Patents

Literature

49results about How to "Fast threshing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

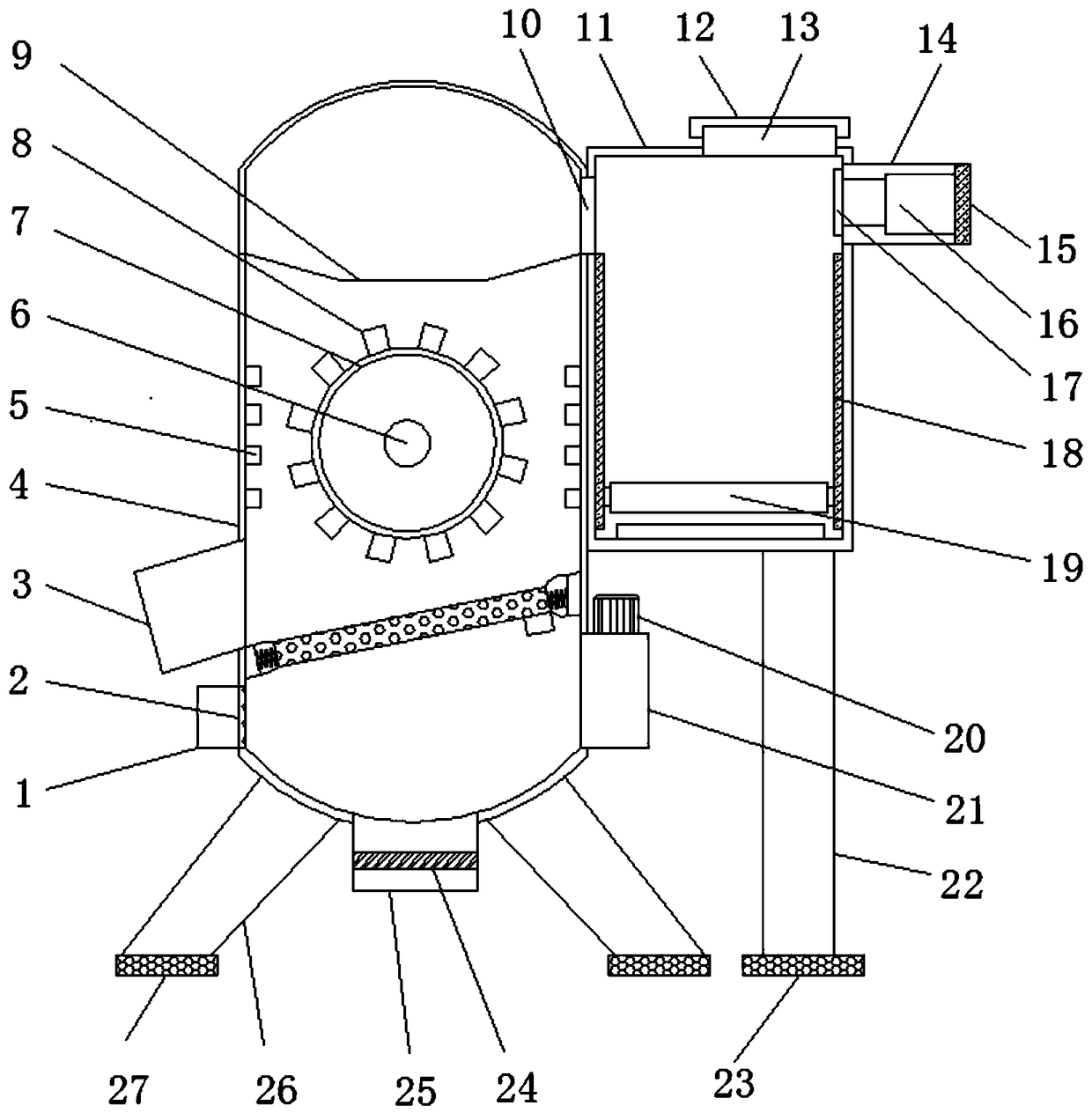

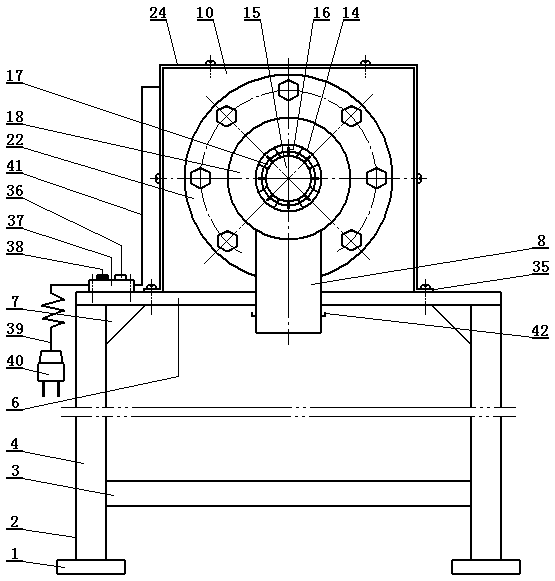

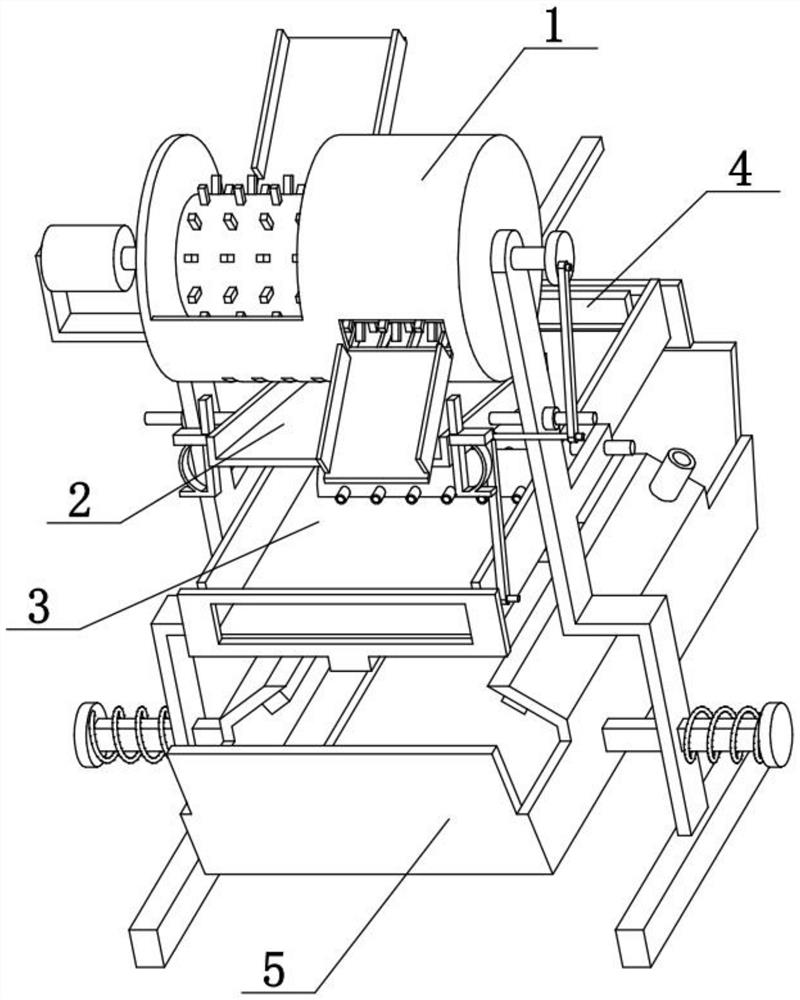

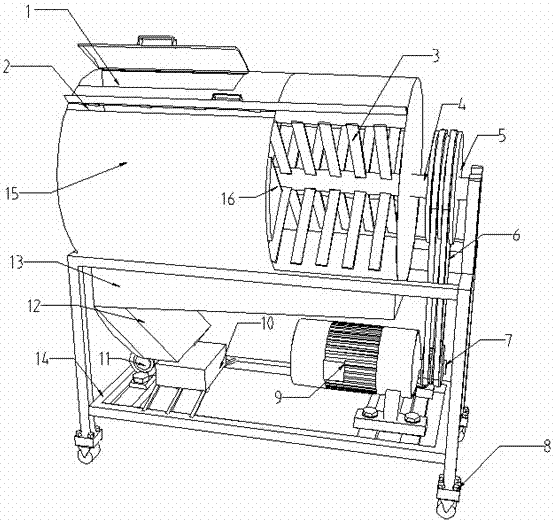

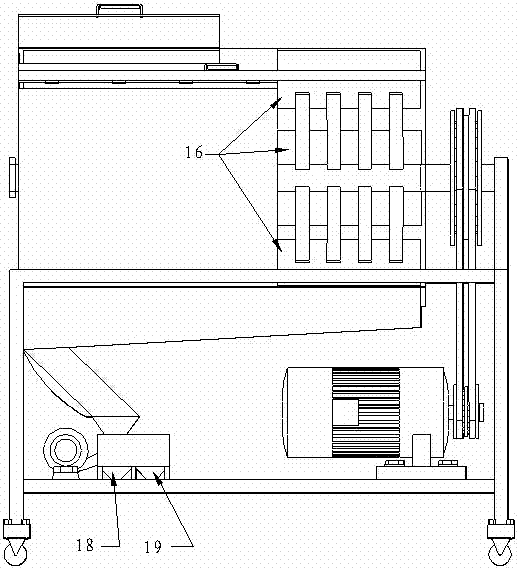

Plot seed threshing machine

The invention relates to the technical field of agricultural machinery and particularly discloses a plot seed threshing machine. The machine mainly comprises a vertical type fruit ear threshing system, a fan, a motor, a vibrating screen, a sorting fan and the like, wherein fruit ears, such as soybeans and the like, enter into a threshing chamber through a feeding port; a vertical type cylindrical concave plate and a spindle with spiral nail teeth are arranged in the threshing chamber; a spiral blade is arranged under the spindle; a high-speed rotating impurity-sucking fan is arranged above the spindle; when the spindle rotates at an intermediate speed, grains are separated by the cylindrical concave plate under the action of centrifugal force and under the rubbing action of the nail teeth and the cylindrical concave plate; stalks and big broken straws enter into a sorting system; chaffs and a majority of straws are discharged from a straw outlet, under the action of the spiral blade and speedily rotating fan; the grains and big broken fruit ears fall into a vibrating sorting screen; the broken fruit ears in the grains are filtered through grids; and the seeds fall into a seed receiving bucket while the broken fruit ears and straws are discharged from the straw outlet. By using the plot seed threshing machine, the residual quantity in the machine is almost zero and the time for cleaning the machine is shorter.

Owner:贾新民

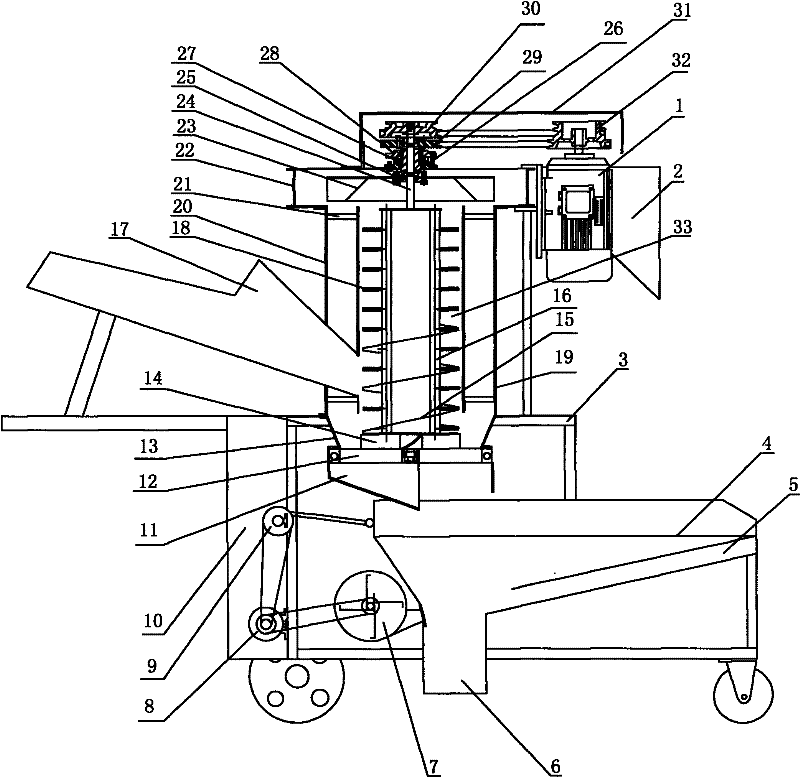

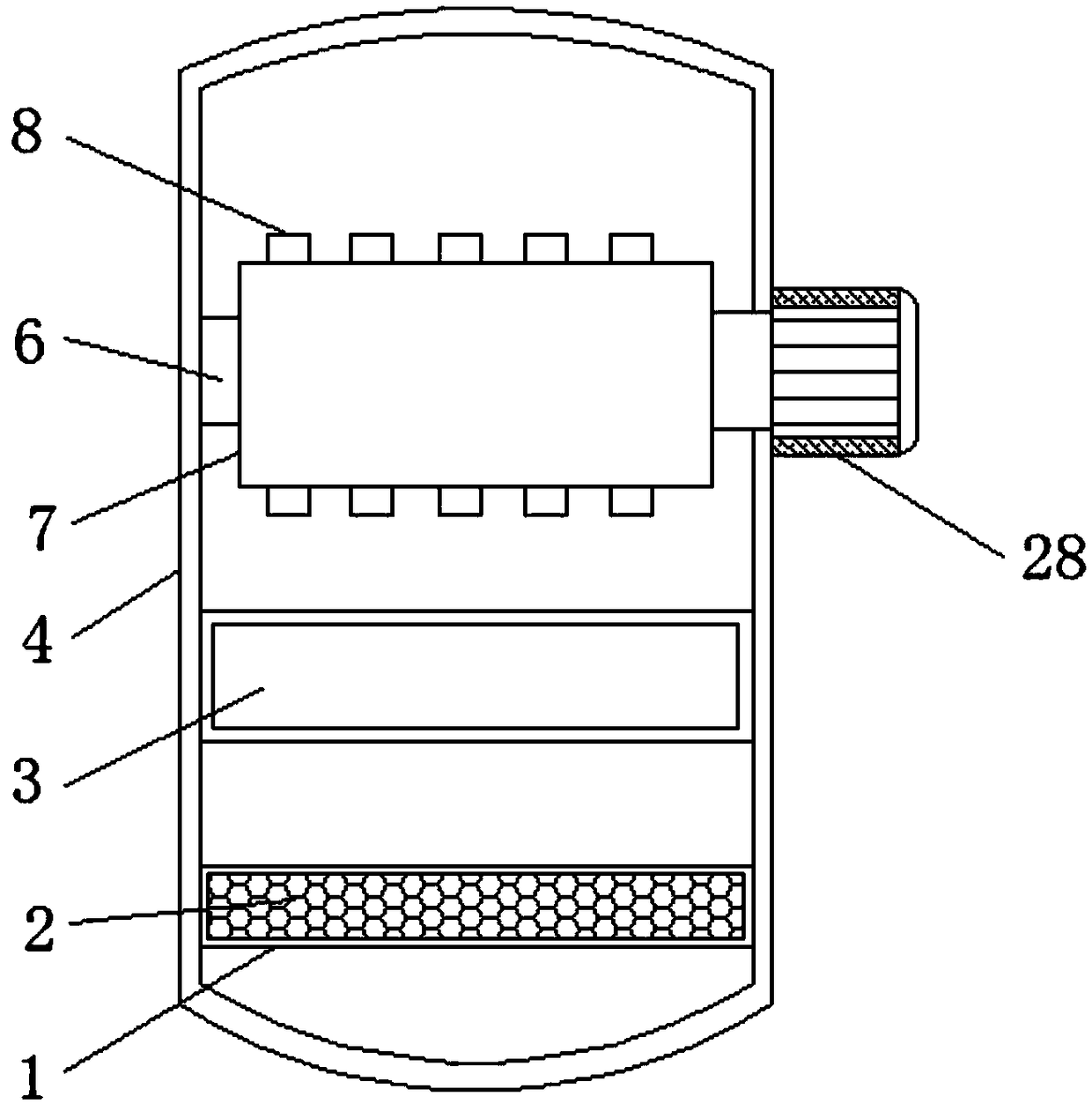

Sesame threshing machine

The invention relates to a sesame threshing machine, which mainly consists of a drive roll, a driven roll, an adjusting rail, a motor, a screen, a rack and a transverse air pipe, wherein the drive roll and the driven roll are adjacently arranged side by side to form a spore grinding and crushing mechanism; moving adjustment is performed on spacing between the driven roll and the drive roll by the adjusting rail; the upper part of the spore grinding and crushing mechanism is provided with a feed hopper, and the lower part of the spore grinding and crushing mechanism is provided with the screen; all components are connected into a whole by the rack. According to the sesame threshing machine, the drive roll and the driven roll form the sesame spore crushing mechanism, and moreover, surfaces of the two rolls are respectively made of an elastic material; the spacing between the two rolls can also be adjusted; sesame can be rapidly threshed clean, and sesame grains can be kept complete; the sesame threshing machine is the best special threshing machine for the sesame.

