Patents

Literature

135results about How to "Control the feeding amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

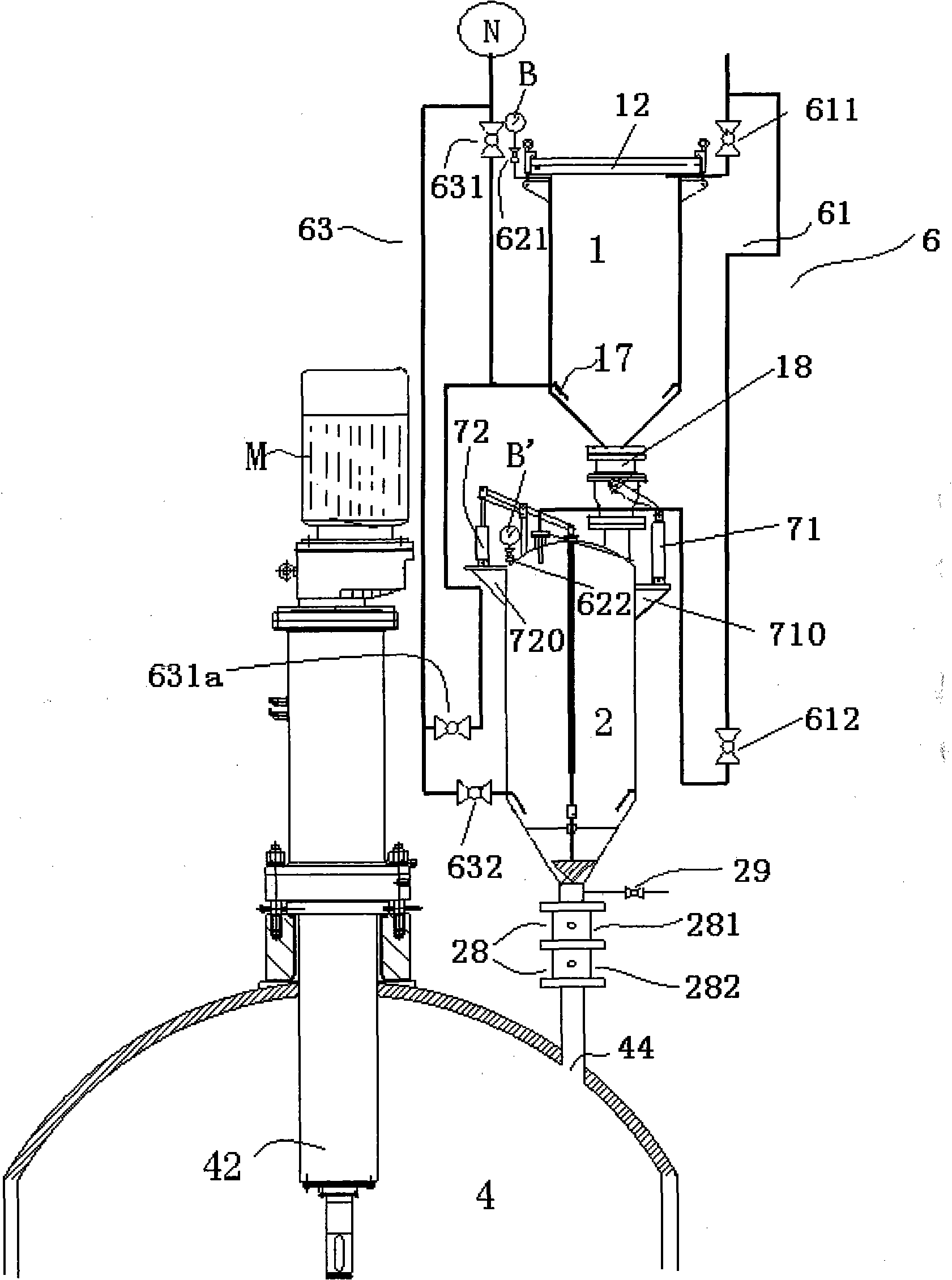

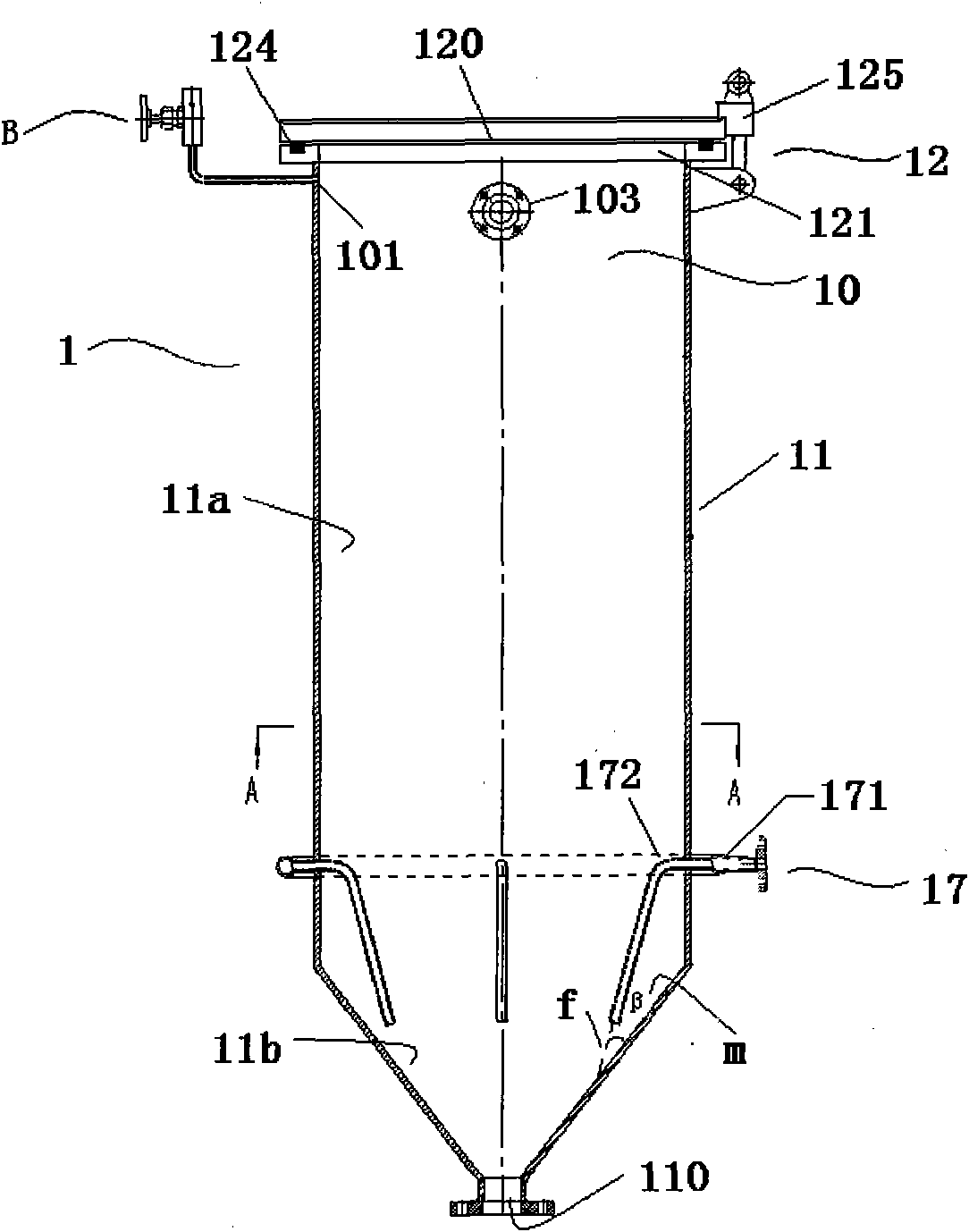

Deprivation technique based on semi-dry process

InactiveCN101385943AControl the feeding amountGuaranteed emission concentrationDispersed particle separationAir quality improvementMulti pollutantSmall footprint

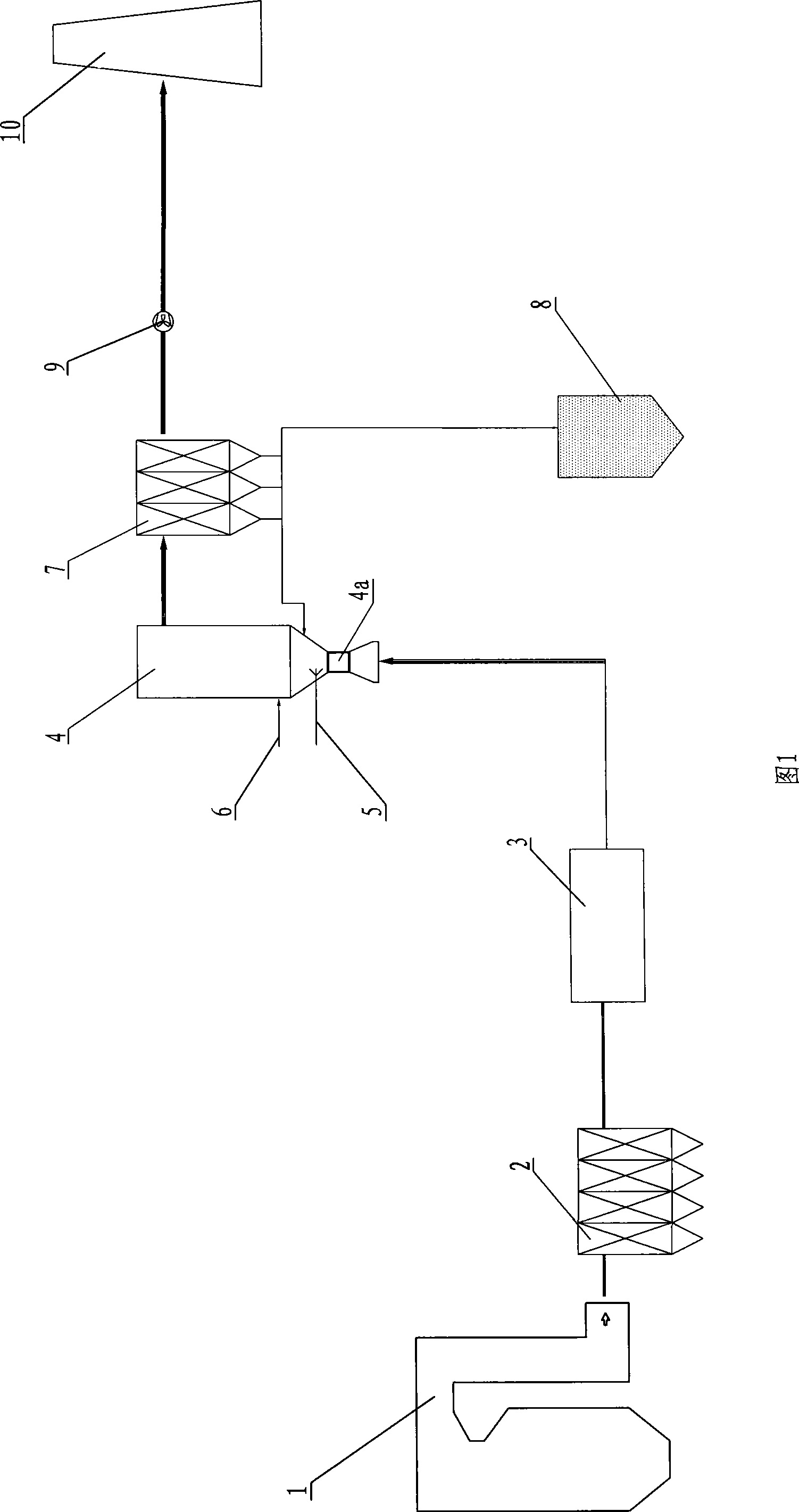

The invention discloses a simultaneously-removing technology based on a semidry method, which has the following steps: (1) pretreatment for removing dust; (2) oxidation reaction between hydrogen peroxide and smoke gas: NO+H2O2=NO2+H2O, and 2NO+O2=2NO2, SO2+H2O2=SO3+H2O; (3) reaction in an absorption tower: Ca(OH)2+SO2=CaSO3.1 / 2H2O+1 / 2H2O, CaSO3.1 / 2H2O+1 / 2O2=CaSO4.1 / 2H2O; Ca(OH)2+H2O+NO2=Ca(NO3)2+2H2O, Ca(OH)2+2HCl=CaCl2+2H2O, and Ca(OH)2+2HF=CaF2+2H2O; (4) after the reaction, the smoke gas is discharged after dust removal. The technology has integrated design, and various pollutants, such as SO2, NOx, can be simultaneously removed in one reaction tower; the invention has the advantages of simple technology, simplified system, small area occupation and low investment and running cost; the system adopts a semidry technique, the water consumption is low, and the technology is particularly suitable for water-deficient areas; the market supply of quick lime or white lime used as system removing agents is abundant, and the removing agents are convenient to buy in local; byproducts belong to available resources; and the removing system can almost completely remove sulfur trioxide in smoke gas. Therefore, the whole device does not need corrosion prevention.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke

The invention relates to a calcining method for preparing aluminum-electrolytic pre-baked carbon anode petroleum coke, which is characterized in that calcination temperature is controlled at 1300-1350 DEG C; the fluctuation range of temperature is not larger than 30 DEG C; discharging amount is controlled by the volatile matter content in the petroleum coke, and the volatile matter is controlled in 10-15%; the secondary ventilation quantity of a rotary kiln is 2000-2600 m3 / h, and the third ventilation quantity is 1600-2200m3 / h; and negative pressure is controlled in 20- 40Pa. the invention causes a calcining process to obtain system optimization, the coke performance after calcination is greatly improved, the oxidation resistance and the electrical conductivity after calcination are significantly increased, and the true density is more than 2.05g / cm3. The produced anode quality is more uniform and stable, the ratio of first-grade products is significantly increased, and the electrolytic carbon consumption is greatly reduced.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

