Sagger Crusher

A crusher and saggar technology is applied in the field of equipment for crushing solid materials in saggers, which can solve the problem that solid materials cannot be poured into a hopper, and achieve the effect of automatic crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

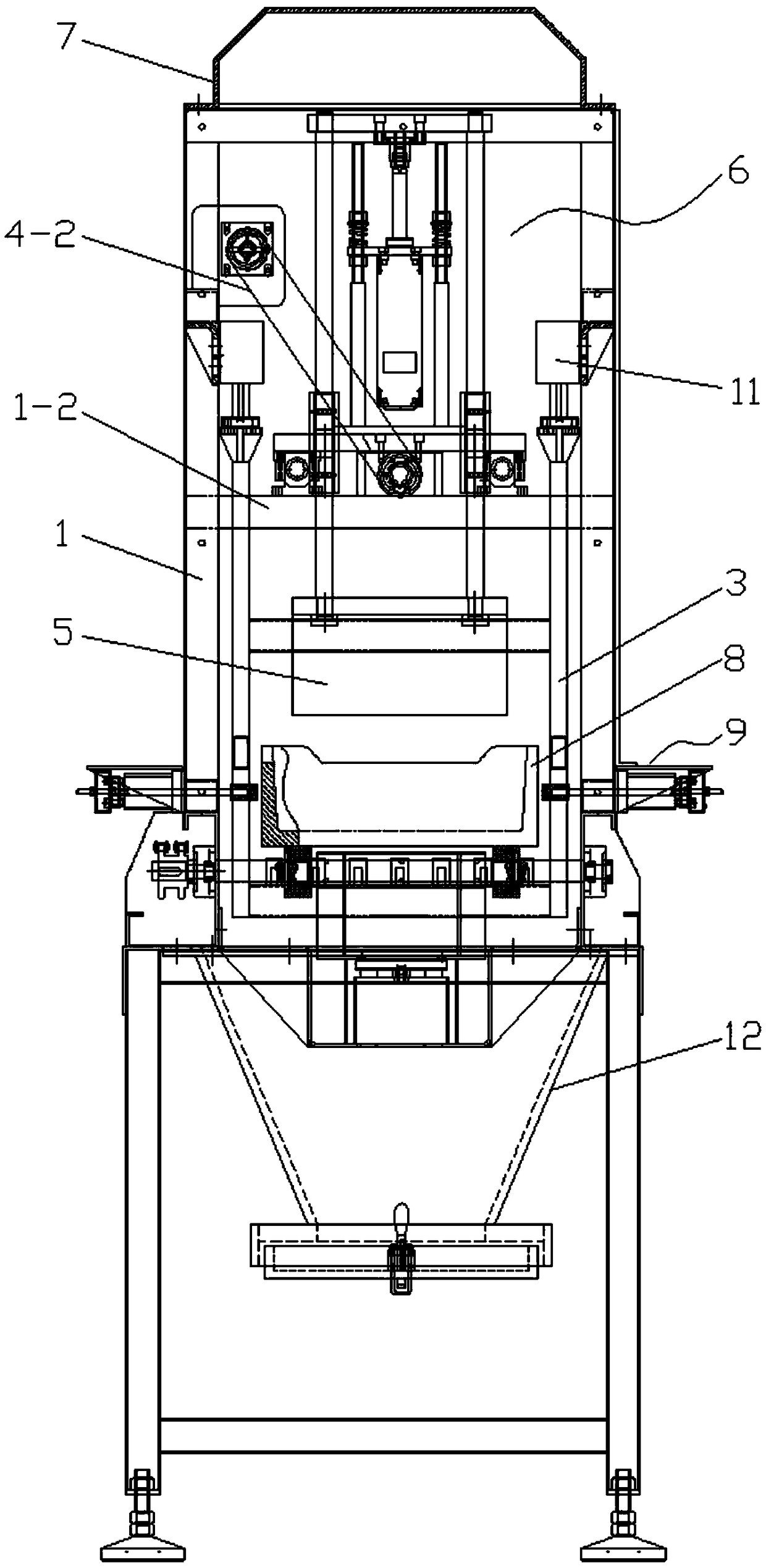

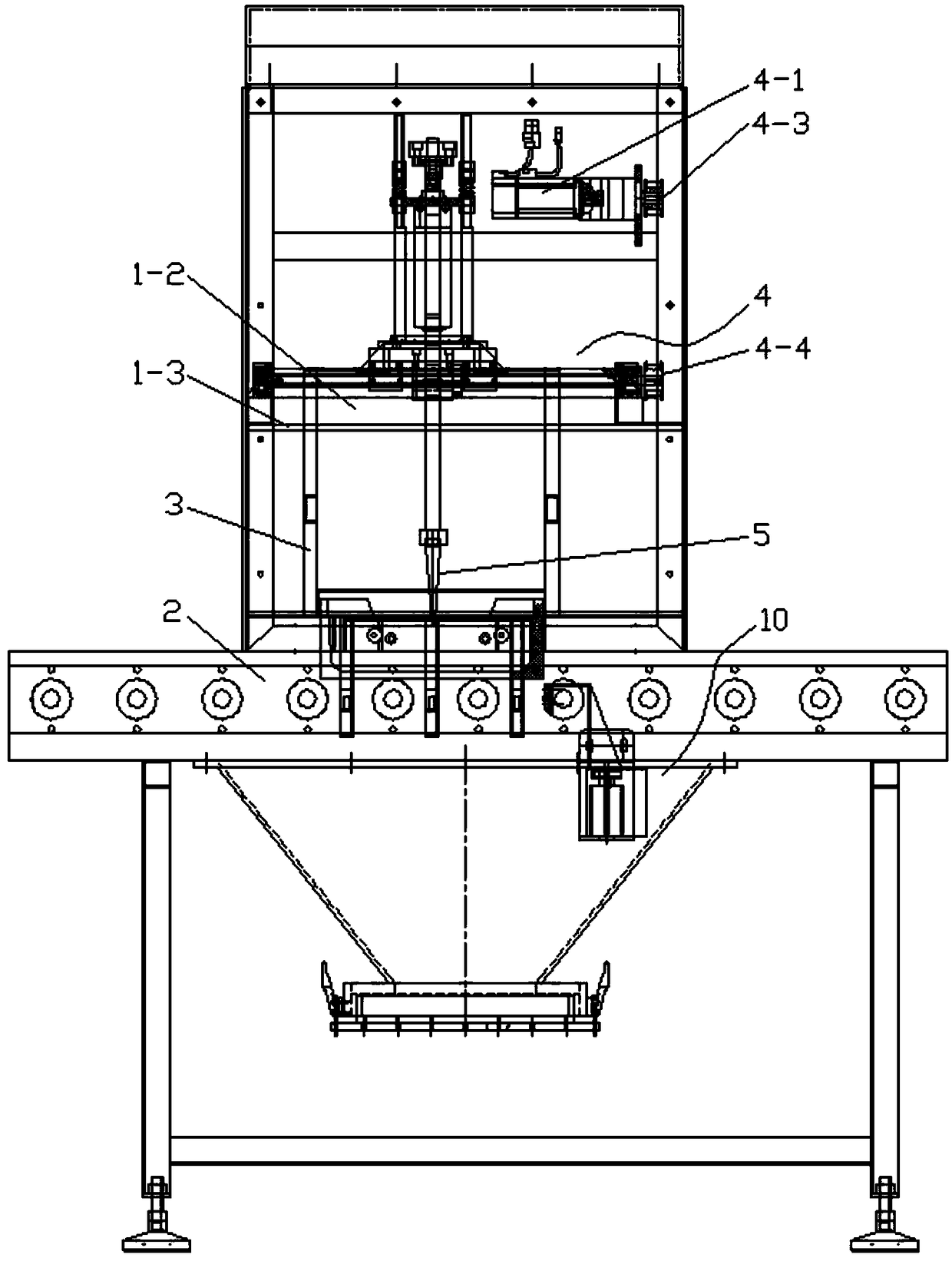

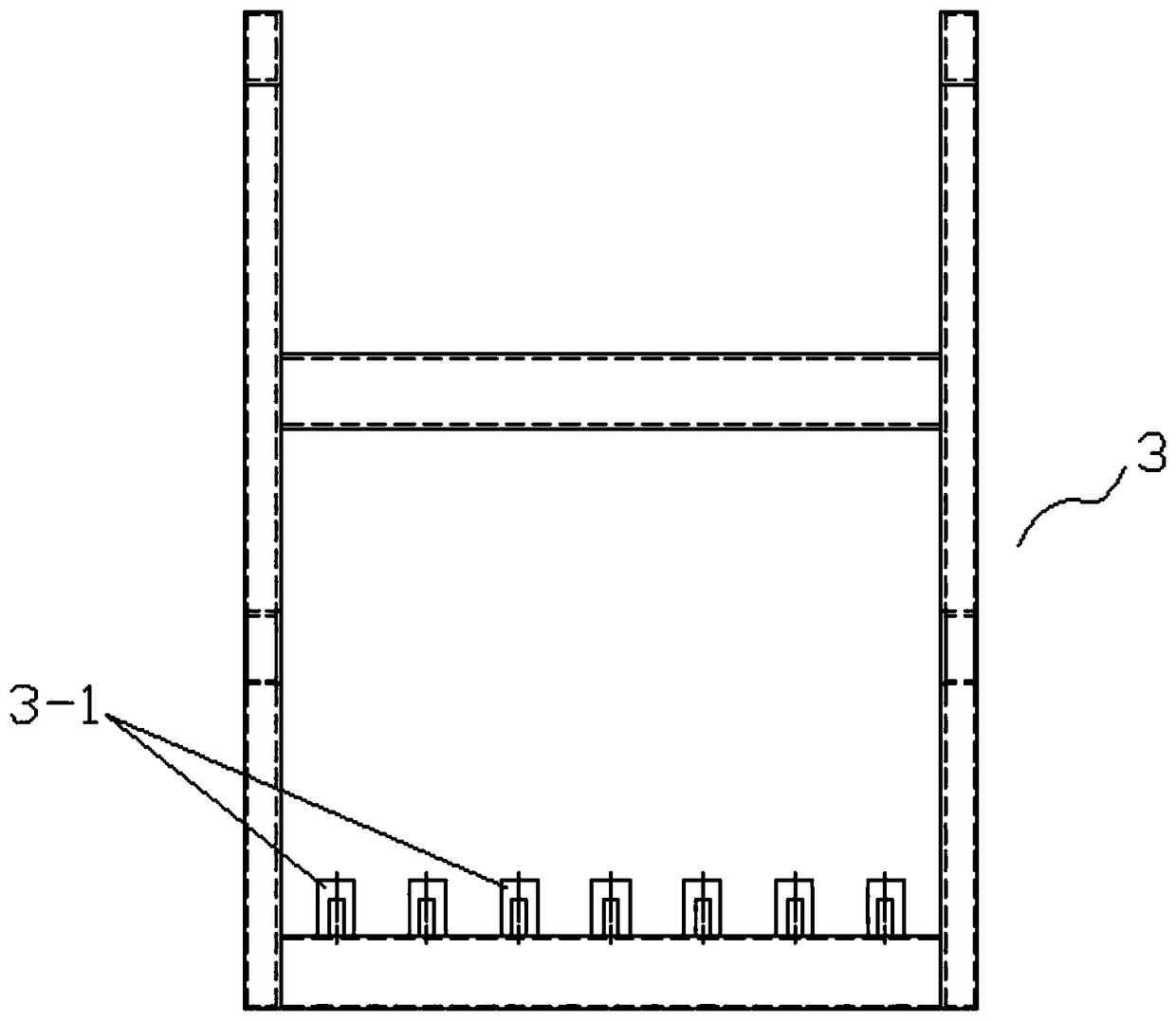

[0036] The invention discloses a sagger material crusher, such as Figure 1-6 As shown, it includes a bracket 1, a roller conveyor line 2, a lifting frame 3, a lifting frame driving device, a translation device 4, a crushing knife 5, a crushing knife lifting device 6 and a closed top cover 7, and the roller conveyor line is along the left and right The direction is installed in the middle of the height direction of the support for transporting the sagger 8 to and from the crushing station. The sagger travels in a left-right direction on the roller conveyor line. The lifting frame driving device is installed on the support and is located above the roller conveyor line, the lifting frame is installed on the lower part of the lifting frame driving device, driven by the lifting frame driving device, it can Moving up and down. The lifting frame is provided with a sagger supporting surface, and when the lifting frame is at the lowest point of the stroke, the sagger supporting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com