Owner:王庆忠

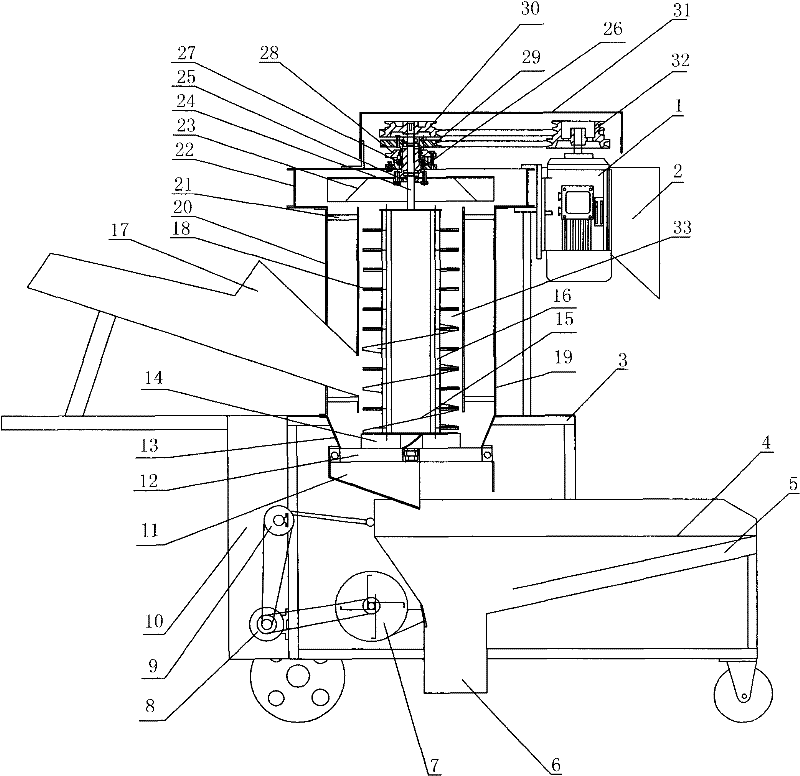

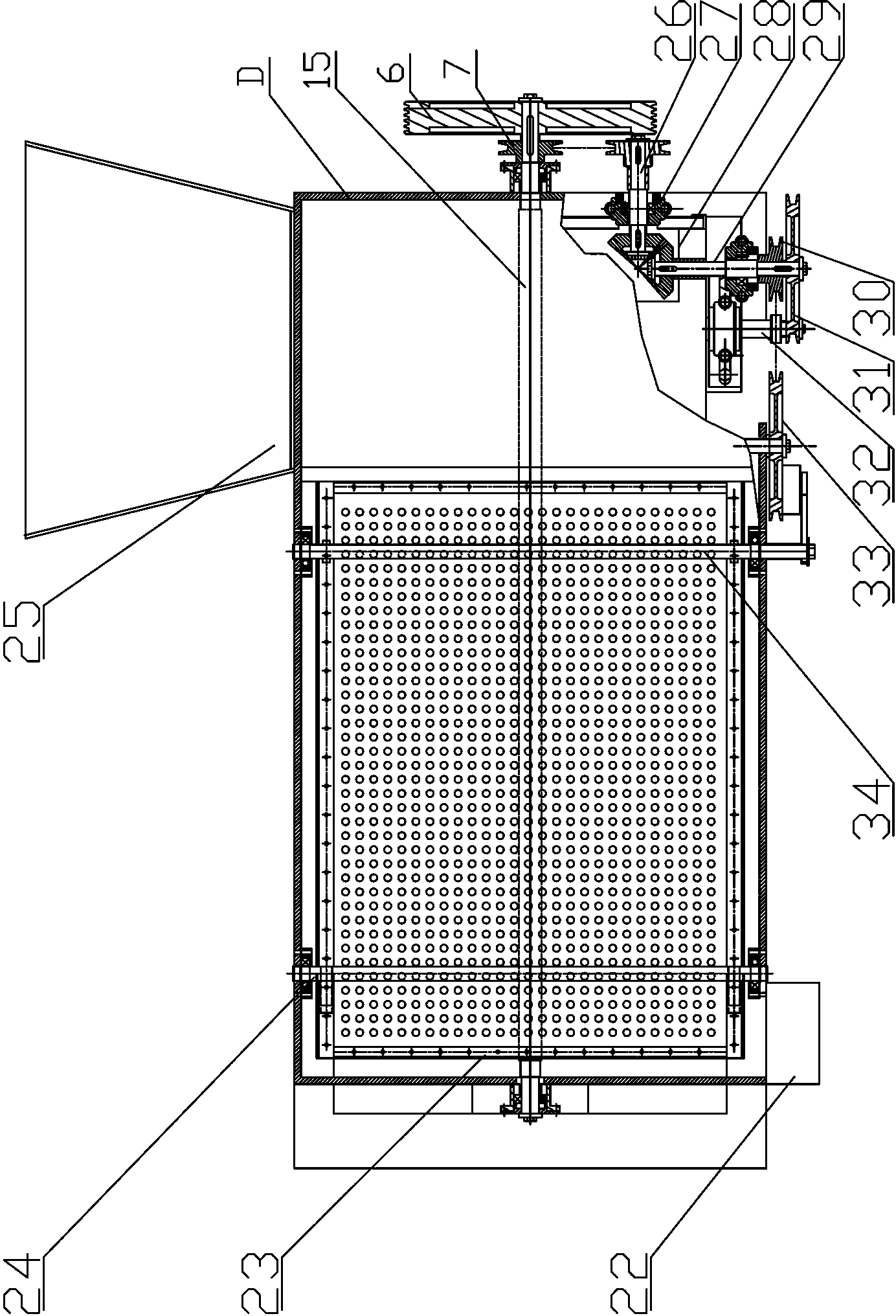

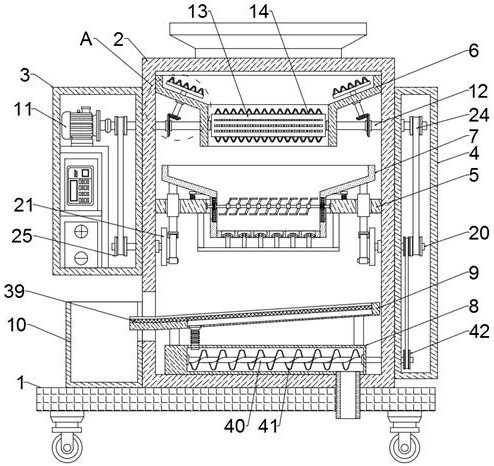

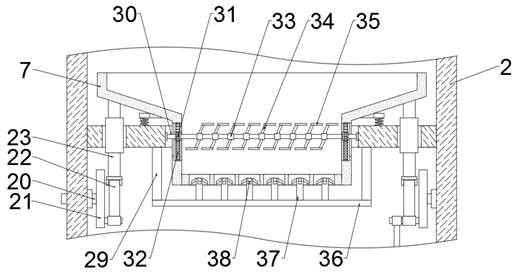

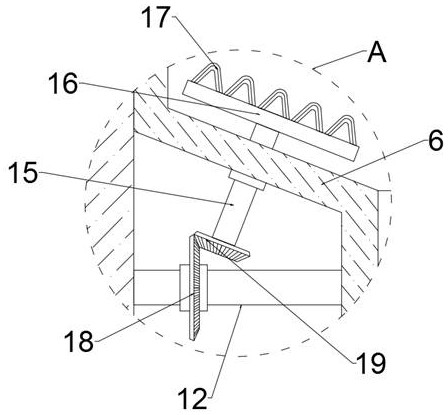

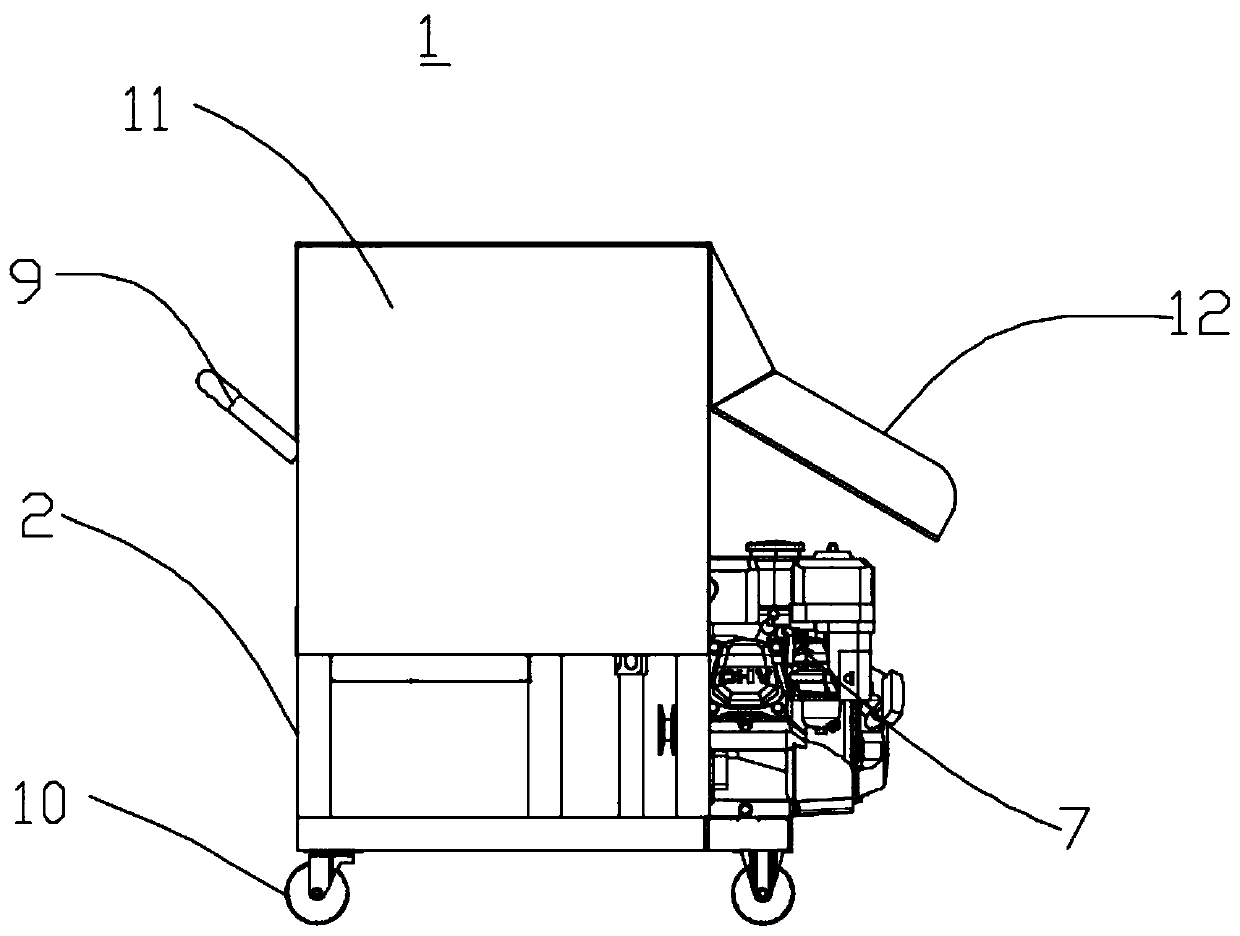

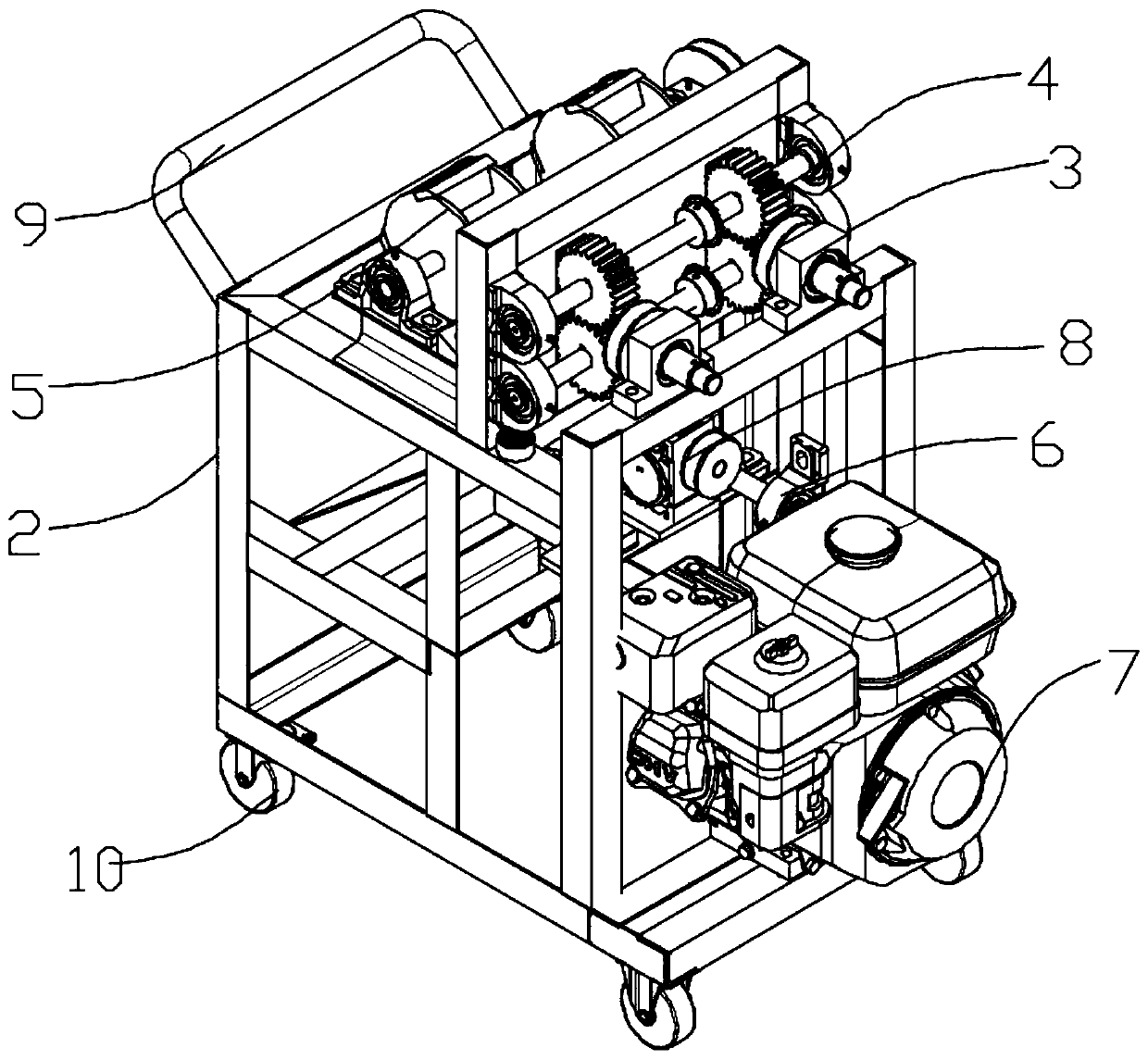

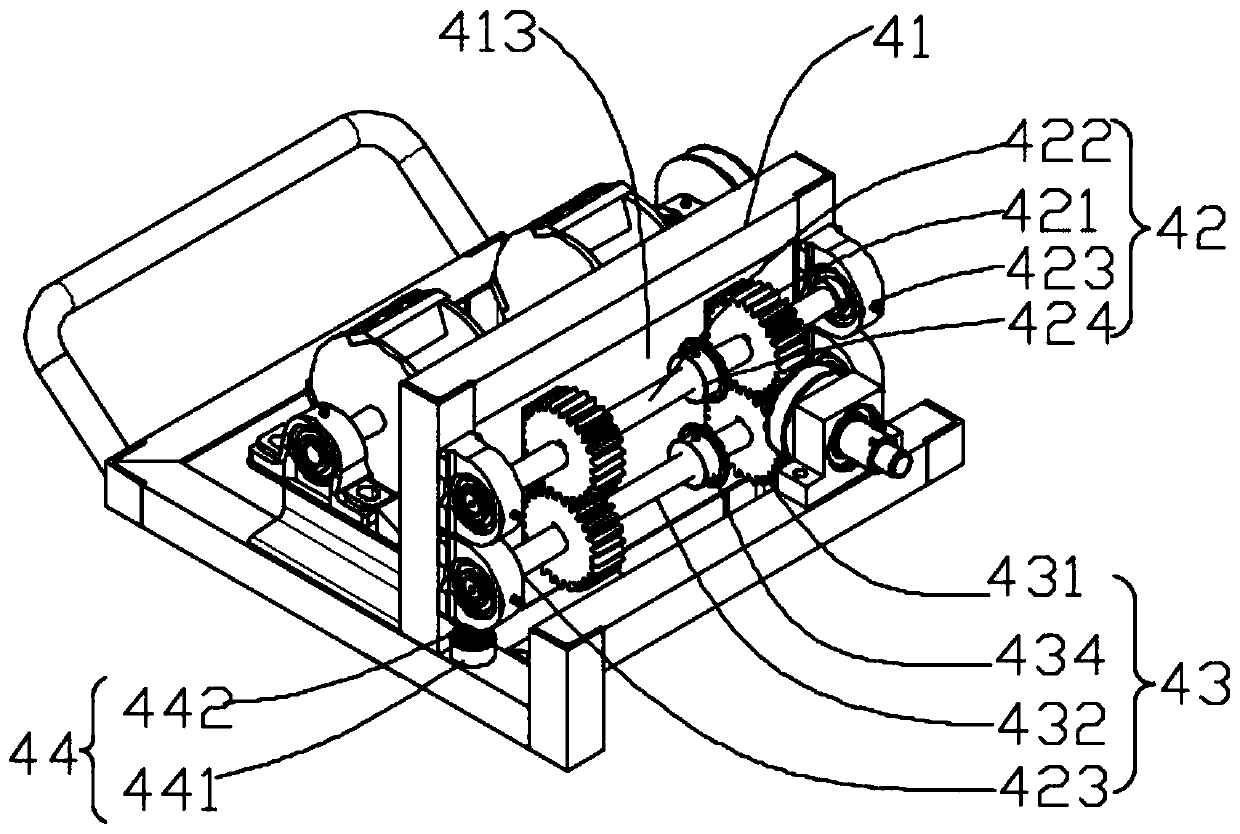

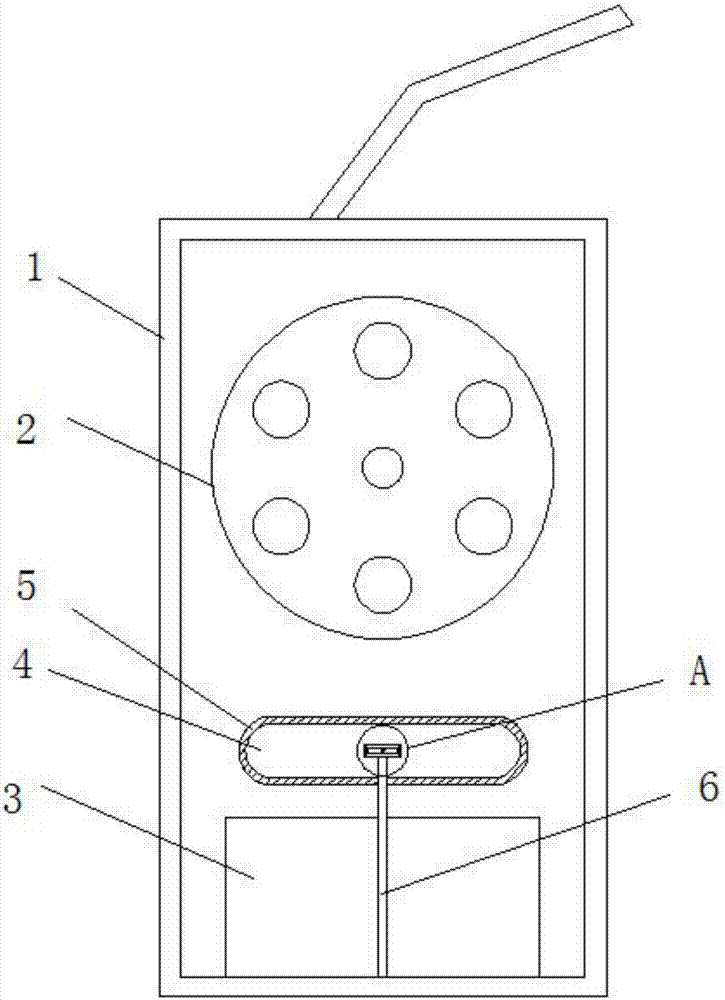

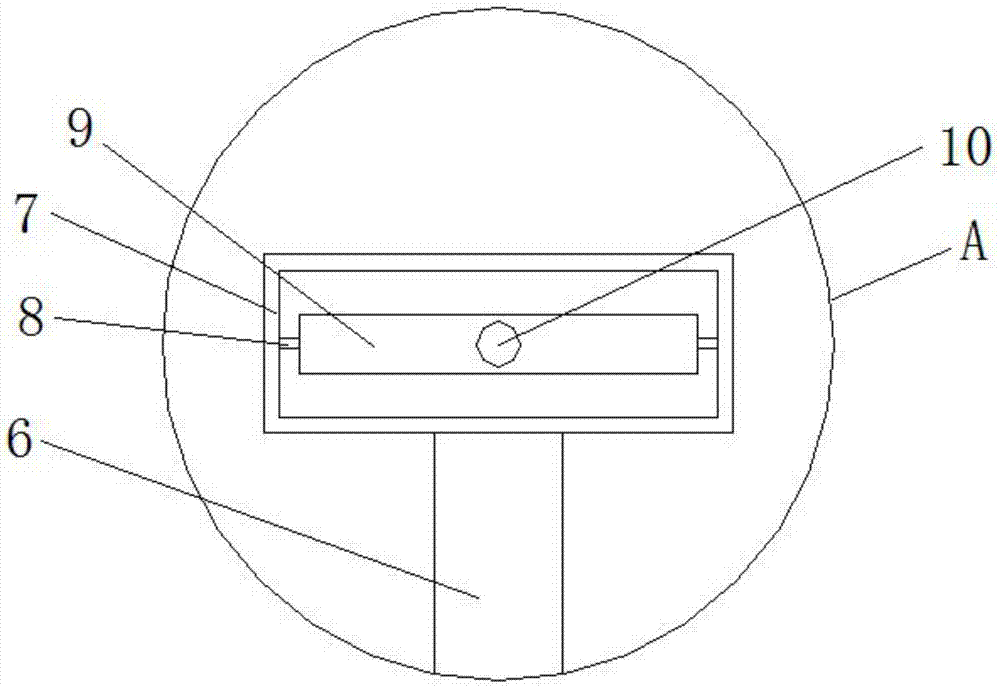

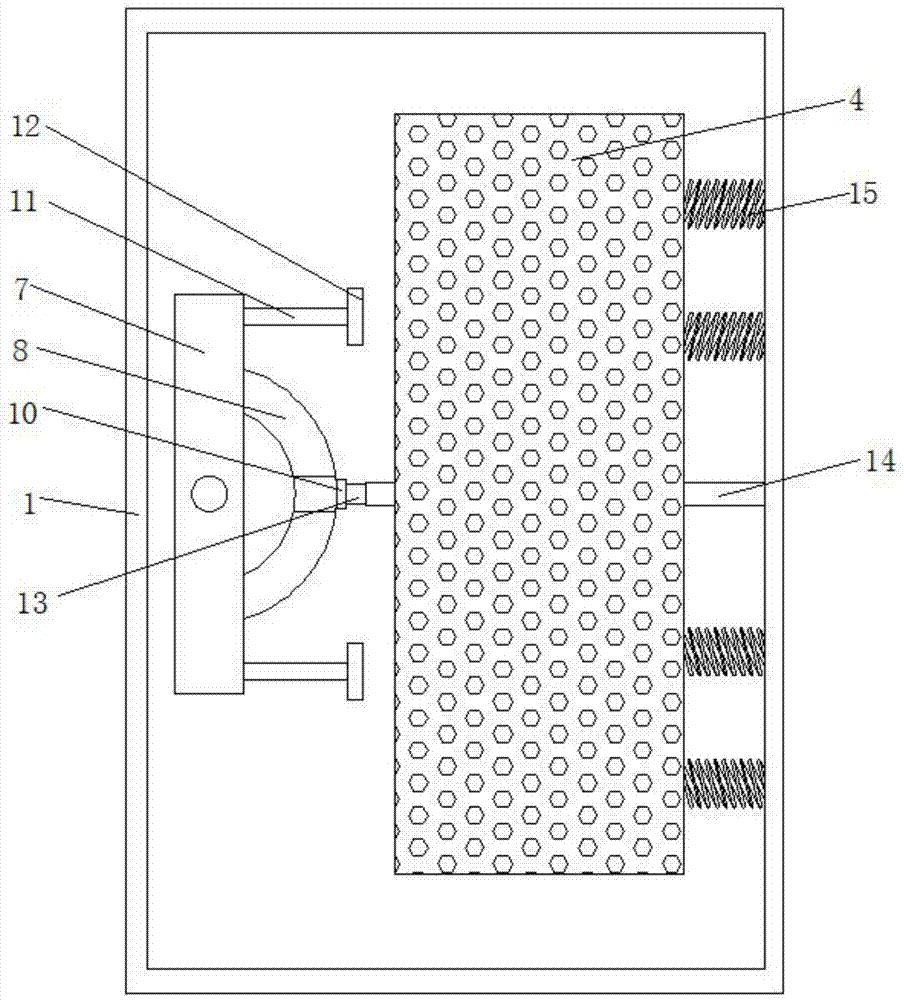

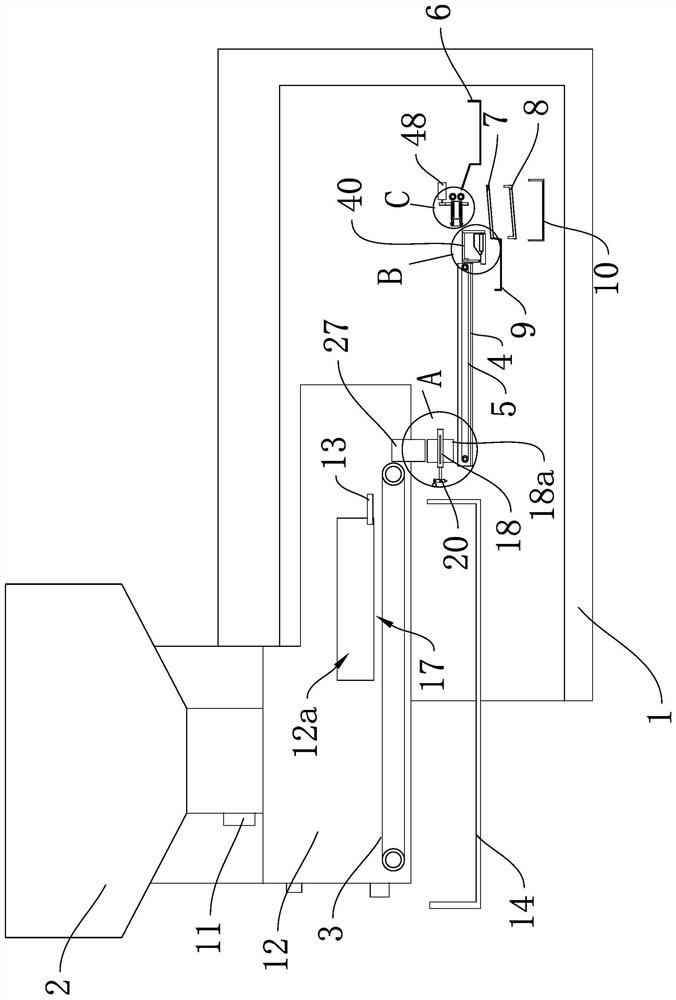

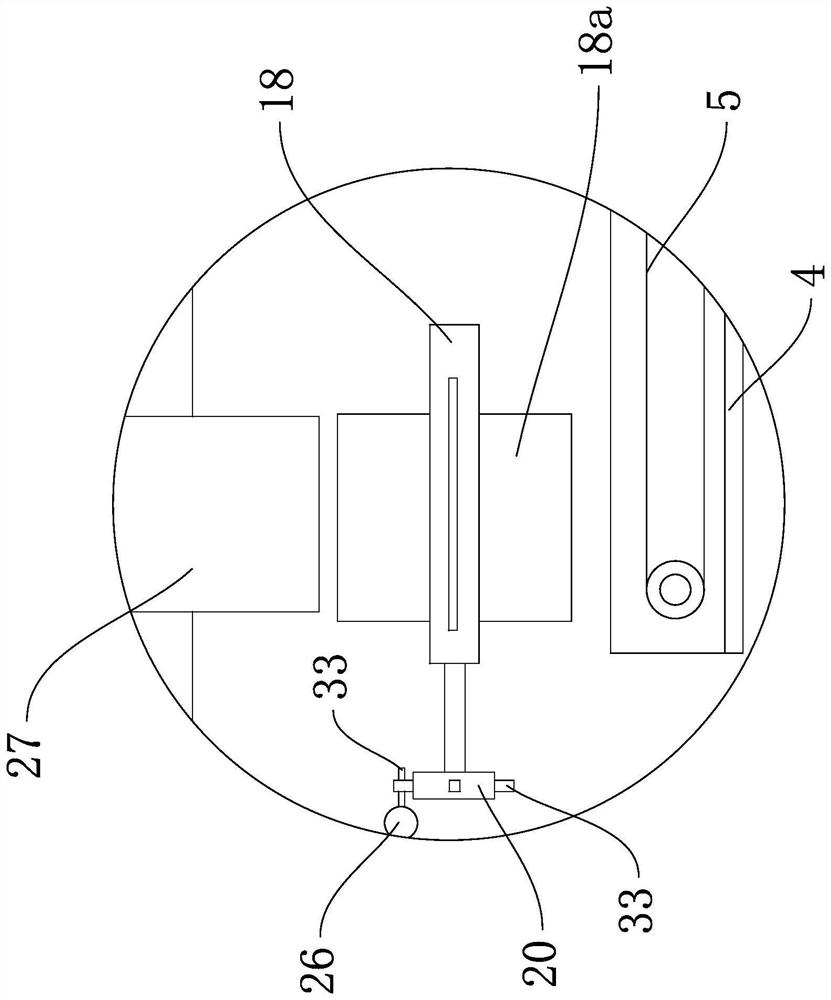

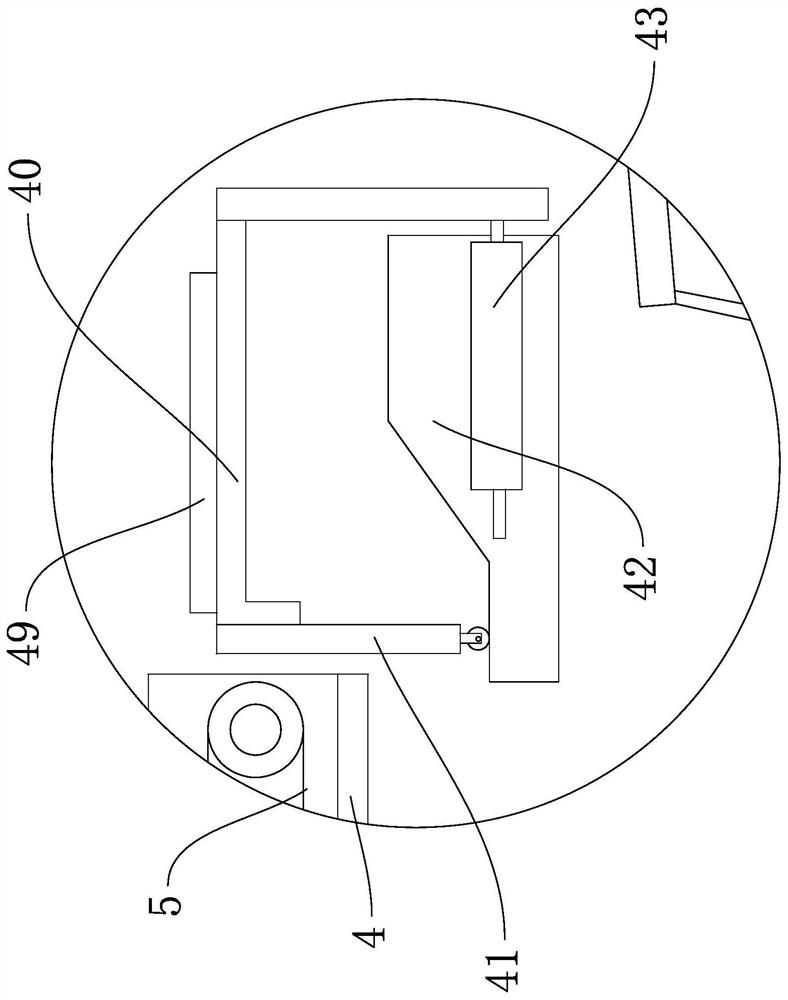

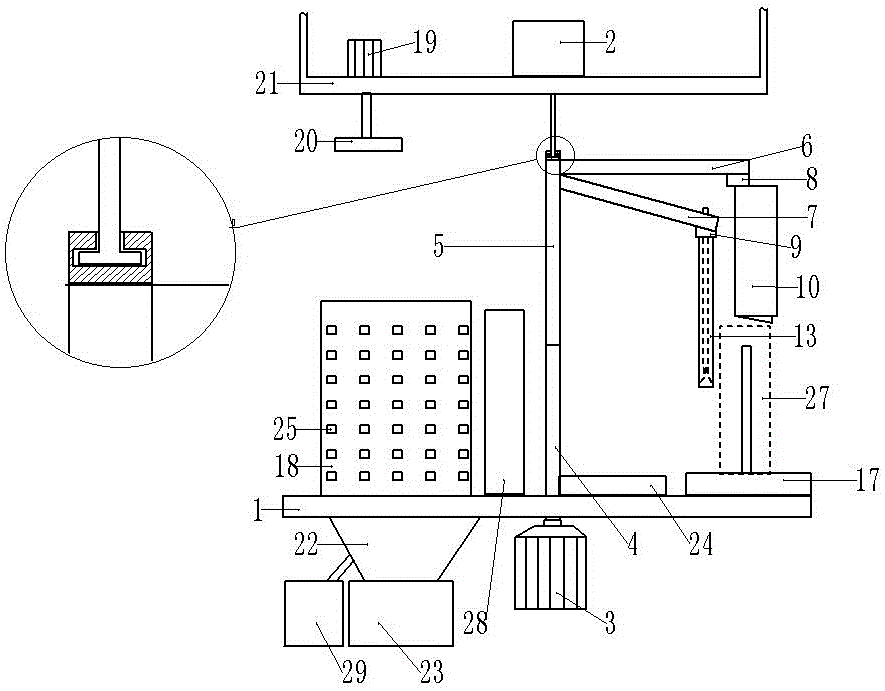

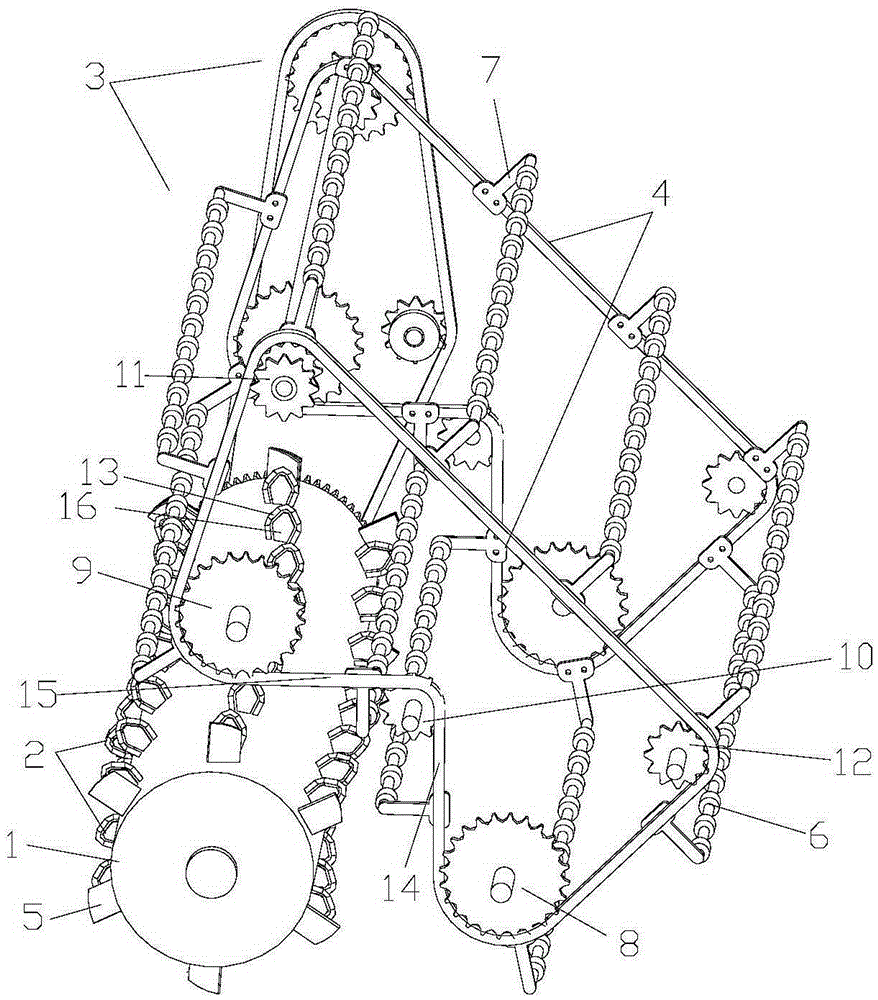

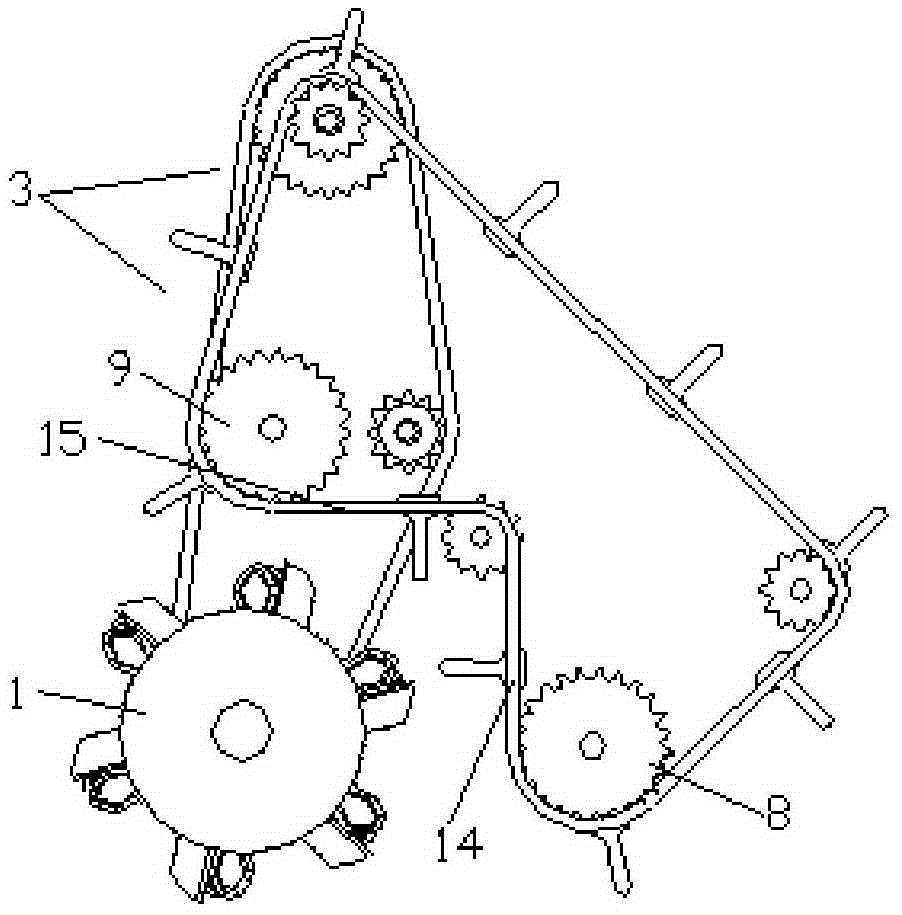

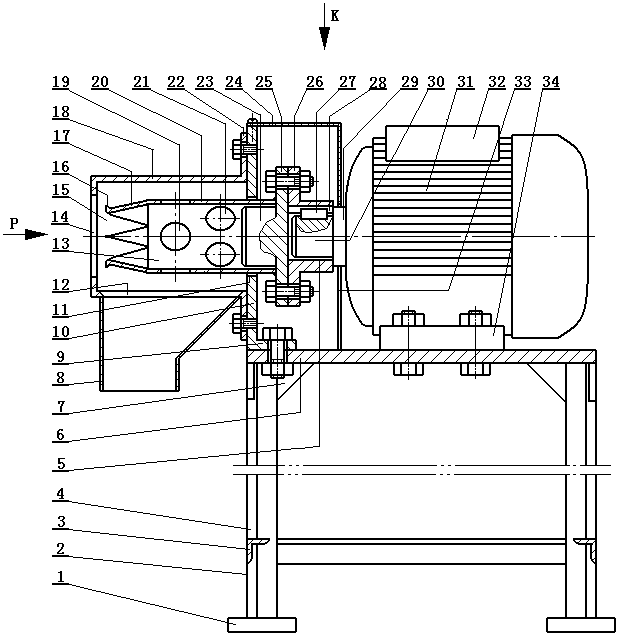

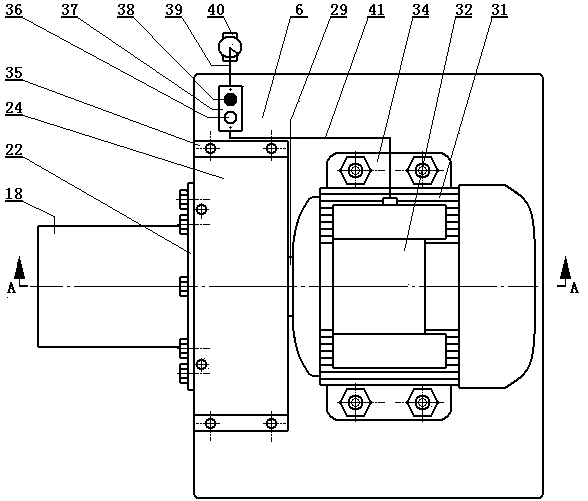

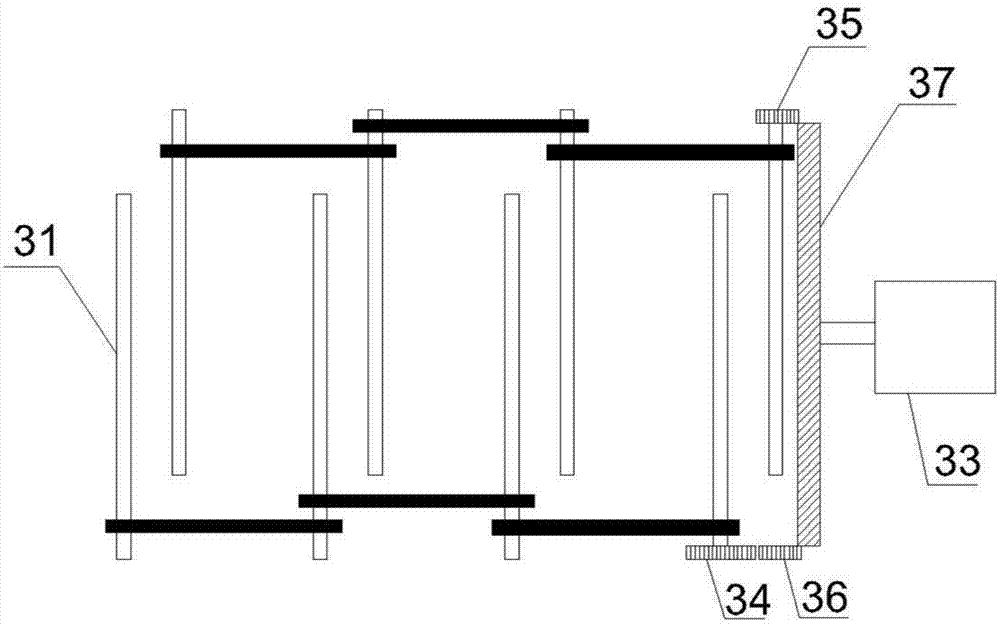

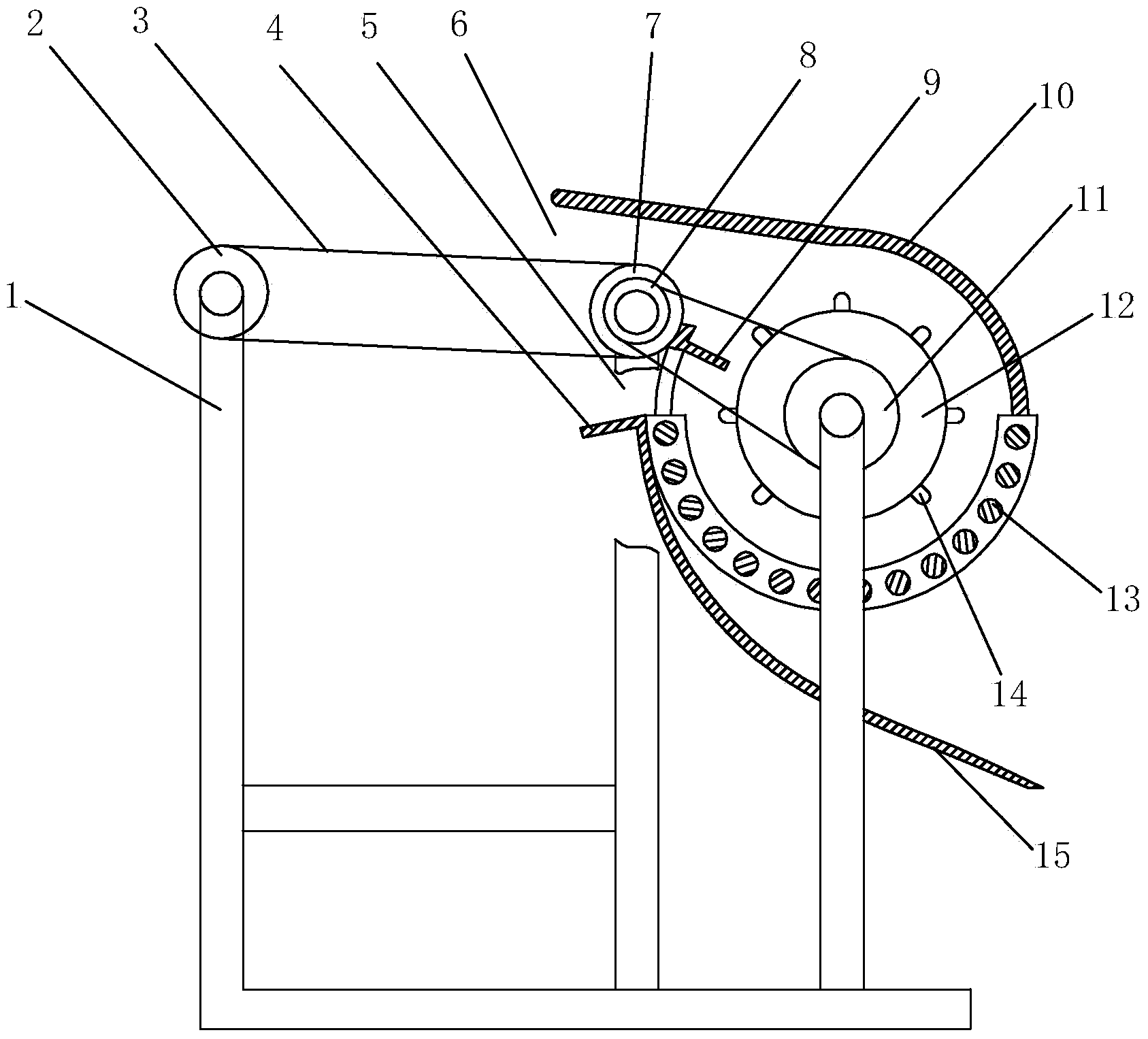

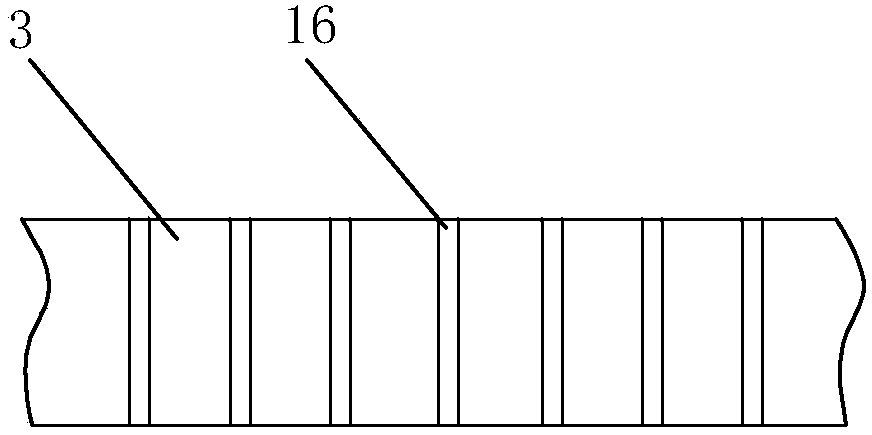

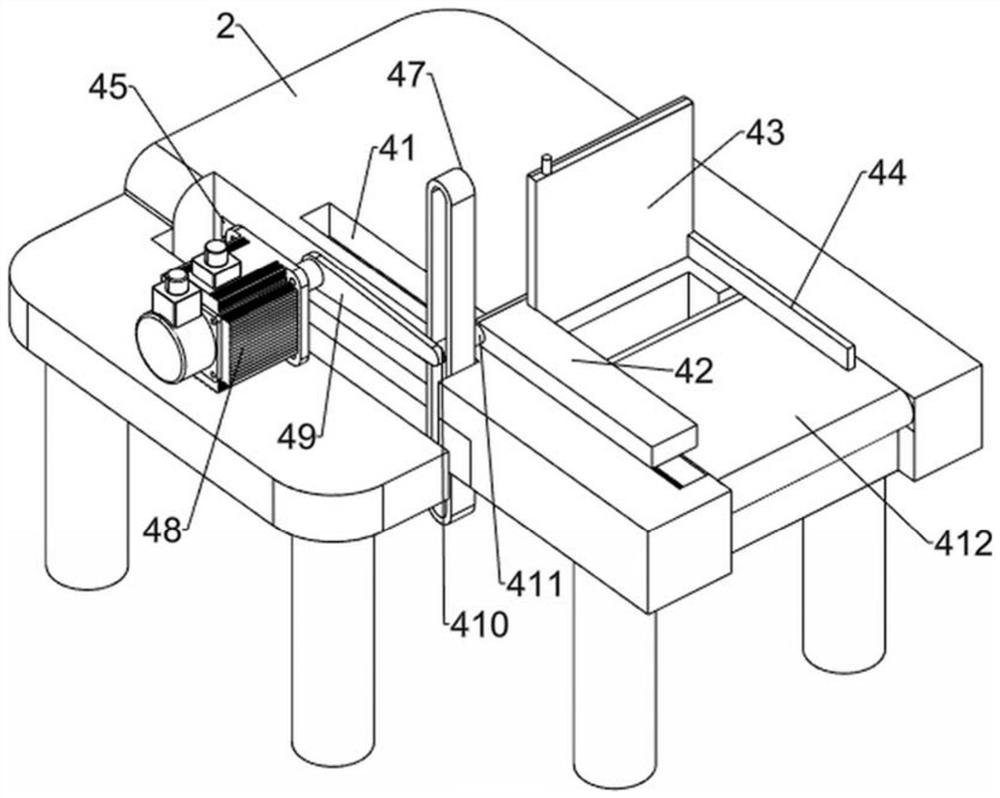

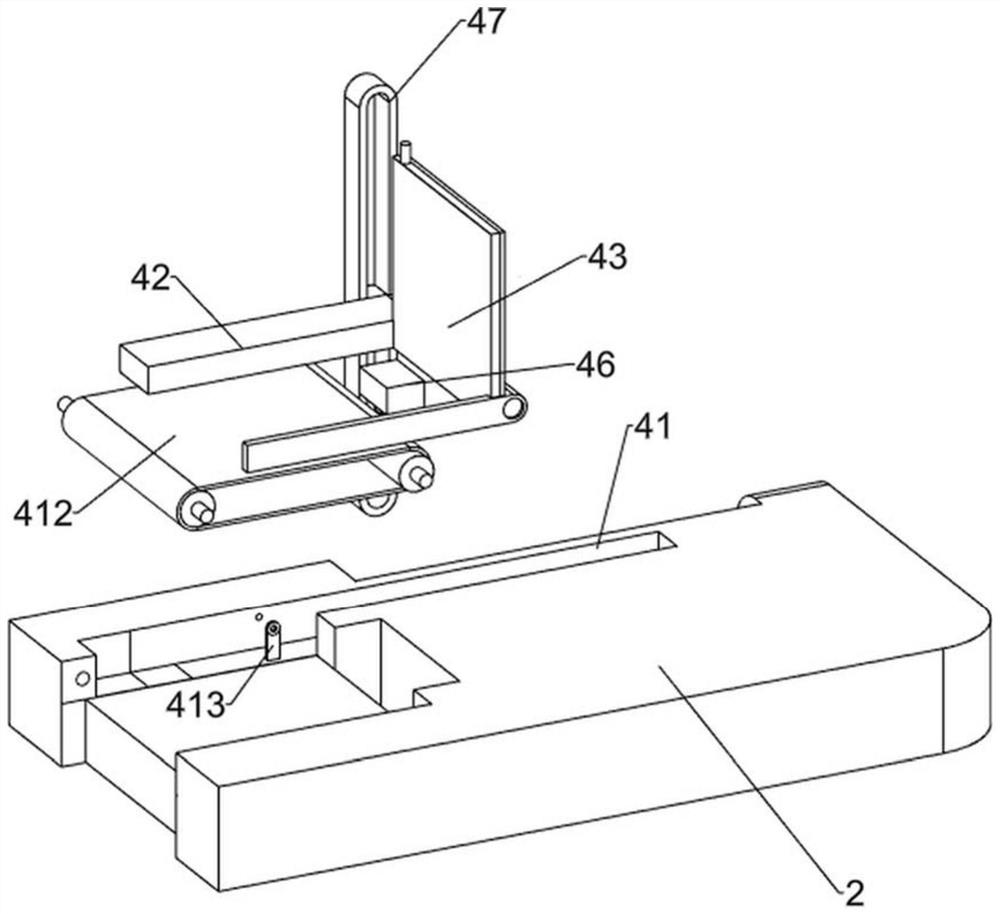

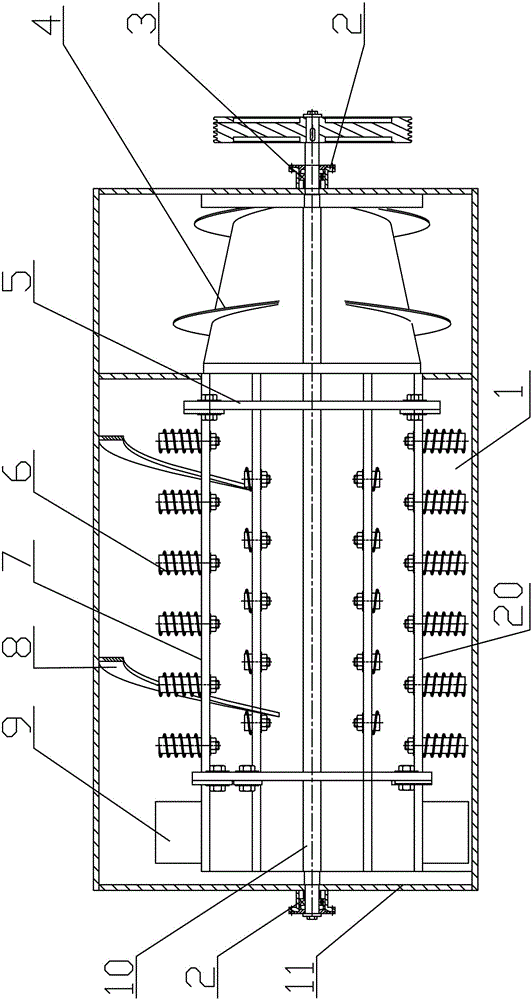

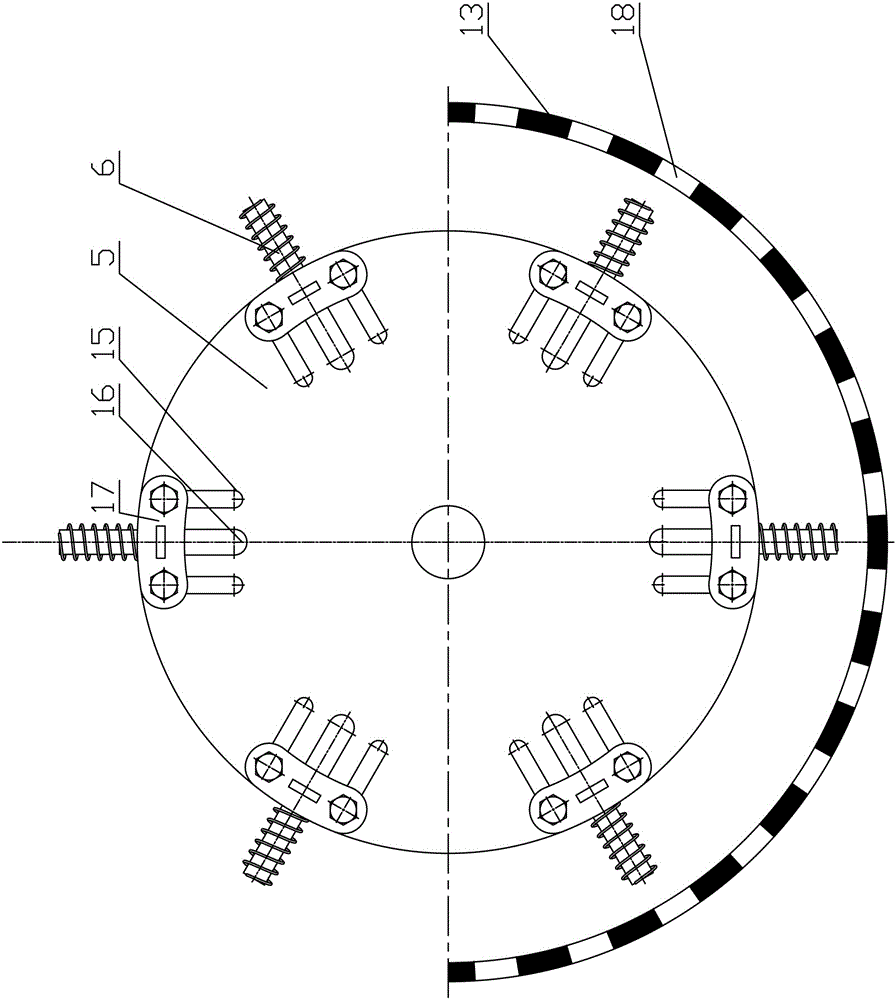

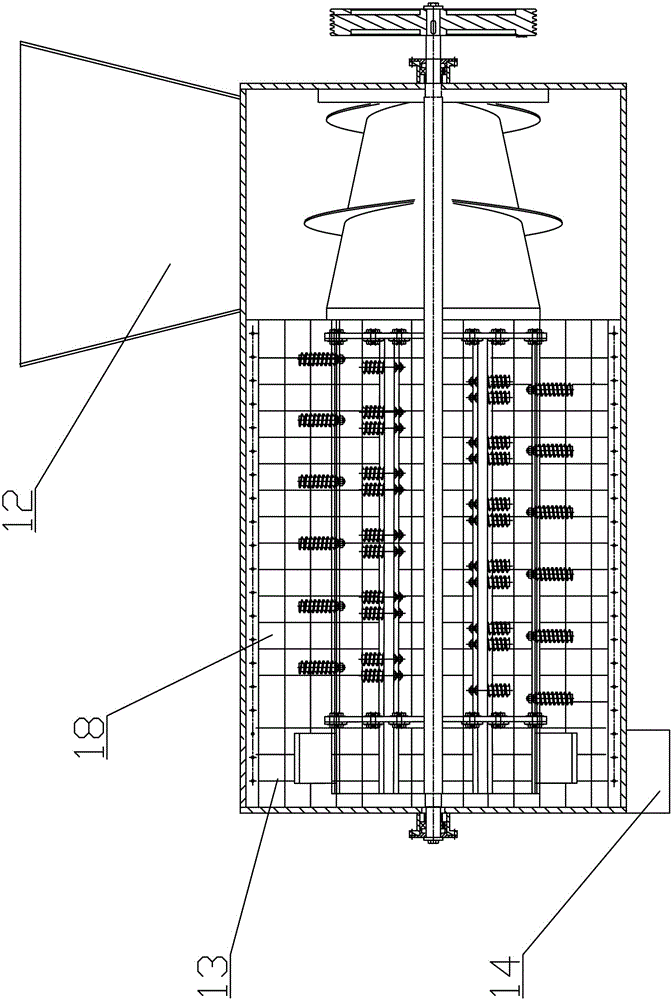

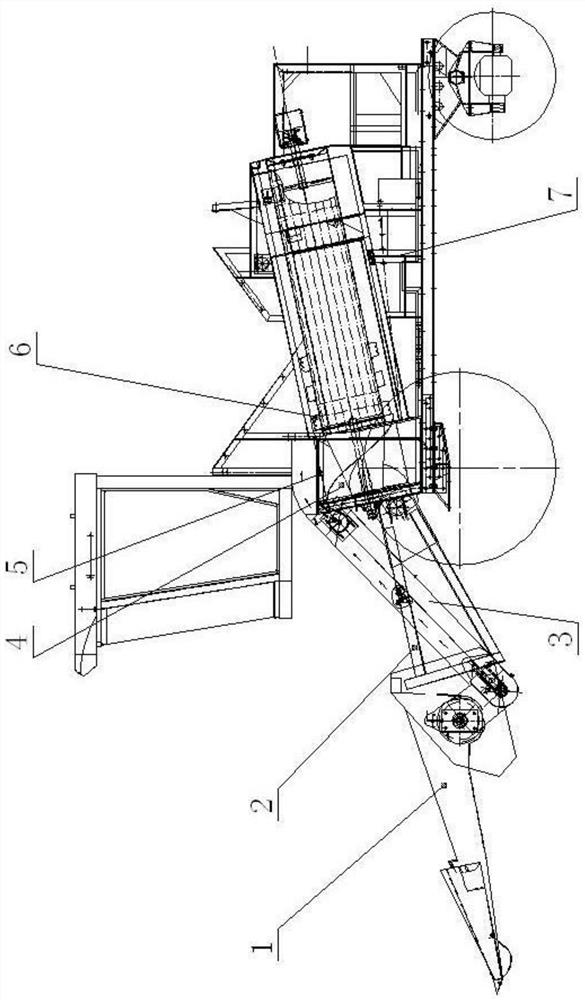

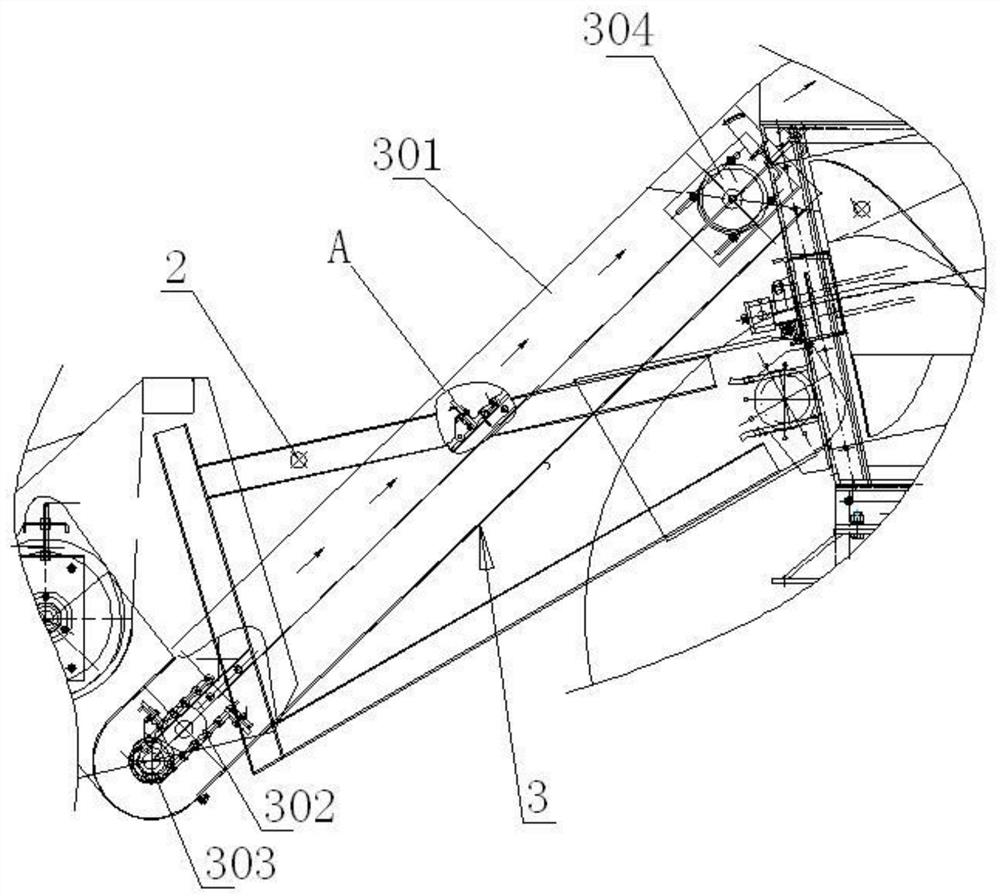

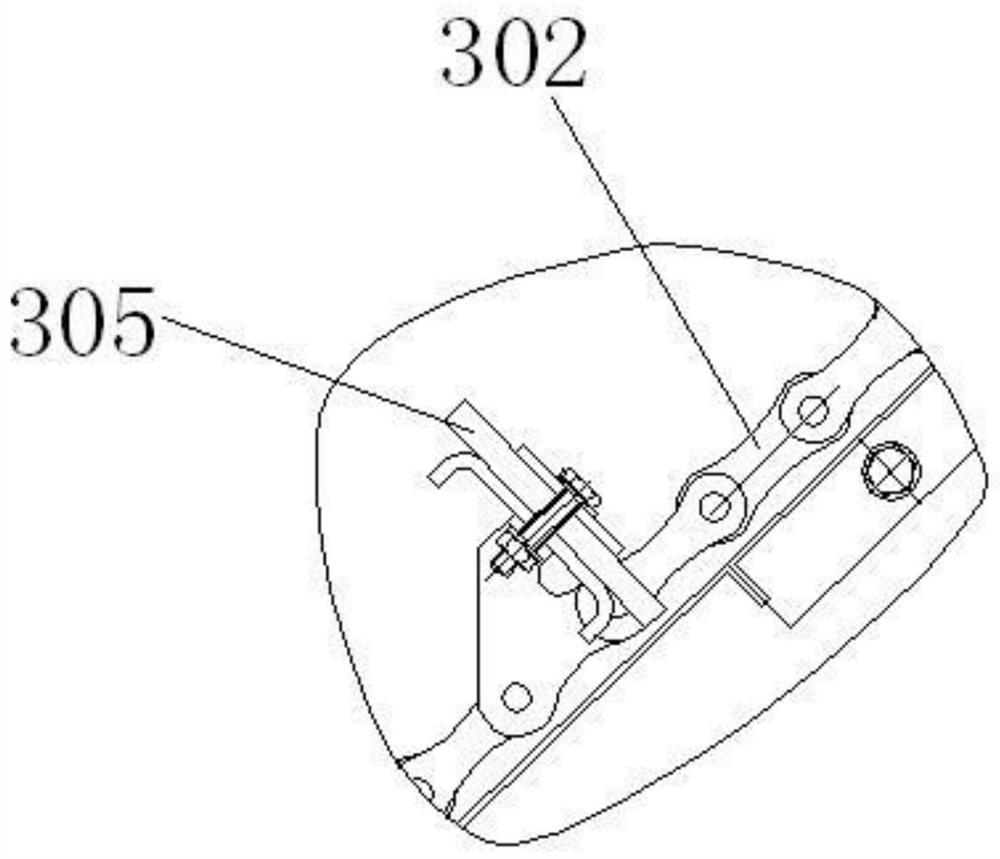

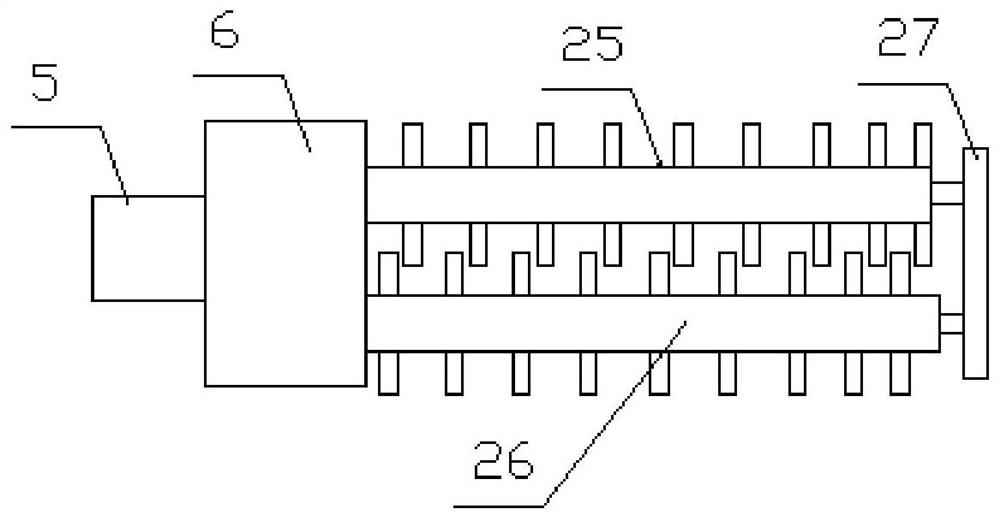

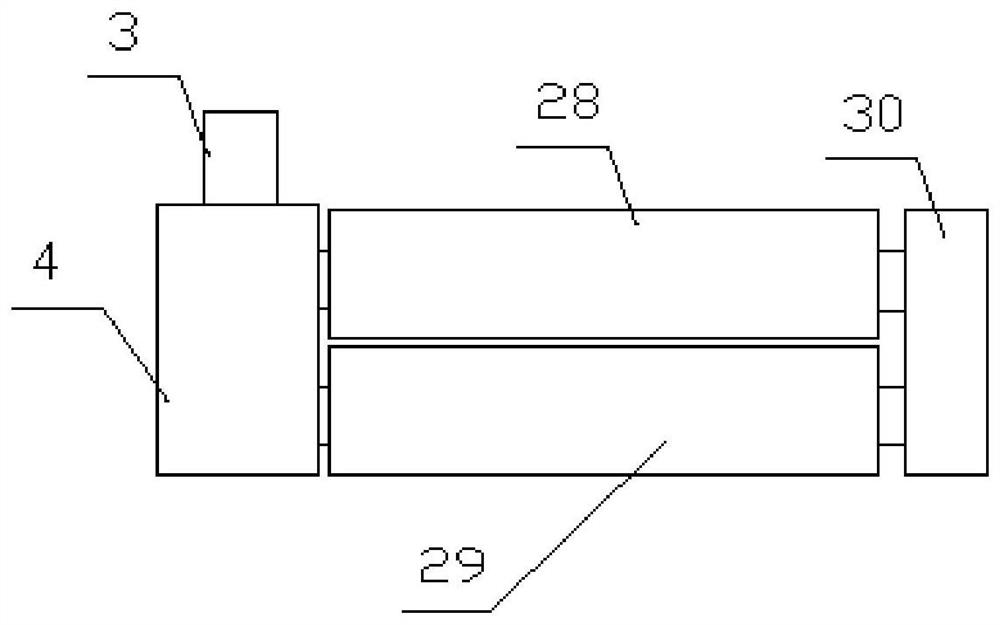

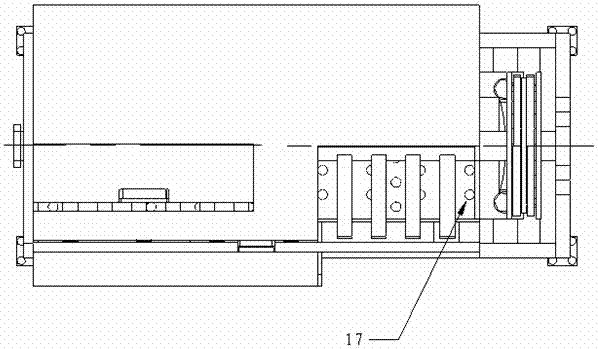

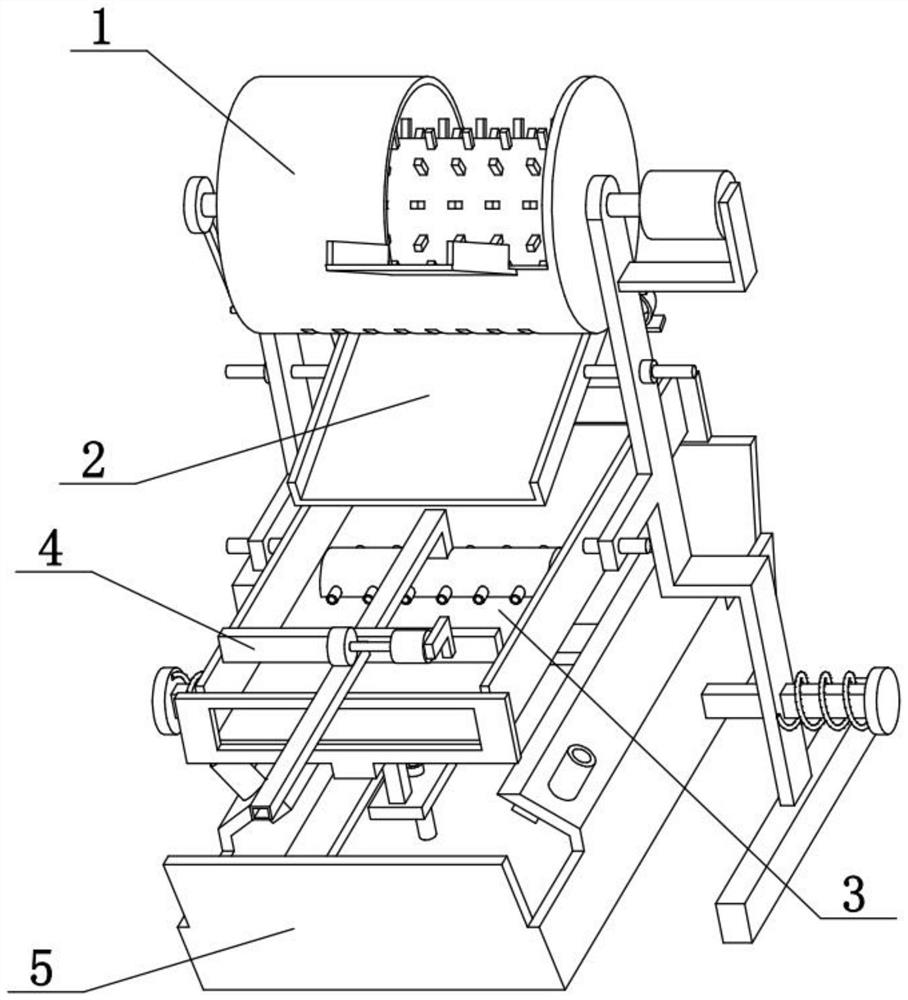

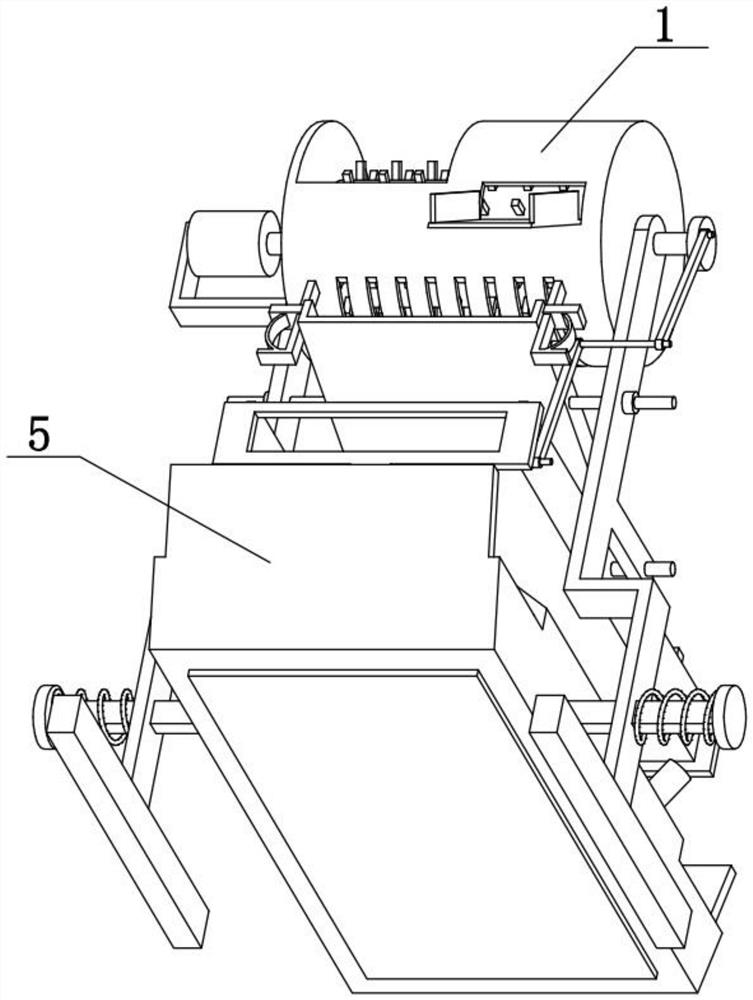

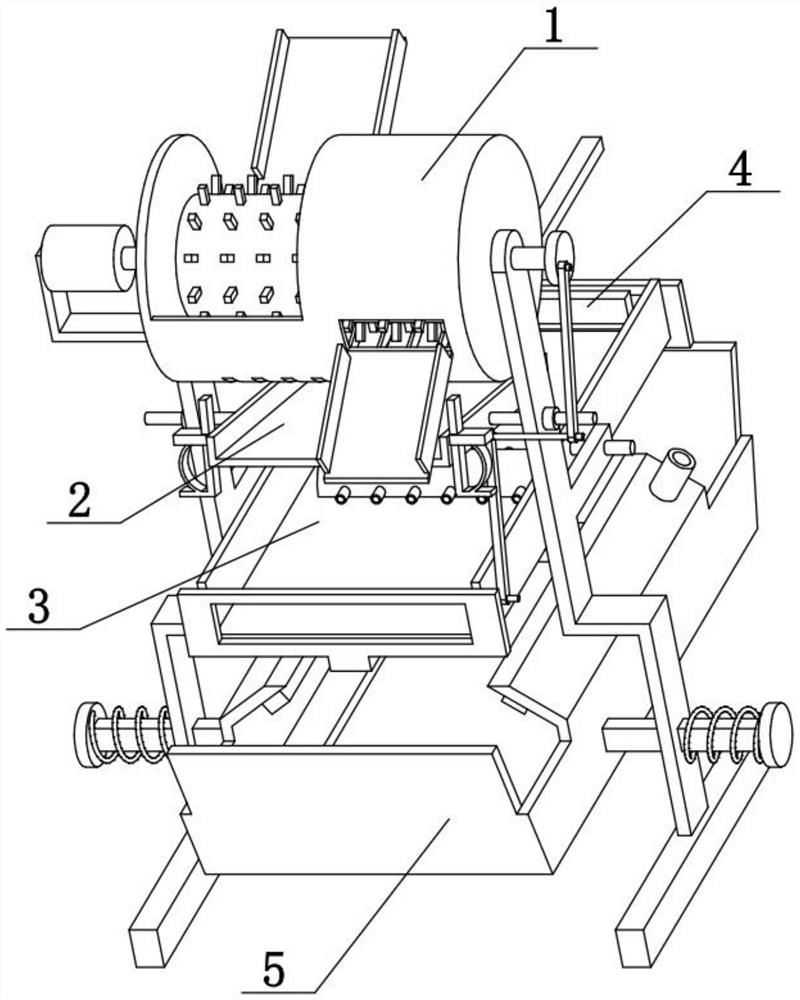

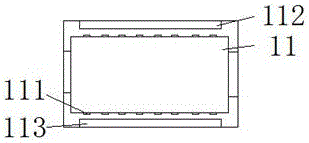

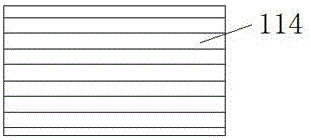

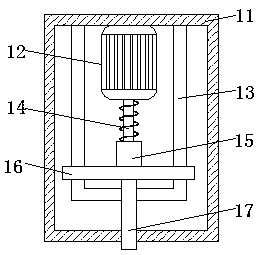

Breeding seed threshing machine used in oilseed rape fields

ActiveCN103975706AFast threshingImprove productivityThreshersAgricultural engineeringTransmission system