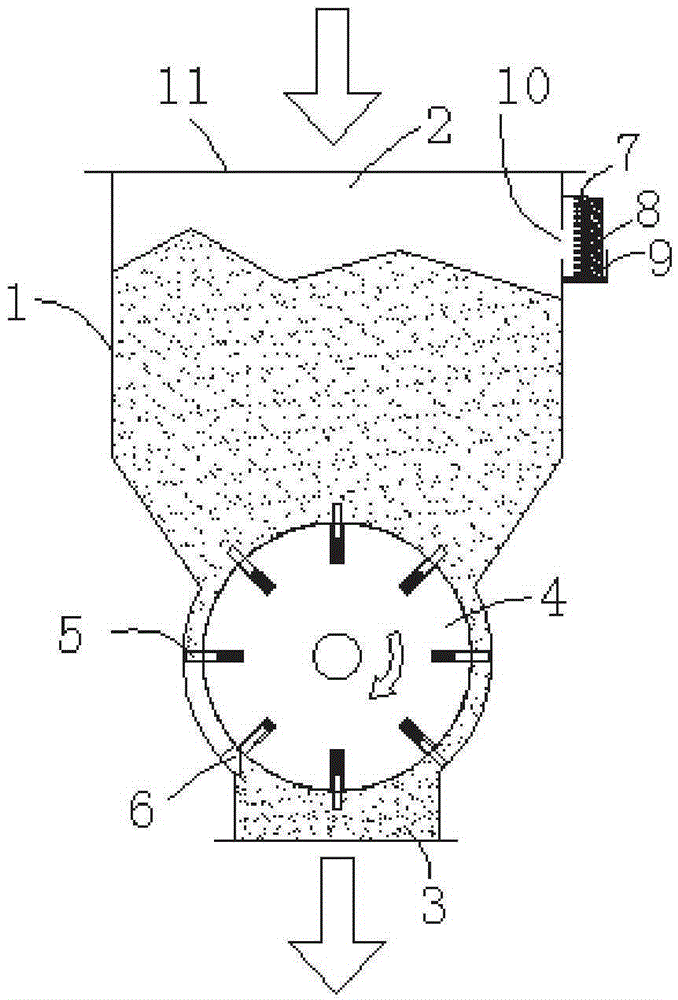

Continuous feeding device for aluminum electrolysis cell and electrolysis cell with same

The invention belongs to the technical field of aluminum electrolysis cells, and particularly relates to a continuous feeding device for an aluminum electrolysis cell and an electrolysis cell with the same. The continuous feeding device for the aluminum electrolysis cell is capable of improving the stability of the electrolysis cell, lowering energy consumption, reducing sediment and pressure drop at the furnace bottom and prolonging the service life of the cell. According to the technical scheme, the continuous feeding device for the aluminum electrolysis cell comprises a sleeve, a funnel and an upper delivery pipe, wherein the open end of the funnel is fixedly connected with the bottom of the sleeve; and the outlet end of the funnel is fixedly connected with one end of the upper delivery pipe. Since the funnel is arranged at the bottom of the sleeve, so that the flow velocity of fed materials can be reduced, continuous feeding is realized, and the problem caused when alumina powder which is not completely dissolved sinks into the aluminum liquid is avoided.

Owner:HUNAN CHUANGYUAN ALUMINUM IND

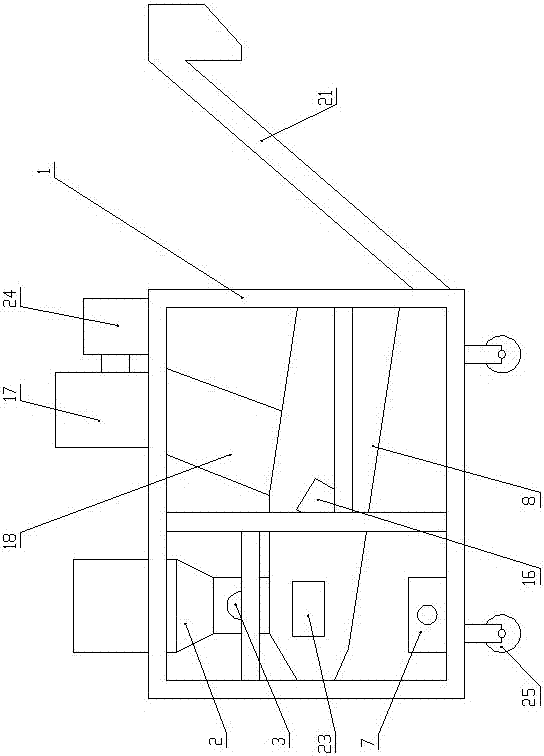

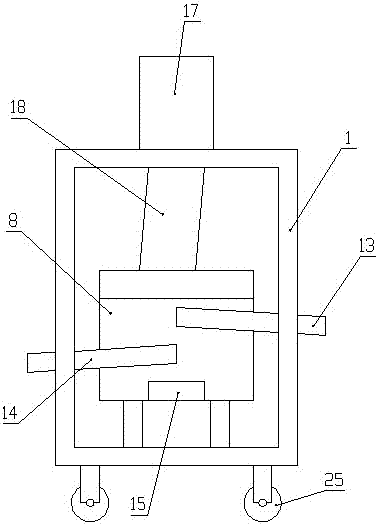

Feeding machine

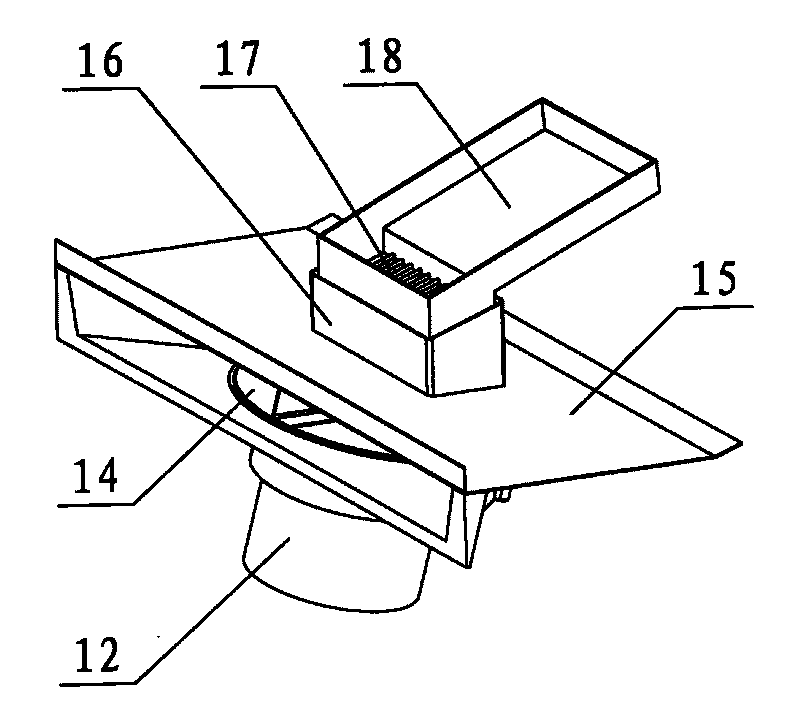

ActiveCN101755701AWill not cause automatic slipControl the feeding amountPisciculture and aquariaBall bearingReciprocating motion

The invention provides a feeding machine, which mainly consists of a machine box, a controller, a baiting mechanism which carries out throwing movement, a material throwing motor, a material throwing disc, a box cover, a box bottom plate and the like, wherein a lower shaft is arranged at the baiting opening end of a material passing groove, the lower shaft is connected with an upper shaft through a connecting rod, the upper shaft is fixed under a material hopper, a bearing seat is arranged under the material passing groove, a roller bearing is arranged in the bearing seat and is connected with a motor shaft through an eccentric sleeve, and the motor shaft is supported on the middle of the material passing groove. The throwing movement refers to the movement that when the baiting motor rotates in the positive direction, the eccentric sleeve drives the roller bearing to revolute around the motor shaft, at the same time, the autorotation of the roller bearing drives the material passing groove to do the circumferential reciprocating movement, and an upper shaft and a lower shaft of the non-baiting end are hinged with the connecting rod for swinging, so the feedstuff is gradually thrown towards the baiting opening in the material passing groove to enter a material collector and to fall on the material throwing disc.

