Automatic crushing system of super-hard material compound blocks

A crushing system and superhard material technology, applied in grain processing and other directions, can solve the problems of lack of superhard material composite block automatic crushing system, worker safety cannot be guaranteed, serious dust on production site, etc. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

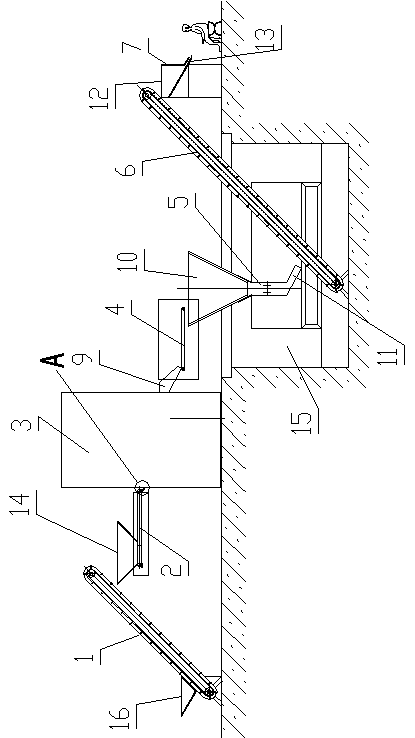

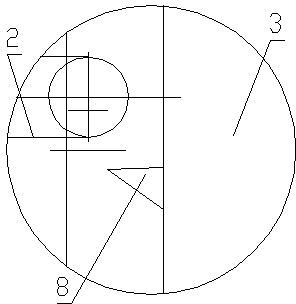

[0011] Such as figure 1 and figure 2 As shown, the hard material synthetic block automatic crushing system of the present invention includes a first conveyor belt 1, a quantitative conveyor belt 2, a crusher 3, a second conveyor belt 4, a crusher 5, a third conveyor belt 6 and a loading hopper 7 along the moving direction of the material.

[0012] The first conveyer belt 1 and the third conveyer belt 6 are all arranged obliquely, and the lower ends of both are both feeding ends, and the upper ends of both are both feeding ends.

[0013] The discharge end of the first conveyor belt 1 is located above the feed end of the quantitative conveyor belt 2 . The crusher 3 is provided with a crushing feeding port 8 and a crushing discharge pipe 9, the feeding end of the quantitative conveyor belt 2 is located above the crushing feeding port 8; the crushing and discharging pipe 9 is located above the feeding end of the second conveyor belt 4.

[0014] The top of the pulverizer 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com