A breeding seed threshing machine used in oilseed rape fields comprises a threshing system, a screening system and a transmission system which are mounted on a frame. The threshing system comprises a threshing chamber, a roller shaft penetrates through the threshing chamber, a feeding auger, a threshing roller and a grass removing plate are sequentially arranged on the roller shaft, a feeding inlet is arranged on the feeding auger, the grass removing plate is provided with a straw outlet, threshing spike teeth which are spirally distributed are arranged on the threshing roller, and a concave screen is arranged below the threshing roller. The screening system comprises a vibrating screen arranged below the concave screen, a seed discharging port is formed below the vibrating screen, a fan air inlet is formed on the frame on one side of the seed discharging port, a screening fan is mounted on the fan air inlet, and a bran outlet is arranged at the position, corresponding to the fan air inlet, of the frame. The transmission system provides power to the roller shaft, the screening fan and the vibrating screen. The breeding seed threshing machine has the advantages that almost no seeds are left in the threshing machine, a good screening effect and short screening time are achieved and an oil seed breakage rate is low.

Owner:HUNAN AGRICULTURAL UNIV

Corn threshing equipment with good safety performance for agricultural production

InactiveCN108990555AFast threshingReduce volumeThreshersDrying machines with local agitationHydraulic cylinderAgricultural engineering

The invention belongs to the technical field of agricultural production and particularly relates to corn threshing equipment with good safety performance for agricultural production. In view of the problem that corn threshing equipment in agricultural production is poor in safety performance, a scheme is proposed at present as follows: the corn threshing equipment comprises a threshing box body, wherein external walls of four corners of the bottom of the threshing box body are all connected with vertically-arranged supporting