Owner:ZHEJIANG FORDY MACHINERY

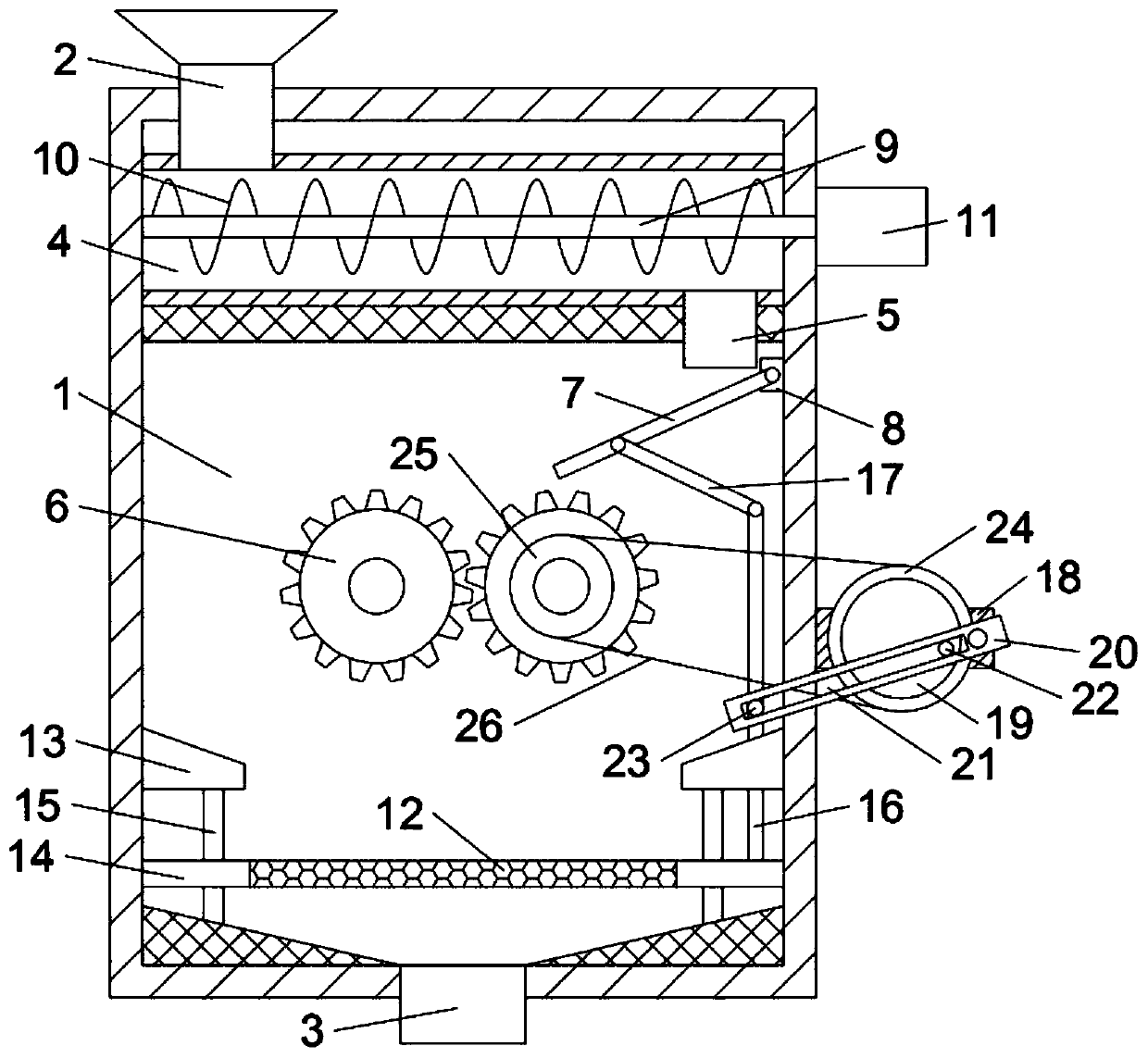

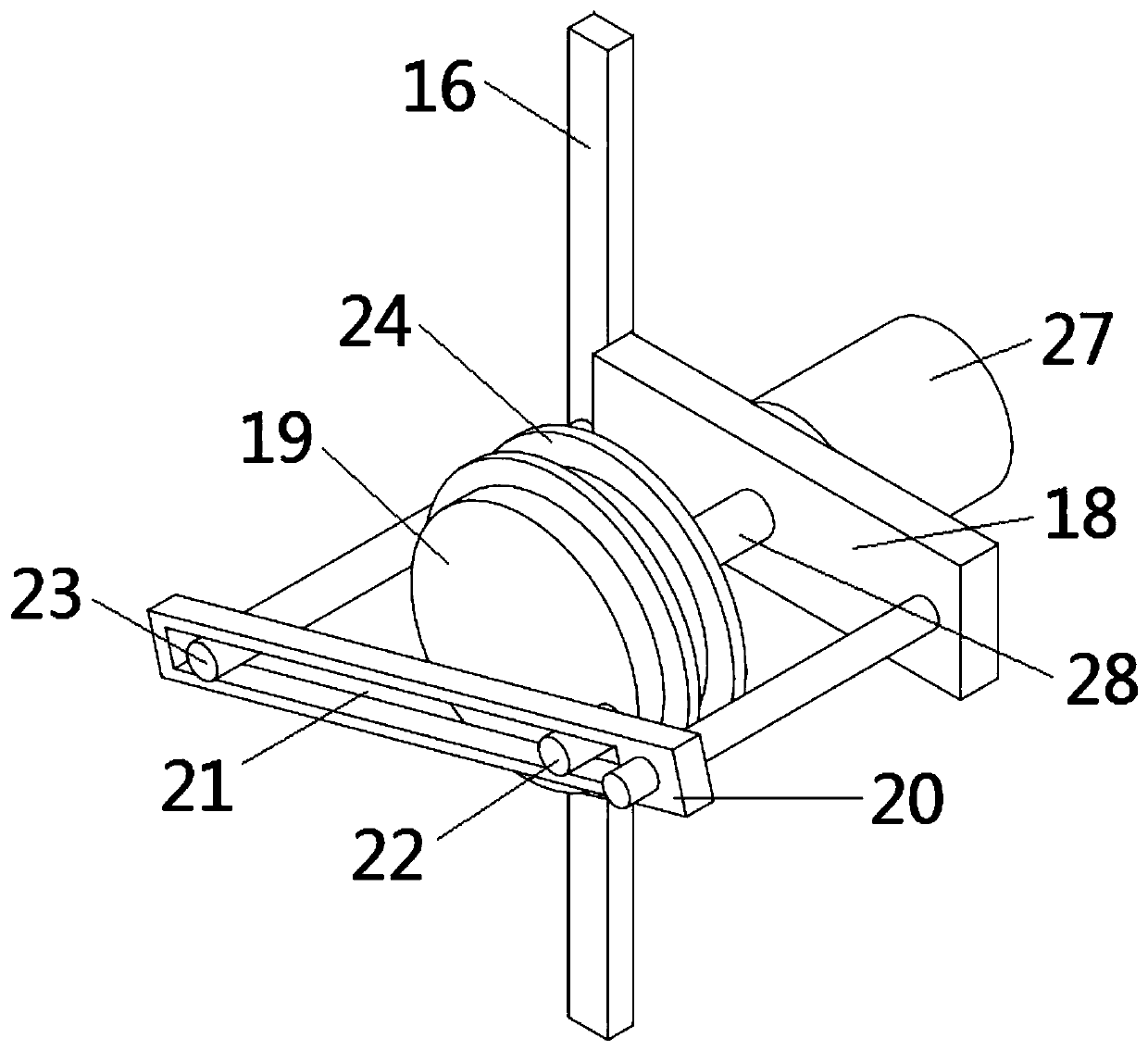

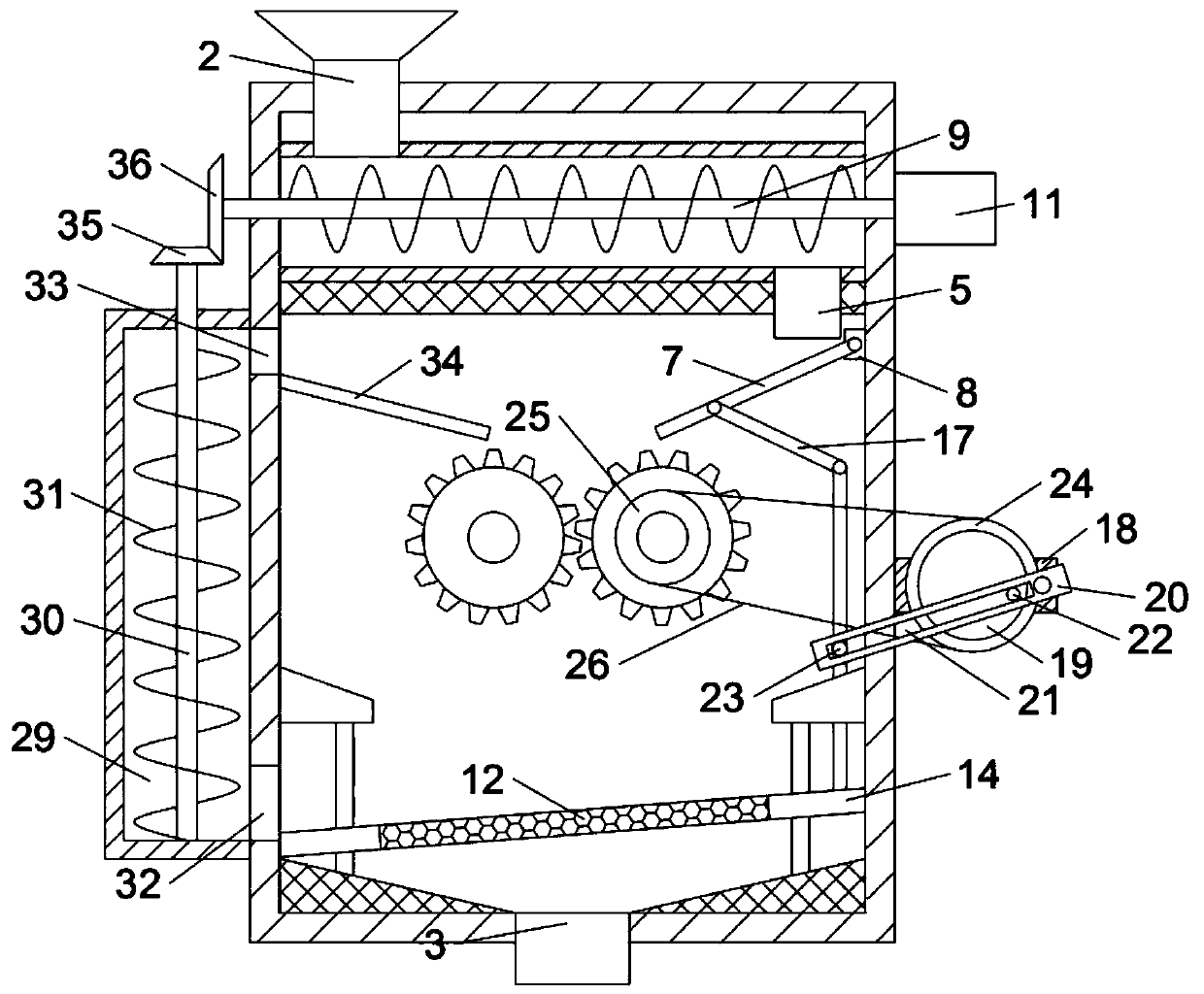

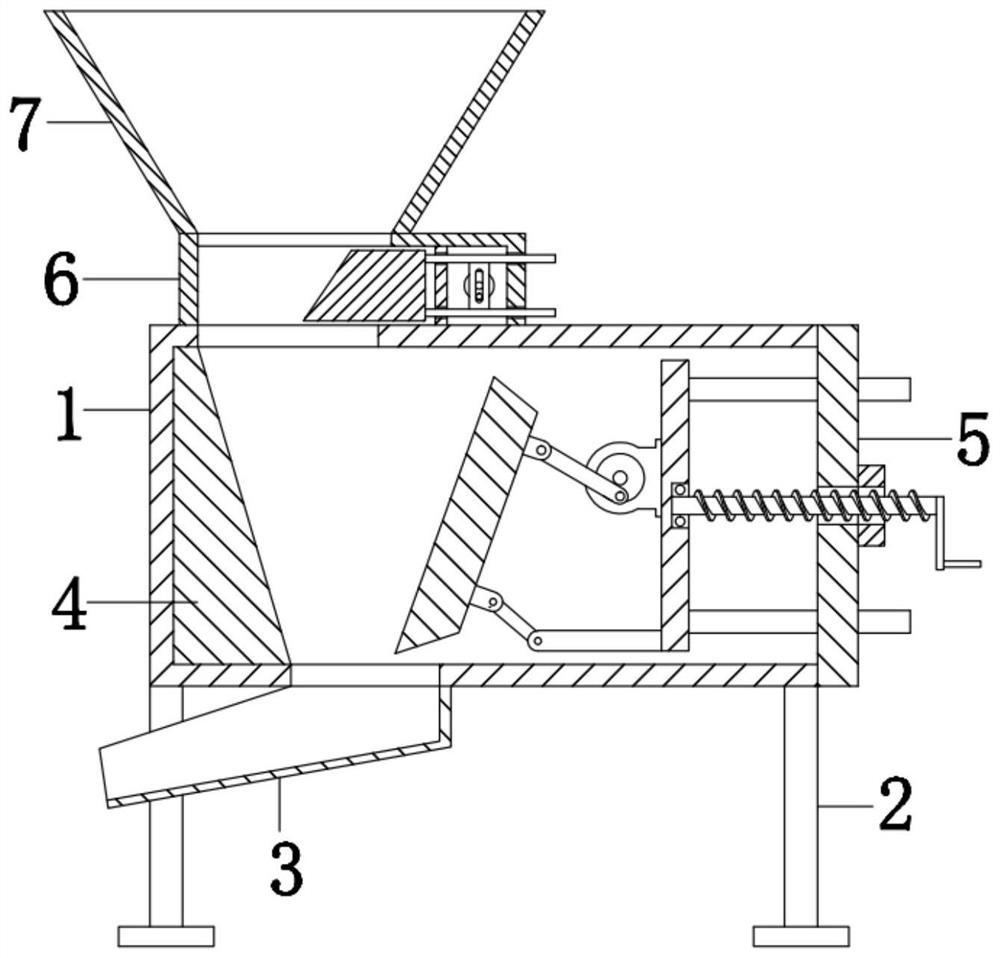

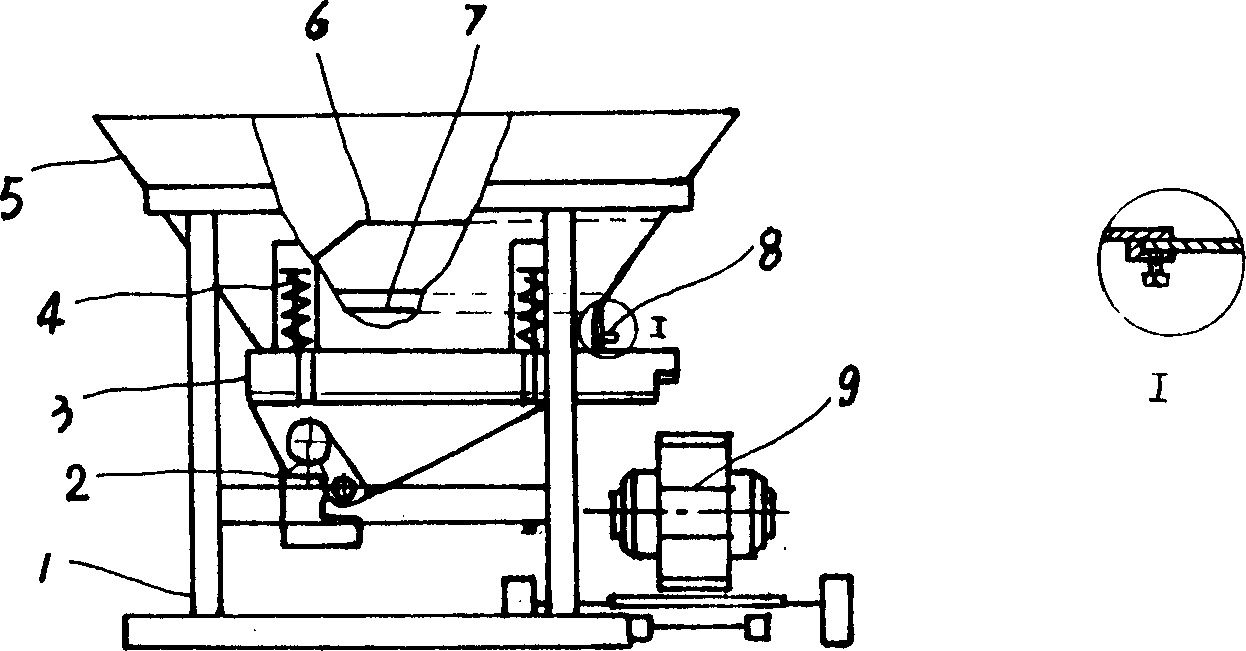

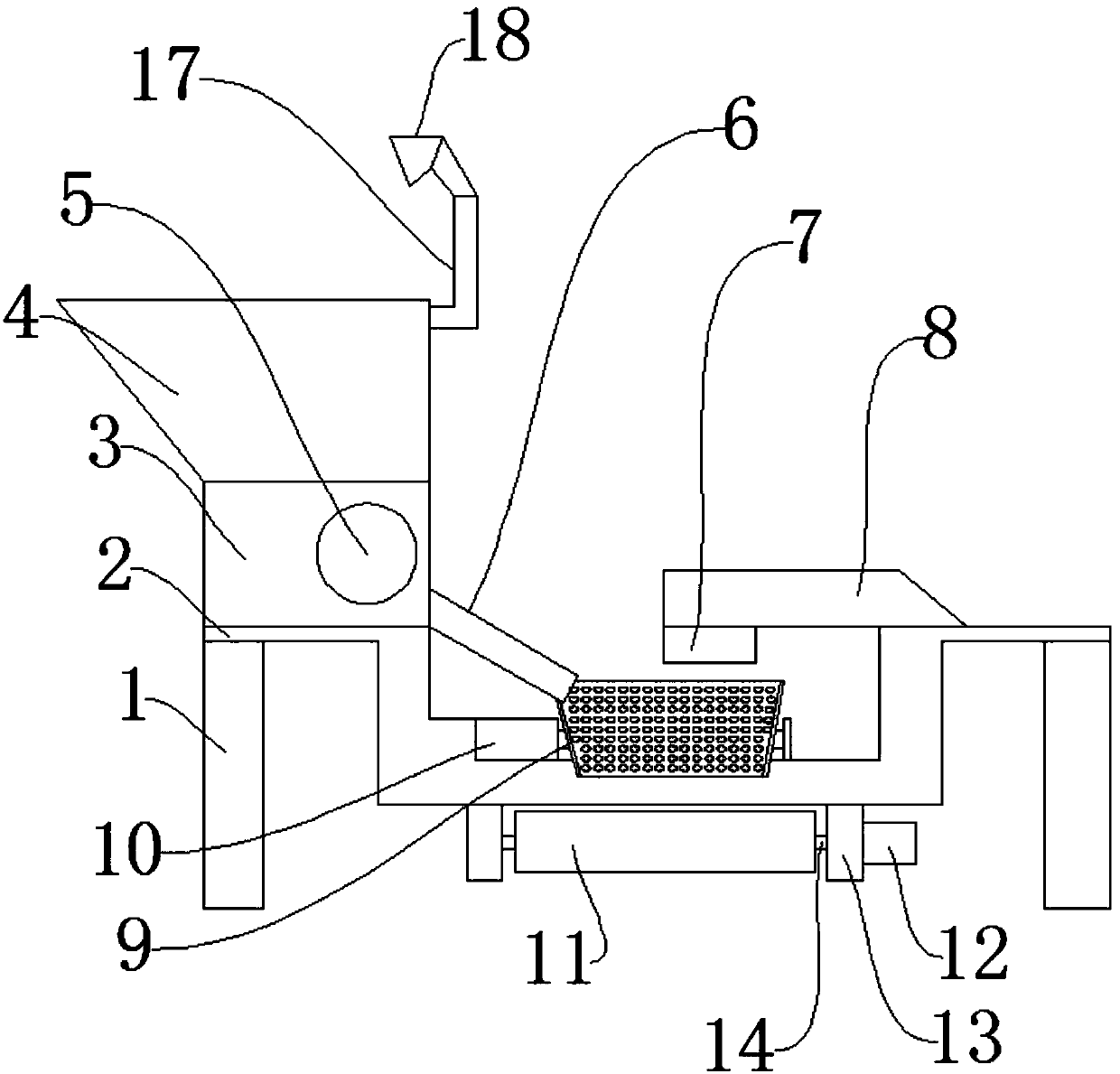

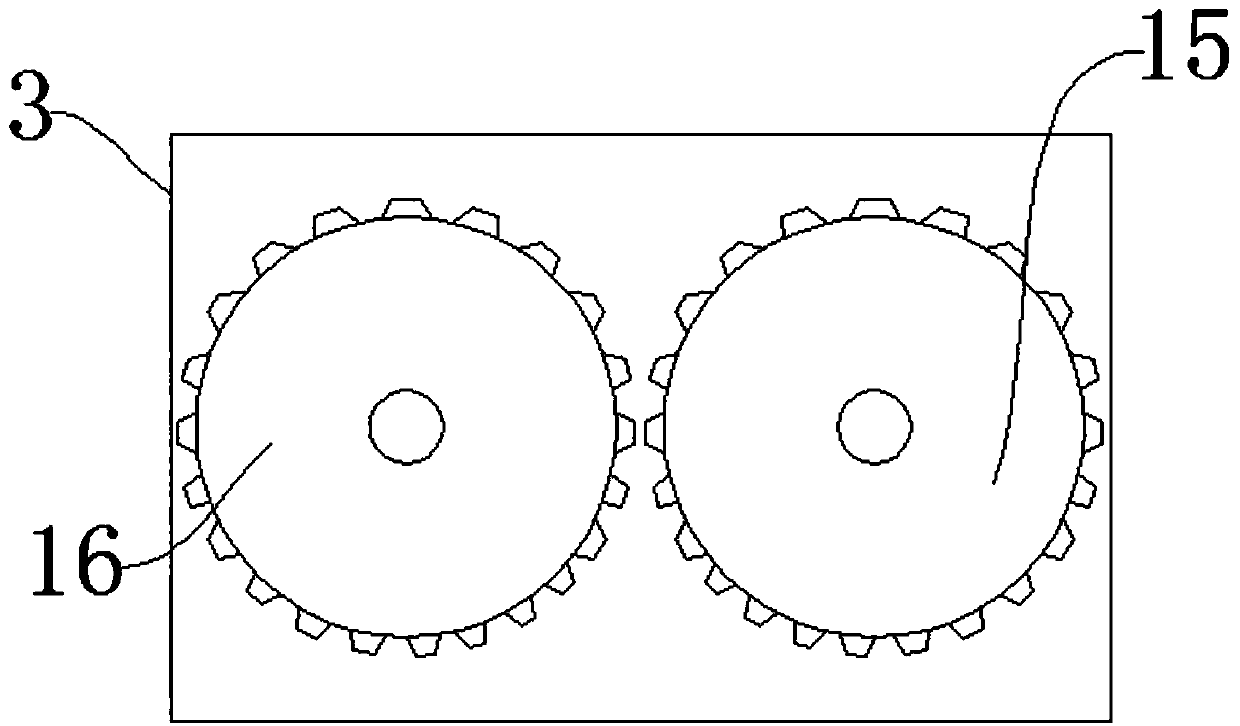

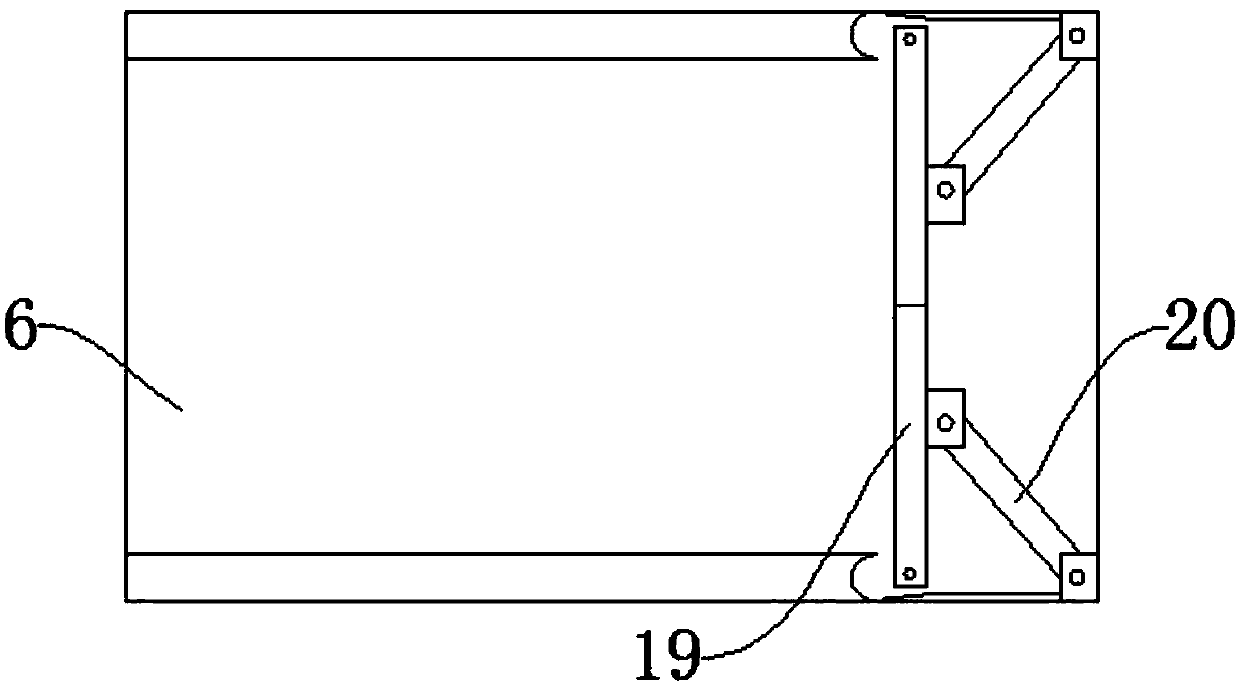

Agricultural and sideline product crushing device with screening function

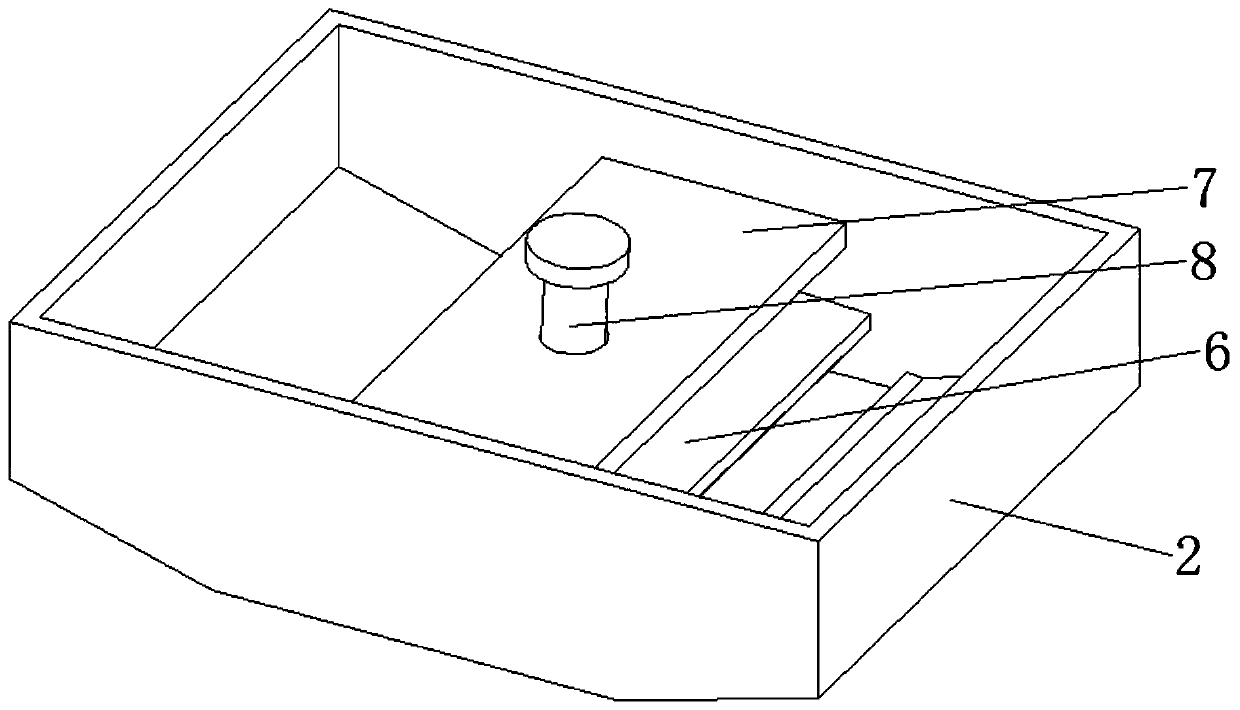

ActiveCN110215959AControl the feeding amountImprove crushing effectGrain treatmentsScreening effectEngineering

The invention discloses an agricultural and sideline product crushing device with a screening function, and belongs to the field of agricultural and sideline product processing. The crushing device comprises a box. A feeding hopper on the box communicates with a guide pipe through a conveying assembly. The guide pipe communicates with the box. A crushing assembly and a screen are arranged in the box. A baffle used for blocking the guide pipe is rotationally arranged below the guide pipe. The screen is arranged below the crushing assembly in a sliding manner. A sliding rod is arranged in the box in a sliding manner and is connected with the baffle through a first moving rod. A drive mechanism used for driving the sliding rod to do reciprocating longitudinal sliding and driving the crushingassembly to carry out crushing operation is further arranged on the box. The sliding rod can be driven by the drive mechanism to do reciprocating longitudinal sliding, and therefore the baffle