A poplar seed thresher and poplar seed thresher method

A thresher and seed technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., to achieve the effects of saving production costs, fast threshing, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

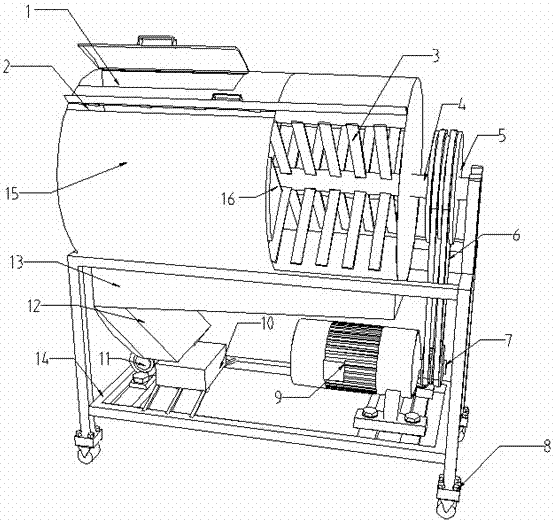

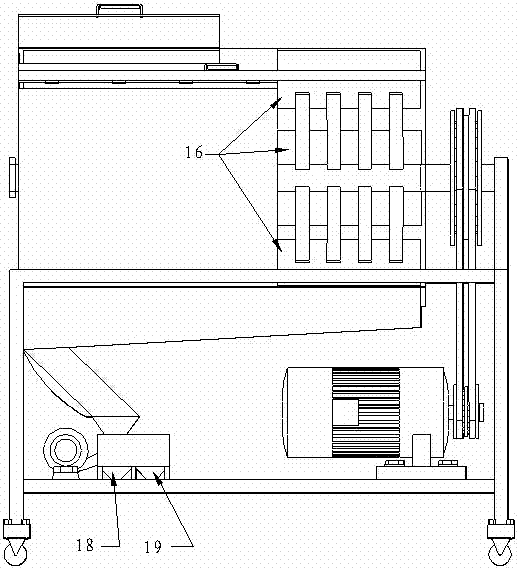

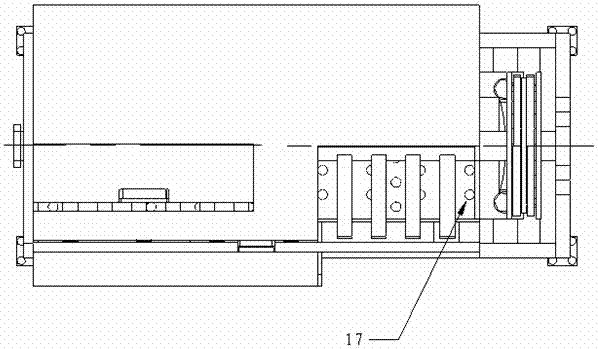

[0031] Such as figure 1 , 2 Shown, a kind of poplar seed thresher comprises power unit, threshing device and screening device, and described power unit, threshing device and screening device are all arranged on the frame 14 that has caster 8.

[0032] The threshing device includes an outer cylinder 15 and a rotating shaft 4, the outer cylinder 15 is cylindrical, and a steel plate 16 is fixed inside the outer cylinder 15, such as Image 6 As shown, two steel plates 16 are welded vertically up and down on the inner wall of the outer cylinder 15, the height from the inner wall of the outer cylinder 15 to the edge of the steel plate is 130 mm, and the thickness is 3 mm. On both sides of the inner wall of the outer cylinder 15, two steel plates 16 Welding forms a sector-shaped space, wherein the radial vertical distance from the welding edge to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com