Energy-saving and environment-friendly large gravel aggregate crusher for construction industry

An energy saving, environmental protection, construction industry technology, applied in grain processing and other directions, can solve the problems of difficult sand and gravel screening and collection, achieve automatic feeding and unloading, improve work efficiency, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

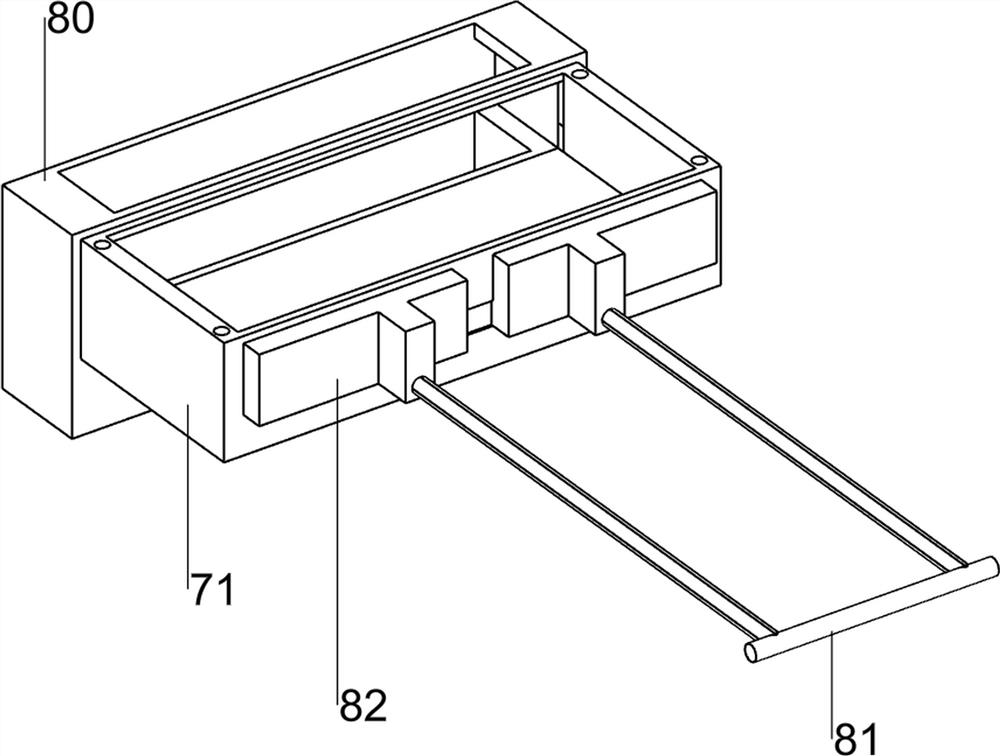

[0064] An energy-saving and environment-friendly large-scale sand and gravel aggregate crusher for construction industry, such as figure 1 As shown, it includes a base 1, a pillar 2, a crushing mechanism 3 and a protection mechanism 4. The pillars 2 are evenly arranged on the front and rear sides of the left part of the base 1, the crushing mechanism 3 is arranged in the middle of the left side of the base 1, and the protection mechanism is arranged on the base 1. 4.

[0065] When people need to crush the sand and gravel, first place the sand and gravel on the protective mechanism 4, then adjust the parts of the protective mechanism 4, and then control the downward movement of the components of the crushing mechanism 3, so that the sand and gravel are broken, and the process is completed. Finally, the components of the crushing mechanism 3 are controlled to move upwards and reset, and at the same time, the crushed gravel can be taken out.

