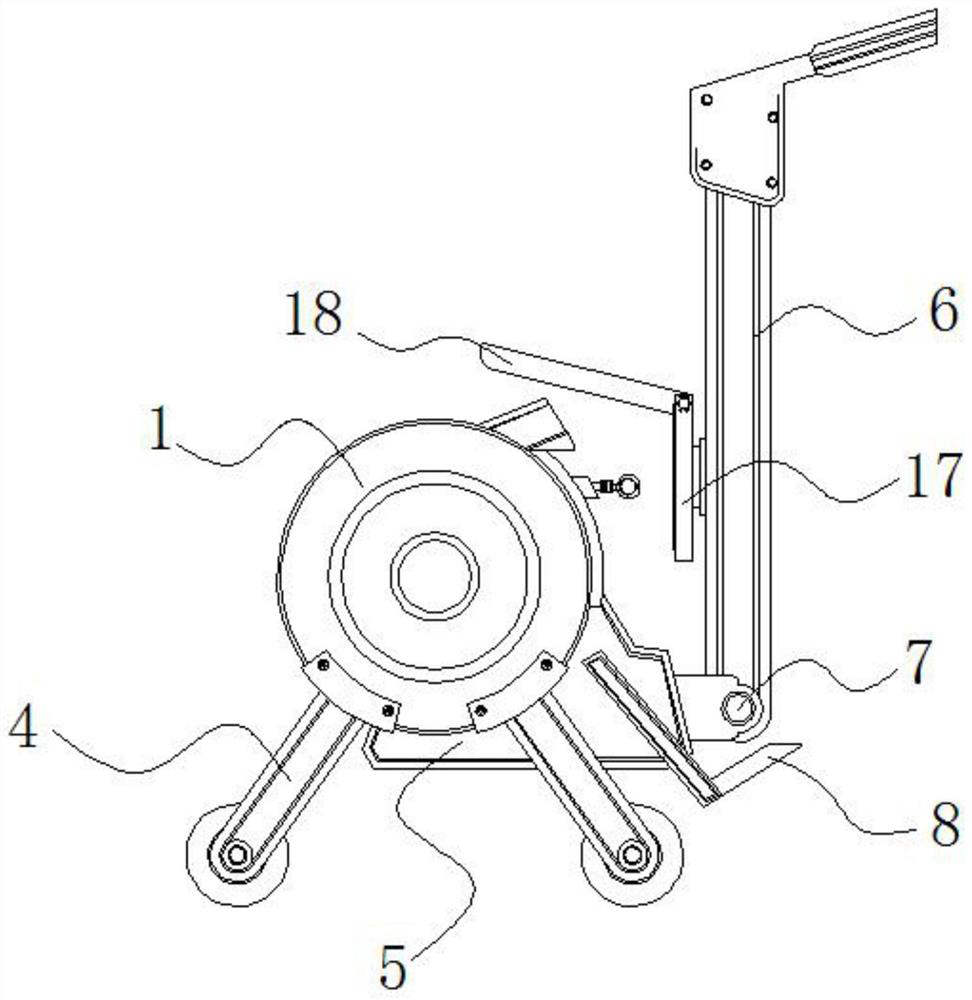

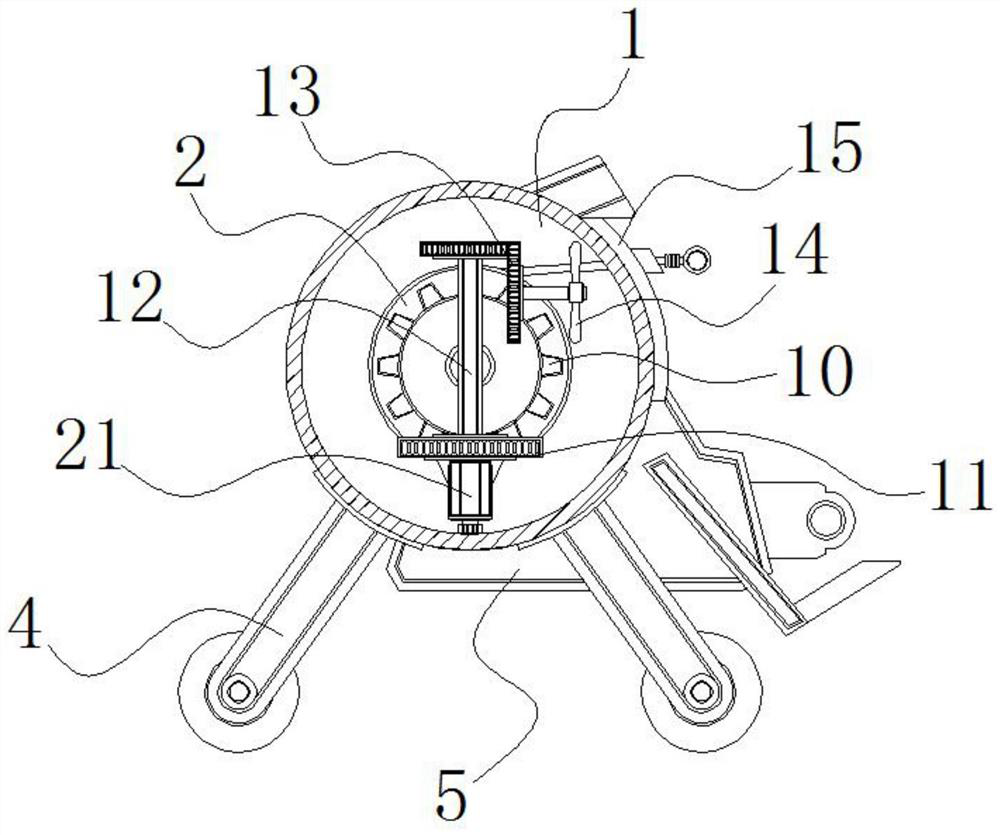

Rowing machine for physical fitness

InactiveCN112023339AImprove comfortAvoid excessive recliningBatteries circuit arrangementsElectric powerPhysical fitnessFoot supports

The invention discloses a rowing machine for physical fitness, and relates to the technical field of fitness rowing machines, wherein the rowing machine particularly comprises a pull rope box, a posture correction seat assembly and a simulation fan assembly, a rotary pull rope cylinder is arranged in the pull rope box, and one side of a supporting foot plate is fixedly connected with the two sidesof a foot supporting plate frame; the posture correction seat assembly is arranged on the upper surface of a supporting sliding rail, the simulation fan assembly is connected with the rotary pull rope cylinder through a tooth groove, and entertainment equipment clamping assemblies are arranged on the back face of the pull rope box and the bottom of a transmission gear rod. According to the rowingmachine for physical fitness, the rotary pull rope cylinder rotates and drives an adaptive fan to rotate through a tooth groove, the transmission gear rod and the fan gear to generate airflow, and the airflow penetrates through a shutter windshield curtain to be blown to the surface of a human body, so that simulation of a real motion scene is facilitated, and the human body immersion is improved; and the rotating speed of the adaptive fan adapts to the speed of pulling a rowing pull rope back and forth by a human body, so that the wind power adapts to the intensity of motion, and the simulation effect is improved.