can bedriven to intermittently block the guide pipe and drive the screen to do reciprocating up-and-down motion at the same time so as to achieve the aims of controlling the discharging quantity, improvingthe crushing effect and improving the screening effect.

Owner:扬州市泽扬机械设备有限公司

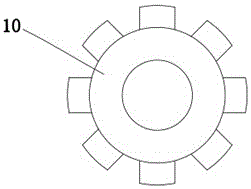

Flocculant feeding device

ActiveCN105346877AImprove sealingNot susceptible to moistureLarge containersTank wagonsImpellerEngineering

The invention discloses a flocculant feeding device which includes a bin, an impeller rotor and a cooling dehumidification device, wherein a feeding hole is formed in the top of the bin; a discharge outlet is formed in the bottom of the bin; the impeller rotor is arranged in the bin, and when the impeller rotor does not rotate, the discharging outlet is blocked by the impeller rotor, and when the impeller rotor rotates, the impeller rotor drives the material to be discharged; the cooling dehumidification device is installed on the side wall, close to the feeding hole, of the bin and comprises an evaporator, a refrigeration chip and a water absorption layer. The refrigeration chip cools the air in the bin via the evaporator, and the water absorbing layer adsorbs the cooled water and discharges the water out of the bin. The flocculant feeding device has good seal performance, ensures the drying of a flocculant, reduces the agglomeration phenomenon caused by damp, can still run normally after affected with damp to further guarantee the accuracy of the dose of the flocculant, and is simple and reliable in structure.

