Patents

Literature

38results about How to "Reduce direct collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

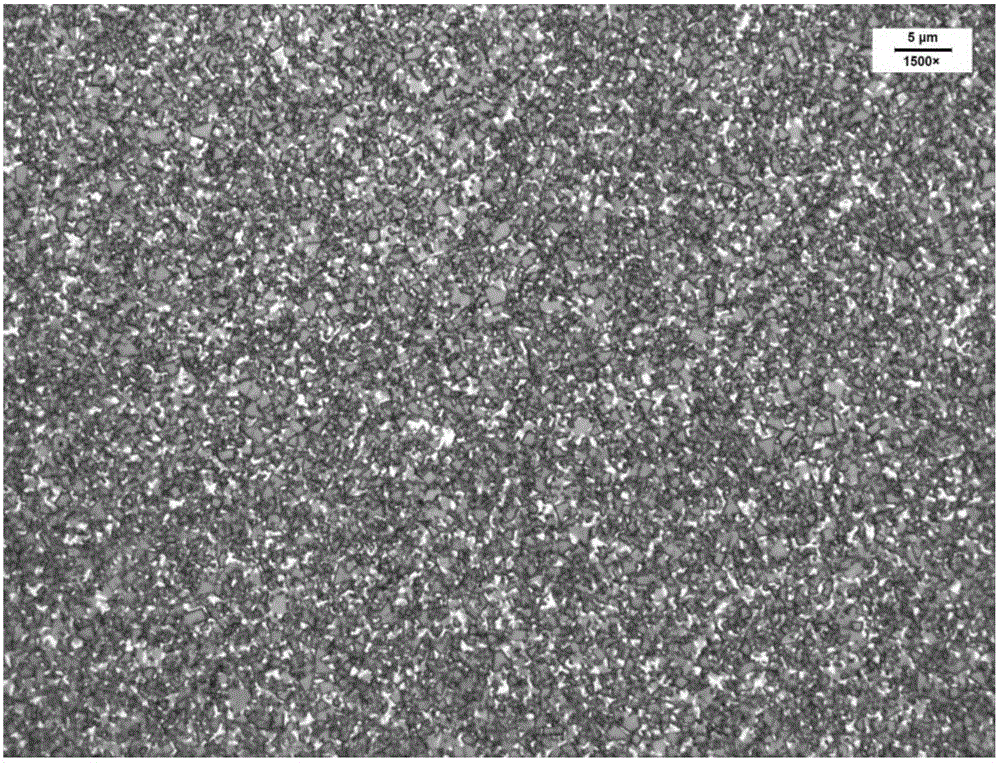

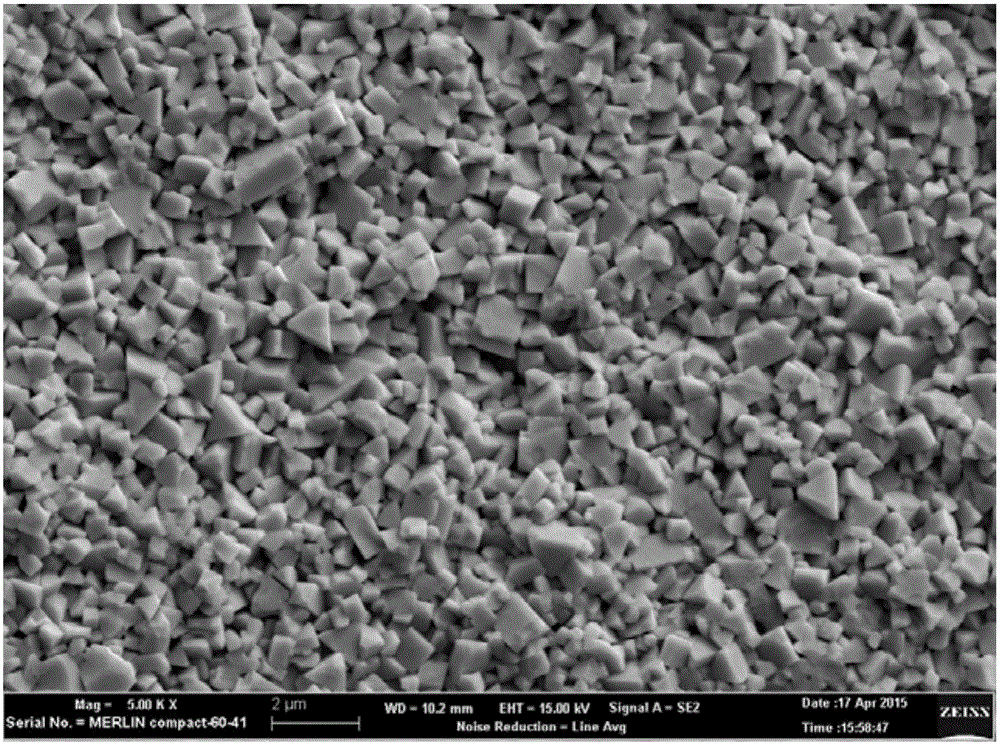

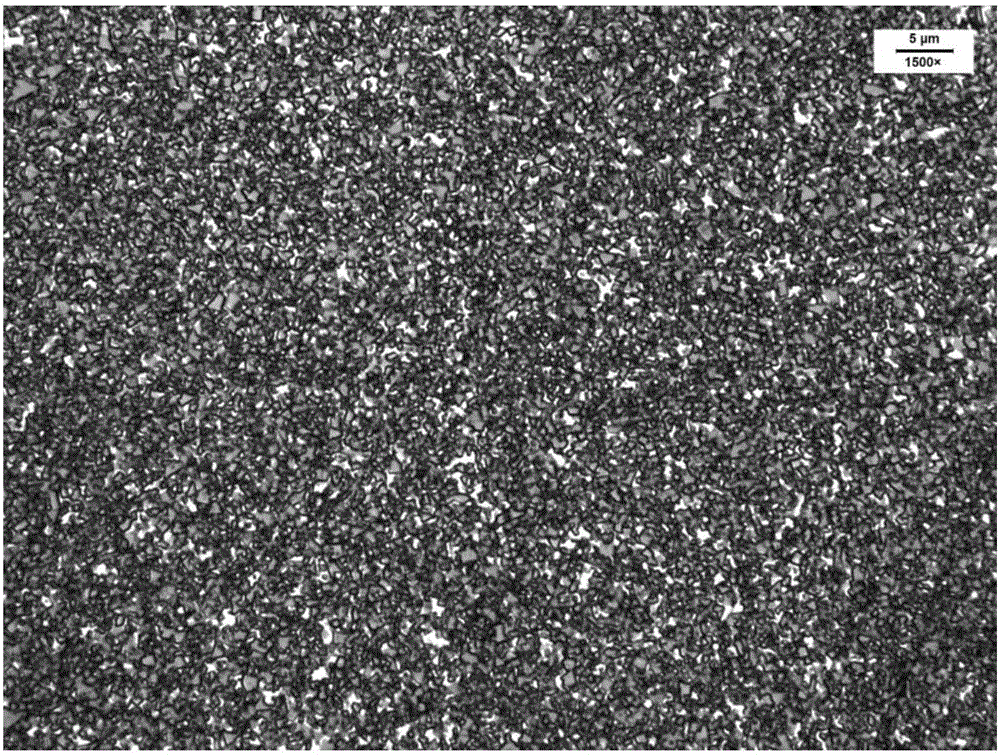

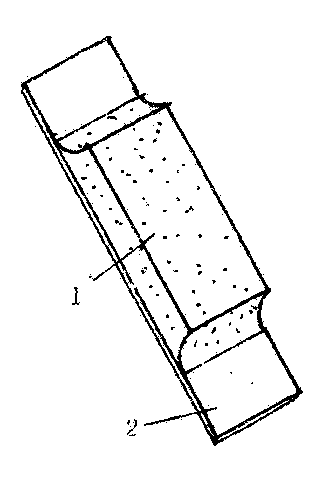

Preparing method for ultra-fine hard alloy

InactiveCN105734321ASimple processLow costTransportation and packagingMetal-working apparatusUltra fineAlloy

The invention relates to a preparing method for an ultra-fine hard alloy. The preparing method comprises the steps of inhibitor pre-dispersing, burdening, wet grinding, drying, pressing and sintering. According to inhibitor pre-dispersing, an inhibitor and all Co powder are subjected to ball milling and mixing treatment, ultra-fine WC is added to be subjected to burdening after inhibitor pre-dispersing, and the purpose of even dispersing of the inhibitor in a mixture is achieved. The preparing method is simple in technology and low in cost, and the prepared hard alloy is even in microstructure and high in comprehensive performance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

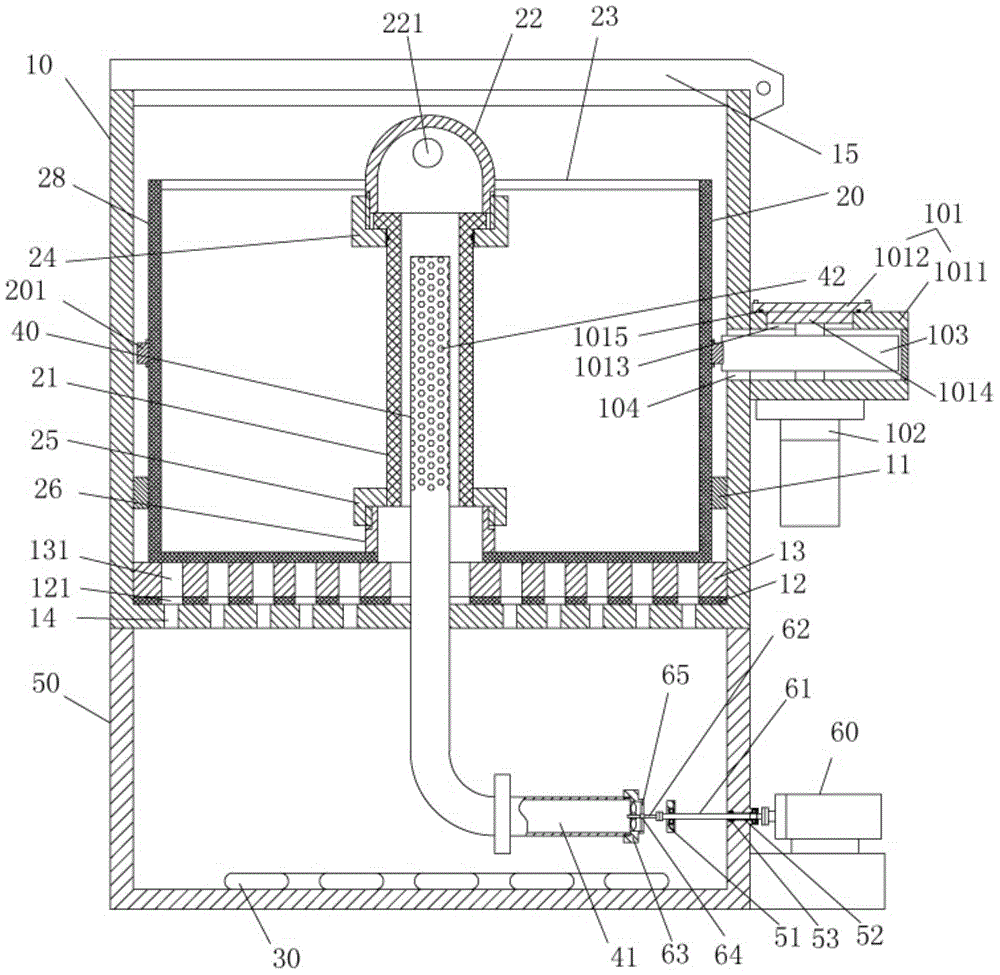

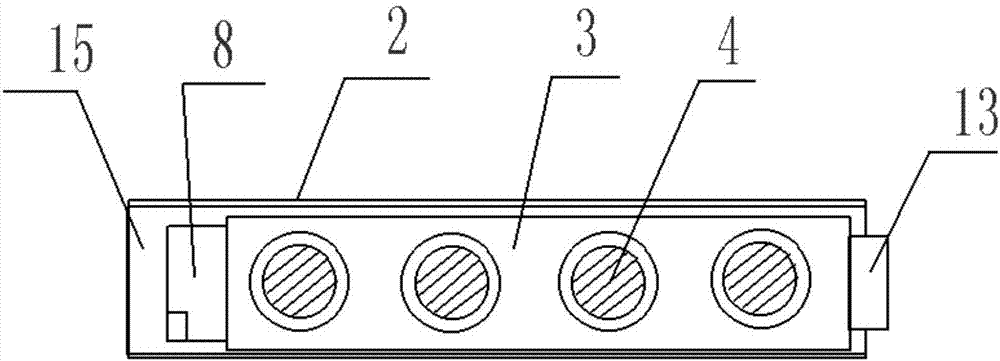

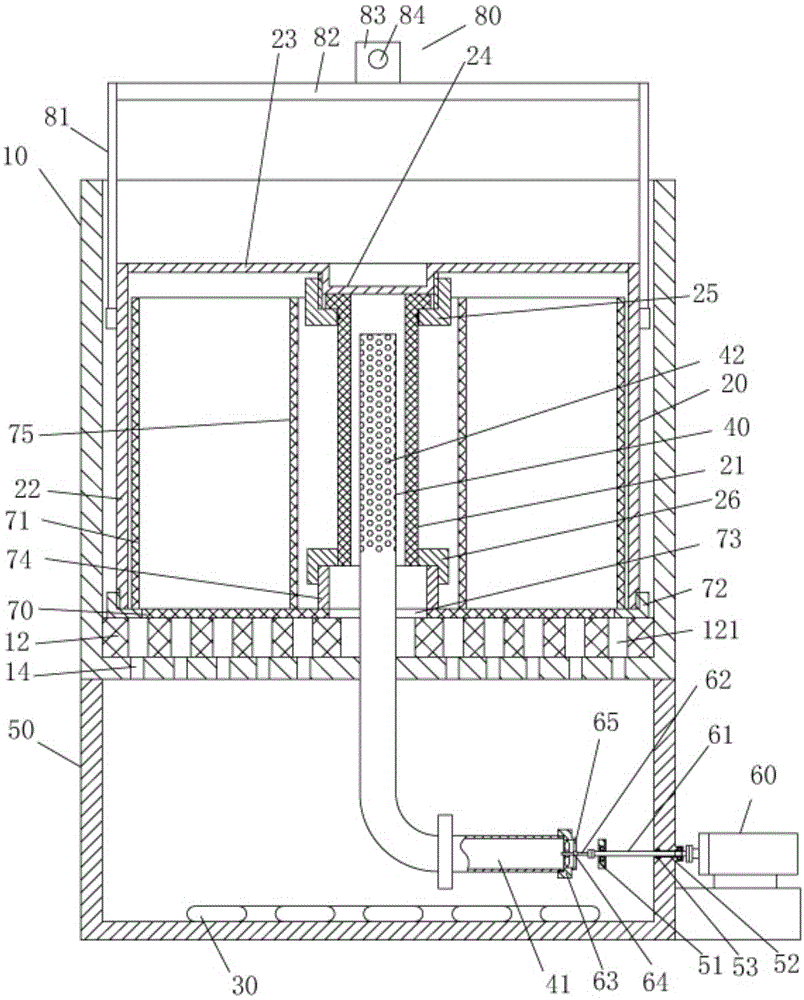

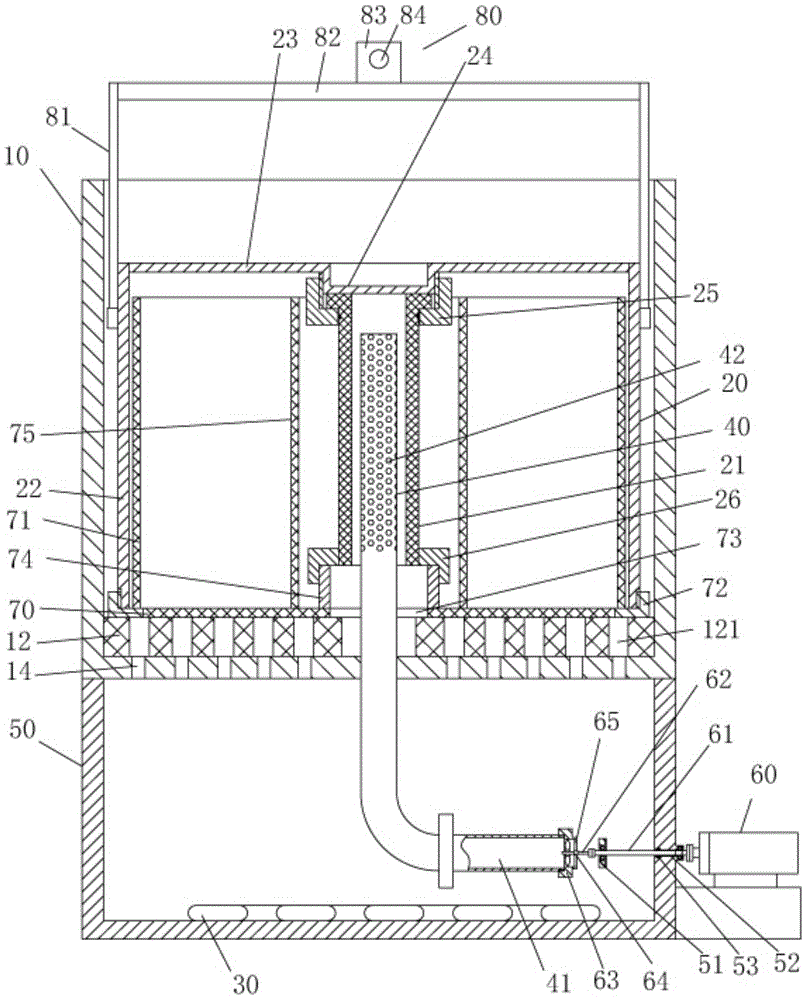

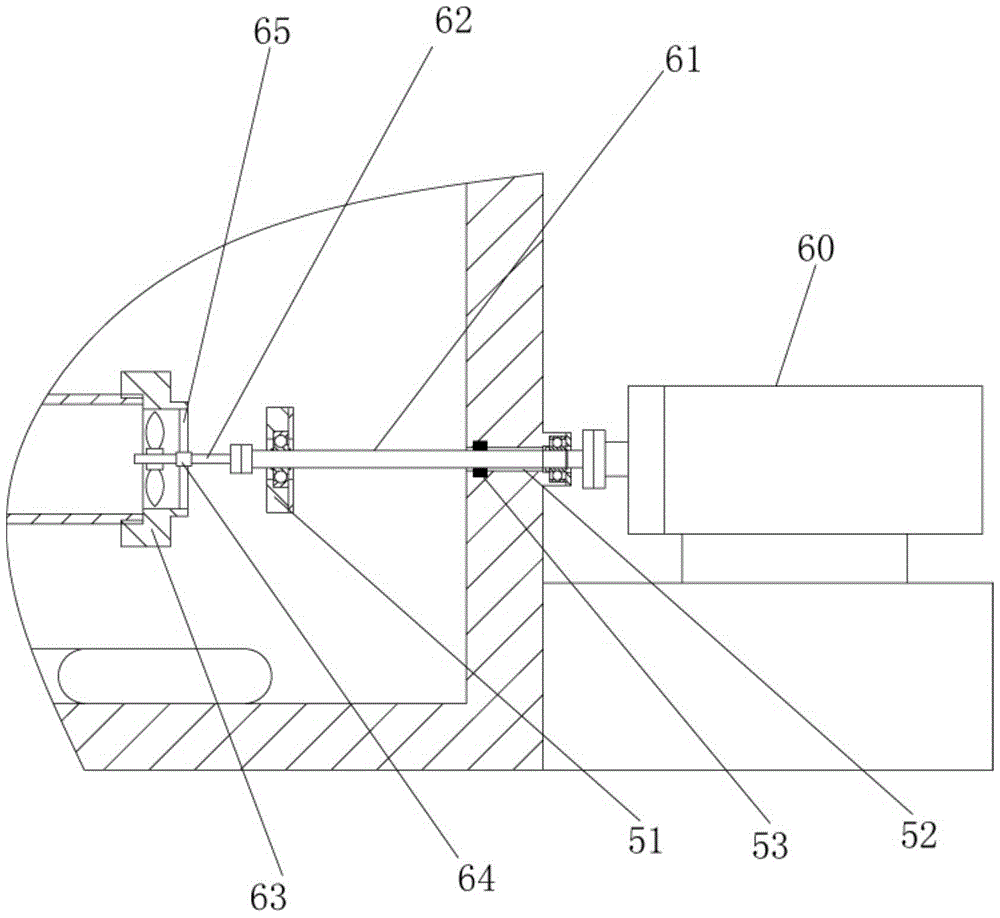

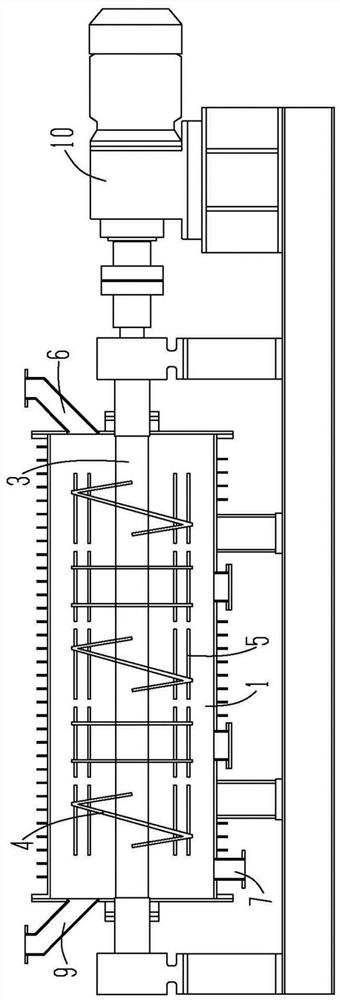

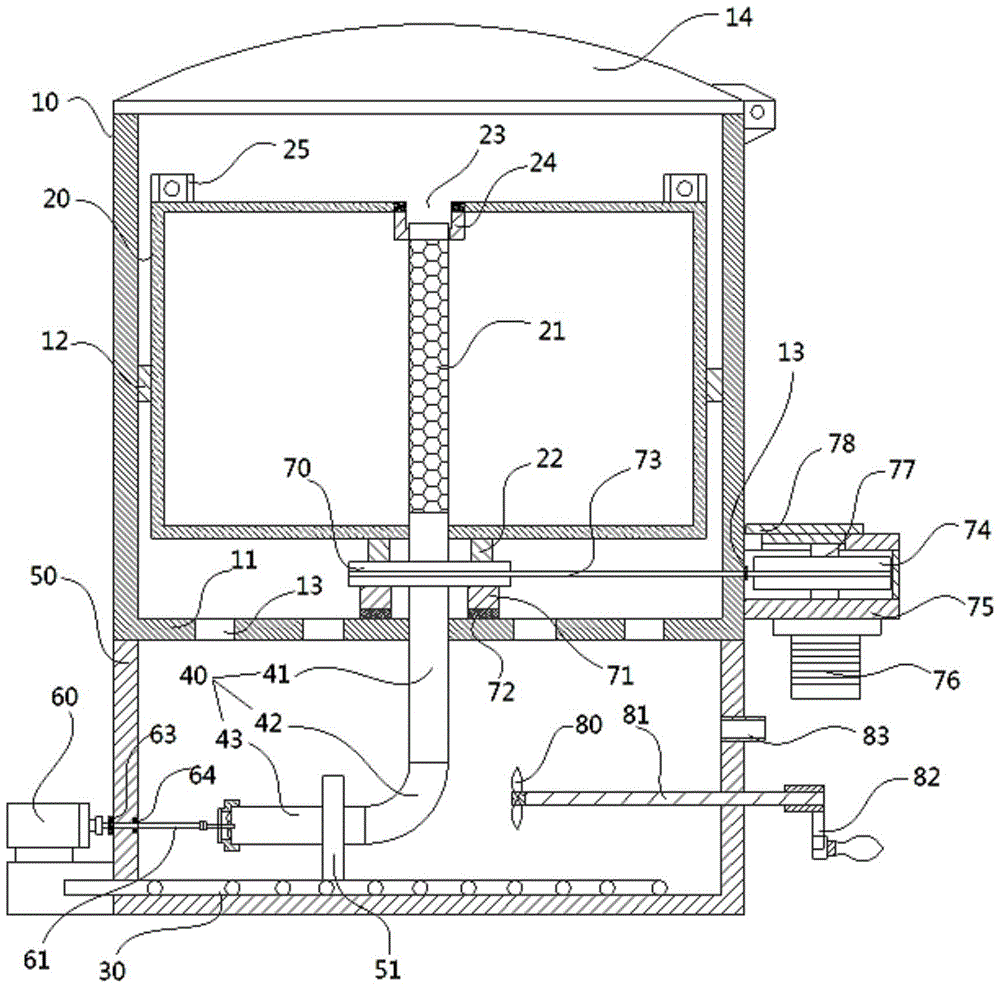

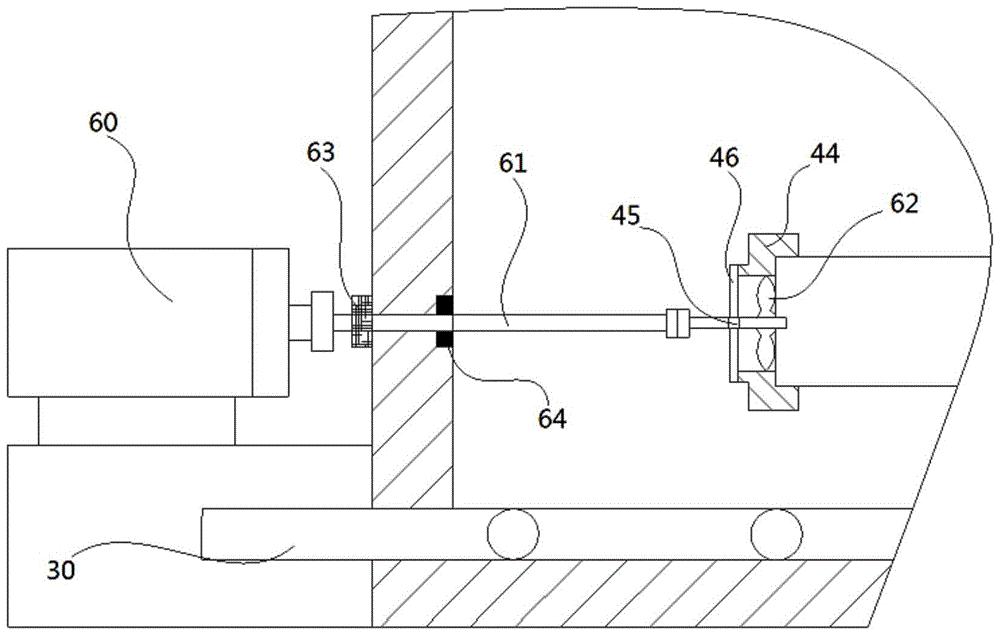

Loose fiber dyeing machine with rotatable fiber cage

InactiveCN104611858AReduce direct collisionExtended service lifeTextile treatment containersTextile treatment machine arrangementsDrive motorWear resistant

The invention discloses a loose fiber dyeing machine with a rotatable fiber cage. The loose fiber dyeing machine comprises a dyeing vat, the fiber cage, a heating coil and a central spray pipe, wherein a dye tank is fixed at the bottom of the dyeing vat; the heating coil is fixed inside the dye tank; a driving motor is fixed on the outer wall of the dye tank; the output shaft of the driving motor is connected with a central rotating shaft through a coupling; a cushion pad is fixed on a bottom plate of the dyeing vat; a wear-resistant lubricating block is fixed on the cushion pad; the bottom of the fiber cage is pressed against the wear-resistant lubricating block; a rotating gear ring is fixed on the outer wall of the fiber cage; a gear shell is arranged on the outer wall of the dyeing vat; a rotating motor is fixed at the bottom of the gear shell; a driving gear is fixed on the output shaft of the rotating motor; the driving gear is meshed with a rotating gear ring. The dyeing vat of the loose fiber dyeing machine has a cushioning mechanism, so that when the fiber cage is hung therein, direct collision is reduced and the service life is prolonged; the fiber cage is rotatable, so that the loose fiber dyeing machine is more uniform in dyeing.

