Longitudinal and transverse two-way crusher

A technology of crusher and crushing mechanism, which is applied in the direction of grain processing, etc., and can solve the problems of low metal hardness, manpower consumption, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The accompanying drawings in this application are only schematic diagrams for explaining the principles and structures, and some structures, such as reducers, are omitted without affecting the understanding of those skilled in the art. Therefore, the accompanying drawings cannot be used as a criterion for judging this application.

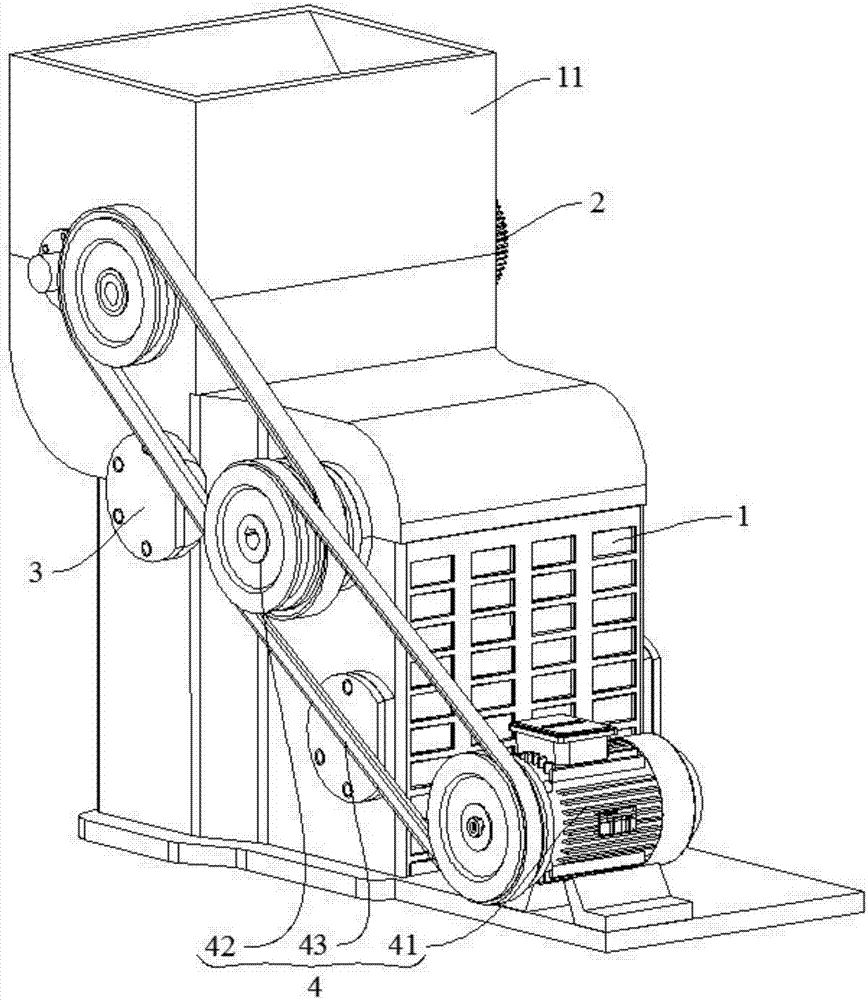

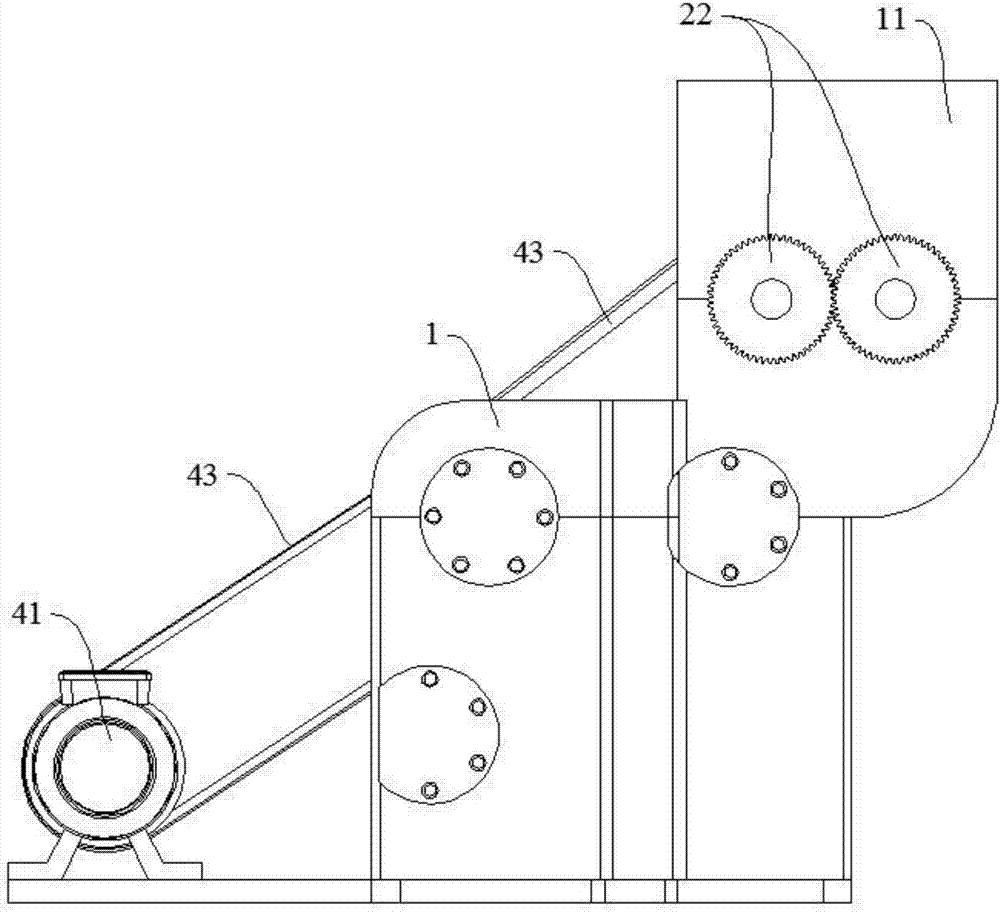

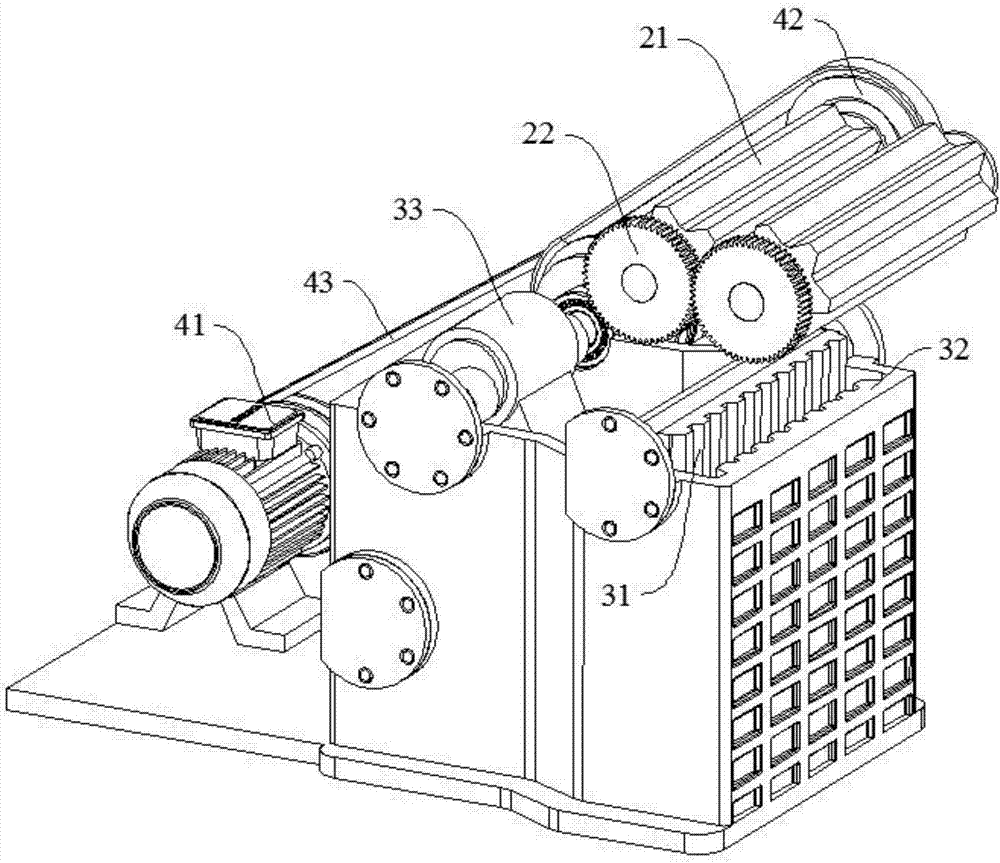

[0021] as attached Figure 1~5 As shown, a vertical and horizontal two-way crusher includes: a fuselage 1, a transverse crushing mechanism 2, a longitudinal crushing mechanism 3, and a power system 4; wherein, the top of the fuselage 1 is provided with a feed hopper 11, and the transverse crushing mechanism 2 is arranged at the inlet In the fuselage 1 below the hopper 11, the transverse crushing mechanism 2 includes a pair of crushing rollers 21. The cross section of the crushing rollers 21 is quincunx-shaped. Continuously narrowing, the lower opening of the feed hopper faces the middle of the pair of crushing rollers 21; the body 1 below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com