Owner:苏州依斯倍环保装备科技有限公司

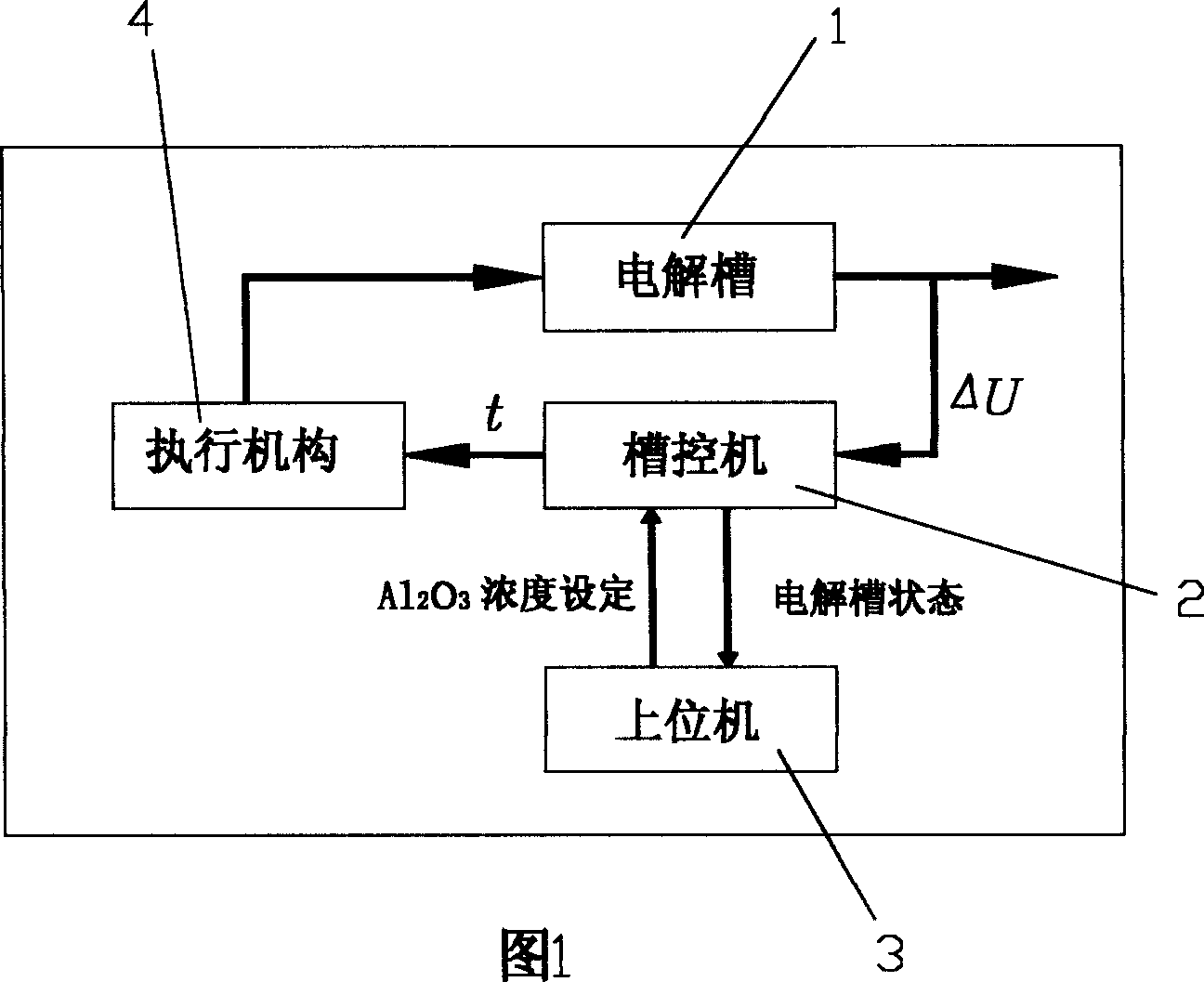

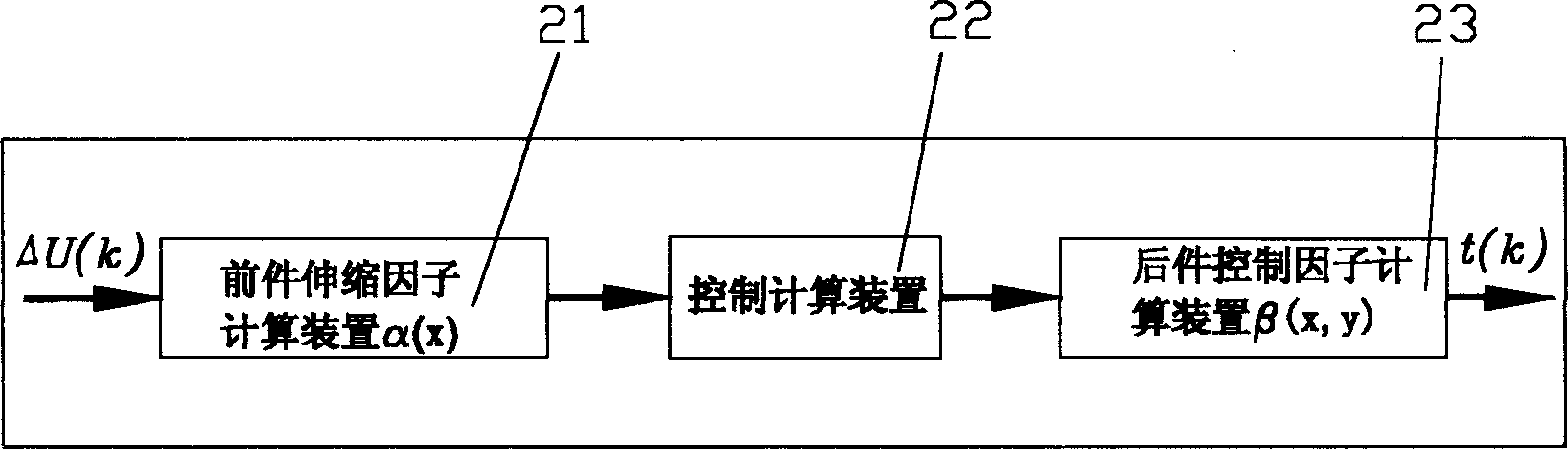

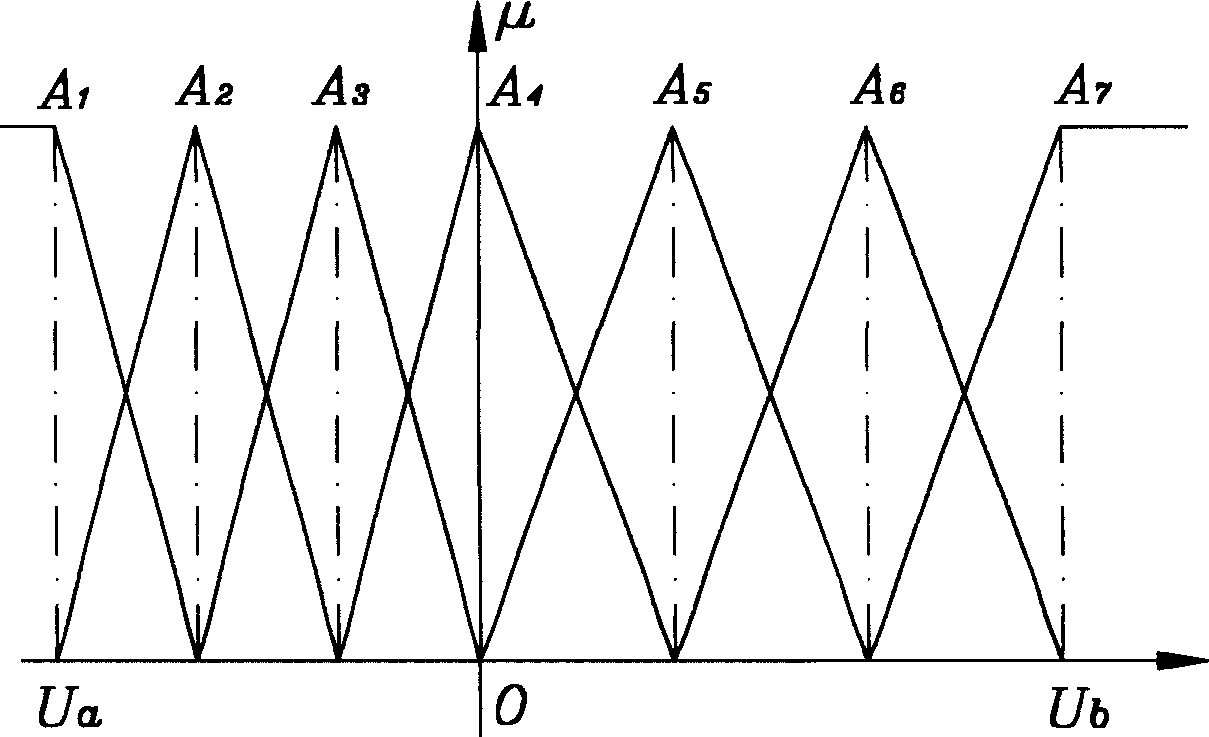

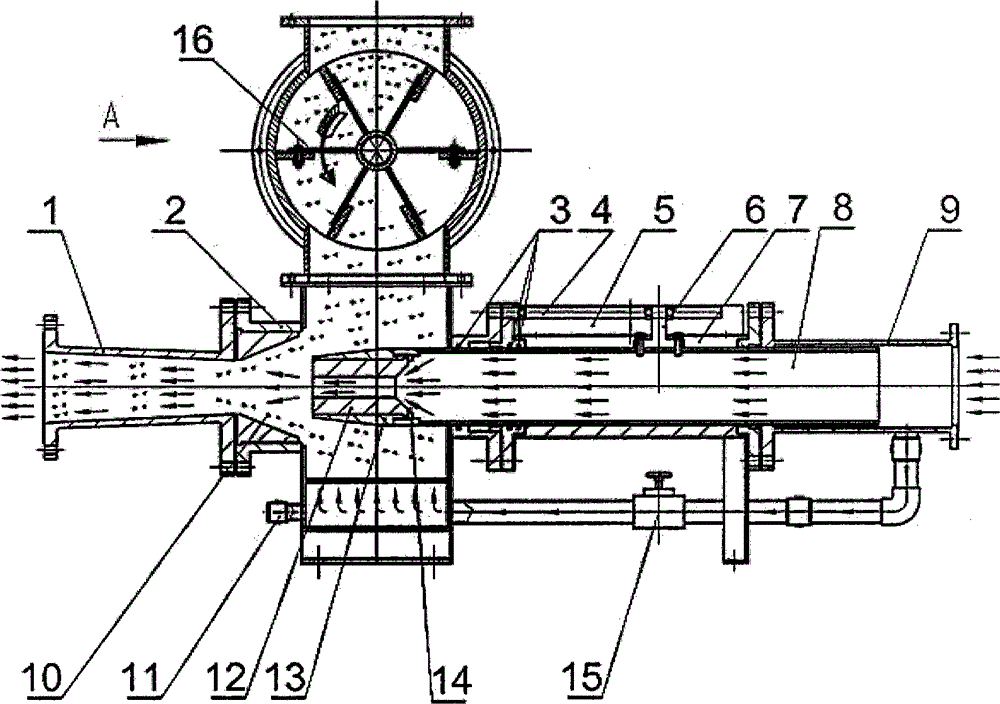

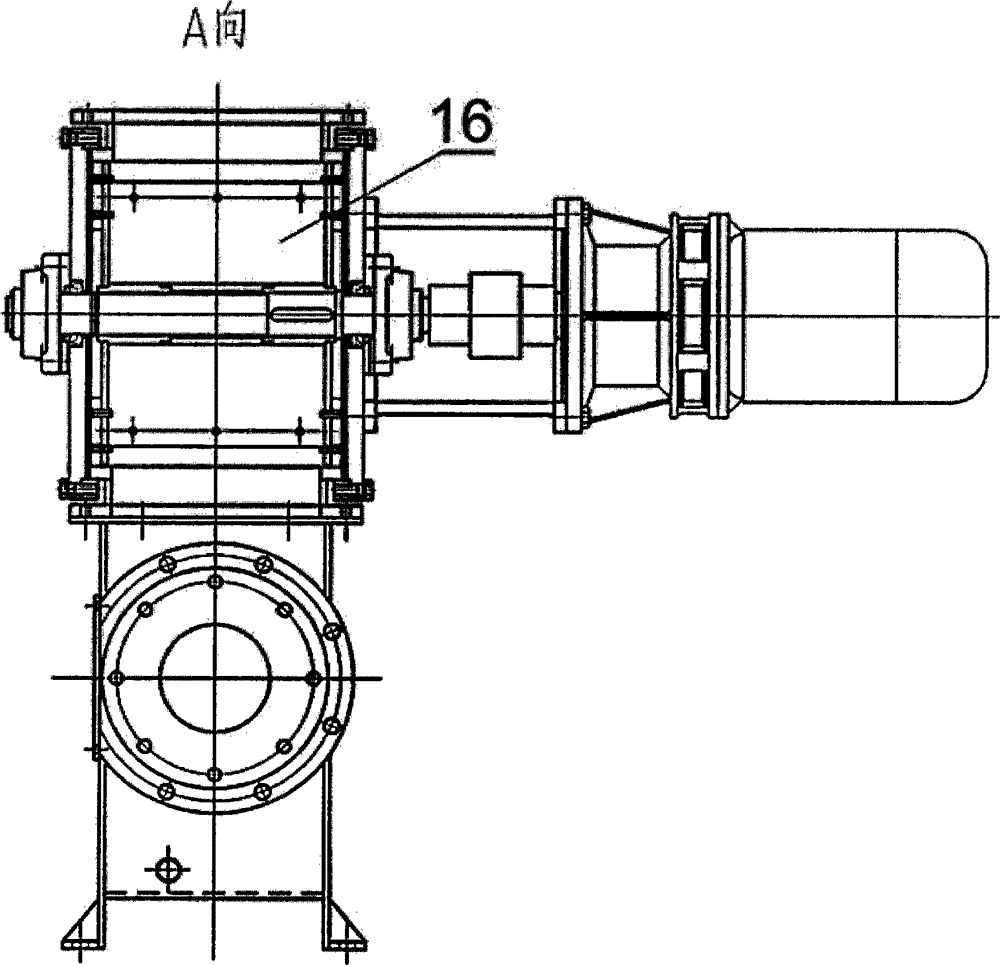

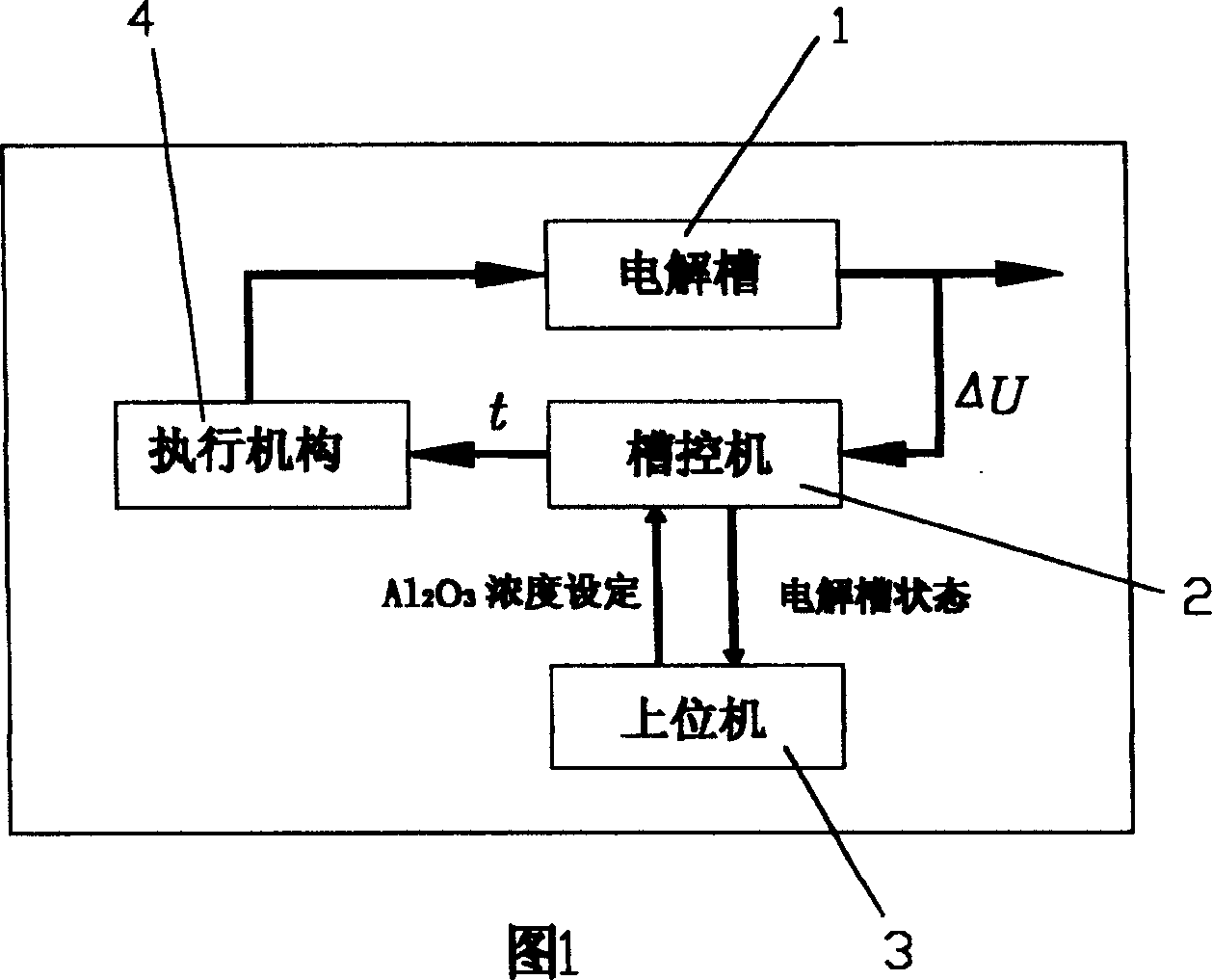

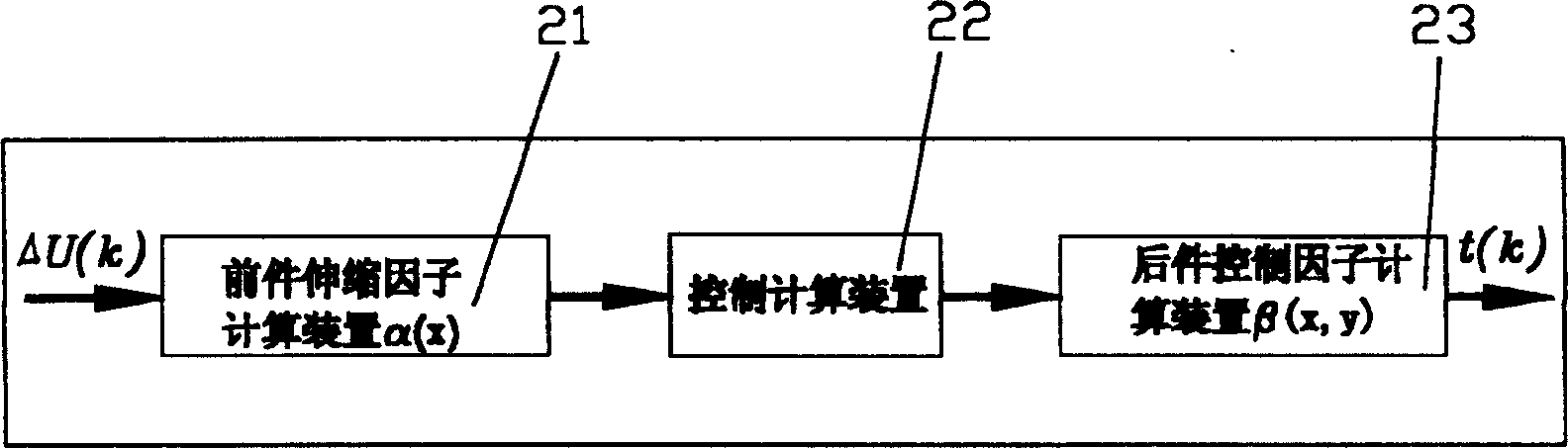

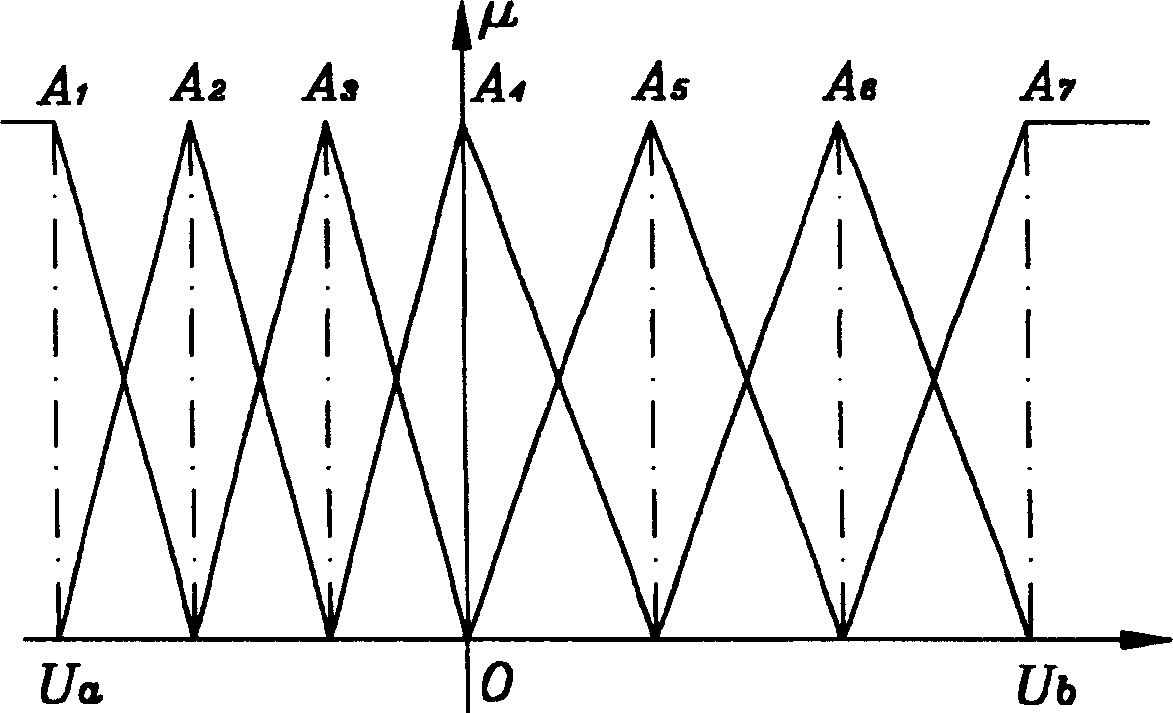

Variable-discourse universe adaptive fuzzy control method and device for pre-roasted electrolytic aluminium production

The present invention is variable-discourse universe adaptive fuzzy control method and device for pre-roasted electrolytic aluminium production. The device includes voltage detecting unit to detect the voltage variance of electrolytic tank; upper computer to set alumina concentration and perform concentrated control of technological operation and material feeding of the electrolytic tank; electrolytic tank controlling computer to receive the set alumina concentration value from the upper computer, perform variable-discourse universe fuzzy control calculation based on the voltage variance to obtain the current alumina feeding interval time; and executing mechanism to control the alumina feeding amount based on the received alumina feeding interval time.

Owner:BEIJING NORMAL UNIVERSITY

Method for preparing CI pigment red 57:1

The invention discloses a method for preparing CI pigment red 57:1. The method comprises the steps as follows: 2-isonaphthol and a sodium hydroxide solution have a carboxylation reaction with carbon dioxide after directly salified and dehydrated; a product is neutralized and subjected to filter pressing to obtain a monosodium salt solution of 2-hydroxyl-3-naphthoic acid; the solution directly has a coupling reaction with diazonium salt of 4-toluidine-3-sulfoacid after purified by a resin absorption column; and a product is subjected to color lake by an inorganic calcium compound to obtain the CI pigment red 57:1 finally. According to the method, the step of purification by the resin absorption column is added, and the steps that in the prior art, 2, 3-acid powder is obtained