Owner:响水县嘉亿纺织有限公司

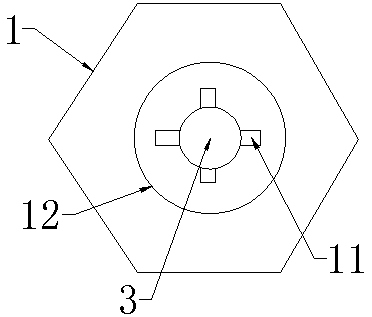

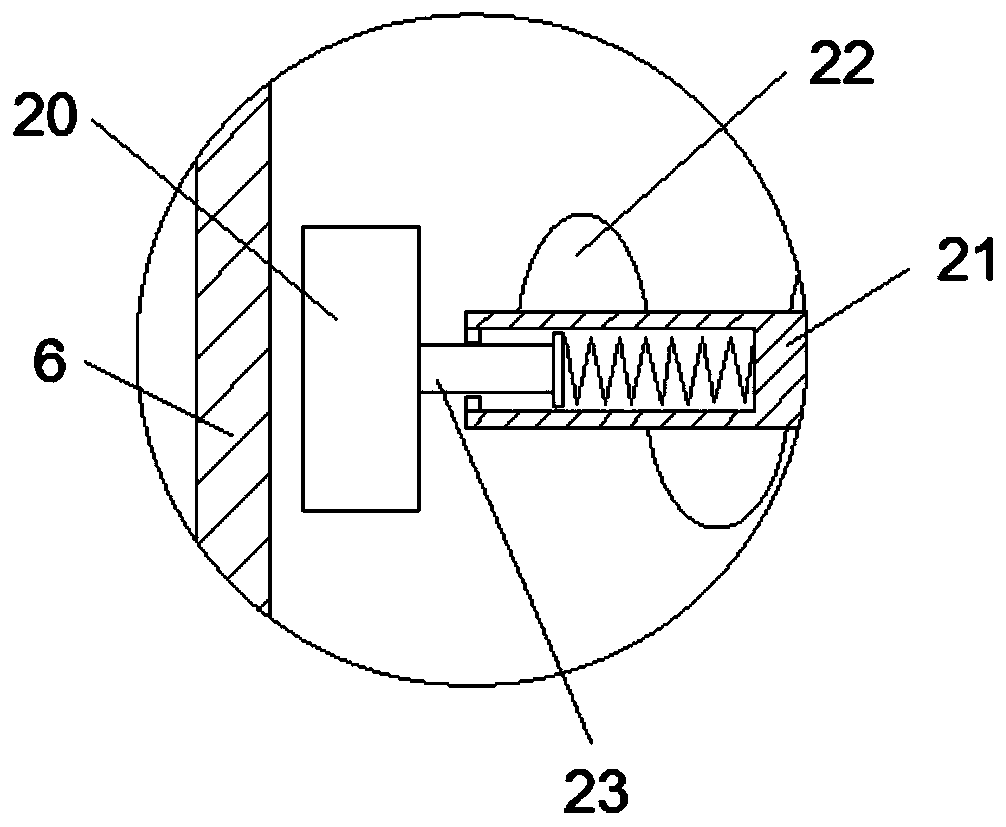

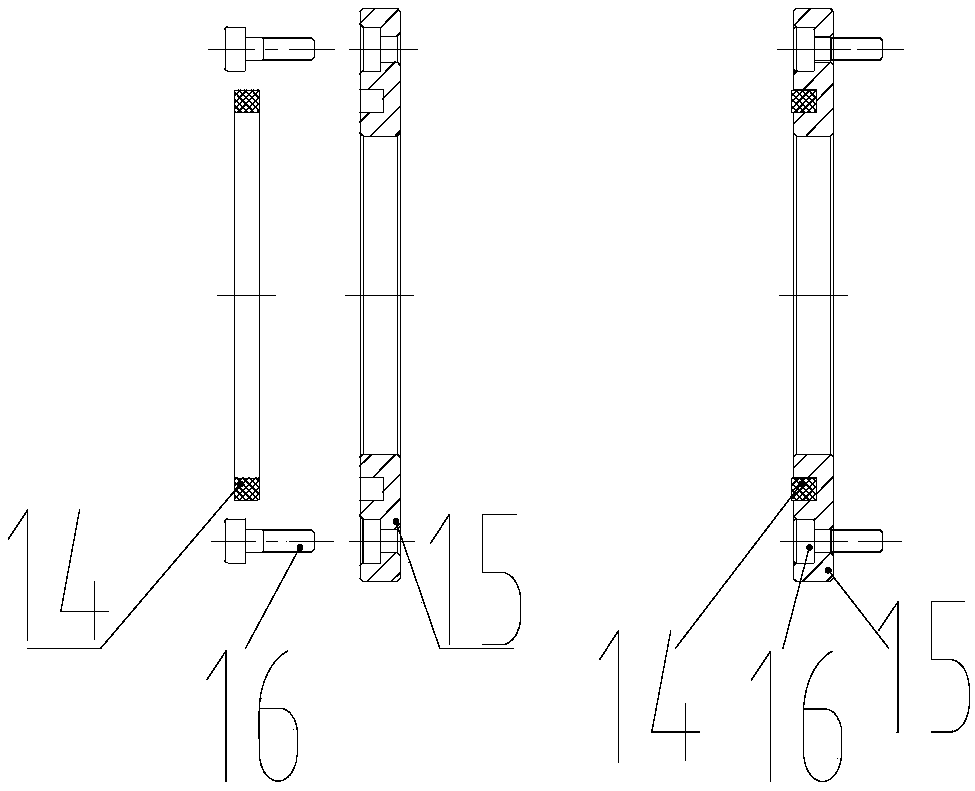

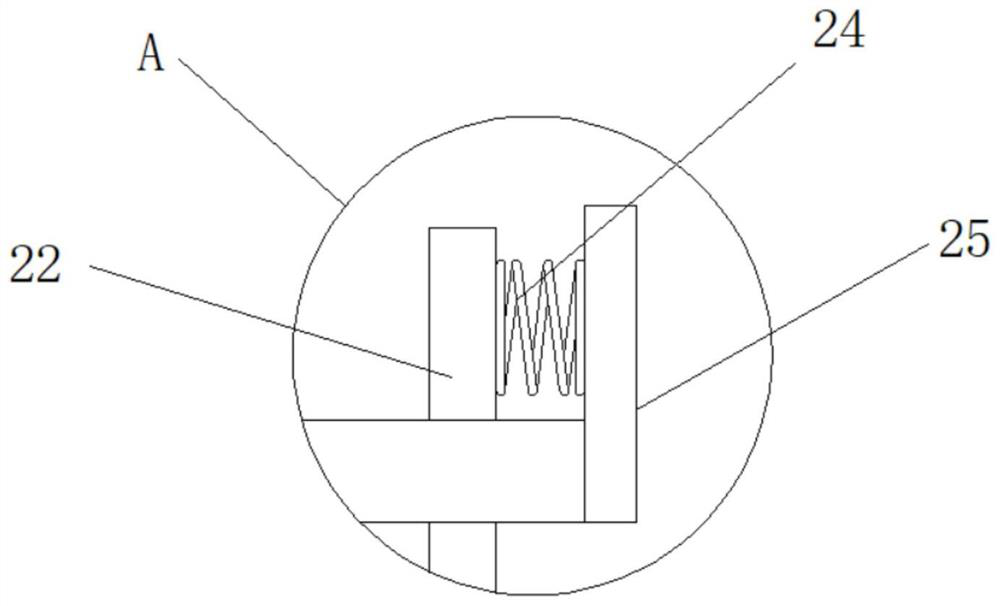

Self-pressure relief bolt

The invention discloses a self-pressure relief bolt, and belongs to the technical field of fasteners. The self-pressure relief bolt comprises a bolt head and a screw rod. A screwdriver groove is formed in the upper central position of the bolt head. Threads are formed on the outer ring surface of the screw rod. The screw rod is arranged at the lower central position of the bolt head. A pressure relief channel is arranged at the central position of the bolt head and the screw rod in the vertical axial direction. A plurality of corresponding pressure relief openings are formed in the screw rod from top to bottom. The pressure relief channel is provided with a guide pipe, and a fixed plate is welded to the lower end of the guide pipe. The fixed plate is welded and fixed to the lower portion of the screw rod, a spring is arranged in the guide pipe, one end of the spring is connected with the fixed plate, a sliding block is arranged at the other end of the spring, the sliding block is arranged on the upper portion of the guide pipe, and the sliding block is positioned in the pressure relief channel and is in sliding connection with the inner portion of the pressure relief channel. The self-pressure relief bolt has an automatic pressure relief function and can effectively reduce the pressure in a closed container.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

Loose stock dyeing device with rotatable fiber cage

InactiveCN104790145AStir wellPromote circulationTextile treatment machine arrangementsTextile treatment with treating outlet contectImpellerFiber

The invention discloses a loose stock dyeing device with a rotatable fiber cage. The loose stock dyeing device comprises a dyeing vat, the fiber cage, a heating coil pipe and a central spraying pipe, a dye tank is fixed to the bottom of the dyeing vat, a rotary wheel is arranged between the fiber cage and a bottom plate of the dyeing vat, and the rotary wheel is connected with a driving wheel through a driving belt. A mounting hole is formed in the upper end face of the rotary wheel, a mounting shaft corresponding to the mounting hole is arranged at the bottom end of the fiber cage, a locating hole is formed in the top of the fiber cage, locating blocks are arranged on the two sides of the locating hole, the upper side of the central spraying pipe is clamped by the locating blocks, and dye through holes communicated with the dye tank are evenly formed in the bottom plate of the dyeing vat. A stirring impeller is arranged in the dye tank, the stirring impeller is arranged on a lead screw, the end of the part, stretching out of the dye tank, of the lead screw is in pivot joint with a stirring handle, and a dye adding opening is formed in the position, on one side of the lead screw, of the side wall of the dye tank. When the fiber cage is hoisted down into the dyeing vat, the fiber cage does not rigidly collide with the dyeing vat, dye is not likely to be caked when added, the fiber cage rotates, and therefore dyeing is more even.

Owner:湖州市菱湖东方丝织厂

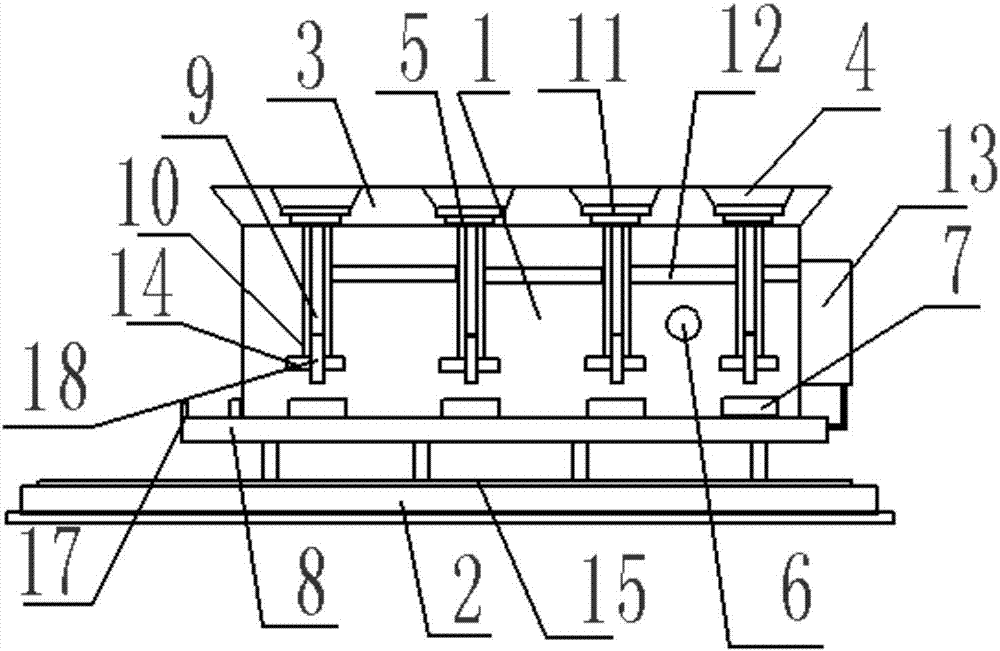

Tablet pressing forming machine

InactiveCN107877915ASimple structureStable structureShaping pressBiochemical engineeringSolenoid valve

The invention discloses a tablet compression molding machine, which comprises a tablet mold box, a transmission mechanism and a feeding box body, and is characterized in that: the feeding box body is installed above the tablet mold box, and more than one feeding port is opened on it ; The feeding port is provided with a control solenoid valve; the inner wall of the medicine mold box is fixedly connected with a vacuum pump; the transmission mechanism is fixedly installed under the tablet mold box and supported by a support frame; the bottom of the tablet mold box A pressing mold is provided; a baffle plate is movably connected to the bottom of the pressing mold; an injection pipeline corresponding to the feeding port is provided above the tablet mold box; The fixed connection has a lifting mechanism. The invention has simple structure, convenient installation, stable structure, long service life, low cost, vacuum and environmental protection in the pressing process, and reduces bacterial interference. PLC control is more flexible, high work efficiency, less manual participation, and precise control.

Owner:FOSHAN XUNYUAN MEDICAL EQUIP CO LTD

White-smoke-free promotion flux for steel fastener hot dip galvanizing and application process of white-smoke-free promotion flux

PendingCN108193154AReduce pollutionImprove working environmentHot-dipping/immersion processesHexamethylenetetramineChloride

The invention relates to the technical field of steel fastener hot dip galvanizing, in particular to white-smoke-free promotion flux for steel fastener hot dip galvanizing and an application process of the white-smoke-free promotion flux. The white-smoke-free promotion flux for steel fastener hot dip galvanizing comprises the following components: 100-200g / L of zinc chloride, 10-40g / L of magnesiumchloride, 8.0-13g / L of nickel chloride, 6.0-12g / L of hydrochloric acid, 2.0-3.5g / L of hexamethylenetetramine, 2.0-10g / L of a flux additive, and the balance of water. The application process of the white-smoke-free promotion flux comprises steps of degreasing, water cleaning, rust-removing, secondary water cleaning, promotion flux adhering, drying, galvanizing and the like. The white-smoke-free promotion flux for steel fastener hot dip galvanizing disclosed by the invention does not contain ammonium chloride which generates white smoke while encountering molten metal zinc, and can greatly reduce generation of soot during hot-dip galvanizing of the steel fastener; and a hot-dip galvanizing process which uses the promotion flux is more optimized, and has the advantages of being low in production cost, stable in plating assistance quality, capable of producing steel fasteners for hot dip galvanizing on a large scale, and the like.

