Patents

Literature

62results about How to "Realize automatic crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

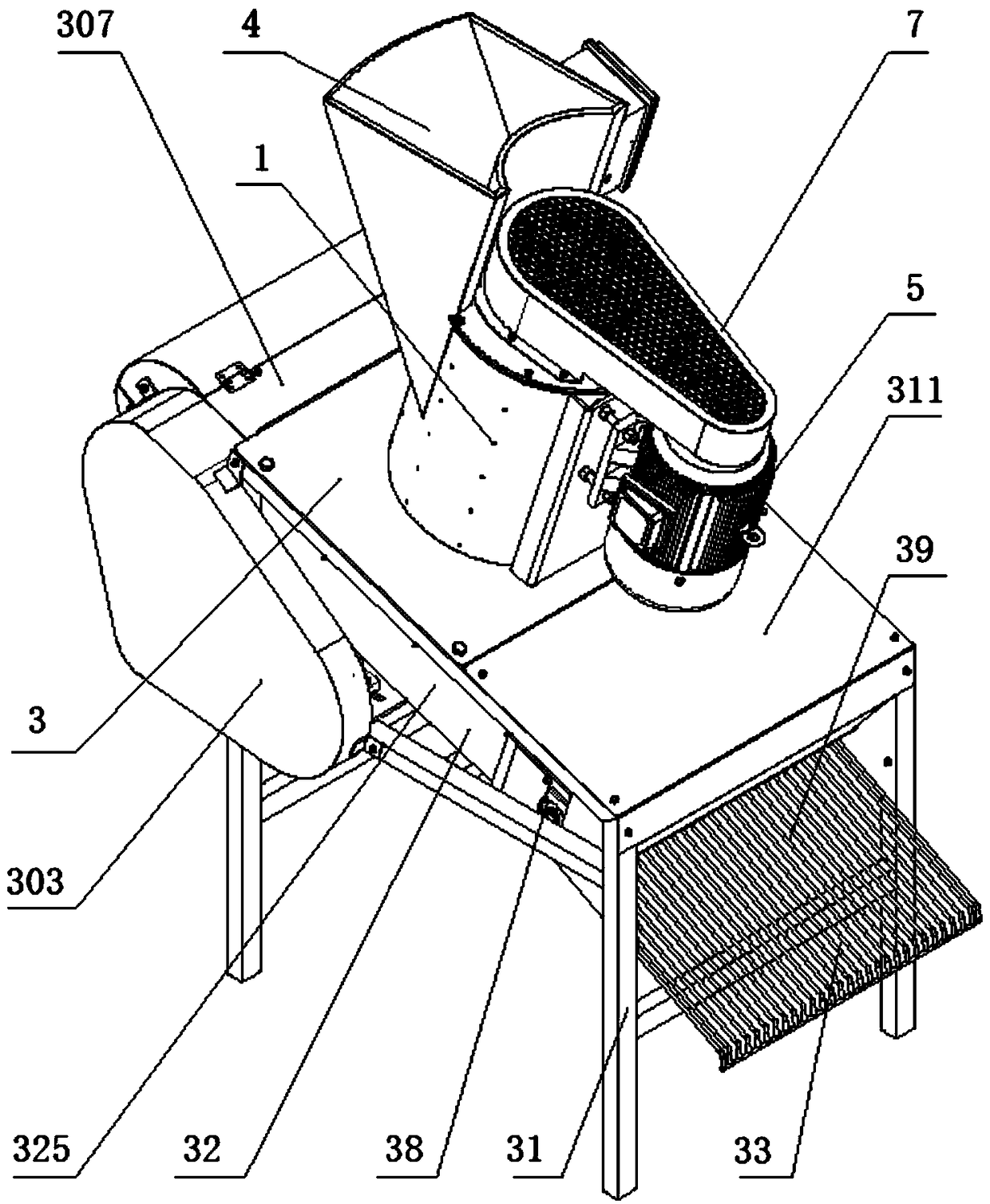

Automatic crushing device for construction waste materials

ActiveCN104096708ARealize automatic crushingNo manual screening requiredSievingConstruction waste recoveryCrusherWaste material

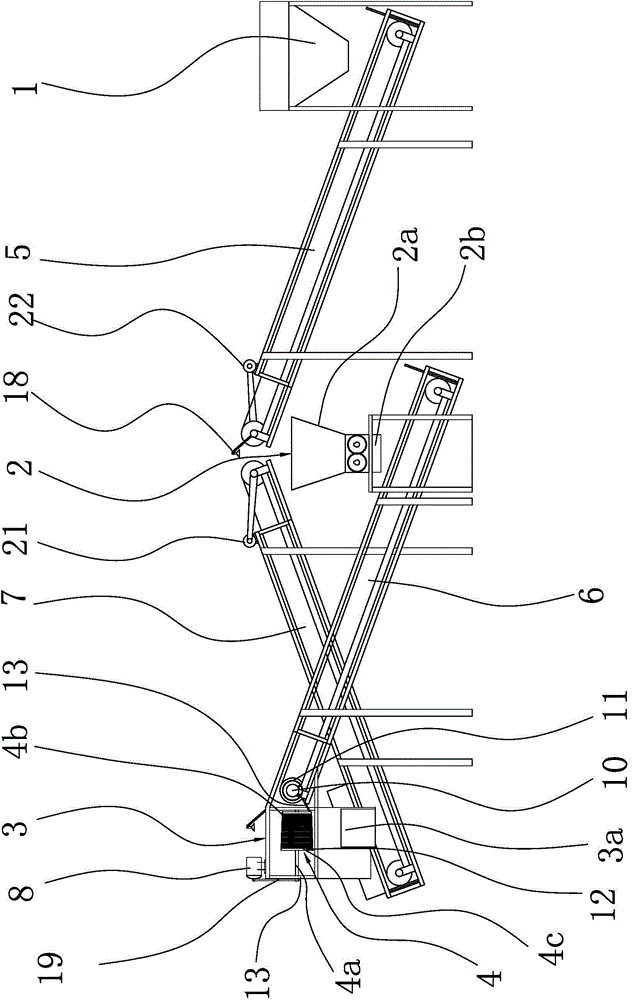

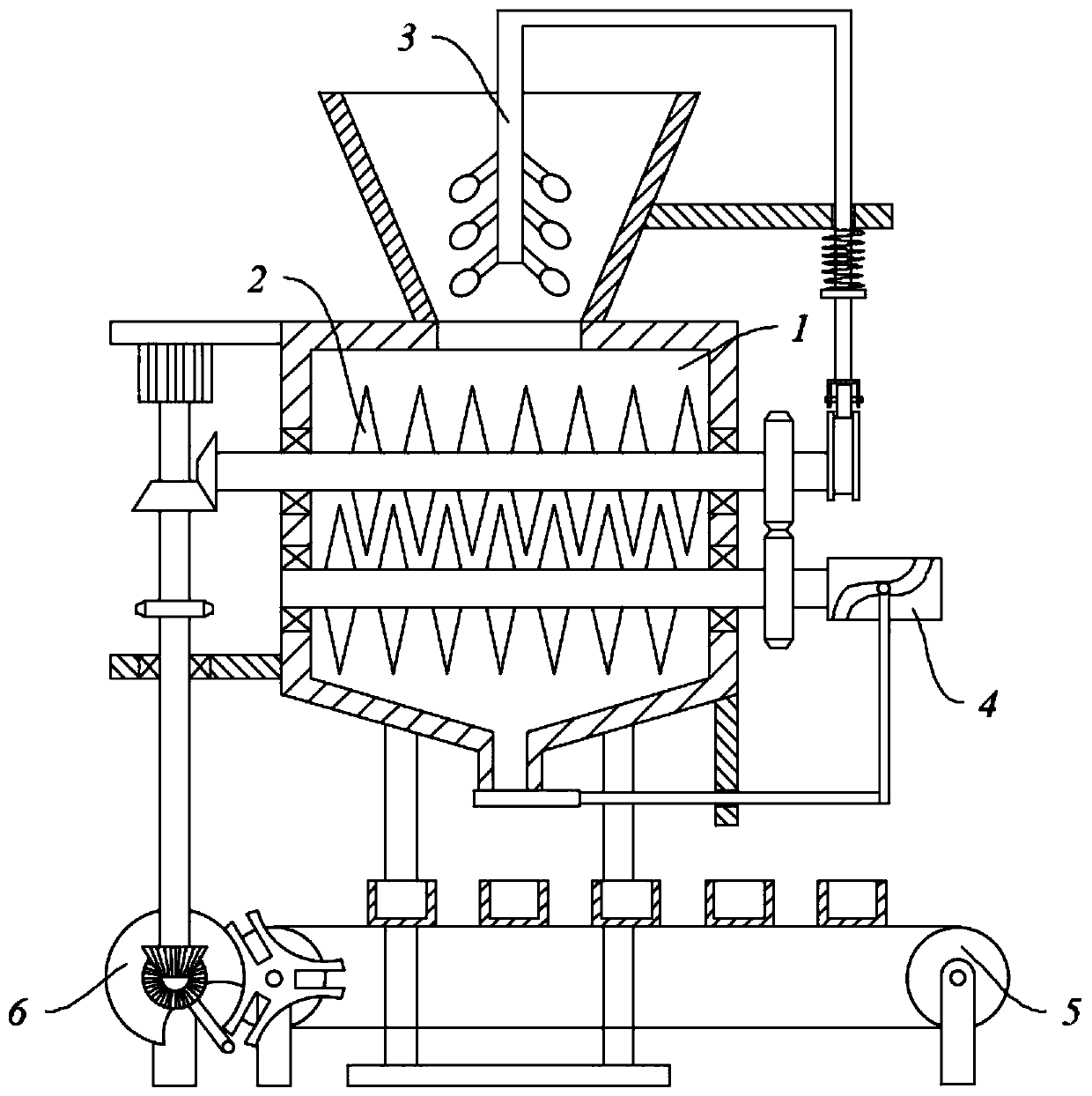

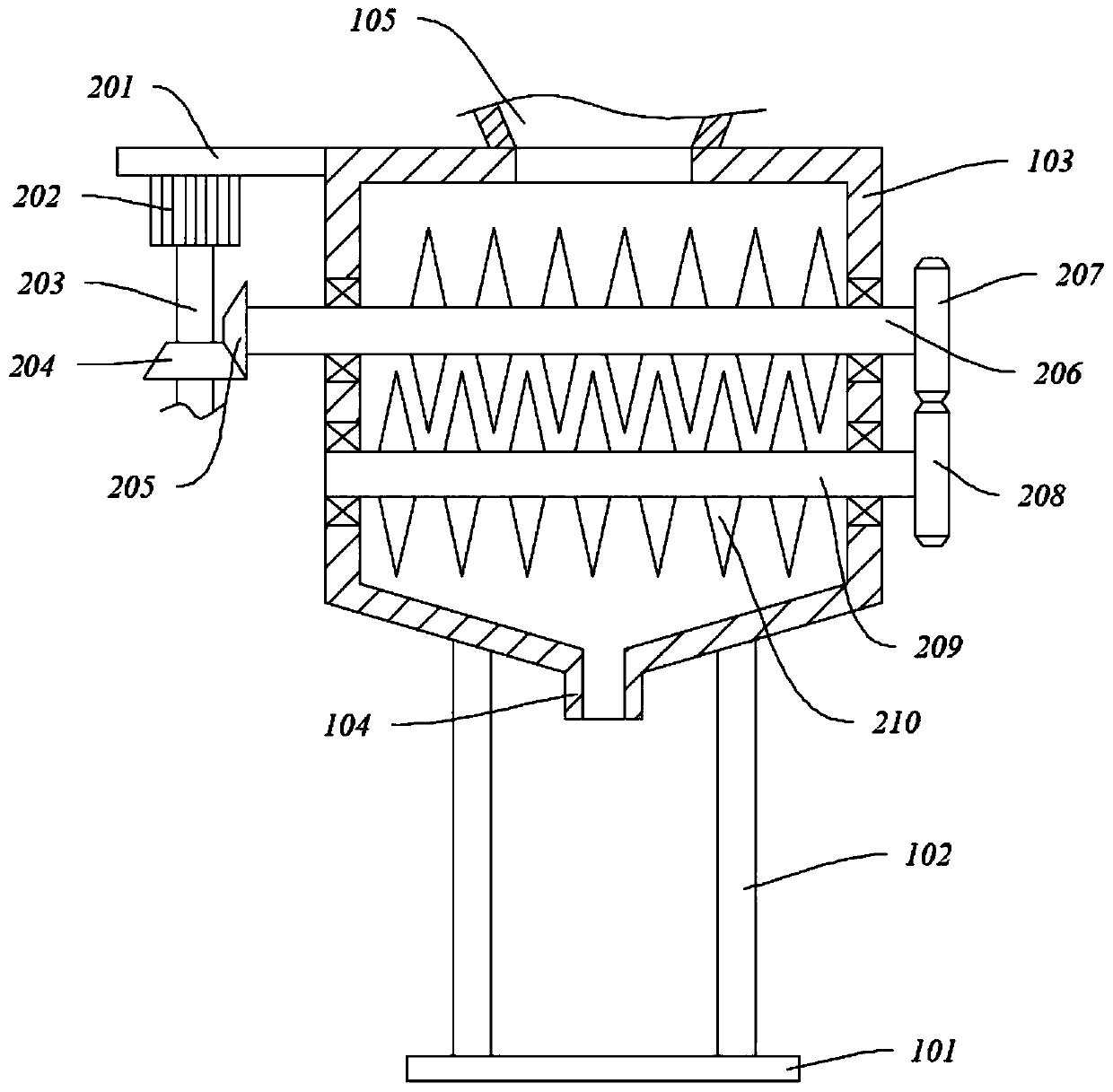

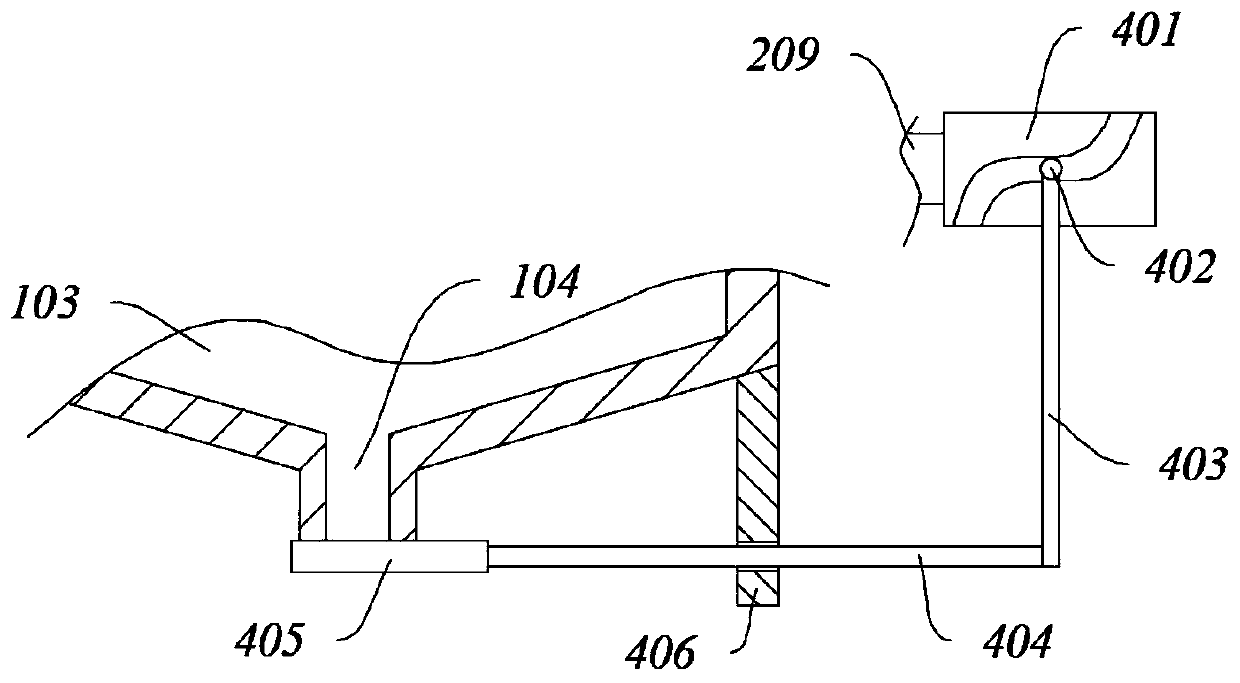

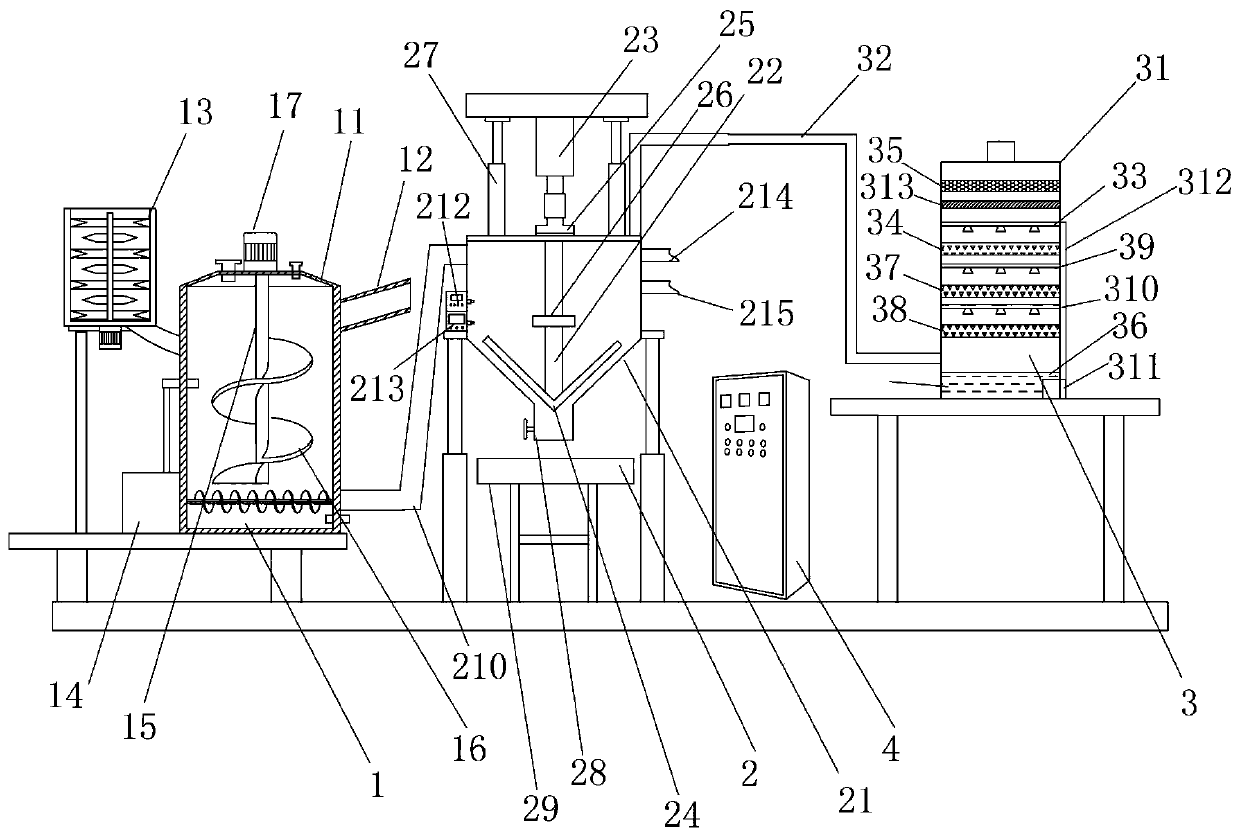

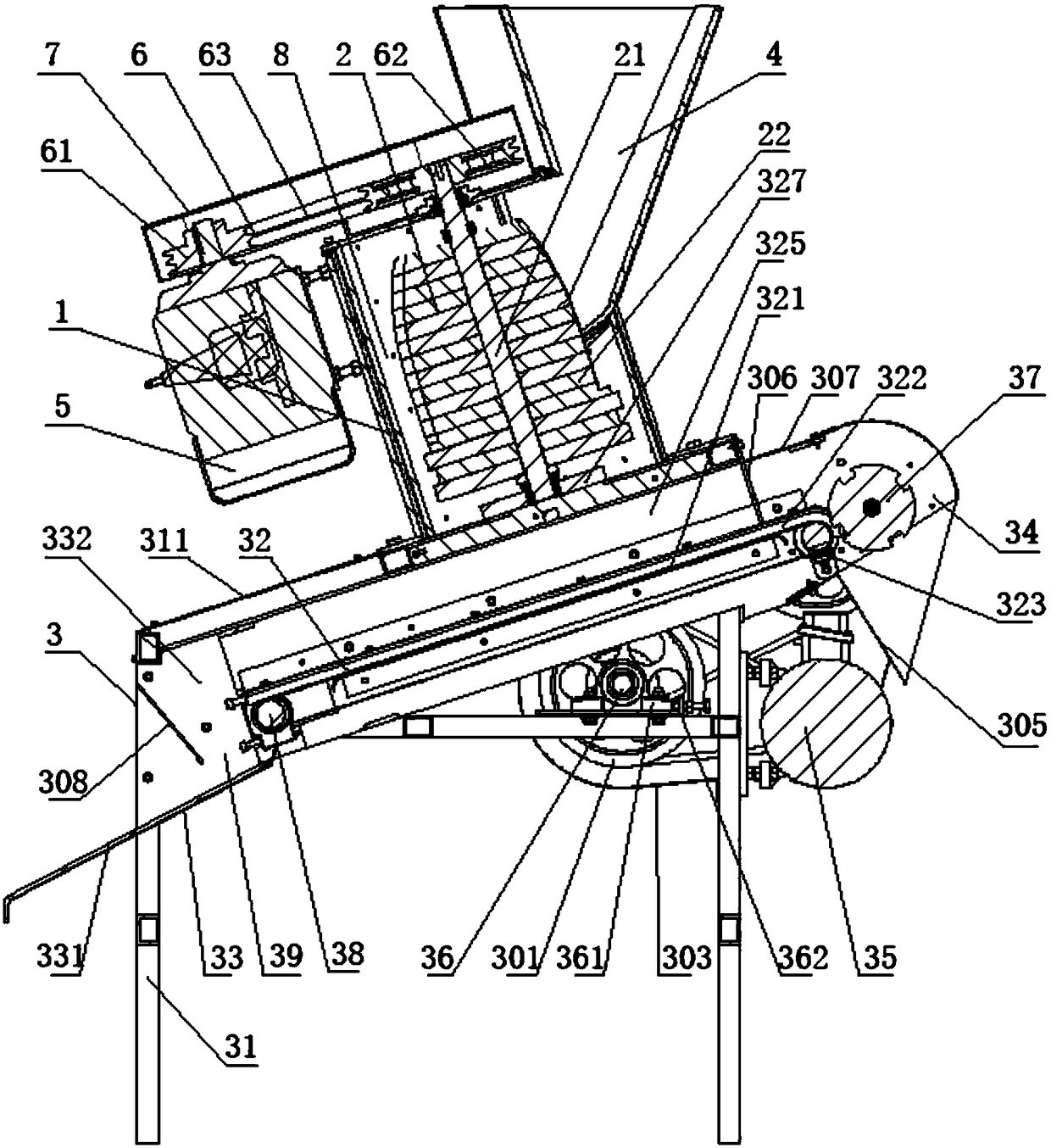

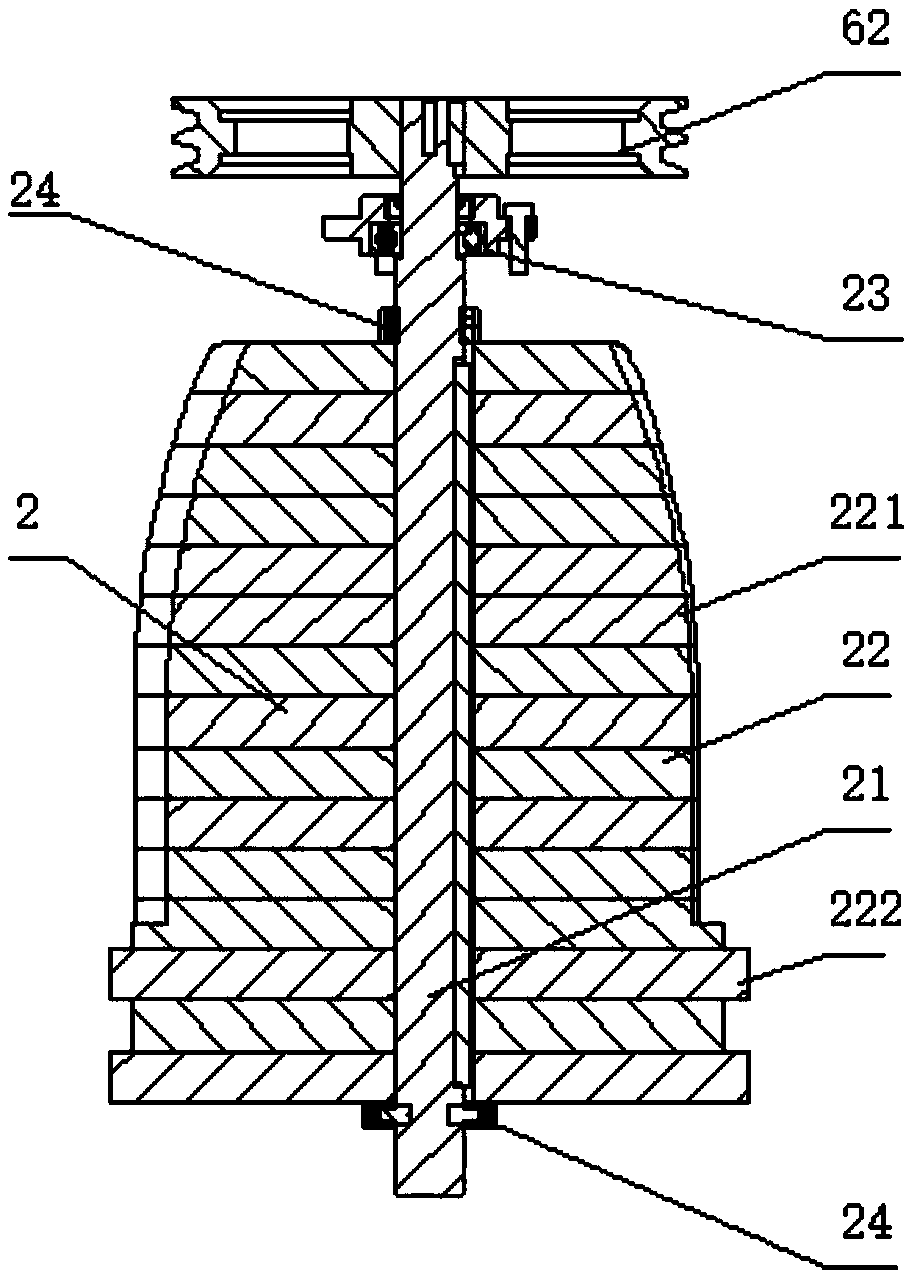

The invention discloses an automatic crushing device for construction waste materials, belongs to the technical field of construction material production, and solves the problem that the efficiency of conventional crushing of the construction waste materials is low. The automatic crushing device for the construction waste materials comprises a feeding hopper, a crushing machine, a screening rack and a screening cylinder, wherein the screening rack is provided with a discharging chute; the screening cylinder is arranged on the screening rack; the discharging chute is arranged below the screening cylinder in an inclined manner; a conveying belt I inclined upwards is arranged under the feeding hopper; the discharging end of the conveying belt I is positioned above the feeding inlet of the crushing machine; a conveying belt II inclined upwards is arranged below the discharging outlet of the crushing machine; the screening cylinder is arranged horizontally; one end of the screening cylinder is connected with the discharging end of the conveying belt II, and the other end of the screening cylinder is connected with a dropping chute inclined downwards; a conveying belt III is arranged below the dropping chute; the discharging end of the conveying belt III is positioned above the feeding inlet of the crushing machine. The automatic crushing device can crush the construction waste materials, and can automatically re-crush and re-screen waste materials of which the granule size is larger until the granule size meets the crushing requirement, and then, the materials are discharged.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