Owner:张向东

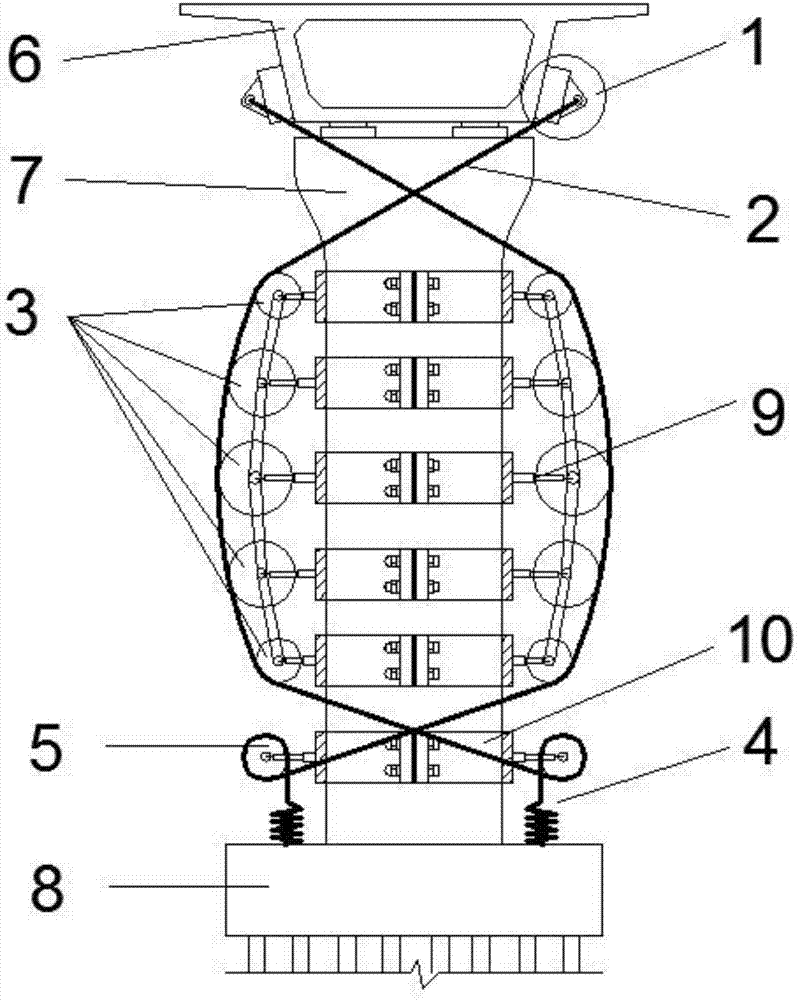

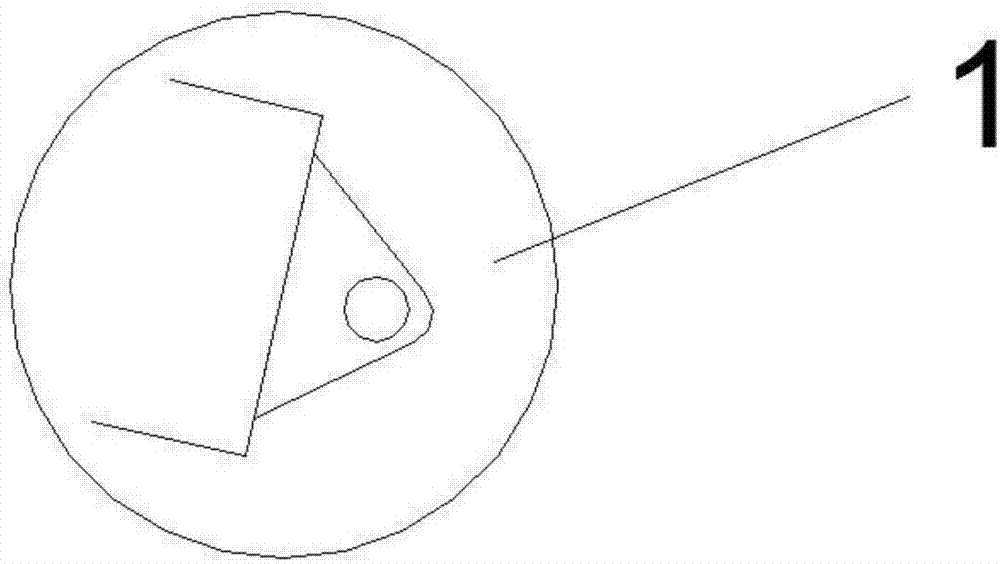

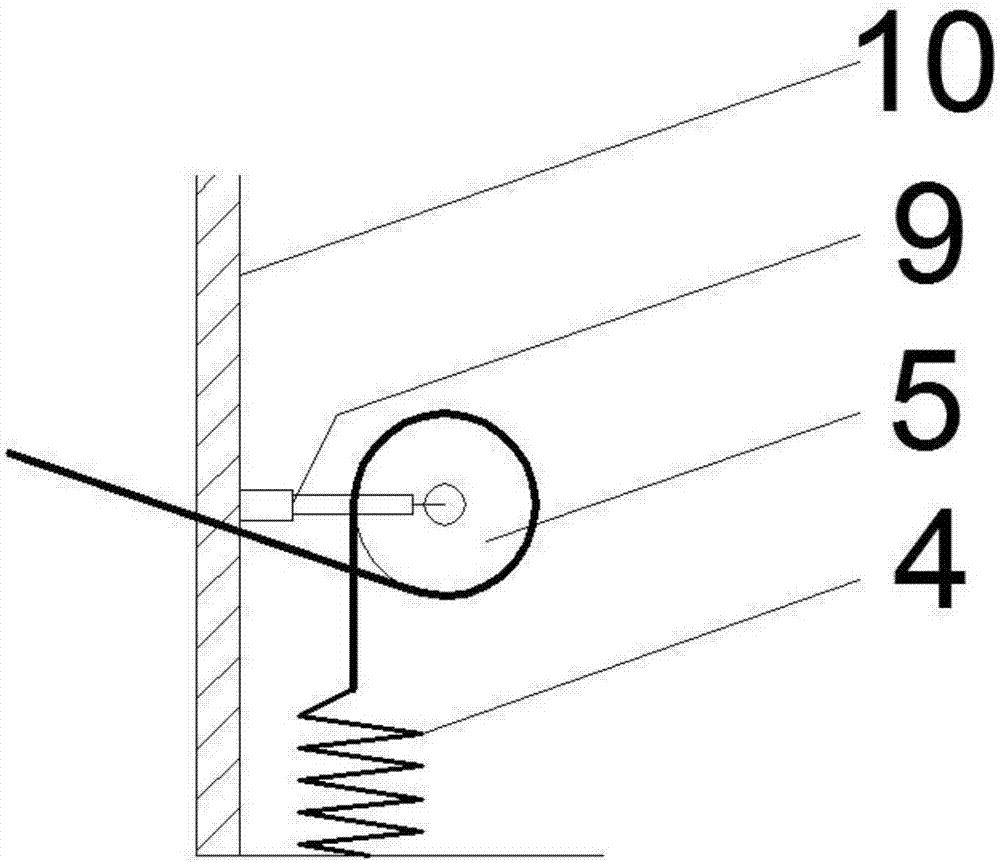

Friction-type quality turning wheel damper

InactiveCN107191046AGreat effortImprove shock absorptionProtective buildings/sheltersShock proofingEngineeringField coil

A friction-type quality turning wheel damper comprises a spiral actuating rod. The spiral actuating rod is connected with a round connecting plate after penetrating through a high strength shell, an upper positioning pressure bearing body, quality turning wheels and a lower positioning pressure bearing body sequentially. The upper end of the spiral actuating rod stretches out of the high strength shell, a first pre-pressing spring is arranged between the lower positioning pressure bearing body and the round connecting plate, a second pre-pressing spring is arranged between the round connecting plate and a sub plate fixed at the lower end portion of the high strength shell, and a connecting rod is connected to the lower end portion of the high strength shell. Slide grooves are formed in the upper positioning pressure bearing body and the lower positioning pressure bearing body, arc-shaped friction plates are mounted in the slide grooves, the arc-shaped friction plates are matched with the quality turning wheels, arch-shaped hinges are connected to the arc-shaped friction plates, and ultra-magnetostriction materials are connected to the arc-shaped hinges. Skeleton sleeves are arranged on the ultra-magnetostriction materials, field coils are wound on the skeleton sleeves, and the other ends of the ultra-magnetostriction materials are fixed on the high strength shell. The friction-type quality turning wheel damper can adapt to energy dissipation and seismic mitigation under different seismic actions, and increase the output force of the damper at the same time, and is high in response speed.

Owner:XIJING UNIV

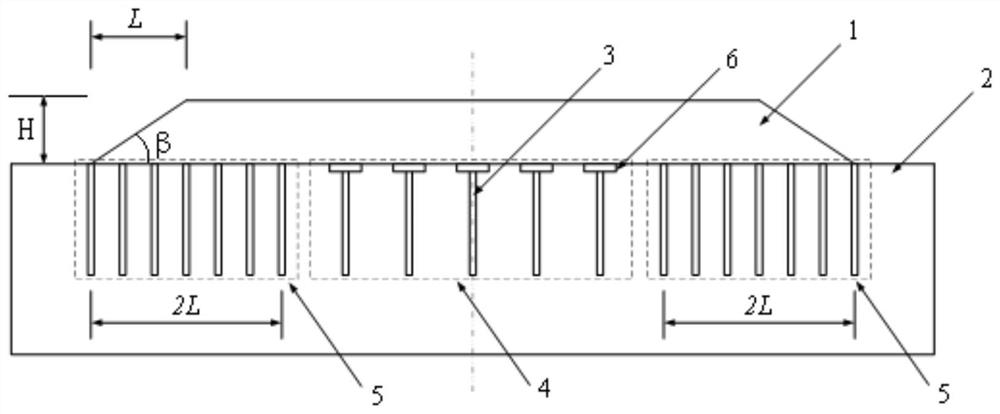

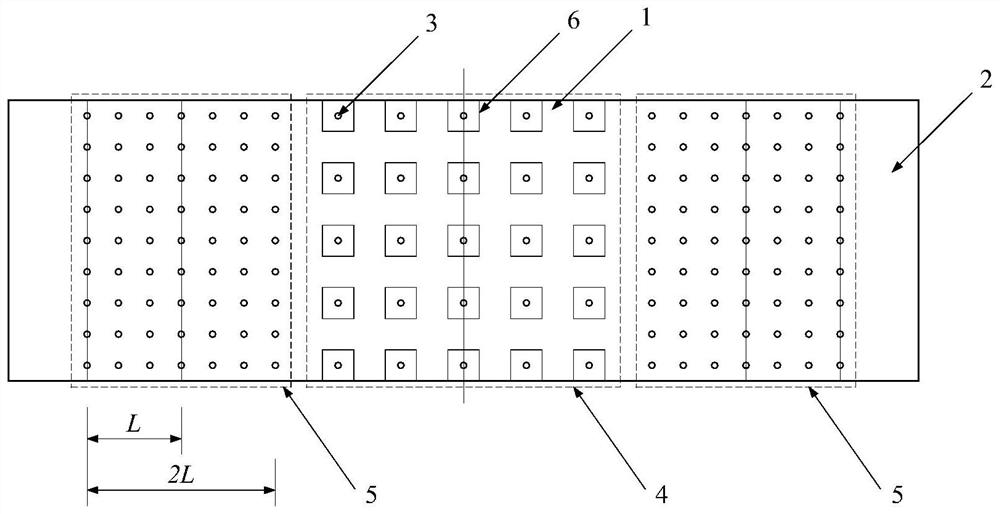

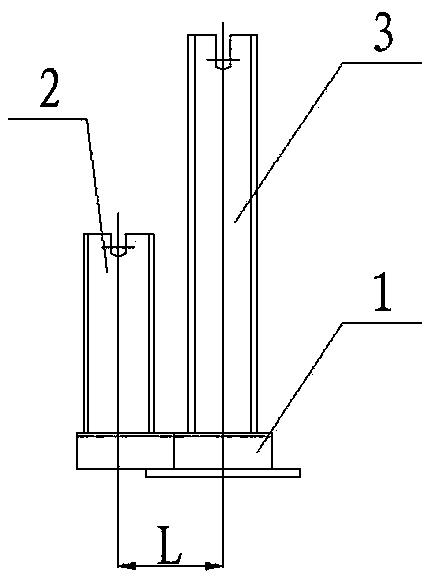

Variable-spacing rigid pile composite foundation for improving embankment stability

