Equipment and process for crushing and automatically metering and conveying industrial solid wastes and biomass fuel

A biomass fuel, industrial solid waste technology, applied in grain processing, swirling devices, etc., to achieve efficient disposal, no secondary pollution, and clean air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

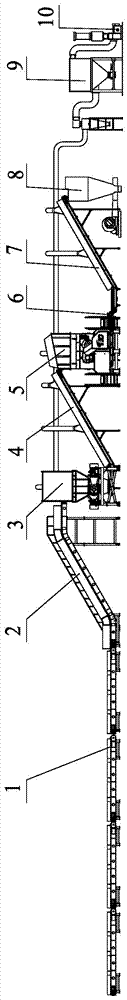

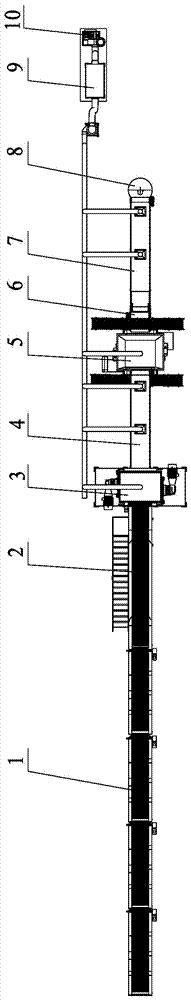

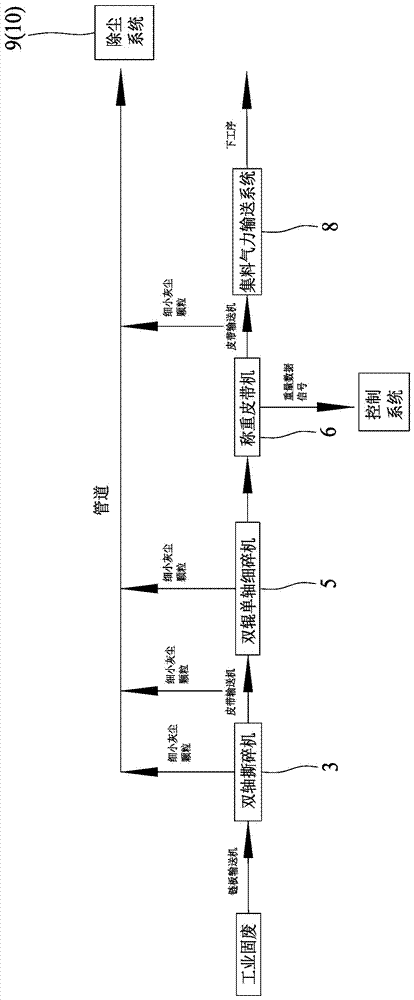

[0025] like figure 1 , figure 2 As shown, the present invention is an automatic metering and conveying equipment for industrial solid waste and biomass fuel crushing, including a chain conveyor 1, a climbing chain conveyor 2, a double-shaft shredder 3, a first belt conveyor 4, Double-roller single-shaft fine crusher 5, weighing belt conveyor 6, second belt conveyor 7, aggregate pneumatic conveying system 8, cyclone collector 9, dust collector 10.

[0026] The chain plate conveyor 1, the climbing chain plate conveyor 2, the double shaft shredder 3, the belt conveyor 4, the double roller single shaft fine shredder 5, the weighing belt machine 6, the belt conveyor 7, the aggregate The pneumatic conveying system 8 is connected sequentially; the upper part of the double-shaft shredder 3, the upper part of the first belt conveyor 4, the upper part of the double-roller single-shaft fine shredder 5, and the upper part of the second belt conveyor 7 are all provided with a dust cover....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com