Owner:WENZHOU XINDE ELECTRIC FITTINGS +2

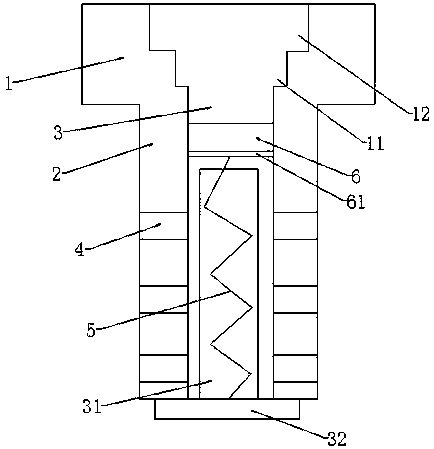

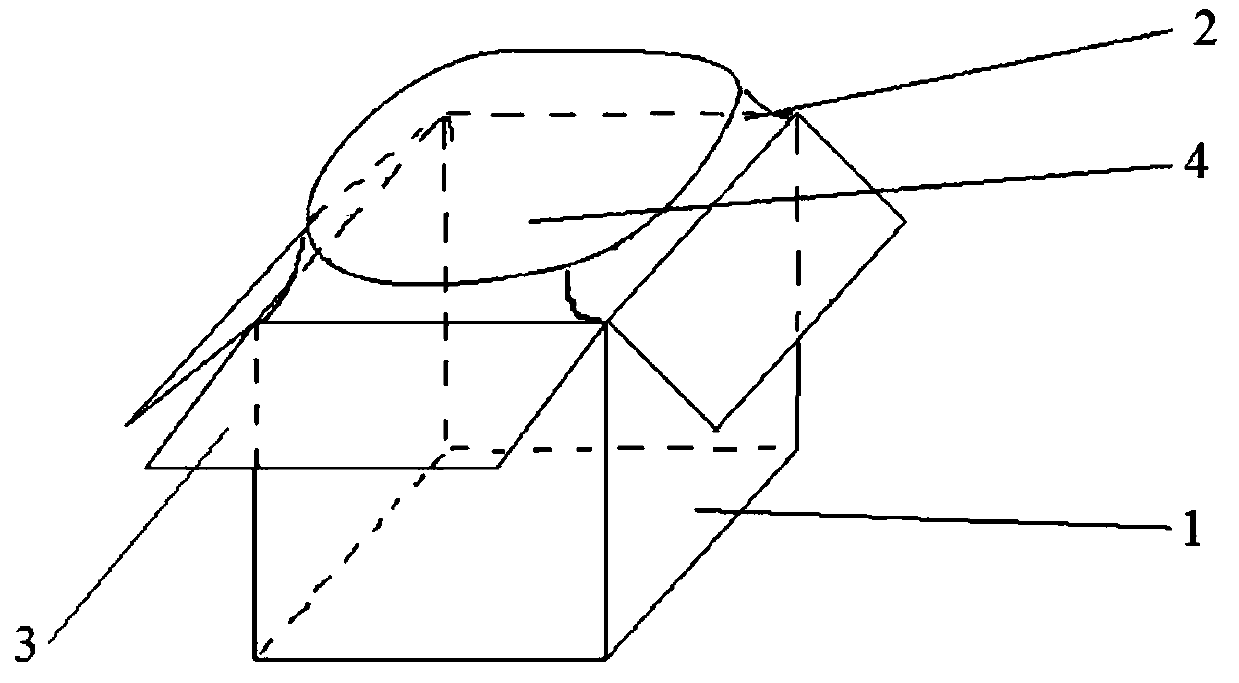

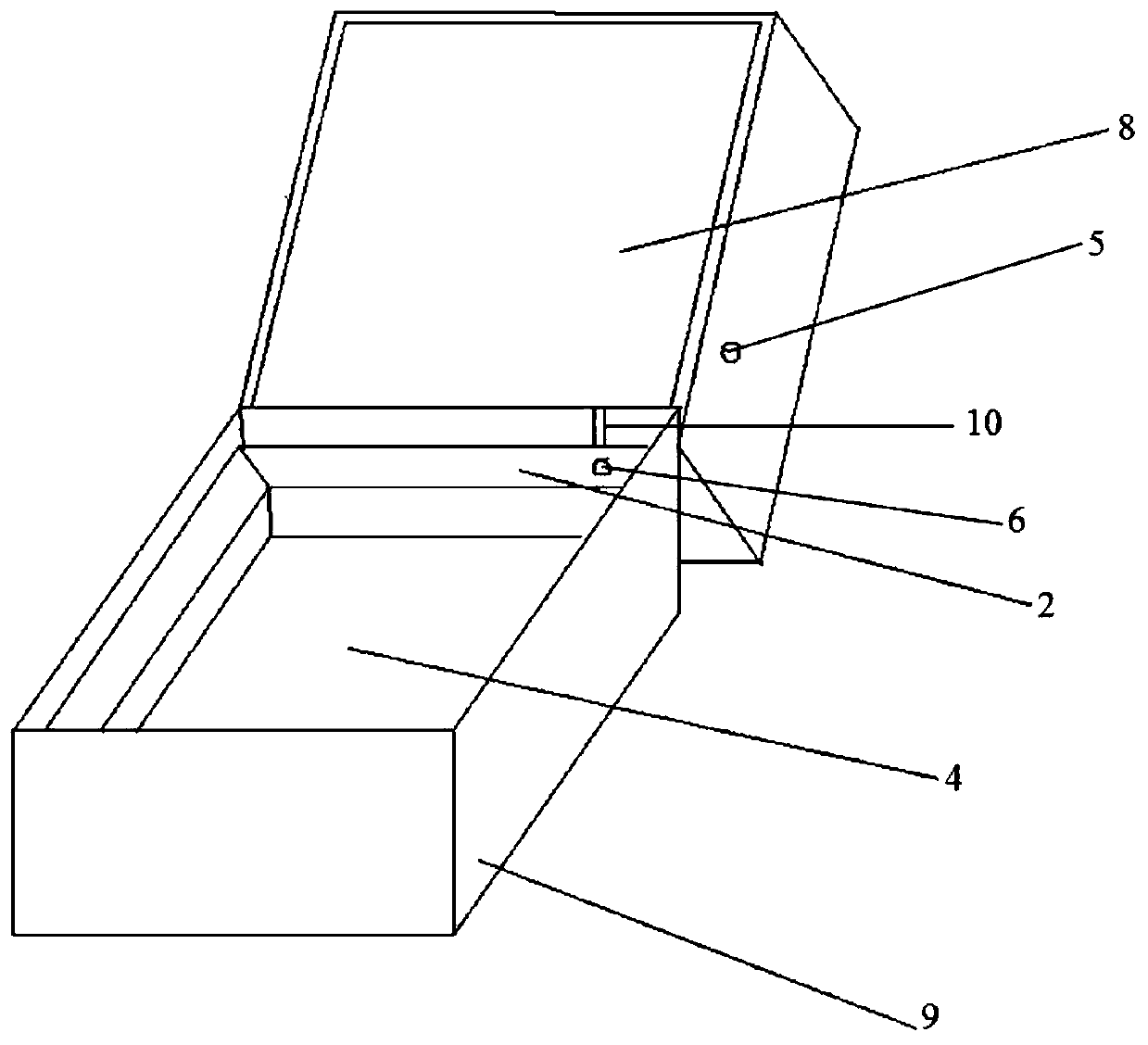

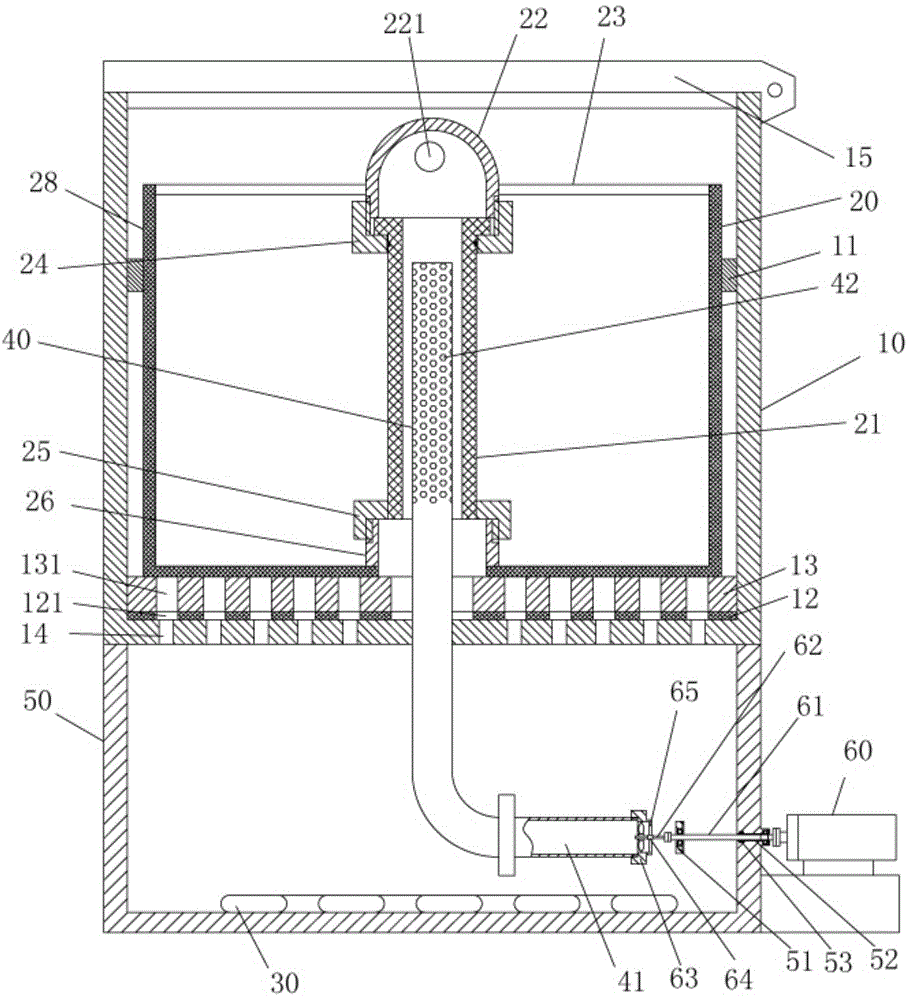

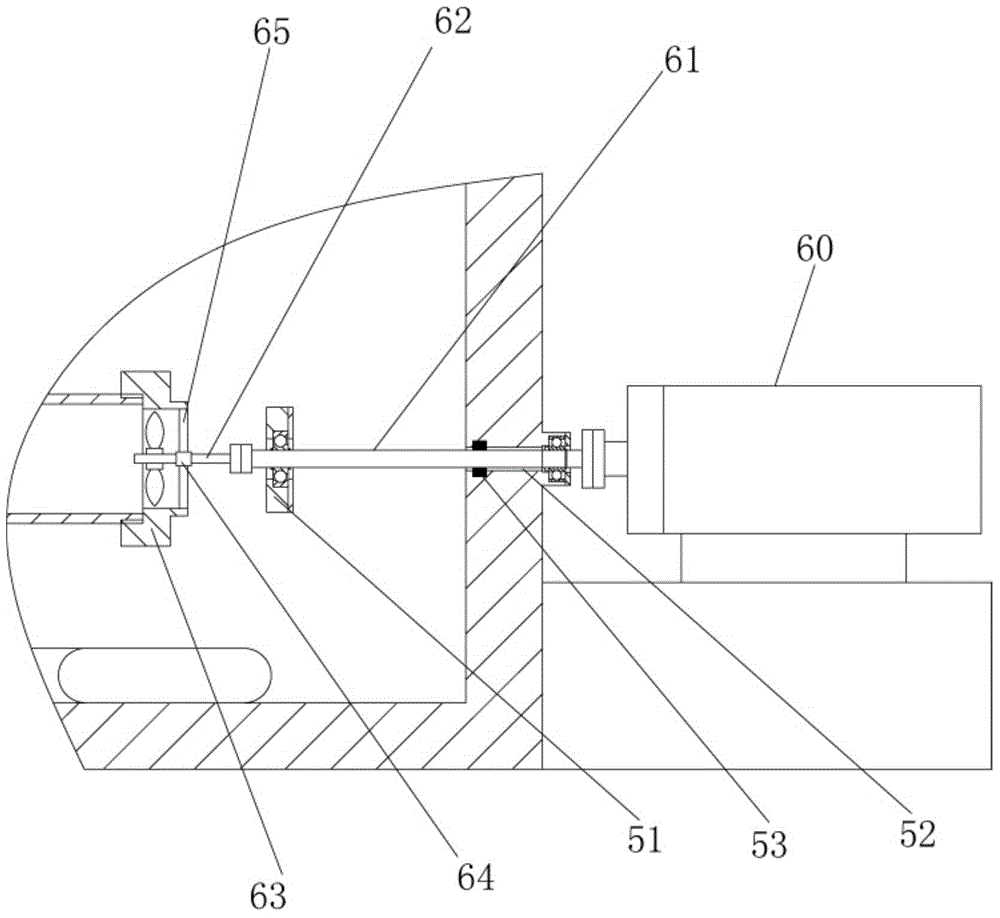

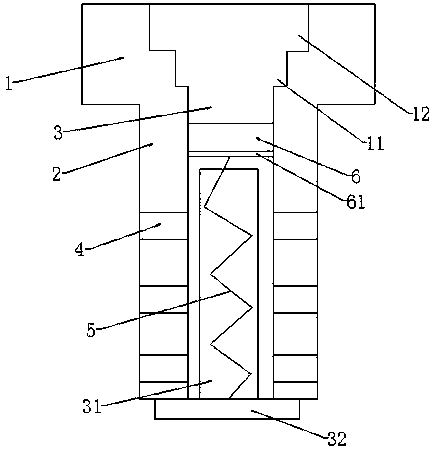

Novel hanging frame type loose fiber dyeing machine

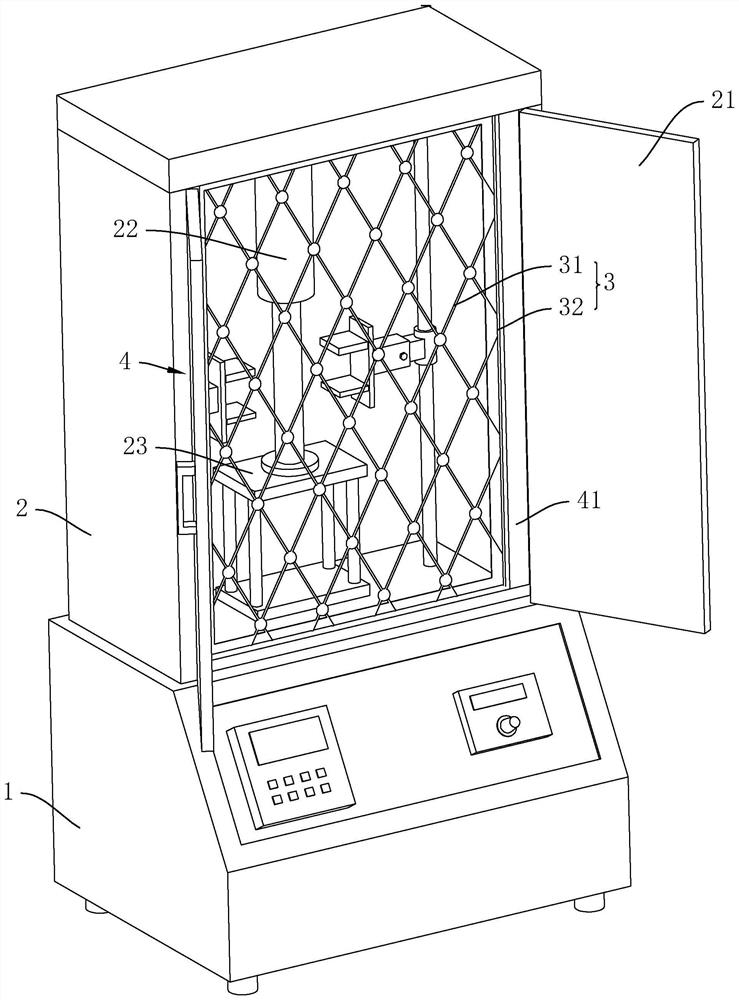

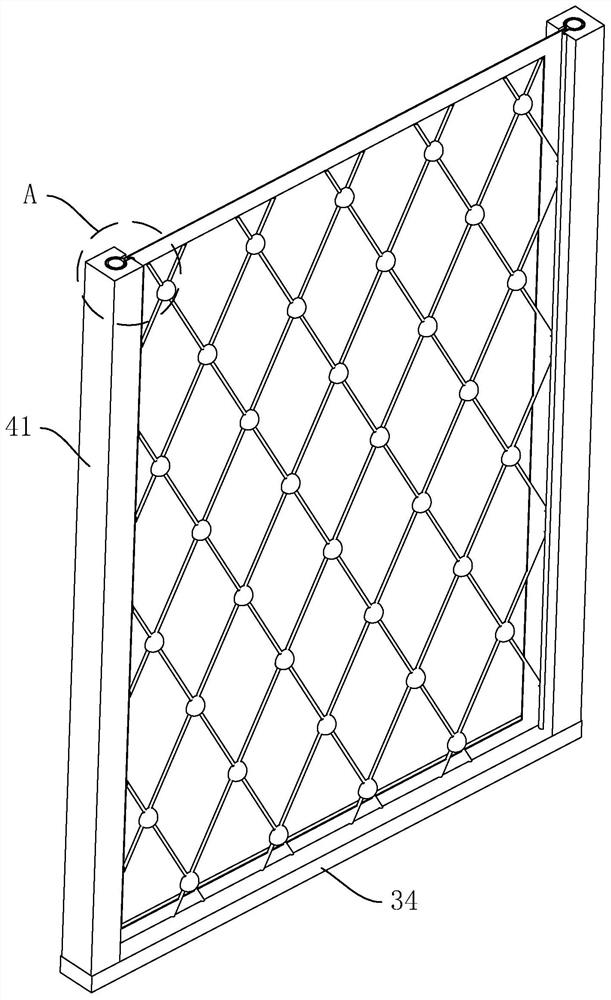

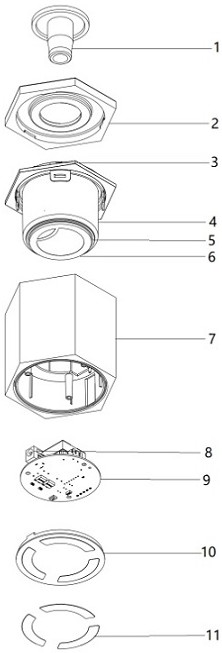

ActiveCN104611860AReduce direct collisionExtended service lifeTextile treatment containersTextile treatment with treating outlet contectFiberArchitectural engineering

The invention discloses a novel hanging frame type loose fiber dyeing machine which comprises a dye vat, a fiber cage, a heating coil and a central spray pipe, wherein a dye tank is fixed at the bottom of the dye vat; the heating coil is fixed in the dye tank; a driving motor is fixed on the outer wall of the dye tank; the fiber cage is placed in the dye vat; the bottom of the fiber cage is in threaded connection with a fiber cage cover; a built-in sleeve is fixed on the top surface of the fiber cage cover; the built-in sleeve is inserted in the fiber cage; a lifting mechanism is fixed at the top of the fiber cage; the fiber cage cover is pressed on a cushion fixed on the bottom plate of the dye vat; the upper end of the central spray pipe penetrates through the cushion and the fiber cage cover and extends into a middle upright pipe body of the fiber cage; spray holes are formed in the side wall at the upper end of the central spray pipe. According to the novel hanging frame type loose fiber dyeing machine, a lifting appliance doesn't need to be dismounted after the fiber cage is placed on the dye vat, the novel hanging frame type loose fiber dyeing machine is simple and convenient as the dye vat doesn't need to be equipped with a vat lid, and the dye vat is provided with a cushion mechanism so as to reduce direct collisions caused when the fiber cage is lifted and prolong the service life.

Owner:广州市盟鸿机械工业有限公司

Anti-collision door sticker

InactiveCN103790459AReduce direct collisionAvoid loud noiseBuilding braking devicesEngineeringMechanical engineering

The invention provides an anti-collision door sticker. The door sticker is that a soft rubber block is arranged on an elongated sticking base block. When the door sticker is used, the soft rubber block is sticked and fixed at the collided position between a door or a frame or a wall body through the sticking base block, direct collision between the door or the frame or the wall body can be relieved and buffered during opening and closing, and damage and produced noise are avoided.

Owner:YICHENG NO 3 SENIOR HIGH SCHOOL

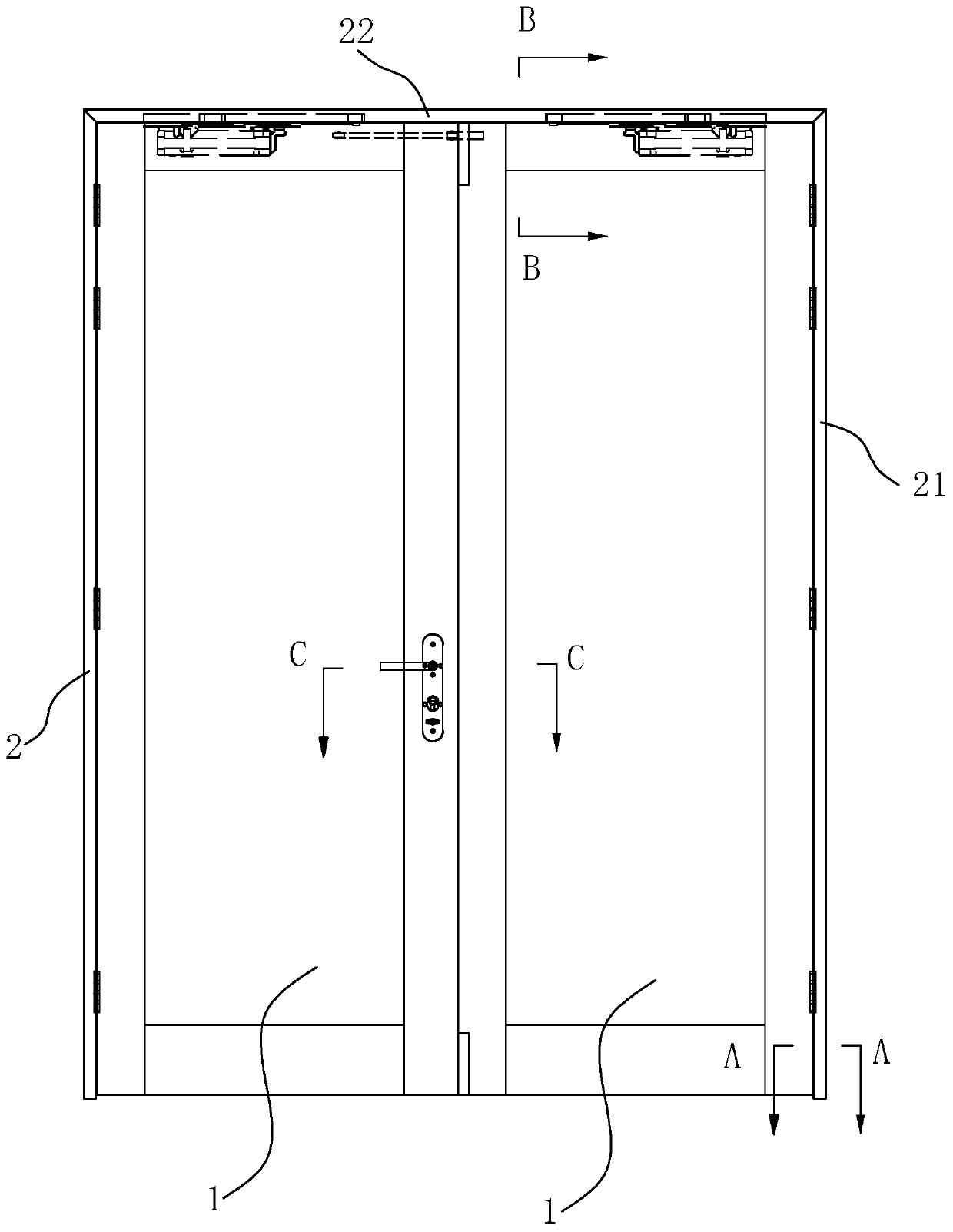

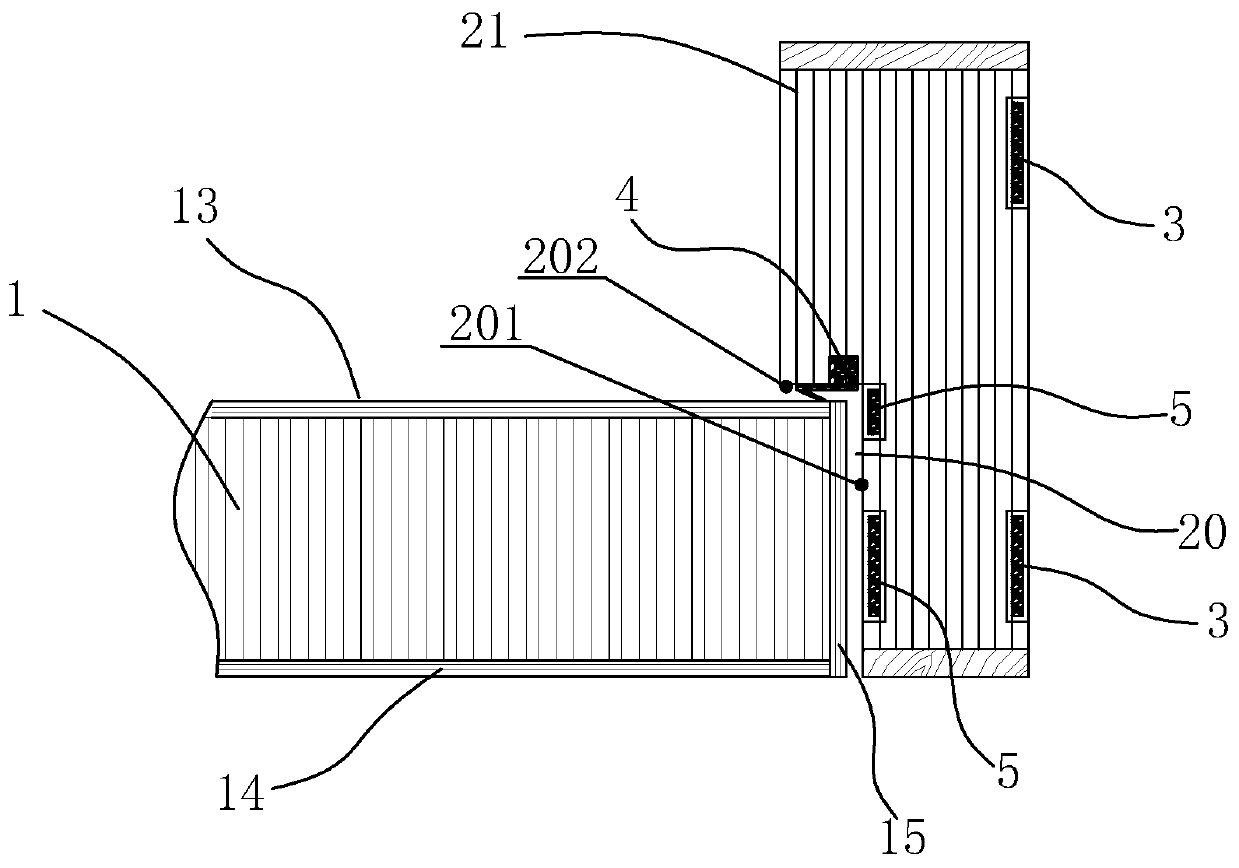

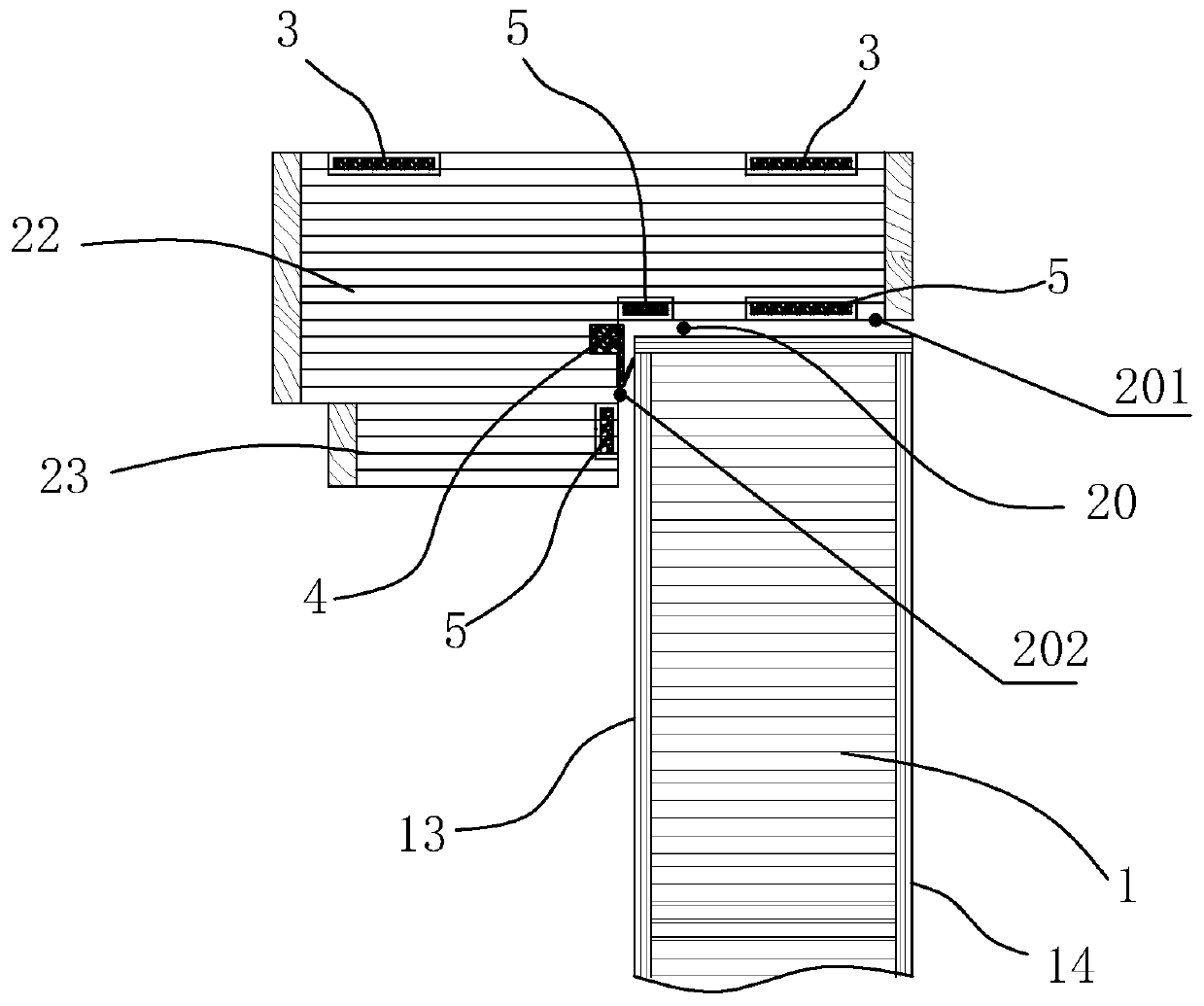

Fireproof door

PendingCN109989691AReduce impactExtended service lifeFireproof doorsSealing arrangementsEngineeringFire - disasters

The invention provides a fireproof door, comprising a door leaf and a door frame, one side of the door frame is connected with a wall, a groove corresponding to the periphery of the door leaf is formed in the other side of the door frame, and a first fireproof sealing strip is embedded in the face, connected with the wall, of the door frame; a second fireproof sealing strip and a third fireproof sealing strip are embedded in the groove; the first fireproof sealing strip is in a flat strip shape; the second fireproof sealing strip comprises a strip-shaped main body, one side of the main body horizontally extends to form a wide edge, one side, away from the main body, of the wide edge is obliquely bent to form an elastic folded edge, the main body of the second fireproof sealing strip on thedoor frame is embedded in the groove wall of the groove, the wide edge is attached to the surface of the door frame, and the elastic folded edge abuts against the door leaf. According to the fireproof door, through cooperation of the fireproof sealing strips of multiple structures, an installation gap can be blocked in time when a fire disaster occurs, fire penetration and poisonous smoke invasion of the installation gap are prevented, the anti-collision effect can be achieved, and the applicability of the fireproof door is improved.

