Municipal solid waste crushing, extruding and recycling equipment

A technology for solid waste and recycling equipment, which can be used in solid waste removal, presses, grain processing, etc., and can solve problems such as troublesome, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

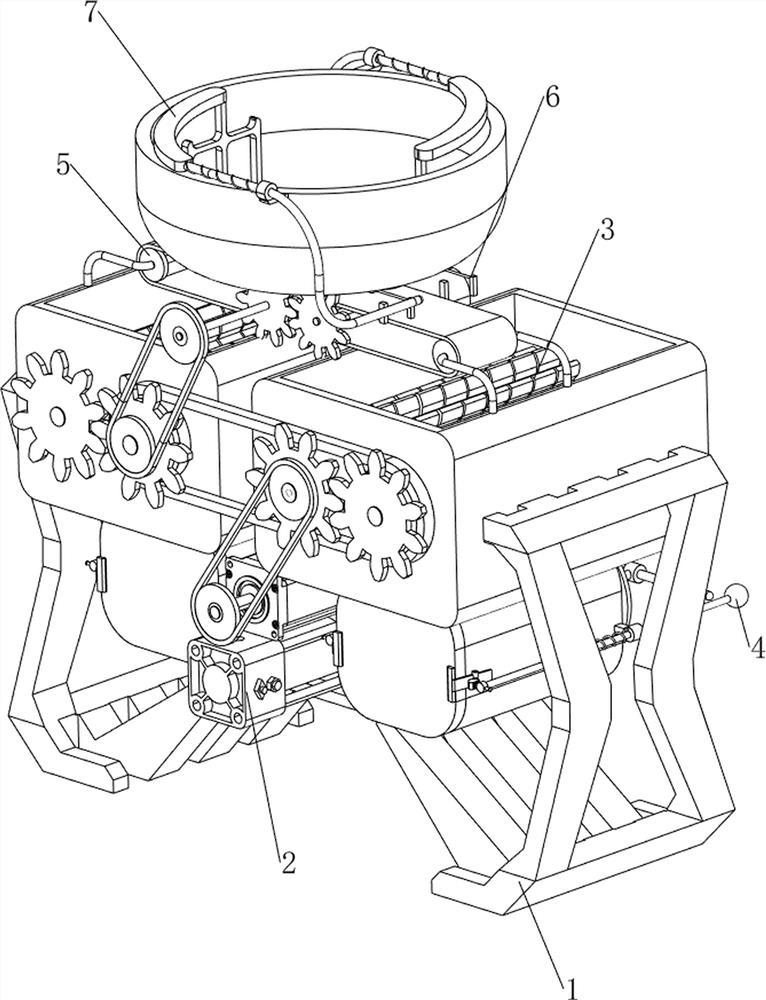

[0066] A municipal solid waste crushing extrusion recovery equipment, such as Figure 1-4 As shown, it includes a support frame 1 , a compression mechanism 2 and a crushing mechanism 3 , the support frame 1 is provided with a compression mechanism 2 , and a crushing mechanism 3 is connected between the support frame 1 and the compression mechanism 2 .

[0067] The compression mechanism 2 includes a cylinder 21, a forming barrel 22, a briquetting block 23 and a first connecting rod 24. A cylinder 21 is arranged in the middle of the support frame 1, and a forming barrel 22 is arranged on the left and right sides of the support frame 1, and the forming barrel 22 slides There are briquetting blocks 23 connected in the same way, and first connecting rods 24 are connected between the briquetting blocks 23 and between the cylinders 21 .

