Trinexapacethyl water dispersible granule preparation and preparation method thereof

A technology of trinexapac-ethyl and dispersible granules, applied in the fields of botanical equipment and methods, biocides, animal repellents, etc., can solve the problems of strict disintegration of products, easy heating during granulation, cumbersome processing, etc. The effect of easy measurement and packaging, good fluidity and convenient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

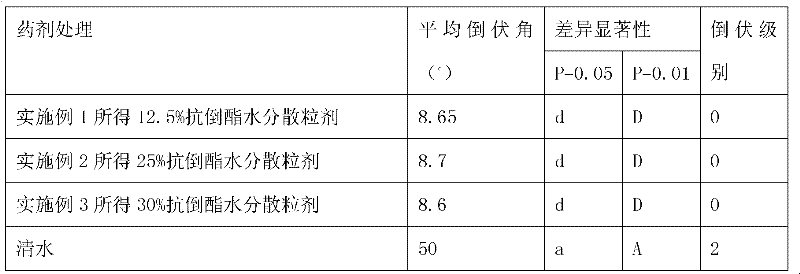

Examples

Embodiment 1

[0026] Put 120 kilograms of white carbon into the 1000L twin-screw conical mixer, add 31.25 kilograms of molten trinexapac-ethyl through the spray device under stirring, stir and absorb to make master powder, then add 10 kilograms of Morwet-EFW, Morwet D -42512.5 kg, 2.5 kg white sugar, 73.75 kg kaolin. After being evenly mixed, it is pulverized by a jet mill to an average particle size of less than 5 microns; then in a disc granulator, the above-mentioned pulverized material is used as the base material and water is used as a binder for disc granulation. Dried fluidized bed dryer to a moisture content of less than 2.0%, sieve 10 to 120 mesh particles through a shaking sieve, and obtain the product after passing the test.

Embodiment 2

[0028] Put 135 kilograms of white carbon black into the 1000L twin-screw conical mixer, add 62.5 kilograms of molten trinexapac-ethyl through the spray device under stirring, and mix and absorb all the ingredients into master powder, and then add them in sequence LZ / B 10 kg, Reax 88A 15 kg, urea 2.5 kg, diatomaceous earth 25 kg. After being evenly mixed, it is pulverized by a jet mill to an average particle size of less than 5 microns; then in a disc granulator, the above-mentioned pulverized material is used as the base material and water is used as a binder for disc granulation. Dried fluidized bed dryer to a moisture content of less than 2.0%, sieve 10 to 120 mesh particles through a shaking sieve, and obtain the product after passing the test.

Embodiment 3

[0030] Put 150 kilograms of white carbon black into a 1000L twin-screw conical mixer, add 70 kilograms of molten trinexapac-ethyl through a spray device under stirring, and then mix and absorb all of them into master powder, and then add 10 kilograms of tea saponin, PVP K-30 15 kg, sodium chloride 2.5 kg, activated clay 2.5 kg. After being evenly mixed, it is pulverized by a jet mill to an average particle size of less than 5 microns; then in a disc granulator, the above-mentioned pulverized material is used as the base material and water is used as a binder for disc granulation. Dried fluidized bed dryer to a moisture content of less than 2.0%, sieve 10 to 120 mesh particles through a shaking sieve, and obtain the product after passing the test.

[0031] The adsorption equipment used in the above embodiment is a twin-screw conical mixer with a heating jacket and a spray device. The disc granulator used is equipped with a spray device with adjustable flow rate and atomization de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com