legs through bolts, external walls of bottoms of the four supportinglegs are all connected with horizontally-arranged second rubber gaskets through bolts, a first opening is formed in the external wall of the center of the bottom of the threshing box body, and the internal wall of the first opening is connected with a vertically-arranged discharging pipe through a bolt. According to the corn threshing equipment with good safety performance for agricultural production, provided by the invention, a drying box is arranged, thus, prior to threshing corn, the corn is firstly subjected to drying treatment, then, the corn is fed into the threshing box body for threshing through a combination of an electric guide rail and a hydraulic cylinder, dried corn kernels become loose, and thus, the threshing can become easier.

Owner:郑州希硕物联科技有限公司

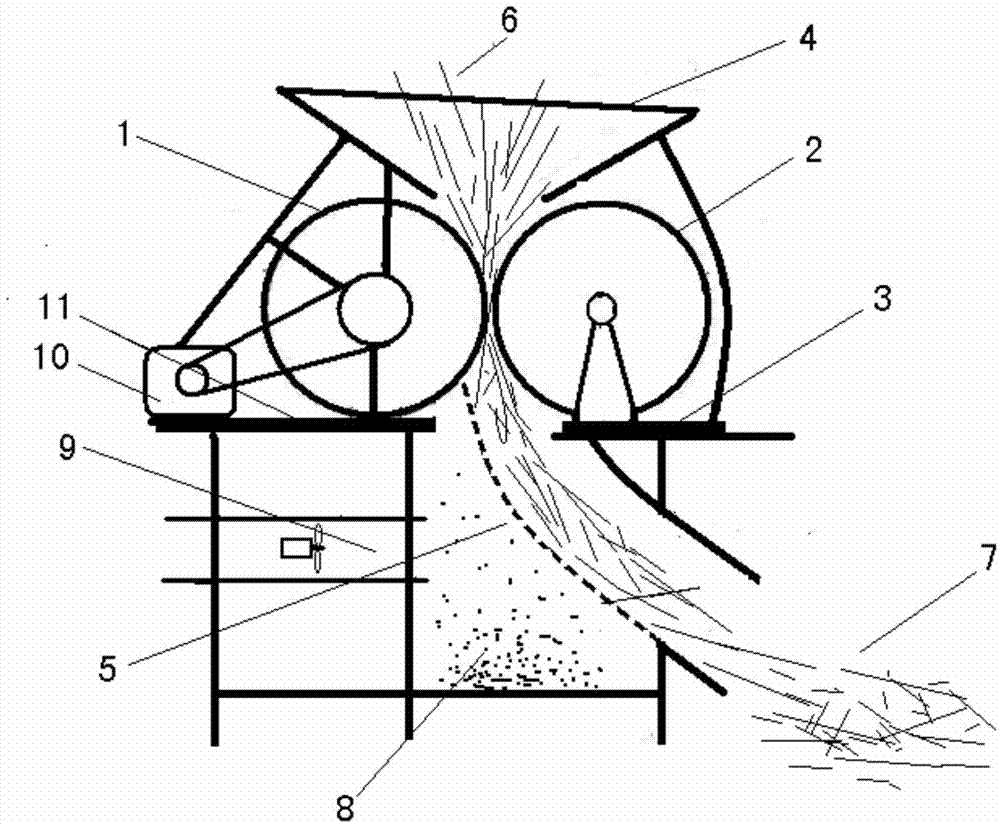

Centrifugal type threshing and grinding machine

InactiveCN107736138AImprove threshing effectAvoid wastingThreshersGrain treatmentsEngineeringPower unit

The invention discloses a centrifugal threshing grinder, comprising: a shell, the bottom surface of which forms a powder outlet, one side is provided with a core body outlet and an air inlet, and the other side is provided with an air outlet; A threshing cylinder, which includes a guide cylinder, a tooth cylinder, and a first motor; a first pair of roller layers and a second pair of roller layers; a conveyor belt assembly that guides the corncobs out of the housing; a blower and an exhaust fan; a vibration assembly , which includes a fixed plate and a pair of vibrating screens; a pair of grinding components, which include a grinding plate, a screw and a grinding stone, a support table, and a power unit. The invention can be fast, efficient, line-type threshing and grinding, effectively separate corn kernels, corn cobs and dust, reduce procedures, improve work efficiency, and facilitate maintenance and maintenance.