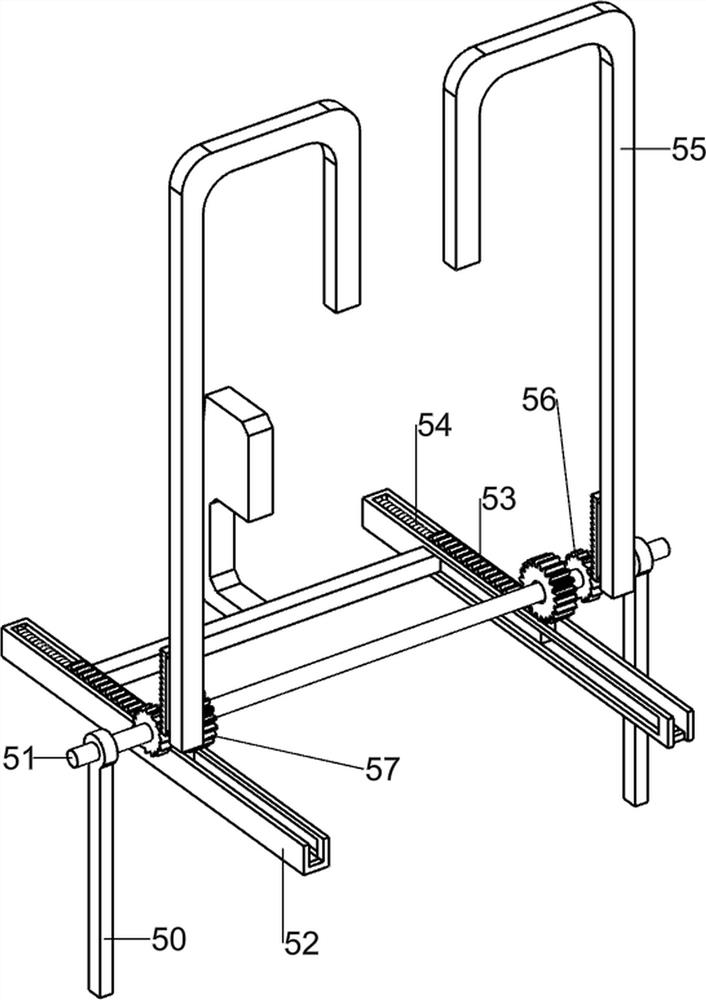

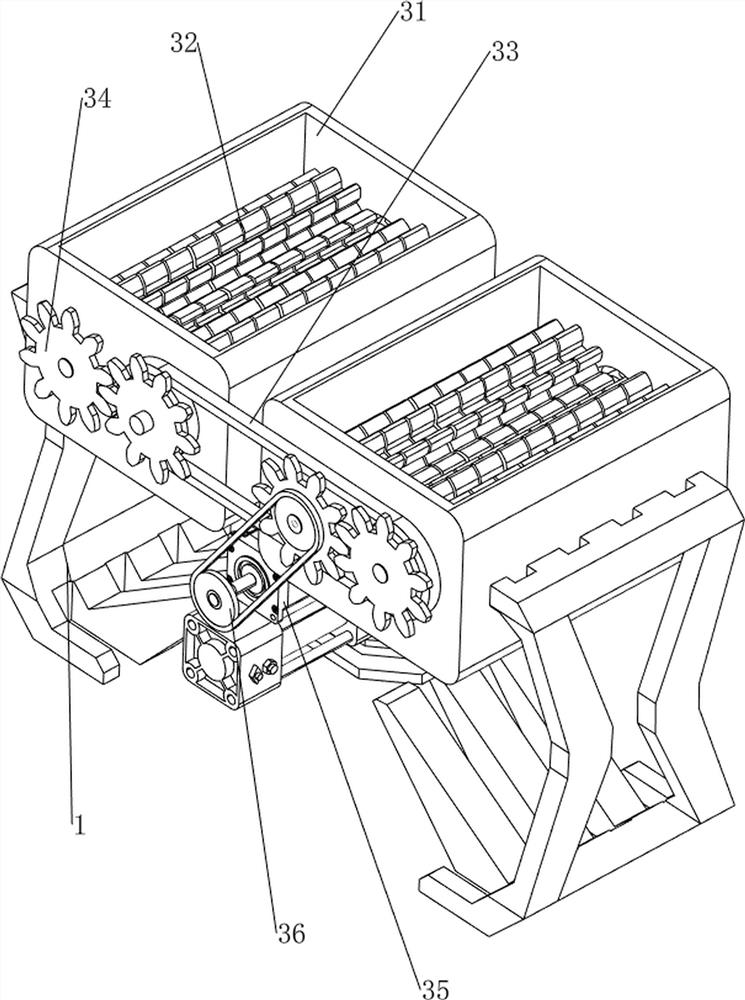

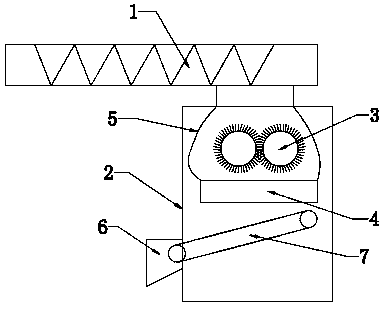

Crushing equipment of waste plasterboards

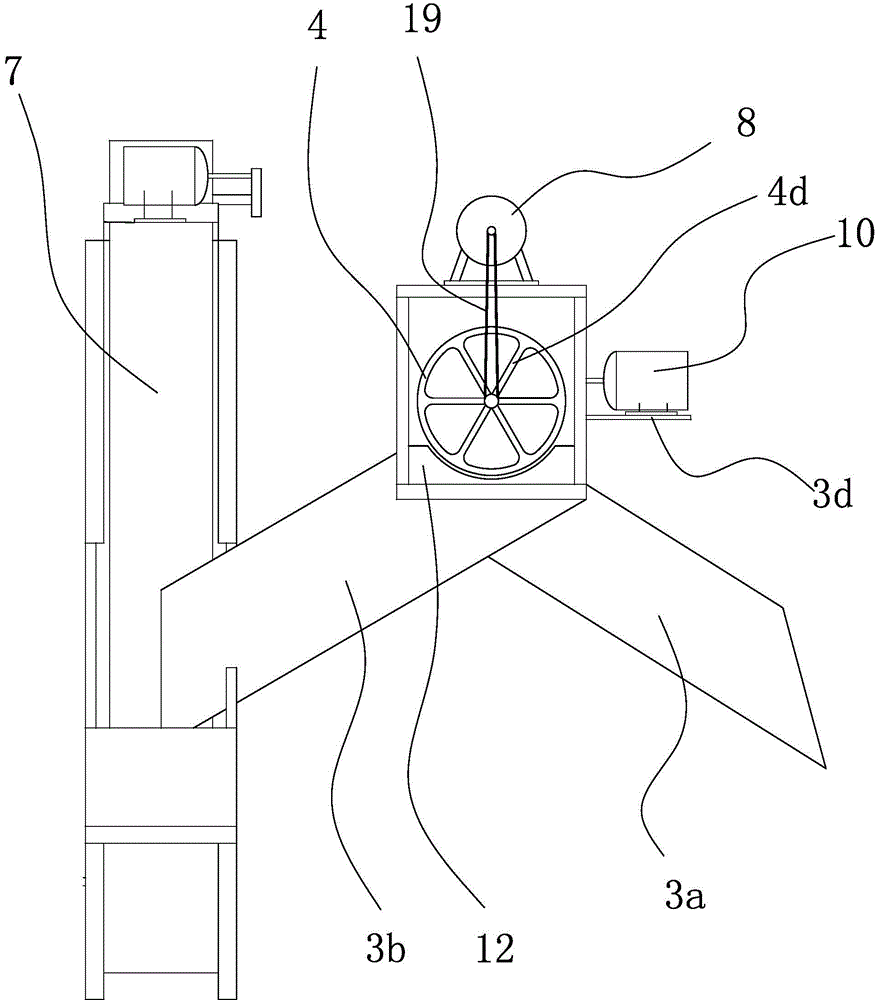

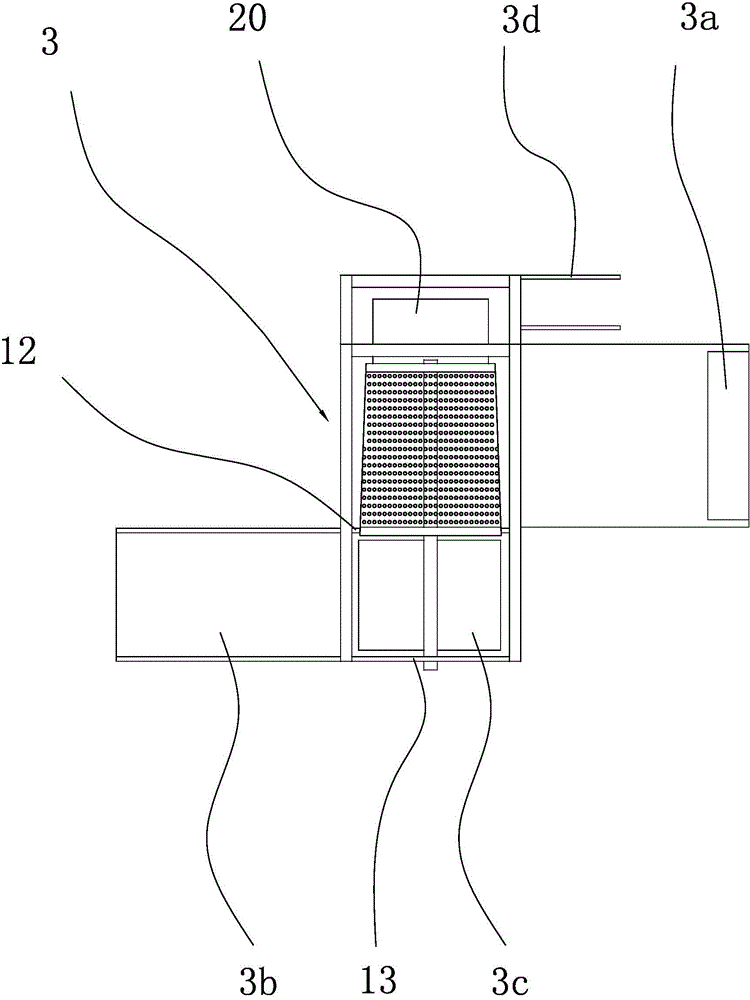

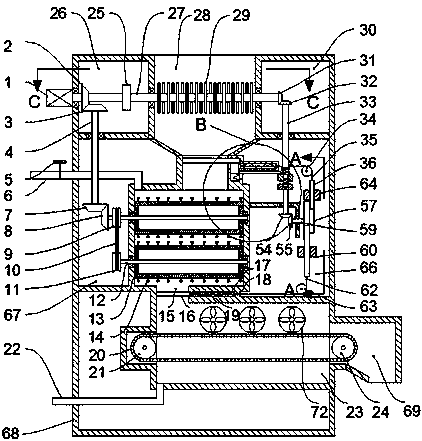

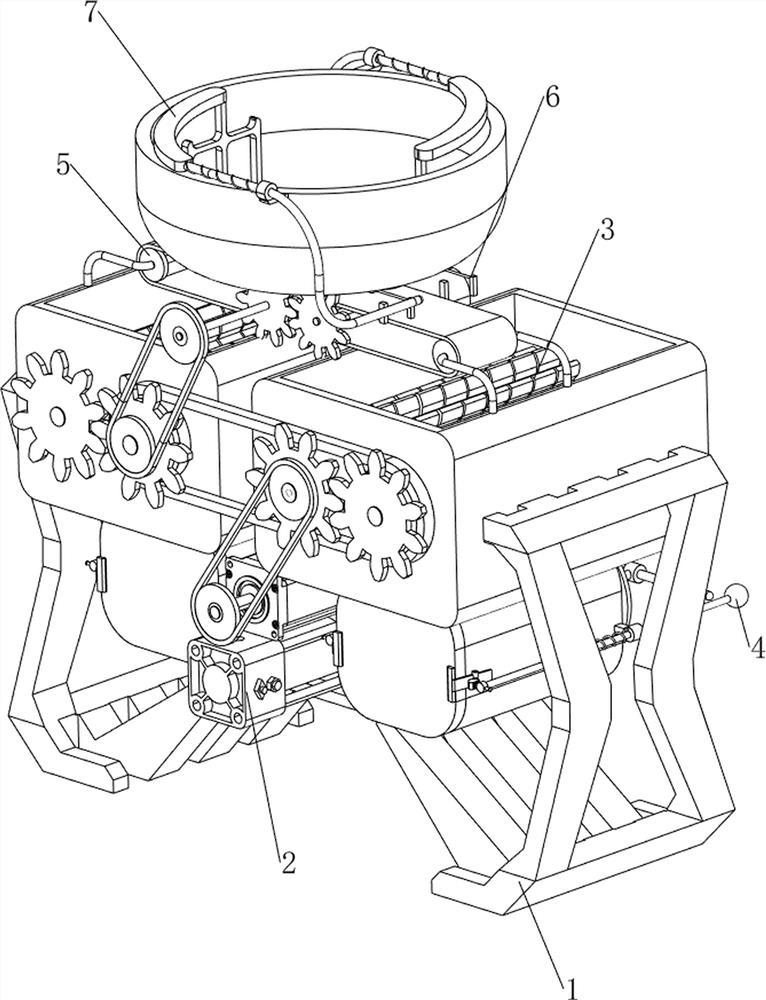

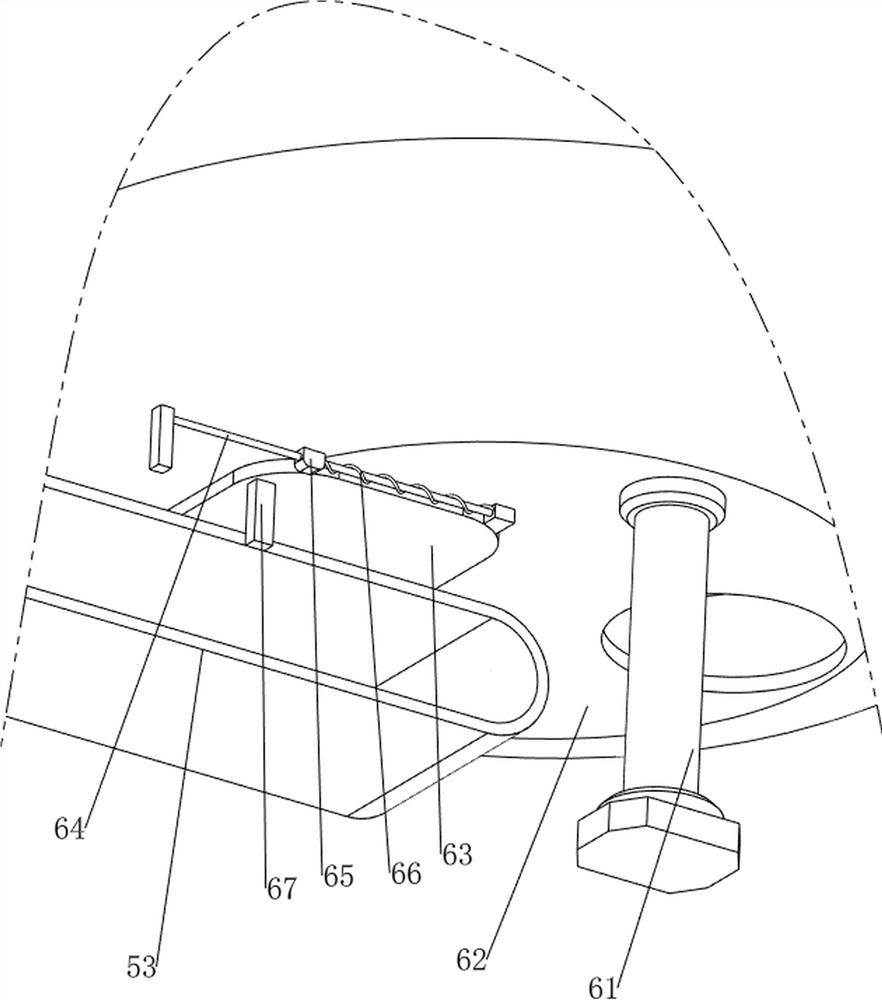

The invention belongs to the field of building waste material recovery equipment, and especially relates to crushing equipment of waste plasterboards. The crushing equipment comprises a machine frame,a cover cap, a conveyer belt, a breaking device, a crushing device, and a stirring device; the cover cap and the conveyer belt are fixedly arranged on the machine frame; the breaking device comprisesa driving mechanism and a breaking mechanism which is connected with the driving mechanism; the driving mechanism and the breaking mechanism are both arranged on the cover cap; the crushing device comprises an accommodation tank body, a push mechanism, and a crushing mechanism connected with the push mechanism; the accommodation tank body is fixedly arranged on the machine frame; the push mechanism is arranged in the machine frame; the accommodation tank body is provided with a blanking port, and a discharge port; the stirring device comprises a blanking tank body and a stirring mechanism; the blanking tank body is fixedly arranged in the machine frame; an unwinding mechanism is arranged between the accommodation tank and the blanking tank body; the stirring mechanism is arranged on the blanking tank body; and the blanking tank body is provided with a blanking slideway. The crushing equipemtn is capable of realizing automatic crushing of waste plasterboards, and crushing waste plasterboards into plaster powder, and is convenient in operation.

Owner:黄忠南

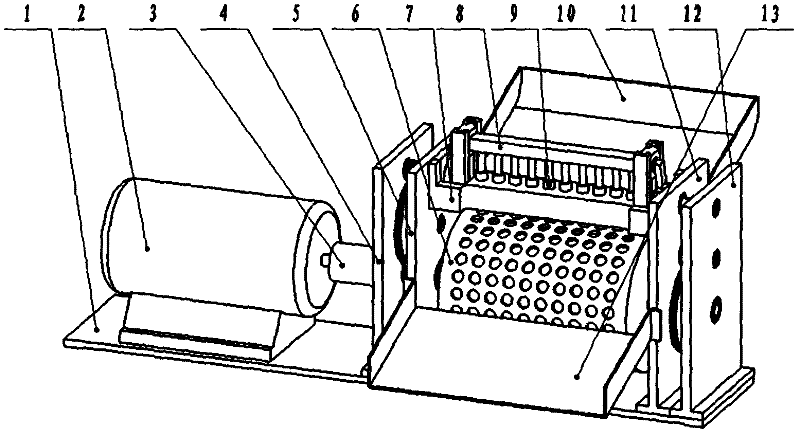

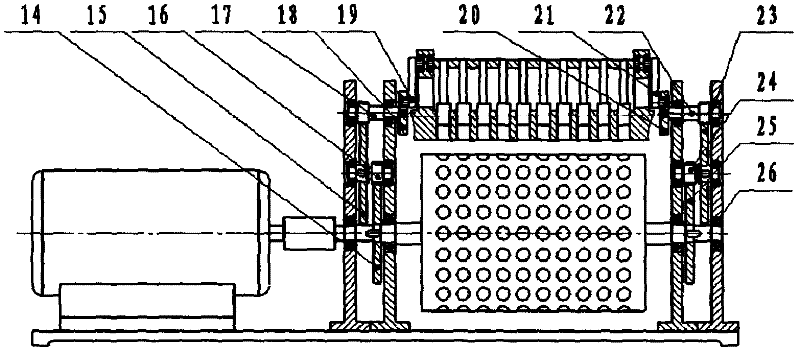

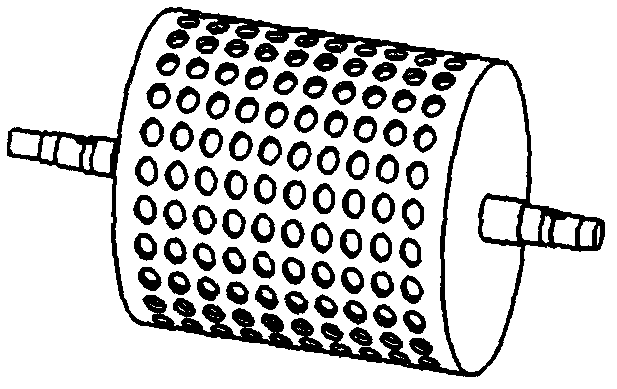

Automatic pine nut breaker

An automatic pine nut breaker comprises a bottom plate, a motor, a coupling, outer vertical plates, inner vertical plates, a porous roll, small hammers, a feed bucket, a discharge bucket, upper large gears, lower large gears, upper gear shafts, lower gear shafts, eccentric wheels, rockers and bearings. The automatic pine nut breaker is characterized in that the motor, the inner vertical plates and the outer vertical plates are fixedly mounted on the bottom plate, the porous roll is mounted between the two inner vertical plates, the left lower large gear, the right lower large gear, the left upper large gear, the right upper large gear, the left lower gear shaft, the right lower gear shaft, the left upper gear shaft and the right upper gear shaft are mounted between the left and the right inner vertical plates and the left and the right outer vertical plates respectively, the eccentric wheels are mounted on the inner sides of the upper gear shafts, the rockers are mounted on the eccentric wheels, the rockers are used for driving sliders to lead the small hammers mounted below the sliders to cyclically move up and down, and accordingly pine nuts carried in holes on the porous roll are broken. The automatic pine nut breaker is capable of automatically breaking pine nuts.

Owner:RUGAO PACKING FOOD MACHINERY

Crusher

InactiveCN107159368AHigh degree of automationRealize automatic crushingRoads maintainenceGrain treatmentsGear transmissionAerospace engineering

The invention relates to a crusher, which comprises a lower cylinder and an upper cylinder. The upper cylinder can rotate coaxially around the center of the lower cylinder; The upper cylinder shaft center is set eccentrically. The upper and lower parts of the rotary block are conical and cylindrical respectively. A circle of internal pressure teeth is evenly distributed on the cylindrical arc surface of the rotary block; the lower end of the rotary block is connected with the lower cylinder. The central rod of the coaxial line is connected with a central gear at the lower part of the central rod, the right side of the central gear is meshed with a side gear, the right side of the side gear is meshed with a ring gear, and the side gear is connected with a motor. The invention has a high degree of automation, and on the basis of the transmission of the gear teeth, the size of the gap is changed by eccentric rotation and the extrusion of the different rotations of the external pressure teeth and the internal pressure teeth is controlled, which can effectively realize the automatic crushing of batches of large stones into fine stones.

