Stem cell extraction system

An extraction system and stem cell technology, applied in the field of stem cell extraction system, can solve problems such as poor continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

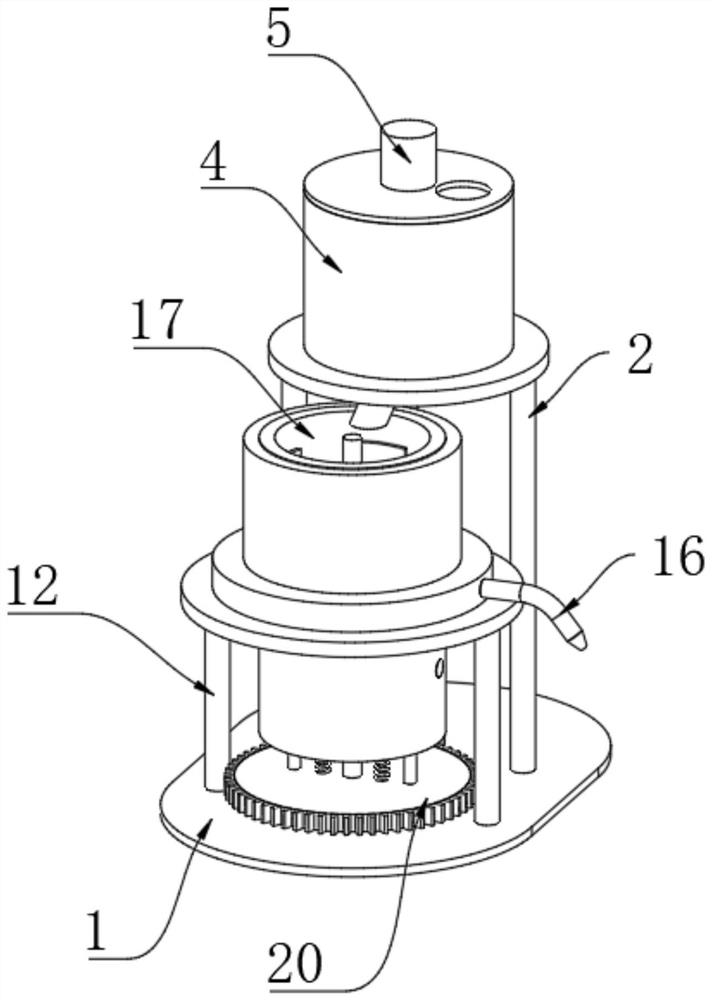

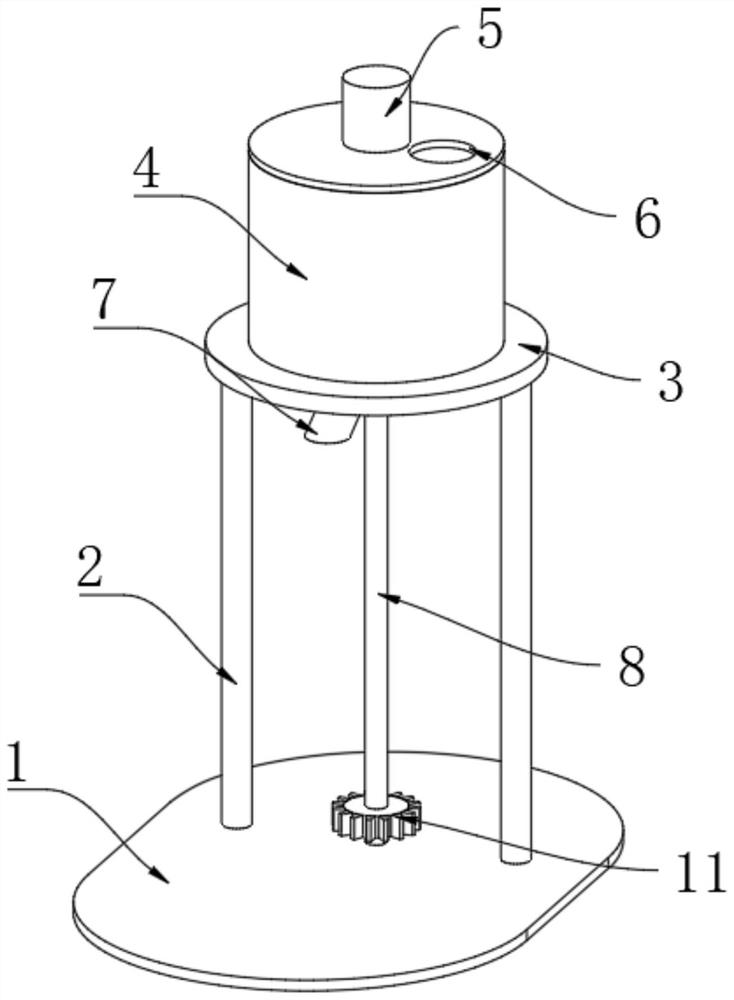

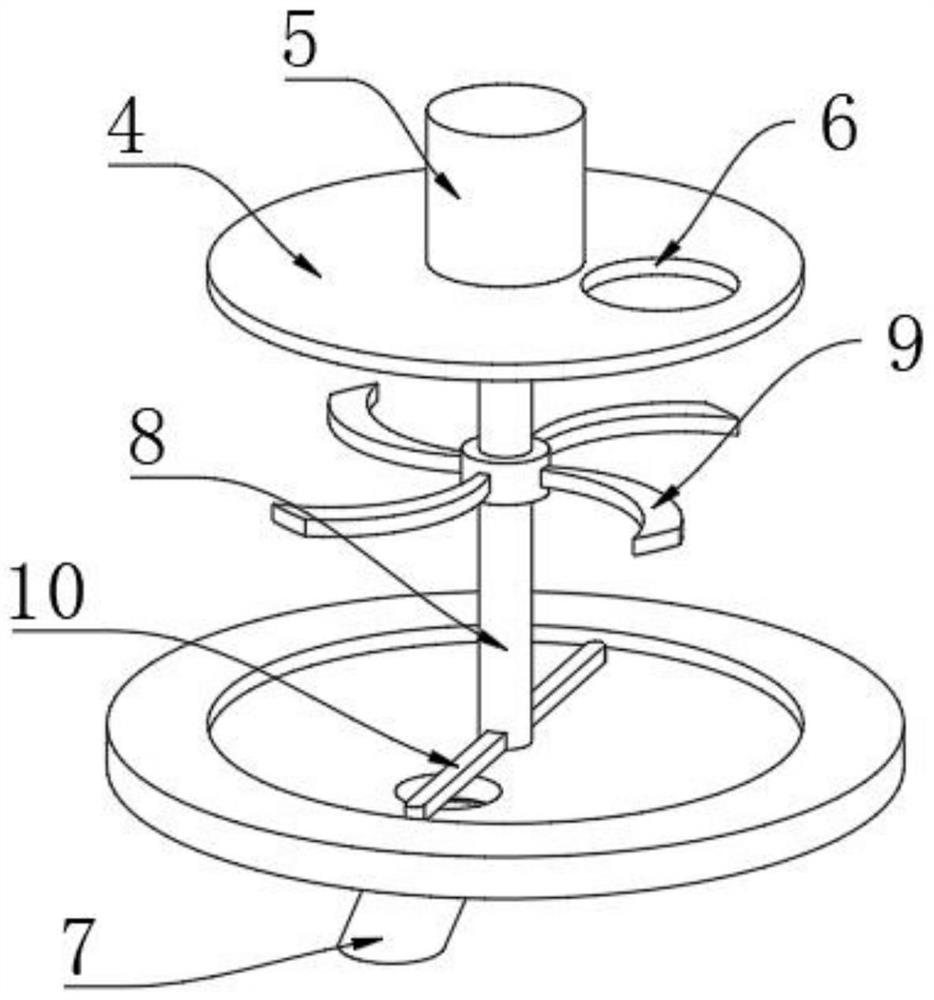

[0031] like Figure 1-Figure 3 As shown, a stem cell extraction system includes an installation base plate 1, the upper surface of the installation base plate 1 is fixedly connected with a support column 1 2, the top of the support column 1 2 is fixedly connected with an installation collar 1 3, and the inner wall of the installation collar 1 is fixed A pulverizing box 4 is connected, and a driving motor 5 is fixedly installed in the middle of the upper surface of the pulverizing box 4. The output end of the driving motor 5 extends to the interior of the pulverizing box 4 and is fixedly connected with a rotating shaft 8, and the bottom end of the rotating shaft 8 penetrates Gear one 11 is fixedly connected to the lower surface of the crushing box 4 and the bottom end of the rotating shaft 8, the bottom of the gear one 11 is fixedly connected to the upper surface of the mounting base plate 1 for rotation, and the outer wall of the rotating shaft 8 is fixedly connected to the int...

Embodiment 2

[0047] like Figure 10 As shown, on the basis of the first embodiment, the scraper 30 is replaced with a brush plate 36. The specific replacement scheme is: the inner wall of the digestion tank 17 is fixedly connected with the support plate 28 relative to the upper position of the cylinder 26, and the connecting rod 21 Running through the upper surface of the support plate 28, the outer wall of the connecting rod 21 is fixedly connected with four groups of evenly distributed stirring rods 29 relative to the upper position of the support plate 28. Closed brush plate 36.

[0048] Since the brush plate 36 is always in contact with the inner wall of the digestion tank 17, when the digestion tank 17 rotates, the brush plate 36 will scrape off the sticky solution on the inner wall of the digestion tank 17, which is beneficial to the subsequent cleaning work. The plate 36 will continuously scrape the position of the liquid outlet 18 with the liquid outlet 18 to prevent the liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com