Drilling simulation device for bolt drawing test

A pull-out test and simulation device technology, applied in the direction of measuring device, installation of anchor rods, testing of mechanical parts, etc. problems, to achieve the effect of reducing material strength, saving manufacturing costs, and saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

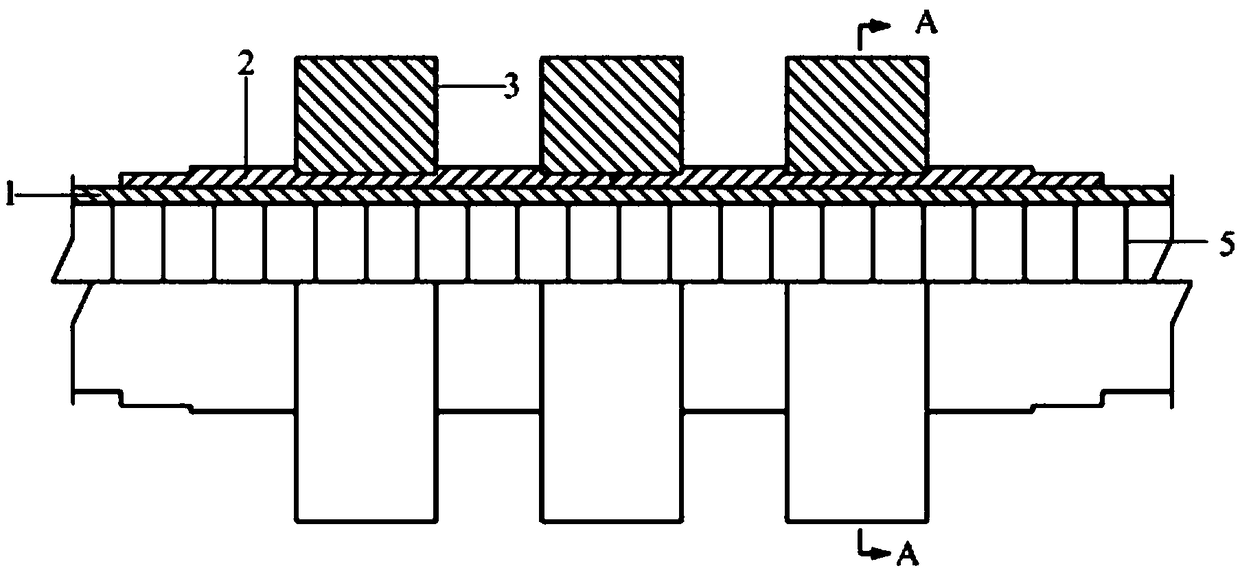

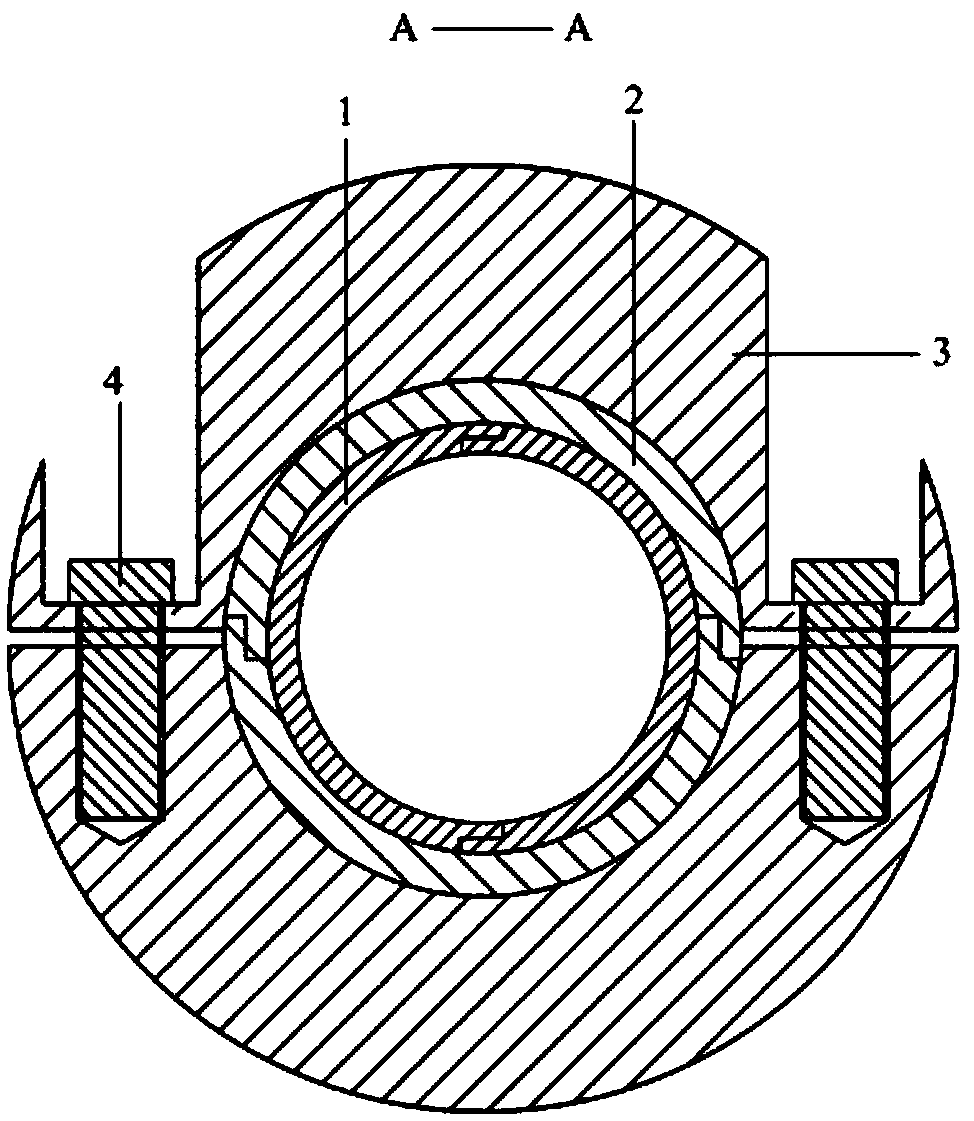

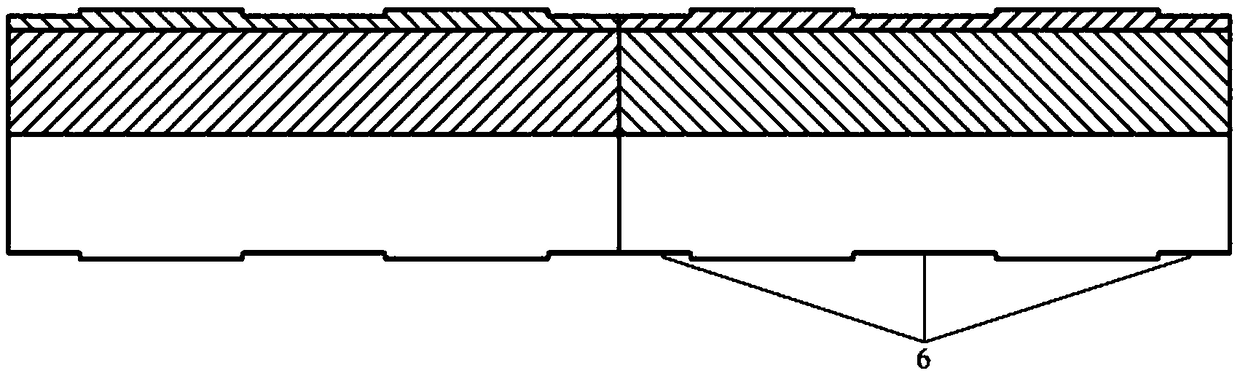

[0024] combine Figure 1 to Figure 6 , the drilling simulation device of the present embodiment comprises a butt-joint steel pipe 1 formed by butting two semicircular pipe walls in the axial direction, and the inner wall of the butt-joint steel pipe has a groove 5 for increasing the coefficient of friction; on the outer wall of the butt-joint steel pipe There are two semicircular buffer steel pads 2 butted on each other on the upper cover, and a positioning groove 6 is arranged on the outer wall of the buffer steel pad, and a steel hoop 3 fixed by a bolt 4 is arranged in the positioning groove.

[0025] The manufacturing method of the butt-joint steel pipe 1 is to choose a thick-walled steel pipe with high rigidity and hardness, a wall thickness of 5mm, an outer diameter of 53mm, and a length of 1.5m as a raw material, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com