Owner:ANHUI PULUN INTELLIGENT EQUIP CO LTD

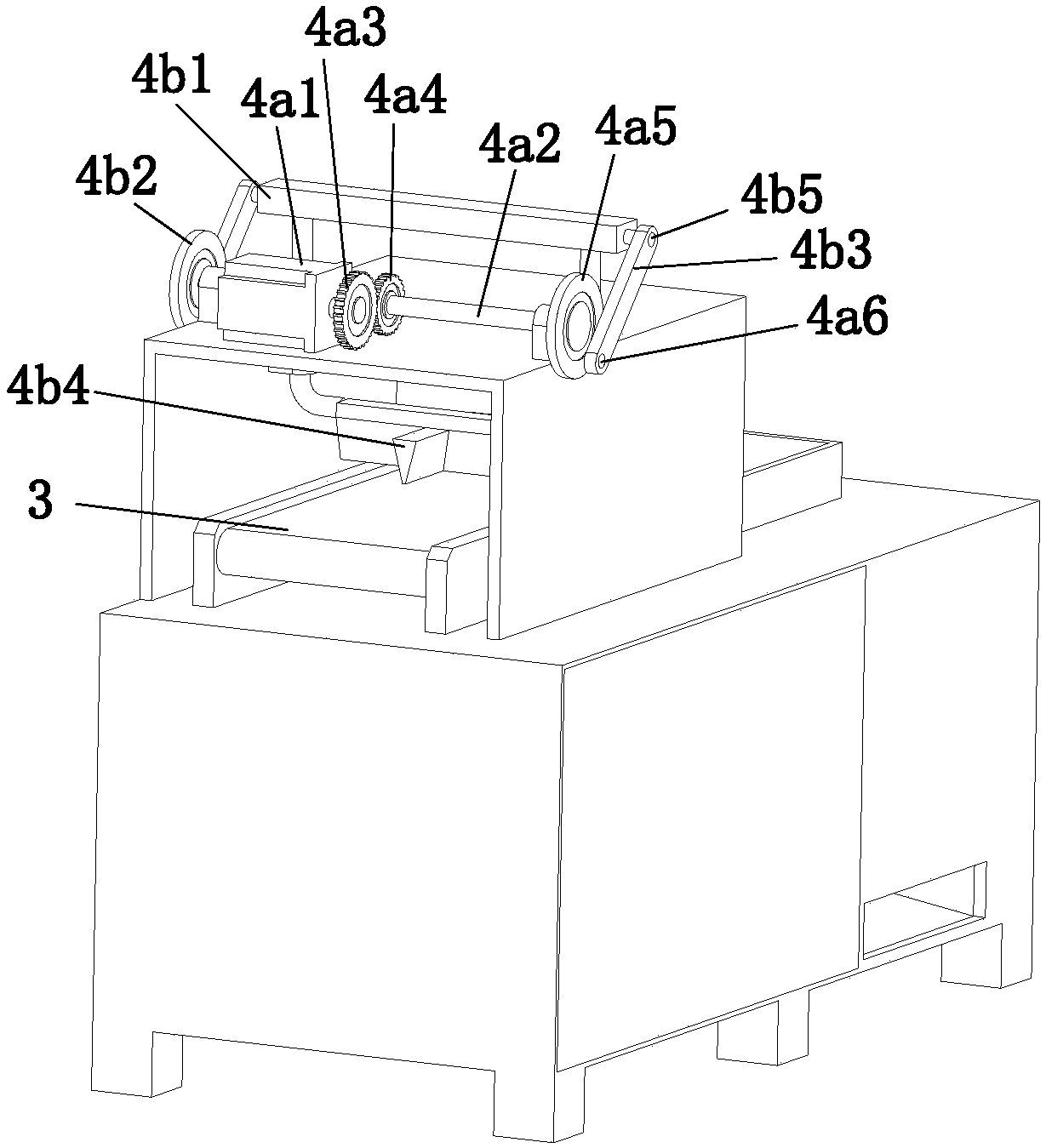

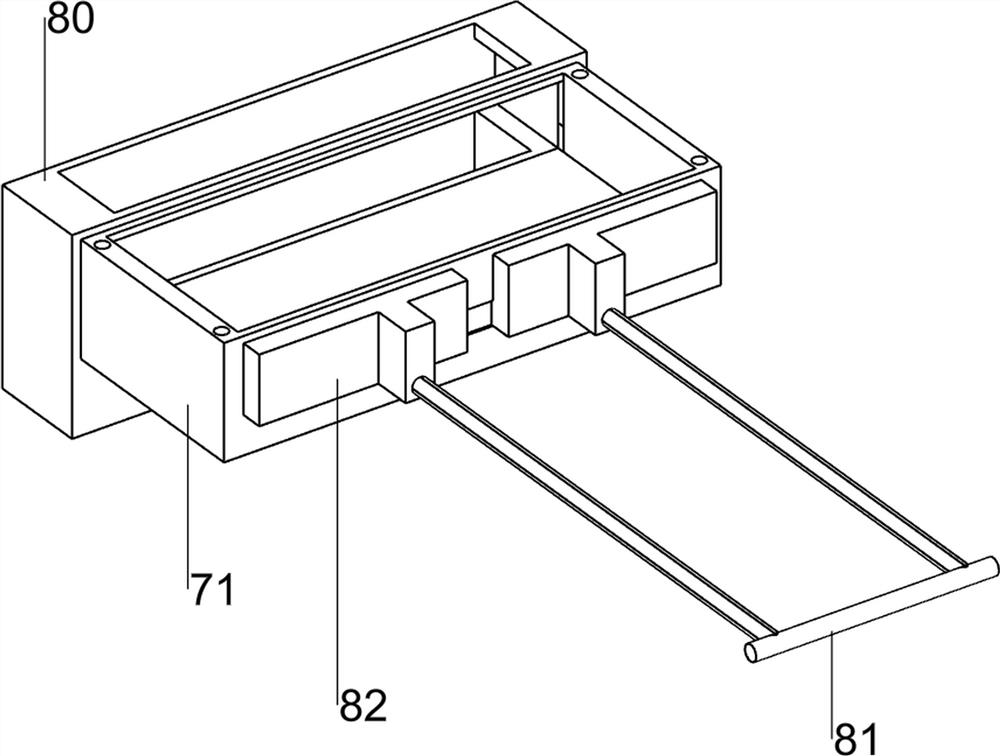

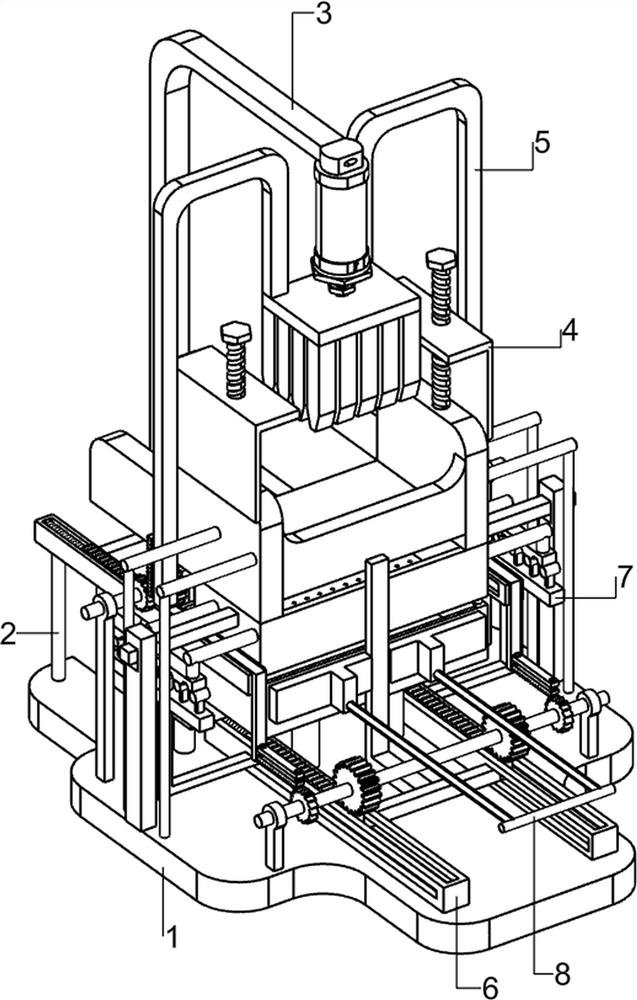

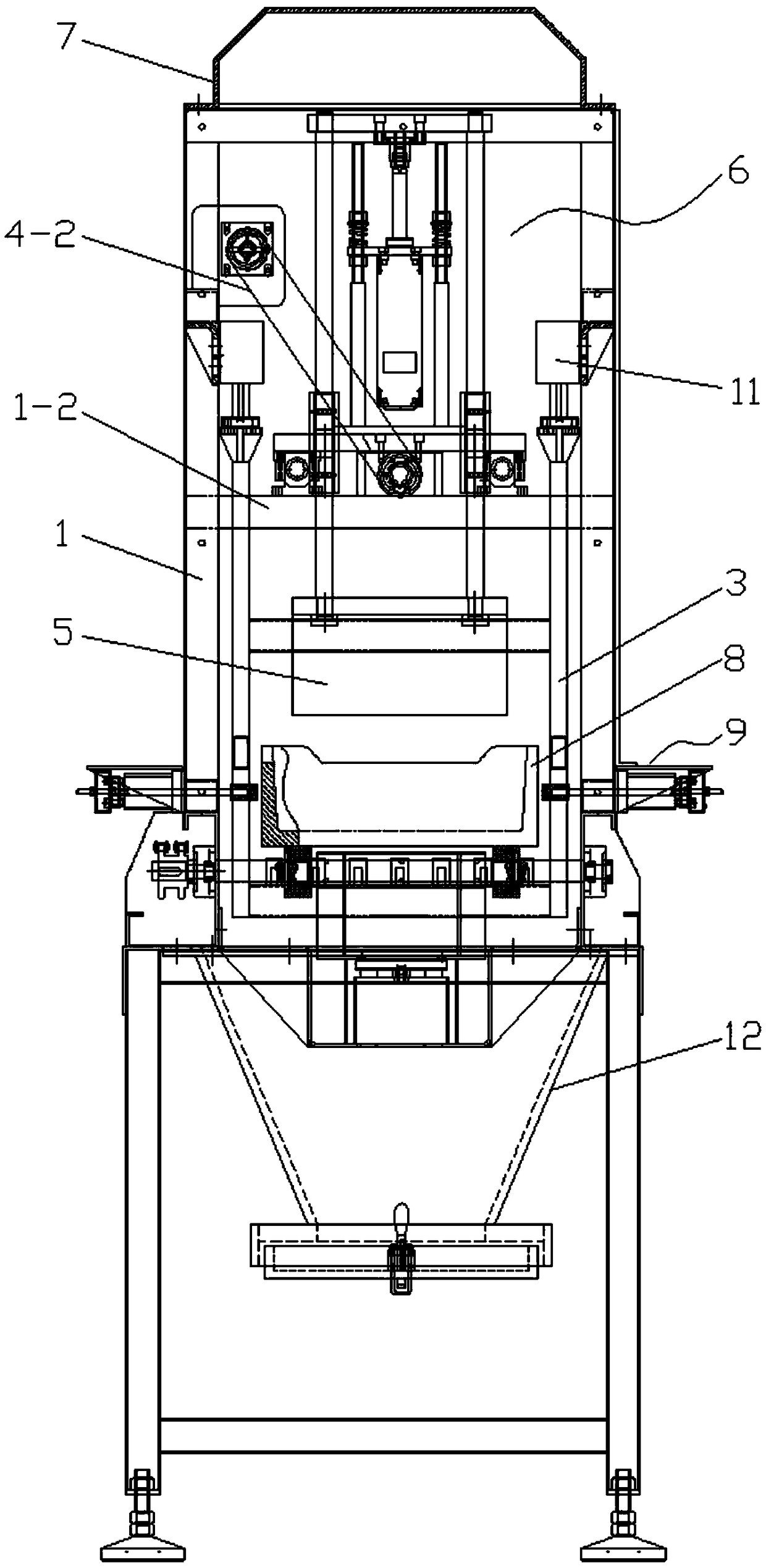

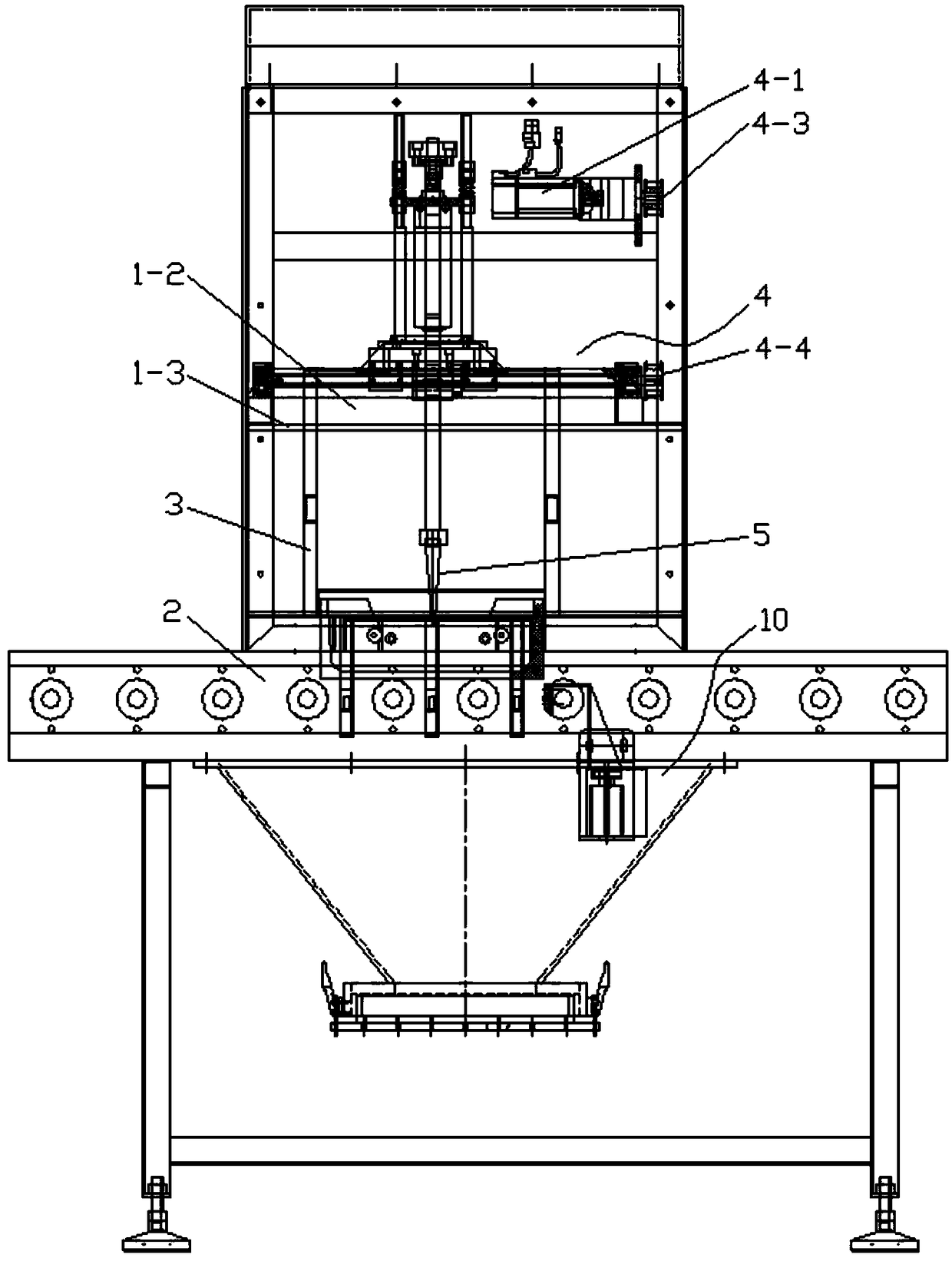

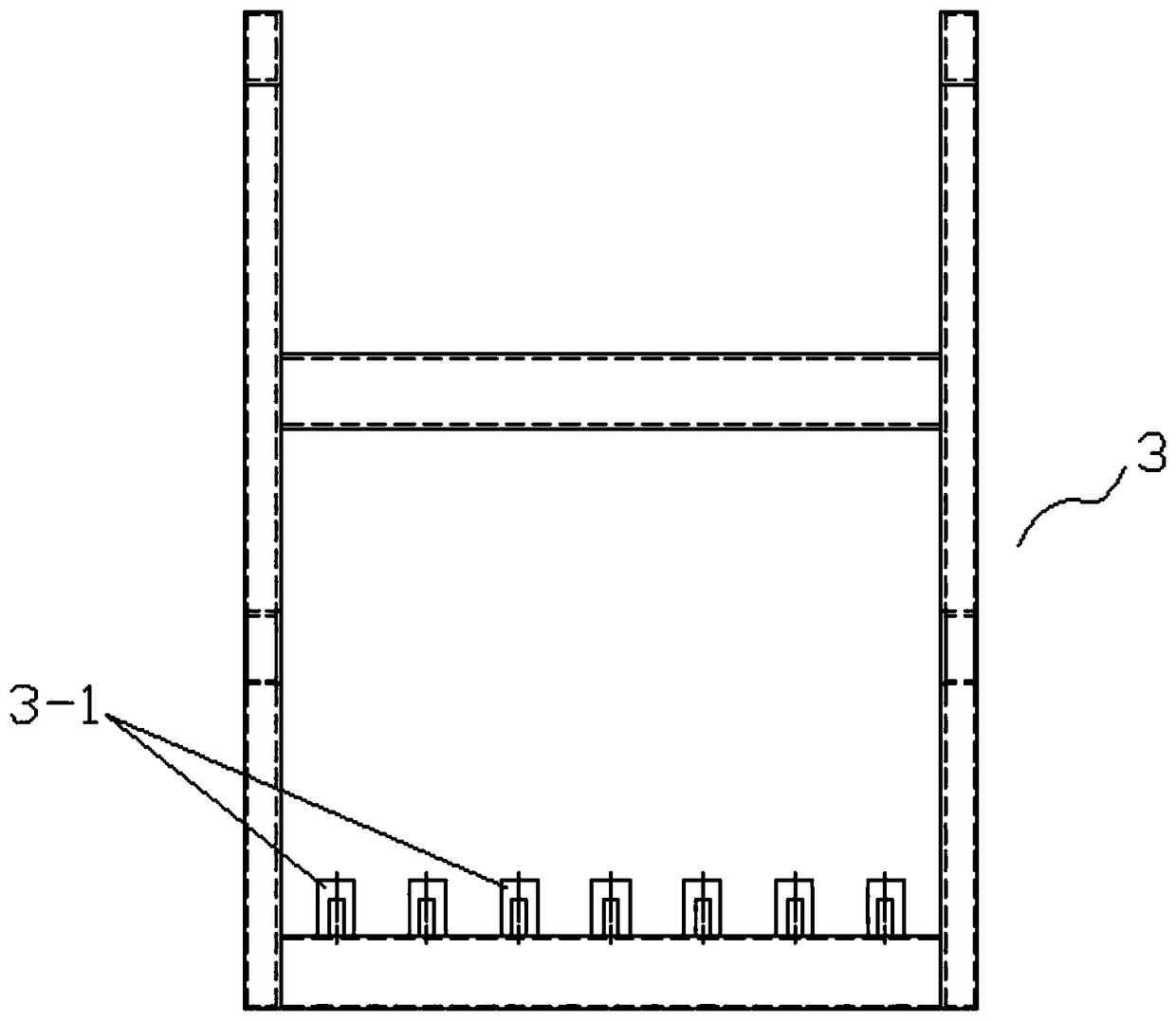

Sagger material crusher

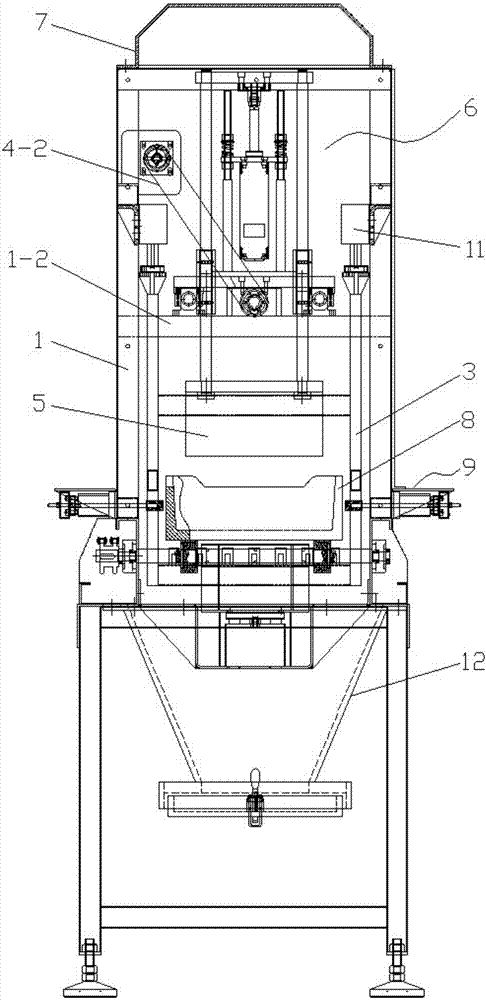

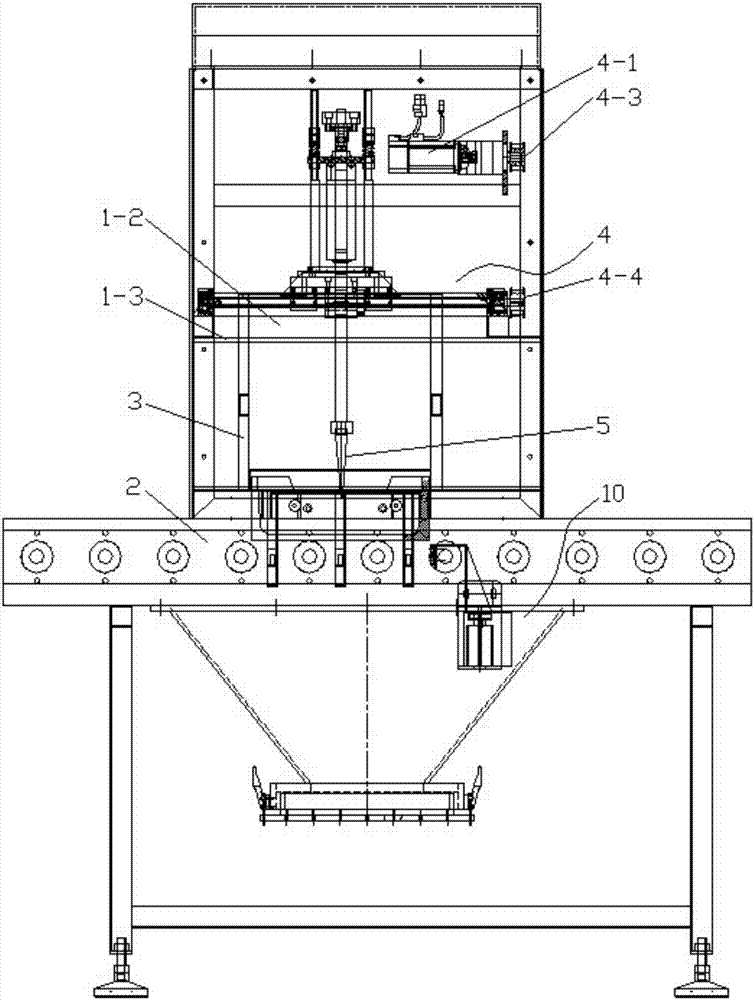

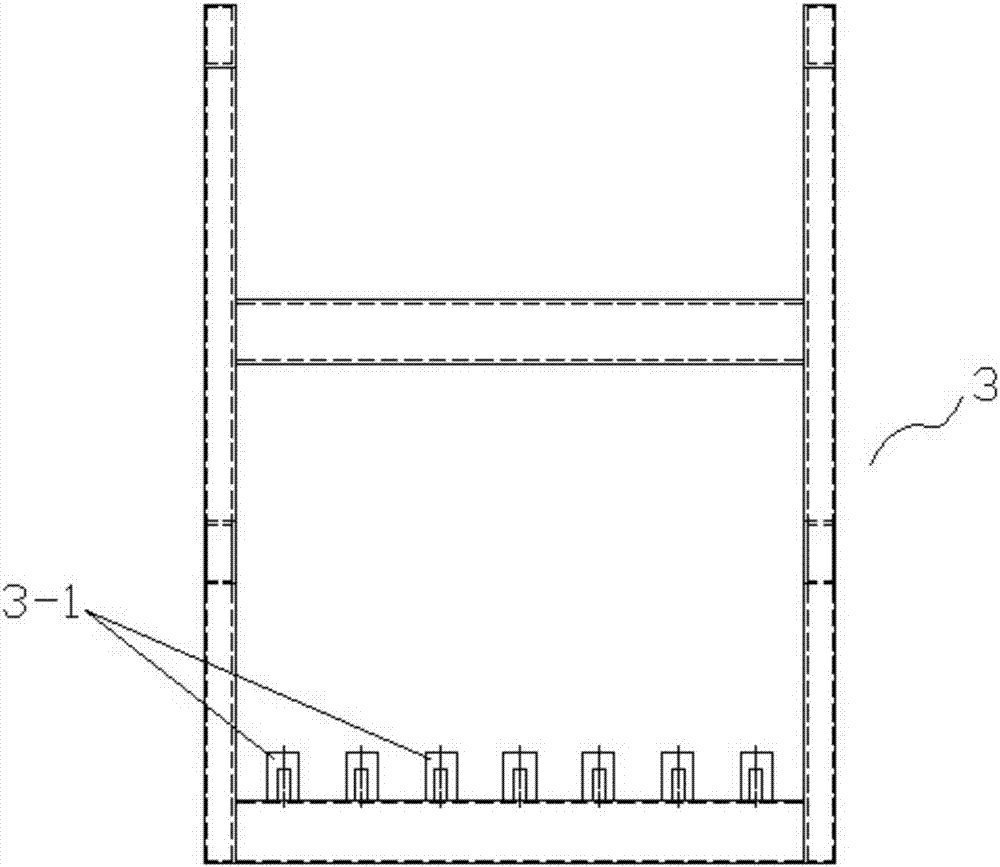

The invention relates to a sagger material crusher. The sagger material crusher comprises a support, a roller way conveying line, a lifting frame, a lifting frame driving device, a translation device, a crushing knife, a crushing knife lifting device and an outer cover, wherein the roller bed conveying line is arranged on the support in the left-right direction, the lifting frame driving device is arranged on the support and is arranged at the lower part of the lifting frame driving device, a sagger bearing surface is arranged on the lifting frame, when the lifting frame is located at the lowest point of the stroke, the sagger bearing surface is located below the roller way top surface of the roller way conveying line, the translation device is arranged on the support, the crushing knife lifting device is arranged on the translation device is driven by the translation device to move left and right, the crushing knife is arranged at the lower end of the crushing knife lifting device, the crushing knife, the crushing knife lifting device and the translation device are located above the roller way conveying line, and the outer cover is arranged on the support. The sagger material crusher has the advantages that cohesive solid materials in a sagger can be crushed to the maximum degree, and therefore the problem that the solid materials in the sagger cannot be poured into a hopper can be effectively solved.

Owner:安徽陆达智能装备科技有限公司

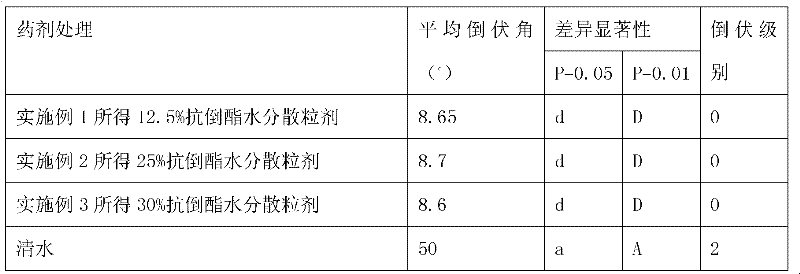

Trinexapacethyl water dispersible granule preparation and preparation method thereof

ActiveCN102415374AReduce usageRealize automatic crushingBiocidePlant growth regulatorsSpherical granuleCircular disc

The invention discloses a trinexapacethyl water dispersible granule preparation, which consists of 10 to 30 percent of trinexapacethyl raw medicine, 1 to 10 percent of wetting agents, 1 to 15 percent of dispersing agents, 1 to 10 percent of disintegrating agents, 30 to 60 percent of absorbing agents and 1 to 50 percent of inert carriers. The trinexapacethyl water dispersible granule preparation is produced by adopting a circular disc granulation mode, the kneading and the granulation are integrated into one step, and work procedures are reduced. Obtained products are spherical granules, the appearance is attractive, the flowability is good, the disintegration is fast, the heat generation is avoided in the granulation process, and the method is suitable for the production of low-melting-point raw medicine.