Owner:中山市富门木制品有限公司

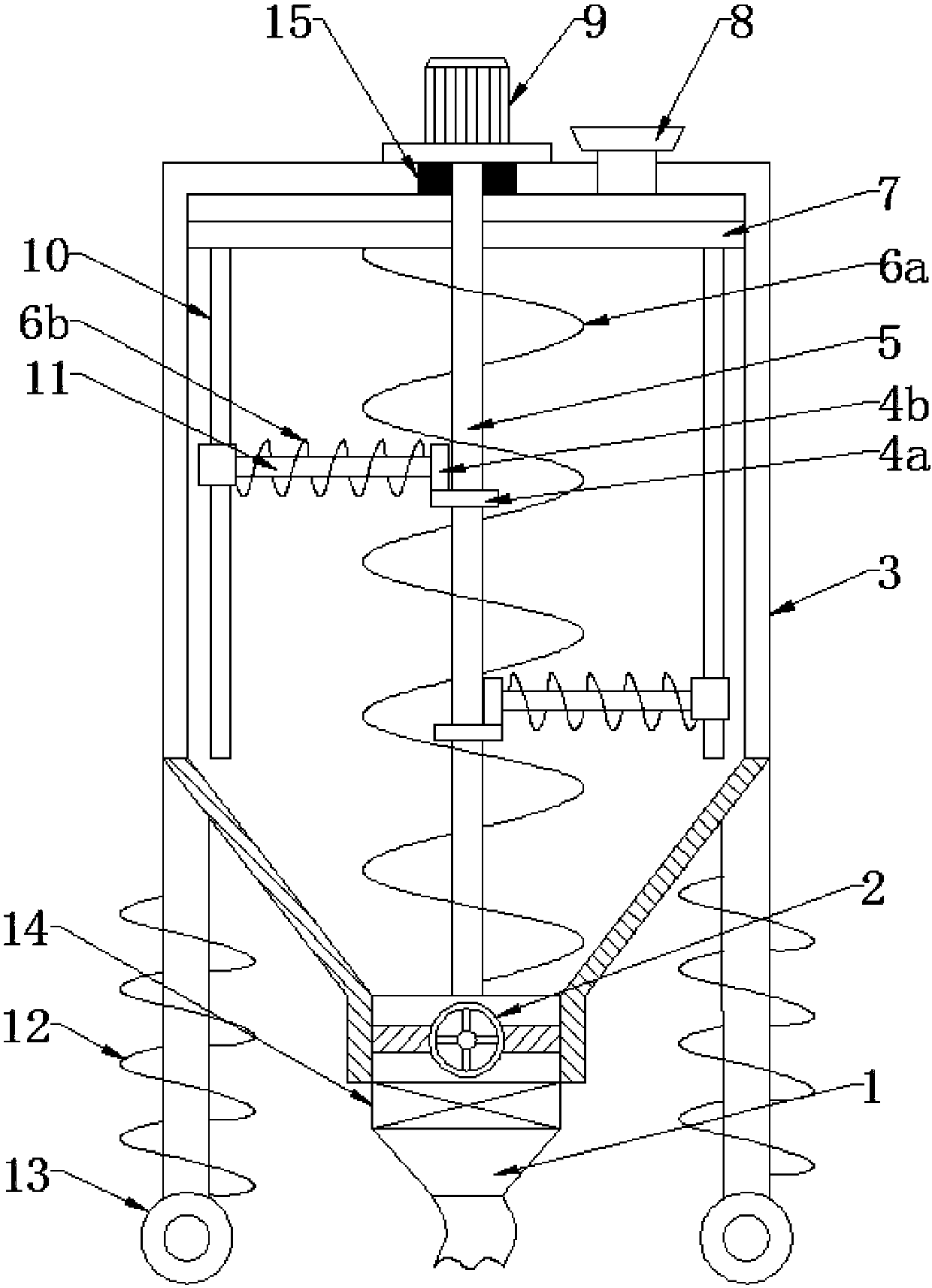

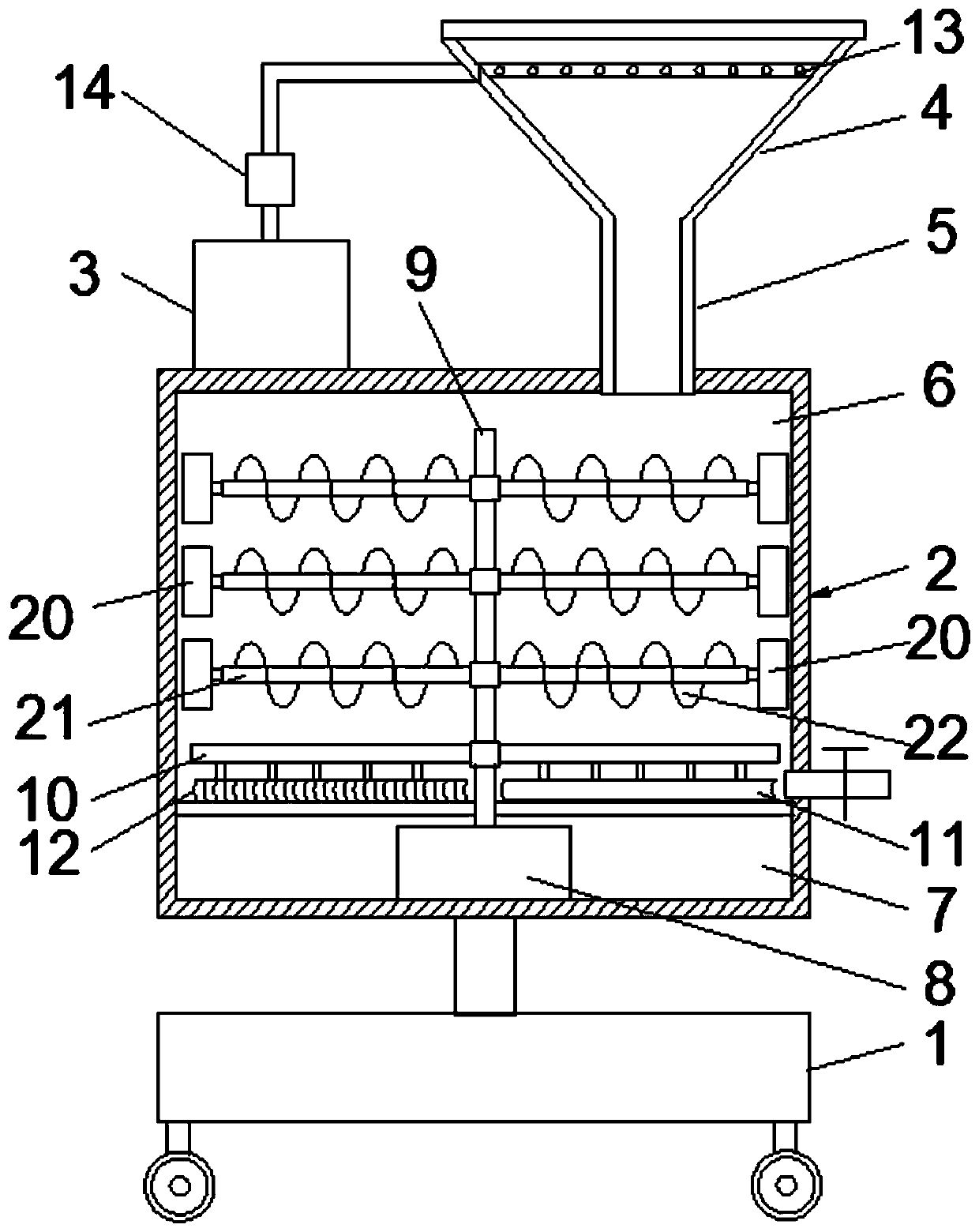

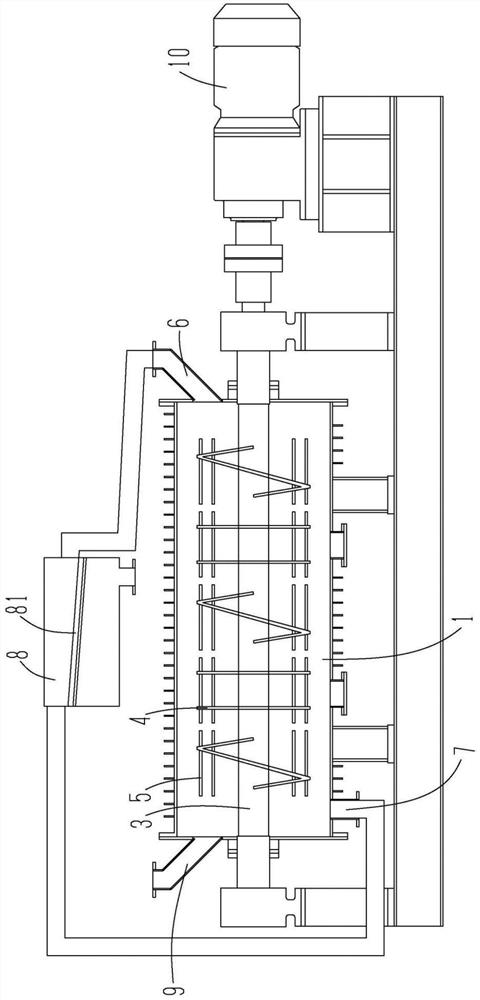

Efficient feed stirring device

InactiveCN107754664APlay the role of stirringImprove stirring efficiencyFeeding-stuffRotary stirring mixersSpiral bladeEngineering

The invention discloses an efficient feed stirring device, belongs to the technical field of feed stirring devices, and solves the problems that an existing feed mixing and stirring device is low in mixing efficiency, the stirring dead points exist in the stirring process as the stirring device is fixed in position on a rotary shaft when the device stirs a feed by rotation of a primary shaft and in the feed mixing process, the feed is inconvenient to store as the temperature is raised. A feed inlet is formed in the upper end of the stirring box, a discharge port is formed in the lower end of the stirring box, a rotary primary shaft is arranged on the stirring box, the rotary primary shaft is connected to a driving motor, a first spiral blade is arranged on the outer side of the rotary primary shaft in a sleeving manner, a rotary bracket is also arranged on the upper section of the rotary primary shaft in a sleeving manner too, a fixed rod is arranged at the lower end of the rotary bracket, a roll shaft is arranged on the fixed rod, the other end of the roll shaft is connected to the rotary primary shaft, and a second spiral blade is arranged on the outer side of the roll shaft in asleeving manner; and a seal ring is arranged at the upper end of the stirring box, the seal ring is matched with the rotary primary shaft, a cooling device is arranged at the discharge port, and thedischarge port is provided with a control valve.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Vomit receiving device for gigestive department nursing

InactiveCN110236957ARinse in timeReduce direct collisionGrain treatmentsSpittle receiving devicesAgricultural engineeringVomiting

The invention discloses a vomit receiving device for digestive department nursing. The vomit receiving device for digestive department nursing comprises a base, a collecting box, a water tank and a vomit receiving basin; universal wheels are arranged at the bottom of the base, the collecting box is arranged at the top of the base, the water tank and the vomit receiving basin are arranged on the collecting box, and the vomit receiving basin is connected to the collecting box through a feeding pipe; the collecting box is divided into a collecting bin and an isolating bin from top to bottom through a horizontally arranged partition plate, a first motor is arranged in the isolating bin, the output shaft of the first motor penetrates through the partition plate and is connected to a rotating shaft, a plurality of sets of agitating and pulverizing mechanisms are vertically arranged on the rotating shaft, two connecting plates are vertically and symmetrically arranged at the lower part of the rotating shaft, and the connecting plates are provided with a first scraping plate and bristles respectively; a plurality of nozzles communicated with the water tank are annularly embedded in the upper part of the interior of the vomiting receiving basin, a water pump is arranged on a pipeline, and a seal cover is rotatably arranged on the vomit receiving basin. The vomit receiving device for digestive department nursing is reasonable in structure and easy to operate, the vomit in the collecting box can be cleaned, scraped off and discharged, the odor of the vomit can be effectively isolated, and the use effect is good.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