Owner:李斌施

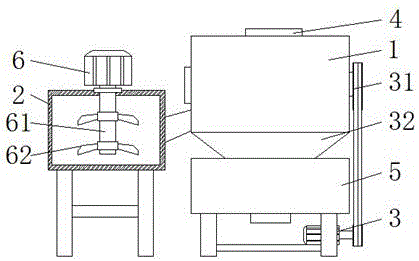

Threshing machine for cereal food processing

InactiveCN112385403AEasy threshingEasy threshing operationGrain huskingGrain polishingAgricultural scienceAgricultural engineering

The invention discloses a threshing machine for cereal food processing. The threshing machine comprises a base, a threshing mechanism, transmission mechanisms, a stirring mechanism and a dredging assembly; a threshing box is fixedly connected to the top face of the base, a driving box is arranged on the upper portion of one side of the threshing box, and a transmission box is arranged on the otherside of the threshing box; a lifting hopper is arranged in a partition plate; the stirring mechanism is arranged in the lifting hopper; the dredging assembly is arranged below the bottom surface of the partition plate; the threshing mechanism is arranged in a collecting hopper; and the transmission mechanisms are arranged at the positions, located at the two sides of the lower portion of the partition plate, on the inner walls of the threshing box. The threshing machine is easy to operate; the working efficiency of grain threshing is effectively improved through the threshing mechanism and ascraping assembly; through cooperative use of the transmission mechanisms and the stirring mechanism, cereals in the lifting hopper can be stirred and stirred conveniently, husks on the cereals can beseparated from kernels conveniently, and the dredging quickness of a discharging hole is effectively improved; the workload of cleaning broken slag by workers is reduced; and the problems that the cereals are prone to blocking a discharging hole and dredging is inconvenient in an existing threshing device are solved.

Owner:潍坊惠米农业科技发展有限公司

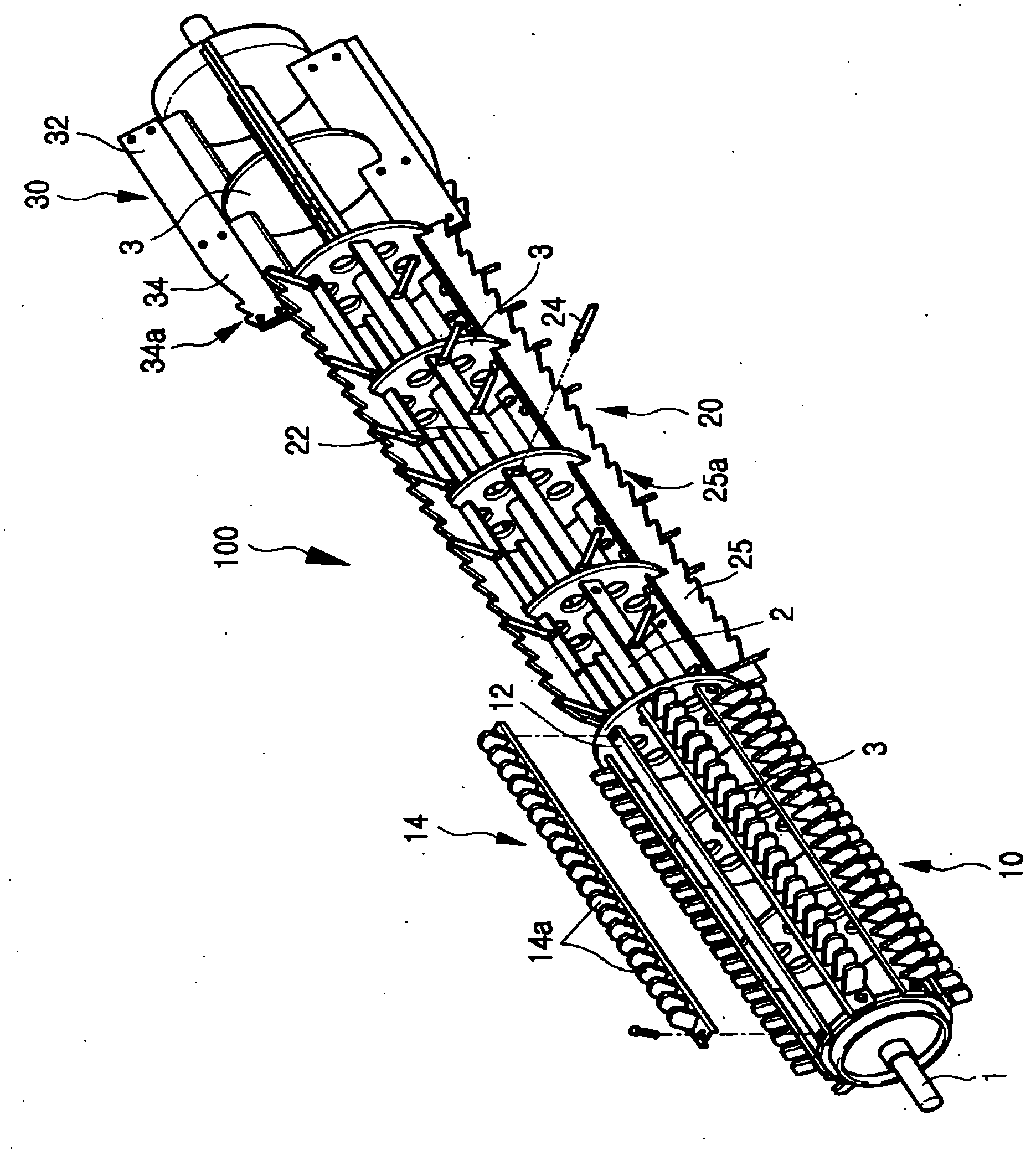

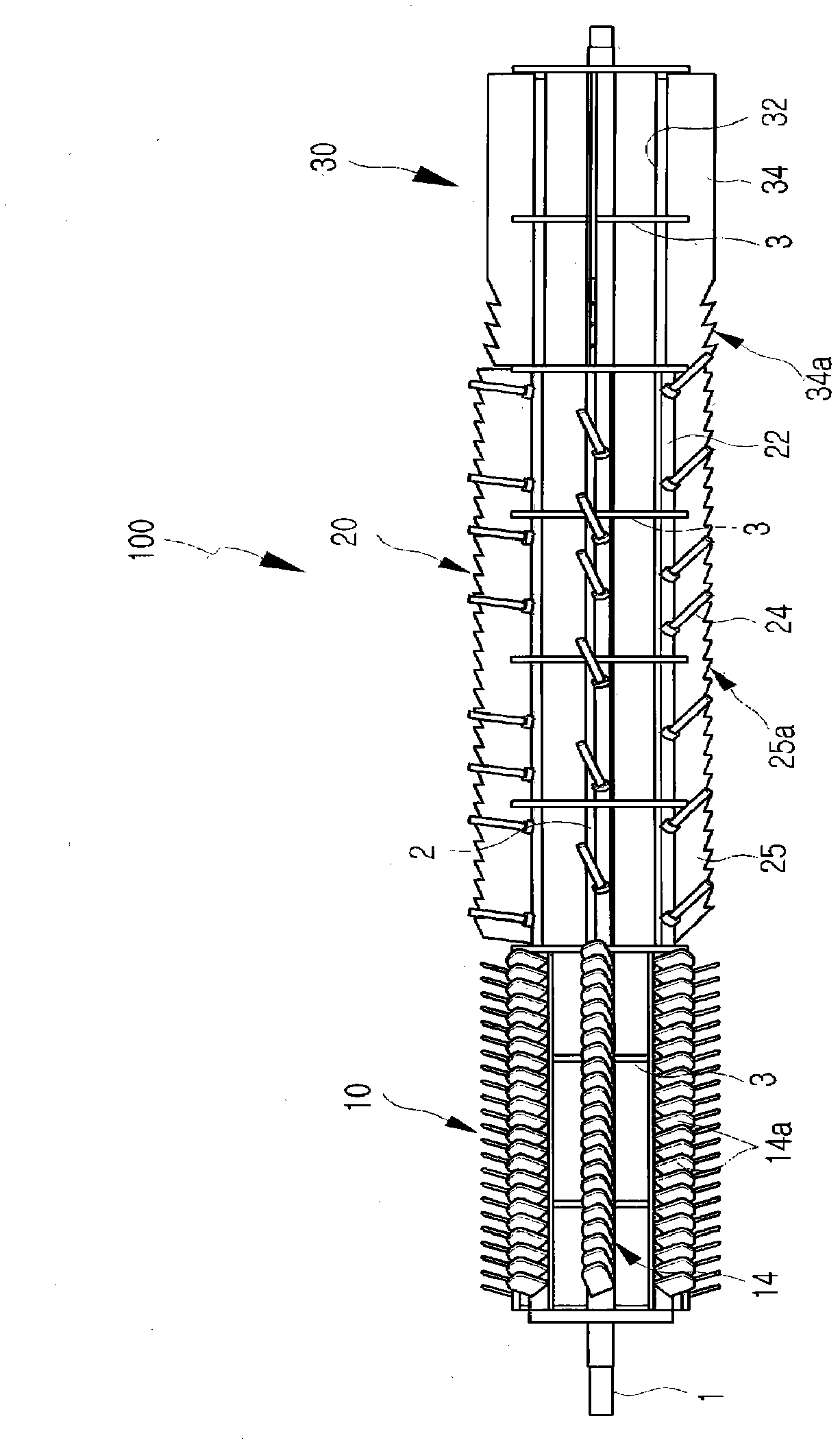

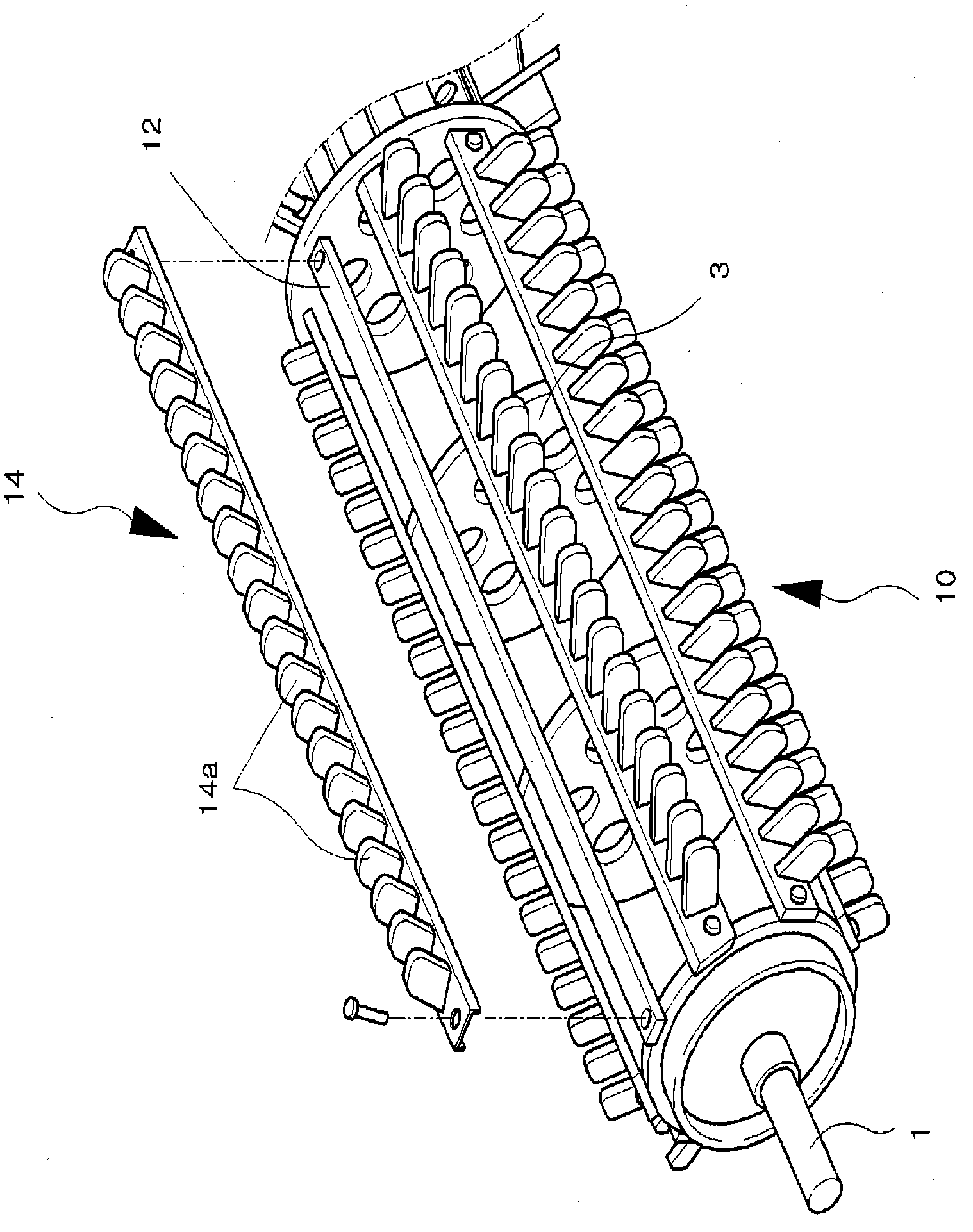

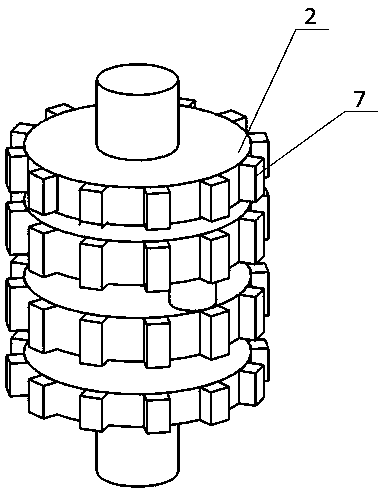

Thrashing drum

The present invention relates to a thrashing drum (100) that can maximize thrashing efficiency while minimizing load occurring when the drum is rotated in a trashing process. The thrashing drum (100) includes a shaft (2) having axle portions formed on its both sides, a plurality of support plates (3) formed on the shaft (2) at specific intervals, a primary thrashing unit configured to primarily separate ears and corns from stems or branches of crops input thereto and that is disposed in the support plates, a secondary thrashing unit configured to secondarily separate by blowing ears and corns that have not been thrashed in the primary thrashing unit and that is disposed in the support plates, and a discharge unit configured to thirdly discharge the stems or branches that have been thrashed and that is disposed in the support plates (3).

Owner:XENITH TRACK

Self-adaptive Sichuan pepper branch spike separator

InactiveCN110249790AGood separation effectImprove efficiencyPlant waste comminutingCuttersSelf adaptiveEngineering

The invention provides a self-adaptive Sichuan pepper branch spike separator, and relates to the field of separating equipment. The separator comprises a rack, a cutter head assembly and a self-adaptive pressing assembly; the lower portion of the rack is fixedly provided with a driving piece, a speed reducer is fixedly arranged in the middle of the rack, the driving piece is in transmission connection with the speed reducer, and the cutter head assembly is arranged at the top side of the rack, is in transmission connection with the speed reducer and is used for loading Sichuan pepper branch spikes and separating peppers on the Sichuan pepper branch spikes. Compared with the prior art, the self-adaptive Sichuan pepper branch spike separator can quickly treat the Sichuan pepper branch spikes and quickly thresh the peppers, and the effect of separating the peppers is good; meanwhile, a second pressing piece can automatically adjust the distance between the second pressing piece and a first pressing piece according to the sizes of the branch spikes and the pressing force for pressing the branch spikes, the pressing demands of the branch spikes of different sizes can be met while the branch spikes are driven to move towards the rear section, the situation that the branch spikes are too large and cannot pass through a pressing channel is avoided, and the overall separating efficiency is greatly improved.

Owner:CHONGQING ACAD OF AGRI SCI +1

Threshing device for peanuts

The invention discloses a threshing device for peanuts, which includes a threshing box. A threshing drum is provided in the threshing box. An ash collection box is fixedly installed on the inner wall of the bottom plate of the threshing box. A transmission device is provided in the middle of the threshing box. The conveyor is provided with an arc baffle, a fixed shaft is installed on the inner wall of the bottom plate of the threshing box, and a fixed frame is installed on the top of the fixed shaft. The fixed frame is installed close to both ends of the side walls of the conveyor. There is a fixed rod, and a rubber block is installed on one end of the fixed rod away from the fixed frame. A first rotating shaft is installed on a set of opposite inner walls in the fixed frame. A rotating leaf is connected between the two sets of first rotating shafts. The rotating page has an arc structure. In the present invention, peanuts can be threshed quickly without manual threshing, which saves labor and a lot of time, improves work efficiency, and can remove dust from the threshed peanuts, saving time for operators. Cleaning time.

Owner:阳新绿源农业科技有限公司

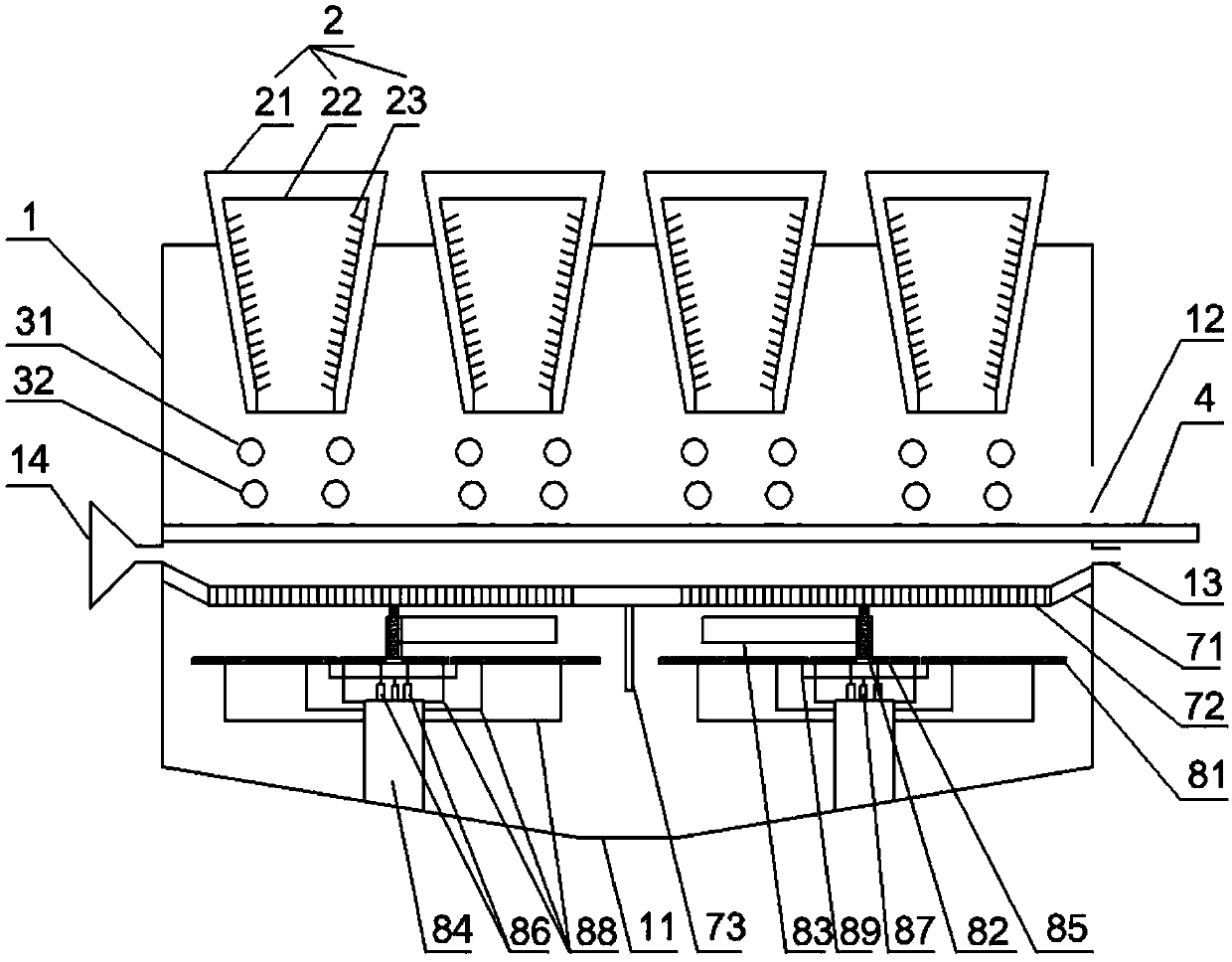

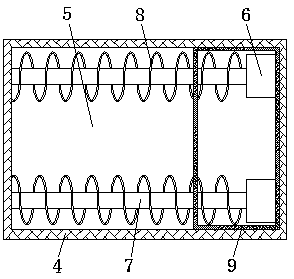

A corn processing device

ActiveCN110881316BFast threshingQuick screening and recyclingThreshersAgricultural scienceAgricultural engineering

Owner:QUZHOU UNIV

Corn threshing method

ActiveCN106717588AEasy threshingReduce mutual support forcesThreshersMetal working apparatusBiologyThreshing

The invention relates to the technical field of corn processing and discloses a corn threshing method. The corn threshing method comprises the following steps that (a) materials are selected; (b) primary cutting is performed, wherein the upper portions and the lower portions of corns are cut off, and corn cobs are obtained after cutting; (c) a cutting device is arrange and comprises a cutter, a hanging cylinder, an insertion seat, a drying box and a frictional plate; (d) secondary cutting is performed, wherein the corn cobs obtained in the step (b) are vertically inserted into the insertion seat and are vertically cut into small corn strips and large corn strips by using the cutter; (e) drying is performed, wherein the small corn strips are delivered to the drying box for drying, the drying temperature is 40-50 DEG C, the drying time is 10-15 minutes, and the large corn strips are automatically hung by using the hanging cylinder; (f) primary threshing is performed, wherein the small corn strips obtained after drying are delivered to the frictional plate through the cutter for threshing; (g) secondary threshing is performed, wherein the large corn strips obtained after drying are delivered to the frictional plate through the hanging cylinder for threshing. By adopting the method, low-damage-rate and rapid corn threshing can be achieved.

Owner:安徽安天食品(集团)有限公司

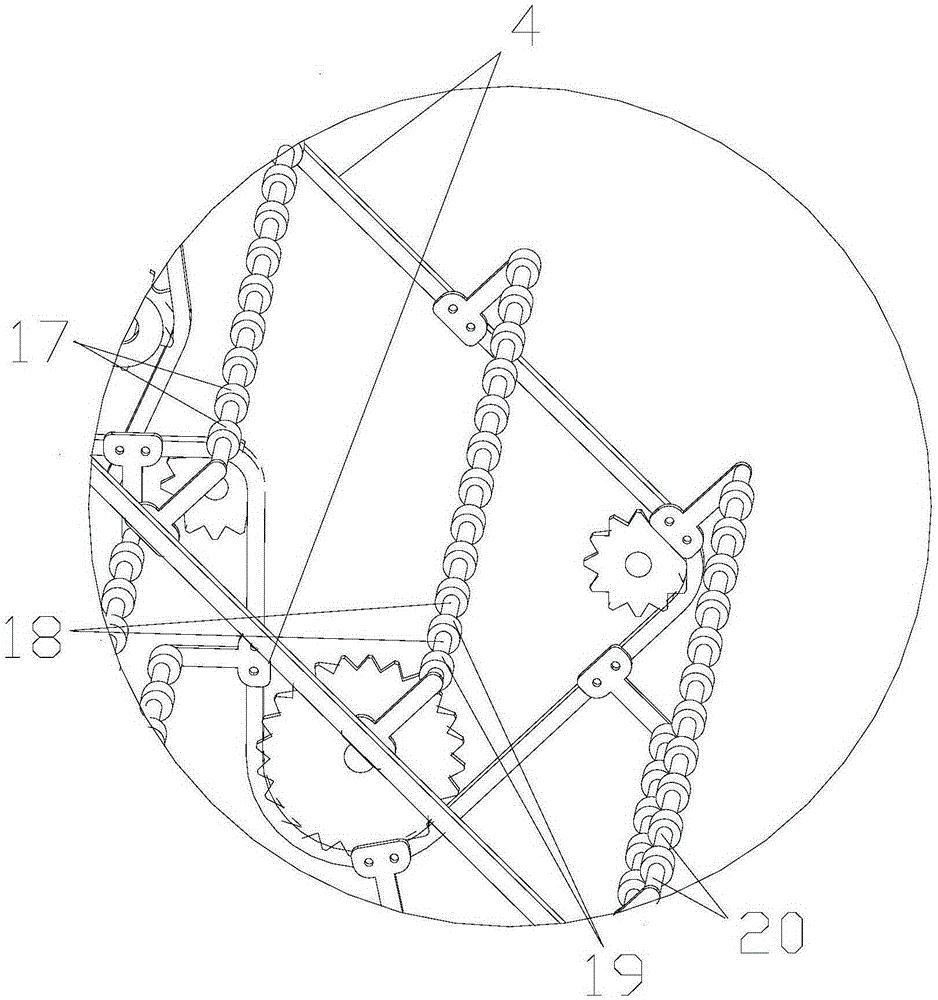

Threshing device of harvester

The invention discloses a threshing device of a harvester and belongs to the field of harvesting equipment components. The threshing device comprises a threshing cylinder, multiple threshing teeth are arranged on the surface of the threshing cylinder, the threshing device further comprises a crop guiding device, the crop guiding device comprises crop guiding chains, crop guiding chain wheels and multiple crop pressing cross bars, the crop pressing cross bars are fixed to the crop guiding chains and circularly move along with the crop guiding chains, the crop guiding chains are located over or above the threshing cylinder, multiple continuous V shapes are formed by the crop guiding chains and threshing cylinder approaching sections, and when moving to the bottom ends of the multiple V shapes along with the crop guiding chains, multiple nearest tangent points are formed between the crop pressing cross bars and the threshing cylinder. By means of the threshing device of the harvester, the crop bars can be twisted continuously and dynamically, the striking direction is changed, the crop ear tip positions are struck multiple times, no special cleaning device is needed to be installed, and the threshing cylinder can achieve the automatic foreign-matter discharging function and the cleaning function.