Owner:MAX RUDONG CHEM

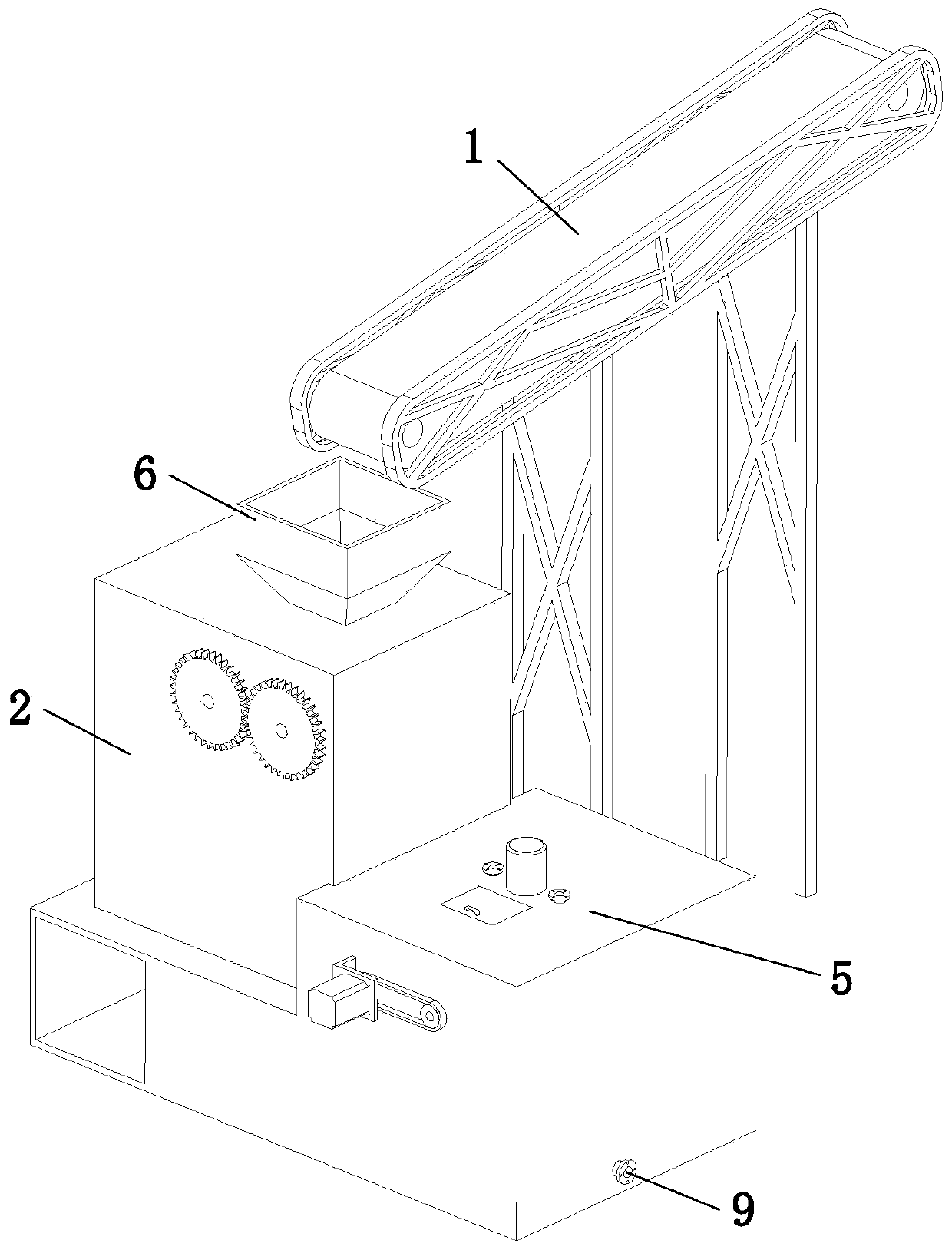

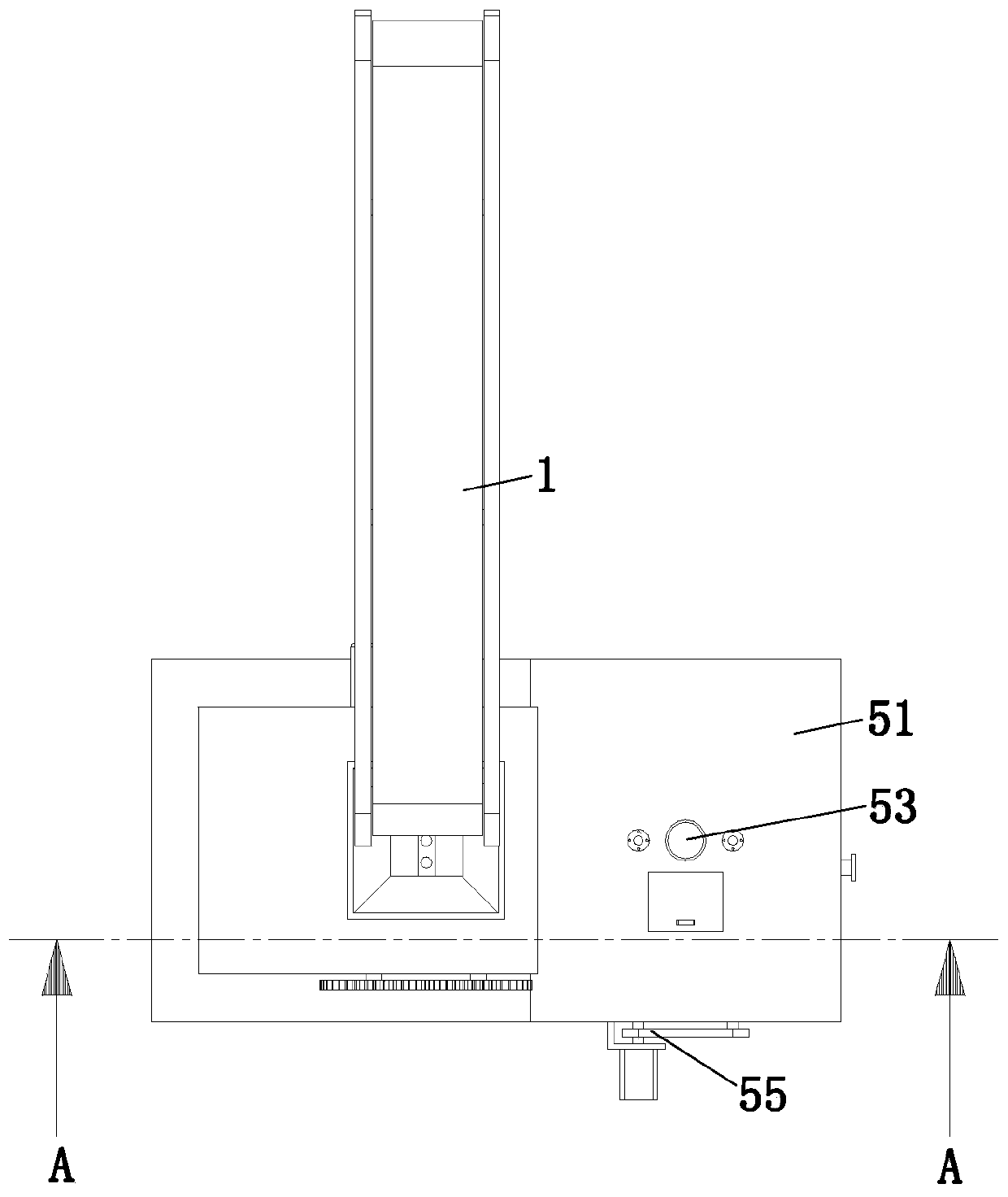

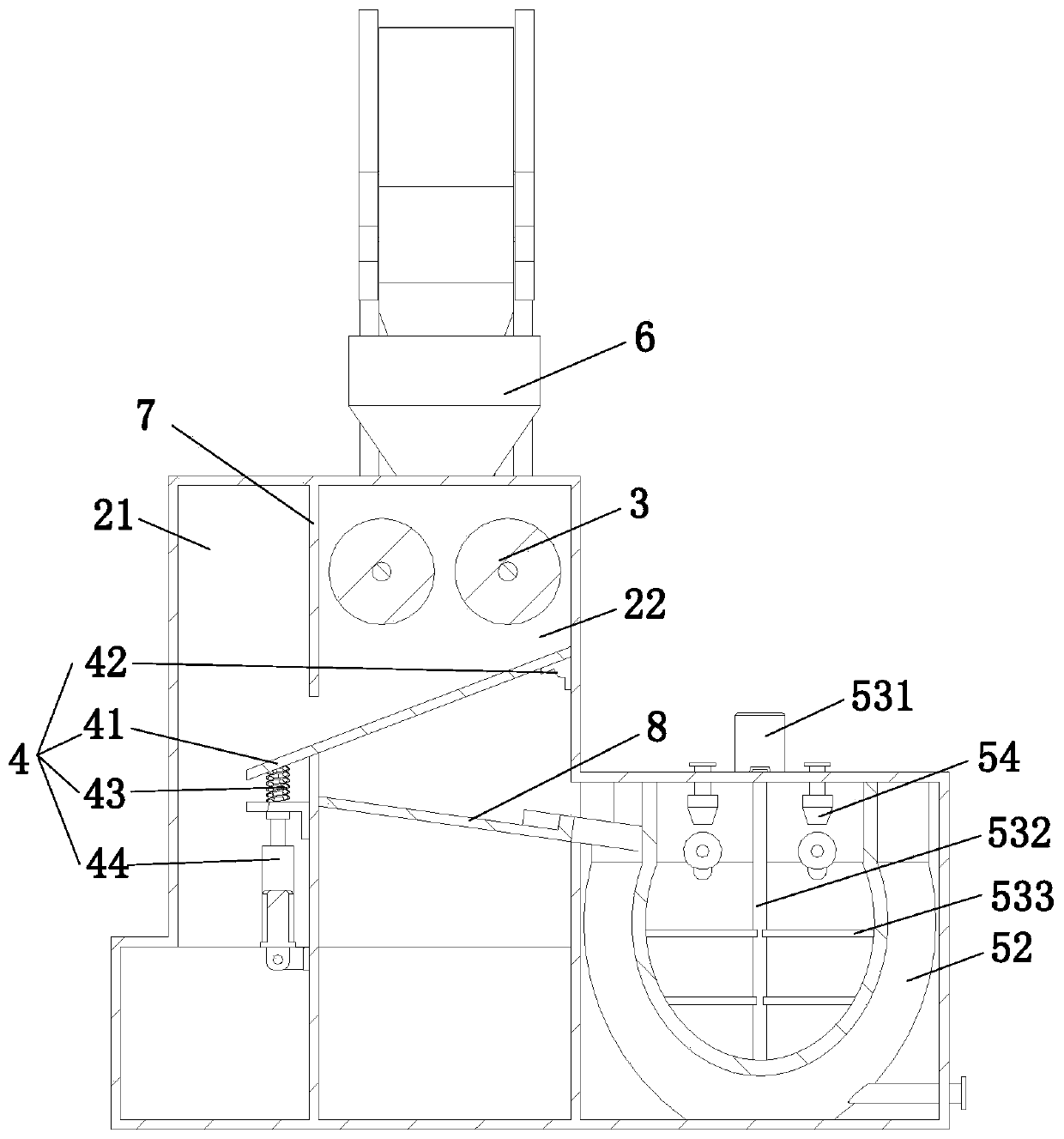

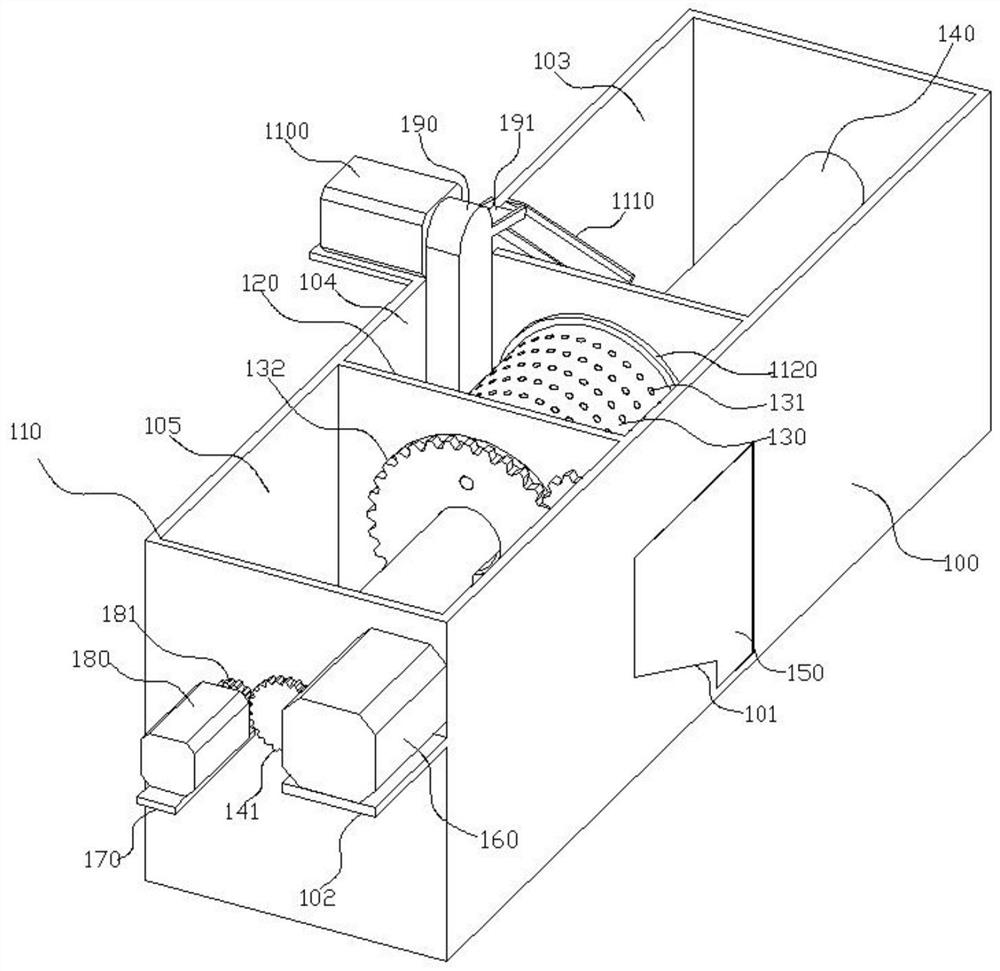

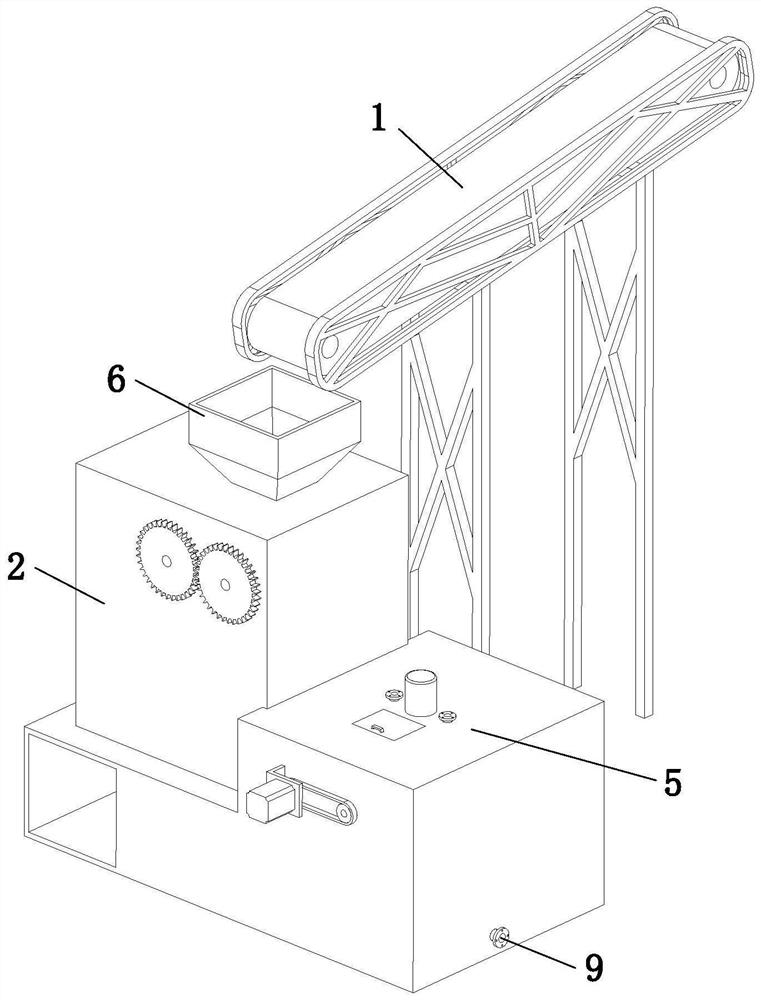

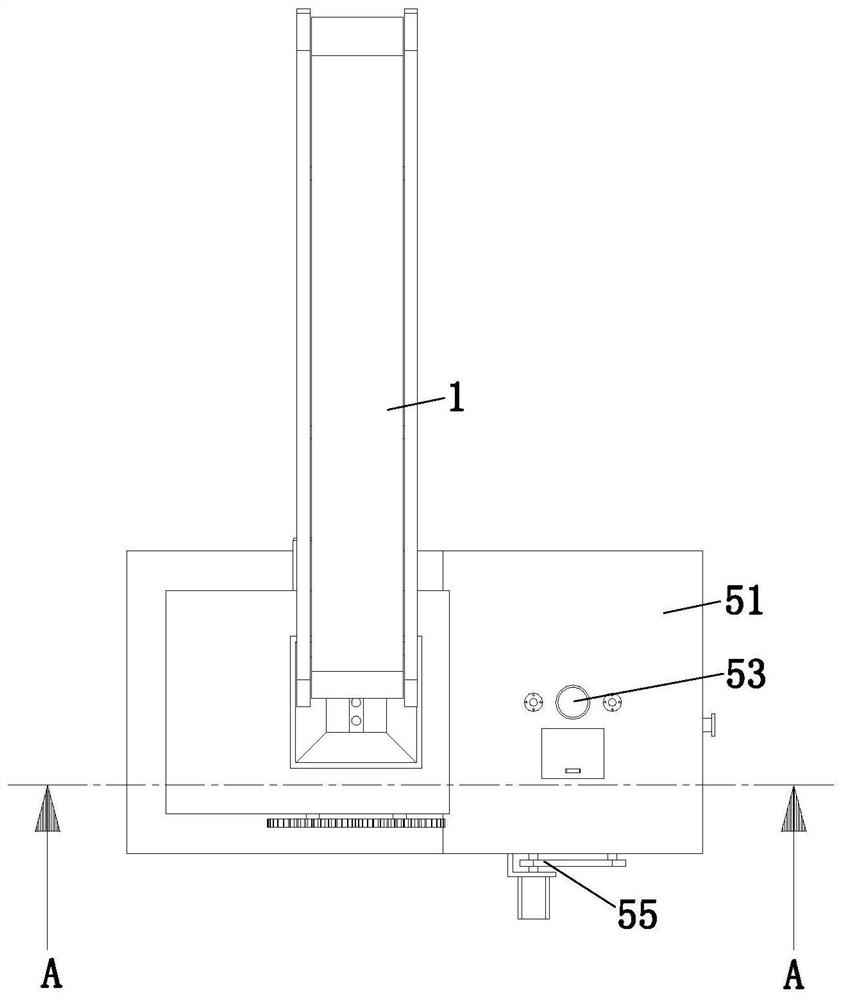

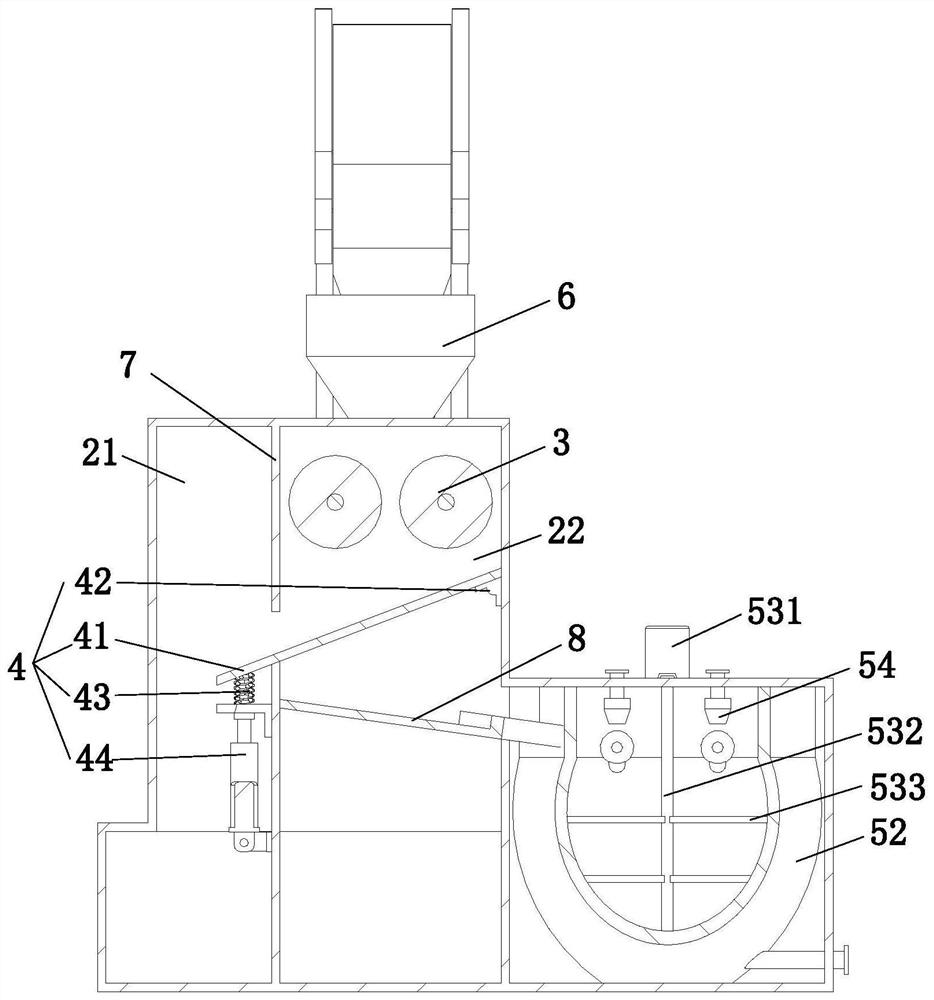

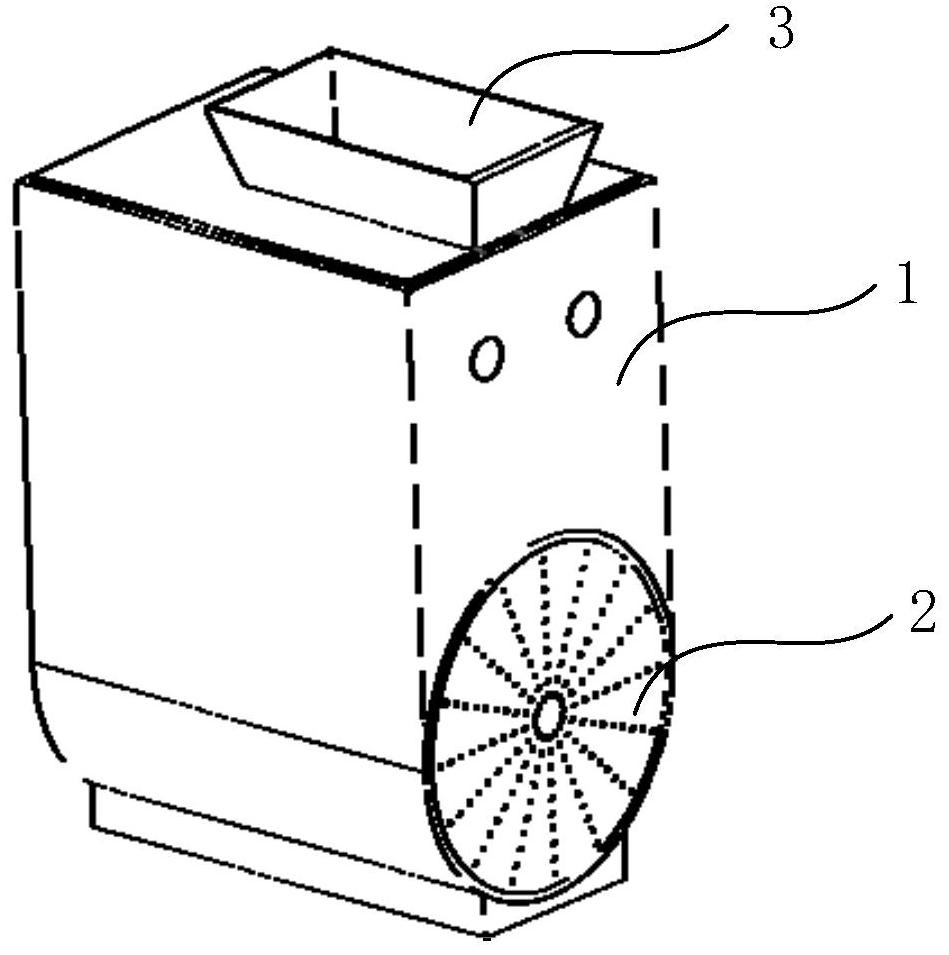

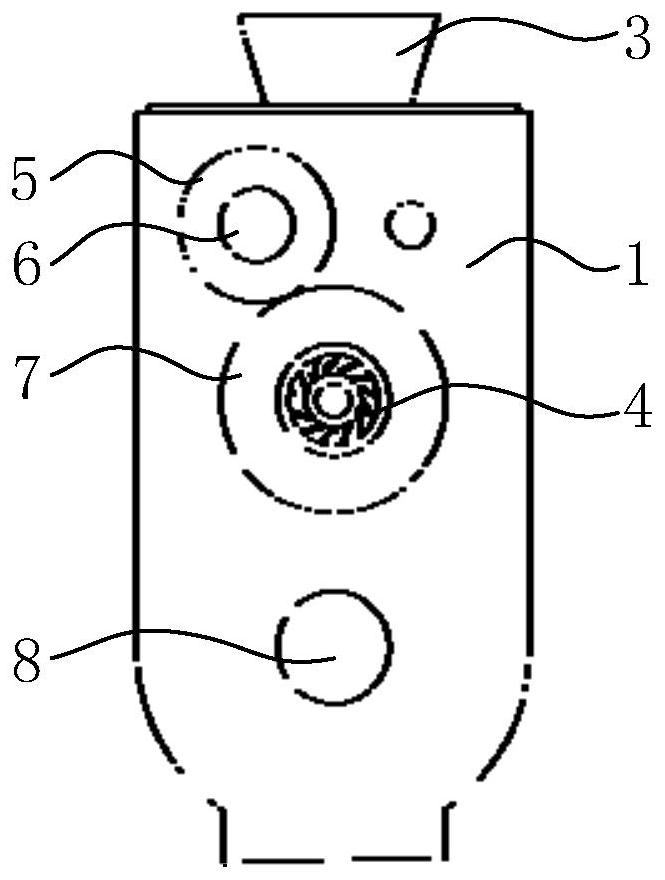

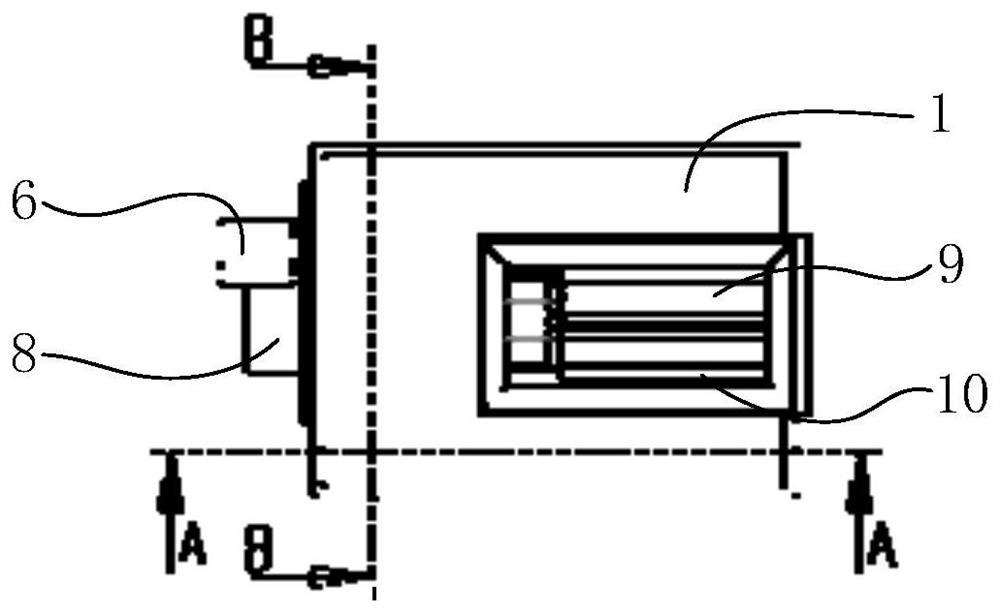

Box filling machine for refractory material recycling

InactiveCN110773288AEasy to operateImprove work efficiencyGrain treatmentsLoading/unloadingPhysicsCartoning machine

The invention relates to the technical field of refractory material recycling equipment, in particular to a box filling machine for refractory material recycling. According to the machine, a discharging hopper is used for putting refractory material waste into a crushing cavity, the waste is crushed in the crushing cavity through a crushing assembly, a discharging assembly enables material discharging to be carried out at intervals to cooperate with a box filling assembly driven by a transmission assembly working based on a grooved pulley to achieve cooperation of material charging and box filling, so that automatic crushing and automatic box filling are achieved, the operation is simple and convenient, and the working efficiency is high. According to the machine, a single motor is used for driving, the crushing assembly is driven to crush the waste, a material dredging assembly performs dredging on the discharging hopper through transmission, the discharging assembly based on the cylindrical cam movement works to carry out material discharging at intervals through transmission, the transmission assembly based on the grooved pulley rotation is driven to work through transmission, and then the box filling assembly is driven to enable a material receiving box to intermittently move, so that the cooperative work is achieved.

