A corn kernel peeling device for corn threshing

A corn threshing and stripping device technology, applied in threshing equipment, applications, agriculture, etc., can solve the problem of inability to thresh multiple corns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

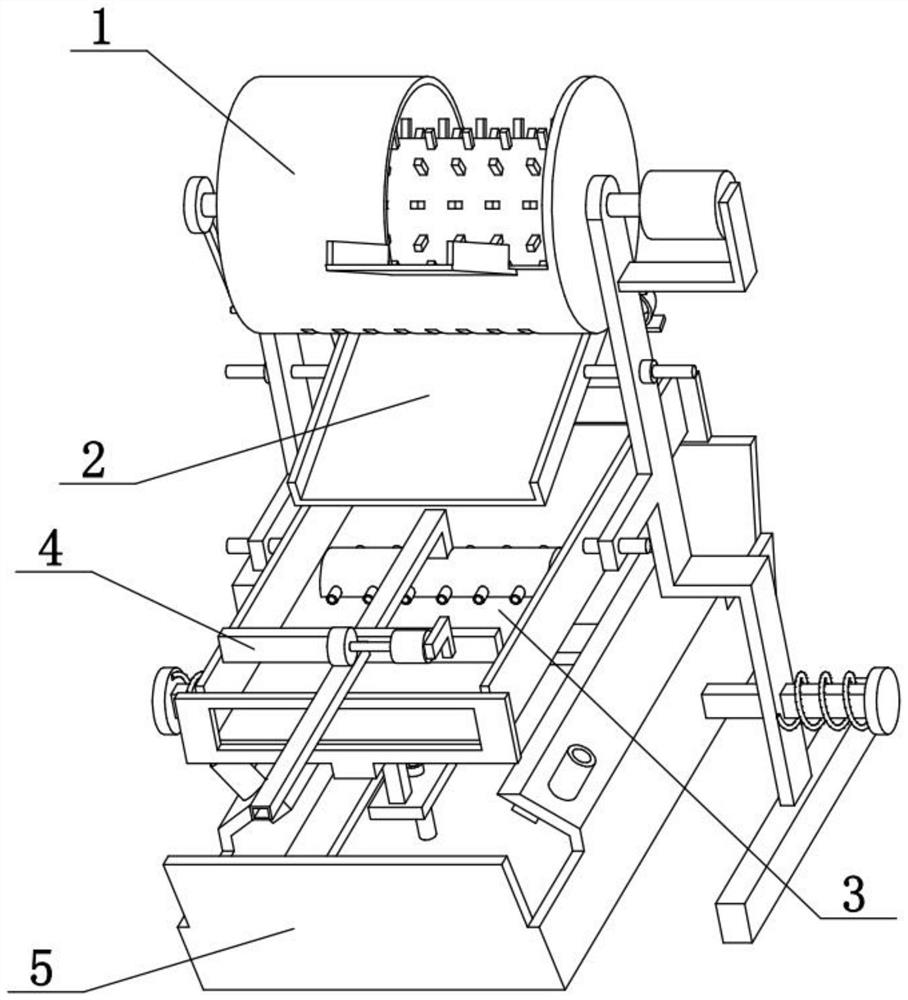

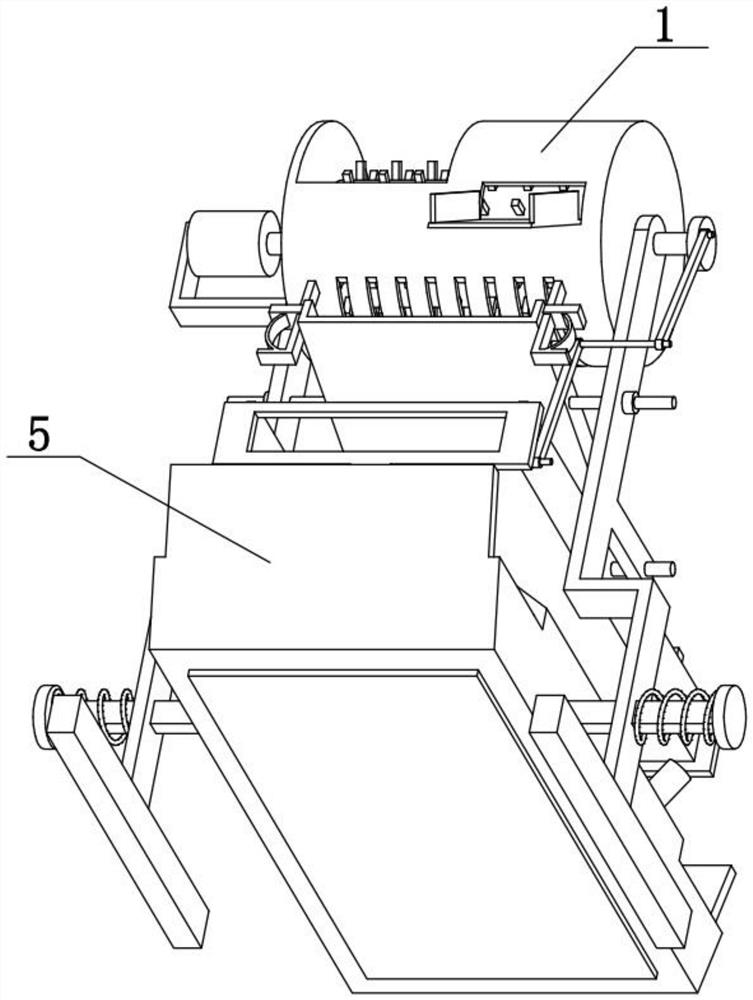

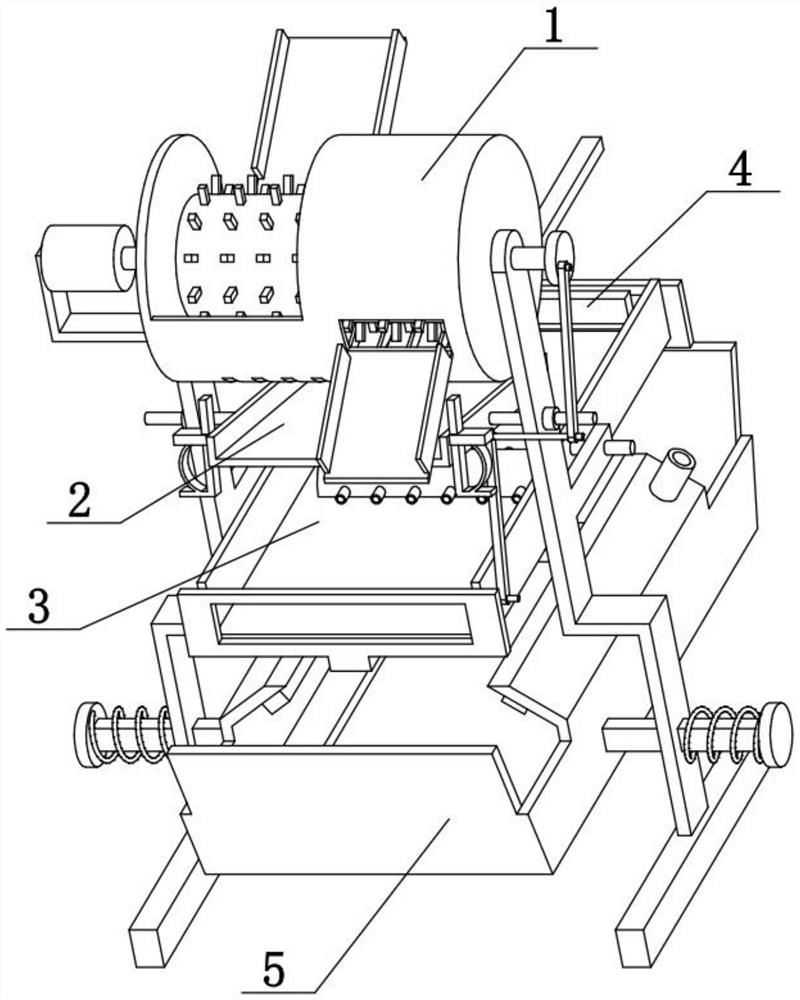

[0031] Combine below Figure 1-9 To illustrate this embodiment, the present invention relates to the field of corn threshing, more specifically, a corn kernel peeling device for corn threshing, including a peeling cylinder 1, a feeding slide 101, a short shaft 102, a pulp discharging slide 103, and a grain leakage hole 104, drum 106 and stripping column 107, the present invention can quickly thresh multiple corns.

[0032] A plurality of peeling columns 107 are fixedly connected to the outer peripheral surface of the rotating drum 106, and short shafts 102 are fixedly connected to the left and right sides of the rotating drum 106. The rotating drum 106 is located in the peeling drum 1, and the two short shafts 102 are connected in rotation In the left and right parts of the stripping cylinder 1, the stripping cylinder 1, the short shaft 102 and the rotating cylinder 106 are coaxially arranged, and a plurality of particle leakage holes 104 are evenly distributed on the lower si...

specific Embodiment approach 2