by droppwise adding sulfuric acid to a monosodium salt solution of 2, 3-acid, drying and packaging are performed, then the sodium hydroxide solution is added to obtain the monosodium salt solution of 2, 3-acid again and the like are omitted; therefore, the problems that the use amount of sulfuric acid and the sodium hydroxide solution is large, 2, 3-acid powder requires to be dried and packaged and the like in a conventional preparation process are solved, the emission of inorganic salt to the environment is reduced, energy consumption and manpower cost are reduced, and wastewater emission load is obviously reduced.

Owner:苏州思睿屹新材料股份有限公司

Powdery material spraying pump

InactiveCN104803197AReduced conveying capacityImprove delivery capacityBulk conveyorsSpray nozzleAutomation

The invention relates to a powdery material spraying pump, which comprises air inlet pipe, a hollow pipe, a pump body, an air closer and a regulating valve, wherein an output opening of the air inlet pipe is communicated with the hollow pipe, one end of the hollow pipe is connected with the air inlet pipe, the other end of the hollow pipe is connected with a spray nozzle, slide iron is fixedly arranged on the hollow pipe, one end of the slide iron is fixedly arranged on the hollow pipe, the other end of the slide iron is arranged on a lead screw in a sleeving way, and the slide iron and the lead screw are screwed and connected; the spray nozzle extends into the pump body, the air closer is arranged above the pump body, one side of the pump body is sequentially connected with the spray nozzle, the hollow pipe and the air inlet pipe, the other side of the pump body is communicated with a cone pipe, the top of the pump body is communicated with the air closer, and the bottom of the pump body is communicated with an airflow source. The powdery material spraying pump has the advantages that the structure is simple, the operation is reliable, the full sealing is realized, no pollution is caused, the system manufacturing cost is low, the operation cost is low, and the automation degree is high.