Owner:浙江长兴振明高科耐火材料有限公司

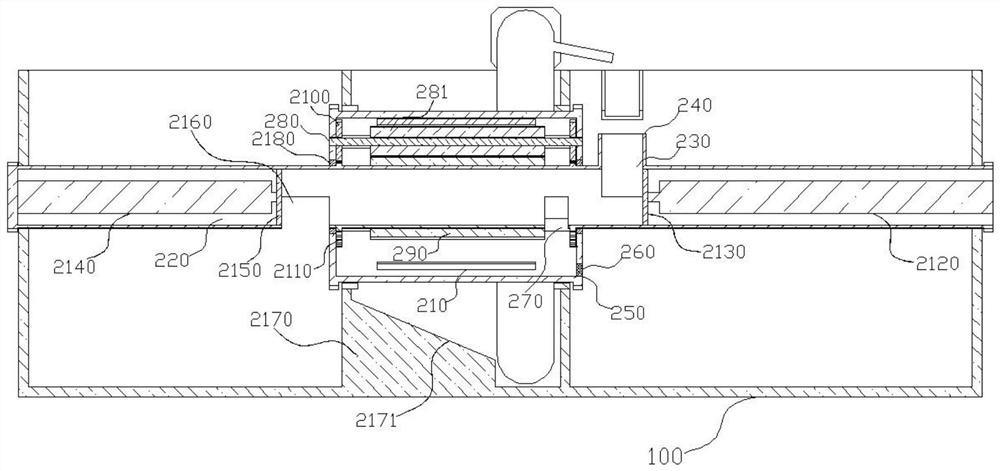

Waste plastic bottle processing equipment

InactiveCN111098434AImprove processing efficiencyAvoid cleaningPlastic recyclingDrying gas arrangementsProcess engineeringEnvironmental engineering

Waste plastic bottle processing equipment comprises a waste plastic bottle processing box and a cleaning cavity arranged in the waste plastic bottle processing box; the cleaning cavity is internally provided with a cleaning device, and the cleaning device comprises a water inlet pipe and a water inlet valve which are arranged at the right end of the top wall of the cleaning cavity; the right sideof the cleaning cavity is provided with a control cavity; and a control device is arranged in the control cavity. The waste plastic bottle processing equipment is simple in mechanism and easy and convenient to use and achieves automatic smashing, automatic cleaning and automatic drying and conveying, the waste plastic bottle processing efficiency is greatly improved, meanwhile, during waste plastic bottle processing, smashed discharge materials are mechanically controlled, the cleaning quality can be precisely controlled, the situation that due to the fact that the smashed discharge materialsare too much or too small, smashed waste plastic is not cleaned sufficiently or cleaning water is wasted is avoided; and the equipment is low in cost and can be popularized in small and medium sized plastic recycling processing stations, and the procurement cost is reduced for enterprises.

Owner:YONGKANG BENYUAN PLASTIC PROD CO LTD

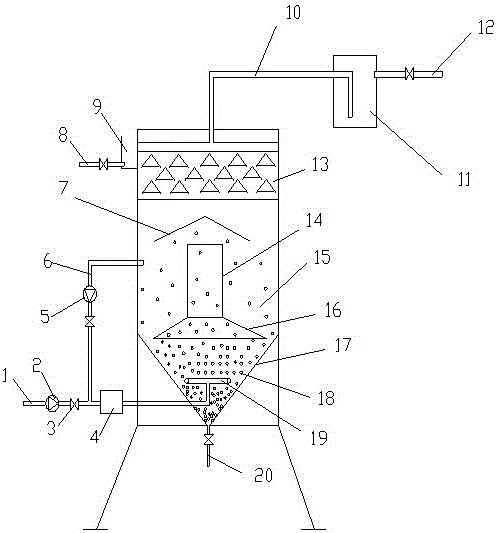

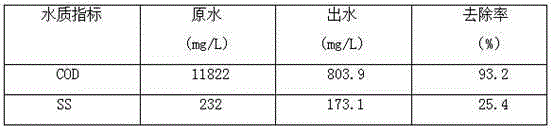

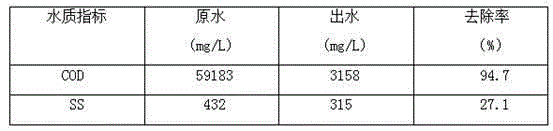

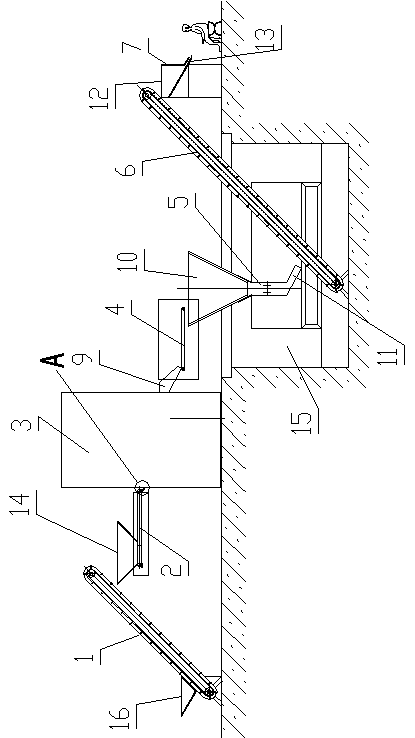

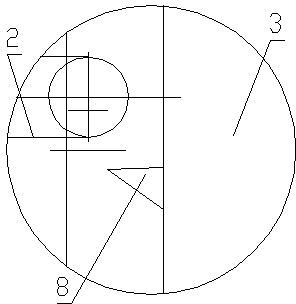

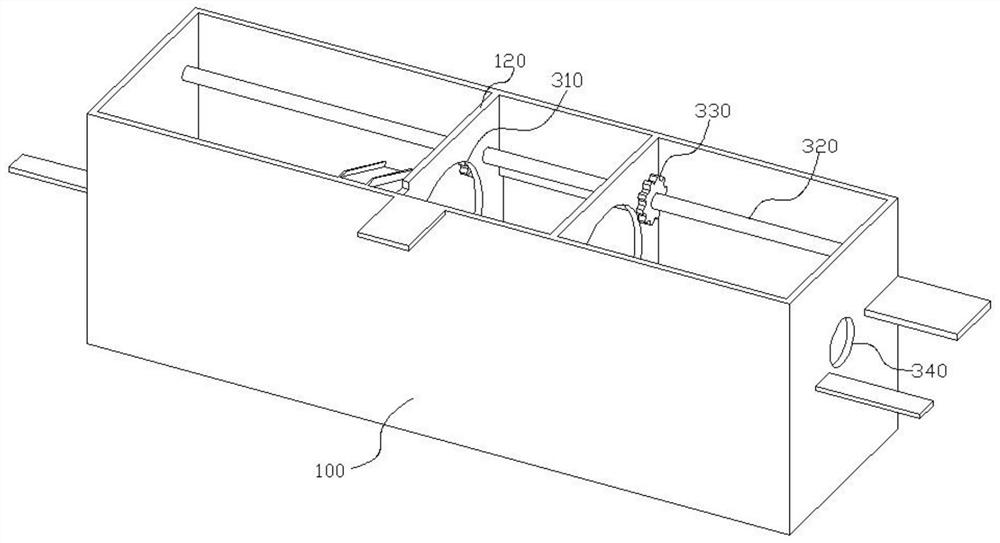

Multi-phase reinforcement and guide type circular and anaerobic granulation reaction processing device

InactiveCN105036325ARealize automatic crushingFully contactedWaste based fuelTreatment with anaerobic digestion processesPulp and paper industryWater circulation

The invention relates to a multi-phase reinforcement and guide type circular and anaerobic granulation reaction processing device applied to high concentrated organic wastewater. The processing device is characterized by comprising a water inlet assembly, a water outlet assembly, a processing device body, a biogas processing assembly and an internal circulation assembly, wherein the biogas processing assembly is arranged on the processing device body, and the internal circulation assembly is arranged in the processing device body; the water inlet assembly is arranged at the lower part of the processing device body, and the water outlet assembly is arranged at the upper part of the processing device body. The processing device has the beneficial effects that the integral structural design is skillful, and the operation is convenient; the rapid granulation of anaerobic sludge in the treatment process of high concentrated organic wastewater is realized by virtue of multiple granulated fillers, internal and external circulation, efficient water distribution and cyclic heating of wastewater, so that the anaerobic debugging time is shortened, meanwhile, the volumetric load and removal rate of an anaerobic reaction device for treating high concentrated organic wastewater are substantially improved, and the construction cost of the anaerobic reaction device is lowered.

Owner:NANJING RUNTRY WATER

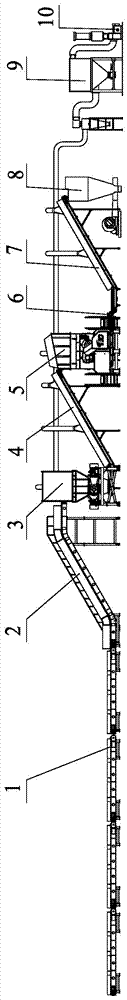

Automatic crushing system of super-hard material compound blocks

The invention discloses an automatic crushing system of super-hard material compound blocks, including a first conveyor belt, a quantitative conveyor belt, a crusher, a second conveyor, a pulverizer, a third conveyor belt and a charging hopper in order along the movement direction of materials; the outlet end of the first conveyor belt is arranged above the inlet end of the quantitative conveyor belt; the crusher is equipped with an inlet port for crushing and an outlet pipe for crushing; the outlet end of the quantitative conveyor belt is arranged above the inlet port for crushing; the outlet pipe for crushing is arranged above the inlet end of the second conveyor belt; the outlet end of the second conveyor belt is arranged above a reception hopper for crushing; the outlet pipe for crushing is arranged above the inlet end of the third conveyor belt; and the outlet end of the third conveyor belt is arranged above the inlet port of the charging hopper. In the invention, automatic crushing, automatic transshipment and automatic pulverization of super-hard material compound blocks are realized so that the environment for crushing compound blocks is greatly improved and the labor intensity of workers is greatly decreased. The automatic crushing system has the advantages of convenient operation, reliable quality and good security etc.

Owner:ZHONGNAN DIAMOND CO LTD

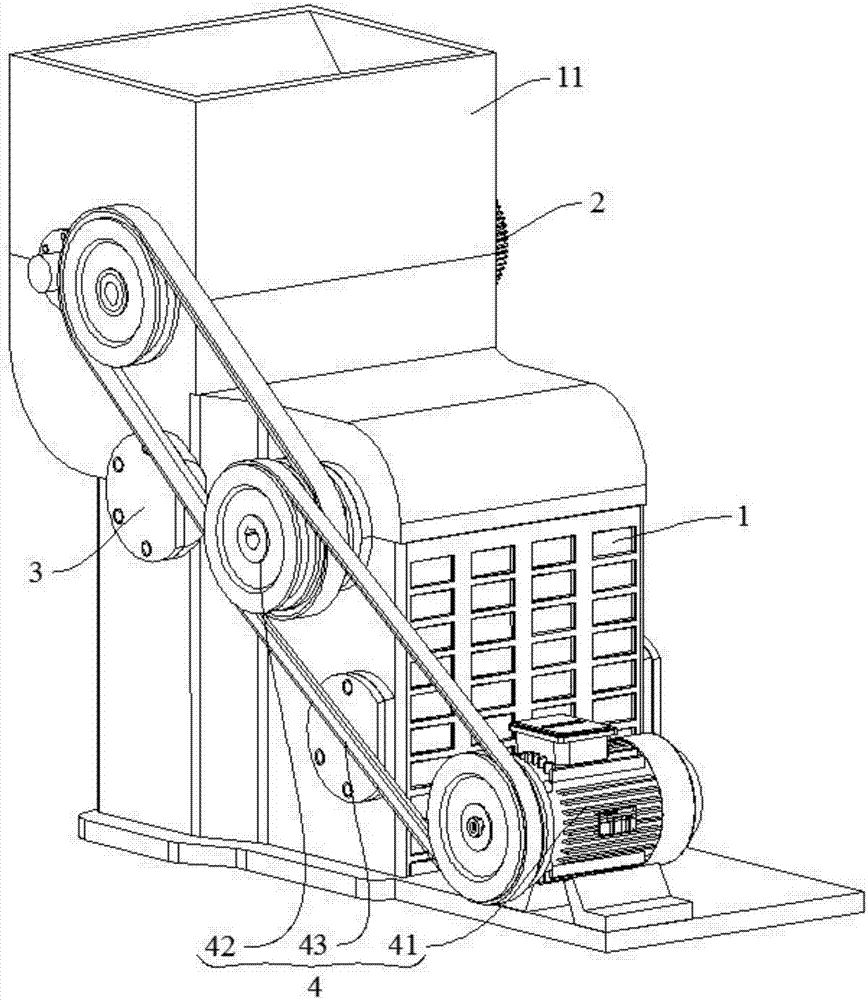

Energy-saving and environment-friendly large gravel aggregate crusher for construction industry

ActiveCN112473793ALabor savingRealize automatic loading and unloadingGrain treatmentsConstruction industryEnvironmental geology

The invention relates to a crusher, in particular to an energy-saving and environment-friendly large gravel aggregate crusher for the construction industry. The technical problem to be solved by the invention is to provide the energy-saving and environment-friendly large gravel aggregate crusher for the construction industry, which is suitable for large and small gravels and is convenient for collecting and screening the gravels. The energy-saving and environment-friendly large gravel aggregate crusher for the construction industry comprises a base and supporting columns, and the supporting columns are evenly arranged on the two sides of the base; the crushing mechanism is arranged on the base; and the protection mechanism is arranged on the base. Through cooperation of the crushing mechanism and the protection mechanism, automatic gravel crushing can be achieved, meanwhile, protection can be conducted in the crushing process, and therefore the labor force of people can be saved.

Owner:易县腾辉矿产建材有限公司

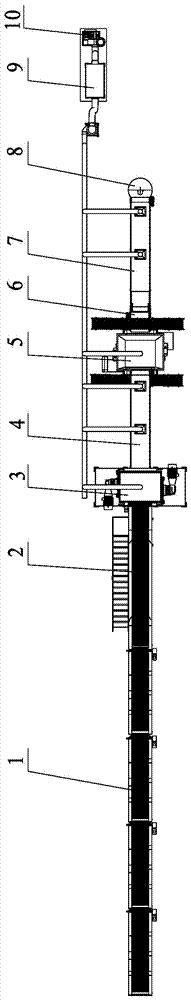

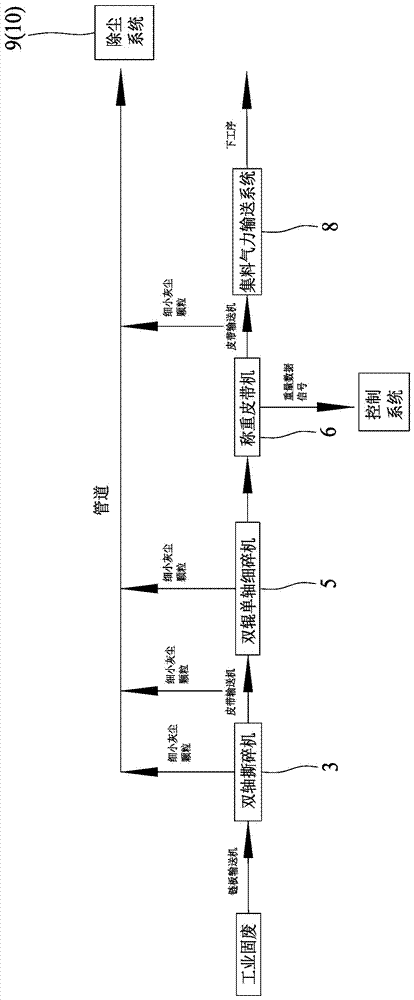

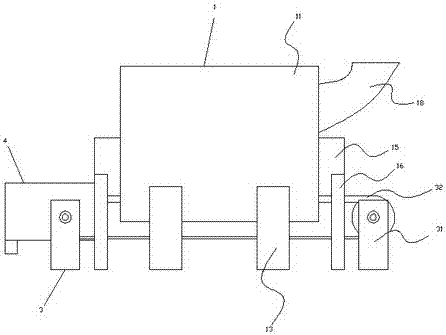

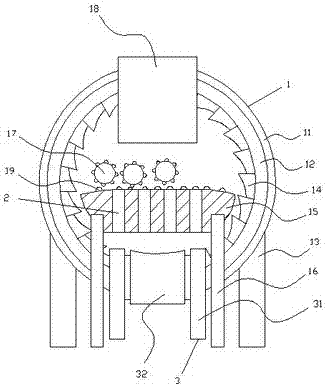

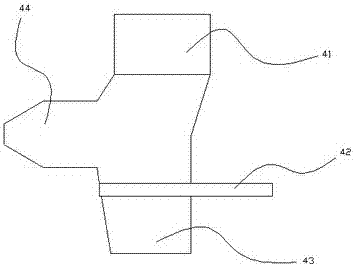

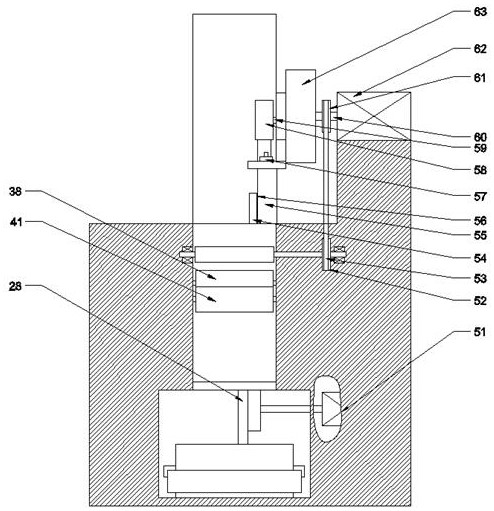

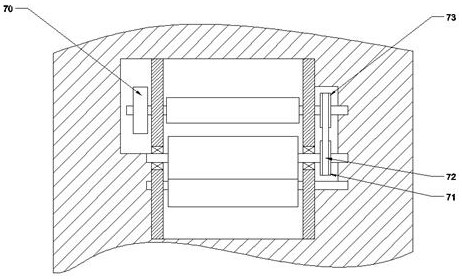

Equipment and process for crushing and automatically metering and conveying industrial solid wastes and biomass fuel

InactiveCN106902959ARealize automatic crushingSmall sizeVortex flow apparatusGrain treatmentsCrusherDelivery system

The invention discloses an automatic metering and conveying equipment and process for industrial solid waste and biomass fuel crushing, which comprises a chain plate conveyor, a double-shaft shredder, a first belt conveyor, a double-roller single-shaft fine shredder, and a weighing machine connected in sequence. The heavy belt conveyor, the second belt conveyor, the aggregate pneumatic conveying system, the cyclone collector, and the dust collector; the double-shaft shredder, the upper part of the first belt conveyor, etc. are all equipped with a dust cover, and the upper end of the dust cover passes through The pipeline is connected with the input pipeline of the cyclone collector, and the output pipeline of the cyclone collector is connected with the input pipeline of the dust collector. The chain plate conveyor and double-shaft shredder of the present invention can realize automatic crushing of industrial solid waste and biomass fuel, and the weighing belt conveyor can realize real-time online measurement and transportation of crushed materials, cyclone collector and dust collector The dust generated during the crushing process can be efficiently disposed of without secondary pollution.

Owner:HUANCHUANG XIAMEN TECH

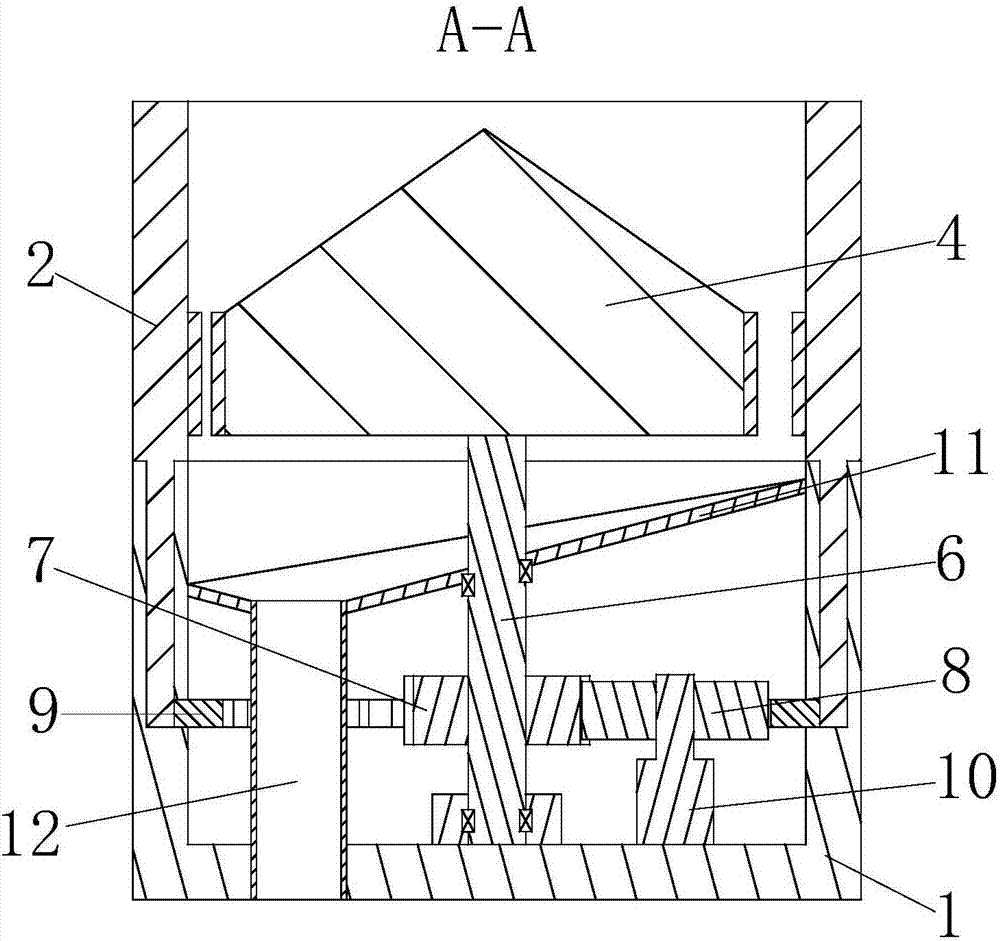

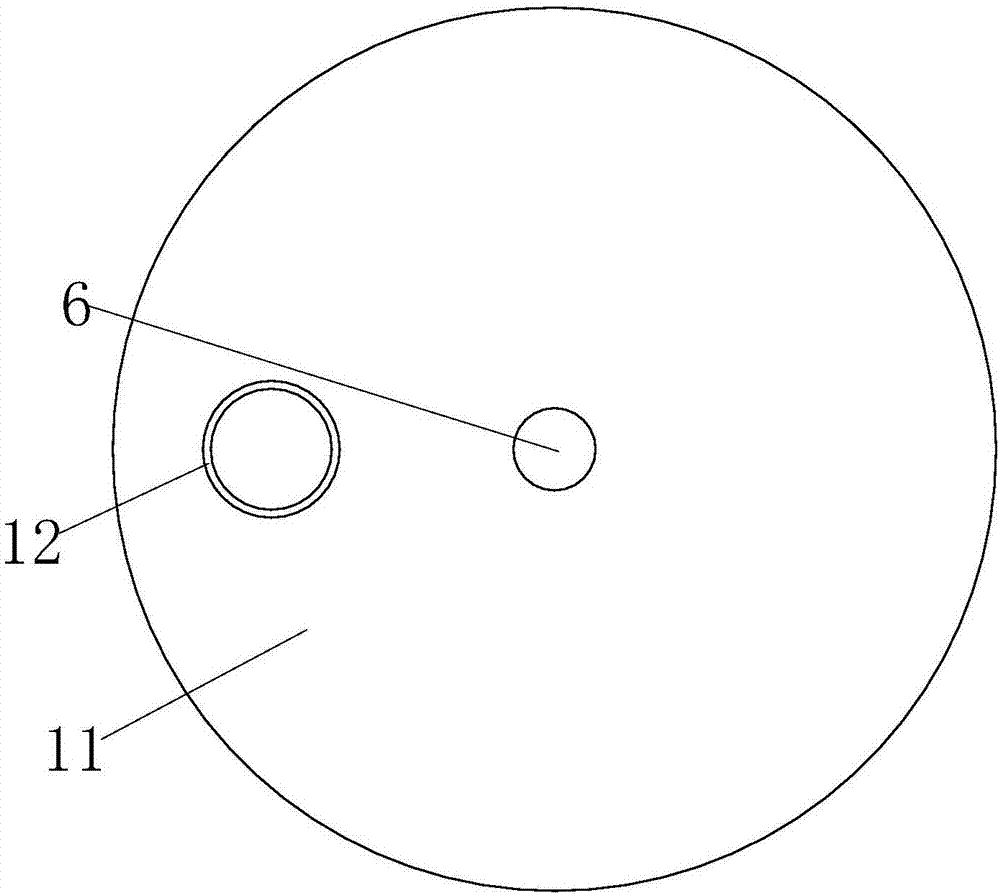

Stone crushing, ball-milling and sieving device for building

The invention discloses a stone crushing and ball milling and screening device for construction, which relates to the technical field of construction machinery and includes a crushing mechanism, a screening mechanism, a conveying mechanism and a discharging mechanism; the crushing mechanism includes a crushing outer cylinder, a crushing inner cylinder, a cylinder bracket, crushing liner, crushing plate, plate bracket and steel ball; the cylinder bracket is fixedly arranged at the lower part of the crushing outer cylinder, the crushing inner cylinder is rotatably arranged inside the crushing outer cylinder, and the crushing The liner is evenly arranged on the inner wall of the crushing inner cylinder, the crushing plate is located inside the crushing inner cylinder and there is a gap between the crushing liner and the upper middle of the crushing plate protrudes upwards, and the plate bracket Fixedly installed at both ends of the crushing plate, the steel balls are located inside the crushing inner cylinder and on the upper side of the crushing plate. The present invention can automatically crush, screen, unload and transport stones, with a high degree of automation , easy to use, conducive to improving production efficiency, and energy saving and environmental protection.

Owner:CHENGDU LYUDI TECH

Automatic fermentation production system

PendingCN110590422ARealize automatic crushingAchieve hybridExcrement fertilisersOrganic fertiliser preparationAutomatic controlControl system

The invention discloses an automatic fermentation production system, which comprises a crushing mixing device, a fermentation device, a deodorization device and an intelligent automatic control system, wherein the material outlet end of the crushing mixing device is communicated to the fermentation device, and the top portion of the fermentation device is communicated to the deodorization device.According to the invention, fermentation raw materials can be cut and stirred at the same time, such that the automatic crushing and mixing can be achieved in the crushing mixing device, the fermentation effect is good due to automatic feeding, the structure is reasonable, the system is economic and practicable, the humidity, the fermentation temperature, the fermentation humidity and the pH valueof the raw materials can be monitored at the same time, and the intelligent display management is performed.