PendingCN111893809AReduce load capacityGuaranteed bearing capacityRailway tracksPile capBrittle fracture

The invention discloses a variable-spacing rigid pile composite foundation for improving embankment stability. The distance from a slope toe to a slope shoulder of an embankment side slope is L, and the arrangement area of all rigid piles is an area covered by an embankment and is divided into an arrangement area of large-spacing piles on the inner side and an arrangement area of small-spacing piles on the outer side; the small-spacing rigid piles adopt rigid piles which have a small spacing and certain ductility and are not provided with pile caps, and the large-spacing rigid piles adopt rigid piles which have a large spacing and are provided with pile caps. The variable-spacing rigid pile composite foundation solves the engineering problems of embankment instability and greatly reduced bearing capacity caused by sequential brittle fracture of the inner side pile bodies due to the fact that the outer side pile bodies of the rigid pile composite foundation are prone to brittle fractureunder large bending moment, and the large-spacing inner side piles with the pile caps can greatly reduce the construction cost on the basis that sedimentation and uneven sedimentation are effectivelycontrolled. The variable-spacing rigid pile composite foundation is simple in construction, good in total settlement control effect, capable of greatly improving the stability of the embankment, highin safety, high in applicability and good in economical efficiency.

Owner:TIANJIN UNIV

Stable charging terminal base and dust collector

PendingCN108493662AAvoid the problem of pulling outImprove experienceBatteries circuit arrangementsElectric discharge tubesDegrees of freedomEngineering

The invention discloses a stable charging terminal base and a dust collector. The stable charging terminal base comprises a charging terminal base, which has a plug and a connection portion which arein vertical connection mutually; a hanger cover plate, which has a hole for allowing the plug to pass; and a hanger base, which has a hook contacting and limiting the connection portion, wherein the hanger cover plate and the hanger base are matched up and down; the charging terminal base is arranged between the hanger cover plate and the hanger base; and the hook limits translational degree of freedom of the charging terminal base to the hanger cover plate. The hook has a vertical arm vertically protruding out of the hanger base and a horizontal hook vertically connected with the top end of the vertical arm, wherein the height of the vertical arm is equal to the vertical thickness of the connection portion, and the side end of the horizontal hook has a limit edge matched with the side profile of the plug. The hanger base limits the degree of freedom of vertical movement of the charging terminal base, thereby preventing the case that when the charging terminal base is under force, thehanger cover plate is pulled out.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

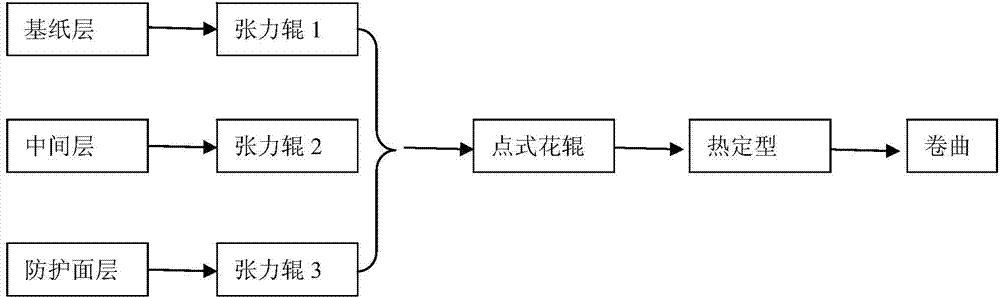

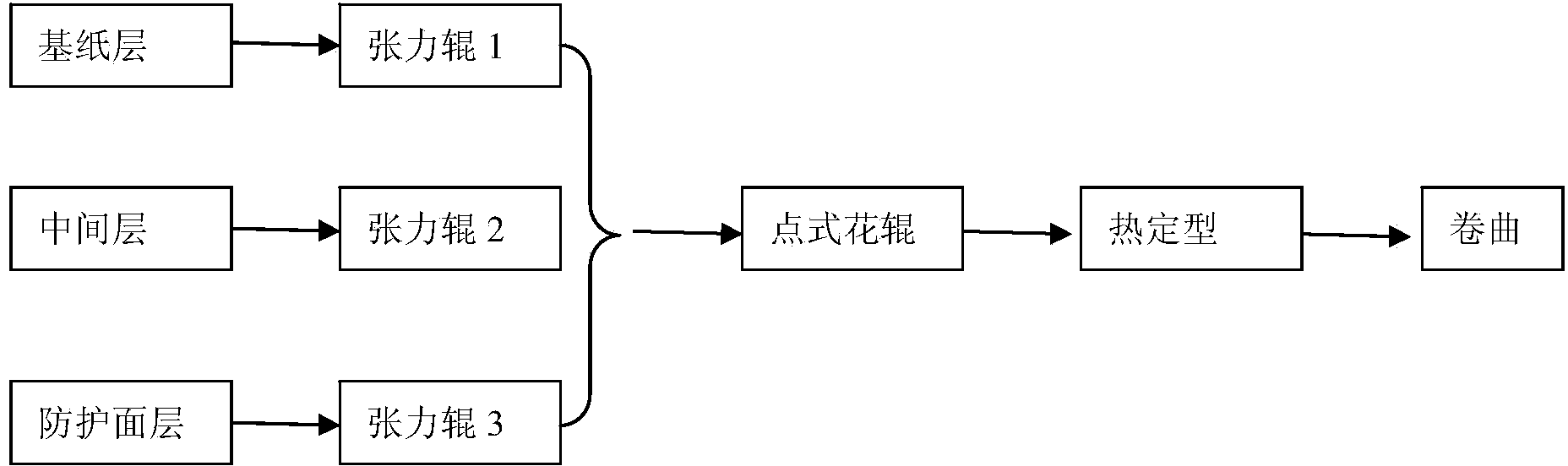

A kind of PBT composite filter material of fuel filter and preparation method

InactiveCN103752088BGive full play to the function of absorbing water in fuelPoint bondingSynthetic resin layered productsLaminationPolyethylene terephthalate glycolPolyvinyl alcohol

The invention relates to a composite filtering material for a fuel filter and a preparation method. The composite filtering material for the fuel filter contains three layers, i.e. a base paper layer, an interlayer and a protective surface layer, wherein the base paper layer contains superfine PBT (polybutylene terephthalate), PVA (polyvinyl alcohol) and viscose chopped fibers with lengths of 2 to 6 millimeters; the interlayer is PBT melt-blown fine cloth; the protective surface layer is PET / PBT (polyethylene terephthalate / polybutylene terephthalate) blended viscose cloth. The preparation method for the composite filtering material comprises the following steps of feeding the three substrate layers into point type patterned rollers through three pairs of tension regulation rollers respectively, and performing hot compression molding. According to the composite filtering material and the preparation method, the base paper layer has a function of completely adsorbing water in a fuel; the three layers contain the superfine PBT fibers, so that the filtering material is soft and resistant to folding, the blocking rate can be maximally reduced, and the filtering efficiency and accuracy are improved; in addition, the superfine PBT fibers are used as a connecting material, so that the operating temperature of the fuel filter can be born, and bending damage to filtering paper during high-speed folding can also be avoided.