Owner:ZHENGZHOU DONGDING DRYING EQUIP

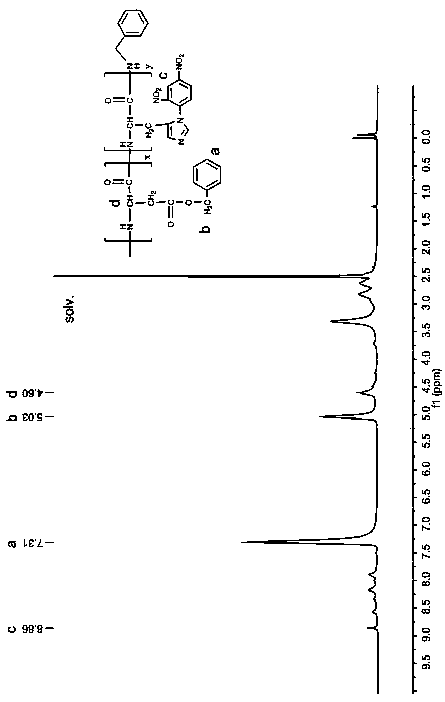

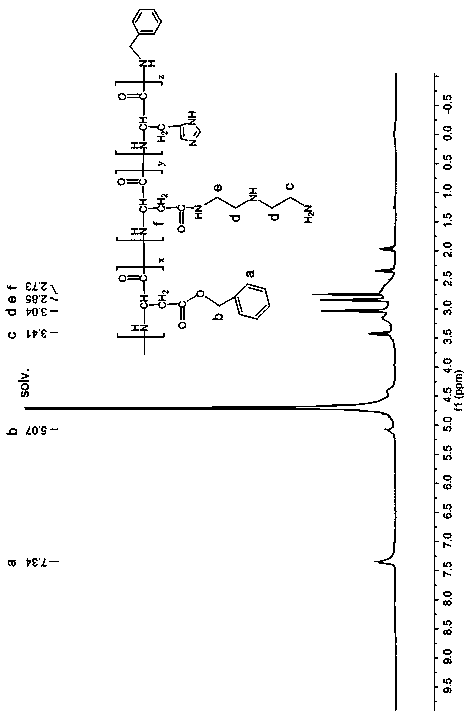

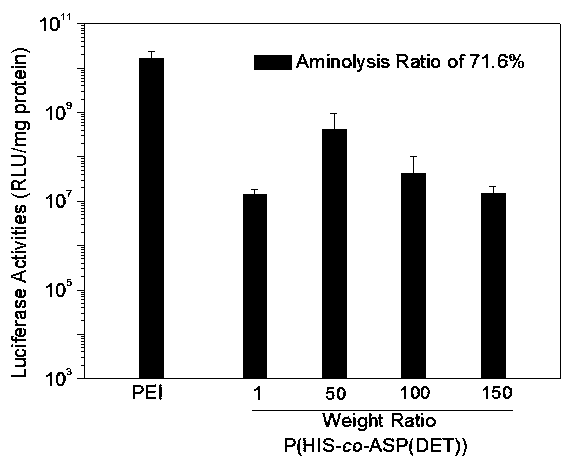

Cationic polyamino acid group carrier material and preparation method thereof

ActiveCN103755955AControl molecular weightControl the feeding amountOther foreign material introduction processesPolymer dissolutionPolymer science

The invention discloses a cationic polyamino acid group carrier material and a preparation method thereof. according to the preparation method, a random copolymer of aspartic acid benzyl ester and histidine is prepared through ring opening polymerization of N-carboxyl-alpha-amino anhydride, and an aminolysis reaction is carried out on an aspartic acid side chain, so as to synthesize the cationic polyamino acid group carrier material. A gel permeation chromatography result shows that the molecular weight of the polymer can be effectively controlled through controlling inventory of an initiator; under different aminolysis proportions, the polymers are different in solubility and transform from hydrophobic property to hydrophilic property; in-vitro gene transfection experiment result shows that polymers P (HIS-(i) co( / i)-ASP (DET)) with aminolysis proportion ranging from 10% to 95% have gene transfection efficiency, and a polymer with the maximum transfection efficiency can be screened out through changing the mass ratio of material to gene; the polymers P (HIS-(i) co( / i)-ASP (DET), compared to a homopolymerized aspartic acid polymer, are obviously low in cytotoxicity; and the obtained polymer is a gene carrier material which is low in toxicity, high in efficiency, excellent in biocompatibility and biodegradable.