Owner:黑龙江省农业科学院畜牧兽医分院

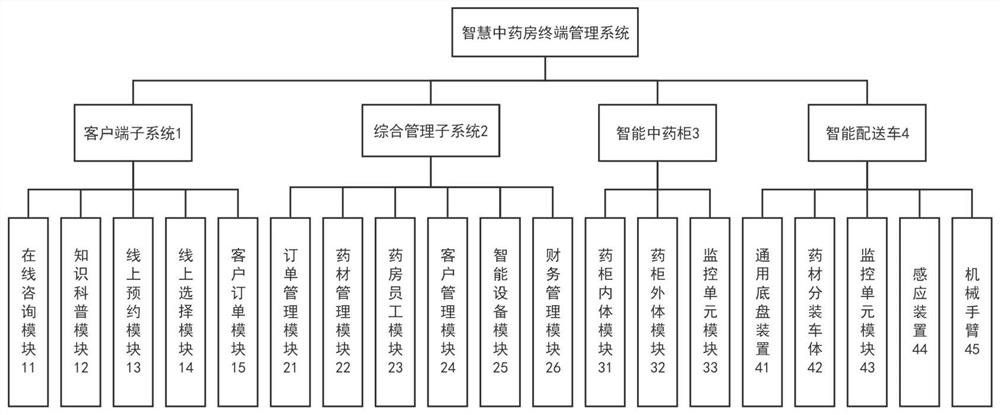

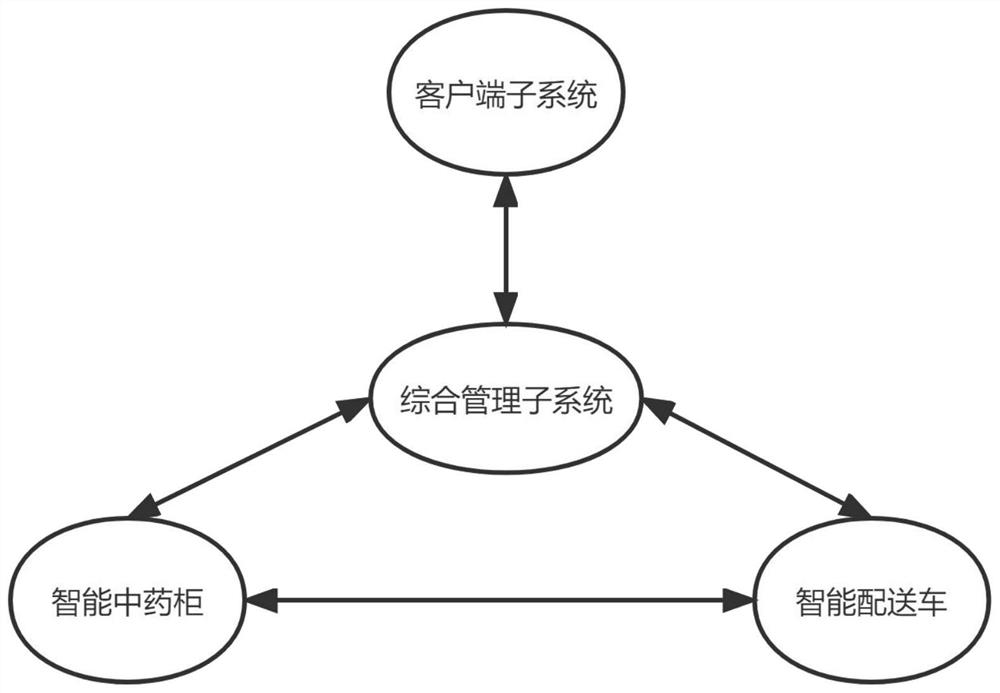

Intelligent traditional Chinese medicine pharmacy terminal management system

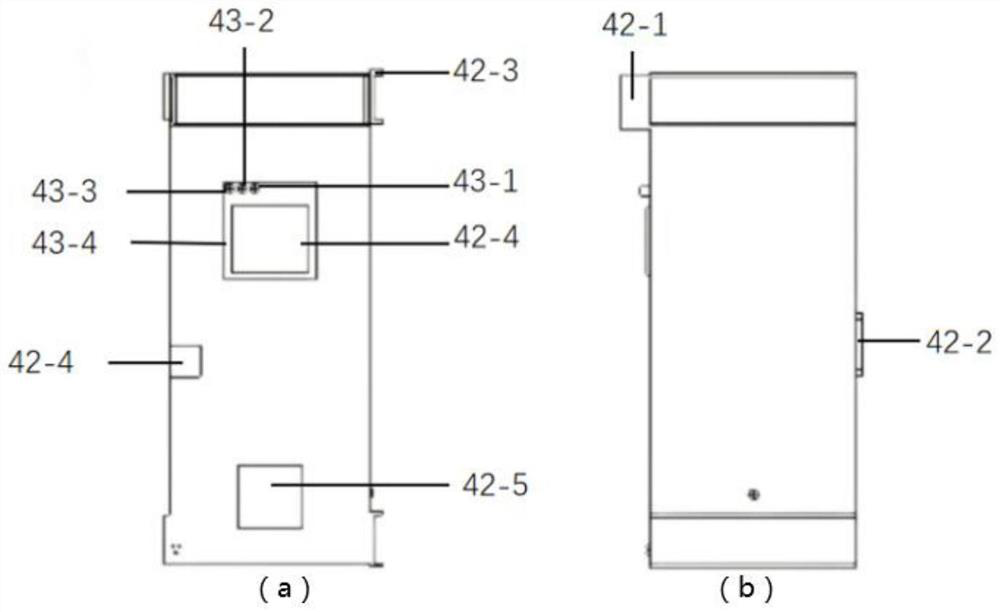

PendingCN114842942ARealize automatic crushingRealize deliverySustainable waste treatmentDrug and medicationsMedicinal herbsPharmacy

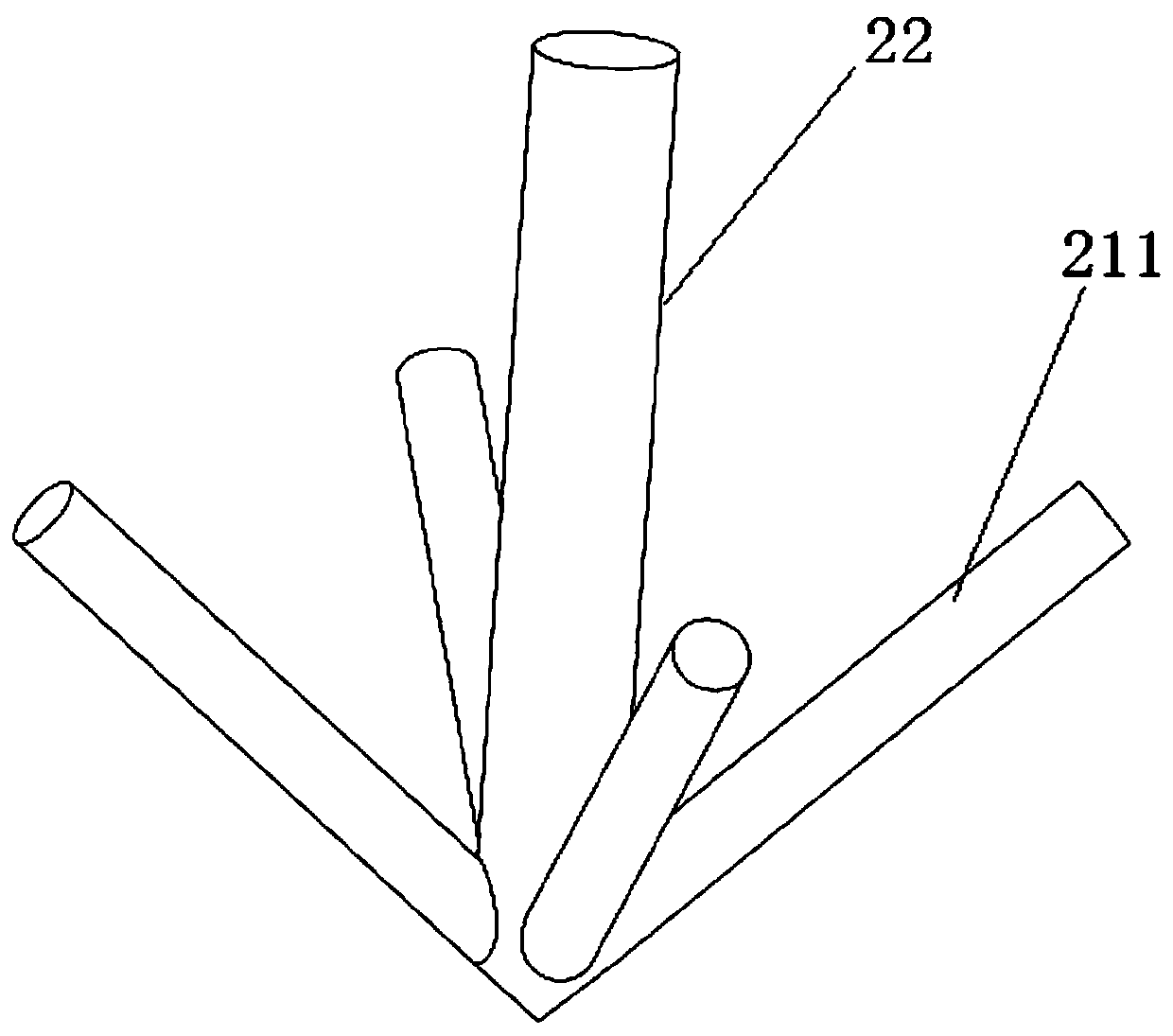

The invention discloses an intelligent terminal management system for a traditional Chinese medicine pharmacy, and the system comprises a comprehensive management subsystem, a client subsystem, an intelligent traditional Chinese medicine cabinet, and an intelligent distribution vehicle. Wherein the client subsystem is connected with the comprehensive management subsystem and is used for providing man-machine interaction for clients and performing data interaction with the comprehensive management subsystem; the intelligent traditional Chinese medicine cabinet is connected with the comprehensive management subsystem and is used for realizing crushing, storage and quantitative output of medicinal materials; the intelligent distribution vehicle is connected with the comprehensive management subsystem and is used for receiving, temporarily storing and distributing target medicinal materials; and the comprehensive management subsystem is used for realizing order management, customer management, medicinal material management and intelligent equipment management.

Owner:WUHAN UNIV OF TECH

Asphalt foaming device

ActiveCN111455780ASave engineering investmentGood for waste disposalRoads maintainenceBuilding materialAsphalt

The invention relates to the field of road building material production equipment, and discloses an asphalt foaming device. The device comprises a conveying belt, a treatment box, a crushing mechanism, a screening mechanism and a mixing mechanism, the conveying belt is arranged beside the treatment box; a feeding hole communicated with the interior of the treatment box is formed in the top of thetreatment box; the output end of the conveying belt is in butt joint with the feeding port. An inner space of the treatment box can be divided into a first cavity and a second cavity; the crushing mechanism and the screening mechanism are both mounted in the second cavity; an inclined guide plate is arranged below the screening mechanism; the guide plate is positioned in the second cavity, and oneend of the guide plate extends to the mixing mechanism; the waste asphalt mixture can be automatically crushed and screened, subsequent asphalt regeneration is facilitated, resource waste and engineering investment are saved, contact between water and the regenerated asphalt and the asphalt foaming quality are improved, efficient asphalt foaming is guaranteed, and the practicability is high.

Owner:枣庄旗胜建设集团有限公司

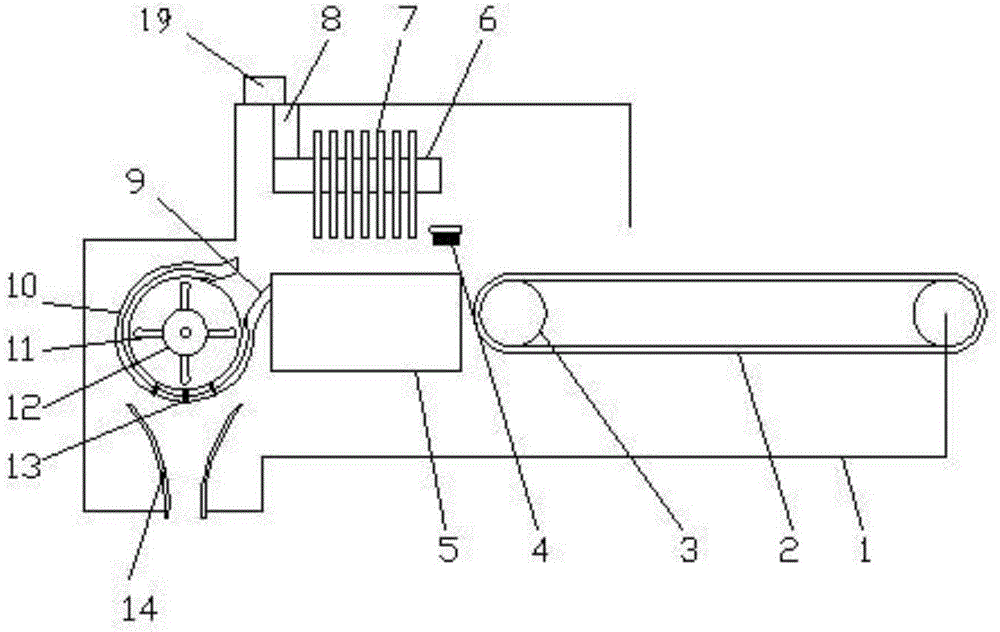

Automatic medical material pulverizer

InactiveCN104668036ARealize automatic crushingImprove crushabilityGrain treatmentsMetal working apparatusMechanical engineeringPulverizer

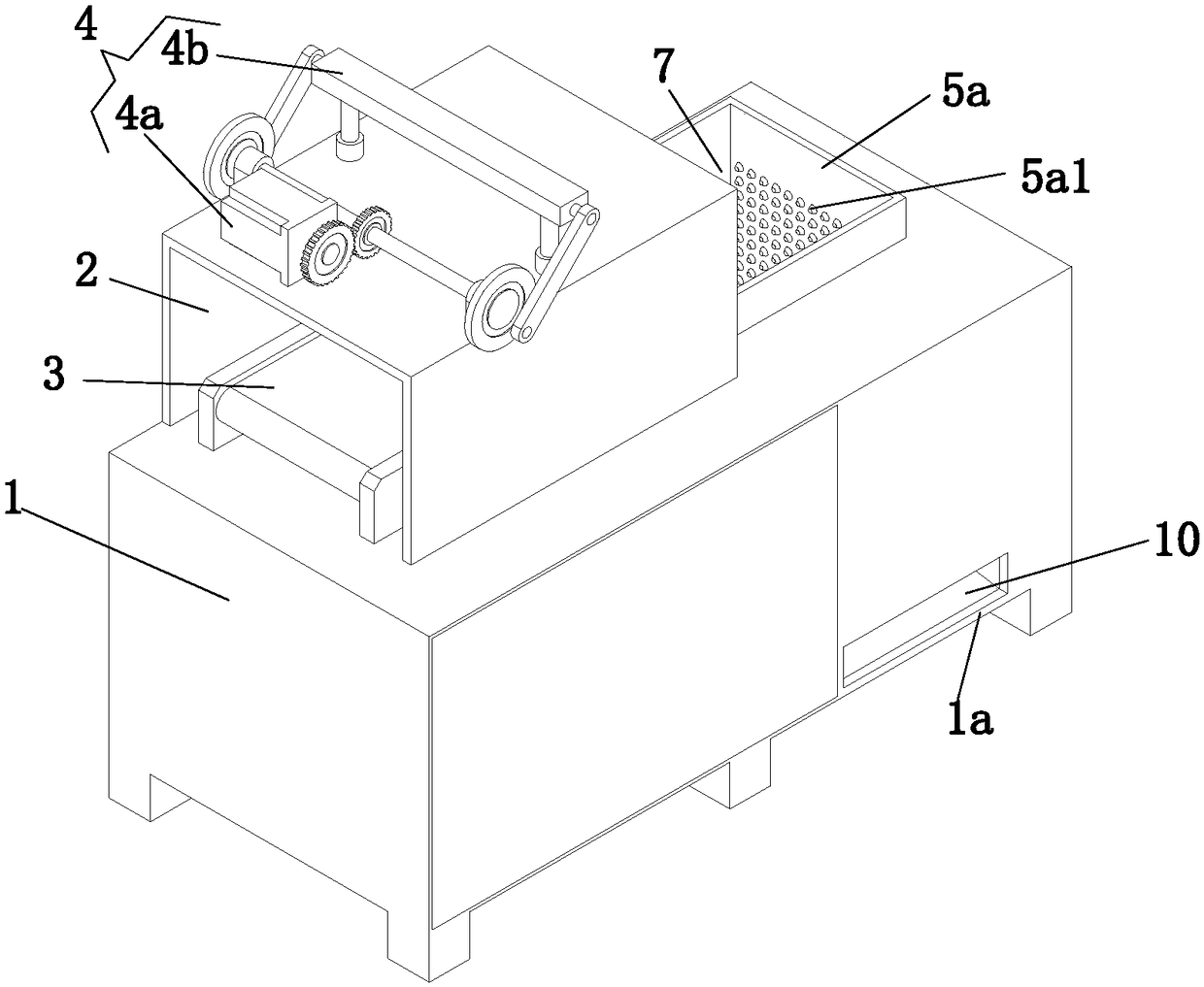

The invention discloses an automatic medical material pulverizer, which comprises a machine case, wherein a transfer component, a cutting component, a crushing component, a platform and a brush are arranged in the machine case; the transfer component is used for transferring medicinal materials; the cutting component is used for cutting medicine sheets; the crushing component is used for hamming the medicinal materials; the platform is used for putting the medicinal materials; the brush is arranged above the platform; a discharge opening is formed in the housing; and a controller for controlling the cutting component and the brush to work is arranged above the outside of the housing. According to the pulverizer disclosed by the invention, firstly, to-be-crushed medicinal materials are transferred to the platform by the transfer component; the medicinal materials are cut into sheets by virtue of the cutting component; the cut medicinal materials are transferred into a round screen drum by the brush, and are further hammed to be crushed by the crushing component; and the crushed medicinal materials are discharged from the discharge opening, so that the automatic crushing of the medicinal materials is realized; the crushing effect is obvious; and the work efficiency is high.

Owner:XIAN LIANKONG ELECTRICAL

Lotus seedpod threshing machine

The invention discloses a lotus seedpod threshing machine. The machine includes a crushing chamber, a crushing device, a scrap separating device and a feeding hopper; the feeding hopper is communicated with the crushing chamber, the crushing device is positioned in the crushing chamber, the scrap separating device includes a belt conveyor which is arranged obliquely, the belt conveyor conveys objects upward, and a scrap outlet is formed in the upper end of the belt conveyor; a lotus outlet is formed in the lower end of the belt conveyor, the crushing chamber is formed above the belt conveyor,lotus seedpods can enter the crushing chamber through the feeding hopper and are crushed by the crushing device, and scraps of the lotus seedpods can fall on the belt conveyor for separation. Automatic crushing of the lotus seedpods is achieved, and automatic separation of lotus seeds with husks from the scraps of the lotus seedpods is achieved; the lotus seeds cannot be scratched, the efficiencyis high, the separation effect is great, and the situation that materials are blocked does not easily occur. The machine is easy to operate and high in safety and reliability.

Owner:广昌县兴莲机械制造有限公司

Municipal solid waste crushing, extruding and recycling equipment

ActiveCN113275073ARealize automatic crushingEasy to take outTransportation and packagingSolid waste disposalProcess engineeringMunicipal solid waste

The invention relates to recycling equipment, in particular to municipal solid waste crushing, extruding and recycling equipment. The technical problem to be solved is to provide the municipal solid waste crushing, extruding and recycling equipment capable of realizing automatic transportation and crushing and extruding. The municipal solid waste crushing, extruding and recycling equipment comprises a supporting frame, a compression mechanism and a crushing mechanism, wherein the compression mechanism is arranged on the supporting frame; and the crushing mechanism is connected between the supporting frame and the compression mechanism. Through cooperation of the compression mechanism, the crushing mechanism and a discharging mechanism, waste can be automatically crushed; and meanwhile, the waste is extruded into blocks, so that people can conveniently take out the waste.