Owner:DONGHUA UNIV

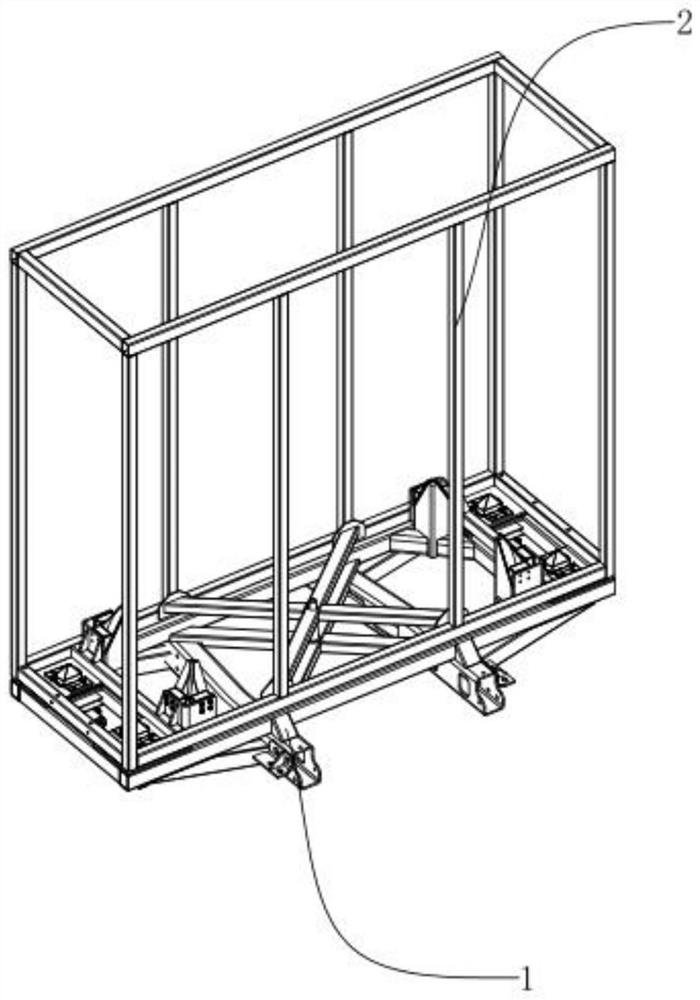

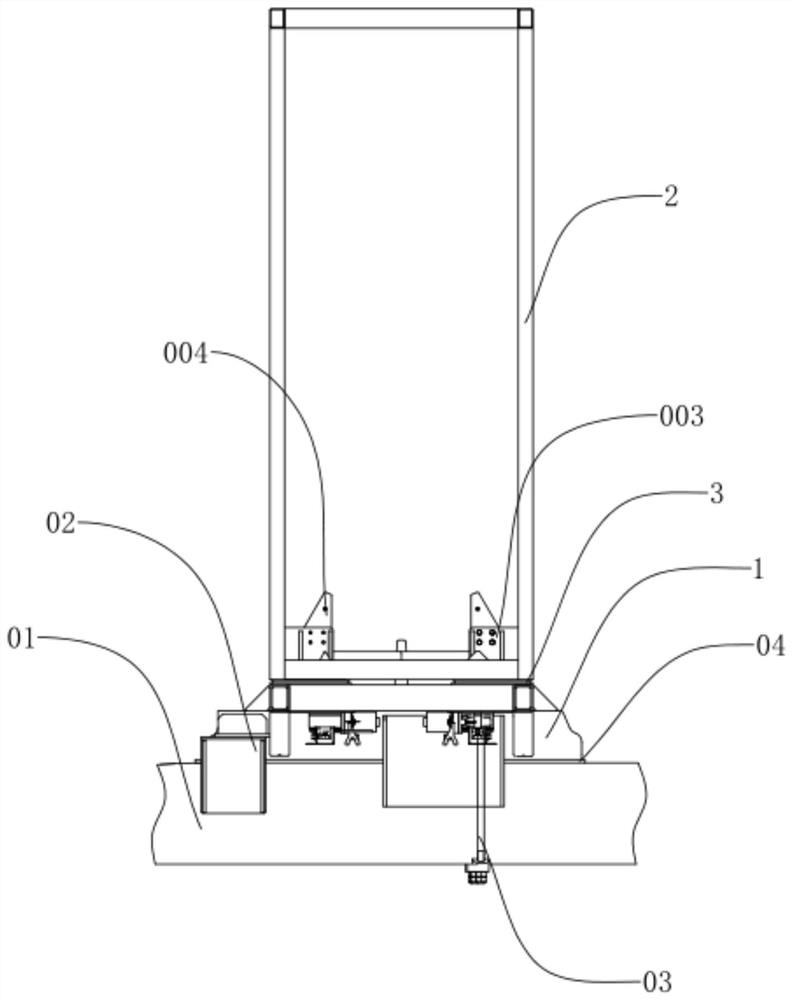

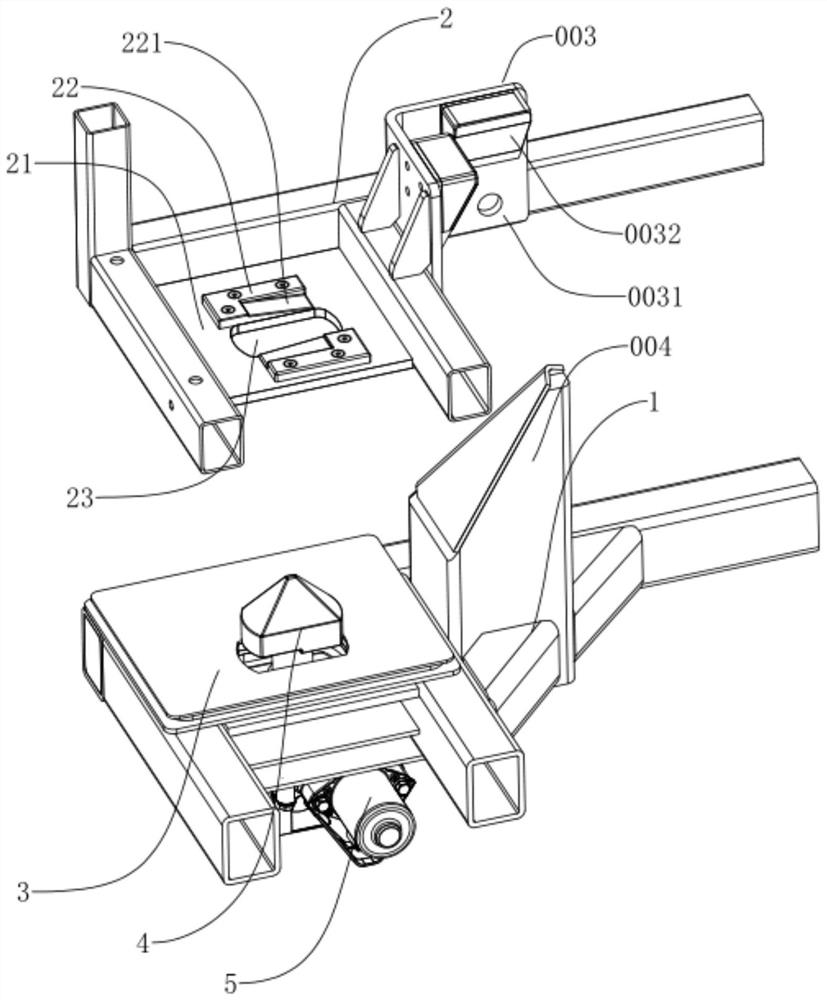

Battery replacement type pure electric heavy truck battery replacement system structure

PendingCN113043906AExtended service lifeReduce the difficulty of installation and removalCharging stationsPropulsion by batteries/cellsTruckIn vehicle

The invention discloses a battery replacement type pure electric heavy truck battery replacement system structure, and relates to the technical field of heavy truck battery replacement systems, the battery replacement type pure electric heavy truck battery replacement system structure comprises a vehicle-mounted battery replacement base and a battery replacement type battery box assembly used for being connected with the vehicle-mounted battery replacement base in a matched mode, and a multi-stage guide assembly is arranged between the vehicle-mounted battery replacement base and the battery replacement type battery box assembly in the height direction; the multi-stage guide assembly is used for limiting the vehicle-mounted battery replacement base and the battery replacement type battery box assembly to do relative displacement movement in the horizontal direction and the vertical direction; wherein the first-stage guide assembly comprises a plurality of locking bases used for being fixedly connected with a vehicle-mounted battery replacing base, and the locking bases are fixedly installed on the battery replacing type battery box assembly and provided with waist-groove-shaped locking groove holes; and the vehicle-mounted battery replacing base is provided with a plurality of rotary knob type locking pins used for being fixed to the corresponding locking bases in a matched mode, and the rotary knob type locking pins are connected with driving pieces for driving the rotary knob type locking pins to rotate. The connecting structure has the effect of being stable.

Owner:ANHUI HUALING AUTOMOBILE

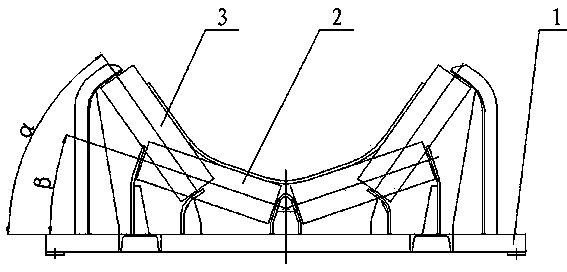

Deep groove carrier roller set

Owner:SHANXI DONGCHANG IND

Integrated circuit packaging finished product detection equipment

PendingCN113933686AReduce wearAvoid damageElectronic circuit testingMeasurement instrument housingProcess engineeringIndustrial engineering

The invention discloses detection equipment for an integrated circuit packaging finished product in the technical field of detection of integrated circuit packaging finished products. The detection equipment comprises a detection table, wherein a positioning mechanism used for positioning an integrated circuit is arranged at the bottom of the detection table. According to the invention, when a packaged integrated circuit needs to be detected every time, the integrated circuit is slowly pushed to an accurate detection position through a positioning mechanism; and in a pushing process, by matching with a follow-up rotating mechanism, the follow-up rotating mechanism is in a protruding state firstly and elastically supports the integrated circuit, when the integrated circuit is pushed, abrasion of the integrated circuit is reduced through follow-up movement so as to protect the integrated circuit and prevent the the integrated circuit from being damaged in the automatic adjustment process, and after the integrated circuit is pushed in place, the follow-up rotating mechanism automatically retracts under the action of the positioning mechanism, so that the bottom of the integrated circuit completely makes contact with the top of the detection table, the integrated circuit is prevented from being extruded to be bent and damaged in the detection process, the integrated circuit is protected, the whole process is automatically carried out, and convenience and rapidness are realized.

