Loose stock dyeing device with rotatable fiber cage

A dyeing device and fiber cage technology, which is applied in the direction of textile material equipment configuration, textile material contact export textile material treatment, etc., can solve the problems of affecting the recycling of dyestuffs, damage to fiber cages and dye vats, and increased maintenance costs, etc., to achieve Not easy to agglomerate, reduce equipment maintenance cost, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

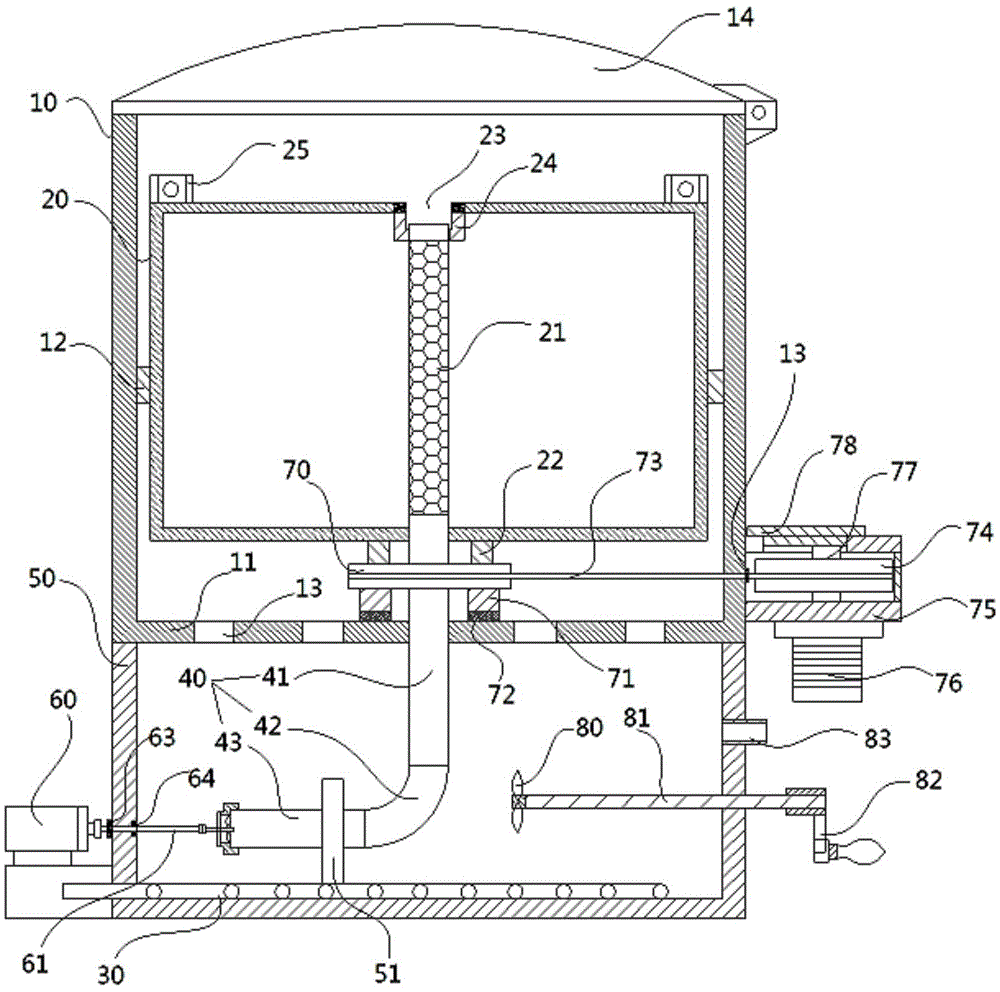

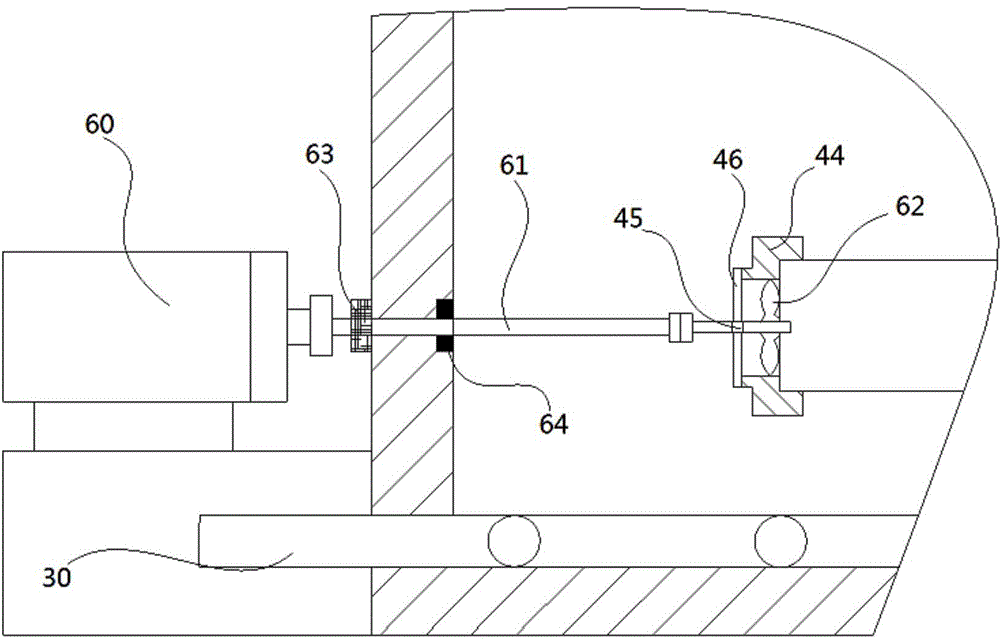

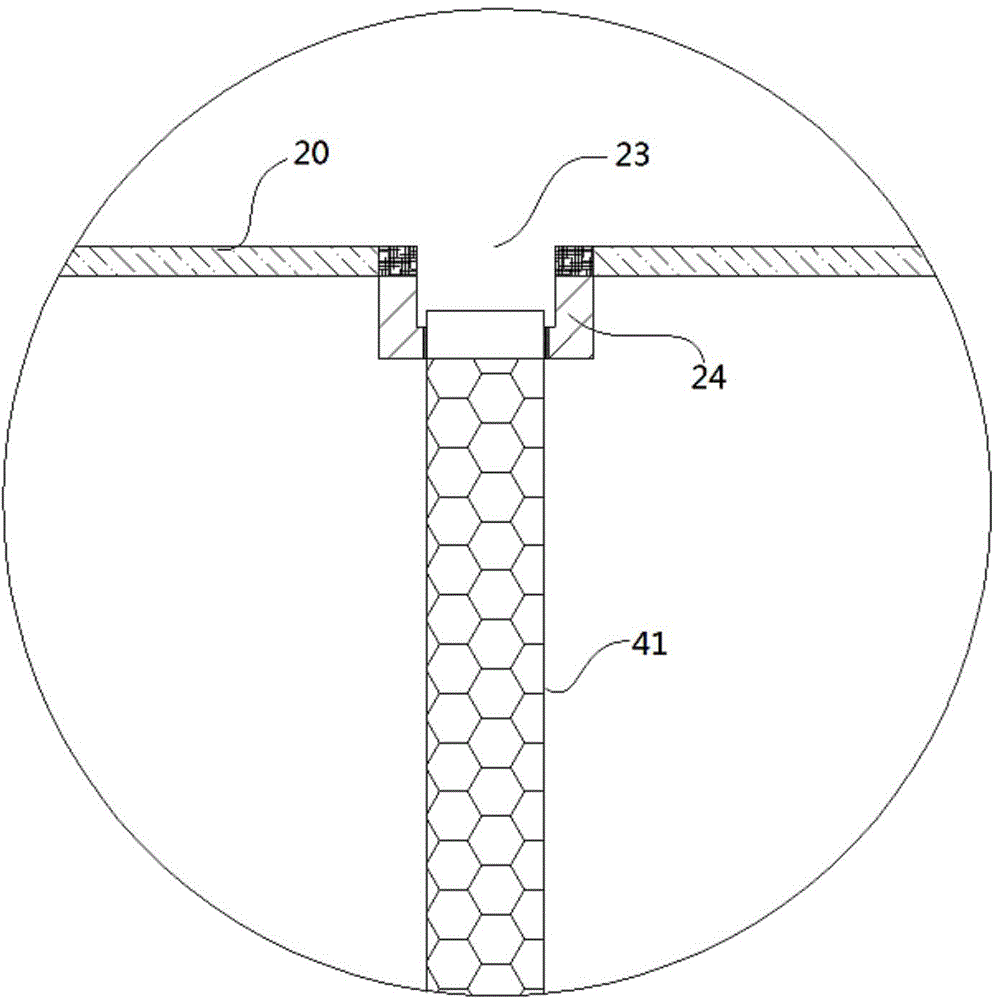

[0025] see Figure 1 to Figure 4 , the loose fiber dyeing device with rotatable fiber cage of the present invention comprises dyeing vat 10, fiber cage 20, heating coil 30 and center spray pipe 40, the bottom of described dyeing vat 40 is fixed with dye tank 50, and the dyestuff A heating coil 30 is fixed on the bottom of the tank 50, and one end of the heating coil 30 extends out of the dye tank 50 and communicates with the steam source; the outer wall of the dye tank 50 is fixed with a driving motor 60, and the output shaft of the driving motor 60 is passed through a shaft coupling. The device is connected with an intermediate rotating shaft 61, the intermediate rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com