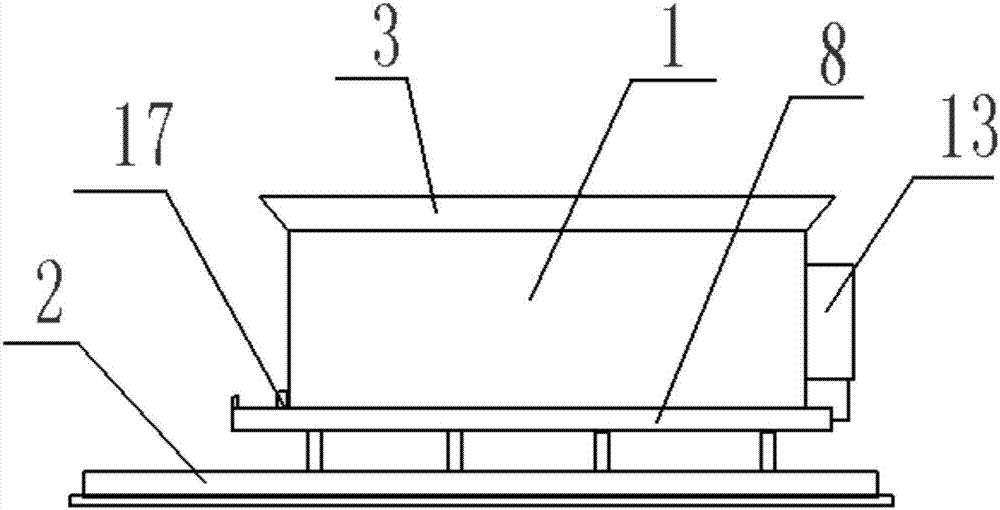

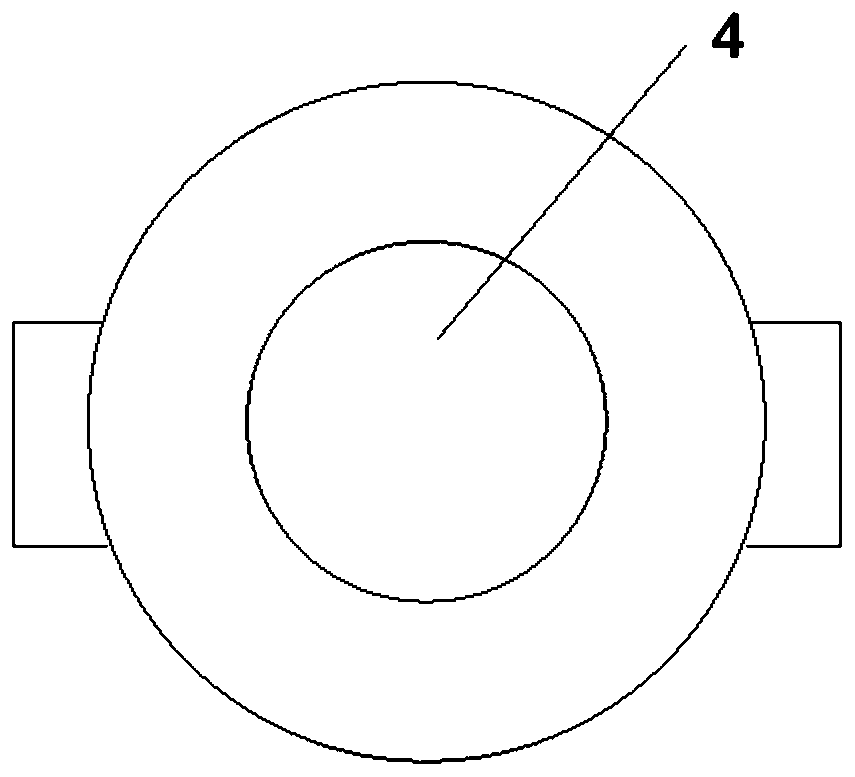

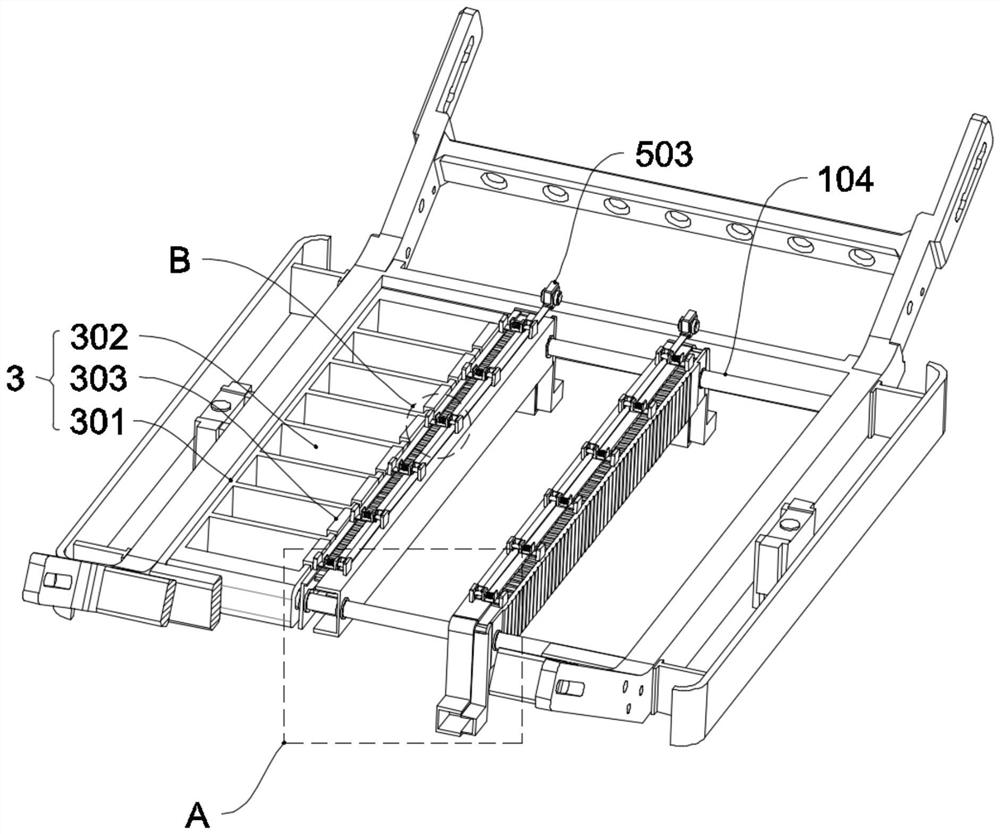

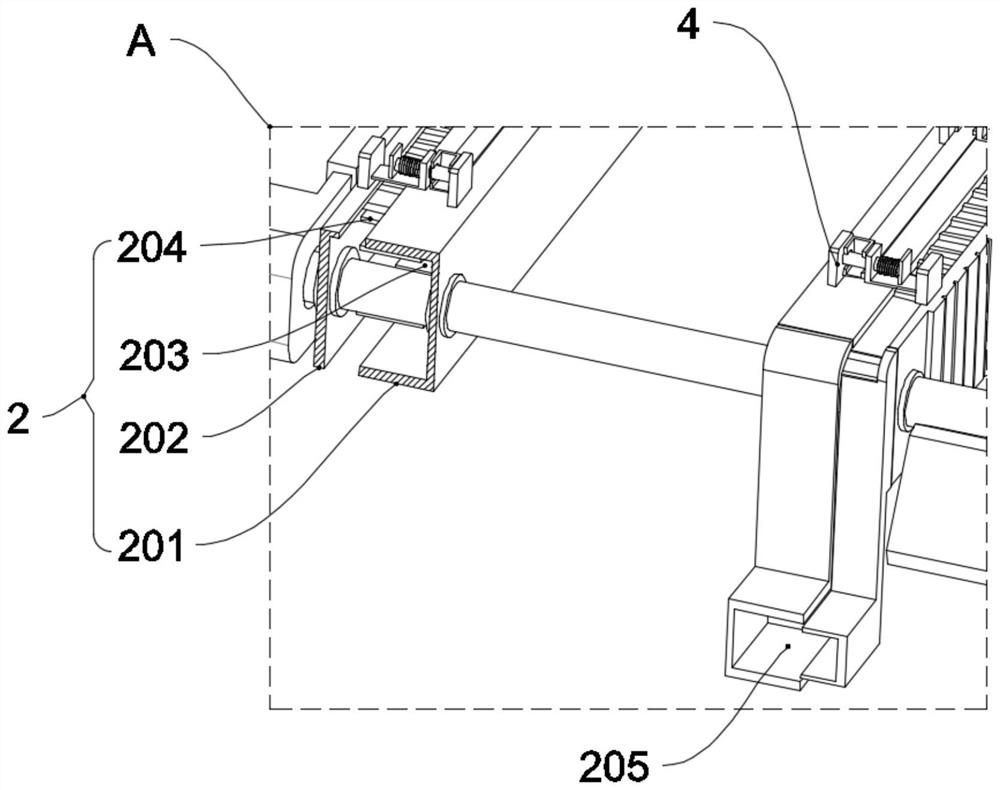

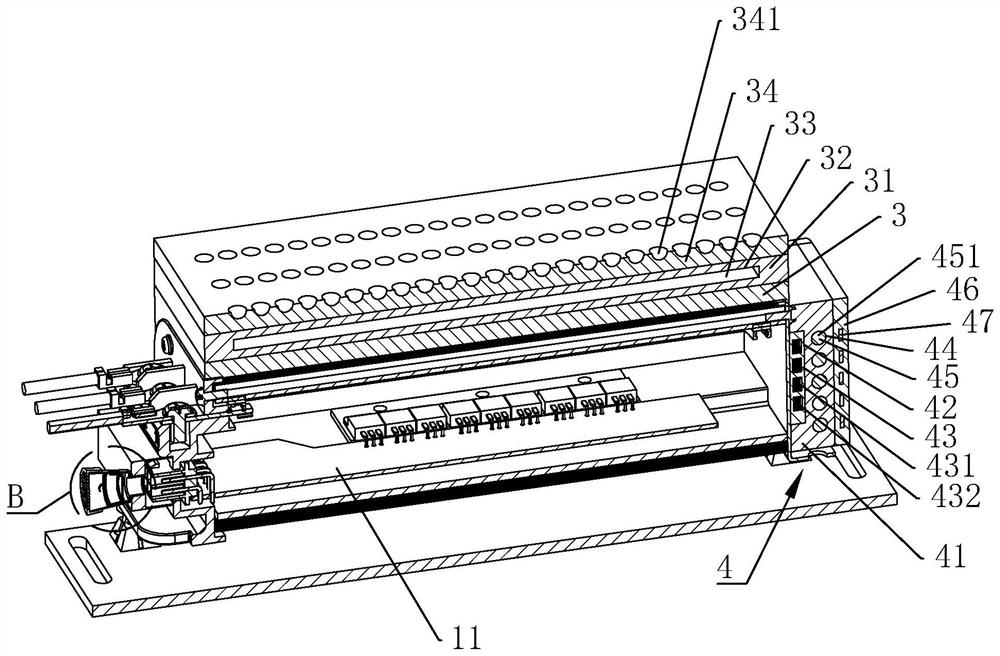

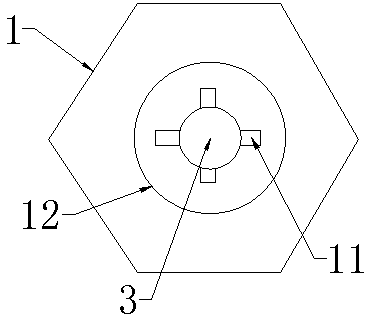

Dumbbell piece packaging device

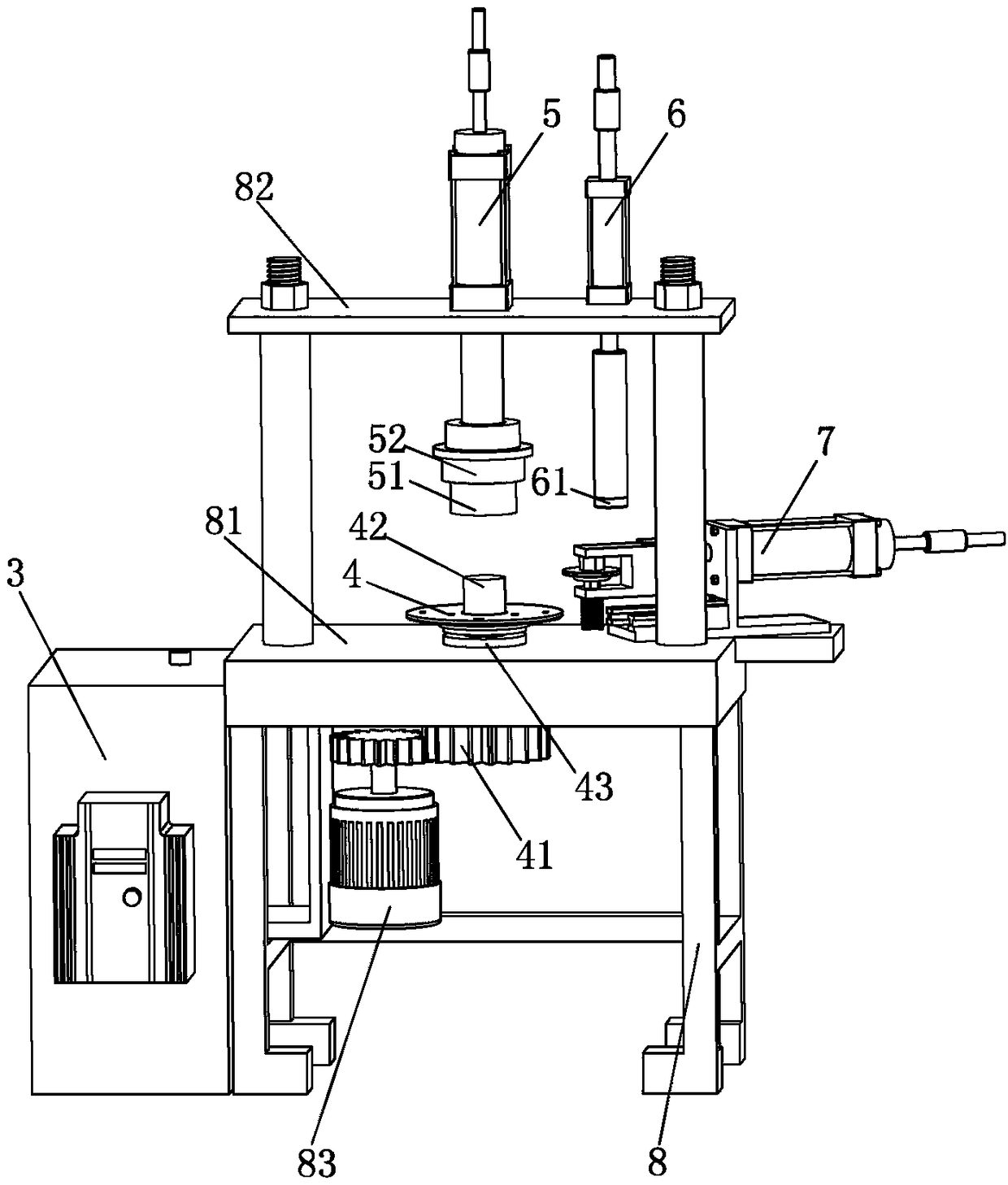

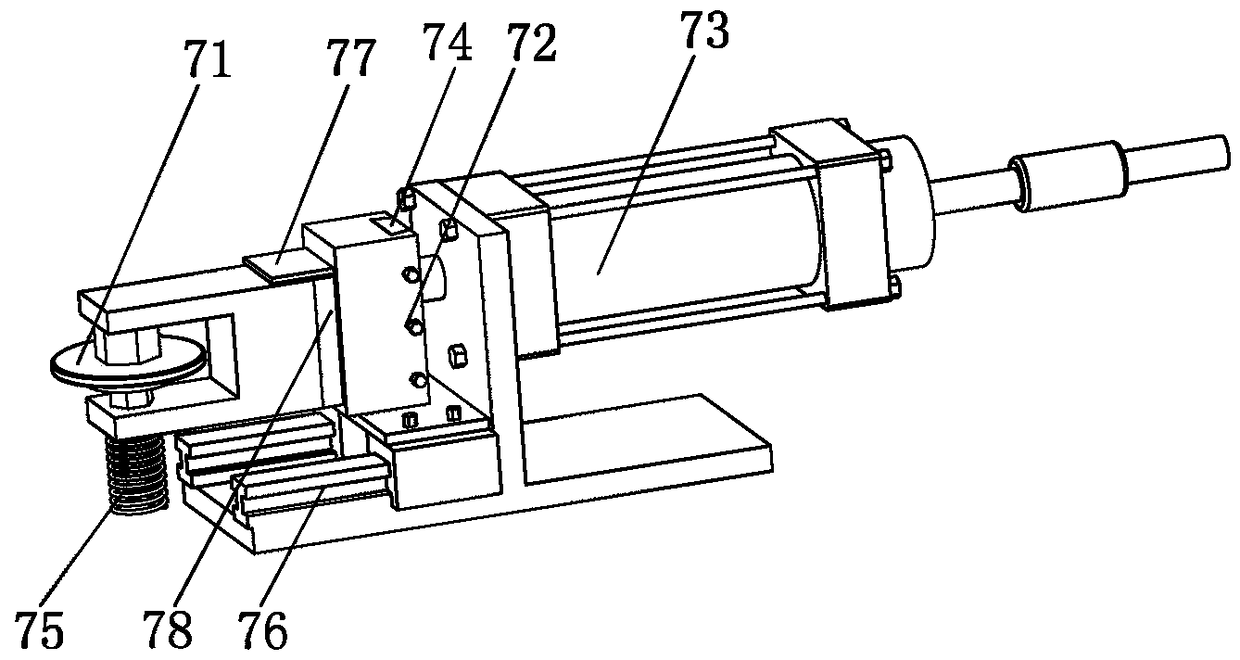

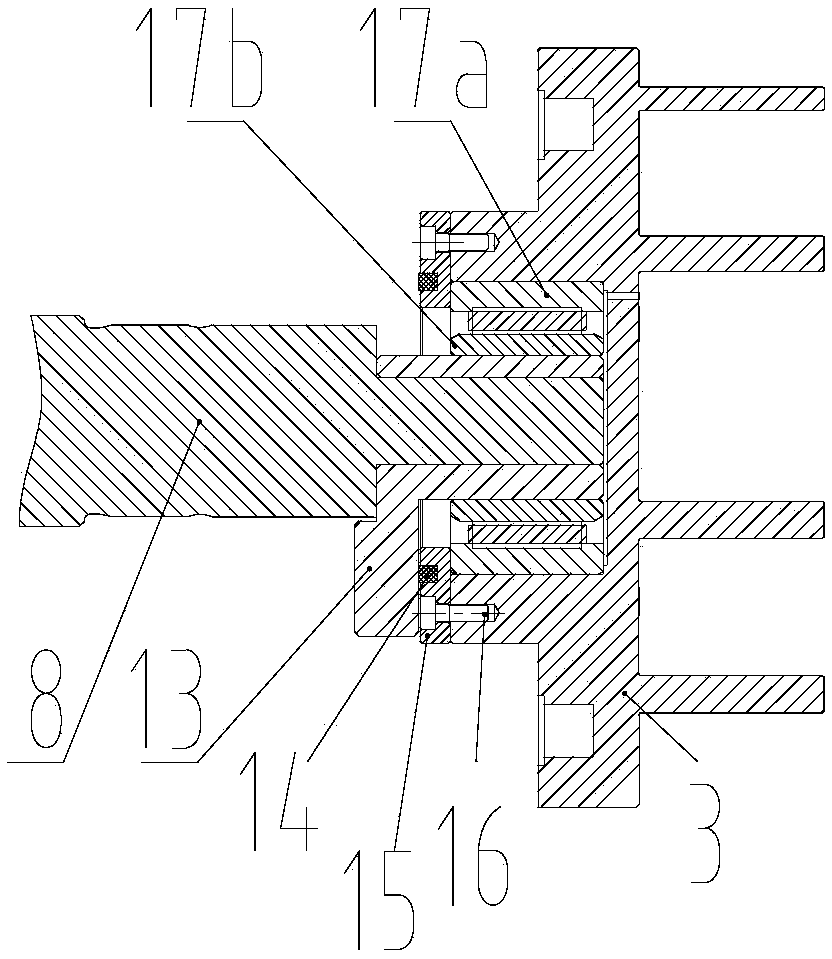

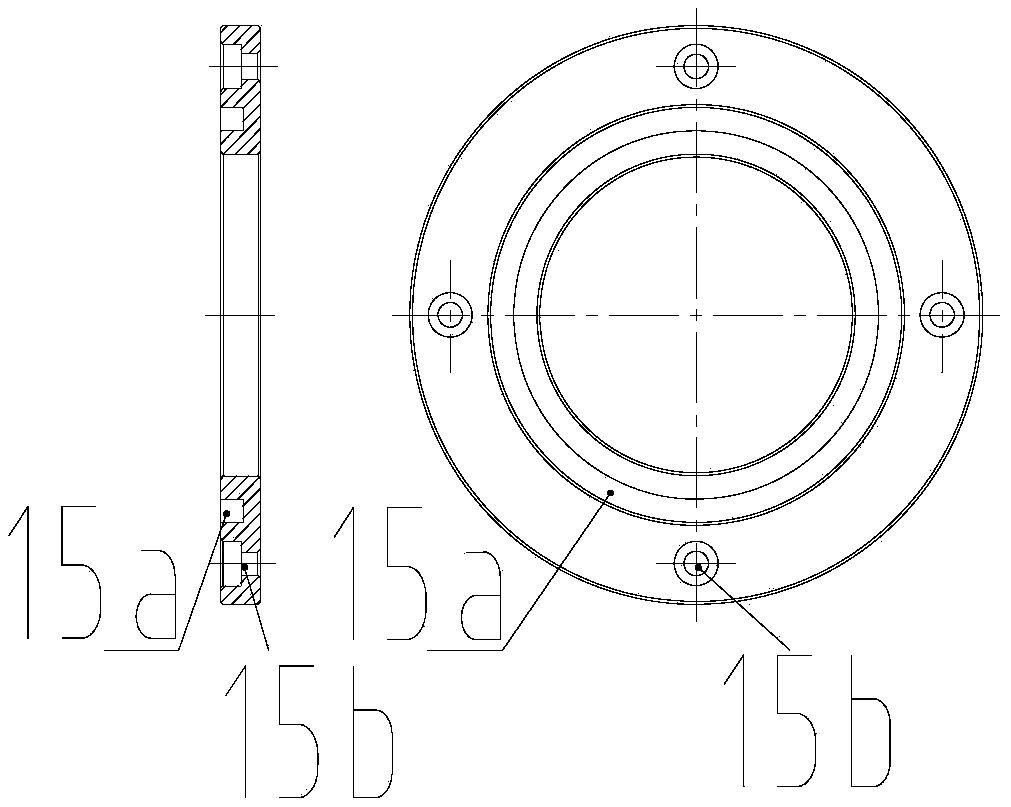

The invention discloses a dumbbell piece packaging device and belongs to the field of fitness equipment manufacturing. A dumbbell piece comprises a shell. The shell is filled with packing. The shell comprises a lower shell and an upper cover, and the upper edge of the side wall of the lower shell is inwards folded and then buckled on the upper cover to achieve packaging. The dumbbell piece packaging device is characterized in that the device comprises a rack, a dumbbell piece clamping mechanism, a rotation driving mechanism and a folding mechanism used for conducting folding treatment on the upper edge of the side wall of the lower shell of the dumbbell piece, wherein the dumbbell piece clamping mechanism, the rotation driving mechanism and the folding mechanism are arranged on the rack. The dumbbell piece clamping mechanism comprises a rotating tray which is arranged in a rotatable manner and is used for carrying the to-be-treated dumbbell piece and a pressing mechanism. The rotationdriving mechanism is used for driving the rotating tray or a pressing part to rotate. The folding mechanism comprises a push wheel used for inwards pushing the upper edge of the side wall of the lowershell of the dumbbell piece from the outer side, and a folding driving mechanism driving the push wheel to move in the radial direction of the dumbbell piece. By means of the above technical scheme,the upper edge of the side wall of the lower shell of the dumbbell piece is inwards folded and then buckled on the upper cover so as to achieve packaging, and therefore the blank in relevant equipmentin the prior art is filled up.

Owner:江山市泓睦体育用品有限公司

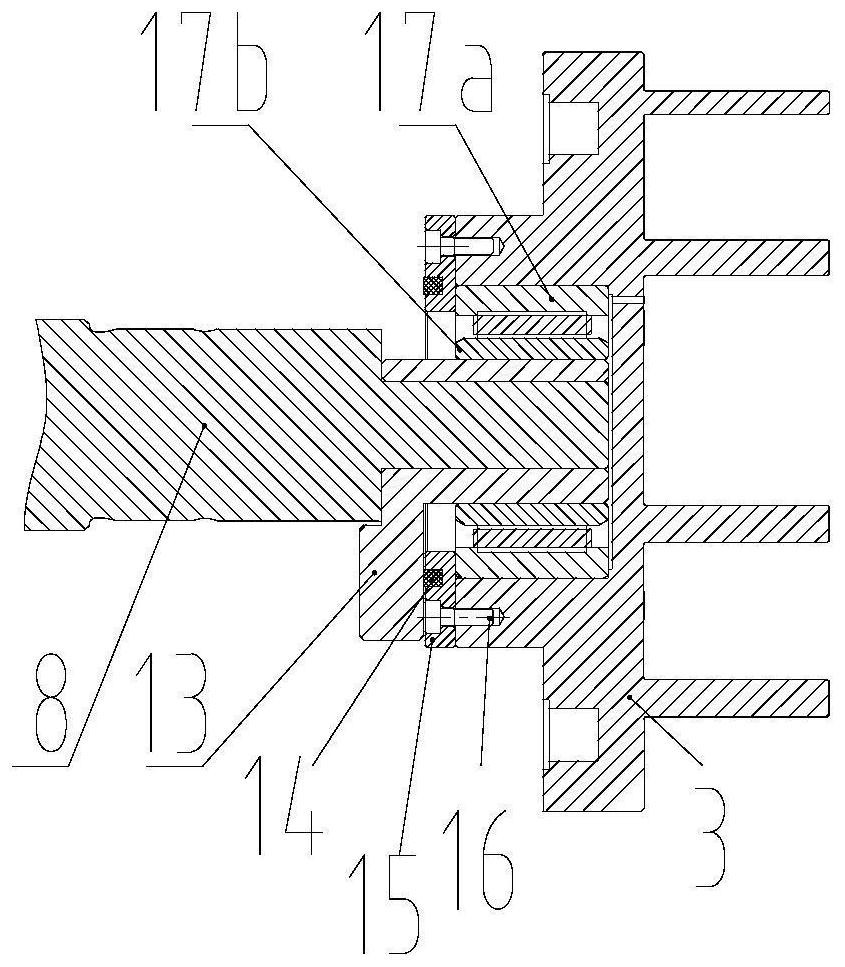

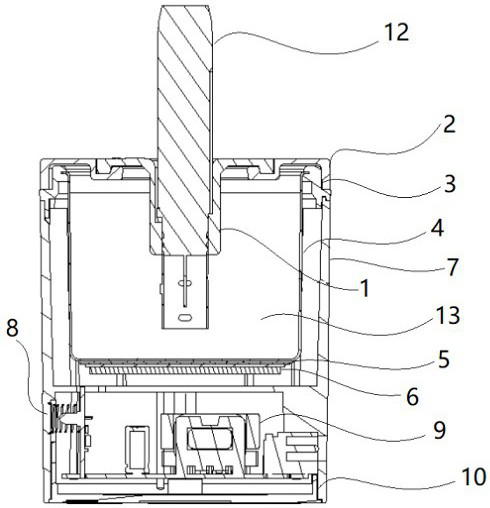

Orbiting scroll and scroll compressor

ActiveCN109488589AReduce frictionSmall footprintRotary/oscillating piston combinations for elastic fluidsCrankshaft bearingsWear resistantMechanical engineering

The invention relates to an orbiting scroll and a scroll compressor. The orbiting scroll is characterized in that an annular bearing protrusion coaxial with the orbiting scroll is arranged on the backsurface of the orbiting scroll, and a bearing hole is formed in an inner cavity of the bearing protrusion; and limiting pieces are arranged on the outer end surface of the bearing protrusion, and wear-resistant pieces are arranged on the outer end surfaces of the limiting pieces. A centripetal bearing is limited in the axial direction by the limiting pieces the when the bearing hole is thermallydeformed or subjected to uneven stress, and complicated processing and material extrusion processes are omitted; direct collision between an eccentric sleeve and the bearing protrusion can be effectively prevented by the wear-resistant pieces during upward channeling of the eccentric sleeve , friction between the eccentric sleeve and other parts is greatly reduced, so that the damage of the partscaused by collision and friction is reduced, and the efficiency of the compressor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

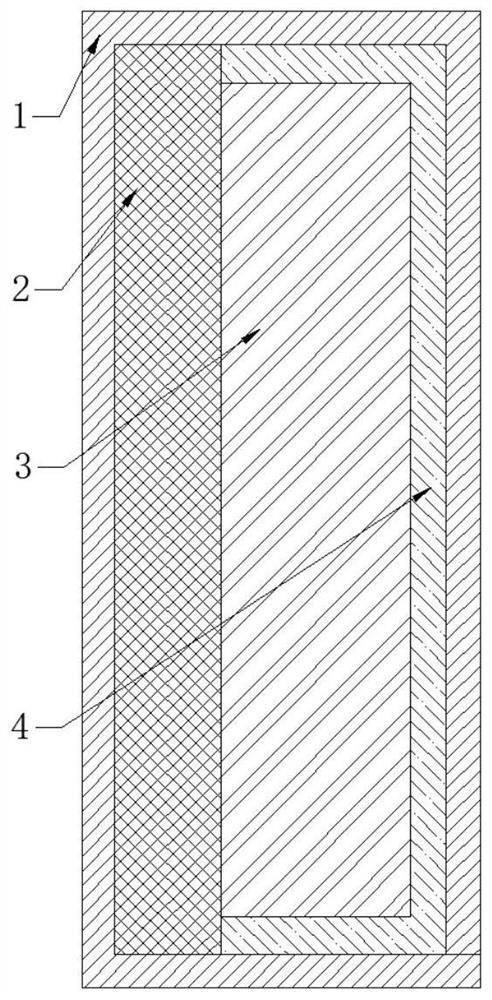

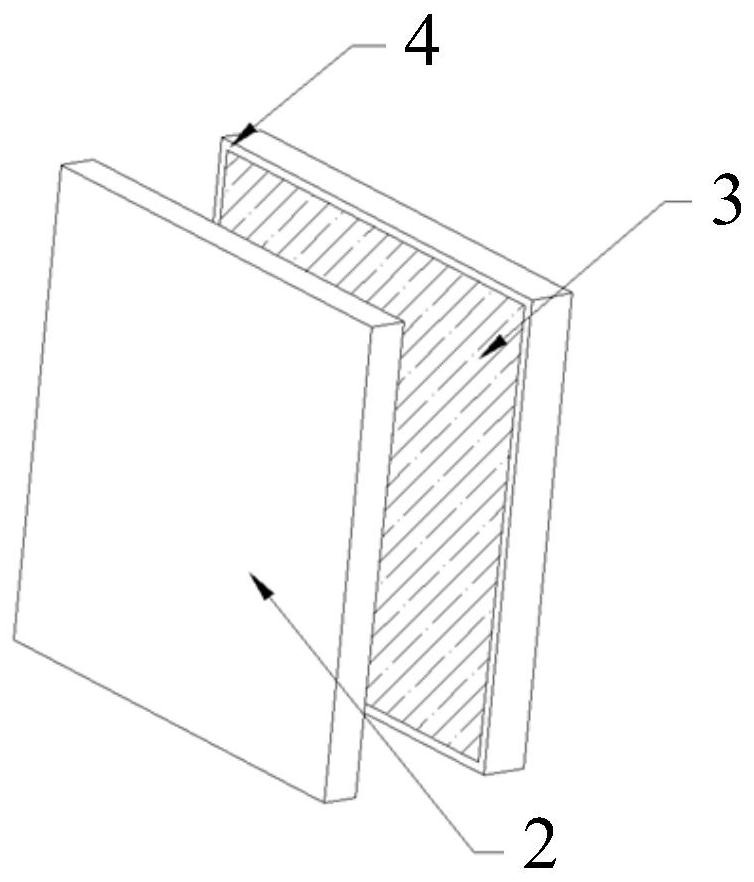

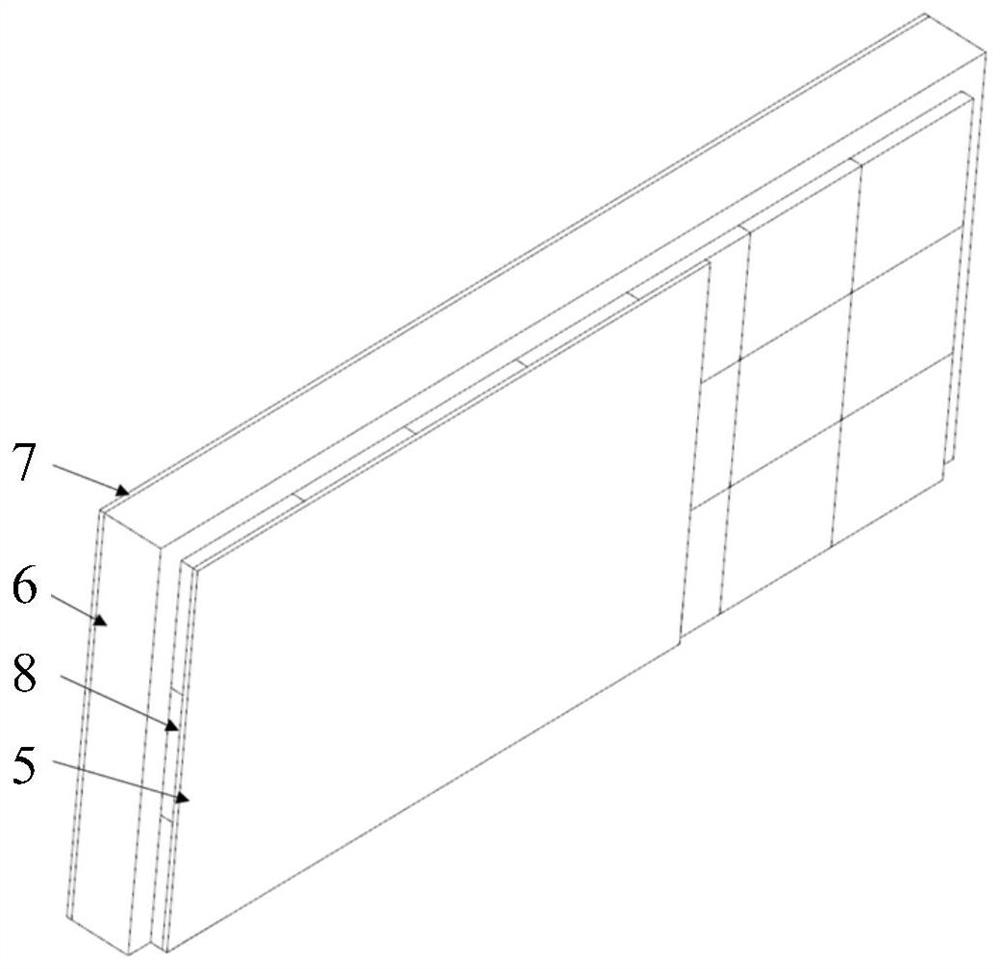

Wall explosion-proof reinforcing module, explosion-proof wall and preparation methods of wall explosion-proof reinforcing module and explosion-proof wall

The invention discloses a wall explosion-proof reinforcing module, an explosion-proof wall and preparation methods of the wall explosion-proof reinforcing module and the explosion-proof wall. The wallexplosion-proof enhancing module comprises a shell layer, and a foam layer, a liquid protection layer and an elastomer layer which are wrapped inside the shell layer, can absorb shock waves generatedby explosion, and is good in explosion-proof effect. For some old buildings, the structural strength of walls of the old buildings is not high, and the explosion-proof capacity is weak when the old buildings face the impact waves; and the explosion-proof module is hung so that absorption and conversion of shock wave energy can be improved, direct collision between the shock waves and wall bodiesis reduced, and therefore the corresponding protection effect is achieved, and meanwhile, the shock waves are adsorbed, so that damage of the diffracted shock waves to other parts is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

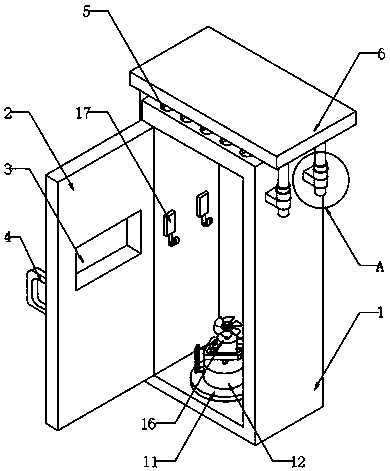

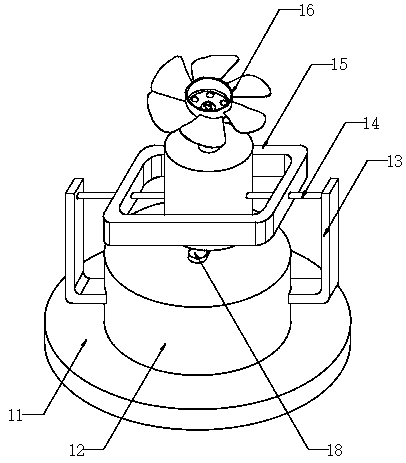

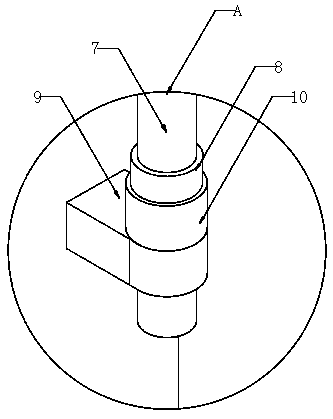

Outdoor control cabinet capable of preventing condensation

InactiveCN110867742AReduce direct collisionReduce bumpsSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsForeign matterEngineering

The invention discloses an outdoor control cabinet capable of preventing condensation. The cabinet comprises a cabinet body and a cabinet door; a plurality of ventilation grooves are formed in the topend of the cabinet body; waterproof films are laid in the ventilation grooves; a shielding structure is arranged at the top of the cabinet body; a pushing handle is fixedly mounted in the middle of one side of the cabinet door; hooks are fixedly arranged in the middle of the inner wall of the cabinet body; dehumidifying bags are movably connected to the four hooks; an observation window is formedin the top of the cabinet door; and a ventilation structure is arranged in the cabinet body. According to the invention, through the arrangement of the shielding structure, when a foreign matter hitsthe ceiling, a blocking ring extrudes a rubber pad, so direct collision between the blocking ring and the fixing ring is reduced, thereby facilitating protection for parts; and by arranging the ventilation structure, a driving motor can drive a rotating base to rotate, the rotating base drives the supporting base to rotate in the rotating process, a cooling fan rotates around the supporting rod,the cooling fan can sweep air in all directions, hot air circulates upwards, and the hot air is dissipated through the ventilation groove.

Owner:西安鼎腾电子科技有限公司

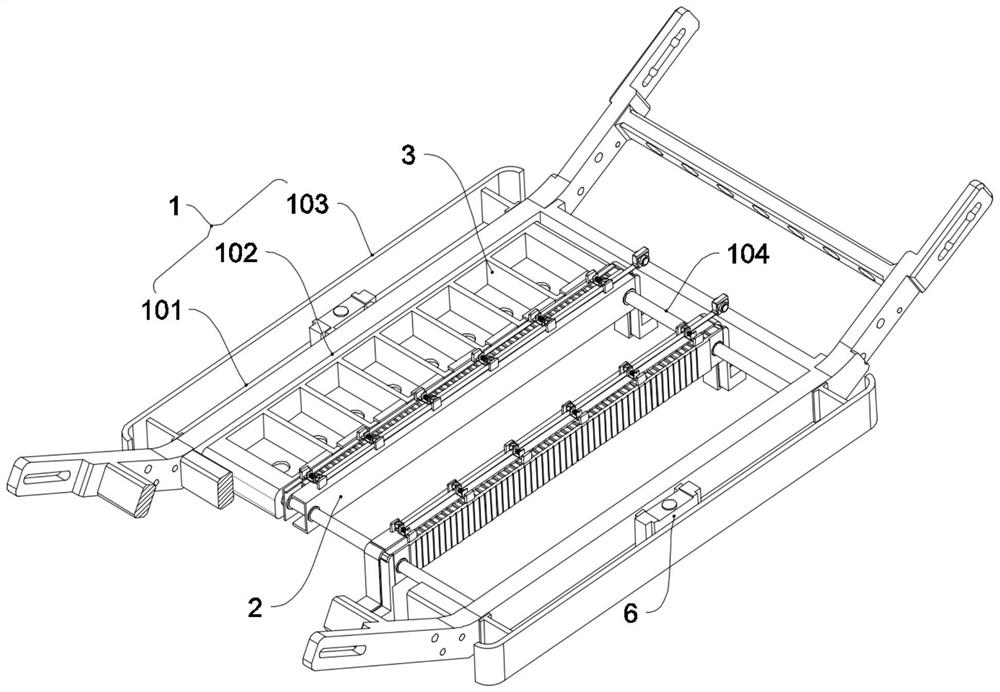

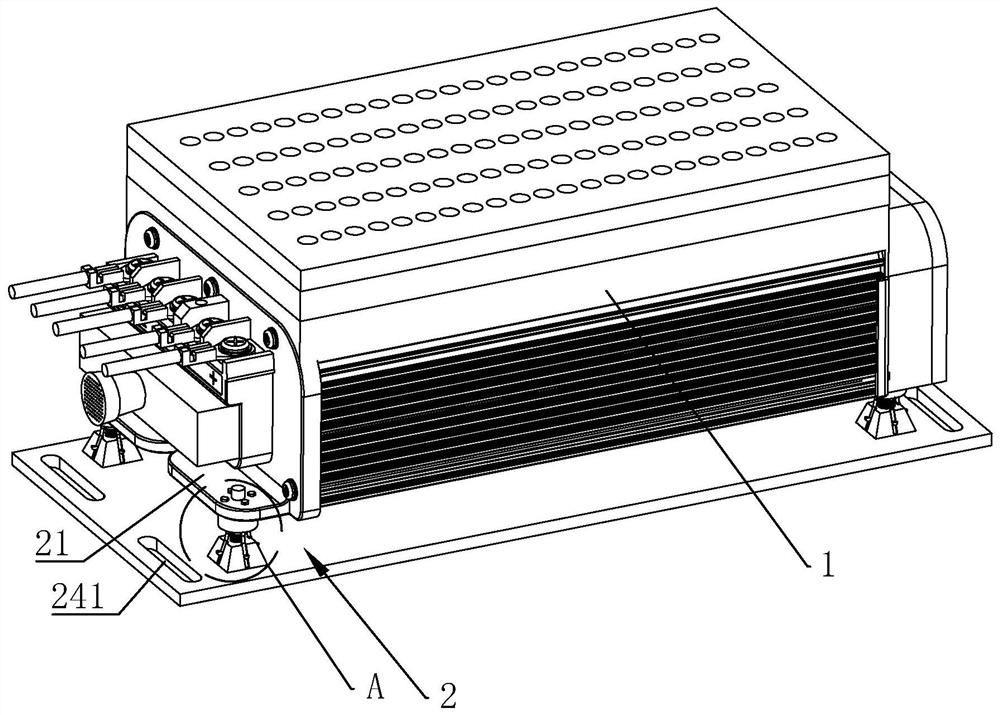

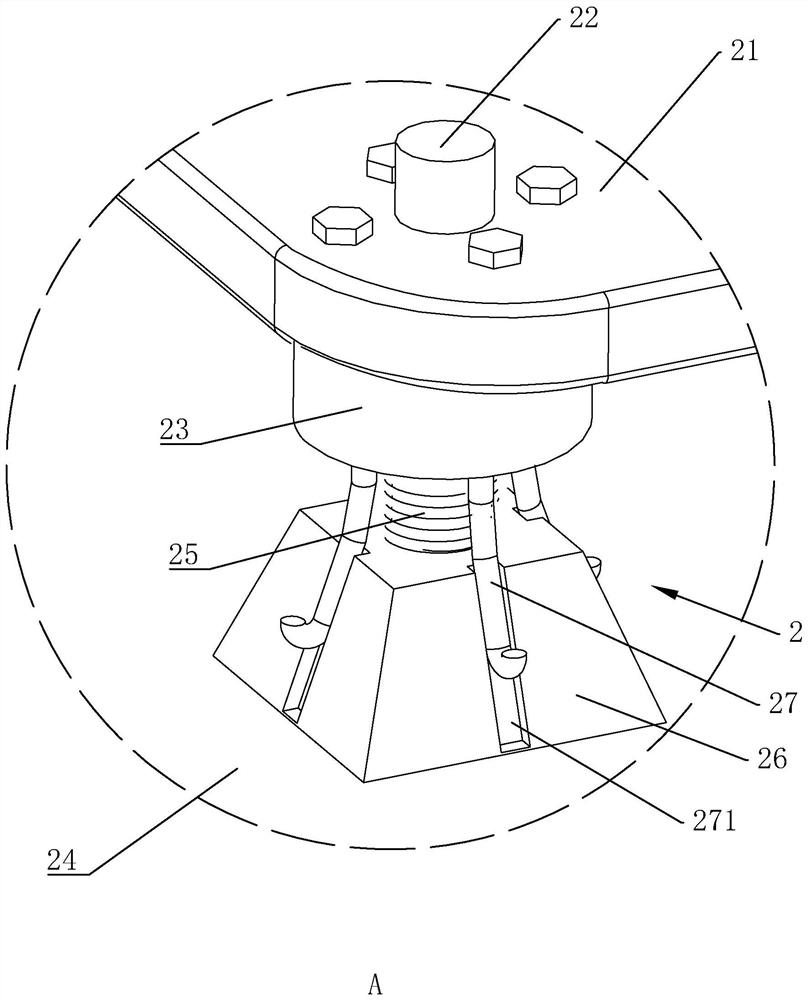

New energy automobile battery pack frame structure

InactiveCN114709519ALower battery temperatureReduce direct collisionSecondary cellsCell component detailsVehicle frameAutomotive battery