Owner:深圳台达创新半导体有限公司

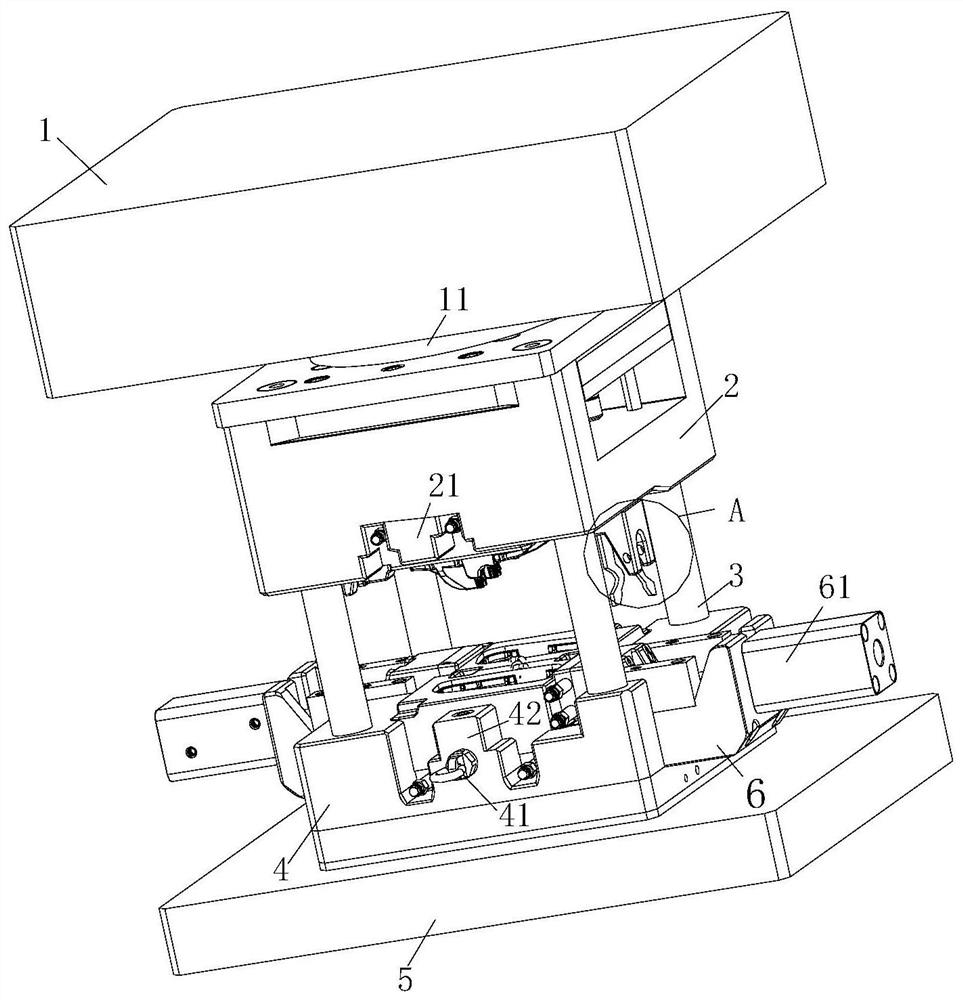

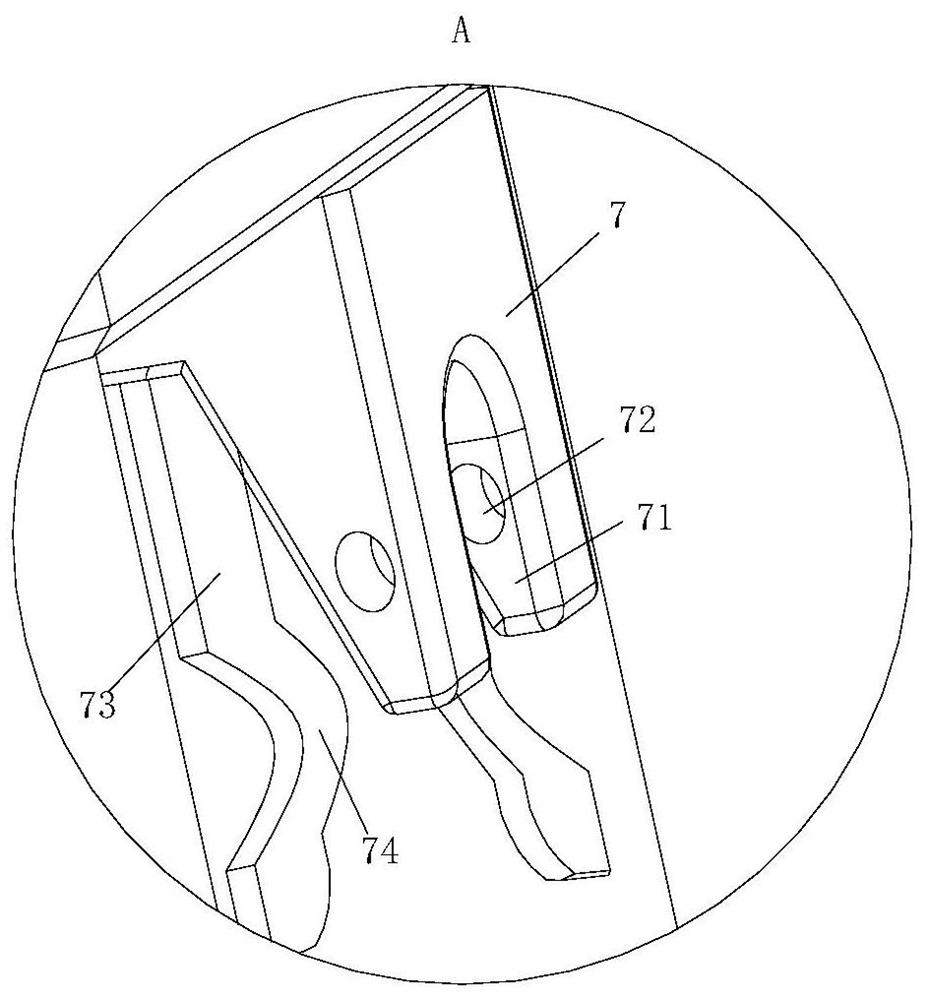

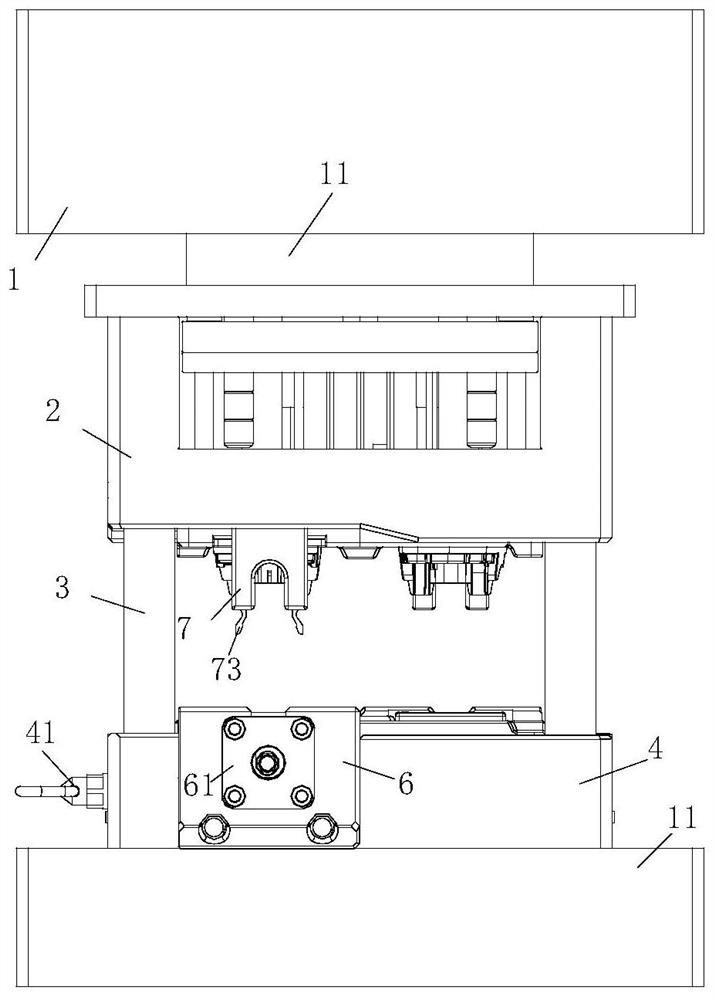

Automatic mold opening and closing mechanism

The invention relates to the technical field of molds, in particular to an automatic mold opening and closing mechanism. The automatic mold opening and closing mechanism comprises an upper mold, a lower mold and a bottom plate, wherein the lower mold is fixedly arranged on the bottom plate, a plurality of guide columns are arranged between the upper mold and the lower mold, the upper end of the upper mold communicates with an oil cylinder through a piston rod, and the upper mold can move up and down along the guide columns under the action of the oil cylinder to do mold opening or mold closingaction; containing boxes with openings in the upper ends are fixedly arranged on the left side and the right side of the lower mold, limiting blocks are fixedly arranged on the front side wall and the rear side wall in each containing box, and arc-shaped surfaces which are arched inwards are arranged in the middles of the limiting blocks; and two elastic pieces which are symmetrically arranged front and back are fixedly arranged on the side wall of the upper mold right above the containing boxes, and arc-shaped extrusion parts matched with the limiting blocks are arranged in the middles of the elastic pieces. According to the automatic mold opening and closing mechanism, the elastic pieces, the limiting blocks, a mold locking block, a first clamping block, an iron block and a permanent magnet chuck are arranged so that the self-locking of multiple positions can be realized while mold closing is carried out, and the energy consumption of mold locking is reduced.