Owner:深圳市博林环保工程有限公司

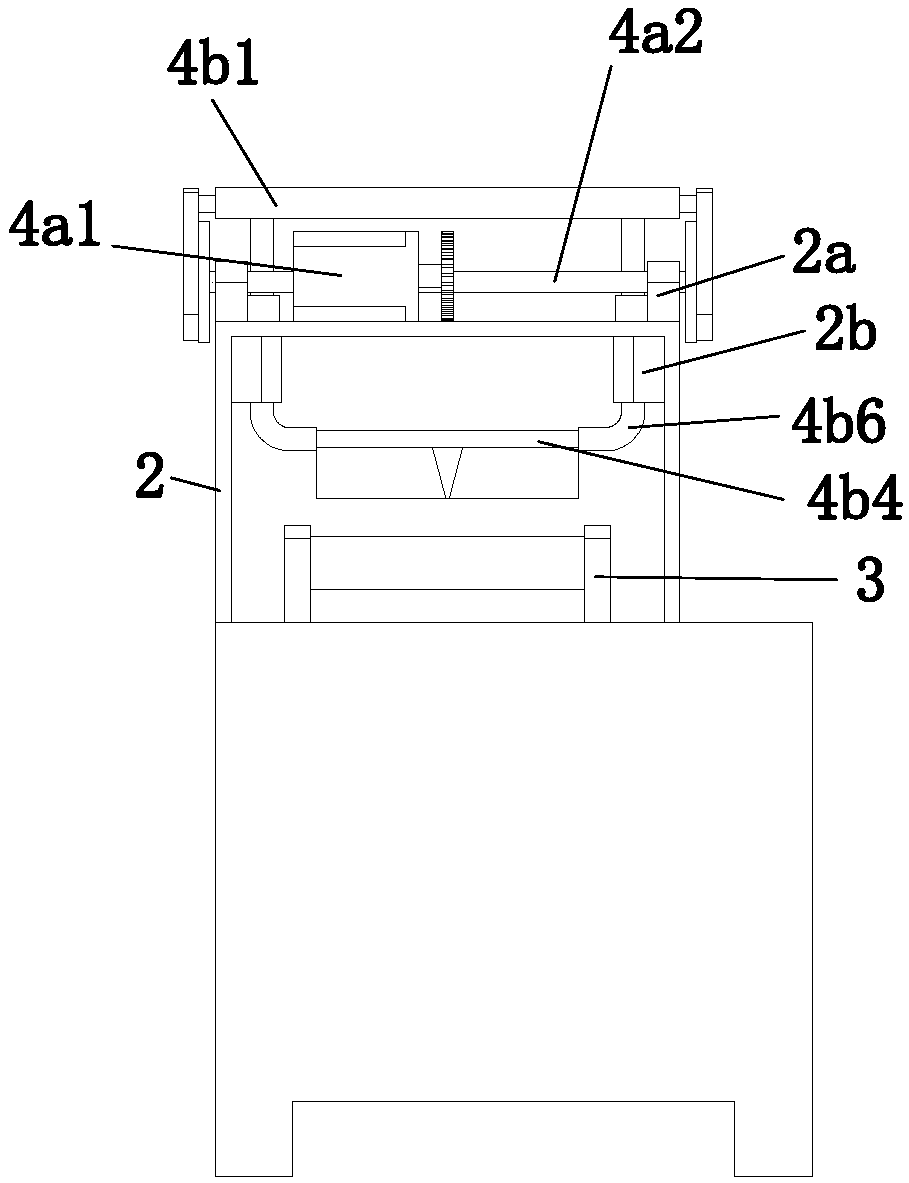

Sagger Crusher

Owner:安徽陆达智能装备科技有限公司

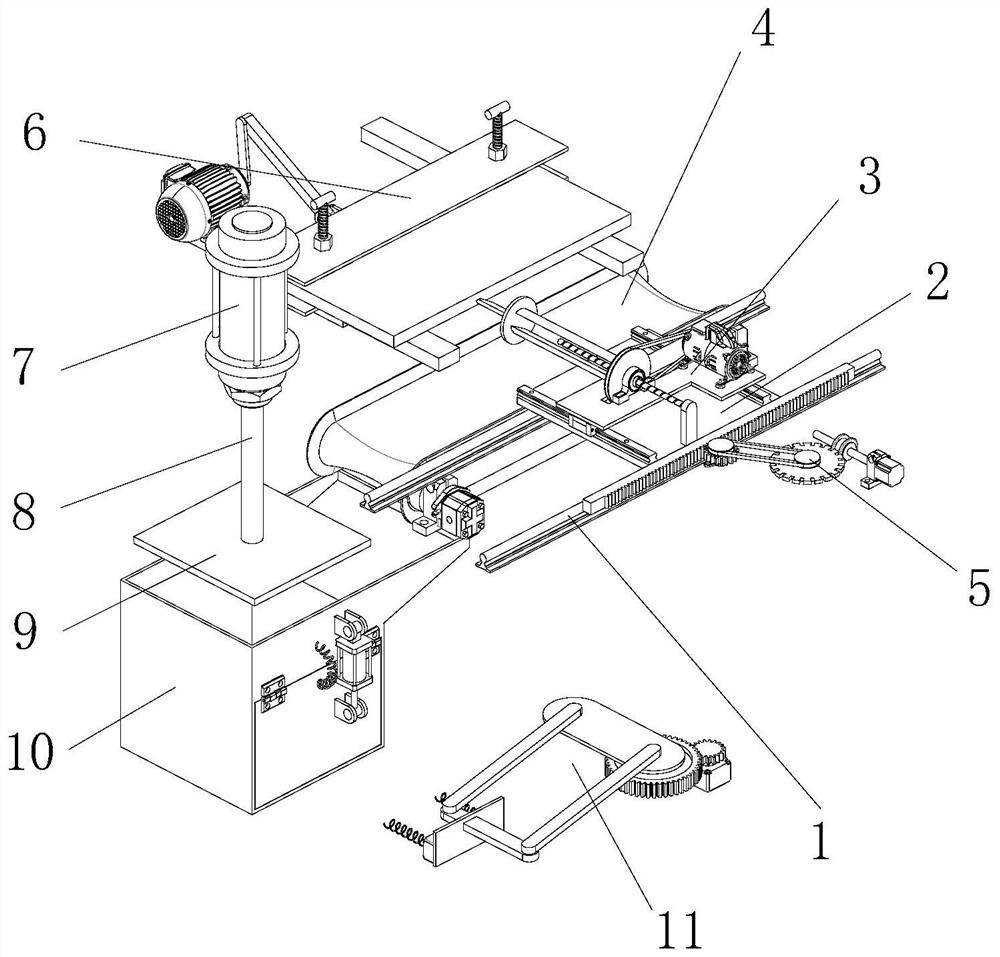

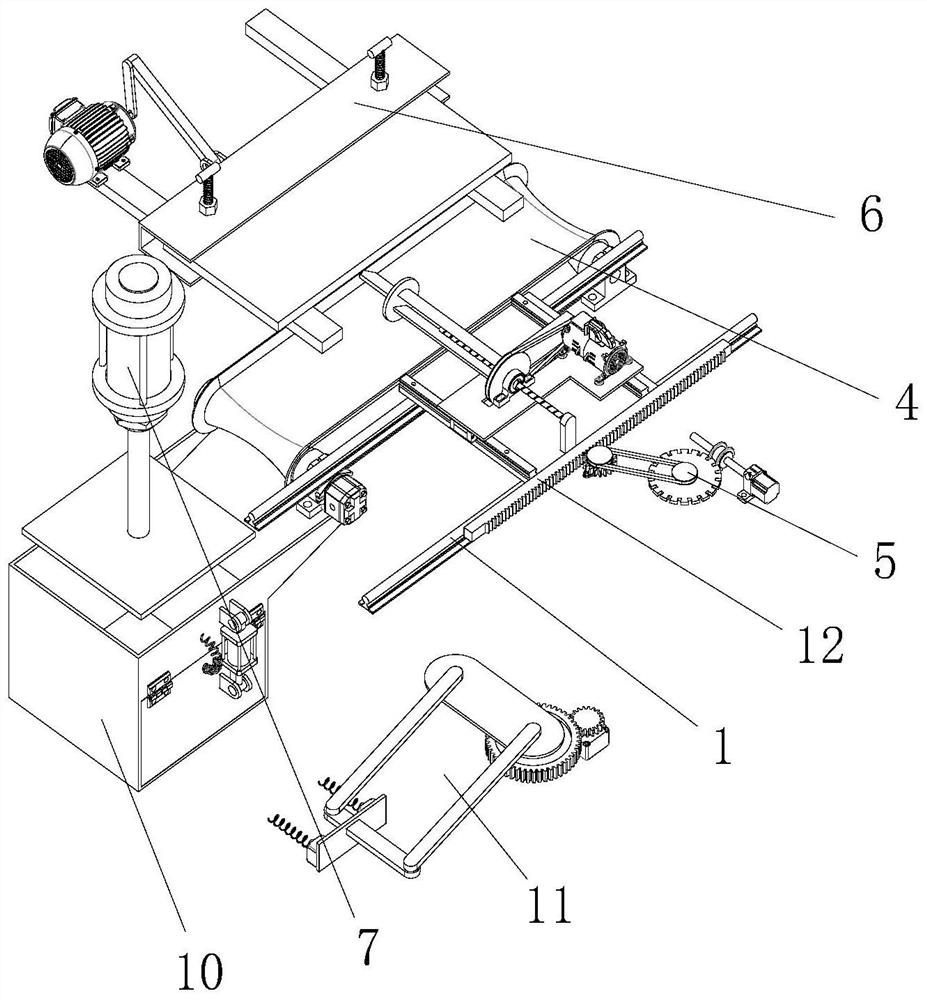

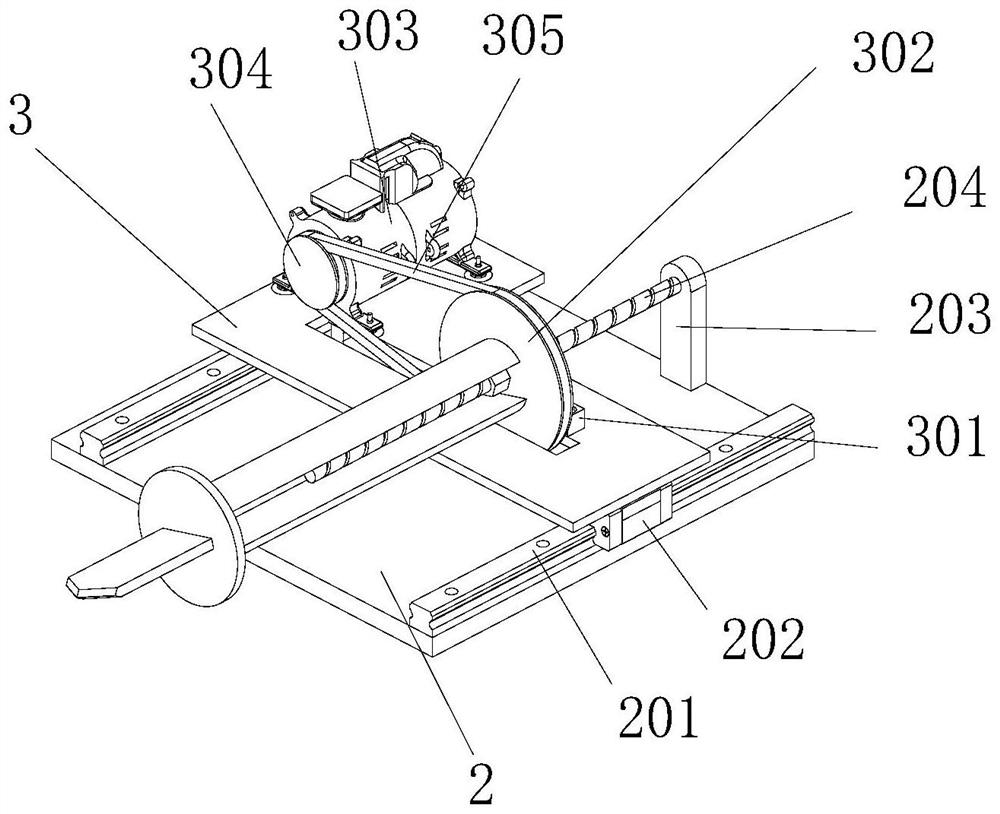

Multi-station milling numerical control machine tool

InactiveCN111890117AGood applicabilityRealize automatic crushingTransportation and packagingSolid waste disposalProcess engineeringWorkbench

The invention relates to the technical field of machine tools, in particular to a multi-station milling numerical control machine tool. The numerical control machine tool comprises a machine tool body, wherein a milling mechanism is arranged at the upper end of the machine tool body, a workbench is arranged in the machine tool body, a clamping mechanism used for fixing a machined part is arrangedon the upper end face of the workbench, a workbench through hole is formed in the workbench, and a waste collecting device is arranged below the workbench. According to the multi-station milling numerical control machine tool, parts of different sizes and shapes can be well clamped, and the applicability is good; and moreover, automatic classification treatment of waste materials and cutting fluidgenerated during part machining is better achieved, meanwhile, automatic crushing treatment of the waste materials is achieved, and subsequent treatment of people on the waste materials is facilitated.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

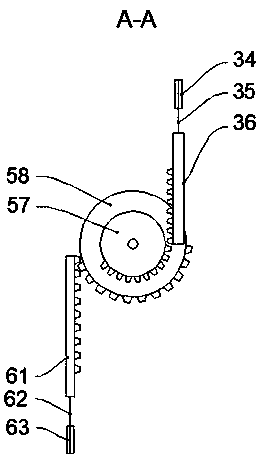

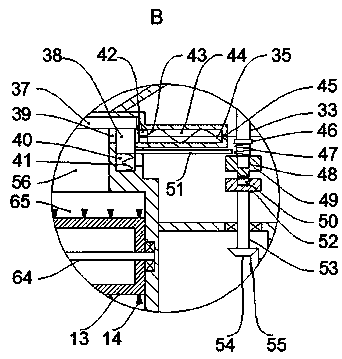

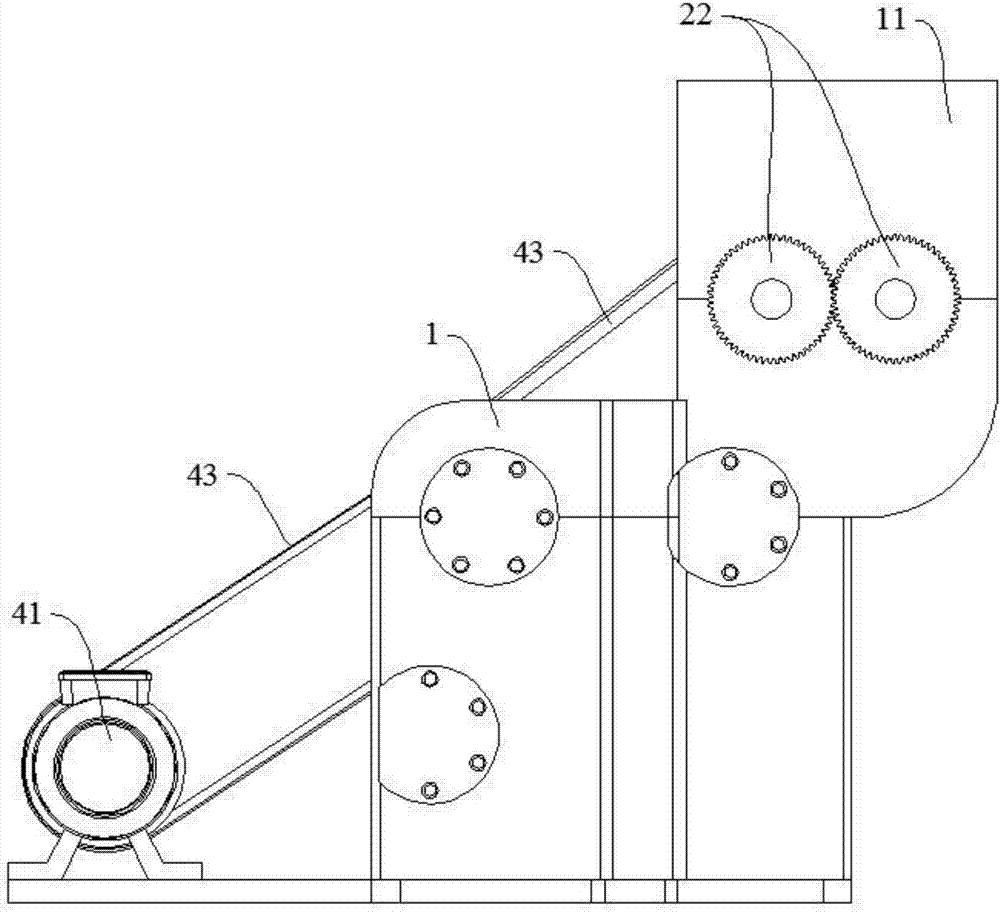

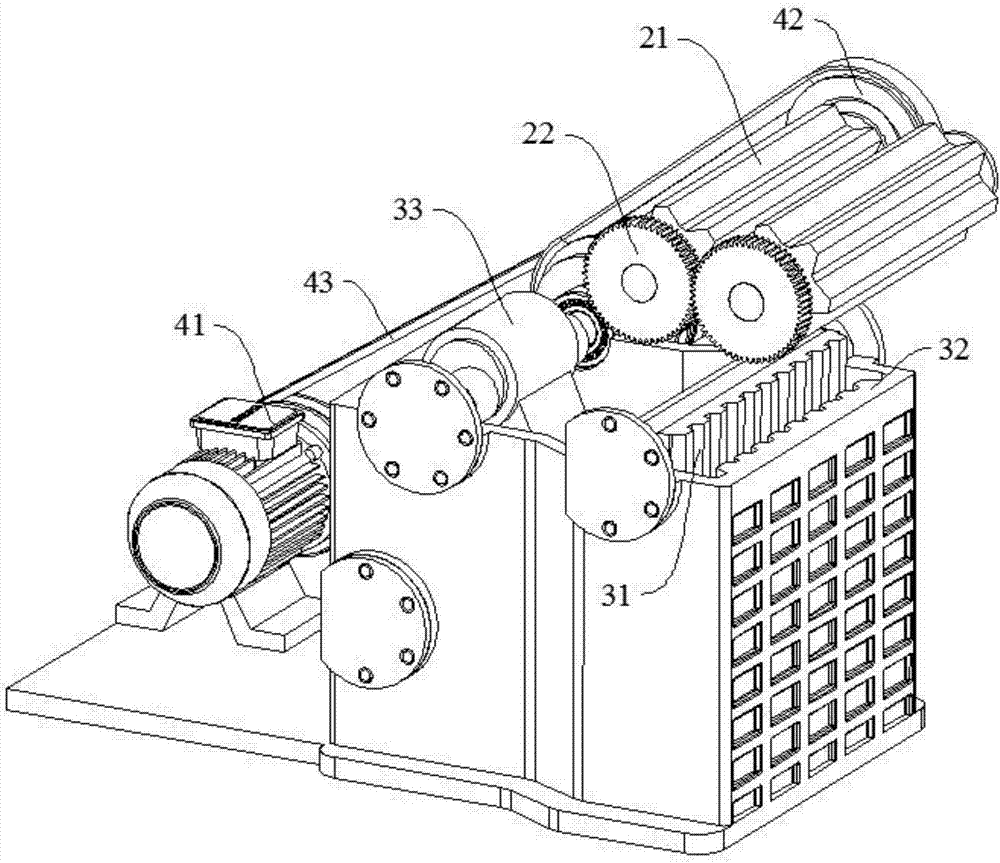

Longitudinal and transverse two-way crusher

InactiveCN106984388ARealize automatic crushingReasonable structureGrain treatmentsEngineeringCrusher

The invention discloses a longitudinal and transverse two-way crusher. A feed hopper is arranged at the top of a machine body; a transverse crushing mechanism is arranged below the feed hopper, and comprises a pair of crushing rollers; one ends of the crushing roller pair are engaged through gears; a lower port of the feed hopper is aligned to the middle of the crushing roller pair; a longitudinal crushing mechanism is arranged below the transverse crushing mechanism; a movable jaw plate and a fixed jaw plate are vertically arranged, and jaw teeth are also vertical; a gap between the movable jaw plate and the fixed jaw plate is aligned to a gap of the crushing roller pair; the upper part of the movable jaw plate is rotationally fixed on the machine body through a bearing; the back surface of the lower part of the movable jaw plate is connected with a first push rod by a hinge; the other end of the first push rod is connected with a second push rod and a third push rod by hinges; the other end of the second push rod is rotationally fixed on the machine body through a rotating shaft; an eccentric shaft is arranged above the second push rod; two ends of the eccentric shaft are rotationally fixed on the machine body; the other end of the third push rod is fixed on the eccentric shaft; and a discharge port is formed below the movable jaw plate and the fixed jaw plate. The longitudinal and transverse two-way crusher is reasonable and reliable in structure, and realizes automatic crushing of a nodulizing agent.

Owner:宁夏铸峰特殊合金有限公司

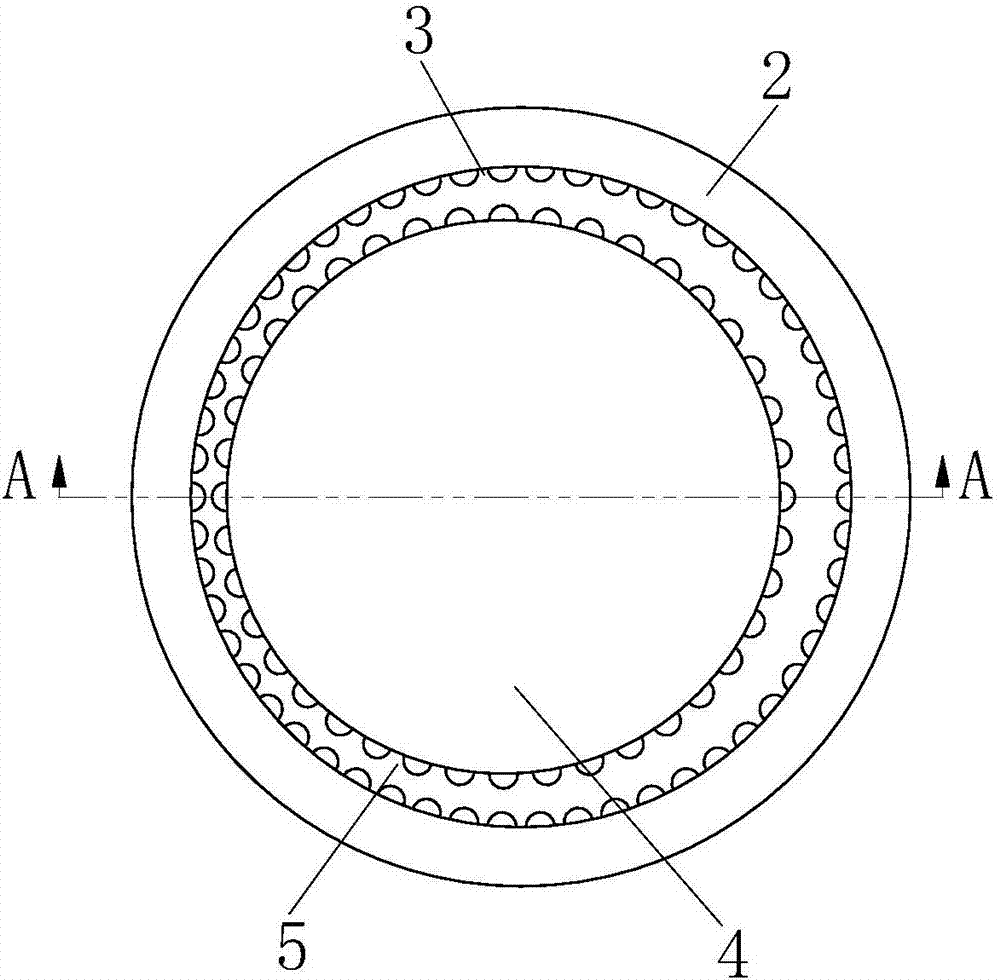

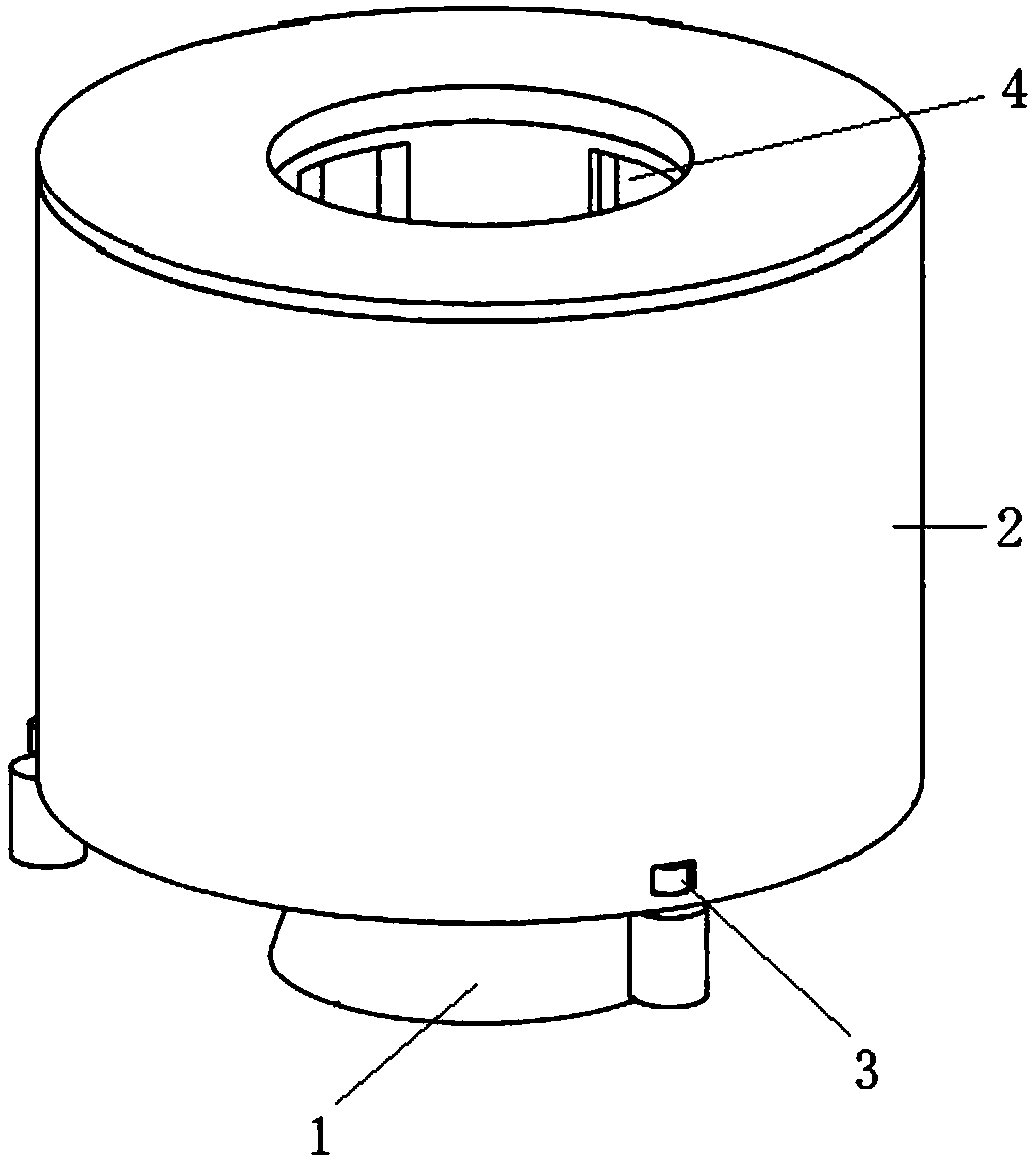

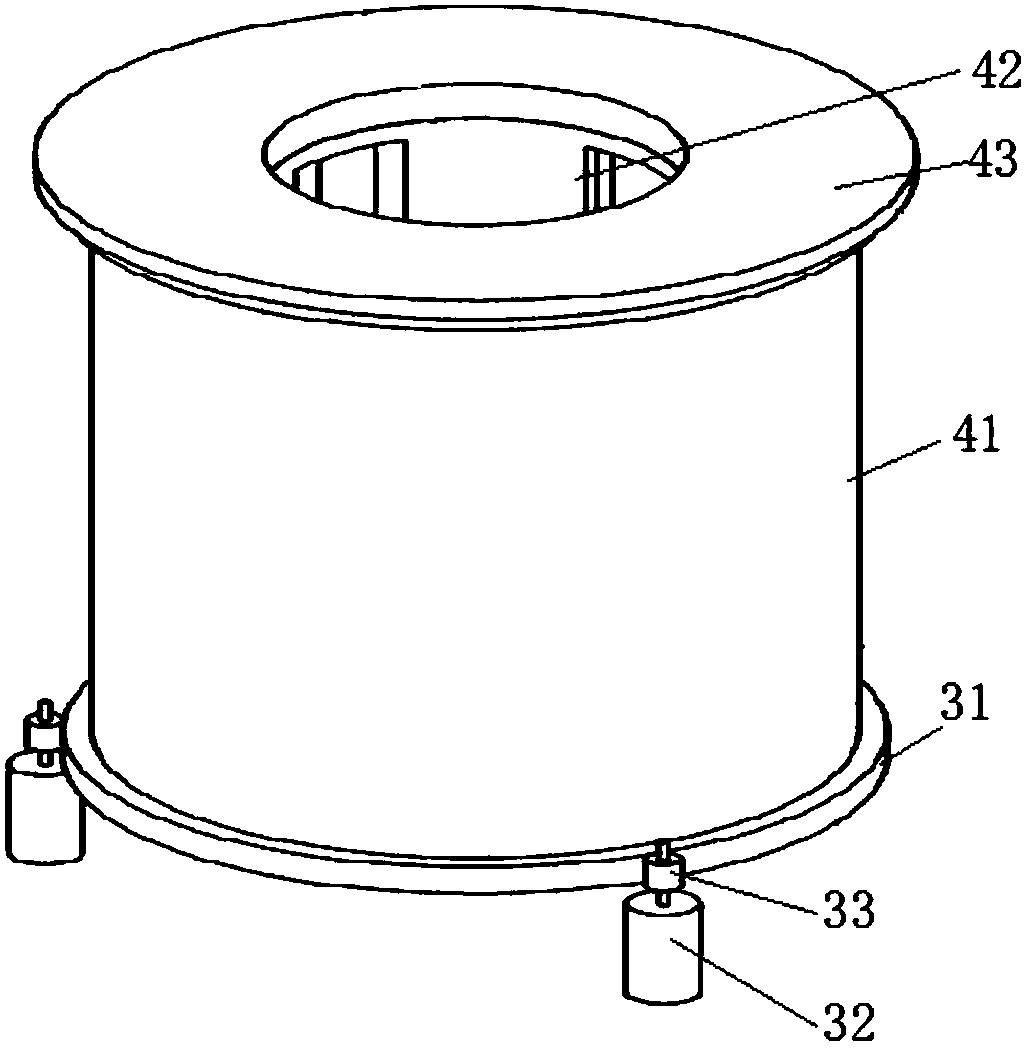

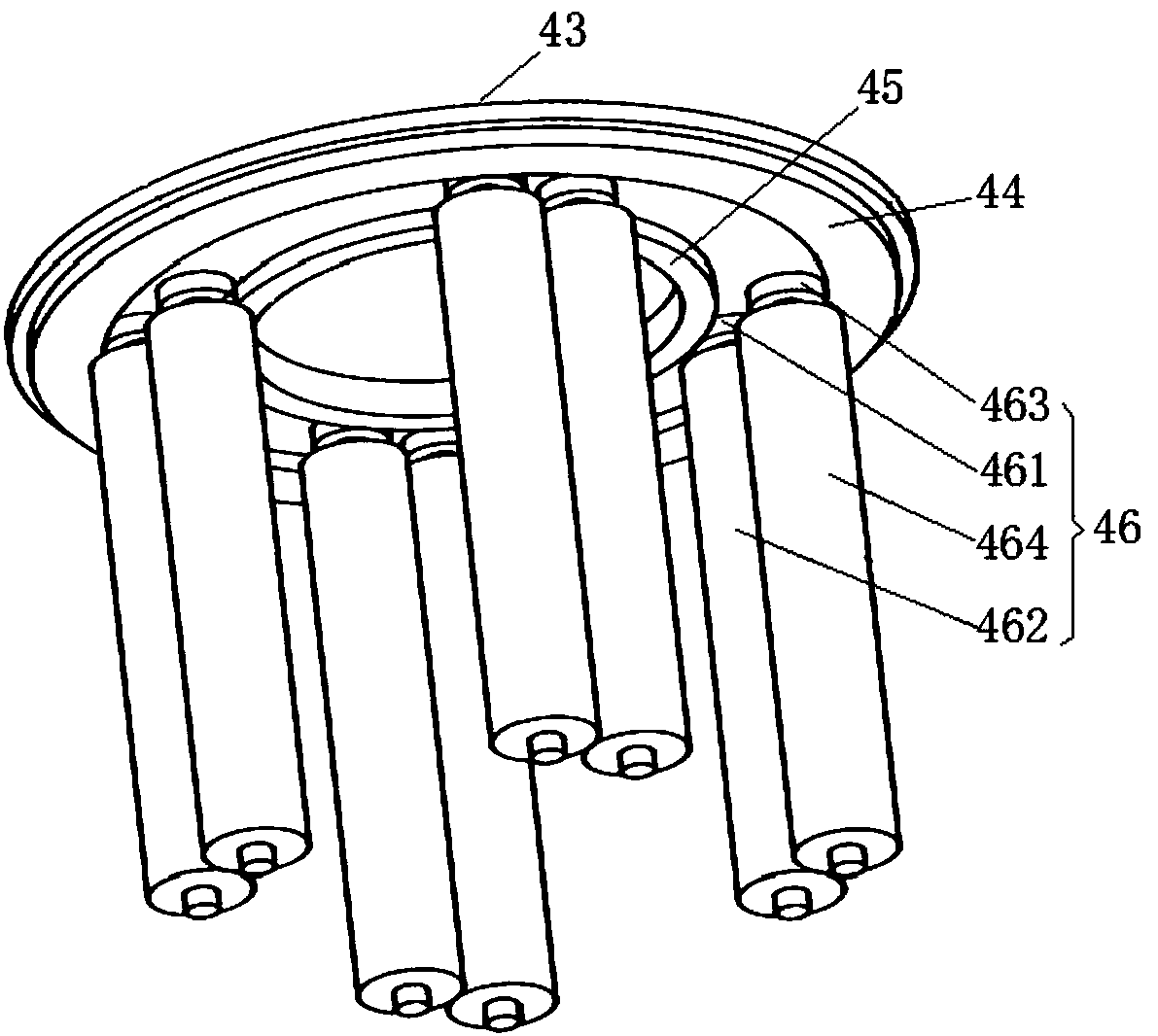

Crusher for fruits of tung oil trees

The invention discloses a crusher for fruits of tung oil trees. The crusher comprises a base and an outer barrel, and further comprises rotary driving units and a crushing unit; the outer barrel is fixed to the upper surface of the base; the rotary driving units are arranged on the outer barrel and are used for driving the crushing unit to rotate; the crushing unit comprises an inner barrel, a baffle, a top cover, an outer gear ring, an inner gear ring and crushing gear sets; the inner barrel is arranged in the outer barrel and is connected to the rotary driving units; the top cover is fixed to the top of the inner barrel; the outer gear ring and the inner gear ring are concentrically arranged on the lower surface of the top cover; the baffle is arranged in the inner barrel; a plurality ofopenings are formed in the bottom of the baffle and correspond to a gap between the inner barrel and the outer barrel; and the crushing gear sets are arranged between the inner barrel and the outer barrel and are used for crushing the fruits of the tung oil trees. The crusher has the advantages that the fruits of the tung oil trees can be automatically crushed, in addition, crushing is sufficient, the efficiency is high, and the workload and the working intensity of workers can be effectively relieved.

