Fireproof door

A fire door and door leaf technology, applied in the field of fire doors, can solve the problems of slow process, single type of sealing strip, unable to block flames and poisonous smoke in time, and achieve the effect of prolonging service life and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

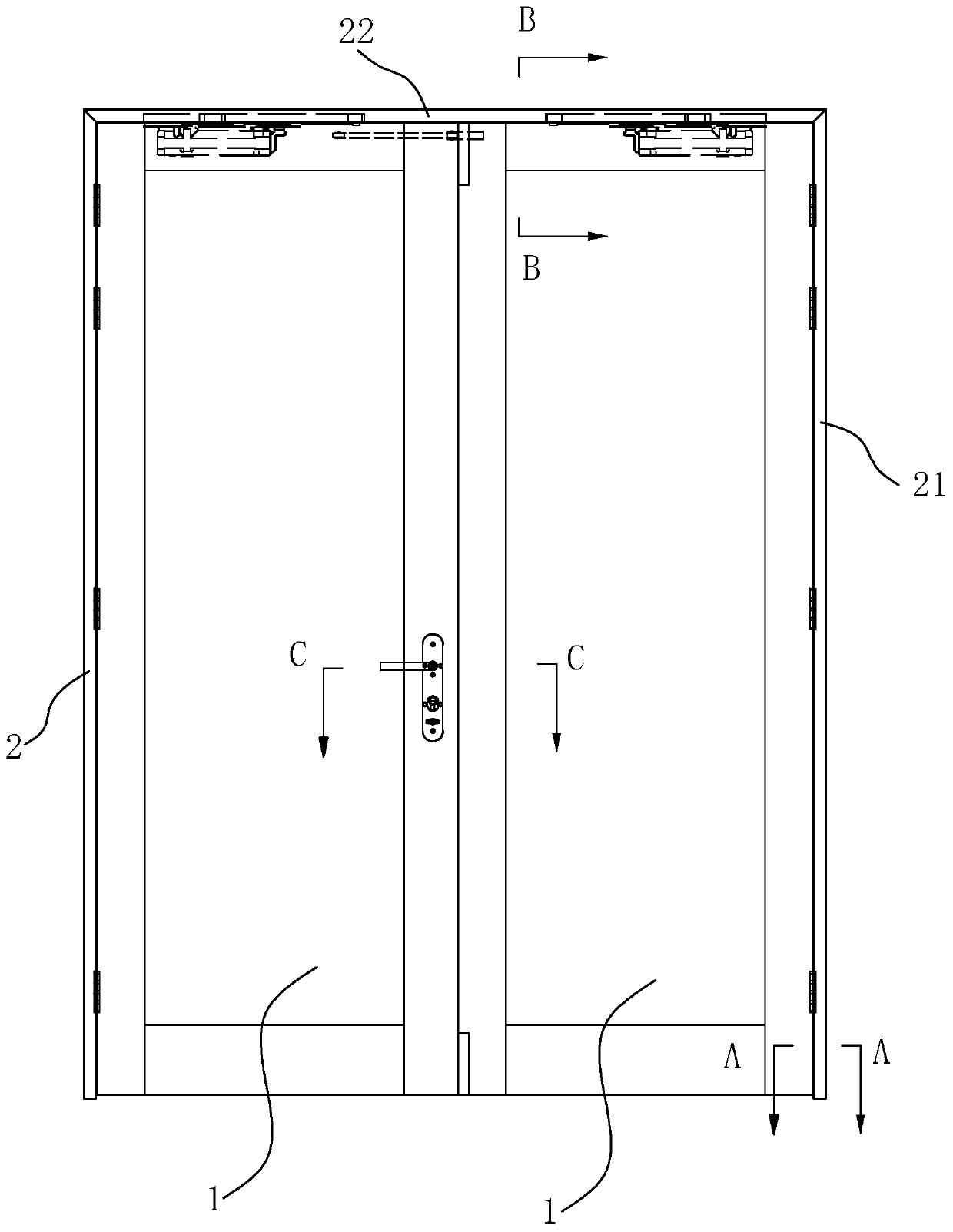

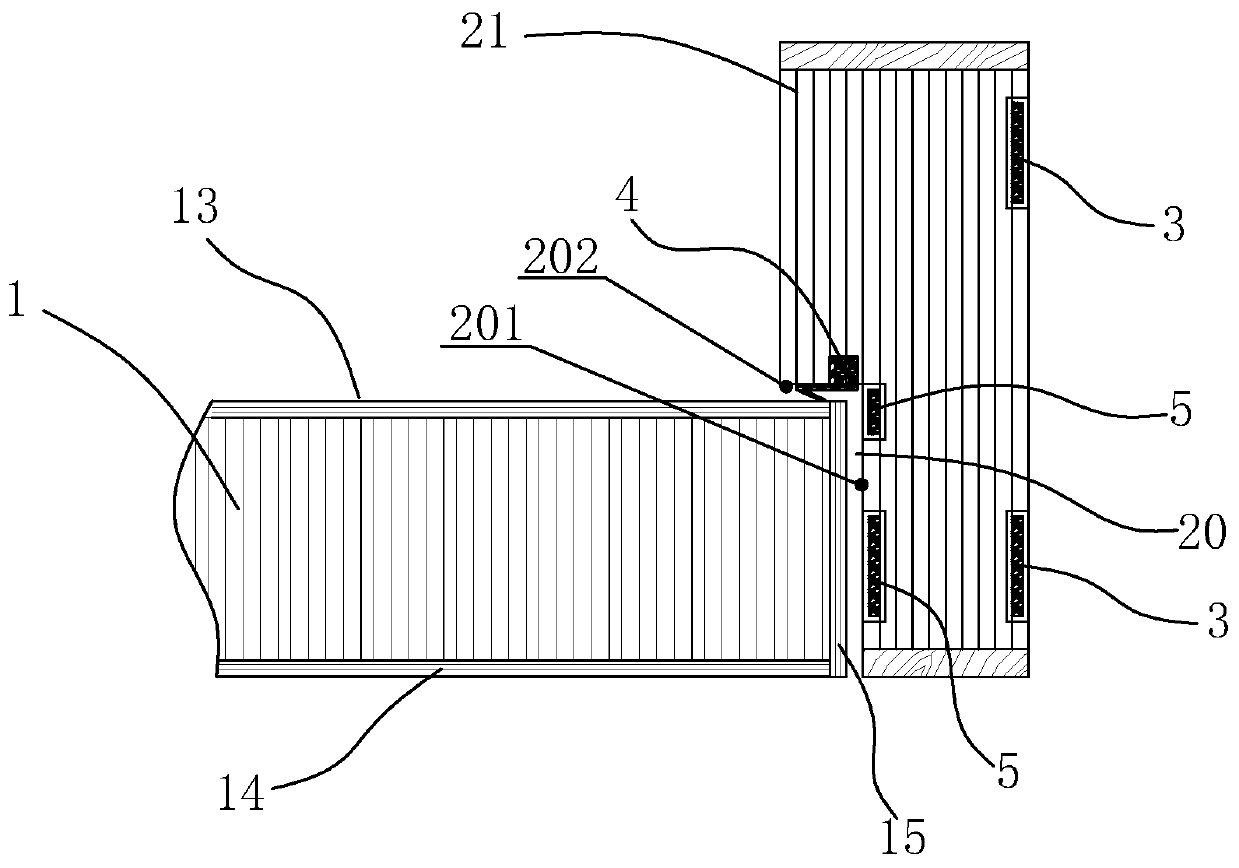

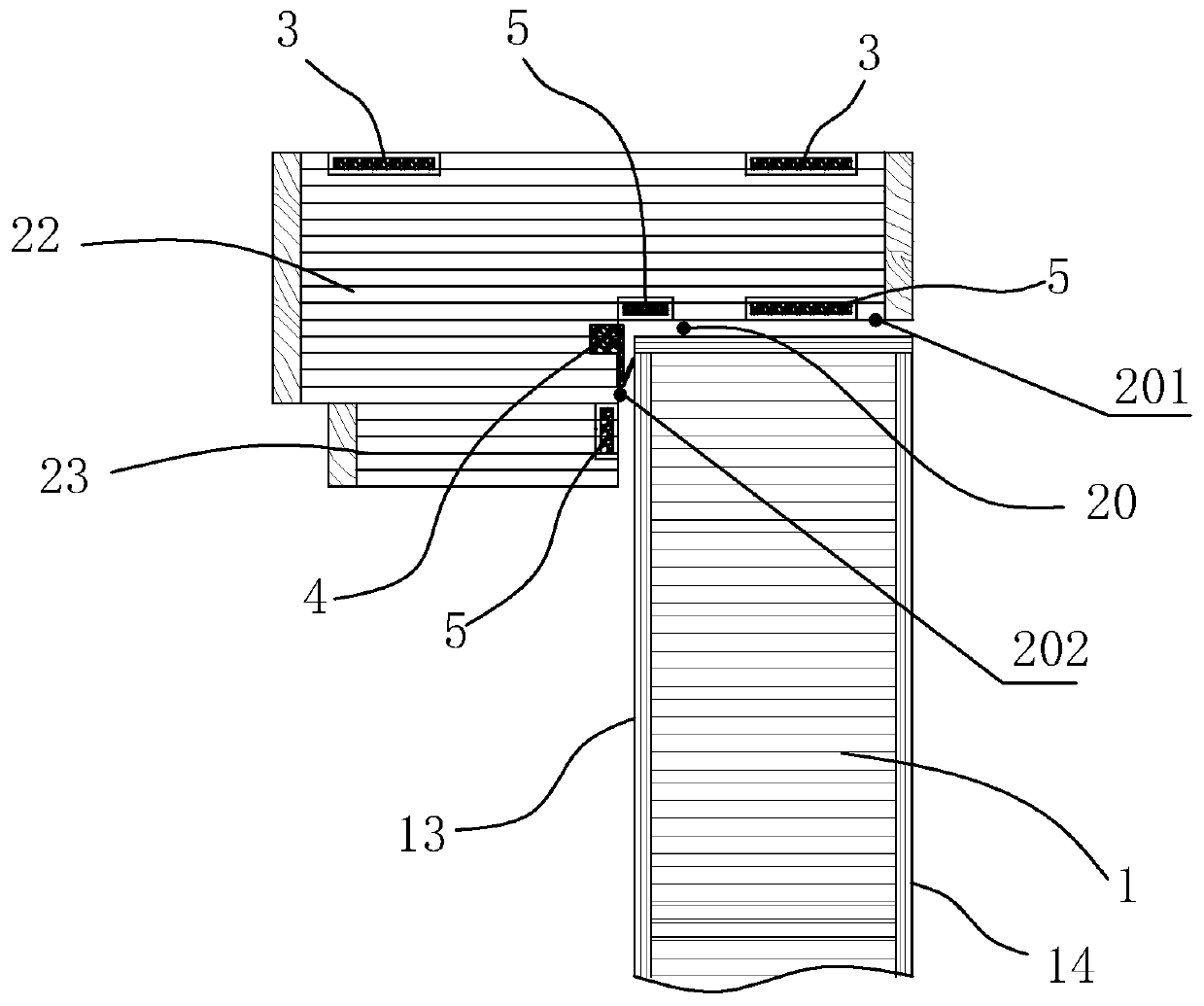

[0029] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

[0030] See attached Figure 1-7 , a fireproof door, comprising a door leaf 1 and a door frame 2, one side of the door frame 2 is connected to a wall, and the other side is provided with a groove 20 corresponding to the periphery of the door leaf 1.

[0031] Two first fireproof sealing strips 3 are embedded on the side where the door frame 2 is connected to the wall. The first fireproof sealing strip 3 is flat and integrally formed of expanded graphite material. There is an installation gap between the door frame 2 and the wall due to the installation process or the size of the wall, which is generally 2-20mm. The first fireproof sealing strip 3 can expand by more than 20 times when heated, and can effectively fill the installation gap , to prevent the installation gap through the fire and the entry of poisonous smoke.

[0032] The groove 20 is embedded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com