The invention discloses a new energy automobile battery pack frame structure, and belongs to the technical field of new energy automobiles, the new energy automobile battery pack frame structure comprises a main frame and guide columns, the guide columns are parallelly assembled in the main frame, a plurality of air guide members are slidably assembled on the guide columns, each air guide member comprises a first C-shaped groove shell and a second C-shaped groove shell, and a plurality of battery bin bases slide on the guide columns and are arranged among the air guide members; the first fixing frame is assembled on the second C-shaped groove shell, one end of the first fixing frame is connected with an L-shaped plate, the second fixing frame is assembled on the first C-shaped groove shell, one end of the second fixing frame is provided with a sliding shaft, and the sliding shaft slides on the L-shaped plate and is connected with the L-shaped plate through an elastic piece. According to the battery compartment assembly, a cooling gas flow channel can be provided in a non-impact environment so as to reduce the temperature of batteries in the battery compartment assembly, and in the transverse impact process, the movement space of the battery compartment assembly can be increased through contraction of the gas guide component so as to reduce direct impact of a battery pack and improve the safety coefficient of transverse impact.

Owner:长春人文学院

A shockproof and drop-proof brushless controller

ActiveCN110958797BPlay a protective effectExtended service lifeNon-rotating vibration suppressionCasings/cabinets/drawers detailsEngineeringStructural engineering

Owner:常州市易尔通电子有限公司

A hanging frame type loose fiber dyeing machine

ActiveCN104611860BReduce direct collisionExtended service lifeTextile treatment containersTextile treatment with treating outlet contectFiberArchitectural engineering

The invention discloses a novel hanging frame type loose fiber dyeing machine which comprises a dye vat, a fiber cage, a heating coil and a central spray pipe, wherein a dye tank is fixed at the bottom of the dye vat; the heating coil is fixed in the dye tank; a driving motor is fixed on the outer wall of the dye tank; the fiber cage is placed in the dye vat; the bottom of the fiber cage is in threaded connection with a fiber cage cover; a built-in sleeve is fixed on the top surface of the fiber cage cover; the built-in sleeve is inserted in the fiber cage; a lifting mechanism is fixed at the top of the fiber cage; the fiber cage cover is pressed on a cushion fixed on the bottom plate of the dye vat; the upper end of the central spray pipe penetrates through the cushion and the fiber cage cover and extends into a middle upright pipe body of the fiber cage; spray holes are formed in the side wall at the upper end of the central spray pipe. According to the novel hanging frame type loose fiber dyeing machine, a lifting appliance doesn't need to be dismounted after the fiber cage is placed on the dye vat, the novel hanging frame type loose fiber dyeing machine is simple and convenient as the dye vat doesn't need to be equipped with a vat lid, and the dye vat is provided with a cushion mechanism so as to reduce direct collisions caused when the fiber cage is lifted and prolong the service life.

Owner:广州市盟鸿机械工业有限公司

Stirring drum internally provided with grooves and stirring mill

PendingCN113786909AReduce direct collisionReduce wear rateGrain treatmentsEngineeringProtection layer

The invention discloses a stirring drum internally provided with grooves and a stirring mill, and relates to the technical field of stirring and grinding equipment. A grinding medium is contained in the stirring drum, the plurality of grooves are formed in the inner wall of the stirring drum, and the minimum width and the minimum length of the grooves are larger than the maximum width of the grinding medium. The stirring mill comprises the stirring drum. When the grinding medium does high-speed centrifugal motion in the stirring drum, the grinding medium is easy to hit to the inner wall of the stirring drum at a high speed and hit into the grooves due to the limited volume of the stirring drum; and due to the width setting of the grooves, the grinding medium is supported by the side walls of the grooves and is fixed in the grooves when the grinding medium is hit into the grooves. When the maximum number of grinding media are clamped in all the grooves, a protective layer is formed on the inner wall of the stirring drum, and other subsequent grinding media collide with the grinding media clamped in the grooves, so that the probability that the grinding media directly collide with the inner wall of the stirring drum is reduced, and the abrasion rate of the inner wall of the stirring drum is reduced.

Owner:CHENGDU LEEJUN IND

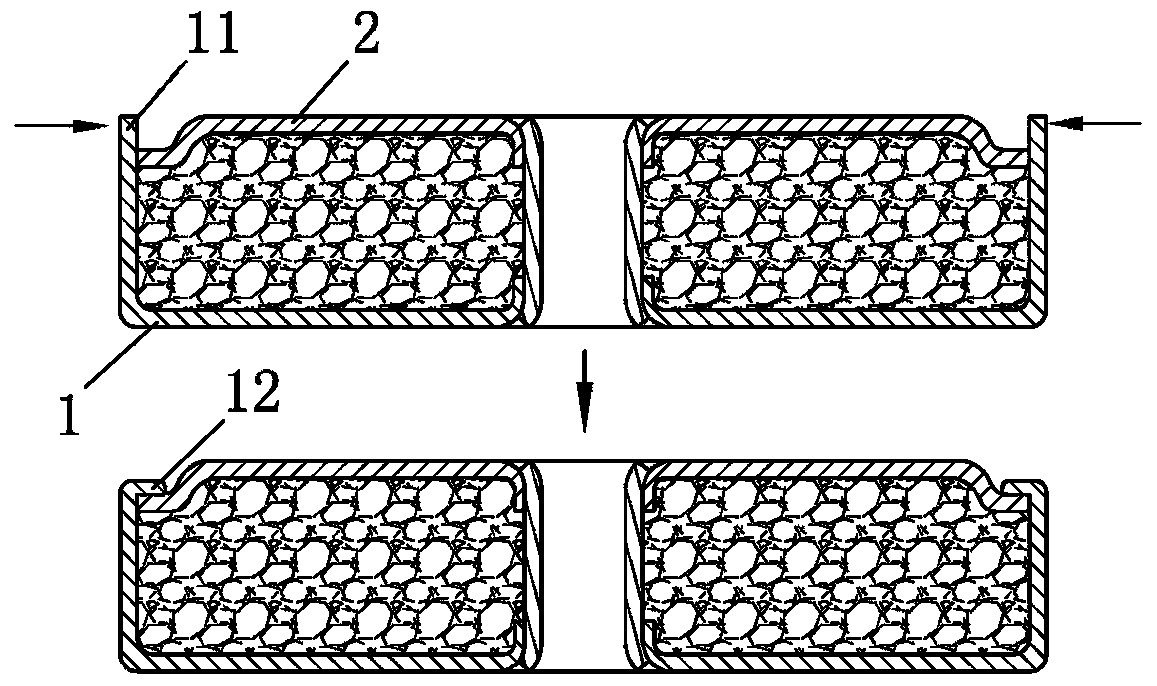

packing box

InactiveCN103407693BReduce direct collisionSo as not to damageContainers to prevent mechanical damageEngineeringCushion

The invention relates to the field of product package, in particular to a packaging box. The packaging box comprises a packaging casing and an inner film layer. The inner film layer is arranged in the packaging casing, the edge of the inner film layer is connected with the inner wall of the packaging casing to form a sealed air bag, and the inner wall of the air bag surrounding the packaging casing forms a storage cavity. The packaging casing is provided with a sealing mouth capable of being opened and closed, wherein the sealing mouth enables an opening of the storage cavity to be sealed. When the packaging box is used, articles are placed in the storage cavity, the air bag outside the articles serves as an air bag cushion layer, and the articles are completely packaged by closing the sealing mouth on the packaging casing. When shake or collision occurs, the air bag cushion layer can reduce direct collision between the articles and external contactants. After the packaging box is used, the sealing mouth of the packaging casing is opened, and the articles are taken out, so that the packaging casing and the air bag are not damaged during stripping, the packaging box can be re-utilized, resource waste is reduced, and the cost is reduced.

Owner:陆晶晶

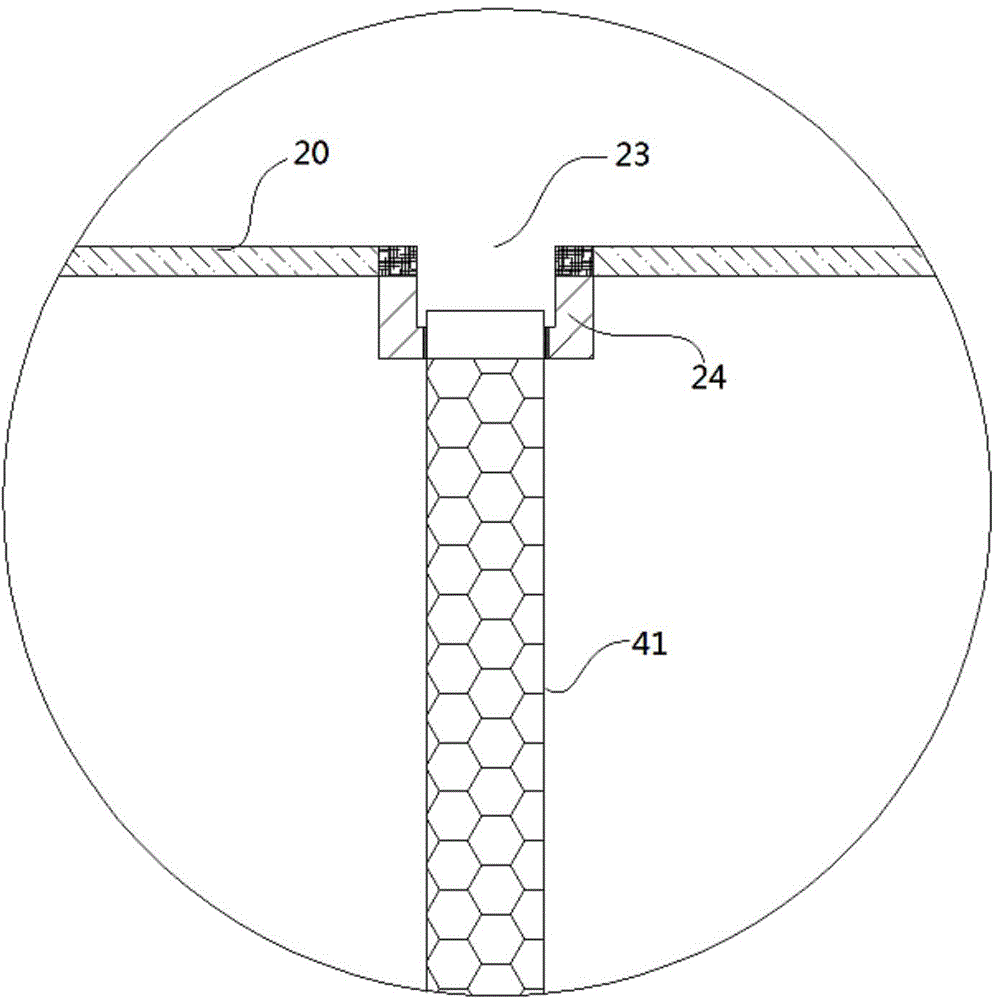

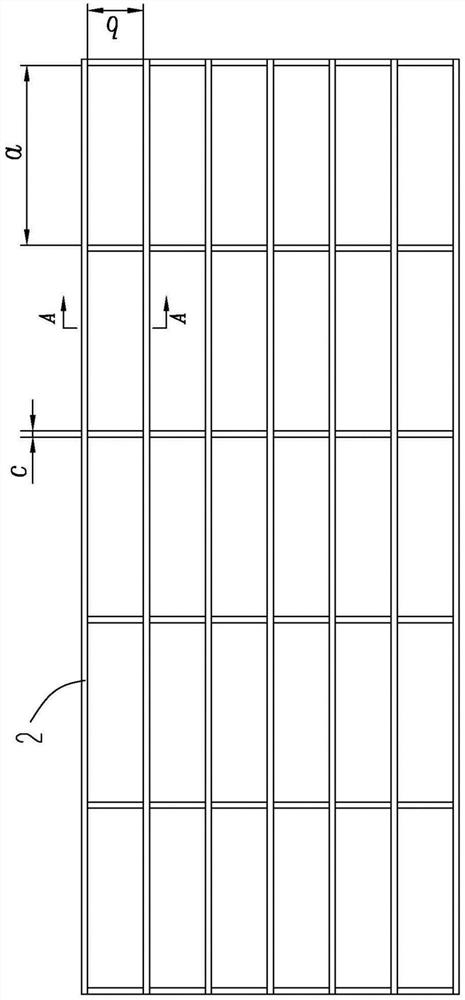

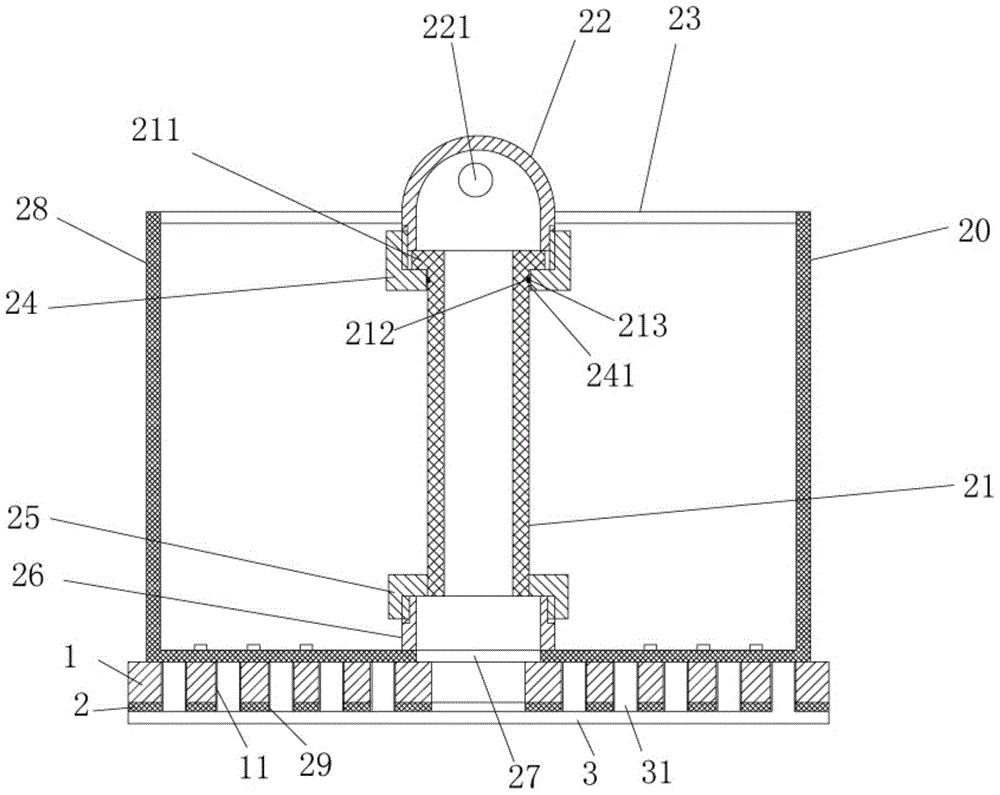

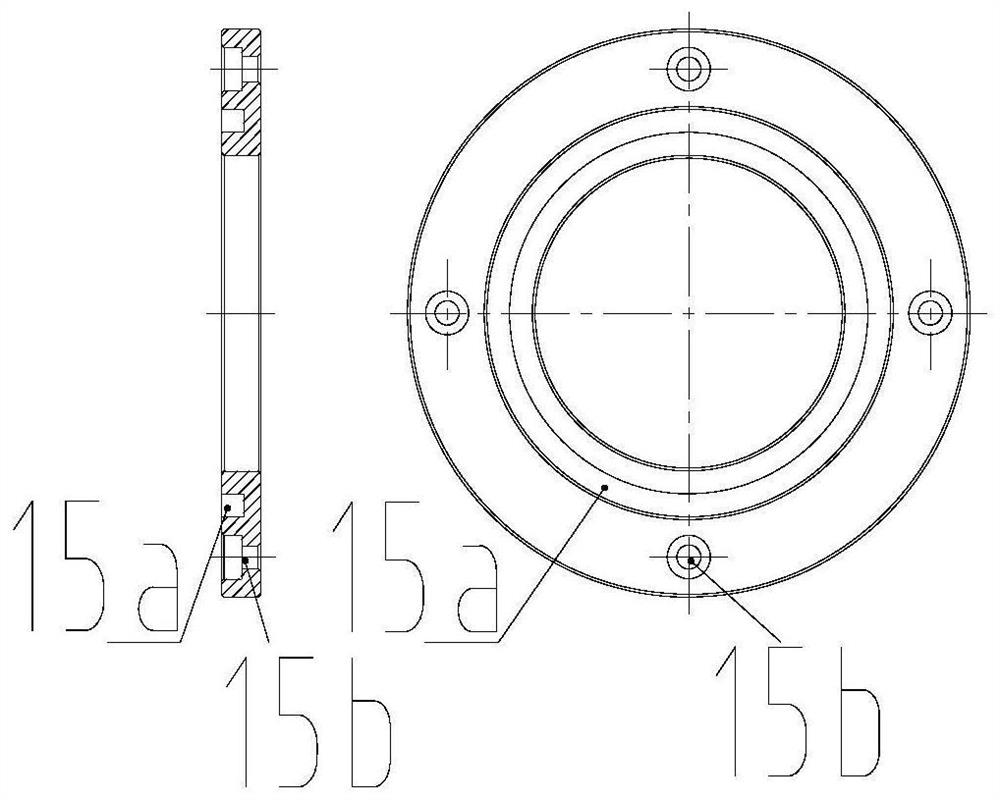

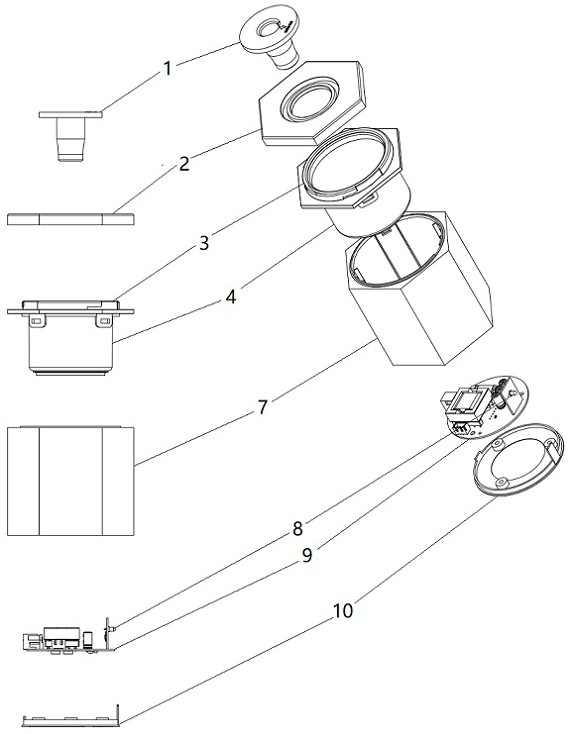

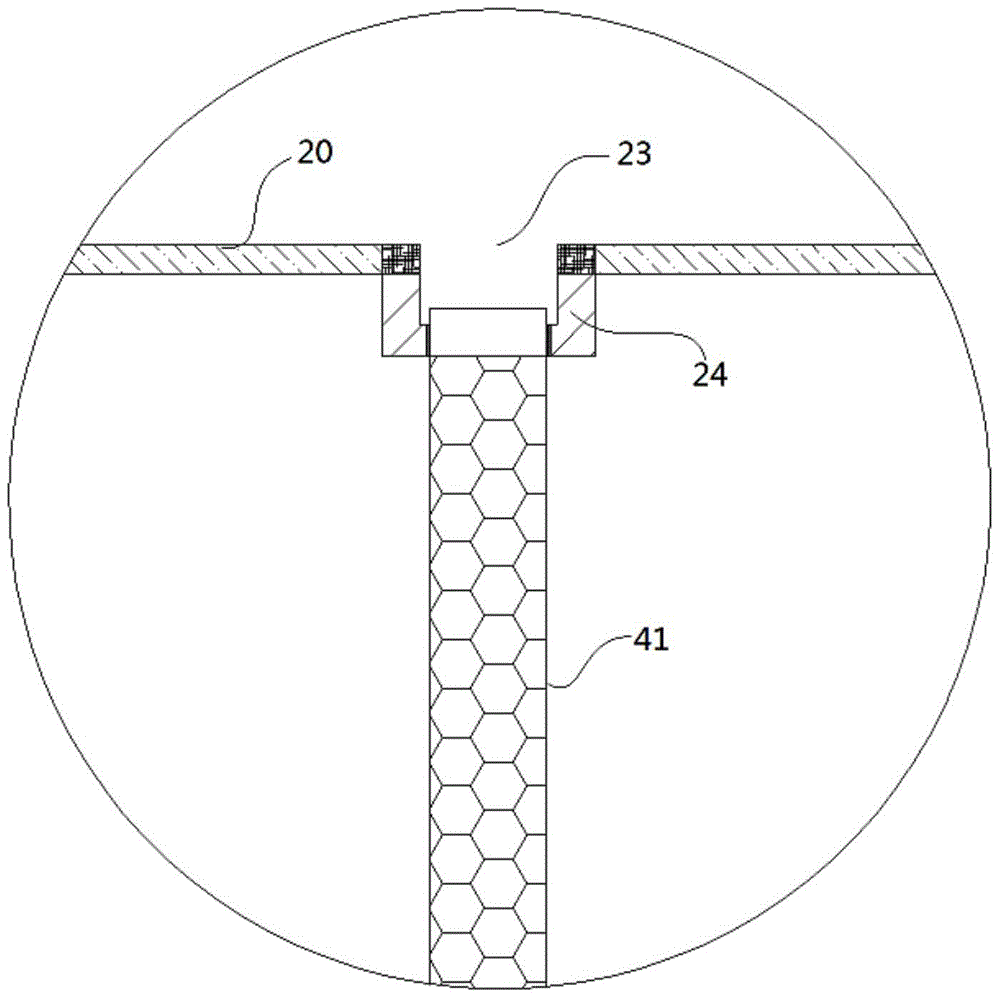

A kind of fiber cage for loose fiber dyeing machine

InactiveCN104674484BReduce direct collisionExtended service lifeTextile treatment carriersVertical tubeFiber

The invention discloses a fiber cage for a loose fiber dyeing machine. The fiber cage comprises a frame body, wherein a connecting sleeve is arranged on the top of the frame body; a plurality of supporting rods are fixed on the outer side wall of the connecting sleeve; the other ends of the supporting rods are welded and fixed on the inner side wall of the frame body; a fixed sleeve is in threaded connection with the bottom end of the connecting sleeve; a middle vertical tube body is inserted in the fixed sleeve in a sleeving mode; a lower connecting sleeve is fixed at the lower end of the middle vertical tube body; the lower connecting sleeve is in threaded connection with a bulged sleeve which is arranged on the middle part of the bottom plate of the frame body; the middle vertical tube body is a net-shaped tube body; the lower end of the bulged sleeve is communicated with a bottom plate through hole in the center of the bottom plate of the frame body; a buffer fixed pad is fixed on the bottom surface of the bottom plate of the frame body; a felt pad layer is fixed on the bottom surface of the buffer fixed pad. The fiber cage is provided with a buffer mechanism, so that direct collision is reduced when the fiber cage is lifted into a dyeing cylinder, and the service life of the fiber cage is prolonged; meanwhile, the middle vertical tube body of the fiber cage can be replaced for conveniently maintaining and repairing the fiber cage without the needs of replacing the whole fiber cage.

