Pill material loosening and dispersing device for shot blasting machine

A technology of dispersing device and shot blasting machine, which is applied in the direction of grain processing, etc., can solve the problems affecting the normal operation of shot blasting, labor and time-consuming, difficult to find plate agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

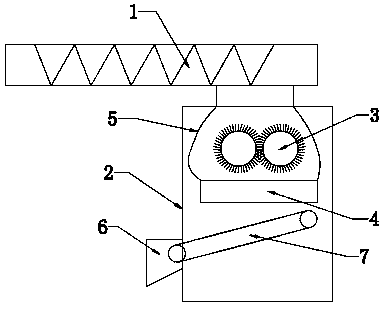

[0011] Below in conjunction with the accompanying drawings and specific embodiments, the shot blasting machine ball loose dispersion device of the present invention includes a crushing chamber 2 connected to the discharge port at the bottom of the screw conveyor 1, and a pair of crushing chambers located directly below the discharge port are arranged in the crushing chamber 2. The crushing roller 3 is provided with a vibrating screen 4 for receiving materials under the crushing roller 3, and a cloth bag 5 for preventing the shot from flying is connected between the vibrating screen 4 and the bottom outlet of the screw conveyor 2, and the vibrating screen 4 A belt conveyor 1 is arranged below, and the belt conveyor 1 can output the crushed pellets.

[0012] Further, one side of the crushing chamber 2 is provided with a shot outlet 6, the output of the belt conveyor 1 is located in the shot outlet 6, the opening of the shot outlet 6 faces downward, and the two sides of the belt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com