[0034] Combine below Figure 1-9 To illustrate this embodiment, the corn kernel peeling device for corn threshing also includes an inclined slide plate 2, a motor I201, a side shaft I202 and a bracket 203, and the left and right sides of the inclined slide plate 2 are fixedly connected with a side shaft I202, and the two sides Axis 1202 is rotatably connected to the middle of the two brackets 203, the inclined slide plate 2 is located below the stripping cylinder 1, and the two short shafts 102 are rotatably connected to the upper parts of the two brackets 203, and the bracket 203 on the right side is fixedly connected with a motor I201, the output shaft of the motor I201 is fixedly connected to the short shaft 102 at the right end. The motor I201 is used to drive the two short shafts 102 and the drum 106 to rotate at a high speed, and then the corn kernels are peeled off from the corn. Inclined slide plate 2 is used to accept the corn kernel that leaks from hole 104, and inc...

specific Embodiment approach 3

[0036] Combine below Figure 1-9To illustrate this embodiment, the corn kernel peeling device for corn threshing also includes a turntable 105, a protruding shaft 208, and a hinged rod I209. Shaft 208, the lower end of hinged rod I209 is rotatably connected on the protruding shaft 208. The motor I201 drives the two short shafts 102 and the rotating drum 106 to rotate and also drives the turntable 105 to rotate. When the turntable 105 rotates, the hinged rod I209 drives the inclined slide 2 to continuously swing up and down, thereby preventing corn kernels from accumulating on the inclined slide 2, which is convenient Corn kernels fall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com