Owner:刘念湘

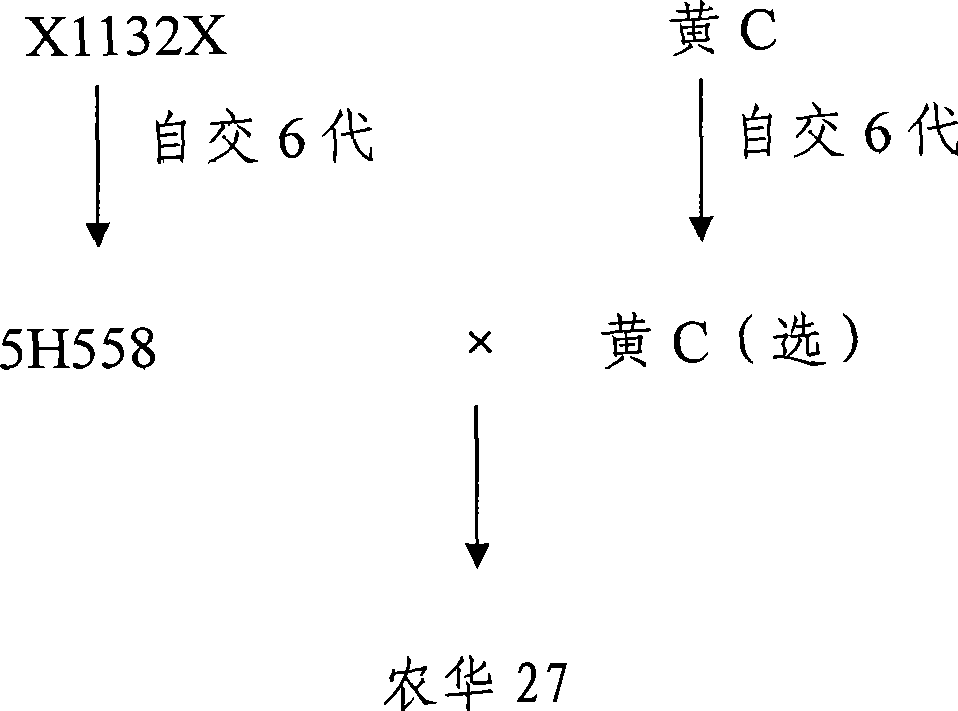

Corn hybrid breeding method

The invention belongs to the field of heterosis utilization, and particularly relates to a seed selection method for corn hybrid species. The method takes inbred line 5H558 as a female parent and takes inbred line yellow C (selected) as a male parent to hybridize so as to prepare a corn hybrid species, Nonghua 27, wherein the inbred line 5H558 is obtained by taking US hybrid species of X1132X as base material, and adopting a pedigree method through continuous inbred 6-generation seed selection, and the inbred line yellow C (selected) is obtained through continuous 6-generation inbred by the pedigree method based on the variant strain of an introduced yellow C. The hybrid species is characterized by high yield, stable yield, high disease resistance, and high biological output.

Owner:BEIJING KINGS NOWER SEED S&T

Small corn thresher suitable for family use

The invention discloses a small corn thresher suitable for family use. The main features are: a motor is provided on the upper surface of the horizontal seat plate at the upper end of the frame, and a coupling is provided on the extended shaft of the motor shaft left end of the integrated structure, and a threshing cylinder support is provided at the left end of the coupling. On the cylindrical seat post with integrated structure on the left end of the cylinder support, there is a threshing cylinder suitable for household use and used for threshing corn. The left end of the threshing cylinder is equipped with 4 to 8 integral structure, evenly distributed, triangular Threshing claws, the left end of each threshing claw is provided with an outwardly curved threshing head; the left end of the upper end of the horizontal seat plate is provided with a square vertical seat plate; The center of the circular baffle at the left end of the cylinder is provided with a circular feeding hole, and the wall at the lower end of the collecting cylinder is provided with a discharge hole. The invention not only can quickly thresh corn cobs, but also has small volume, light weight, power saving and low cost, and is suitable for family use.

Owner:池香娥

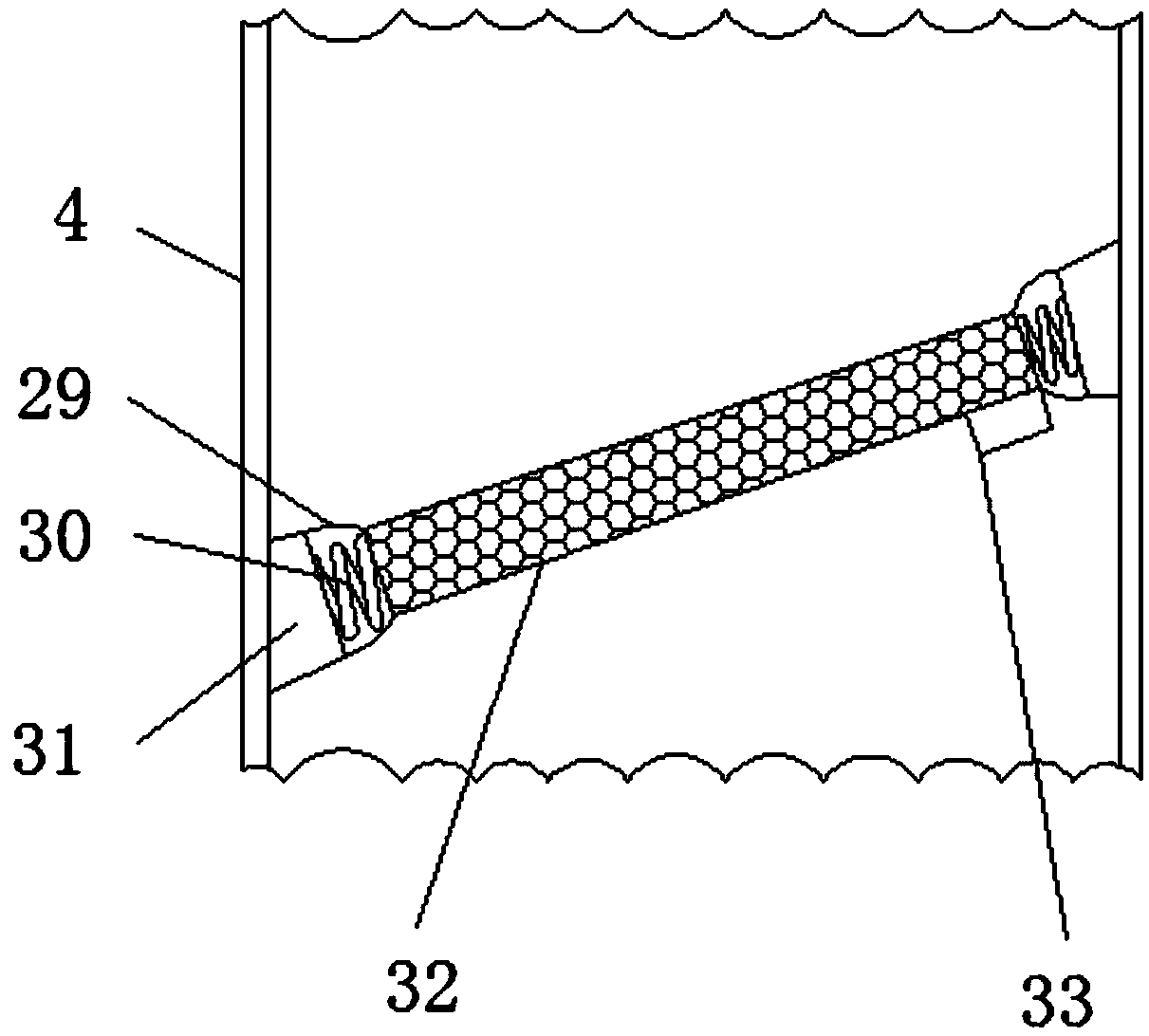

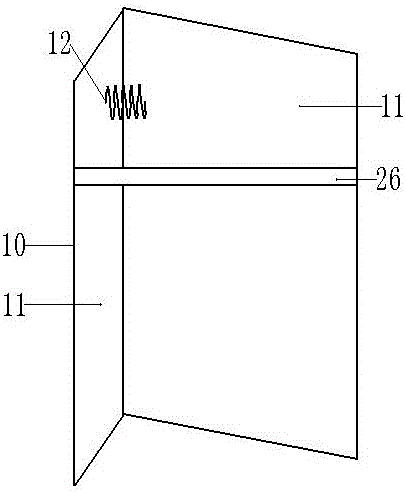

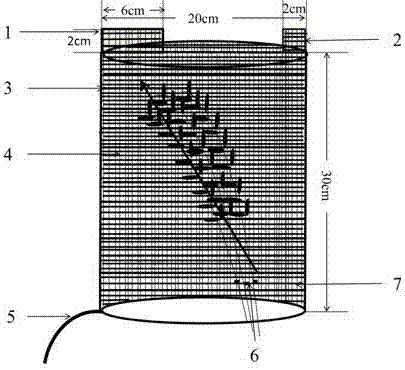

Quick high-efficiency threshing bag for rice single-plant seed selection

PendingCN107996149AExtend your lifeAccelerate the speed of rubbing and threshingThreshersHand equipmentsEngineeringRubbing

The invention discloses a quick high-efficiency threshing bag for rice single-plant seed selection. The quick high-efficiency threshing bag includes a bag cavity, a rubbing block, a bottom holder, anda shrinkage line; the bag cavity is woven by long side threads and wide side threads; the rubbing block and the bottom holder are positioned on a left side and a right side of the bag cavity respectively; and the shrinkage line is positioned on one side of the opening of the bag cavity. A convenient and quick threshing net bag is designed; an inner side of the bag adopts seamless connection loops, and the problem of residue can be solved; the wide side threads are thicker than the long side threads, and the rubbing resistance is increased; the rubbing block can prolong the service life of thenet bag; the bottom holder allows humanized operations, and accelerates the dumping speed.

Owner:江西省农业科学院水稻研究所

Corn threshing and grinding device

The invention discloses a corn threshing and grinding device, comprising: a shell, the bottom surface of which forms a powder outlet, one side is provided with a core body outlet and an air inlet, and the other side is provided with an air outlet; a plurality of threshing Cylinder, which includes a guide cylinder, a tooth cylinder, and a first motor; the first pair of roller layers and the second pair of roller layers; the conveyor belt assembly, which guides the corn cob out of the shell; blower and exhaust fan; vibrating screen; grinding assembly , which includes a leaking plate, a grinding plate, and at least two pairs of screws and grinding stones. The invention can be fast, efficient, line-type threshing and grinding, effectively separate corn kernels, corn cobs and dust, reduce procedures, improve work efficiency, and facilitate maintenance and maintenance.

