Soaking type acoustic cavitation sewage water heat exchanger

A technology of heat exchanger and acoustic cavitation, which is applied to the types of heat exchangers, indirect heat exchangers, and cleaning heat transfer devices, etc., which can solve the problems of sludge accumulation, heavy cleaning workload, and increased system and equipment resistance. , to achieve the effects of strengthening disturbance and turbulence, facilitating maintenance and overhaul, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

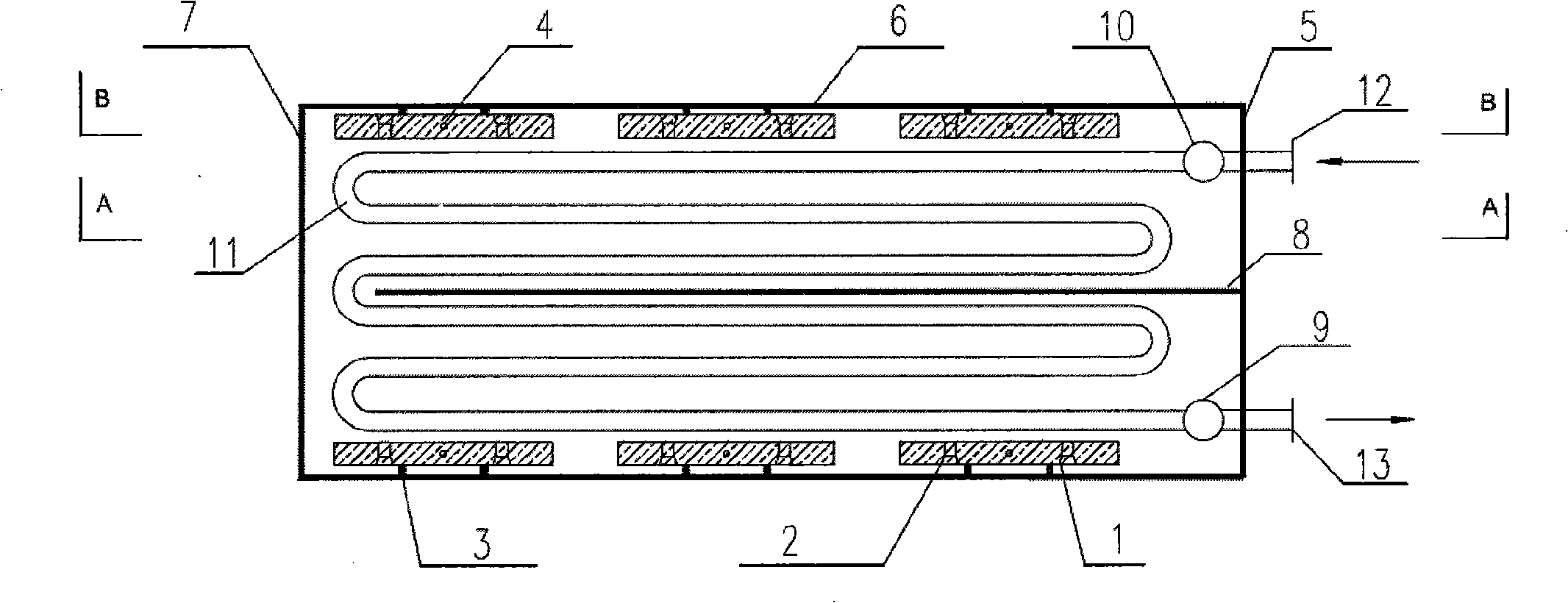