Owner:吴江市佳福纺织有限公司

A kind of moving scroll and scroll compressor

ActiveCN109488589BReduce frictionSmall footprintRotary/oscillating piston combinations for elastic fluidsCrankshaft bearingsThermal deformationEngineering

The present invention relates to a movable scroll and a scroll compressor, characterized in that, the back of the movable scroll is provided with an annular bearing protrusion coaxial therewith, and the inner cavity of the bearing protrusion constitutes a bearing hole; The outer end surface of the bearing protrusion is provided with a limit piece; the outer end surface of the limit piece is provided with a wear-resistant piece. The limiter can axially limit the radial bearing when the bearing hole is thermally deformed or under uneven force, and saves complicated processing and material extrusion processes; the wear-resistant part can effectively prevent the eccentric sleeve from moving up The direct collision with the bearing protrusion greatly reduces the friction between the eccentric sleeve and other components, thereby reducing the damage of parts caused by collision and friction, and improving the efficiency of the compressor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

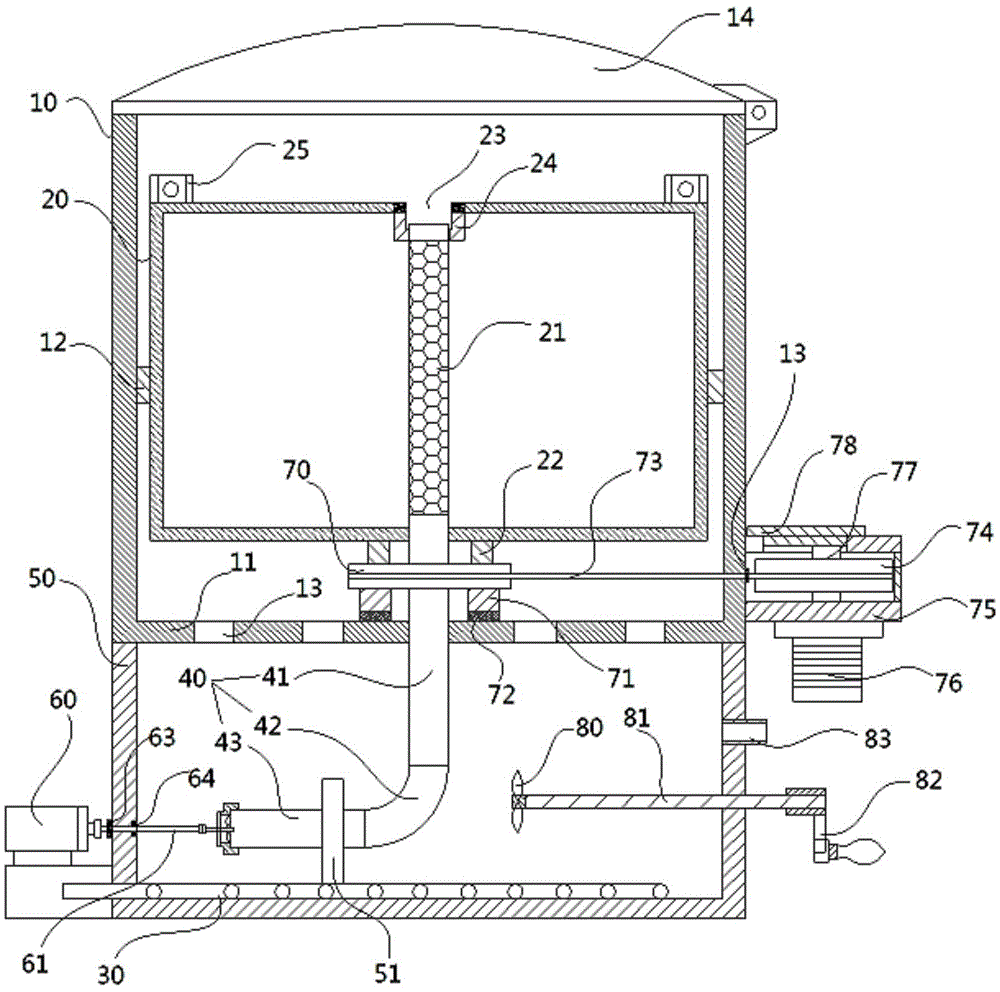

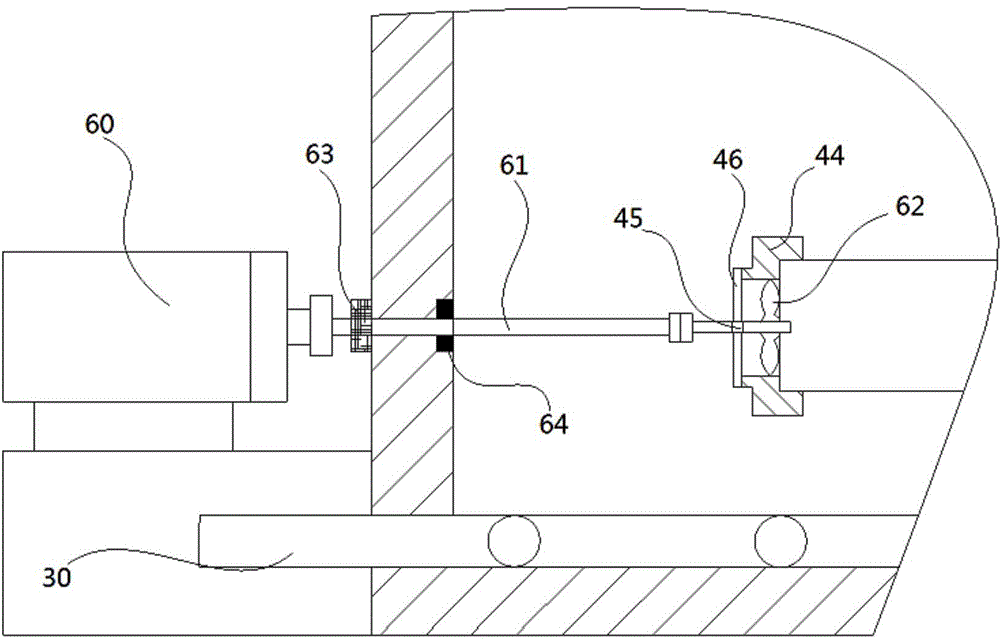

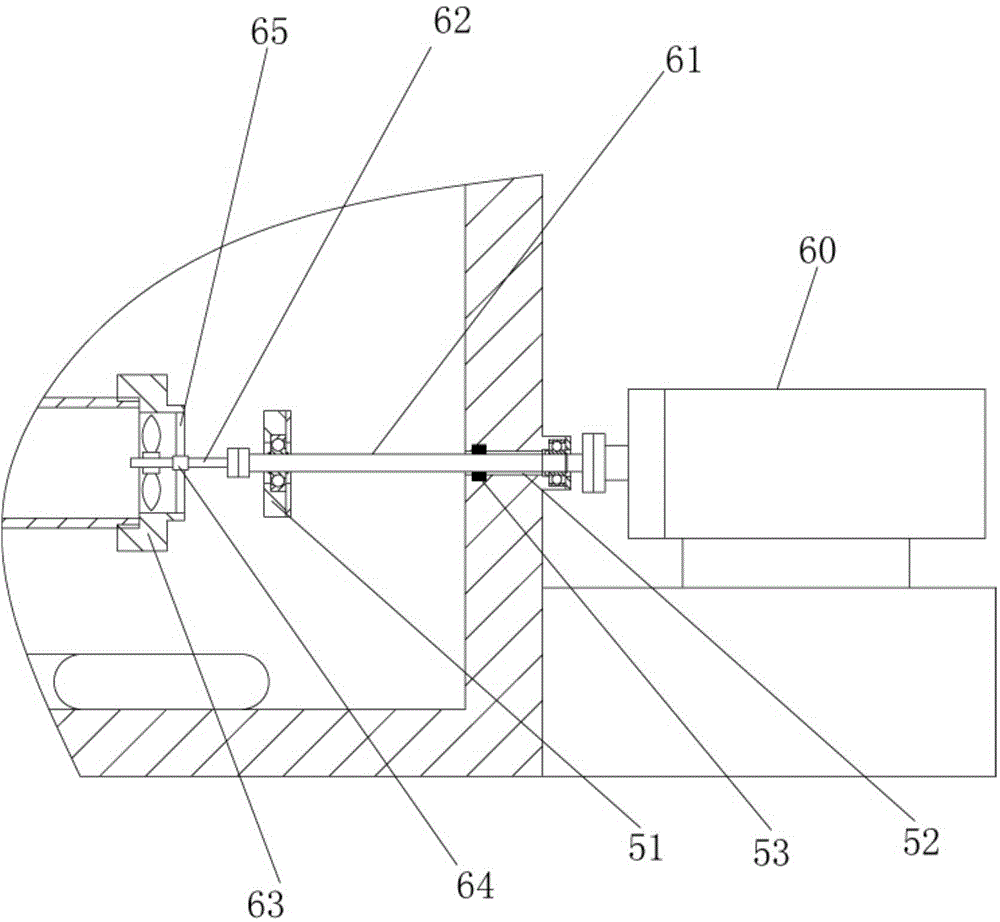

Novel loose fiber dyeing machine

ActiveCN104652060AReduce direct collisionExtended service lifeTextile treatment containersTextile treatment machine arrangementsFiberCoupling

The invention discloses a novel loose fiber dyeing machine which comprises a dye vat, a fiber cage, a heating coil and a center spray pipe, wherein a dye tank is fixed at the bottom of the dye vat; the heating coil is fixed in the dye tank; a driving motor is fixed on the outer wall of the dye tank; a middle rotating shaft is connected to an output shaft of the driving motor through a coupling and extends into the dye tank; the middle rotating shaft is fixed on the dye tank through a bearing; the other end of the middle rotating shaft is connected with a center shaft of a propeller through the coupling; the fiber cage is placed in the dye vat; limiting rings are arranged on the inner side wall of the dye vat; the outer wall of the fiber cage is pressed on the inner side walls of the limiting rings; a cushion pad is fixed on a base plate of the dye vat; a wear-resisting buffer block is fixed on the cushion pad. The dye vat of the novel loose fiber dyeing machine is provided with a buffer mechanism, so that direct collision is reduced when the fiber cage is lifted into the dye vat, and the service life is prolonged; meanwhile, a middle vertical pipe body of the fiber cage can be changed, so the maintenance and repair for the fiber cage are facilitated.

Owner:汪建建

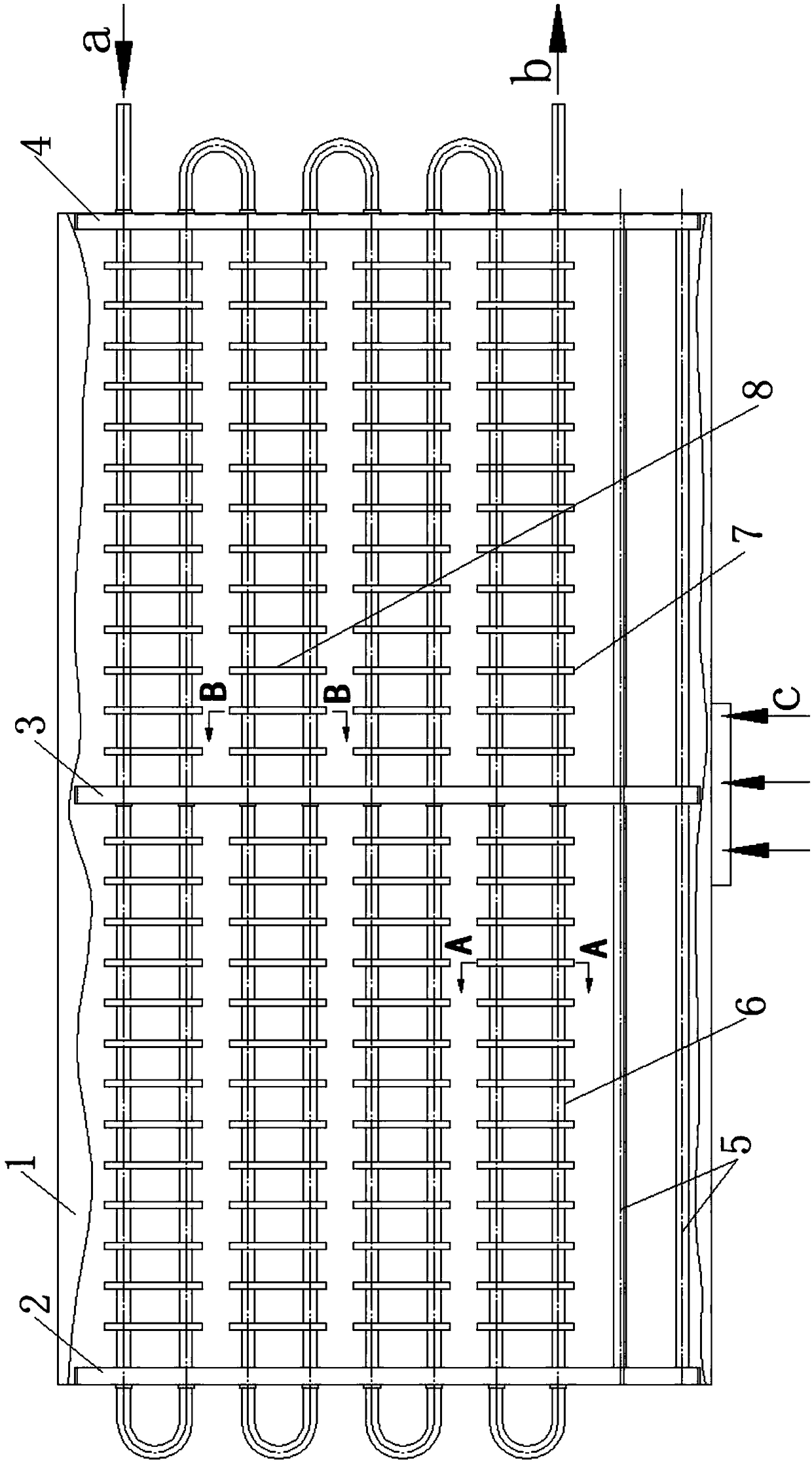

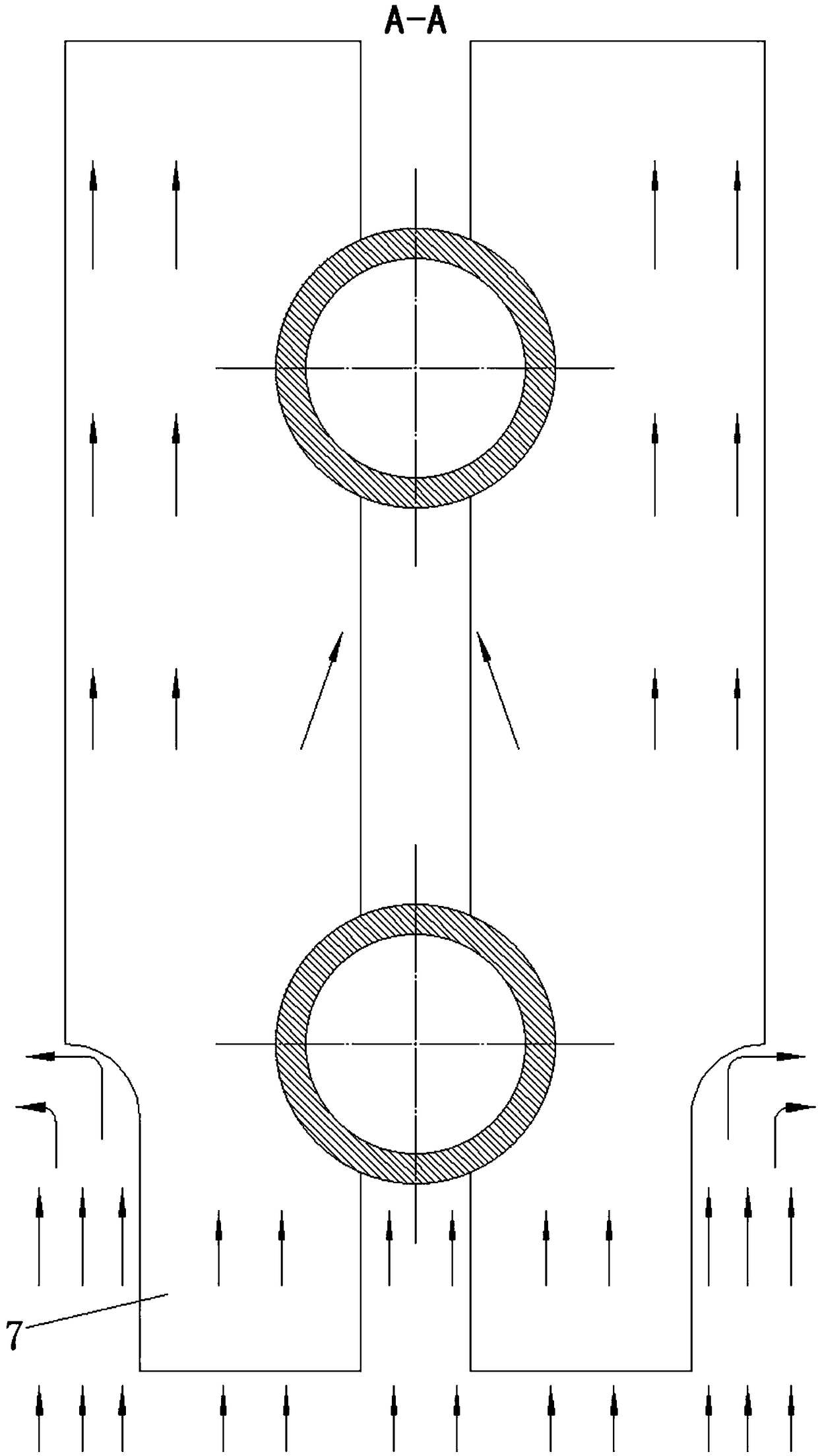

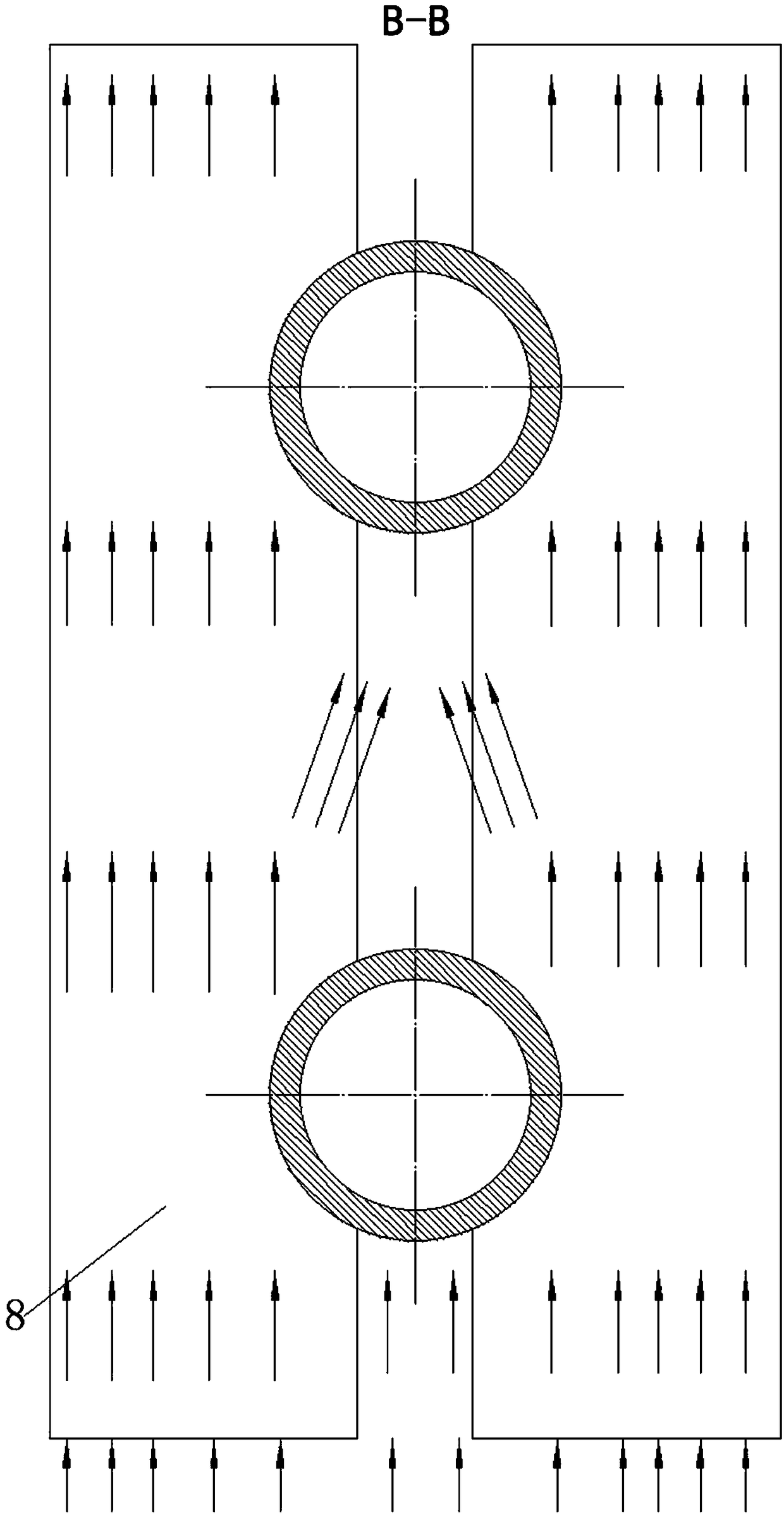

Flue gas deep cooler for achieving gas-liquid-solid condensation and absorbing and restraining low-temperature corrosion

PendingCN108413428AChange directionReduce flow rateLighting and heating apparatusCombustion technology mitigationPower stationFlue gas

The invention discloses a flue gas deep cooler for achieving gas-liquid-solid condensation and absorbing and restraining low-temperature corrosion. The flue gas deep cooler comprises a left pipe plate, a middle pipe plate, a right pipe plate, an anti-abrasion polished pipe, a bent type heat exchange base pipe, a plurality of drainage gap slope type anti-impact wear-resisting H-shaped fins and a plurality of H-shaped fins, wherein the anti-abrasion polished pipe is located on the flue gas impact side and installed on the left pipe plate, the middle pipe plate and the right pipe plate, the benttype heat exchange base pipe is located above the anti-abrasion polished pipe, internally contains circulation cooling water, and is installed on the left pipe plate, the middle pipe plate and the right pipe plate for resisting flue gas impact, the drainage gap slope type anti-impact wear-resisting H-shaped fins are installed on the bent type heat exchange base pipe, and the H-shaped fins are located above the drainage gap slope type anti-impact wear-resisting H-shaped fins and installed on the bent type heat exchange base pipe. The flue gas deep cooler can be widely applied to power station boiler and industrial boiler flue gas treating systems.

Owner:QINGDAO DANENG ENVIRONMENTAL PROTECTION INC

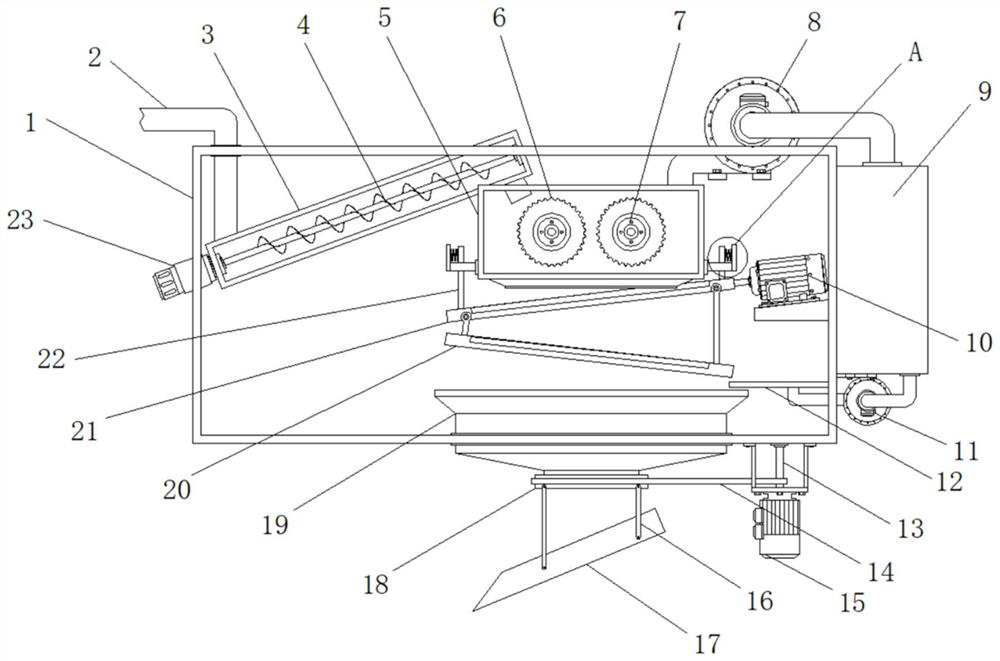

Auxiliary threshing and cleaning device of rice harvester

PendingCN114402816AFast threshingAdjust delivery speedThreshersElectric machineAgricultural engineering

The auxiliary threshing and cleaning device comprises a device body and a feeding pipeline, the feeding pipeline is arranged on one side of the top end of the device body, a conveying chamber is arranged below the feeding pipeline, and a lifting auger is movably connected into the conveying chamber; a first driving motor is fixedly connected to one side of the conveying chamber, the output end of the first driving motor is fixedly connected with a lifting auger through a coupler, and a threshing chamber is arranged on the other side of the conveying chamber. According to the auxiliary threshing and cleaning device of the rice harvester, the discharging barrel, the discharging plate, the rotating disc, the rotating rod and the hanging bracket are arranged, the output end of a third driving motor drives the rotating disc to rotate through rotation of the rotating rod, so that the falling direction of the discharging plate is adjusted, the hanging bracket can adjust the inclination angle of the discharging plate, the harvester can be parked conveniently, and the discharging plate can be rotated while discharging; the discharging effect is better, and the problems that discharged materials are prone to accumulation and bagging is not convenient are solved.