Owner:ZHEJIANG TIANTAI XIANGHE IND CO LTD

PBT (polybutylene terephthalate) composite filtering material for fuel filter and preparation method

InactiveCN103752088AGive full play to the function of absorbing water in fuelPoint bondingSynthetic resin layered productsLaminationCompression moldingPolyethylene terephthalate glycol

The invention relates to a composite filtering material for a fuel filter and a preparation method. The composite filtering material for the fuel filter contains three layers, i.e. a base paper layer, an interlayer and a protective surface layer, wherein the base paper layer contains superfine PBT (polybutylene terephthalate), PVA (polyvinyl alcohol) and viscose chopped fibers with lengths of 2 to 6 millimeters; the interlayer is PBT melt-blown fine cloth; the protective surface layer is PET / PBT (polyethylene terephthalate / polybutylene terephthalate) blended viscose cloth. The preparation method for the composite filtering material comprises the following steps of feeding the three substrate layers into point type patterned rollers through three pairs of tension regulation rollers respectively, and performing hot compression molding. According to the composite filtering material and the preparation method, the base paper layer has a function of completely adsorbing water in a fuel; the three layers contain the superfine PBT fibers, so that the filtering material is soft and resistant to folding, the blocking rate can be maximally reduced, and the filtering efficiency and accuracy are improved; in addition, the superfine PBT fibers are used as a connecting material, so that the operating temperature of the fuel filter can be born, and bending damage to filtering paper during high-speed folding can also be avoided.

Owner:DONGHUA UNIV

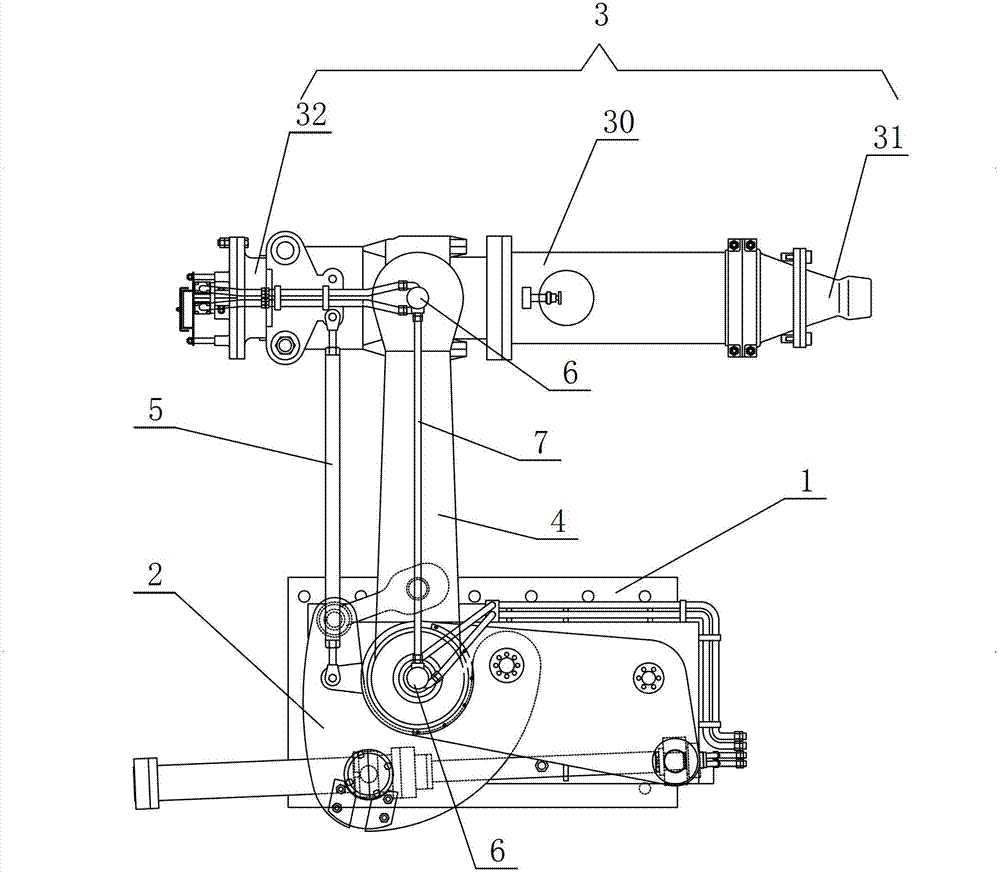

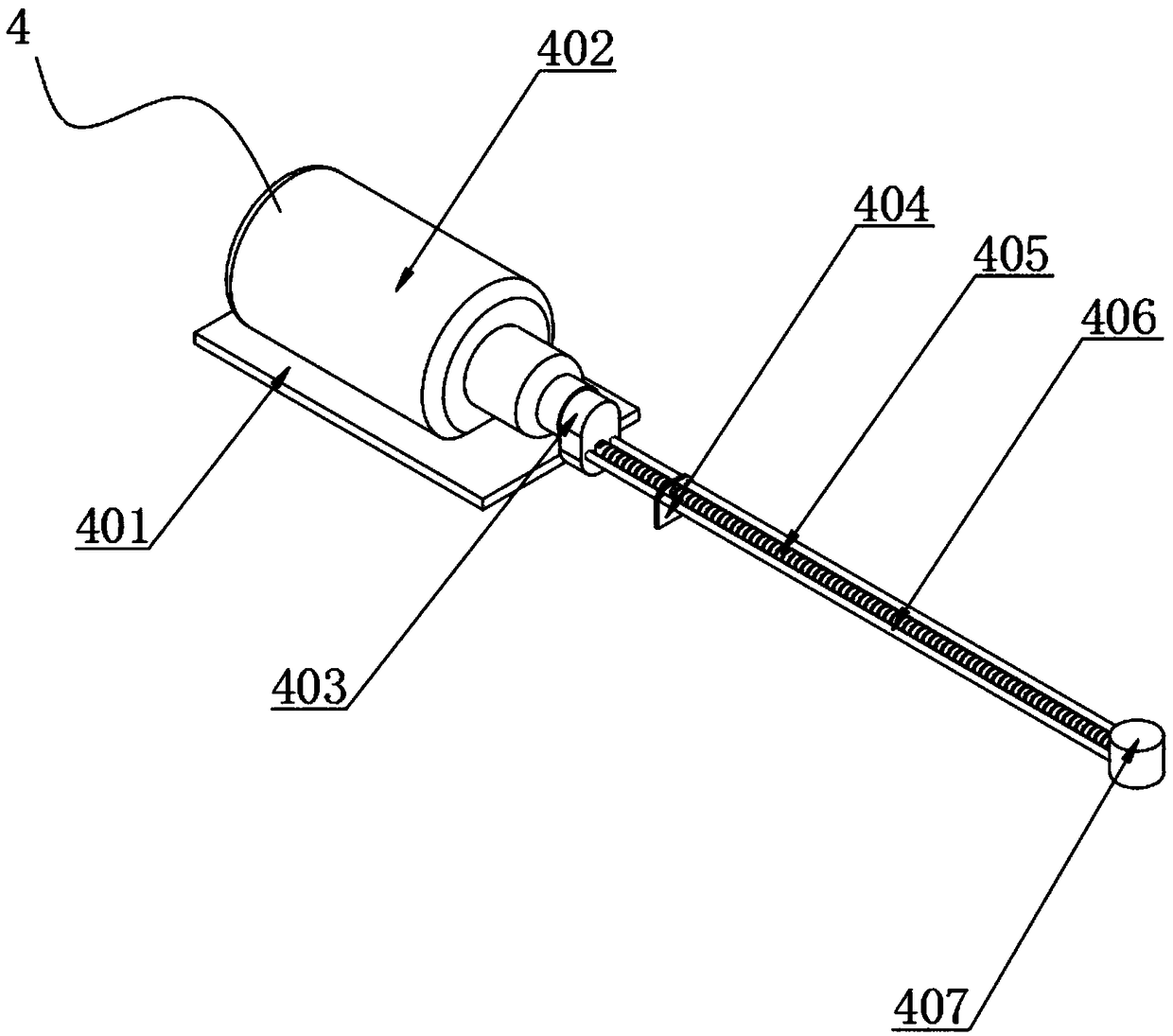

Hydraulic pipeline connection structure of hydraulic mud gun

InactiveCN102827978AAvoid bending damageGuaranteed uptimeBlast furnace componentsBlast furnace detailsEngineeringNozzle

The invention discloses a hydraulic pipeline connection structure of a hydraulic mud gun. The hydraulic pipeline connection structure comprises a base, a crank arm, a gun tube and a tumbler; wherein the crank arm is arranged on the base; a mud filling cylinder and a gun nozzle connected with the mud filling cylinder are arranged at the front end of the gun tube; a mud making cylinder is arranged at the rear end; one end of the tumbler is rotationally connected to the base; the other end is hinged on the gun tube; rotary joints are arranged at two ends of the tumbler and on the joint of the base and the gun tube; a hydraulic hoses of the mud making cylinder are arranged on two rotary joints and connected with a hydraulic station; a control rod is also connected between the gun tube and the base, and the hydraulic hoses of the hydraulic pipeline connection structure of the hydraulic mud gun are arranged on the rotary joints and connected with the hydraulic station. Bending damage of the hydraulic hose is avoided by rotation of the rotary joints, and the overall mechanism can operate safely and reliably.

Owner:无锡市长江液压缸有限公司

Stamping device with size detection function for case side plate machining

InactiveCN113263079ARelieve pressureNo reboundShaping toolsMetal-working feeding devicesHydraulic cylinderElectric machinery

The invention relates to a stamping device with a size detection function for case side plate machining. The device comprises an equipment shell and a second motor, and a first belt conveyor, a first electric sliding rail and a second belt conveyor are sequentially arranged on the lower wall of the interior of the equipment shell from left to right. An auxiliary supporting block, a heating softening mechanism and a second multi-section hydraulic cylinder are sequentially arranged on the rear wall of the interior of the equipment shell from bottom to top, and a third electric sliding rail, a pressing mechanism and a fourth electric sliding rail are sequentially arranged on the upper wall of the interior of the equipment shell from left to right. The stamping device has the advantages that according to the stamping device, a case side plate body is heated and softened through a fire-jet head, so that the pressure needing to be applied when equipment stamps the case side plate body is reduced. After the softened case side plate body is stamped, the situation that the stamping position rebounds is avoided, and the situation that the stamping depth of the equipment to the case side plate body is wrong is prevented.

