Rotary dyeing device for loose fiber dyeing machine

A dyeing device and dyeing machine technology, applied in the direction of textile material contact export textile material processing, textile material carrier processing, textile material container processing, etc., can solve the problem of limited effect, easy extrusion damage of the cylinder, damage to the dyeing vat, etc. problems, to achieve the effect of convenient maintenance and repair, reduce direct collision and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

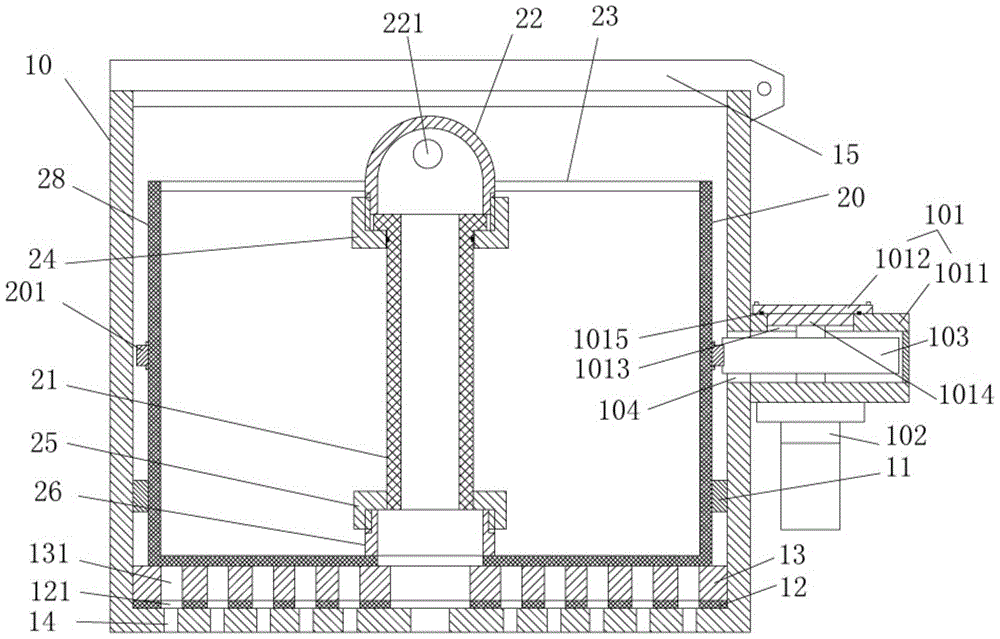

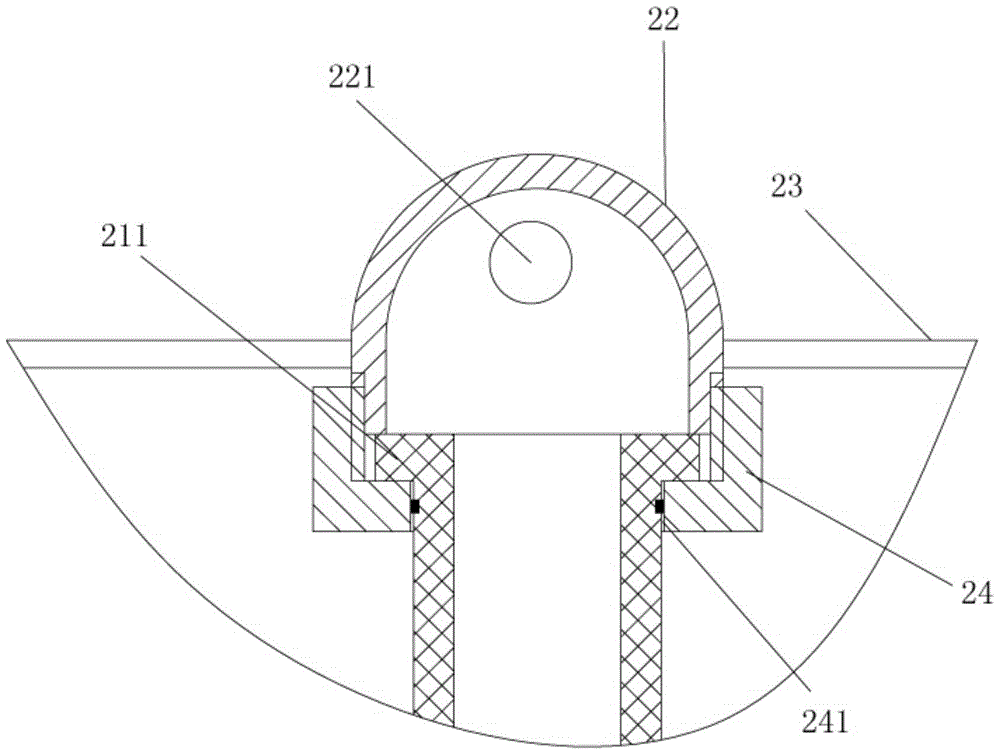

[0018] Examples, see e.g. Figures 1 to 2 Shown is a rotary dyeing device for a loose fiber dyeing machine, comprising a dyeing vat 10 and a fiber cage 20, the fiber cage 20 is placed in the dyeing vat 10, the inside wall of the dyeing vat 10 has a limit ring 11, and the outer wall of the fiber cage 20 Close to the inner side wall of the limit ring 11, a buffer pad 12 is fixed on the bottom plate of the dyeing vat 10, and a wear-resistant lubricating block 13 is fixed on the buffer pad 12. The bottom of the fiber cage 20 is pressed against the wear-resistant lubricating block 13, and the fiber The outer wall of the cage 20 is fixed with a rotating ring gear 201, the outer wall of the dye vat 10 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com