Embodiment 2

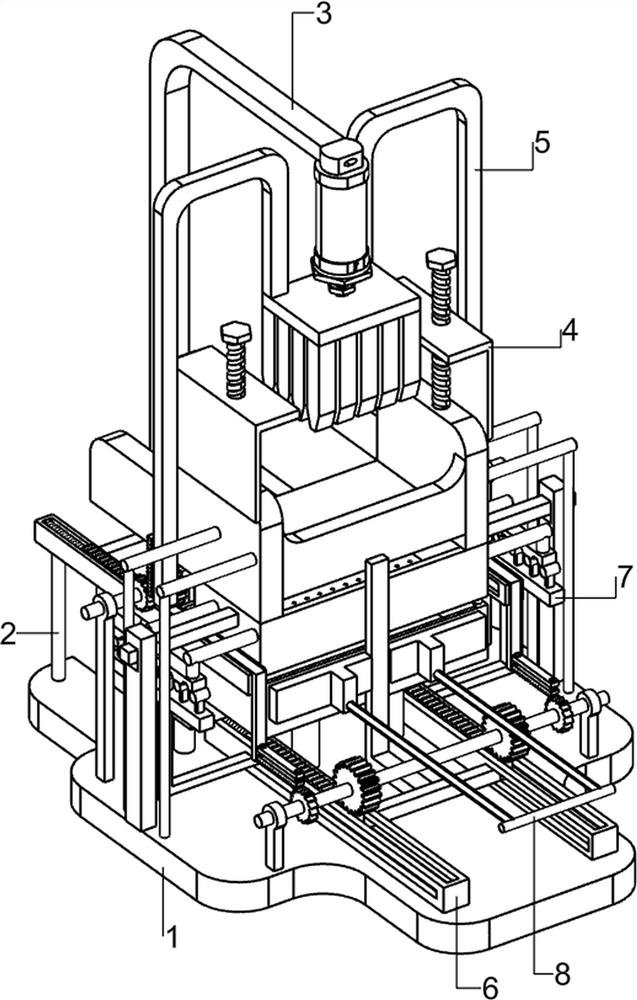

[0067] On the basis of Example 1, such as Figure 2-3 As shown, the crushing mechanism 3 includes an L-shaped rod 30, a cylinder 31, a descending plate 32 and a breaker 33, an L-shaped rod 30 is arranged in the middle of the left side of the base 1, a cylinder 31 is arranged on the L-shaped rod 30, and a cylinder 31 is arranged at the bottom of the cylinder 31. There is a descending plate 32, and the bottom of the descending plate 32 is provided with a breaker 33.

[0068]When people need to crush the gravel, control the extension of the cylinder 31 to drive the descending plate 32 and the crusher 33 to move downward to crush the gravel, and then control the shortening of the cylinder 31 to drive the descending plate 32 and the crusher 33 to move upward and reset , take out the gravel.

[0069] The protection mechanism 4 includes a fixed rod 40, a baffle plate 41, a protective plate 42 and a bolt 43. Two fixed rods 40 are arranged on both sides, front and rear, in the middle ...

Embodiment 3

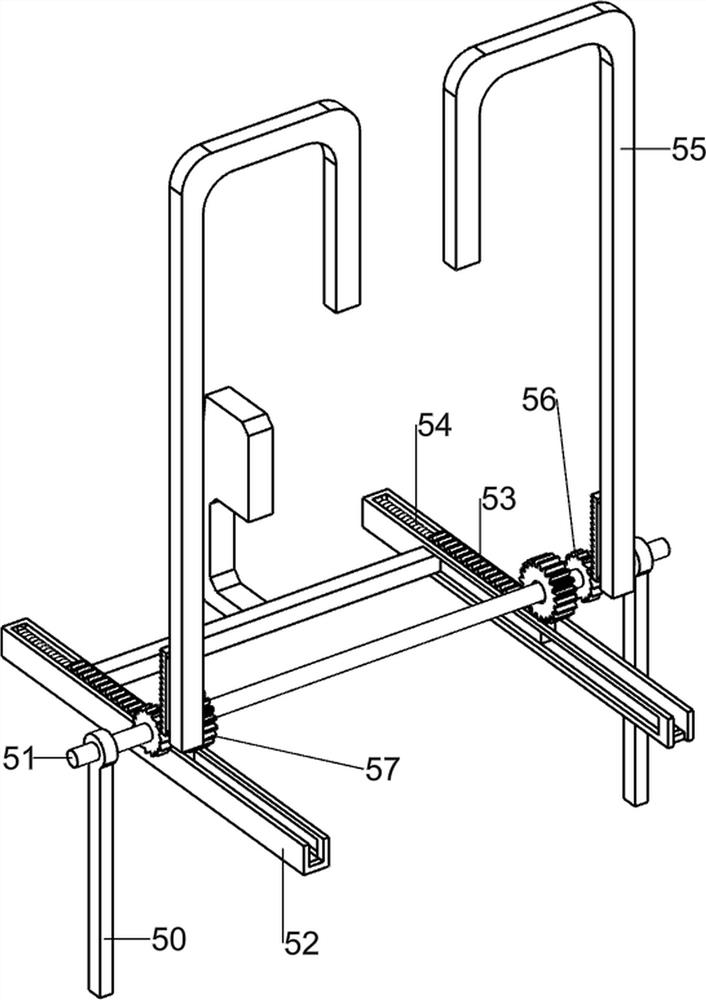

[0072] On the basis of Example 2, such as Figure 4-7 As shown, a feed mechanism 5 is also included, and the feed mechanism 5 includes a first bearing seat 50, a first rotating shaft 51, a first slide rail 52, a first rack 53, a first spring 54, and a first ratchet 55. 1. The first ratchet 56 and the first gear 57, the first bearing seat 50 is connected to the front and rear sides of the left part of the base 1, the first rotating shaft 51 is connected to the first bearing seat 50 in a rotational manner, and the top of the pillar 2 on the same lateral side The first slide rail 52 is arranged between them, and the first rack 53 is slidably connected in the first slide rail 52, and a push rod is connected between the left side of the first rack 53, and the left side of the first rack 53 is connected to the left side of the first rack 53. First springs 54 are arranged between the inner walls of the first slide rails 52 , first ratchets 55 are arranged on the front and rear sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com