Owner:李斌施

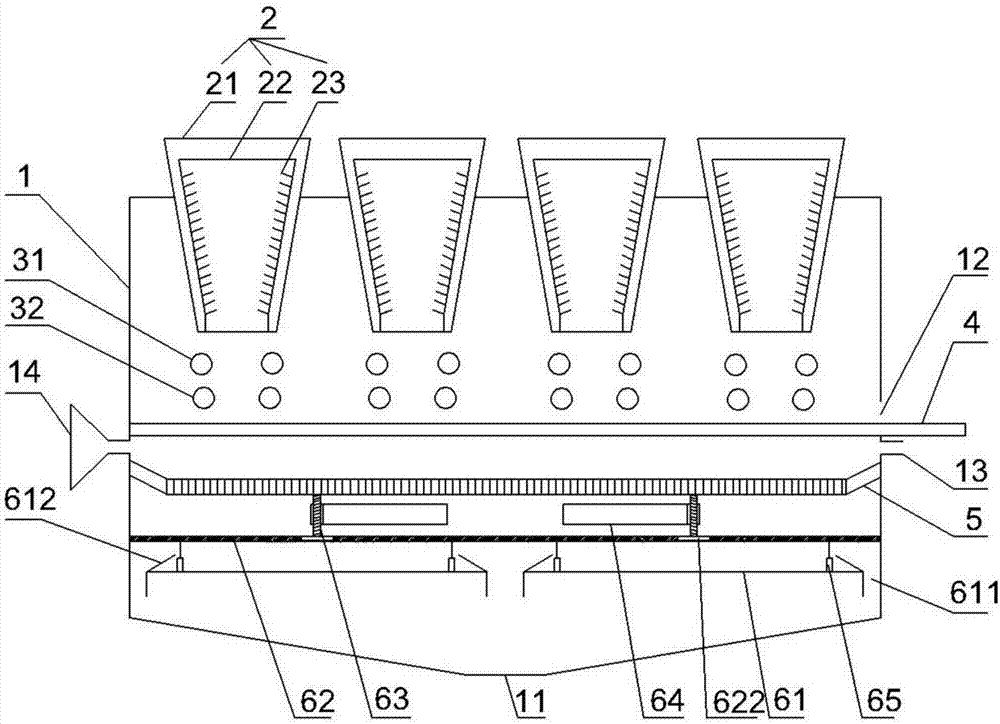

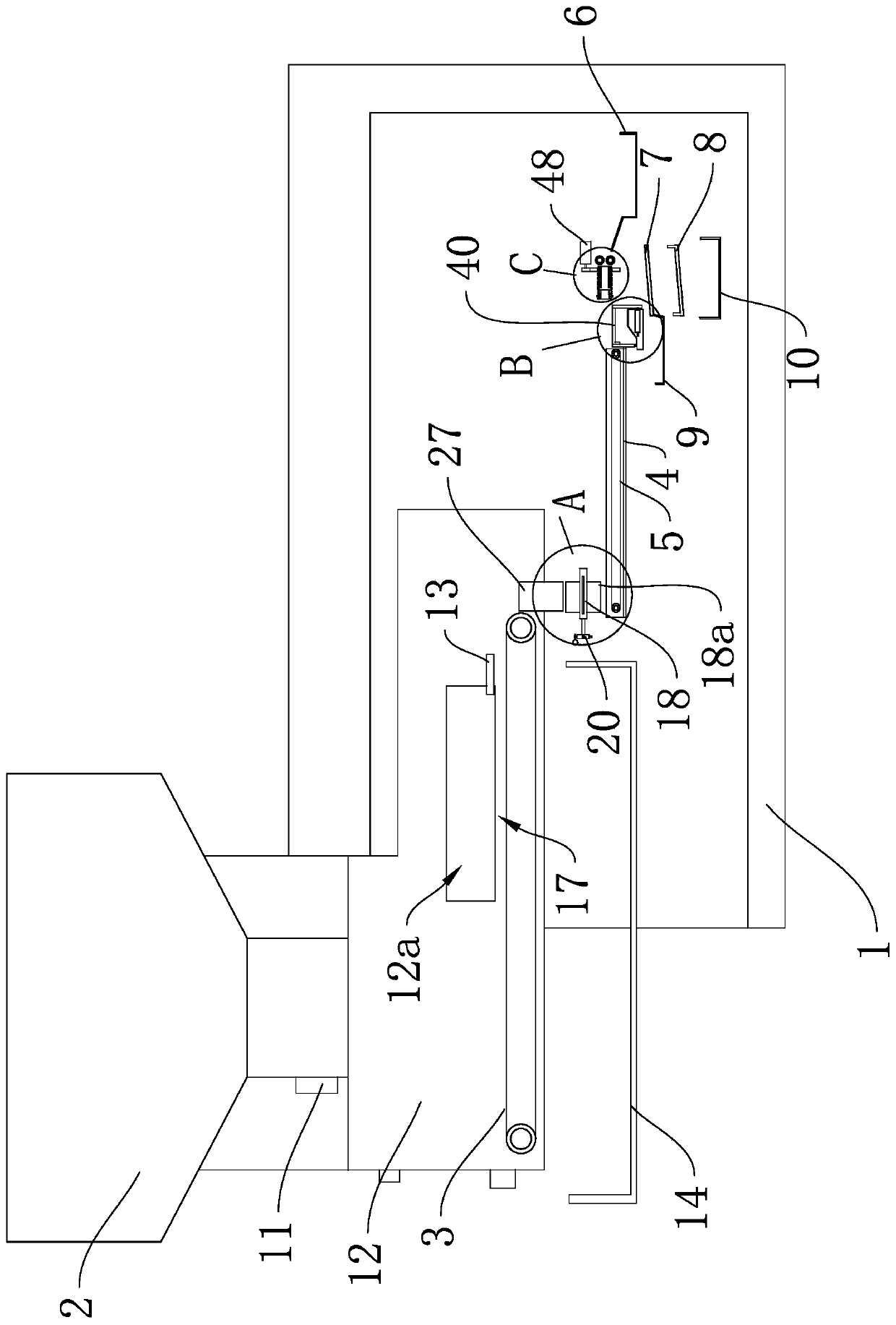

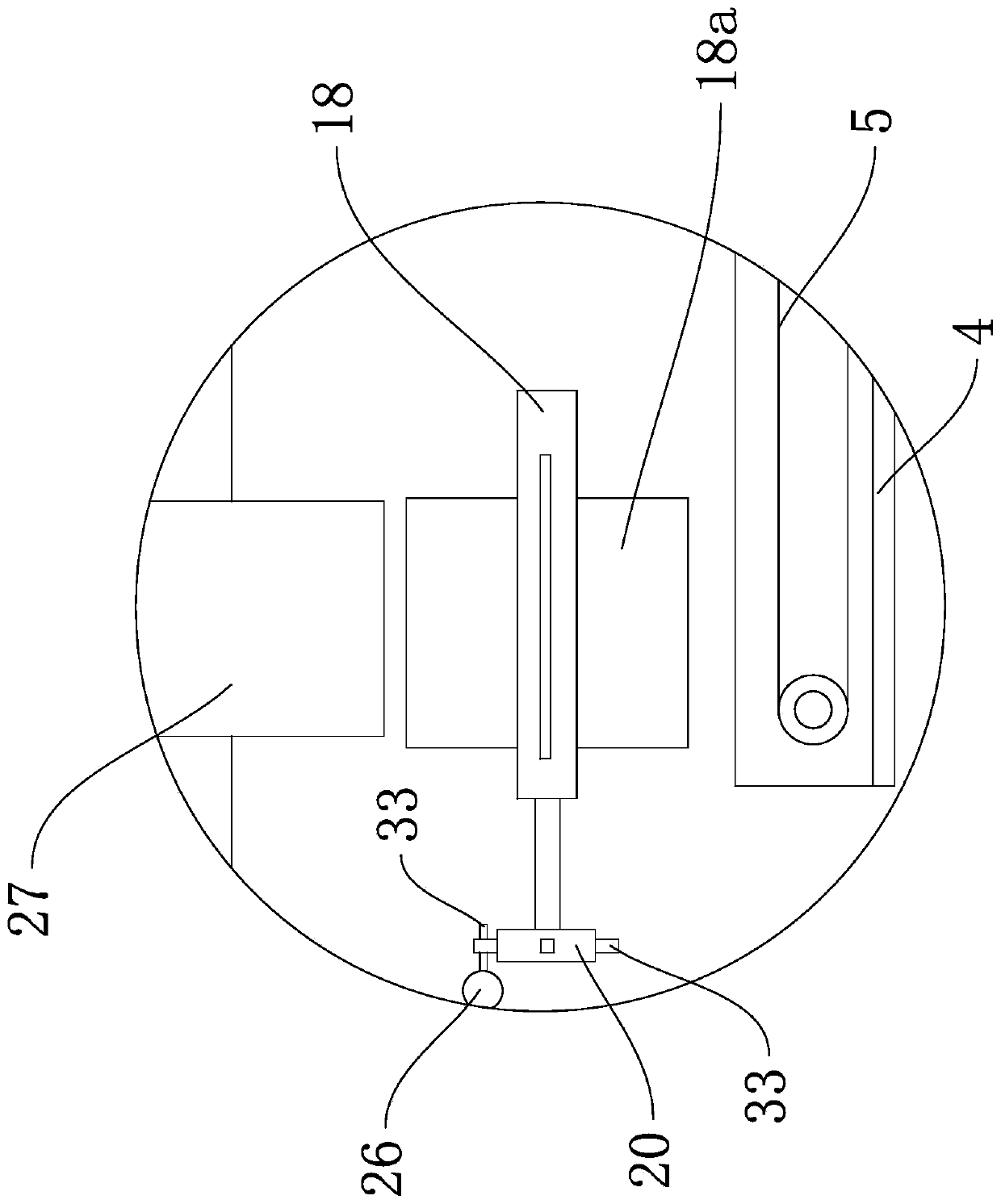

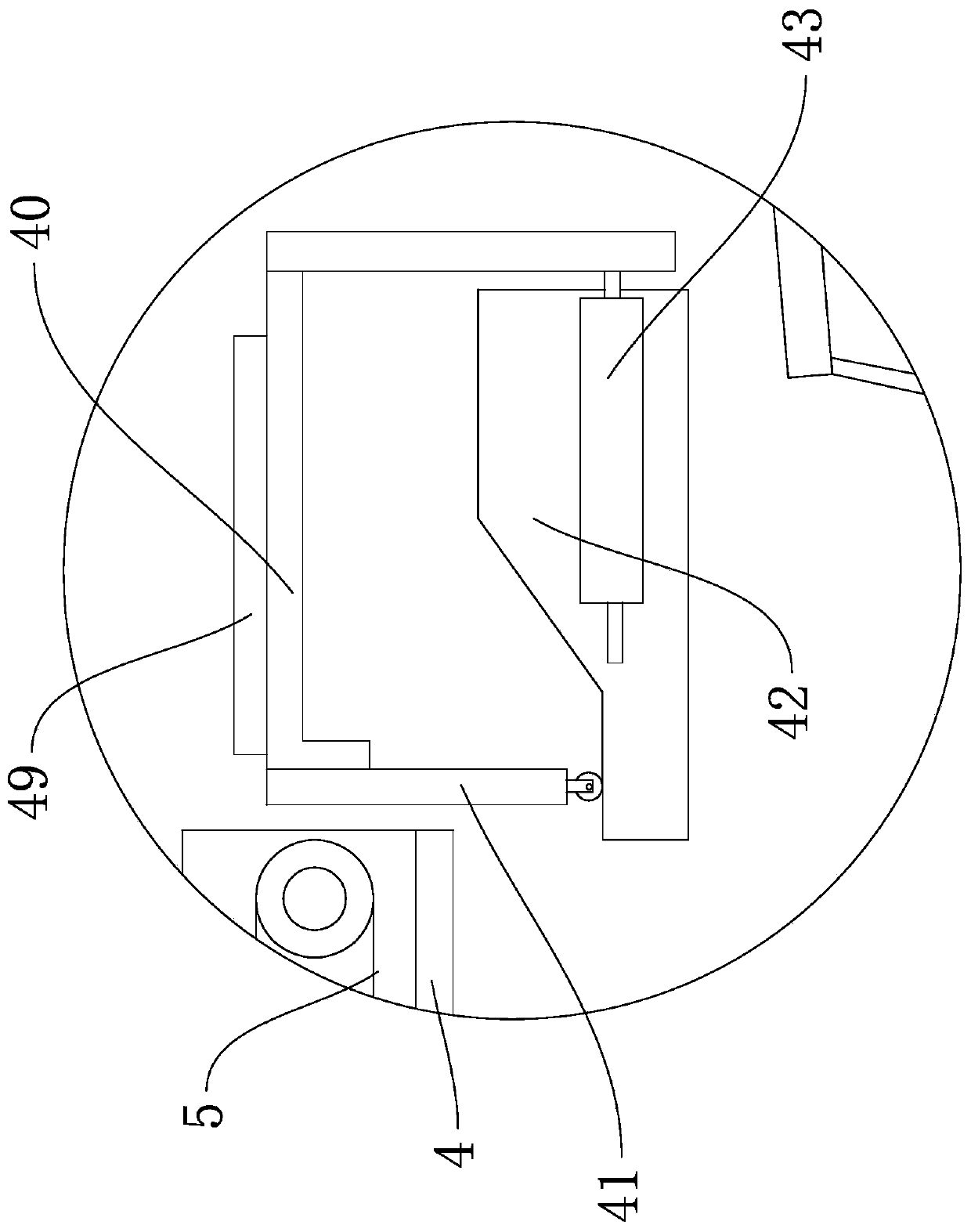

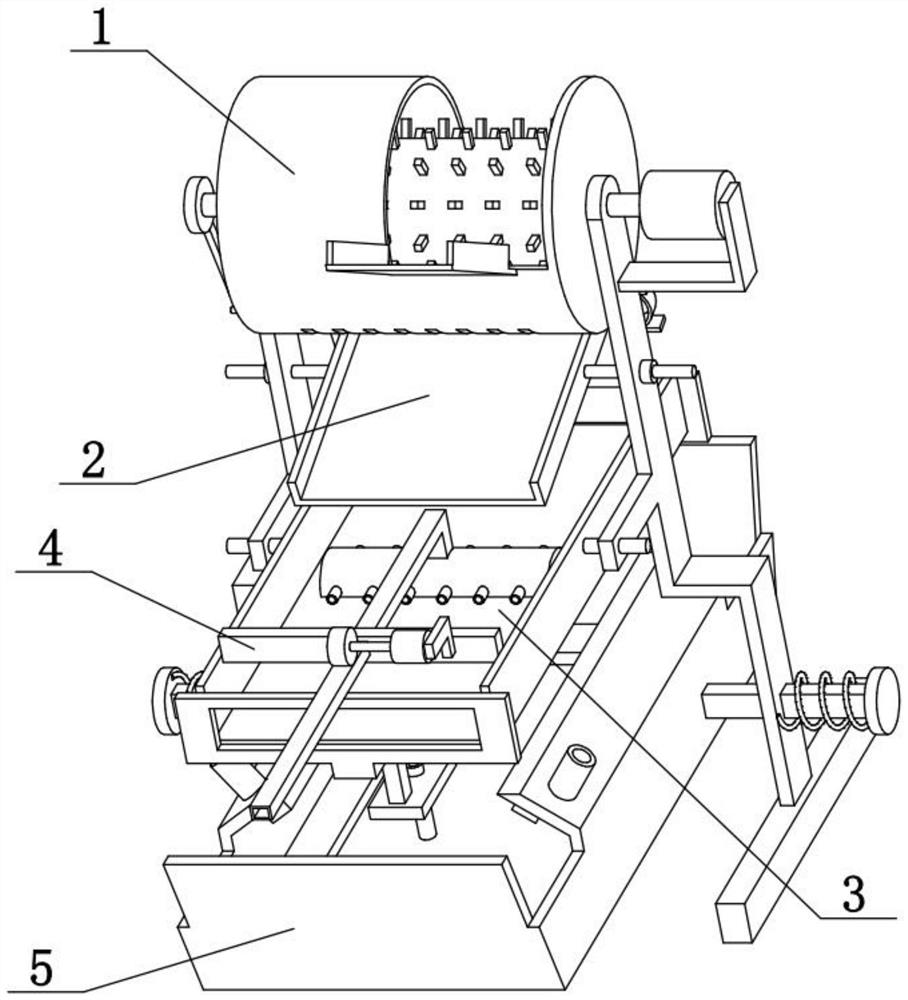

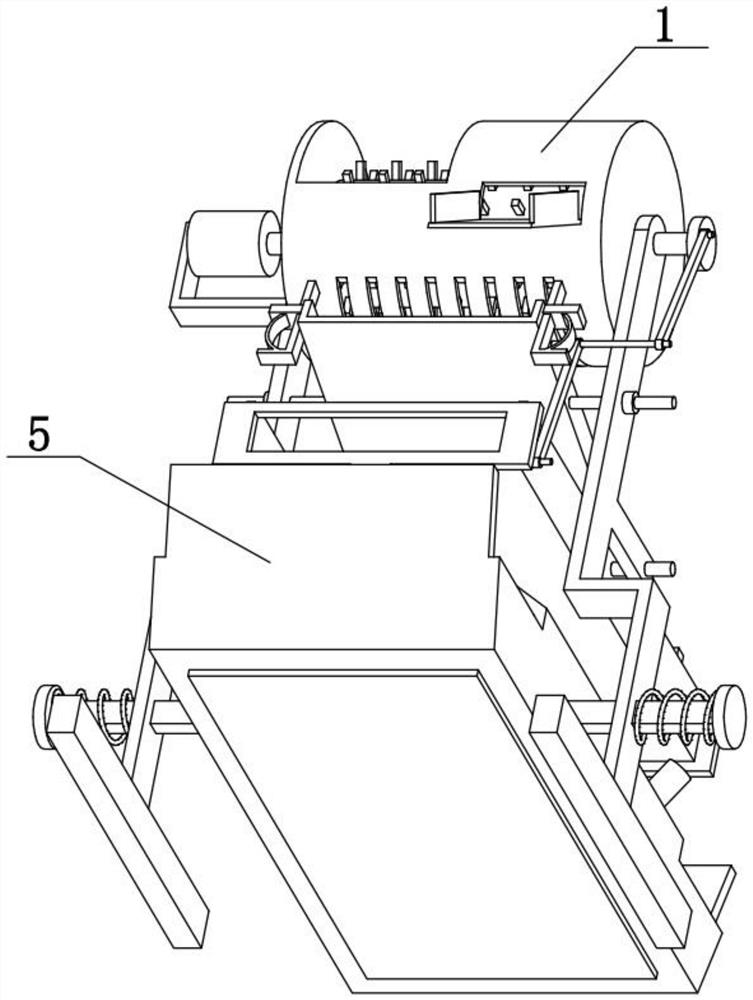

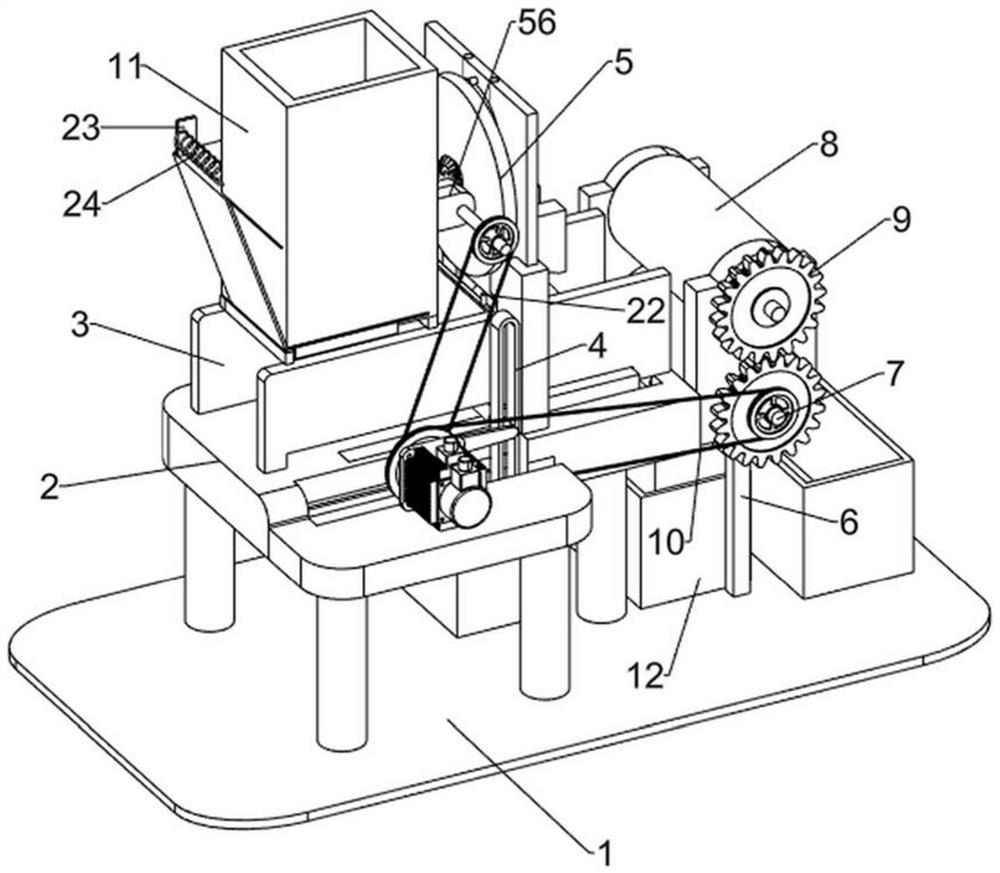

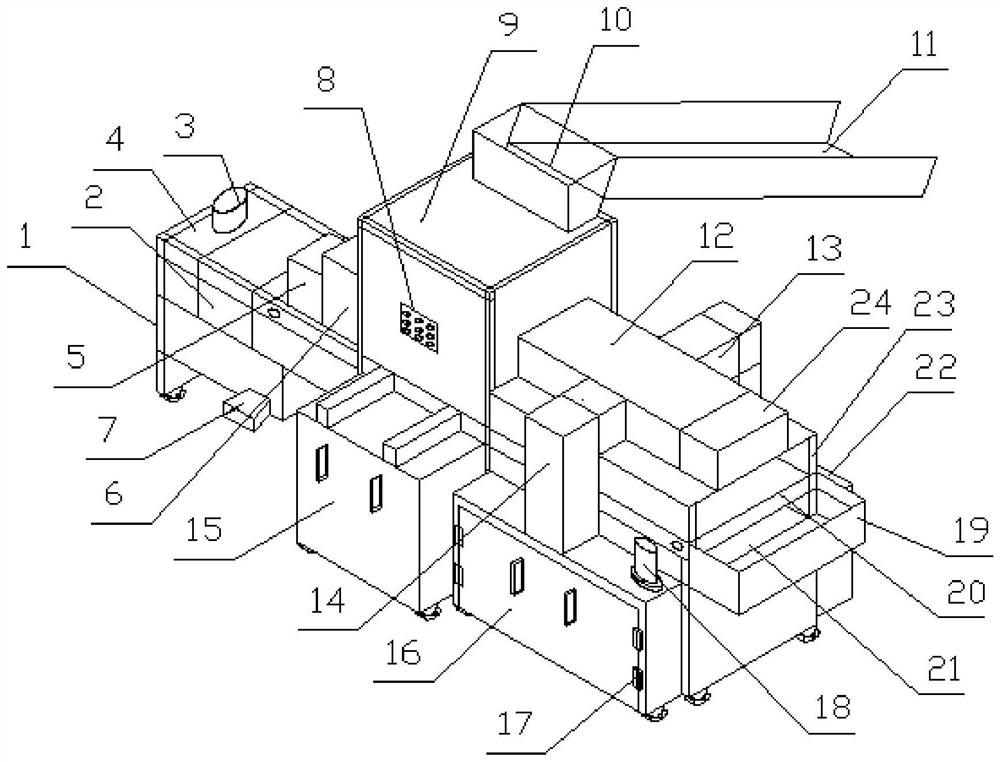

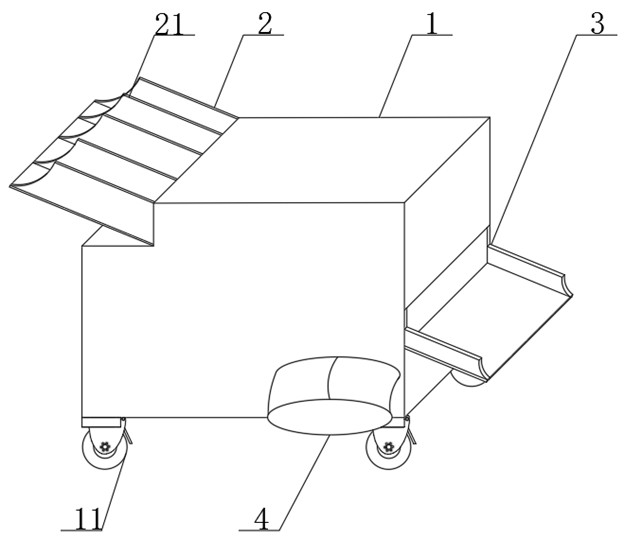

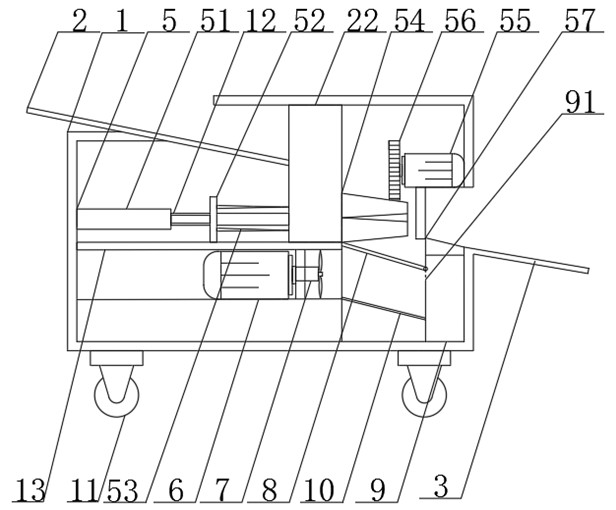

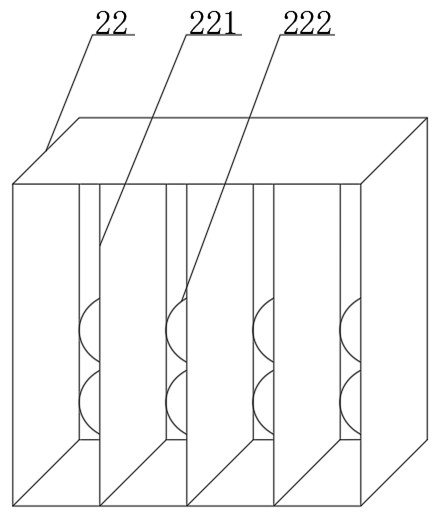

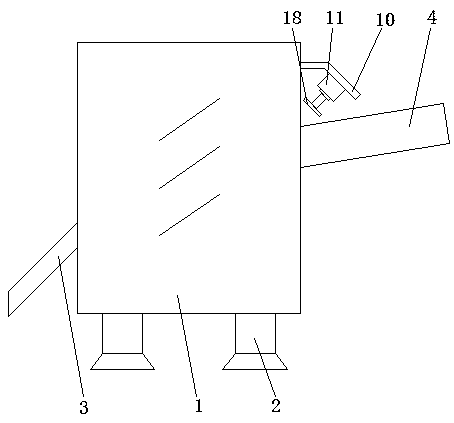

Corn processing device

ActiveCN110881316AFast threshingQuick screening and recyclingThreshersAgricultural engineeringAgricultural science

The invention provides a corn processing device, which belongs to the technical field of agricultural product processing and solves the technical problems of slow peeling efficiency, unclean peeling and the like of the existing corn grains. The corn processing device comprises a machine frame, wherein a feed hopper is fixed to the machine frame; a screening mechanism for transversely outputting corns downwards is arranged below the feed hopper; the screening mechanism comprises a conveyor belt; an outputting mechanism for outputting corns is arranged on one side of the conveyor belt; the outputting mechanism is positioned at the tail end of the conveyor belt in the conveying direction; a conveying groove is fixed to the machine frame; a conveying belt is arranged in the conveying groove; the conveying belt is positioned directly below the outputting mechanism; a peeling mechanism for peeling corn grains is arranged on the machine frame; and a return box is fixed to one side of the peeling mechanism. The device has the advantages of high peeling efficiency of corn grains and clean peeling.

Owner:QUZHOU UNIV

Corn threshing machine

The invention discloses a corn threshing machine which comprises a machine frame and a cylindrical shell. A rotating shaft driven by external power is arranged in the shell. Corn stirring strips are axially arranged on the outer surface of the rotating shaft. One side of the rotating shaft coaxially drives a main belt wheel. An inlet and an outlet are formed in the same side of the upper portion of the shell and are next to each other in the vertical direction. A blocking piece located in the shell is arranged between the inlet and the outlet. A main conveying belt wheel is arranged at the position of the inlet and is coaxially driven by an auxiliary belt wheel on one side of the main conveying belt wheel. The auxiliary belt wheel is connected with the main belt wheel through a belt. One end of a conveying belt is sleeved with the main conveying belt wheel. The portion, away from the inlet, of the other end of the conveying belt is arranged on an auxiliary conveying belt wheel arranged on the machine frame in a sleeving mode. The lower end of the shell is mainly composed of a plurality of columnar threshing rods, and gaps for corn kernels to pass through are reserved between the threshing rods. The corn threshing machine is reasonable in design, capable of achieving rapid corn threshing and high in threshing efficiency; meanwhile, the corn threshing machine is simple in structure, low in manufacturing cost and suitable for application and popularization in villages.

Owner:LONGSHENG COUNTY GUISHENG SMALL CATTLE FARM CO LTD

Corn kernel stripping device for corn threshing

The invention relates to the field of corn threshing, in particular to a corn kernel stripping device for corn threshing. The device comprises a stripping cylinder, a feeding sliding plate, short shafts, a pulp outlet sliding plate, kernel leaking holes, a rotating cylinder and stripping columns, and can be used for quickly threshing a plurality of corns. The multiple stripping columns are fixedly connected to the peripheral surface of the rotating cylinder, the short shafts are fixedly connected to the left side and the right side of the rotating cylinder, the rotating cylinder is located in the stripping cylinder, the two short shafts are rotationally connected to the left portion and the right portion of the stripping cylinder respectively, the stripping cylinder, the short shafts and the rotating cylinder are coaxially arranged, and the plurality of kernel leaking holes are evenly distributed at the lower side of the stripping cylinder. The feeding sliding plate is arranged at the upper side of the stripping cylinder, and the pulp outlet sliding plate is arranged at the lower side of the stripping cylinder. The corn kernel stripping device for corn threshing further comprises an inclined sliding plate, a motor I, side shafts I and supports, the side shafts I are fixedly connected to the left side and the right side of the inclined sliding plate, the two side shafts I are rotationally connected to the middles of the two supports respectively, and the inclined sliding plate is located below the stripping cylinder.

Owner:黑龙江商博士农业发展有限公司

Gorgon fruit threshing device for food processing

ActiveCN111671094BAvoid cutsFast threshingHuskingHullingAgricultural engineeringStructural engineering

Owner:江西谷纬科技有限公司

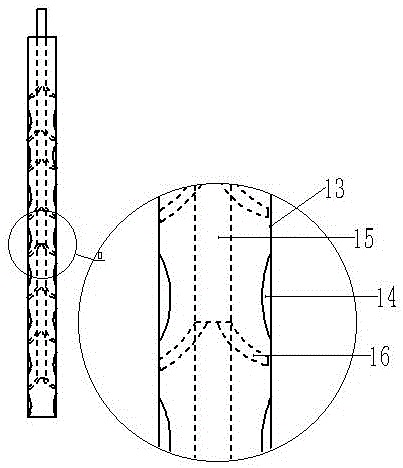

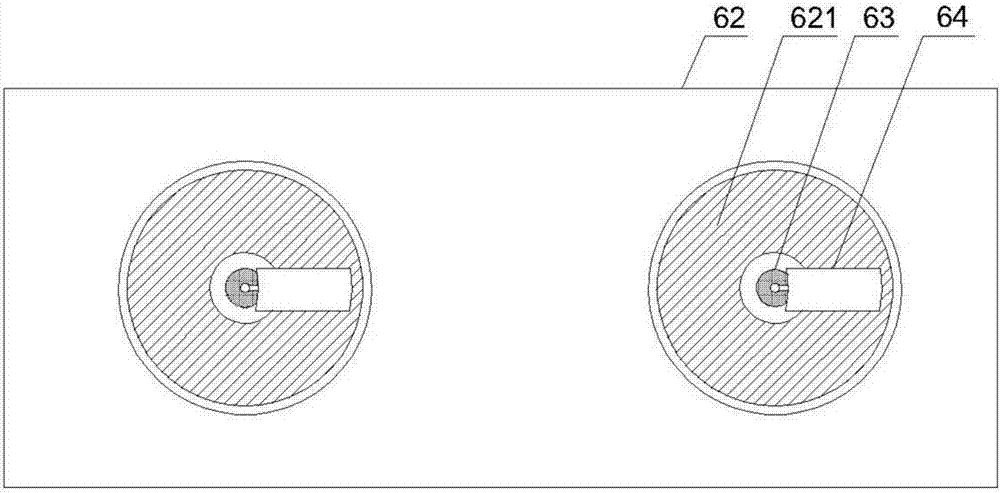

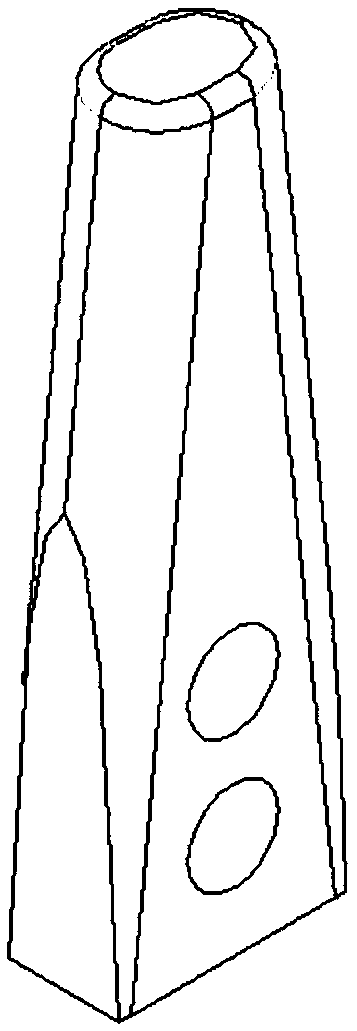

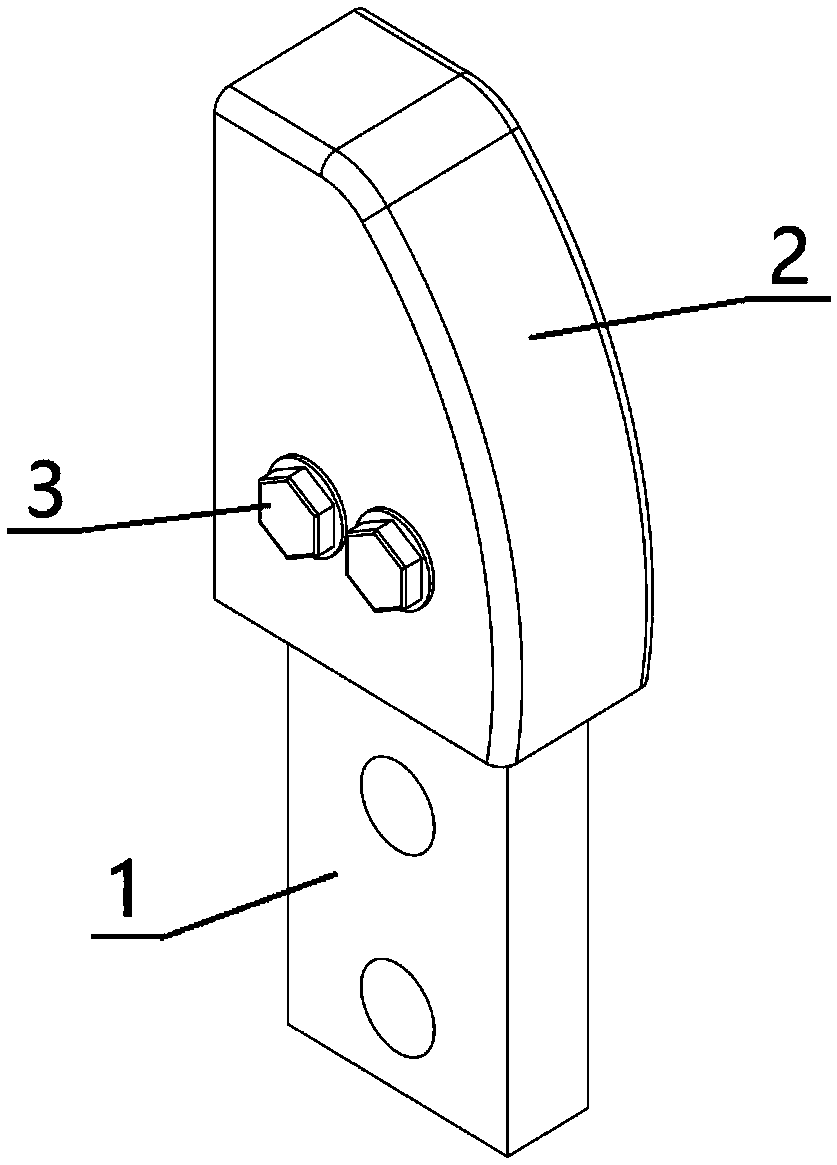

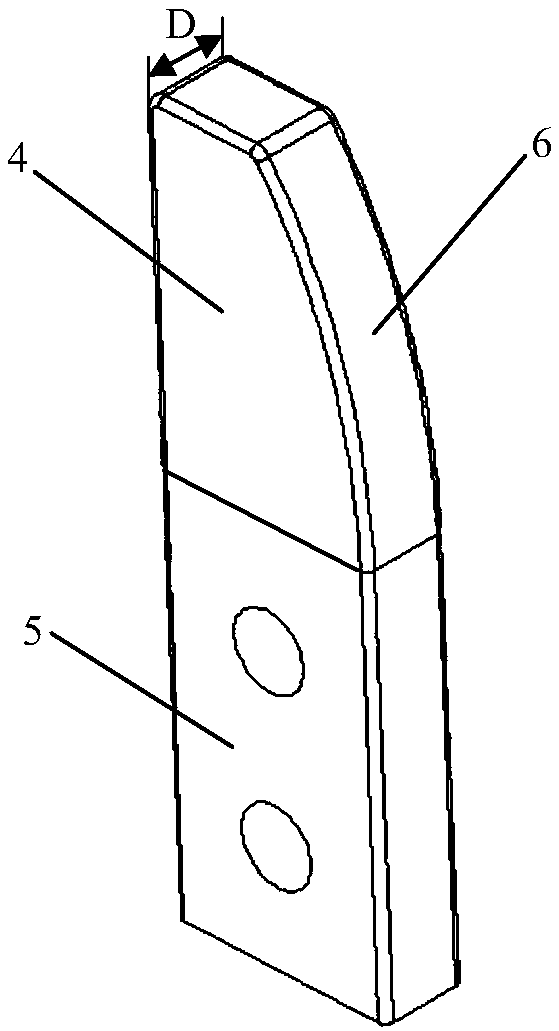

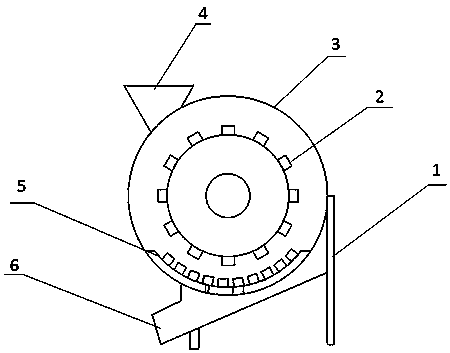

Threshing spike tooth of corn grain harvester

The invention belongs to the technical field of agricultural harvesting machines, and relates to a threshing spike tooth of a corn grain harvester. The threshing spike tooth comprises a spike tooth body (1) and a rubber sleeve (2). The spike tooth body (1) is a platy tooth with a certain thickness, and comprises a working section (4) on the upper side and a fixed section (5) on the lower side. Thefixed section (5) is detachably and fixedly connected to a threshing roller of the corn grain harvester. The thickness end face of the spike tooth body (1) is arranged in the rotating direction of the threshing roller. The thickness end face of one side of the working section (4) of the spike tooth body (1) is a working surface (6), and the working surface (6) is a curved surface. The outer surface of the working section of the spike tooth body (1) is sleeved with the rubber sleeve (2) corresponding to the working section in shape. By means of the threshing spike tooth, corn grain ears can berapidly threshed, the impact of the spike tooth on grains in the threshing process is effectively reduced, and the grain damage rate in the grain harvesting process is reduced.