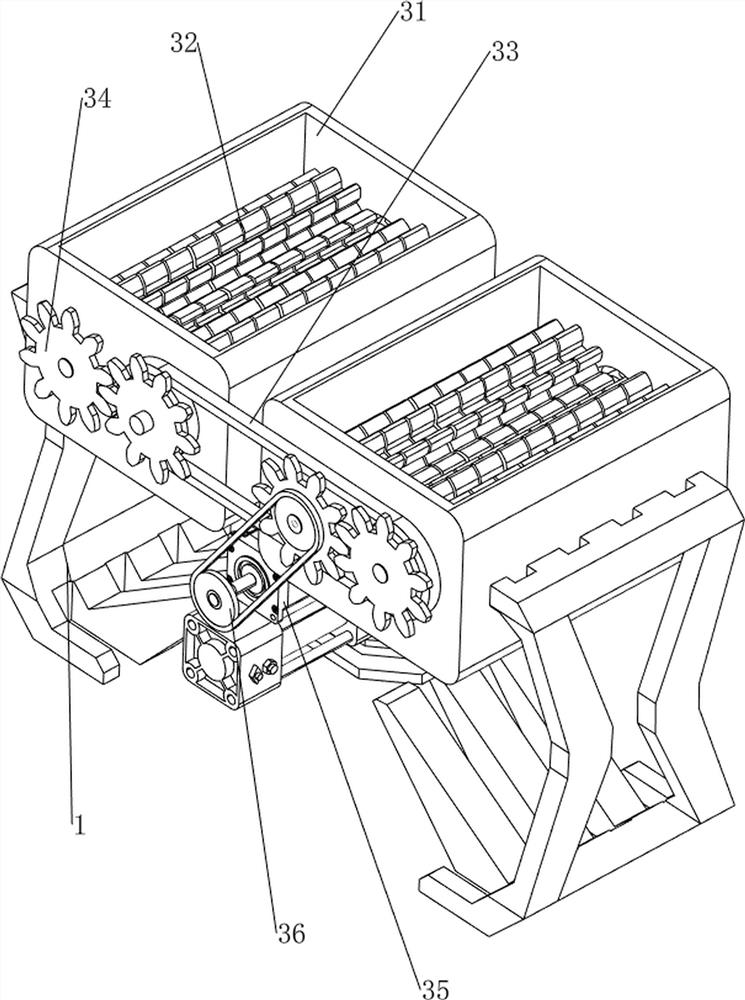

[0068]The crushing mechanism 3 includes a crushing frame 31, a crushing roller 32, a first transmission belt 33, a first straight gear set 34, a se...

Embodiment 2

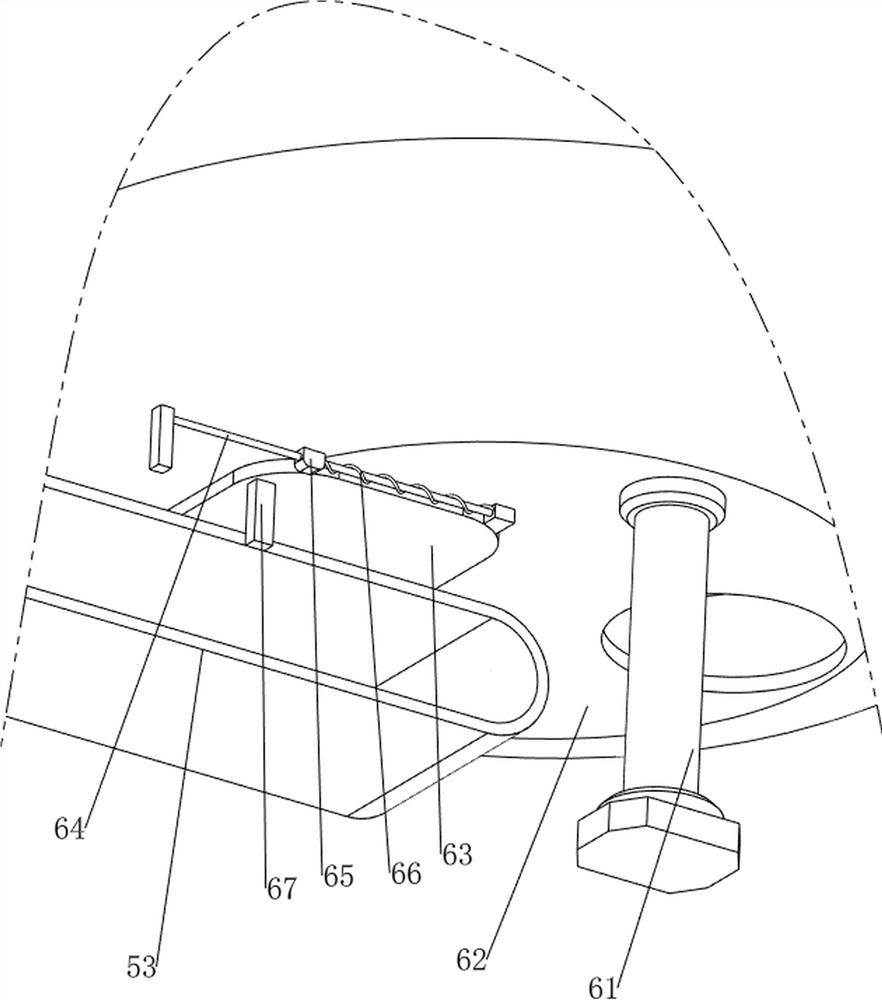

[0071] On the basis of Example 1, such as Figure 5-9 As shown, it also includes a blanking mechanism 4, and the blanking mechanism 4 includes a first block 41, a first spring 42, a first fixed sleeve 43, a first pull rod 44, a second spring 45, a squeeze block 46, a third Spring 47, rotating plate 48, the second fixed cover 49 and the 4th spring 410, the rear side of forming bucket 22 is connected with the first stopper 41 in a rotating manner, and the left and right sides of the first stopper 41 and the forming bucket 22 are all provided with There is a first spring 42, and the left and right sides of the front part of the forming barrel 22 are connected with a first fixed sleeve 43, and the first fixed sleeve 43 is slidably connected with a first pull rod 44, and the rear side of the first pull rod 44 is connected with the first pull rod 44 on the same side. A second spring 45 is provided between the fixed sleeves 43, and a squeeze block 46 is slidably connected to the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com