Owner:源野网络科技(深圳)有限公司

Self-balancing reposition bridge damping device

PendingCN107974926AEasy to produce excessive bending moment problem solvingUniform and reasonable forceBridge structural detailsBlock and tackleBending moment

The invention discloses a self-balancing reposition bridge damping device. The self-balancing reposition bridge damping device comprises anchor blocks, high-strength cables, a fixed pulley block, high-strength springs, deflecting pulleys, connection rods and steel hoops. The anchor blocks are anchored onto the outer side faces of two sides of a main beam. The steel hoops are attached to a pile body and evenly distributed on the pile body. The fixed pulley block comprises a plurality of pulleys with different diameters. The size of the pulley in the middle is the largest, and the sizes of the pulley towards two sides are reduced gradually. The pulleys are anchored onto the steel hoops through the connection rods. The outer side face of the fixed pulley block after mounting is arc-shaped. The lower ends of the high-strength springs are anchored onto a bearing platform or a base. The deflecting pulleys are arranged on the lower portion of the pile body to enable the high-strength cables to be vertically connected with the high-strength springs. The upper ends of the high-strength cables are anchored onto the anchor blocks on the outer side of the main beam, and sequentially pass the fixed pulley block on the other side and the deflecting pulleys on the same side; the lower ends of the high-strength cables are anchored onto the high-strength springs on the same side. By the device,the problem of excessively large bending moment of the pile body is solved effectively.

