Stirring drum internally provided with grooves and stirring mill

A mixing drum and mill technology, applied in grain processing, etc., can solve the problems of inconvenient use, large lining area, and high labor intensity of the stirring mill, and achieve the goal of reducing the probability of direct collision with the inner wall of the mixing drum and reducing the wear rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

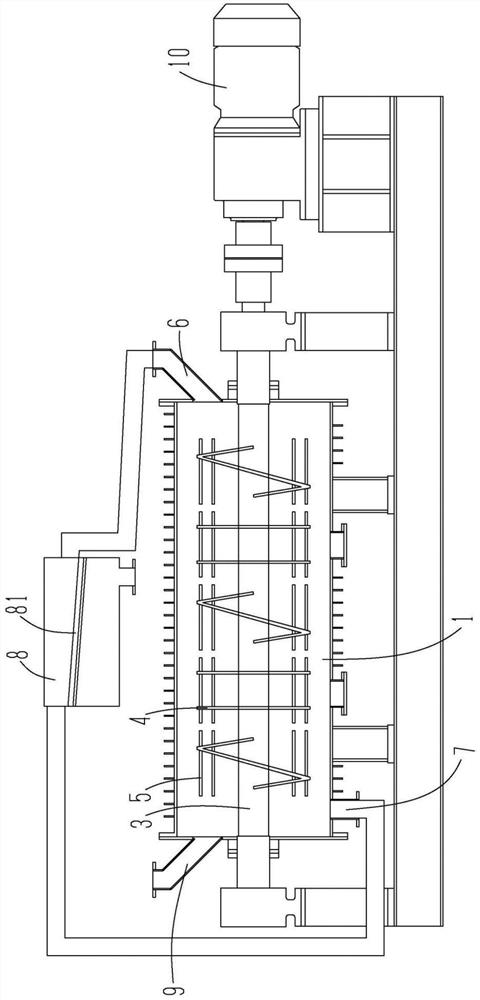

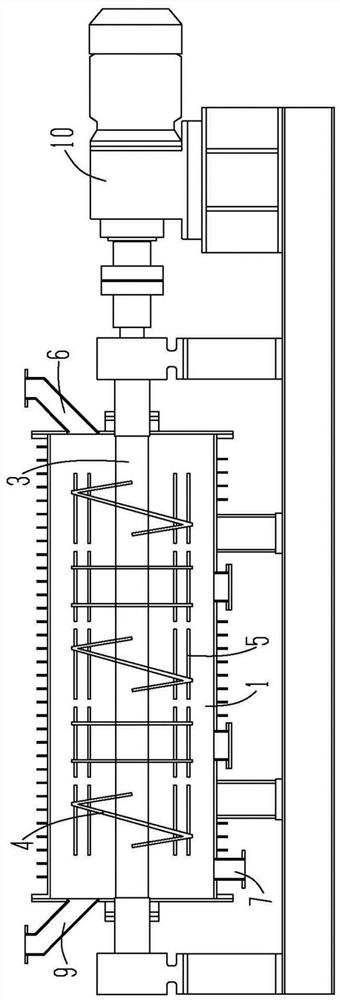

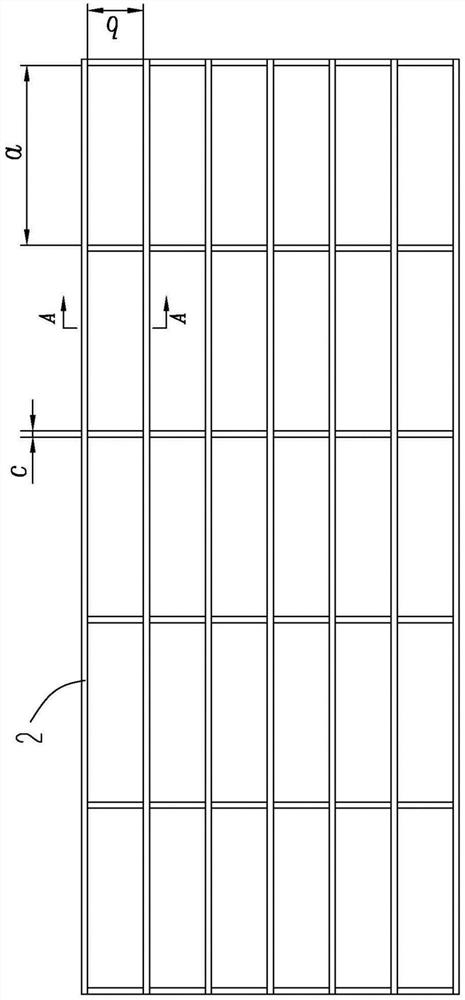

[0035] Please see Figure 1 to Figure 4 , a mixing drum 1 with grooves inside, the main body is the mixing drum 1, which is filled with grinding media, the inner wall of the mixing drum 1 is arranged with a number of lining plates 2 at intervals, and the gap between the lining plates 2 and the lining plates 2 is formed The grooves are arranged along the radial and axial directions of the mixing drum 1, and all the grooves are combined to form a grid shape. When the grinding medium is doing centrifugal movement, it is moved to the inner wall of the mixing drum 1 by the action of centrifugal force. Since the grinding medium moves at a high speed during the grinding process, it is easy to be stuck in the groove; after the maximum number of all grinding media is stuck in the groove, A protective layer will be formed, and most of the other grinding media that do centrifugal movement will collide with the grinding media stuck in the groove and fixed on the inner wall of the mixing d...

Embodiment 2

[0045] Please see Figure 5 , different from the way of forming the grooves in Example 1: the inner wall of the mixing drum 1 is provided with a liner 2, the grooves are set on the liner 2, the grooves are arranged along the radial and axial directions of the mixing drum 1, all the grooves Combine to form a grid shape. The grinding medium is completely isolated from the mixing drum 1. Before the grinding medium is stuck into the groove, the lining plate 2 collides first; the lining plate 2 itself has a groove, and the grinding medium is stuck in the groove on the lining plate 2 to assist The liner 2 protects the mixing drum 1 and prevents the wear of the mixing drum 1; the grinding medium stuck in the groove also protects the liner 2 to a certain extent and reduces the wear rate of the liner 2.

Embodiment 3

[0047] Different from the way of forming the grooves in Embodiment 1 and Embodiment 2: the inner wall of the mixing drum 1 is directly provided with grid-shaped grooves, without fixing the liner 2, and the mixing drum 1 is directly made into the required shape in the early stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com