Automatic medical material pulverizer

A technology of pulverizer and medicinal materials, which is applied in metal processing, grain processing and other directions, can solve the problems of low pulverization fineness, uneven material pulverization, low work efficiency, etc., and achieves obvious pulverization effect, simple and compact structure, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

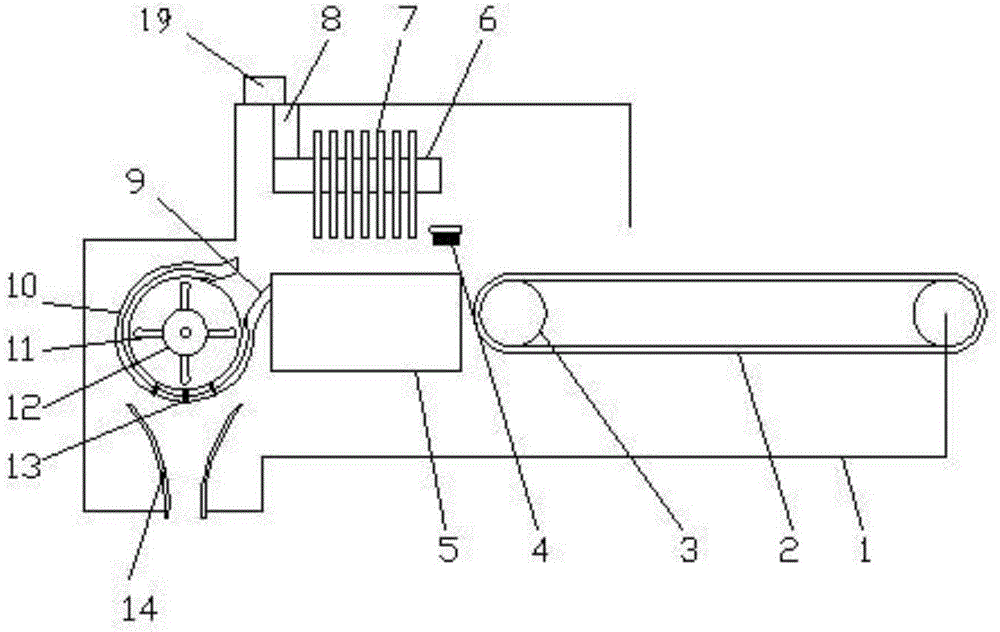

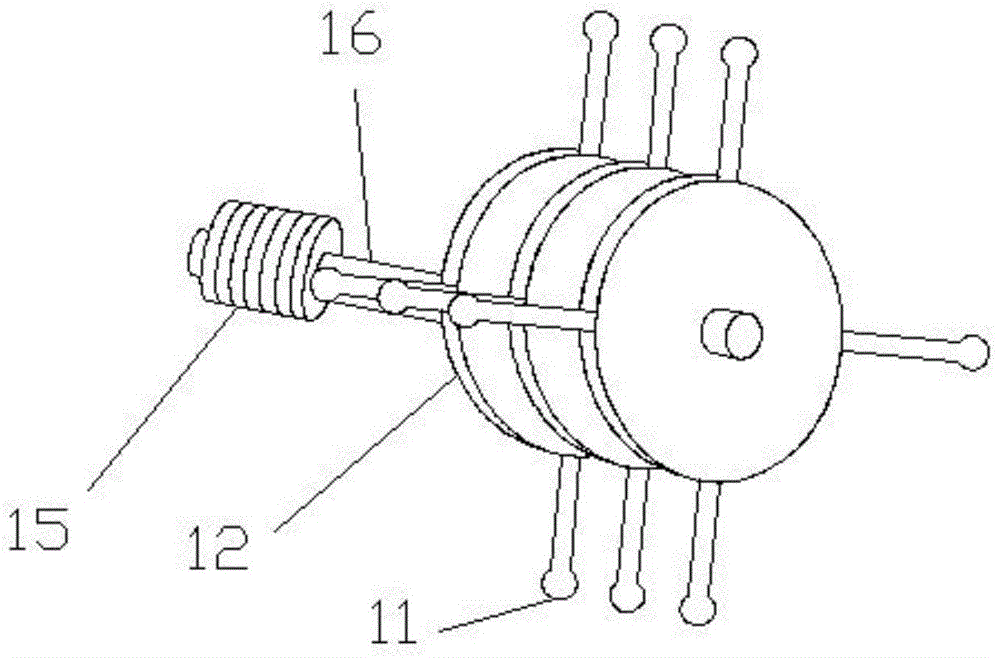

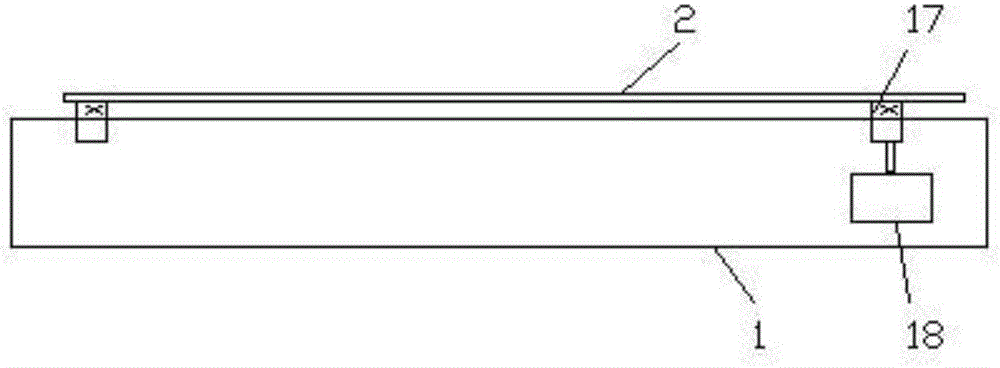

[0021] like figure 1 , figure 2 , image 3 An automatic medicinal material pulverizer is shown, which includes a casing 1, in which are installed a transport assembly for conveying medicinal materials, a slicing assembly for cutting medicinal tablets, a crushing assembly for hammering medicinal materials, and a device for placing medicinal materials. The platform 5 and the brush 4 arranged above the platform 5; the transmission assembly includes a first motor 18 fixedly installed on the inner side of the casing 1, the output shaft of the first motor 18 is connected with a fixed shaft 17, the A gear 3 is installed on the fixed shaft 17, and the gear 3 is covered with a transmission belt 2; the slicing assembly includes a vertical shaft 8 installed on the inside of the casing 1, and a flange 6 is horizontally installed on the vertical shaft 8. A plurality of knives 7 arranged side by side are vertically installed on the blue 6; the crushing assembly includes a circular screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com