Owner:益阳创辉农业机械装备有限公司

A self-relieving bolt

The invention discloses a self-pressure relief bolt, and belongs to the technical field of fasteners. The self-pressure relief bolt comprises a bolt head and a screw rod. A screwdriver groove is formed in the upper central position of the bolt head. Threads are formed on the outer ring surface of the screw rod. The screw rod is arranged at the lower central position of the bolt head. A pressure relief channel is arranged at the central position of the bolt head and the screw rod in the vertical axial direction. A plurality of corresponding pressure relief openings are formed in the screw rod from top to bottom. The pressure relief channel is provided with a guide pipe, and a fixed plate is welded to the lower end of the guide pipe. The fixed plate is welded and fixed to the lower portion of the screw rod, a spring is arranged in the guide pipe, one end of the spring is connected with the fixed plate, a sliding block is arranged at the other end of the spring, the sliding block is arranged on the upper portion of the guide pipe, and the sliding block is positioned in the pressure relief channel and is in sliding connection with the inner portion of the pressure relief channel. The self-pressure relief bolt has an automatic pressure relief function and can effectively reduce the pressure in a closed container.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

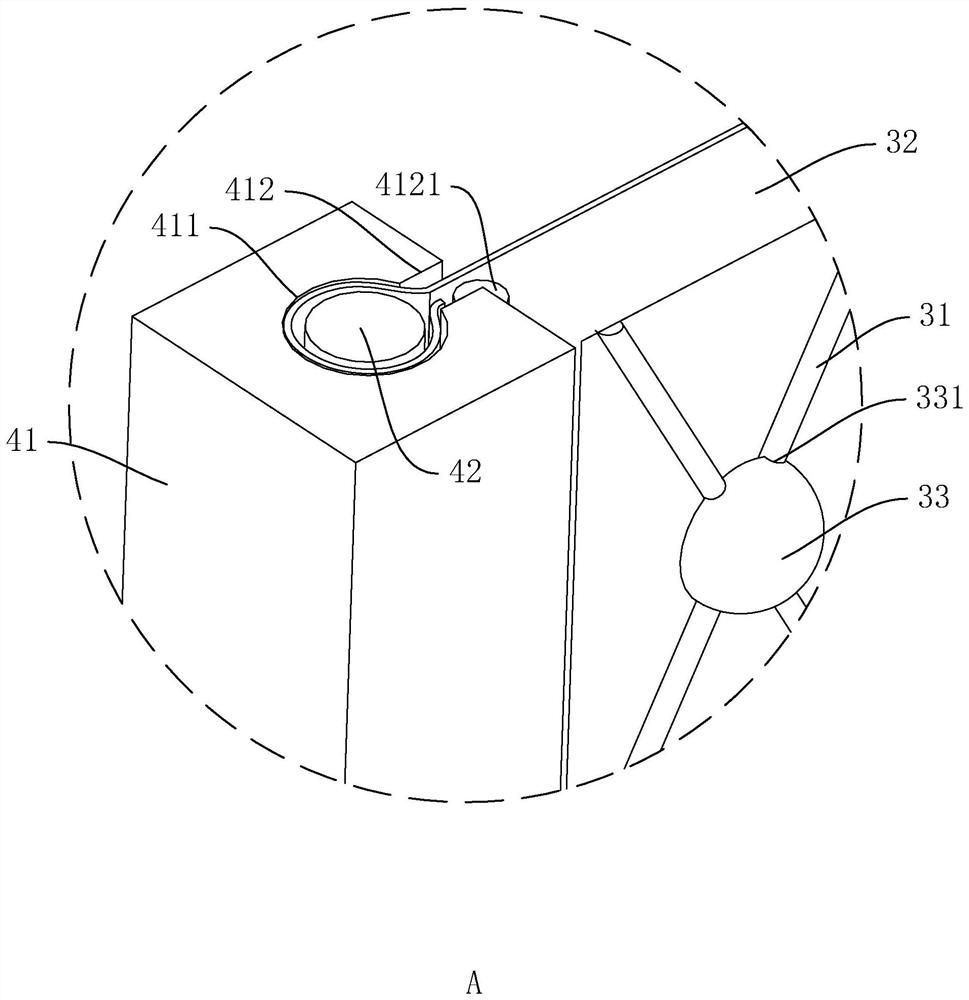

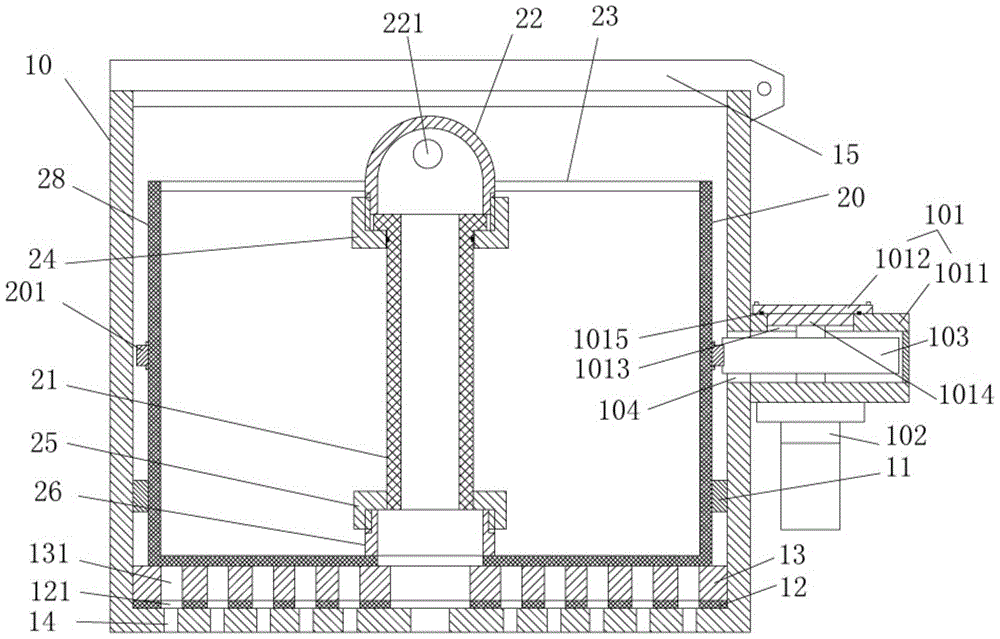

Compression deformation measuring device and measuring method for asphalt mixture compression test

PendingCN113533072AMitigates direct impact on the box doorMitigating damageMaterial strength using tensile/compressive forcesHydraulic cylinderStructural engineering

The invention relates to a compression deformation measuring device and a measuring method for an asphalt mixture compression test, relates to the field of asphalt mixture performance detection equipment, and aims to solve the problem that when a cylindrical asphalt mixture test piece is subjected to pressure test, a hydraulic cylinder continuously applies pressure to the cylindrical asphalt mixture test piece, a box door is damaged due to the fact that a cylindrical asphalt mixture test piece is splashed due to the fact that the cylindrical asphalt mixture test piece is prone to fracture when the strength of the cylindrical asphalt mixture test piece is not qualified in the prior art can be solved, and the device comprises a main machine box and a constant-temperature box, the constant-temperature box is installed on the main machine box, and a box door is installed at a box opening of the constant-temperature box, a protection assembly is arranged at the box opening, the protection assembly blocks the fractured cylindrical asphalt mixture test piece so as to protect the box door, and the protection assembly is further detachably connected with a connecting assembly connected with the box door. The device has the effect that the situation that the box door is damaged after the cylindrical asphalt mixture test piece is broken is relieved.

Owner:南通东洲工程项目管理有限公司

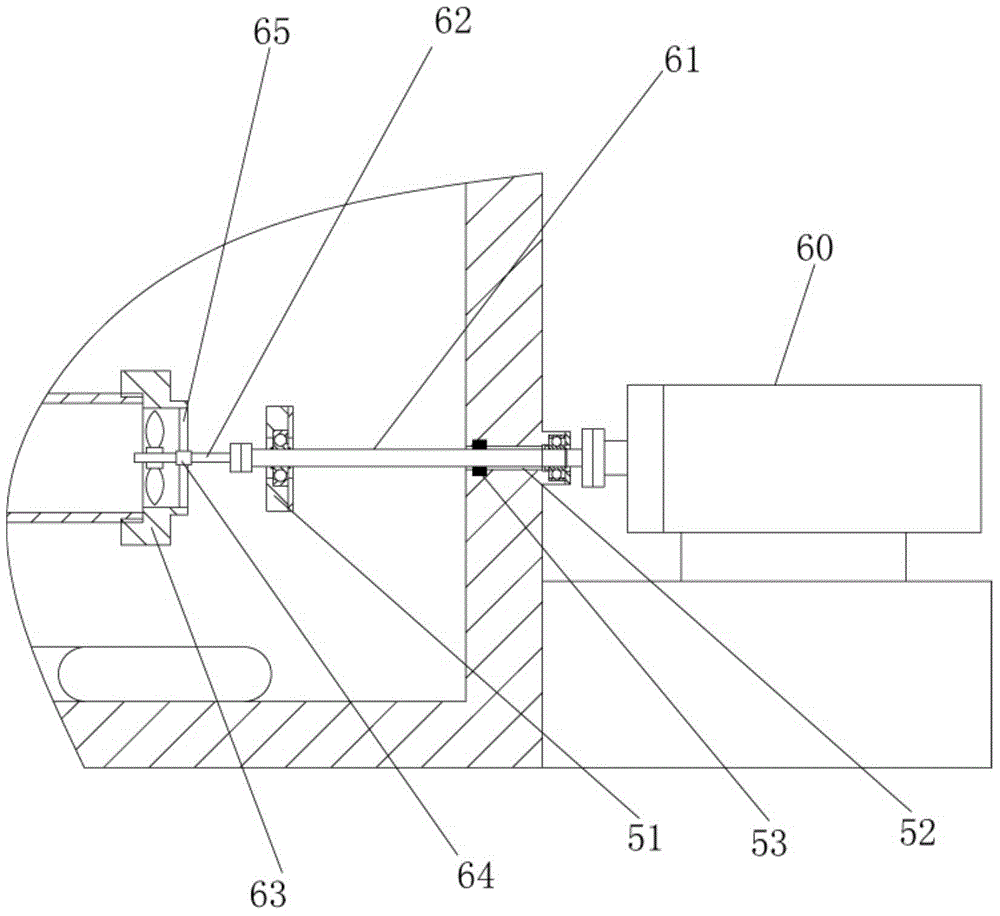

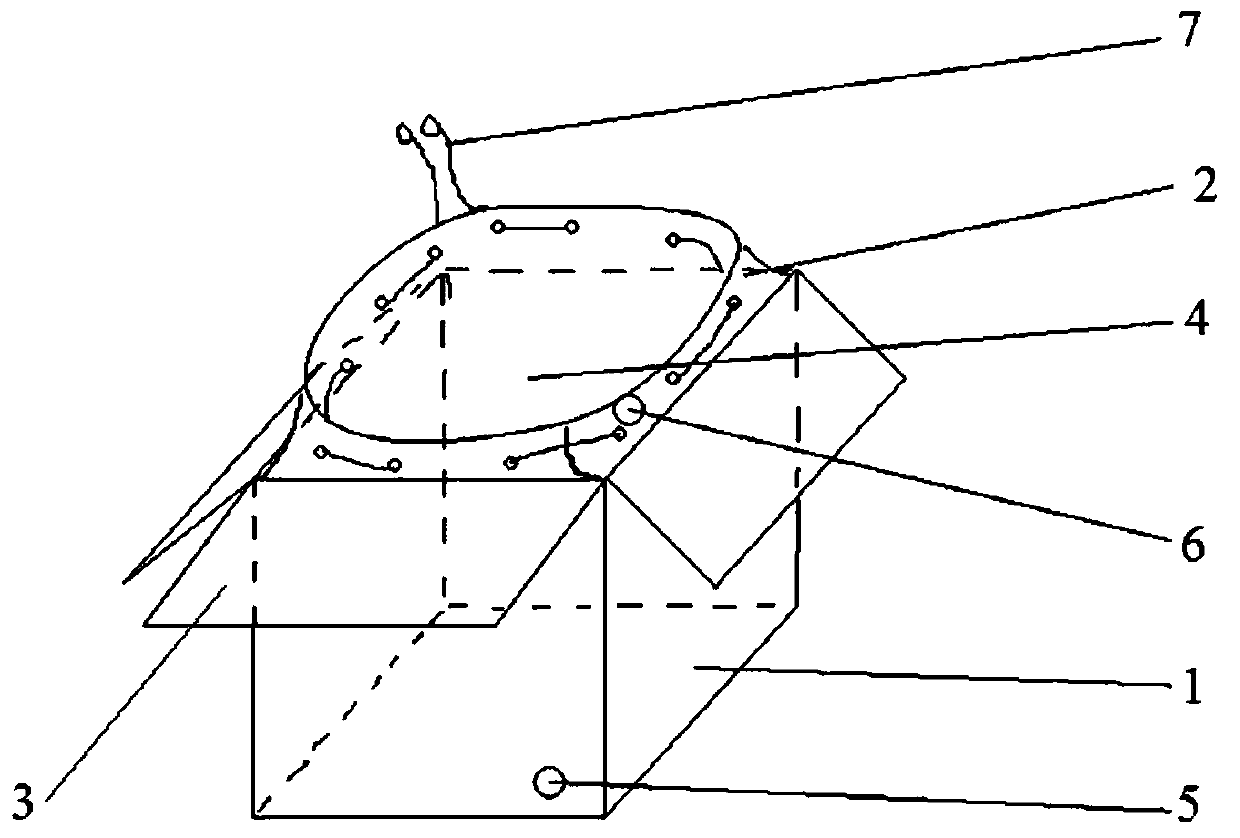

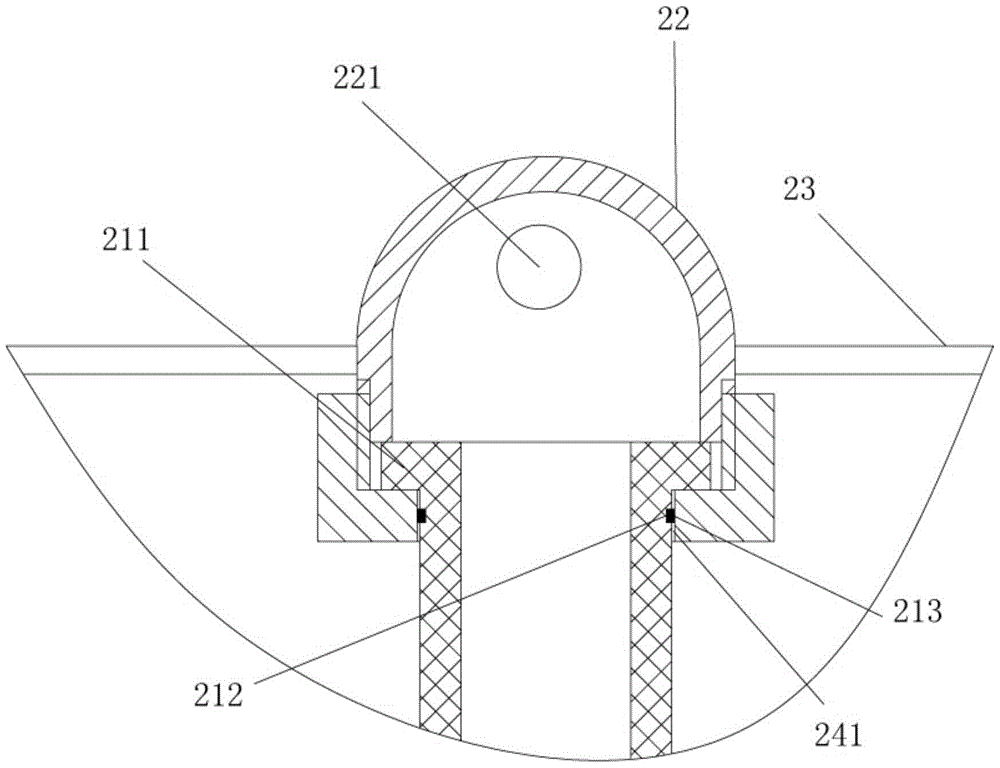

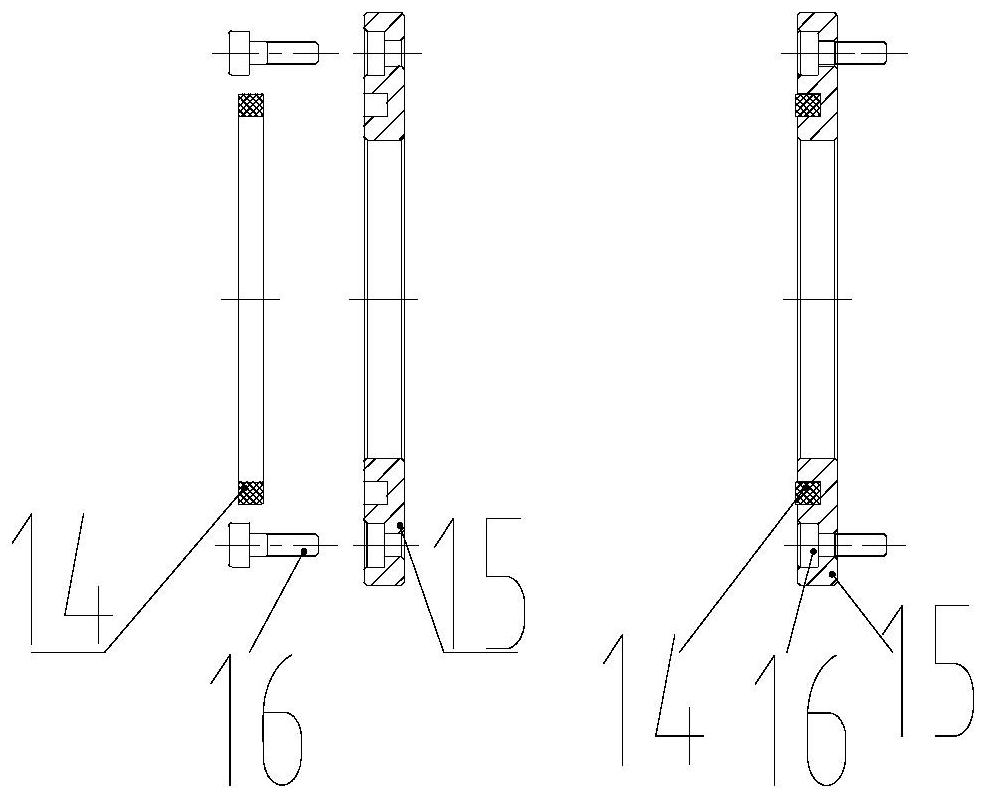

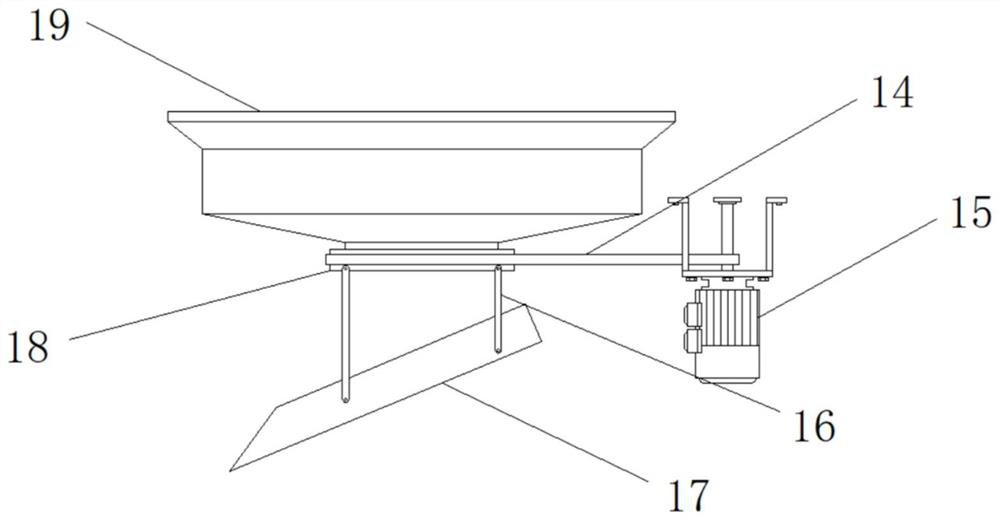

Rotary dyeing device for loose fiber dyeing machine

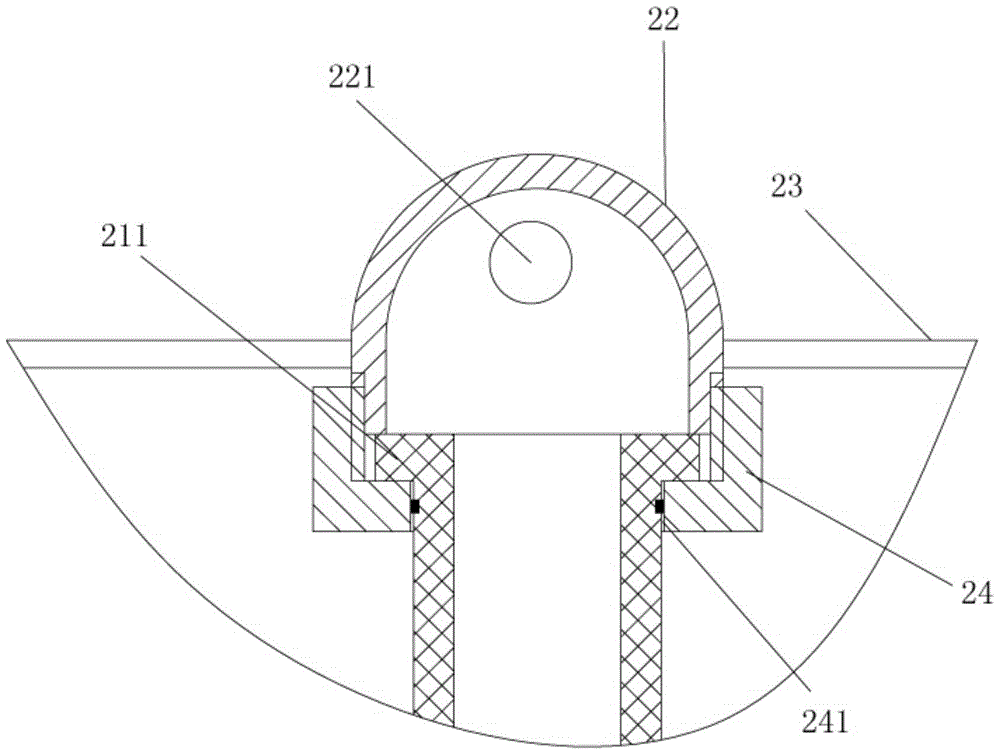

InactiveCN104674483BEasy maintenance and repairReduce direct collisionTextile treatment containersTextile treatment with treating outlet contectFiberGear wheel

The invention discloses a rotary type dyeing device for a loose fiber dyeing machine. The rotary type dyeing device comprises a dyeing cylinder and a fiber cage, wherein the fiber cage is placed in the dyeing cylinder; a limiting ring is arranged on the inner side wall of the dyeing cylinder; the outer wall of the fiber cage is tightly clung to the inner side wall of the limiting ring; a buffer pad is fixed on the bottom plate of the dyeing cylinder; a wear-resisting lubricating block is fixed on the buffer pad; the bottom of the fiber cage is pressed against the wear-resisting lubricating block; a rotary gear ring is fixed on the outer wall of the fiber cage; a gear housing is arranged on the outer wall of the dyeing cylinder; a rotary motor is fixed on the bottom of the gear housing; an output shaft of the rotary motor extends into the gear housing; a drive gear is fixed on the output shaft of the rotary motor; the drive gear partially penetrates through a connecting through slot in the side wall of the dyeing cylinder and extends into the dyeing cylinder; the drive gear is engaged with the rotary gear ring. The rotary type dyeing device is provided with a buffer mechanism, so that the direct collision is reduced when the fiber cage is lifted into a dyeing cylinder, and the service life of the fiber cage is prolonged; meanwhile, the fiber cage can be rotated, so that the sprayed dyes are enabled to be uniform.

Owner:吴江市永达丝绸整理有限责任公司

Ultrasonic cleaning equipment for electronic cigarette

PendingCN112024526AAchieve the purpose of purificationReduce energy lossCleaning using liquidsMegasonic cleaningEngineering

The invention belongs to the technical field of ultrasonic cleaning equipment, and provides the ultrasonic cleaning equipment for an electronic cigarette. The ultrasonic cleaning equipment particularly comprises an inner container and a vibrator, wherein the inner container comprises cleaning liquid; and the vibrator makes contact with the inner container and is used for driving the inner container to vibrate, and the inner container vibrates to drive the cleaning liquid to vibrate so as to be used for cleaning the electronic cigarette.

Owner:SHENZHEN HONGZHANTONG TECH

A loose fiber dyeing device with a rotatable fiber cage

InactiveCN104790145BStir wellPromote circulationTextile treatment machine arrangementsTextile treatment with treating outlet contectFiberImpeller

The invention discloses a loose stock dyeing device with a rotatable fiber cage. The loose stock dyeing device comprises a dyeing vat, the fiber cage, a heating coil pipe and a central spraying pipe, a dye tank is fixed to the bottom of the dyeing vat, a rotary wheel is arranged between the fiber cage and a bottom plate of the dyeing vat, and the rotary wheel is connected with a driving wheel through a driving belt. A mounting hole is formed in the upper end face of the rotary wheel, a mounting shaft corresponding to the mounting hole is arranged at the bottom end of the fiber cage, a locating hole is formed in the top of the fiber cage, locating blocks are arranged on the two sides of the locating hole, the upper side of the central spraying pipe is clamped by the locating blocks, and dye through holes communicated with the dye tank are evenly formed in the bottom plate of the dyeing vat. A stirring impeller is arranged in the dye tank, the stirring impeller is arranged on a lead screw, the end of the part, stretching out of the dye tank, of the lead screw is in pivot joint with a stirring handle, and a dye adding opening is formed in the position, on one side of the lead screw, of the side wall of the dye tank. When the fiber cage is hoisted down into the dyeing vat, the fiber cage does not rigidly collide with the dyeing vat, dye is not likely to be caked when added, the fiber cage rotates, and therefore dyeing is more even.

Owner:湖州市菱湖东方丝织厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com