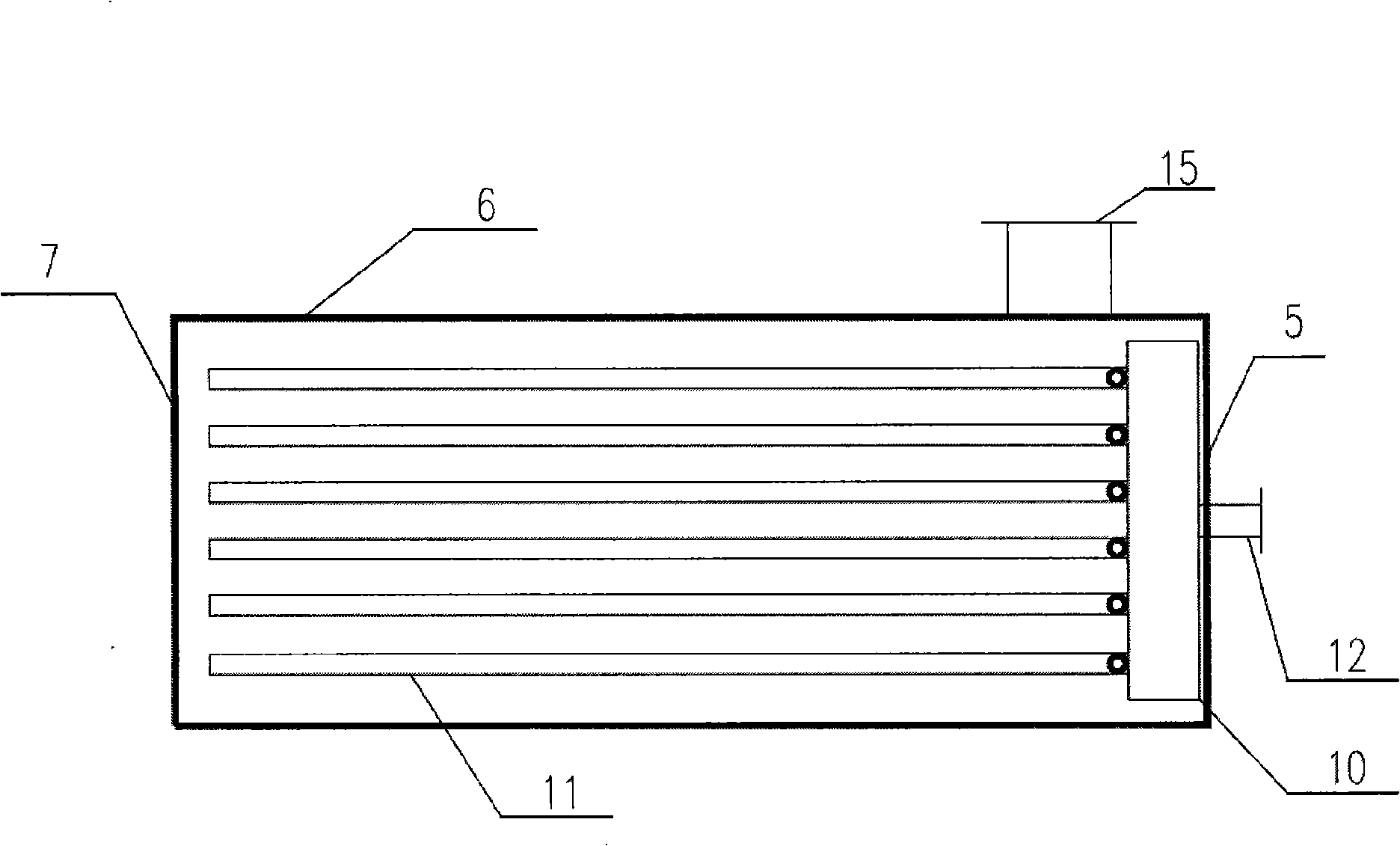

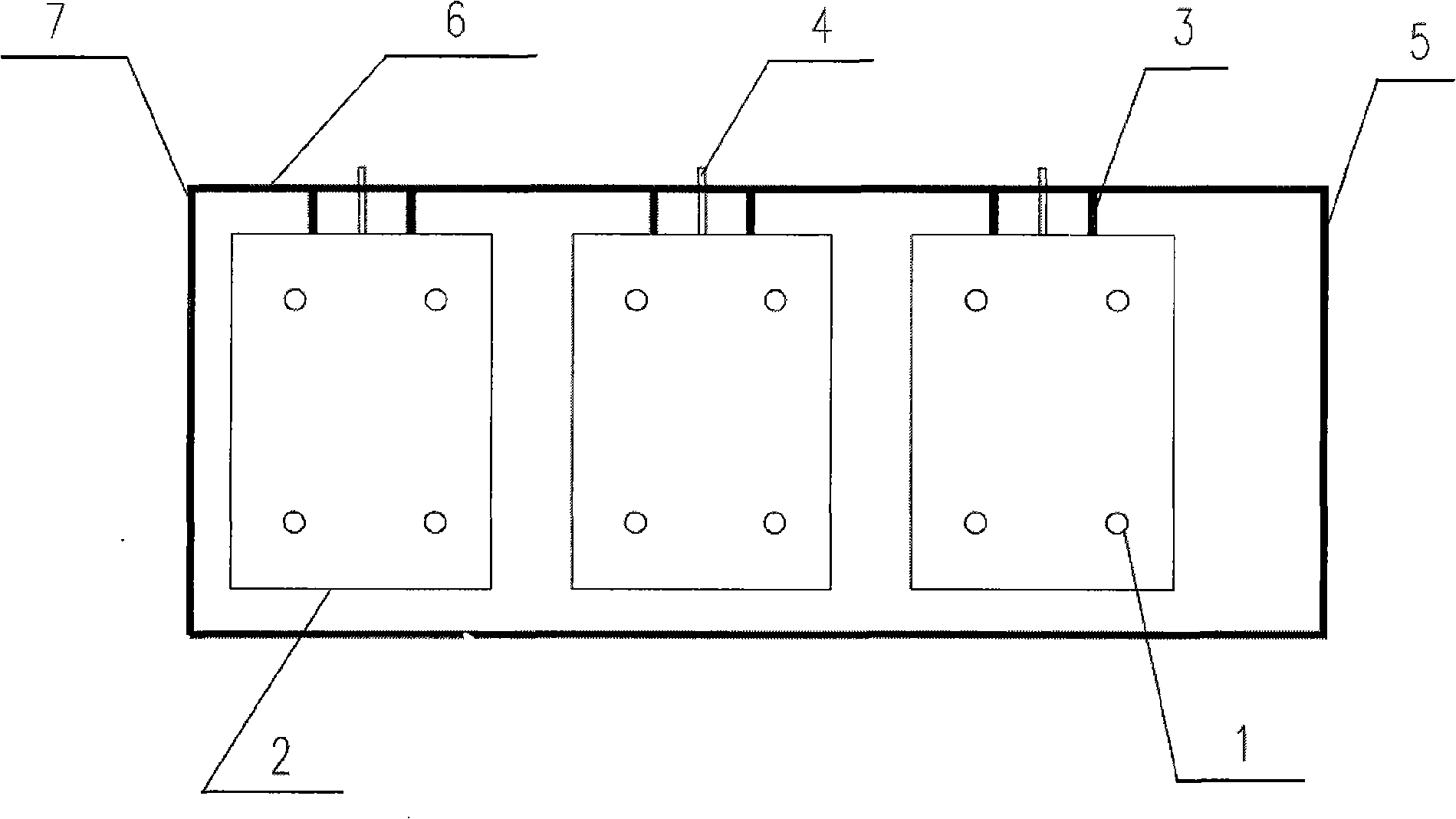

[0021] When realizing the present invention, the heat exchanger partition plate 8 is welded on the right head 5 of the heat exchanger. The medium inlet 12 in the heat exchange tube is welded to the liquid separator header 9, and the medium outlet 13 in the heat exchange tube is welded to the liquid collector header 10. The medium in the tube is distributed to the heat exchange tube bundle 11 by the liquid separator header 9, and exchanged with sewage After heating, it is discharged through the liquid collector header 10 and the medium outlet 13 in the heat exchange tube to form a medium loop in the tube. In the heat exchanger shell 6, the heat exchange tube bundles 11 can be arranged in a straight line or alternately, and the inlets and outlets thereof are welded to the liquid separator header 9 and the liquid collector header 10 respectively. The sewage inlet 14 and the sewage outlet 15 are arranged opposite to the medium inlet 12 in the heat exchange tube and the medium outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com