Owner:SHANGHAI DIANJI UNIV

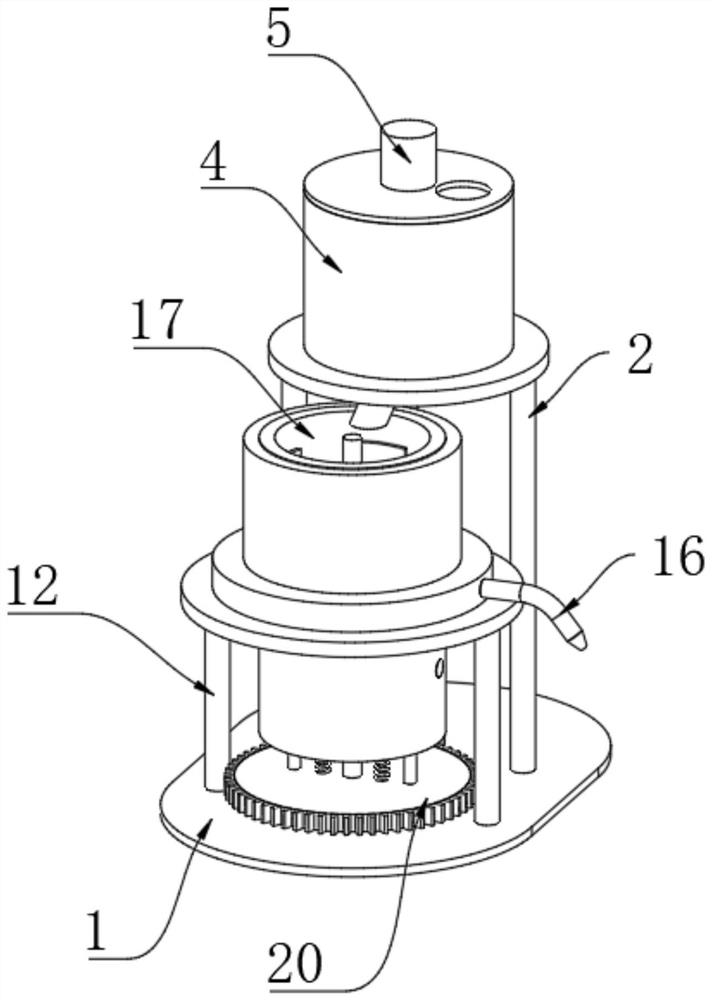

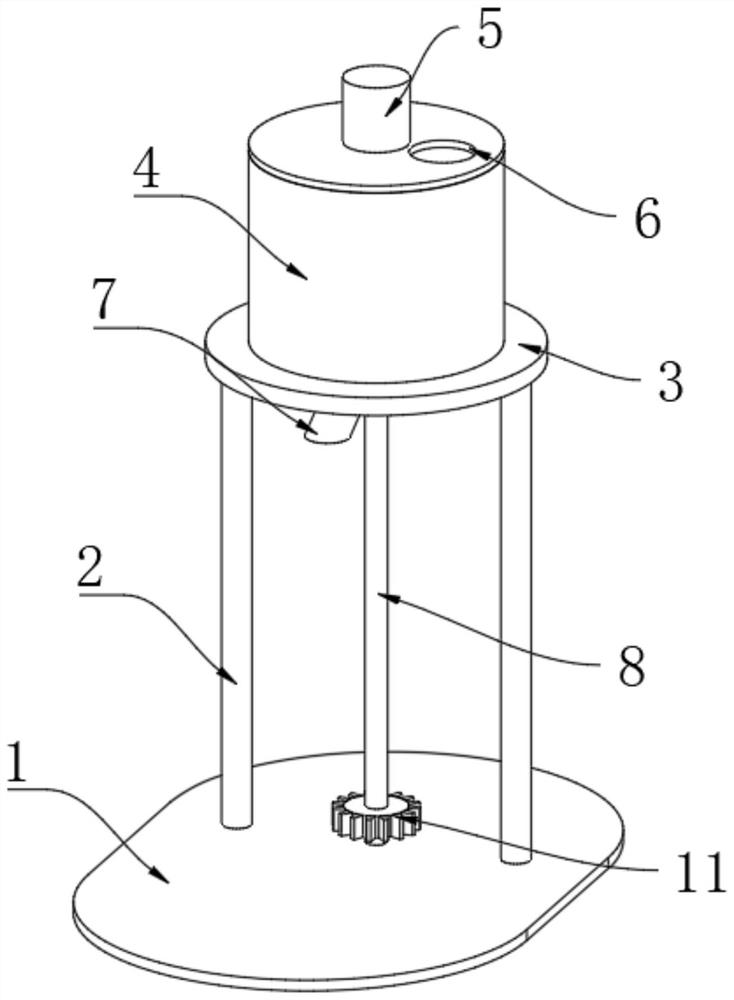

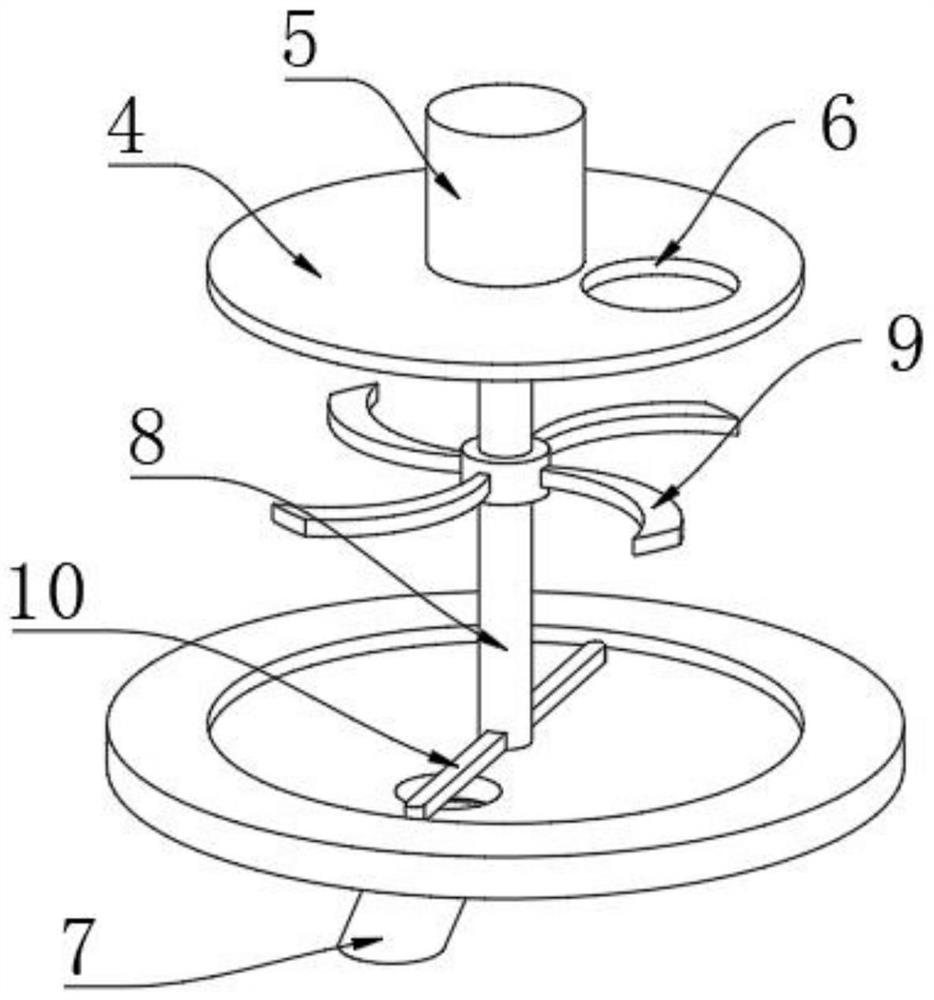

Stem cell extraction system

PendingCN114703056AQuick smashImprove responseBioreactor/fermenter combinationsBiological substance pretreatmentsCell extractionGear wheel

The invention discloses a stem cell extraction system which comprises a mounting bottom plate, a first supporting column is fixedly connected to the upper surface of the mounting bottom plate, a first mounting lantern ring is fixedly connected to the top end of the first supporting column, and a crushing box is fixedly connected to the inner wall of the first mounting lantern ring; a driving motor is fixedly mounted in the middle of the upper surface of the crushing box body, the output end of the driving motor extends into the crushing box body and is fixedly connected with a rotating shaft, the bottom end of the rotating shaft penetrates through the lower surface of the crushing box body, and the bottom end of the rotating shaft is fixedly connected with a gear I. A certain amount of collagenase is added into an inner cavity of the digestion tank; the driving motor is started, the cleaned placentas are poured into the inner cavity of the smashing box body from the position of the feeding opening, the rotating shaft is driven by the driving motor to rotate, then the smashing blades are driven to rotate, the placentas in the inner cavity of the smashing box body are rapidly smashed, and the placentas can conveniently react with collagenase in the follow-up process.

Owner:陶军

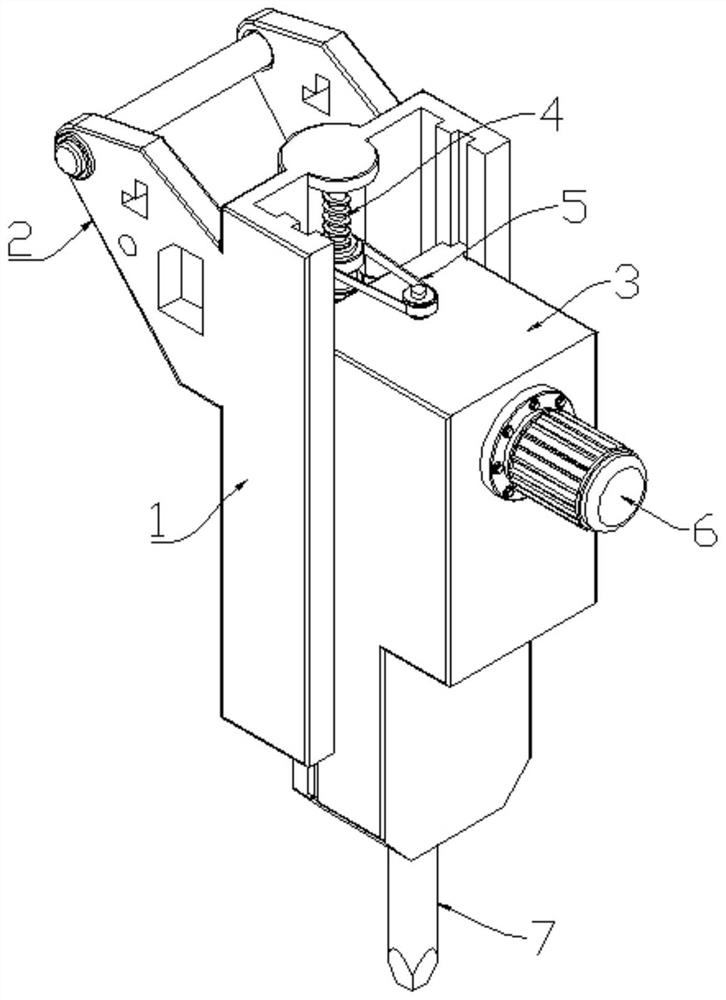

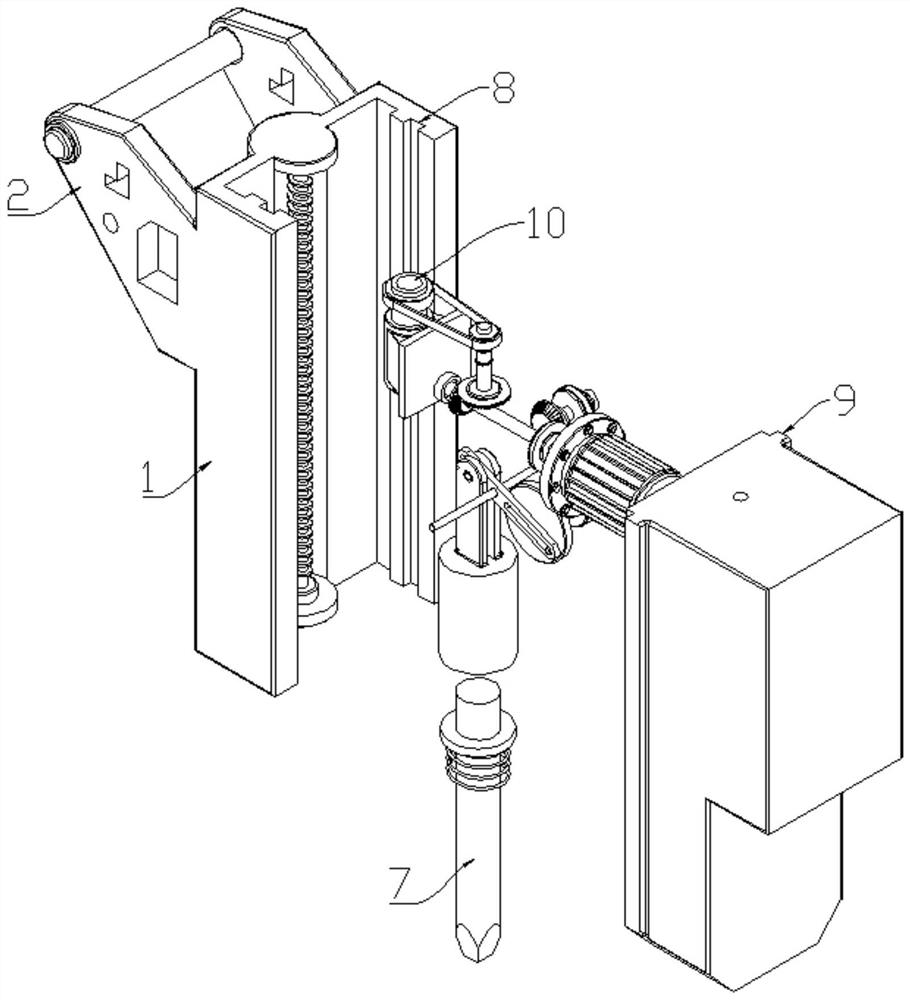

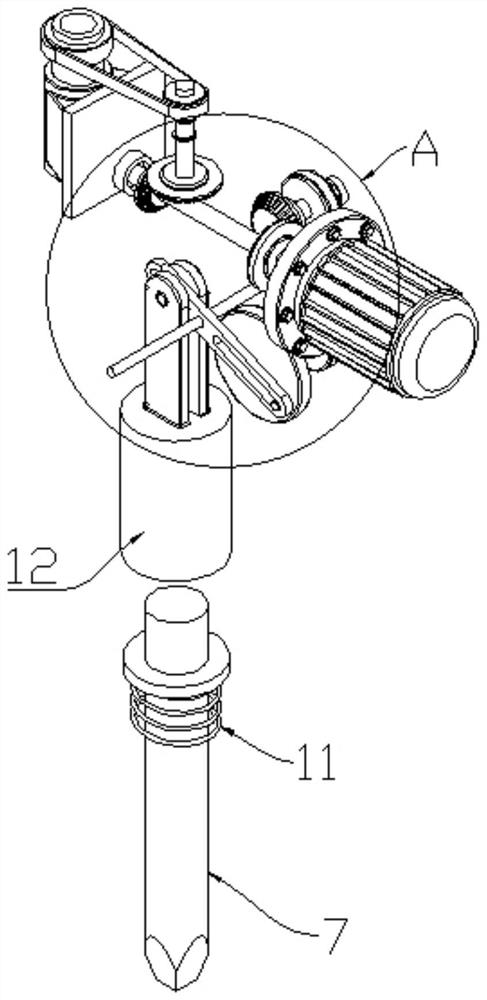

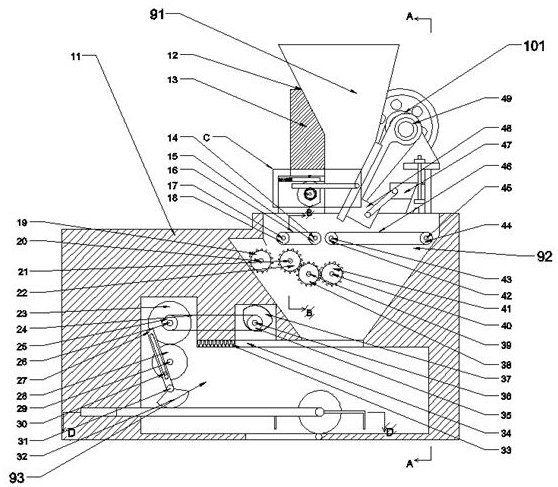

Roadbed crushing device for road and bridge construction

InactiveCN114592556AAchieve brokenReduce the difficulty of operationMechanical machines/dredgersRoads maintainenceArchitectural engineeringElectric machinery

The roadbed crushing device for road and bridge construction comprises an installation frame of a U-shaped structure and a movable shell installed on the inner side of the installation frame in a sliding mode, and a connecting frame used for being connected with a mechanical arm is fixed to the side, away from the movable shell, of the installation frame; a threaded rod is fixed to the inner side of the mounting frame and is in threaded connection with a threaded sleeve rotationally connected with the movable shell, and the threaded sleeve is connected with a motor output shaft through a transmission piece mounted on the movable shell. The output shaft of the motor is further connected with a driving piece installed in the movable shell through a one-way transmission piece. And a first movable groove is further formed in the inner side of the movable shell, a movable sleeve is slidably installed on the inner side of the first movable groove, the end, facing the driving piece, of the movable sleeve is in a sealed shape and connected with the driving piece, the end, away from the driving piece, of the movable sleeve is arranged in an open shape, and an impact block is slidably installed on the inner side of the movable sleeve.

Owner:胡高坤

Novel stone crusher

InactiveCN111921589ASimple structureEasy to operateGrain treatmentsCrushed stoneStructural engineering

The invention discloses a novel stone crusher. The novel stone crusher comprises a machine body and a first crushing cavity with an upward opening, the first crushing cavity is formed in the top in the machine body, the lower portion of the first crushing cavity communicates with a second crushing cavity, a third crushing cavity is formed in the bottom of the second crushing cavity, a crushing device is fixedly arranged at the position, at the right end of the first crushing cavity, of the machine body, the crushing device is used for preliminarily crushing stone, part of overlarge stone cannot be crushed in the crushing process and can be possibly clamped in the first crushing cavity, and a supporting column is fixedly arranged at the left end of the first crushing cavity. According to the novel stone crusher, the structure of the device is simple, the operation is convenient, the building stone is subjected to graded crushing for a plurality of times, screening is carried out twice in the process, all procedures are matched with one another and do not affect one another, automatic crushing of the stone is realized, meanwhile, the crushing is sufficient, thus the practical performance and efficiency of the device are improved, waste of manpower and material resources is effectively avoided, and therefore, the cost is greatly reduced.

Owner:杭州瑞芳容科技有限公司

A bitumen foaming device

ActiveCN111455780BRealize the crushing stepRealize automatic crushingRoads maintainenceArchitectural engineeringConveyor belt

Owner:枣庄旗胜建设集团有限公司

Crushing device for solid food testing

ActiveCN110411803BEvenly mixedRealize automatic crushingPreparing sample for investigationStructural engineeringSolid food

The invention provides a crushing device for solid food detection, belonging to the technical field of food crushing, comprising a box body, a first cutting roller, a second cutting roller, a filter cover, a grinding disc, a controller, the box body is hollow, and the box body There is a discharge port and a feed port on the top, and the bottom surface of the inner cavity of the box is arc-shaped; the first cutting roller is rotated in the box, and a number of first roller teeth are set on the first cutting roller; the second cutting roller is set There are several second roller teeth, the second cutting roller is installed in the box and meshed with the first cutting roller, the meshing part of the first cutting roller and the second cutting roller is opposite to the feeding port; the filter cover covers The discharge port; the grinding disc is circular, and the grinding disc is arranged under the first cutting roller and the second cutting roller. Fitted with the arc-shaped wall of the bottom surface of the inner chamber of the box. The crushing device for detecting solid food provided by the invention is more automatic and makes the crushing of solid food more uniform.

Owner:河北冠卓检测科技股份有限公司

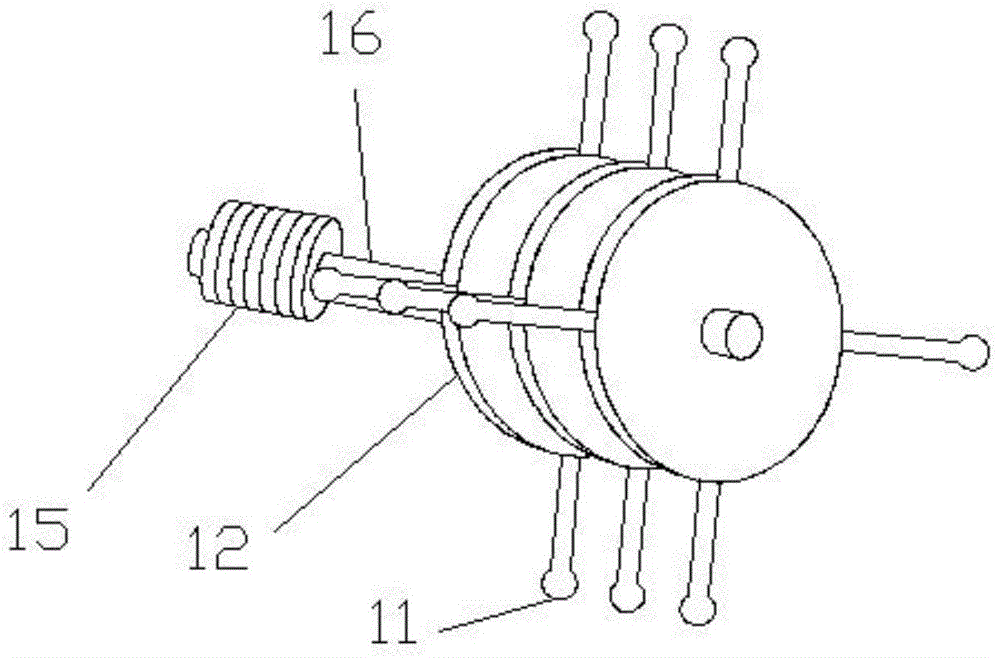

Pill material loosening and dispersing device for shot blasting machine

InactiveCN108607639AGuaranteed uptimeRealize automatic crushingGrain treatmentsScrew conveyorBelt conveyor

The invention discloses a steel plate processing line auxiliary device, and particularly relates to a pill material loosening and dispersing device for a shot blasting machine. The device comprises acrushing cavity connected to a discharge port at the bottom of a screw conveyor, a pair of crushing rollers arranged below the discharge port are arranged in the crushing cavity, a vibrating screen for receiving the material is arranged below the crushing rollers, a cloth bag for preventing the pill material from scattering is connected between the vibrating screen and the discharge port at the bottom of the screw conveyor; a belt conveyor is arranged below the vibrating screen; and the belt conveyor can output the crushed pill material. With the adoption of the structure, the pill material output from the screw conveyor can be crushed by the crushing rollers, the crushed material is dispersed by vibration of the vibrating screen, and output by the belt conveyor after being dispersed, theautomatic crushing is realized, the structural design is ingenious, manual auxiliary crushing is no longer needed, the time and labor are saved and the crushing effect is good, and the continuous running of the shot blasting machine is guaranteed.

Owner:ZHENJIANG SUBAIXIN CONSTR MACHINERY CO LTD

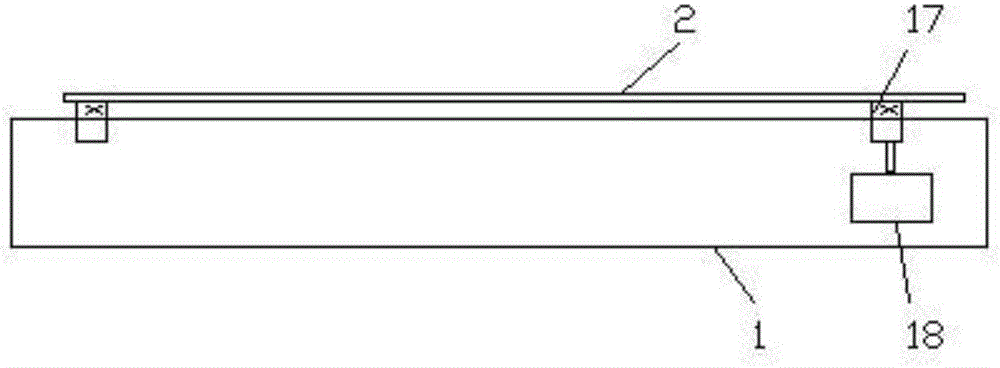

A split mechanism for composite floor

ActiveCN112339053BRealize automatic crushingRealize the function of automatic station replacementWood working apparatusDomestic articlesDrive wheelElectric machinery

The invention discloses a dismantling mechanism of a composite floor, which belongs to the field of plate processing and includes a fixed guide rail. There are two fixed guide rails, and the fixed guide rails are fixedly installed. A stepping stage is installed on the fixed guide rails. , and the bottom end of the stepping stage is provided with a slider that matches the fixed guide rail, the stepping stage and the fixed guide rail are slidably connected, and the top of the crushing table is provided with a reserved groove that matches the propulsion wheel , the lower half of the propulsion wheel is interspersed in the reserved slot in the middle of the crushing table, a crushing motor is installed on one side of the crushing table, and a drive wheel is installed at the output end of the crushing motor, and the drive wheel and the propulsion wheel pass through The propulsion belt is connected, and one side of the propulsion wheel is provided with two expansion pieces, and the end of the expansion piece away from the propulsion wheel is equipped with an end plate, and a crushing knife is installed on one side of the end plate. The invention can save manpower cost and is convenient for automatic unloading.

Owner:浦江县颐硕科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com