Owner:HEBEI UNIV OF TECH

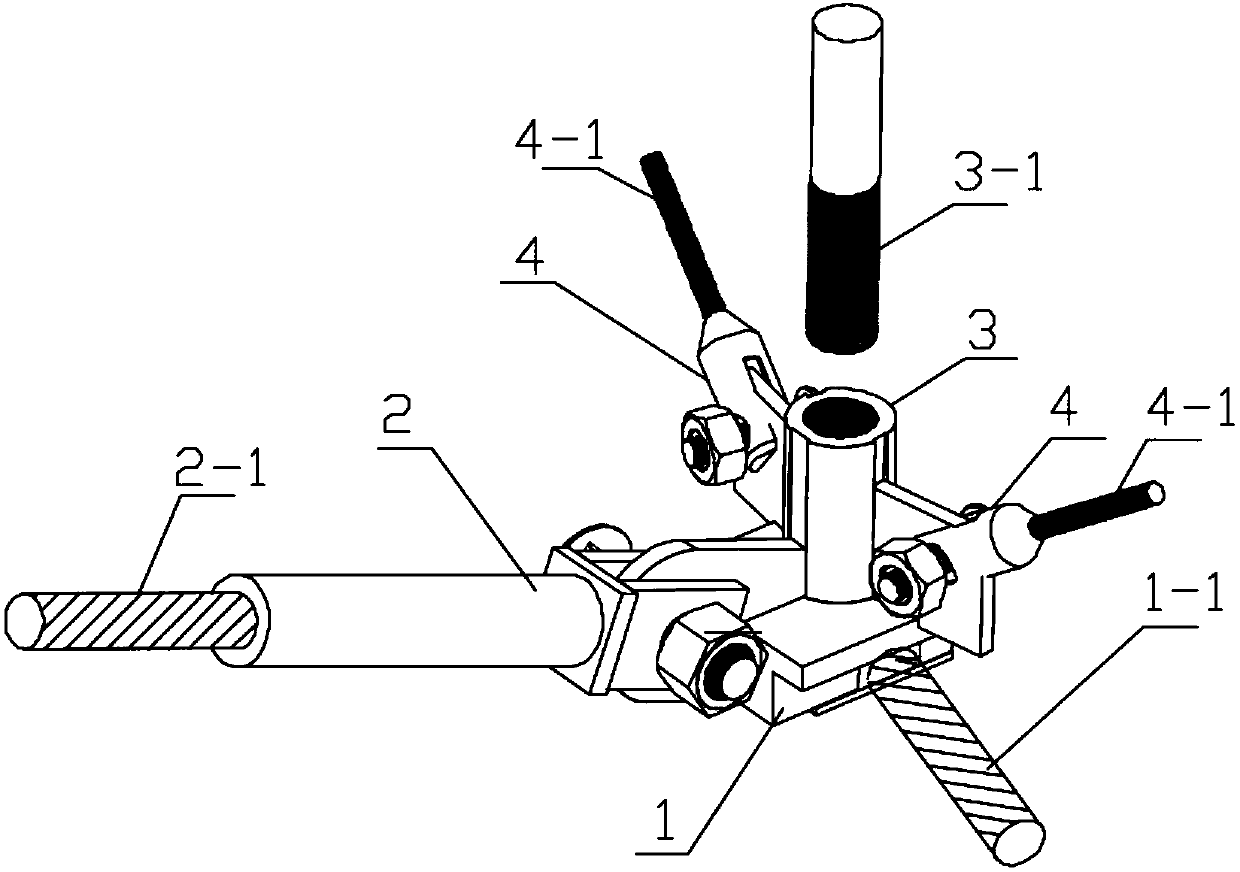

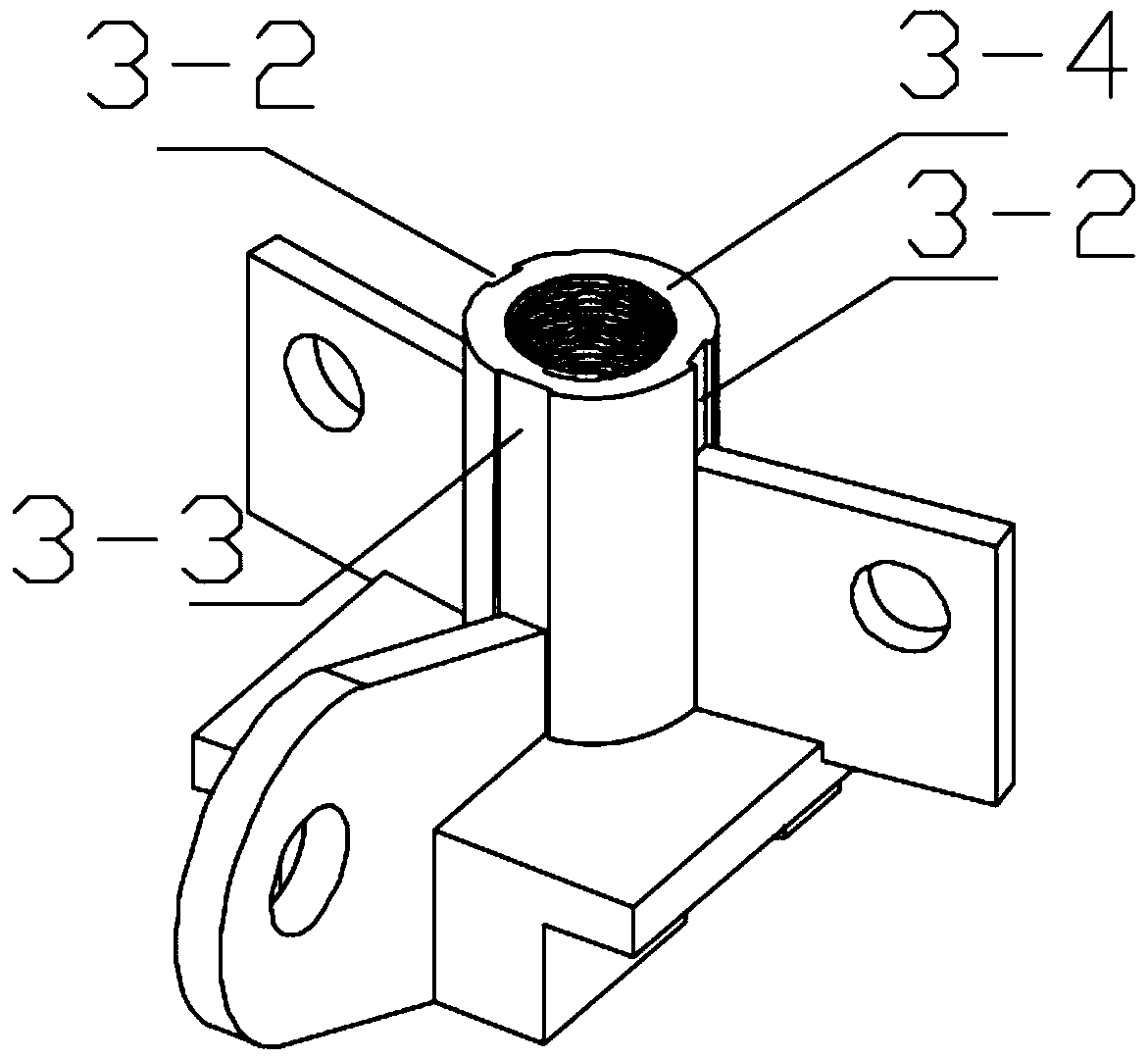

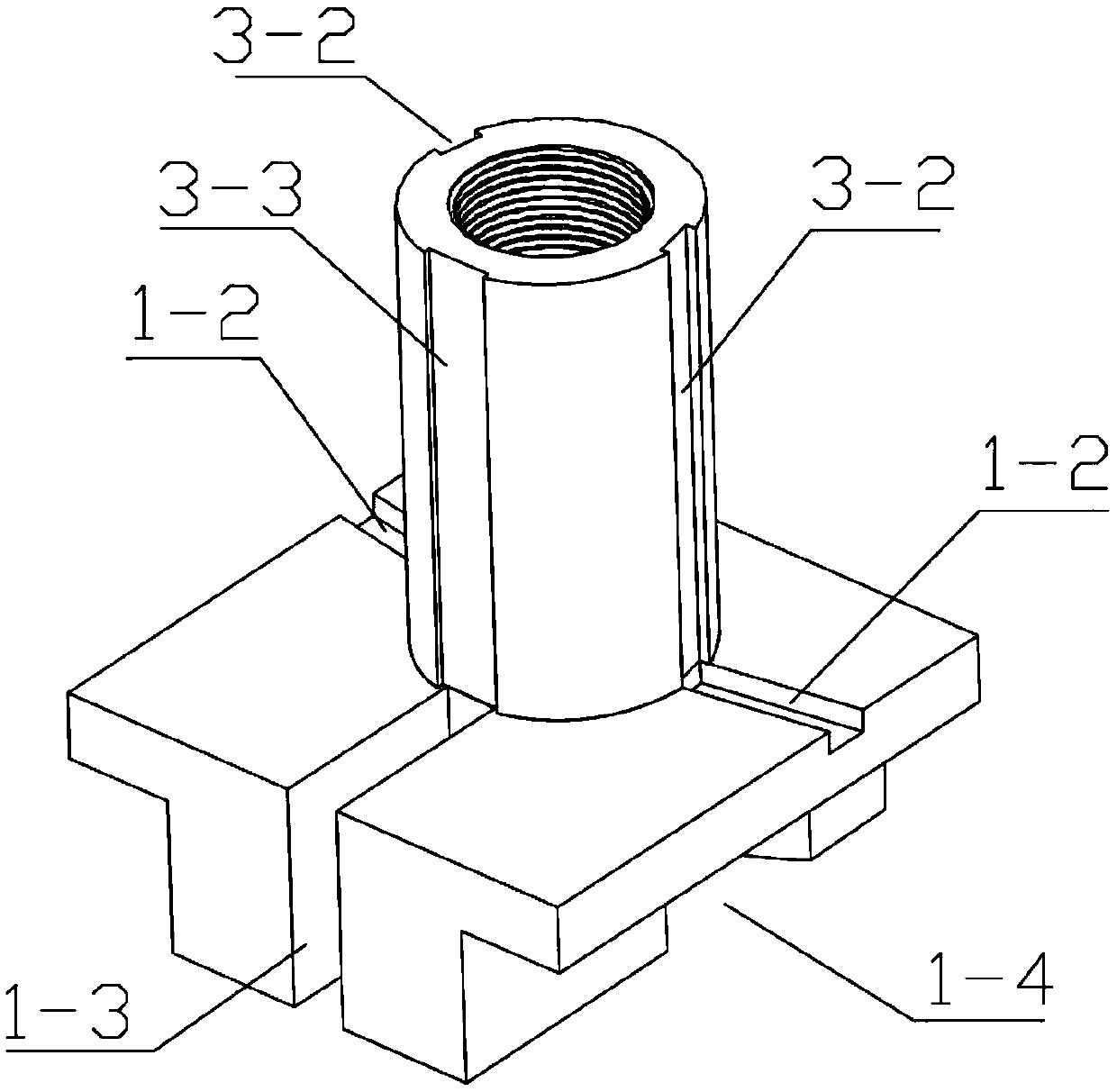

Multi-directional node connection device for CFRP cable suspen-dome structure

The invention provides a multi-directional node connection device for a CFRP cable suspen-dome structure. The multi-directional node connection device comprises a fixed end main body, a radial anchoring component, a vertical supported rod connection component and a diagonal support connecting component; the vertical supported rod connection component is fixedly mounted on the upper face of the fixed end main body and used for connecting rod parts in the vertical direction; an arc groove is formed in the bottom of the fixed end main body, a cover plate is arranged on the body of the fixed end main body, and the arc groove and the cover plate are used for fixing a circumferential CFRP cable; the radial anchoring component and the diagonal supported connection component are arranged between the vertical supported rod connection component and the fixed end main body and used for connecting rod parts in the radial and diagonal directions. The multi-directional node connection device effectively connects a CFRP radial cable, the CFRP circumferential cable and the multi-directional rod parts such as the vertical supported rod parts and the diagonal supported rod parts together to work, and also overcomes the defects of poor shear resistance and large prestressing loss of CFRP cables.

Owner:JIANGSU UNIV

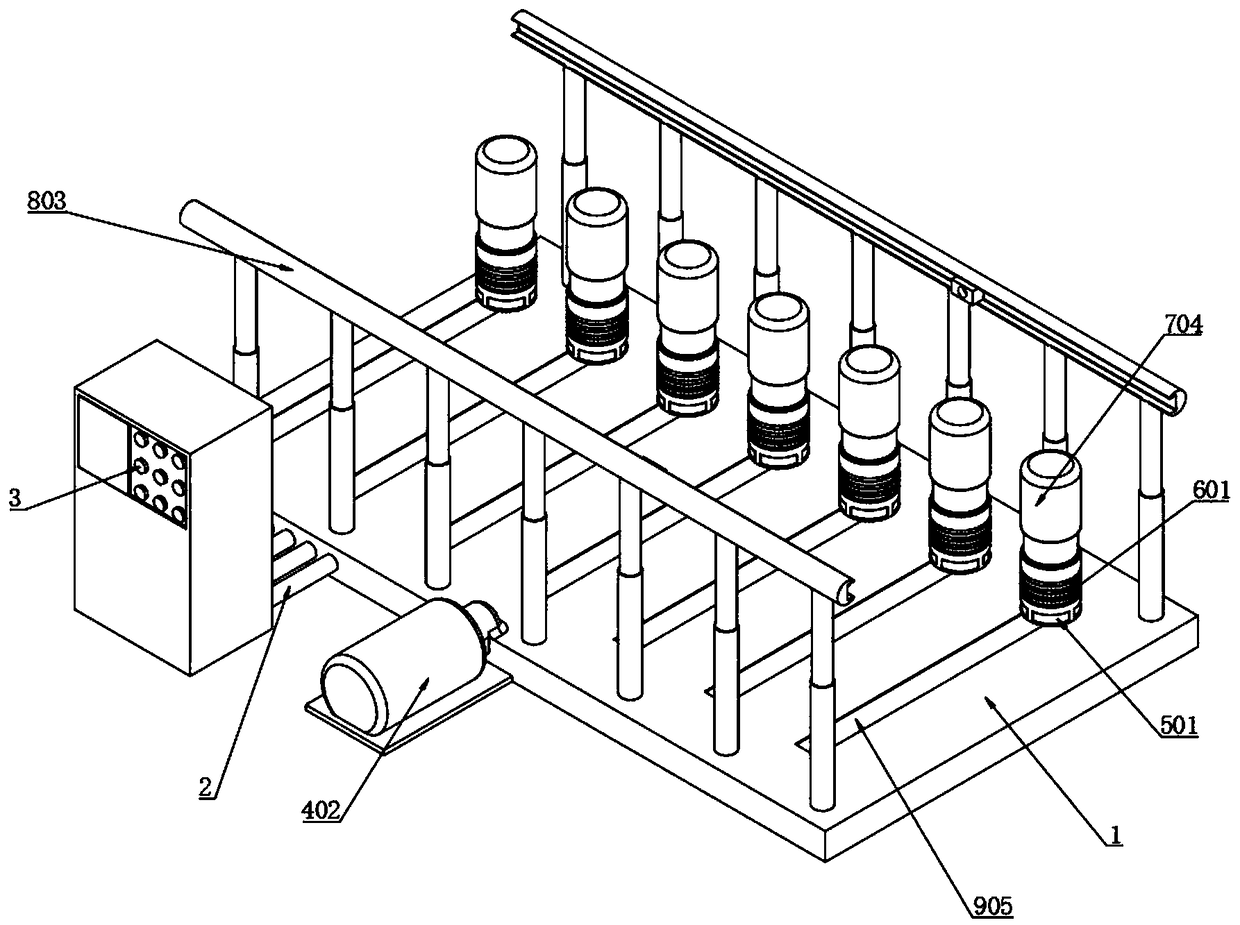

Self-moving type obstacle rod for flexibility training of soccer players

ActiveCN109432739AScientific and reasonable structureEasy to useSport apparatusElectric machineryDrive motor

The invention discloses a self-moving type obstacle rod for the flexibility training of soccer players. A training base is included, conveying lines are uniformly installed at one end of the trainingbase, one ends of the conveying lines are connected with a control box, a motor installing plate is installed on the part, corresponding to the training base, of one sides of the conveying lines, thetop of the motor installing plate is fixedly connected with a driving motor, and a conveying seat is installed at one end of the driving motor. The self-moving type obstacle rod has the advantages that the structure is scientific and reasonable, the use is safe and convenient, an alarming lamp which is installed on an alarming lamp installing seat is operated to illuminate light if a soccer playertouches a touch switch on the alarming seat, light is emitted through a sanded transparent plate so that the soccer player can be alarmed when the soccer player is trained, a rebounding seat which isbent by touching can be restored through a fixing soft column, a rubber rebounding soft column and a restoring spring which are arranged in a rebounding seat, and the damage of the rebounding seat caused by the long-term touching performed by the soccer player can be avoided.

Owner:SHENYANG SPORT UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com