Loose fiber dyeing machine with rotatable fiber cage

A fiber cage and rotating technology, which is applied in spraying/spraying textile material processing, textile material carrier processing, textile material container processing, etc., can solve the problem of high replacement cost of fiber cage, easy extrusion damage of cylinder body, and increased maintenance cost and other problems, to achieve the effect of improving service life, reducing maintenance costs, and facilitating maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

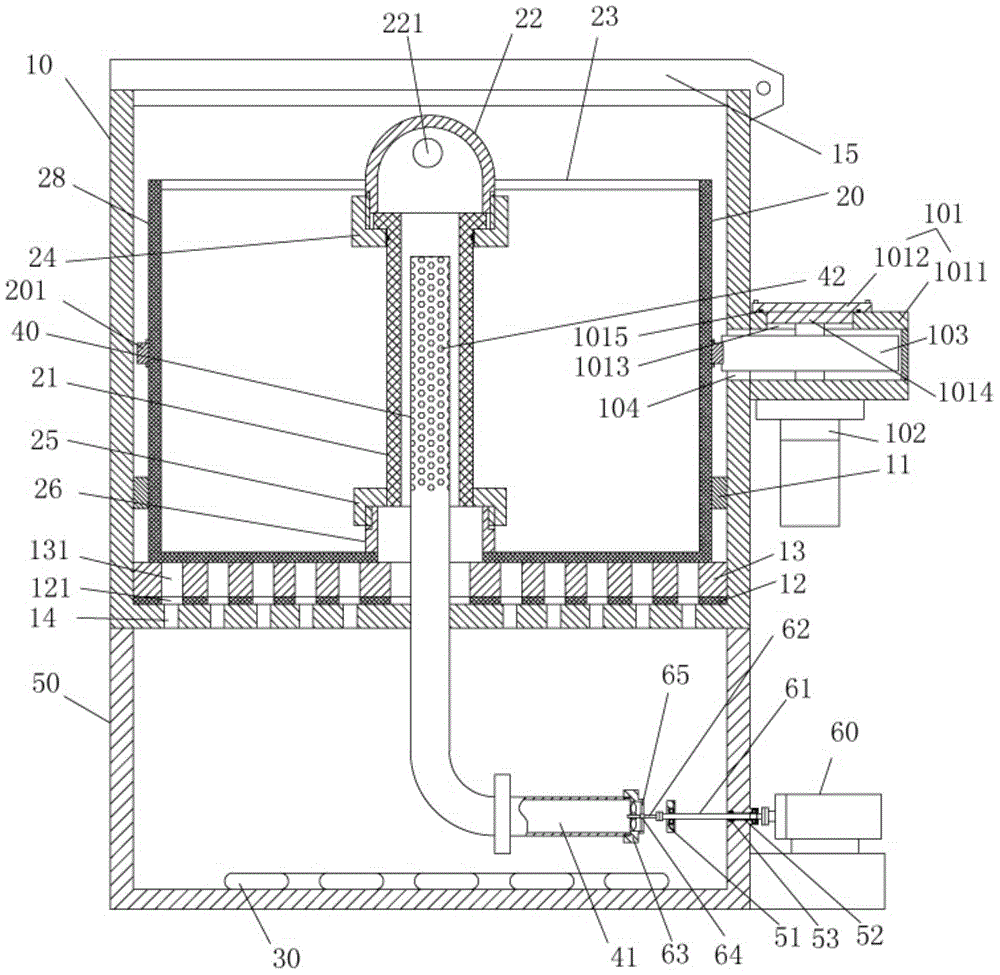

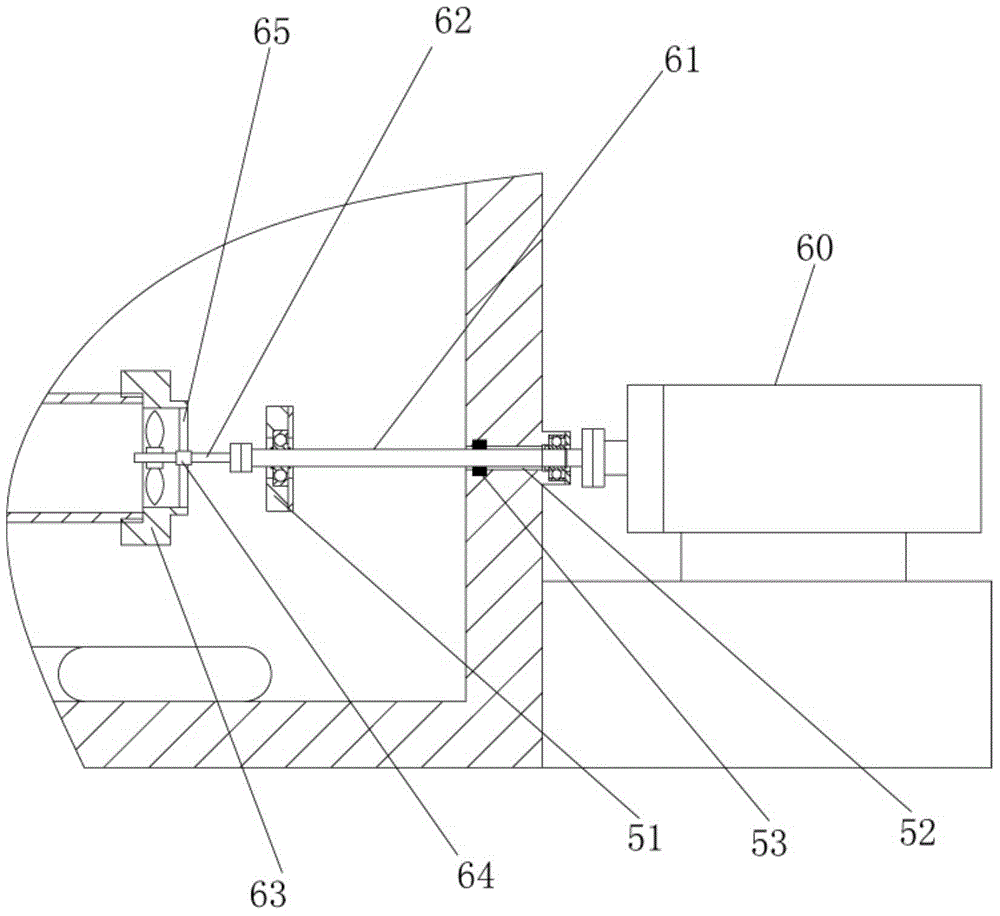

[0022] Examples, see e.g. Figures 1 to 2 Shown, a kind of fiber cage rotatable loose fiber dyeing machine, comprises dye vat 10, fiber cage 20, heating coil 30 and center spray pipe 40, the bottom of described dye vat 10 is fixed with dye tank 50, and dye tank 50 is fixed with The heating coil 30 and the outer wall of the dye tank 50 are fixed with a driving motor 60, the output shaft of the driving motor 60 is connected with an intermediate rotating shaft 61 through a coupling, the intermediate rotating shaft 61 extends into the dye tank 50, and the intermediate rotating shaft 61 passes through the bearing Fixed on the dye tank 50, the other end of the intermediate rotating shaft 61 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com