Owner:CHINA AGRI UNIV

Corn crankshaft threshing machine

The invention provides a corn crankshaft threshing machine. The corn crankshaft threshing machine comprises a machine frame, a threshing bin is arranged on the machine frame, and a threshing roller isarranged in the threshing bin; a feeding opening and a bottom discharging opening are formed outside the threshing bin; the threshing roller is a crankshaft threshing roller, and threshing teeth arearranged on the outer side of a crankshaft of the crankshaft threshing roller; a threshing arc corresponding to a crankcase is arranged below the crankshaft threshing roller; the number of the feedingopening and the number of the discharging opening are matched with the number of the crankshaft of the crankshaft threshing roller. The corn crankshaft threshing machine is simple in structure, and can achieve rapid threshing.

Owner:广西万联重工科技有限公司

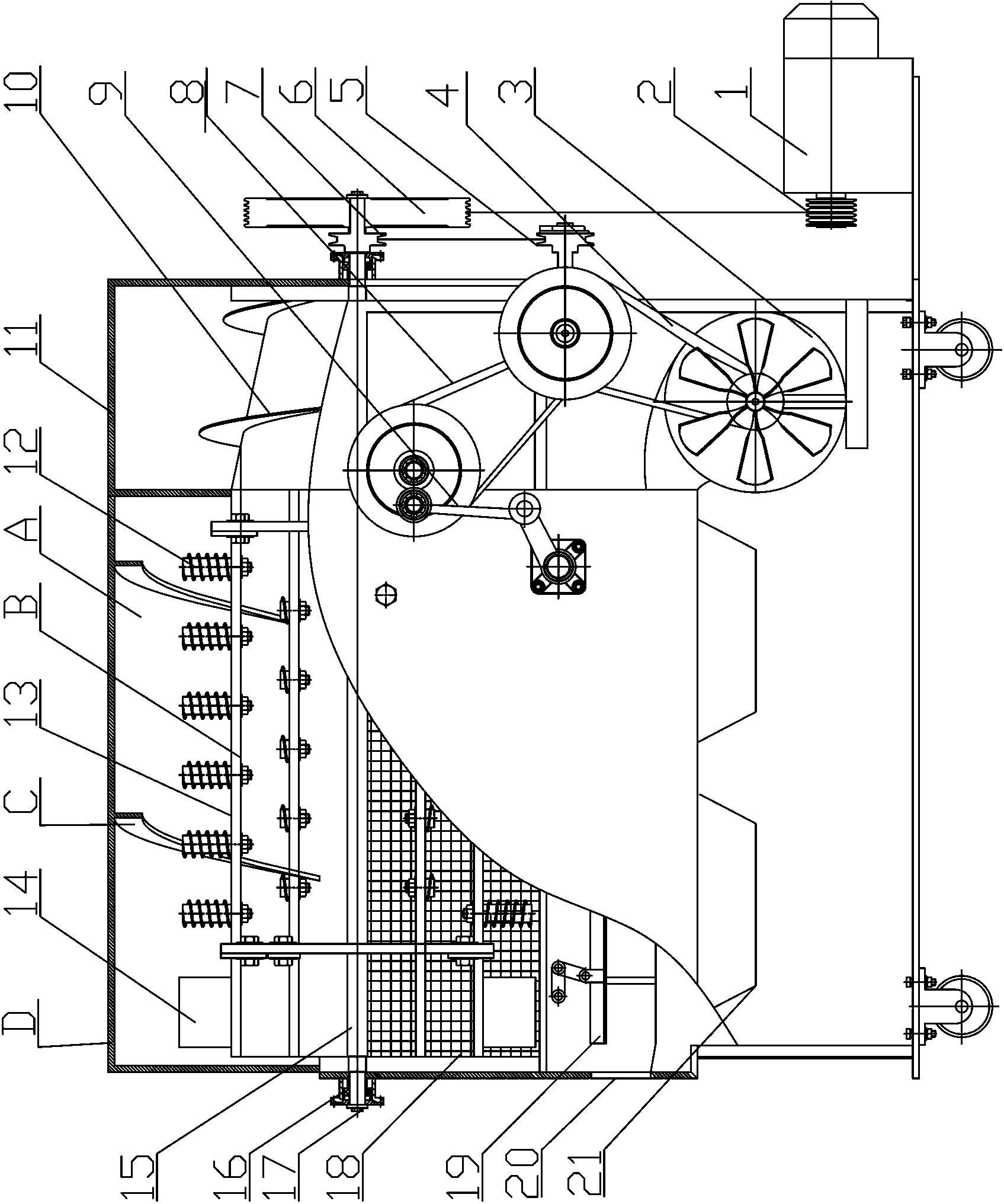

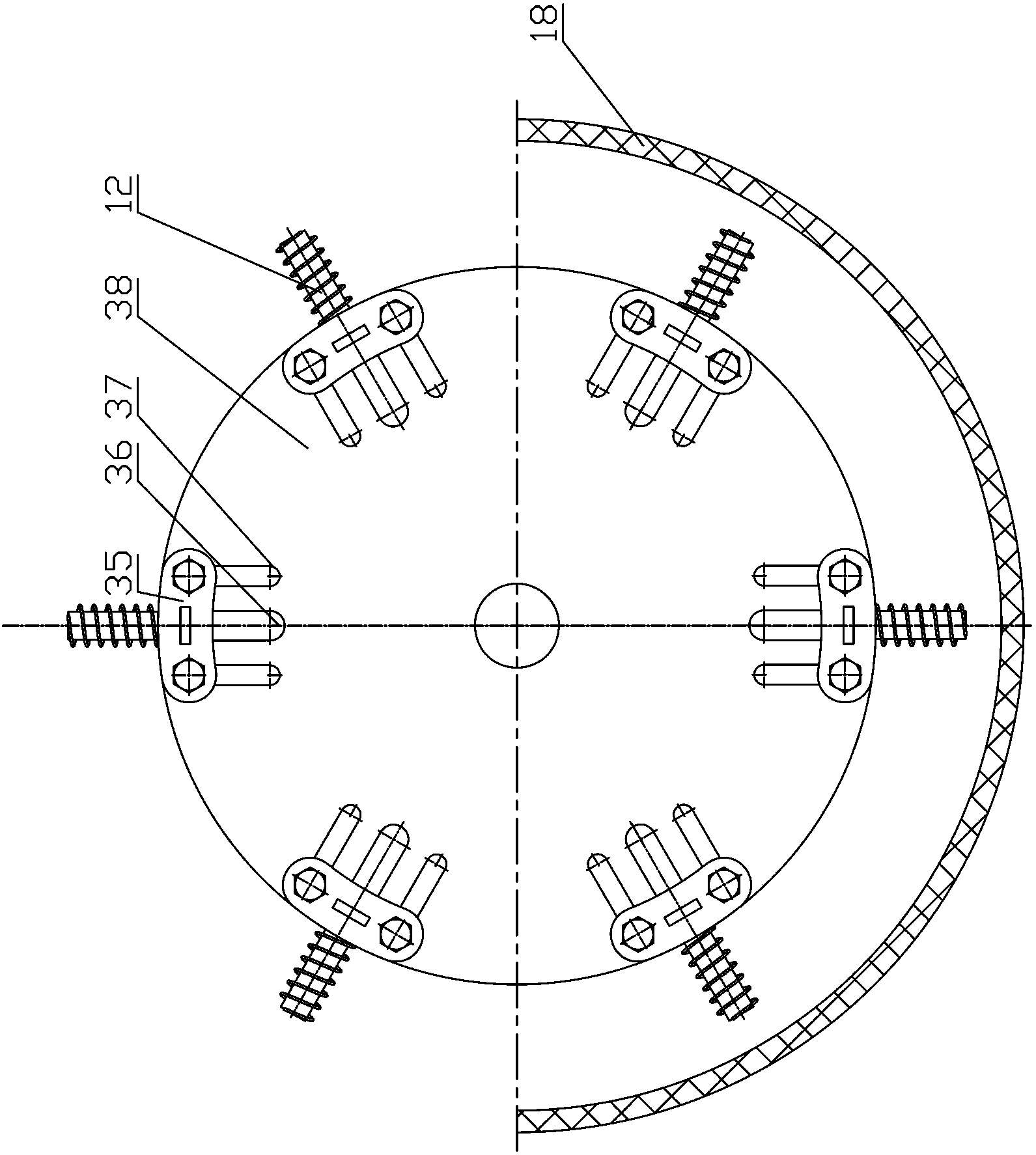

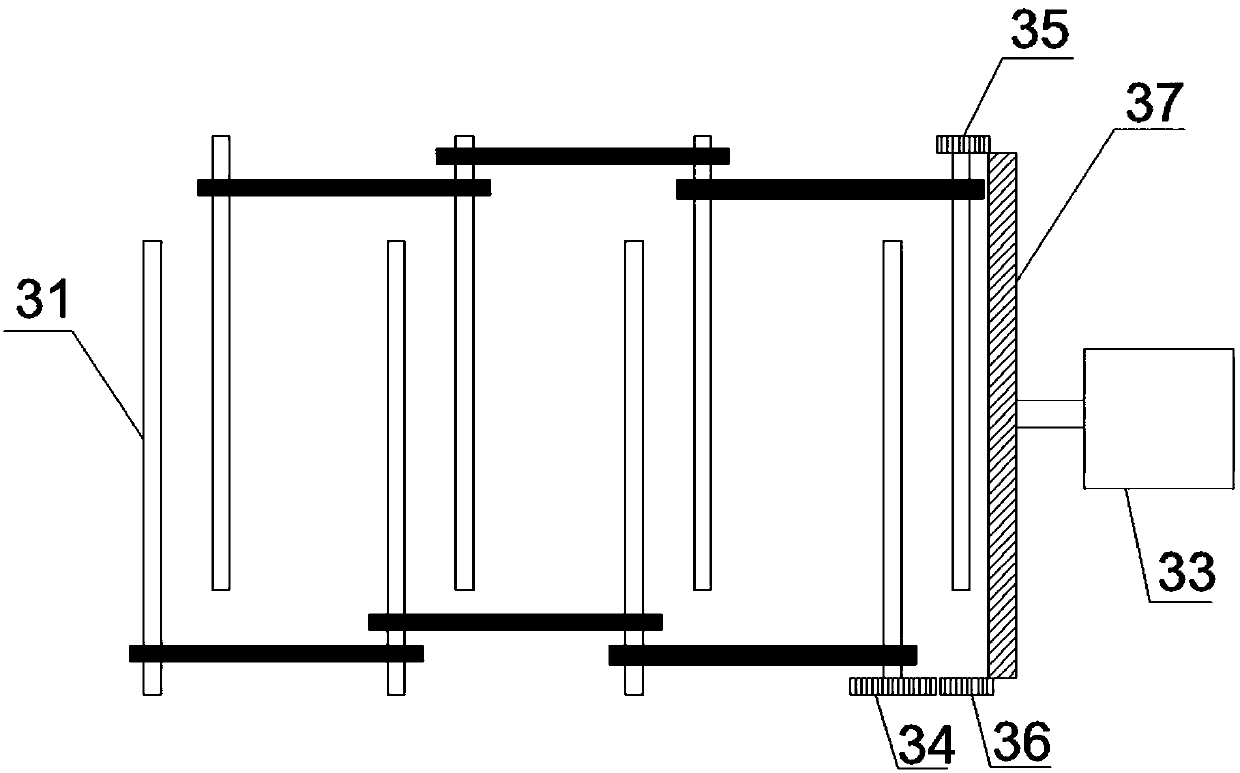

Flexible tooth threshing system with adjustable threshing gap

The invention discloses a flexible-tooth threshing system with an adjustable threshing gap. The flexible-tooth threshing system comprises a threshing roller arranged on a rack and a concave grid, wherein the threshing roller is arranged in a threshing chamber, and comprises two gap regulating end plates fixedly arranged on roller shafts; a plurality of threshing tooth fixing rods with flexible threshing spike teeth are arranged between the two gap regulating end plates; a feeding auger which is distributed in a spiral manner is arranged on the roller shaft at the input end of the threshing roller; a feeding hole is formed in a roller housing corresponding to the feeding auger; a plurality of grass discharging plates are distributed on the roller shaft at the output end of the threshing roller; a straw outlet is formed in the roller housing corresponding to the grass discharging plates. The flexible-tooth threshing system with the adjustable threshing gap disclosed by the invention is used, so that acting time of crop silique on the flexible threshing spike teeth is prolonged, instant impact force is lowered, and crushing rate of rapeseeds can be lowered; meanwhile, the gap between the threshing roller and the concave grid is adjustable, and therefore, the flexible-tooth threshing system can meet threshing requirements varies by physical characteristics of a to-be-threshed material, and improves adaptation to the threshing material.

Owner:HUNAN AGRICULTURAL UNIV

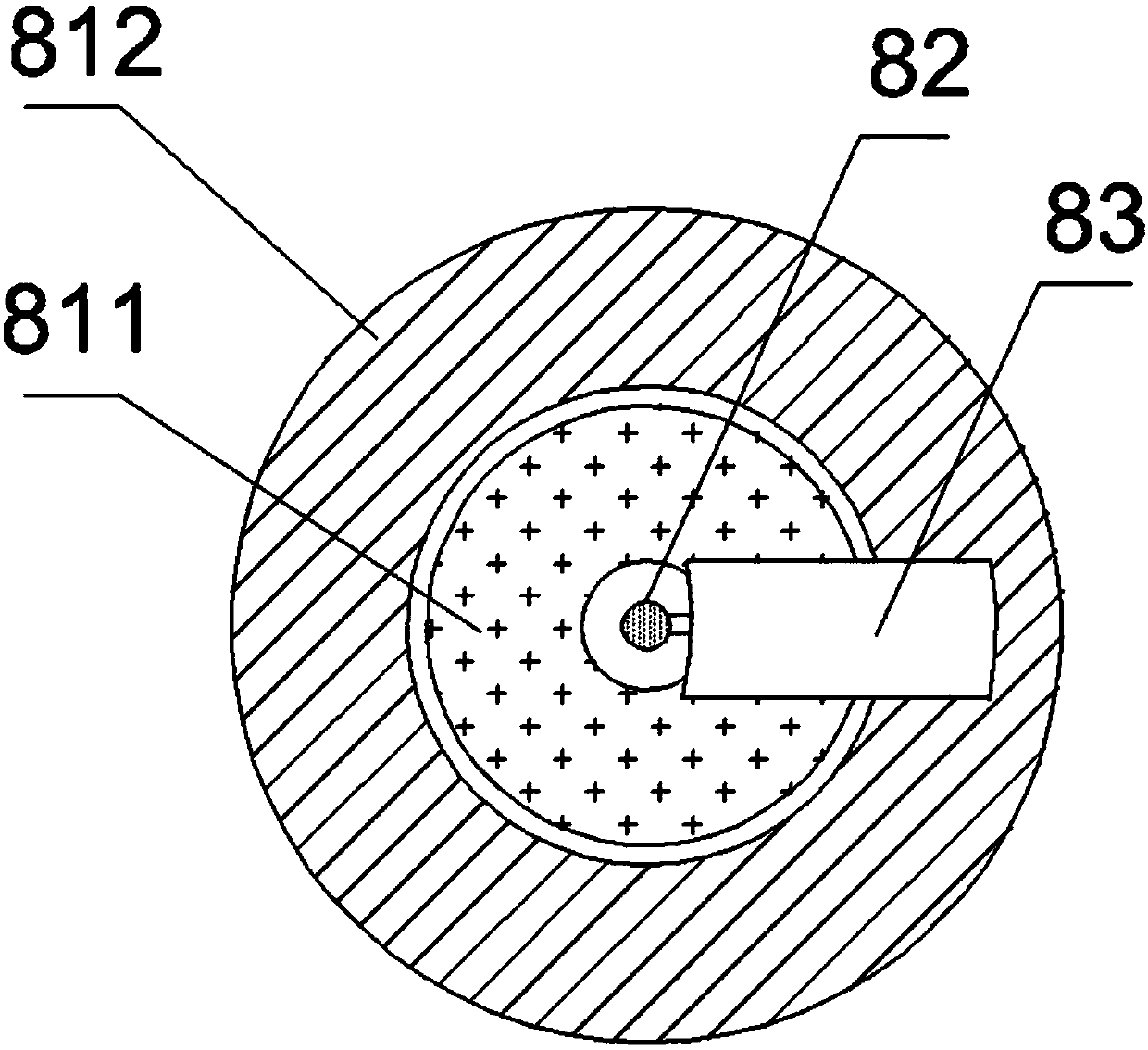

A corn grain combine harvester under high moisture content

ActiveCN111066476BReduce breakage rateAvoid damageHarvestersThreshersAgricultural engineeringStructural engineering

The invention discloses a corn grain combine harvester under high water content. It includes a header, an elevator, a feeding cylinder, a plate-type axial flow threshing drum, and a threshing concave plate. It is installed on the frame of the harvester obliquely upwards. The front end of the plate axial flow threshing drum is provided with a feeding auger, and several threshing plates A and B are connected to the outer surface of the threshing cylinder of the plate axial flow threshing drum. The outer end of the threshing plate A has a tooth-shaped structure, the feeding cylinder is set outside the feeding auger, the front end of the elevator is located below the header, and the rear end of the elevator is correspondingly located above the feeding auger. The threshing concave plate is composed of several cylindrical threshing tubes arranged in parallel and connected by an arc-shaped fixed plate. The threshing concave plate is coaxially arranged on the outer lower part of the plate axial flow threshing drum. There is a threshing gap between them.

Owner:山东时风(集团)有限责任公司

A fully automatic corn threshing grinder

ActiveCN108901371BSave human effortUniform feedingThreshersGrain treatmentsAgricultural engineeringDust control

The invention discloses a fully automatic corn threshing grinder, comprising a grinder body, a grinding box, a first motor, a first gear box, a second motor, a second gear box, a discharge port, a power control board, a threshing box, Feeding hopper, feeding conveyor belt, dust suction fan box, this device can automatically transport corn to the threshing box for threshing, saving manpower, feeding evenly, and preventing blockage; it can quickly thresh the corn, and then threshing the corn The granules are processed by dust removal and drying to improve the quality of corn; the waste materials after threshing are collected to prevent the waste materials from splashing into the corn and causing impurities in the corn; the dried corn can be ground into a powder device, which is convenient for packaging and storage. It is processed according to different needs; it is convenient for people to deal with waste materials without manual removal, which improves efficiency, saves time, reduces labor costs, and brings convenience to people.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

A poplar seed thresher and poplar seed thresher method

The invention relates to the field of forest product processing machine and processing method, in particular to a poplar seed threshing machine. The poplar seed threshing machine comprises a power device, a threshing device and a screening device. The threshing device comprises an outer drum and a rotating shaft. The rotating shaft is arranged in an outer drum cavity. Shaft racks are fixedly arranged on the rotating shaft in the axial direction. A steel plate is fixed in the outer drum. The shaft racks can make contact with the steel plate. The power device drives the rotating shaft to rotate. The screening device is arranged under the outer drum. At the same time, the invention further discloses a poplar seed threshing method utilizing the poplar seed threshing device. The poplar seed threshing machine and the poplar seed threshing method have the advantages that the operation is simple, the structure is reasonable, manpower labor is emancipated, and threshing can be conducted on the poplar seed quickly; at the same time, the quality of the poplar seed is guaranteed, thereby the production cost is saved, and the seedling and sowing area of poplar sexual propagation can be enlarged quickly in a short time.

Owner:NANJING UNIV OF INFORMATION SCI & TECH +1

Corn threshing device

InactiveCN114303653AWon't hurtGuaranteed qualityThreshersAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and particularly relates to a corn threshing device which comprises a corn threshing vehicle, a feeding plate is installed at the top end of the corn threshing vehicle, a corncob discharging port is formed in the side face of the corn threshing vehicle, and a corn kernel discharging port is formed in the side face of the long edge of the corn threshing vehicle. A discharging groove is formed in the position, located at the bottom end of the feeding plate, in the corn threshing vehicle, a supporting plate is installed in the corn threshing vehicle, a propelling threshing mechanism is installed on the upper end face of the supporting plate, the second motor is installed on the lower end face of the supporting plate, and a blowing fan is installed on a driving shaft of the second motor. A filter plate is installed at the position, close to the corncob discharging port, in the corn threshing vehicle, the arranged discharging groove is matched with the propelling threshing mechanism to achieve rapid threshing of corn cobs, production efficiency is improved, labor intensity of people is relieved, compared with an existing corn thresher, threshed corn kernels cannot be damaged, and the corn thresher is convenient to use and popularize. And the quality of the corn is ensured.

Owner:董玉龙

A corn kernel peeling device for corn threshing

The invention relates to the field of corn threshing, more specifically a corn kernel peeling device for corn threshing, including a peeling cylinder, a feeding slide, a short shaft, a pulp discharging slide, a leaking hole, a rotating cylinder and a peeling column. The invention allows rapid threshing of multiple corns. A plurality of peeling columns are fixedly connected to the outer peripheral surface of the rotating drum, short shafts are fixedly connected to the left and right sides of the rotating drum, the rotating drum is located in the peeling drum, and the two short shafts are respectively connected to the left and right parts of the peeling drum in rotation. , the peeling cylinder, the short shaft and the rotating cylinder are coaxially arranged, and the lower side of the peeling cylinder is evenly distributed with a plurality of leakage holes, the upper side of the peeling cylinder is provided with a feeding slide plate, and the lower side of the peeling cylinder is provided with a pulp discharge slide plate. The corn grain peeling device for corn threshing also includes an inclined slide plate, a motor I, a side shaft I and a support, and the left and right sides of the inclined slide plate are fixedly connected with side shafts I, and the two side shafts I are respectively rotatably connected to two In the middle part of the support, the inclined slide plate is located under the stripping cylinder.

Owner:黑龙江商博士农业发展有限公司

Device having corn threshing chamber and corn cob smashing chamber

InactiveCN106717584ARealize automatic crushingLow costPlant waste comminutingCuttersEngineeringMaterial storage

The invention discloses a device having a corn threshing chamber and a corn cob smashing chamber. The device comprises the threshing chamber, the smashing chamber and a material storage chamber, wherein the threshing chamber is of a rectangular structure, a roller is installed internally, a feeding port is formed in the middle of the top of the threshing chamber, two ends of the roller are in rotary connection with the inner wall of the threshing chamber, the smashing chamber is arranged on the threshing chamber, a smashing system is installed inside the smashing chamber and comprises a second motor, a connecting shaft and a blade, the material storage chamber is installed at the bottom of the threshing chamber, is communicated with the threshing chamber and is provided with a cone, a discharging port is formed in the middle of the top of the material storage chamber, a driving structure is installed on a rack at the bottom of the material storage chamber and comprises a first motor and a belt wheel. Automatic threshed corn cob smashing can be achieved by adding the smashing system on a corn thresher without corn cob re-processing and re-smashing through other smashing devices, and the cost is reduced.

Owner:WUXI X RES PROD DESIGN & RES

Corn thresher convenient for blanking for agriculture use

The invention discloses a corn thresher convenient for blanking for agriculture use. The corn thresher includes a machine body; the bottom of the machine body is fixedly connected to two supporting legs which are in left and right symmetry; the left side of the machine body is in fixedly hinged joint with a discharging slide plate; the right side of the machine body is fixedly connected to a charging slide plate; the top of the charging slide plate is provided with a feeding groove; and the inner surface on the right side of the feeding groove is fixedly connected to two synchronous motors which are in front and rear symmetry. Through the arrangement of the two symmetrical synchronous motors, rotating rods and spiral scraper blades, power-assisted action on put corns can be realized, the corns can be descended by gravity, the effects of corn descending efficiency can be greatly enhanced, the situation of jamming of a charging track can be avoided during a charging process of the corns,and the effects of convenient feeding can be achieved, and can be ensured that work personnel can perform rapid threshing treatment on the corns.

Owner:朱德仲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com