Owner:SUN YAT SEN UNIV

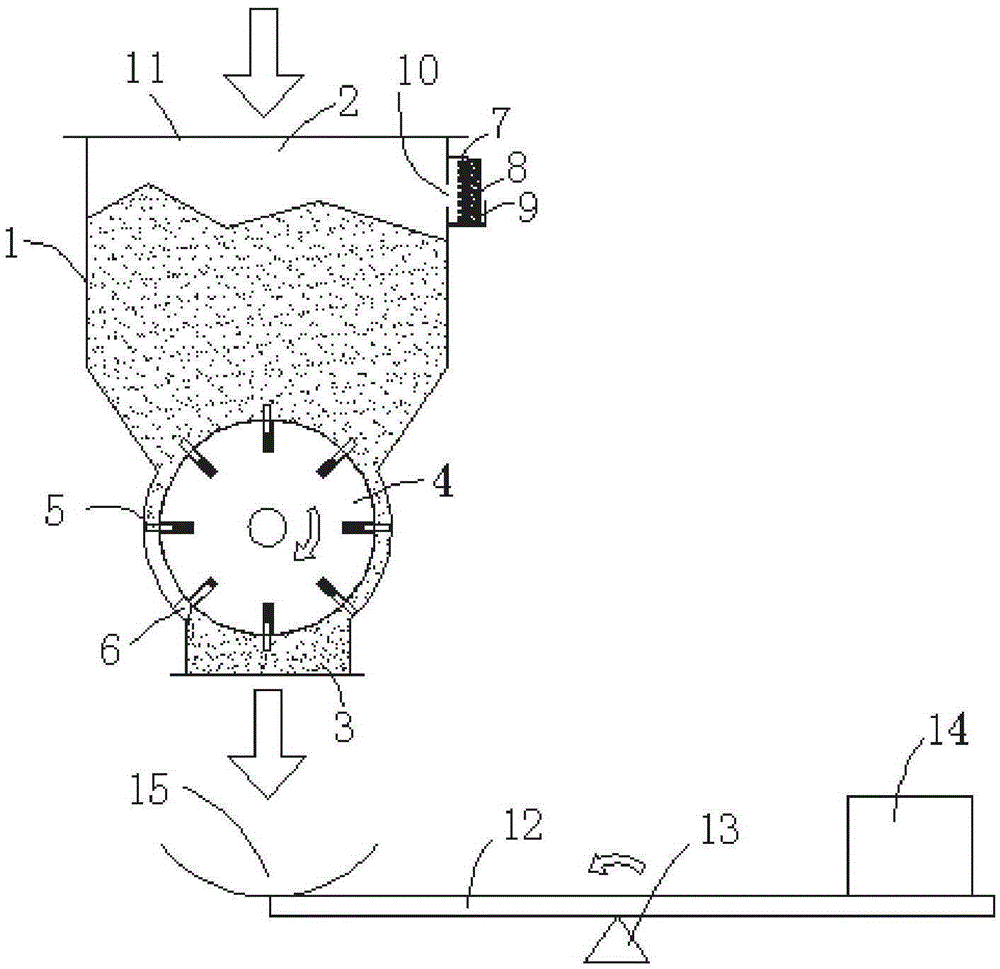

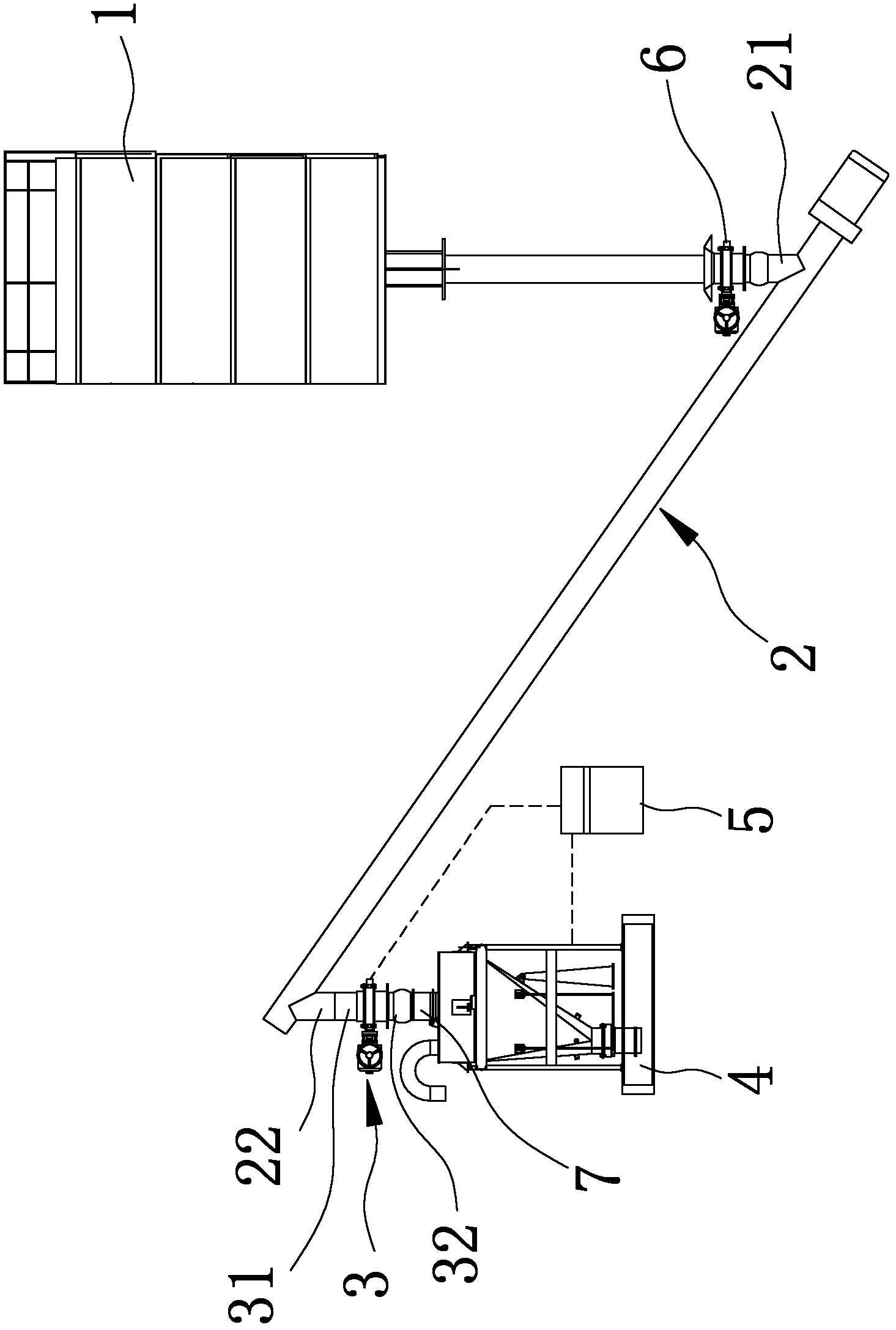

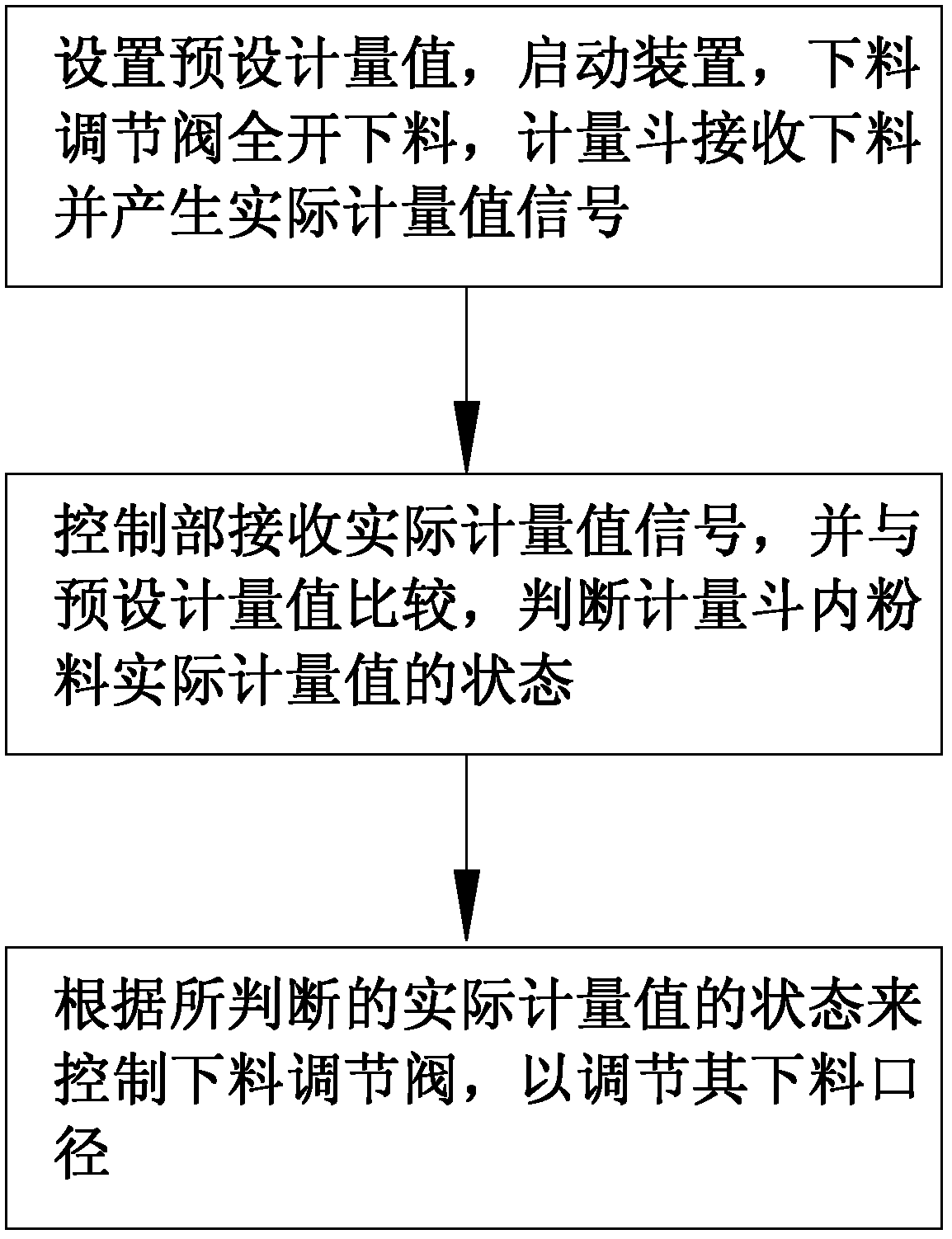

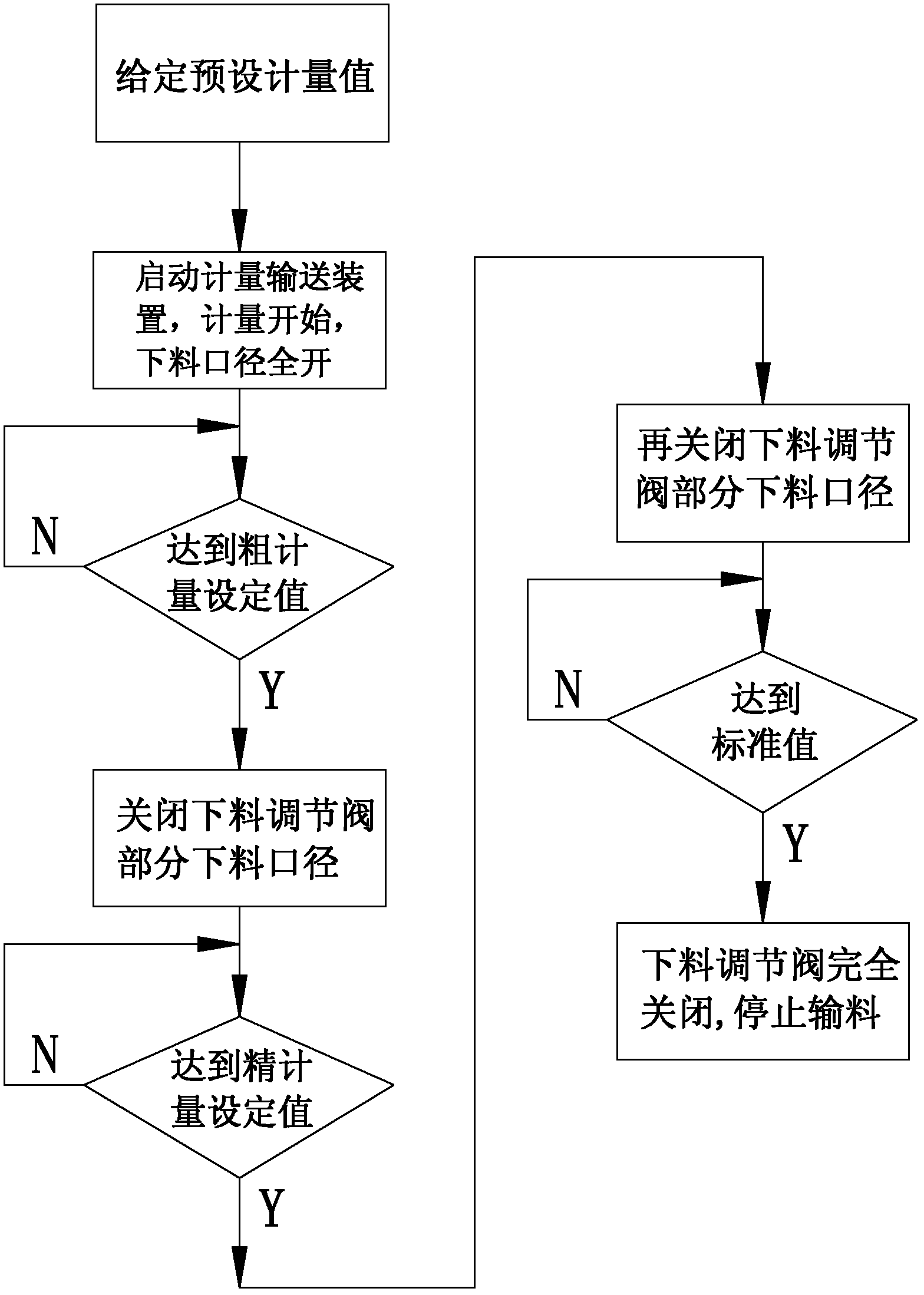

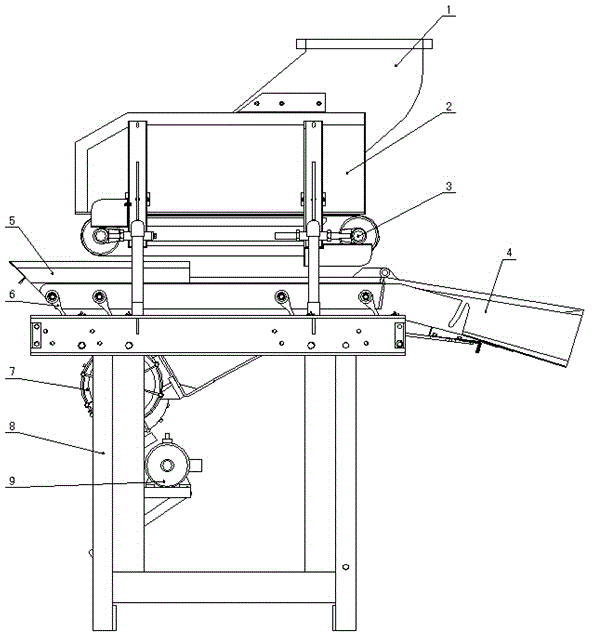

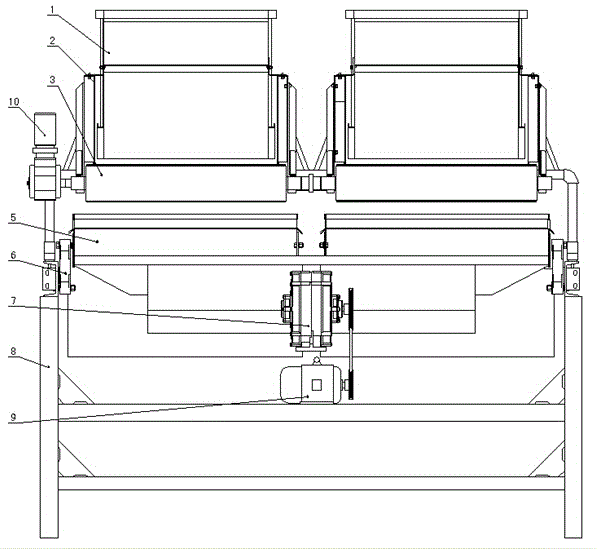

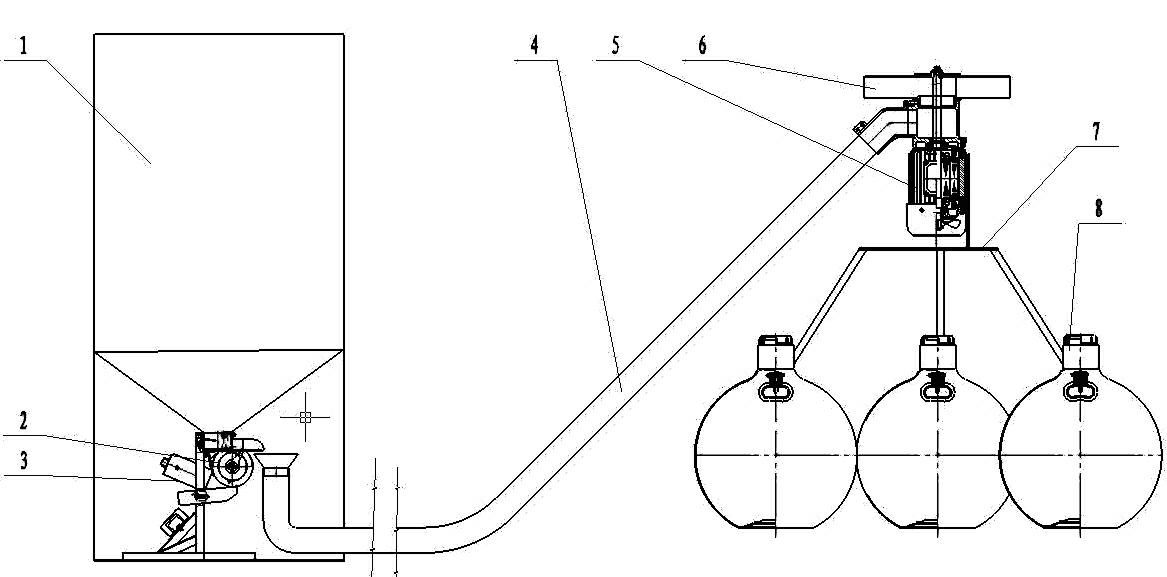

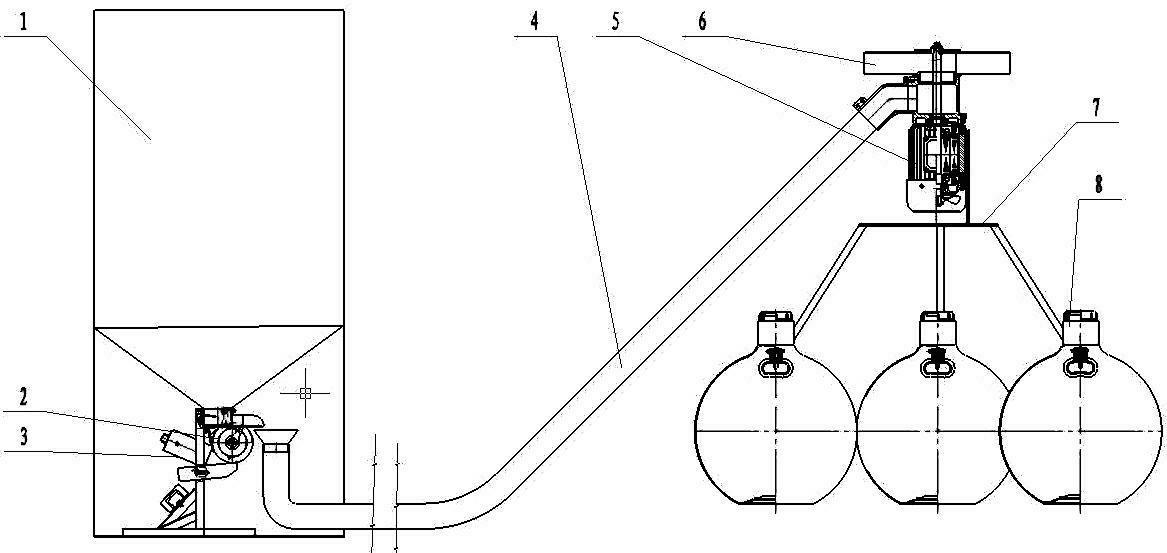

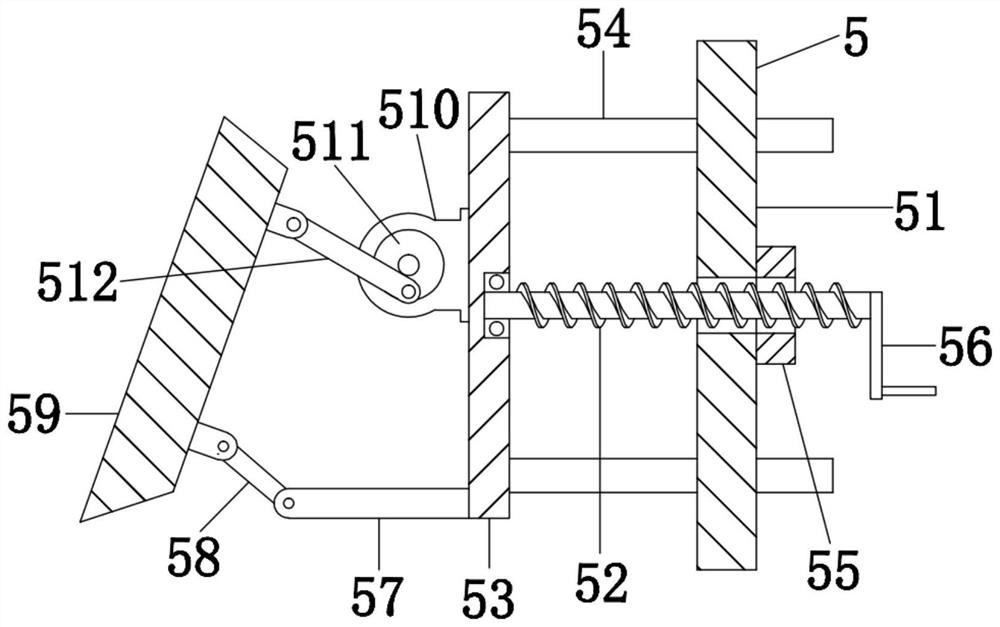

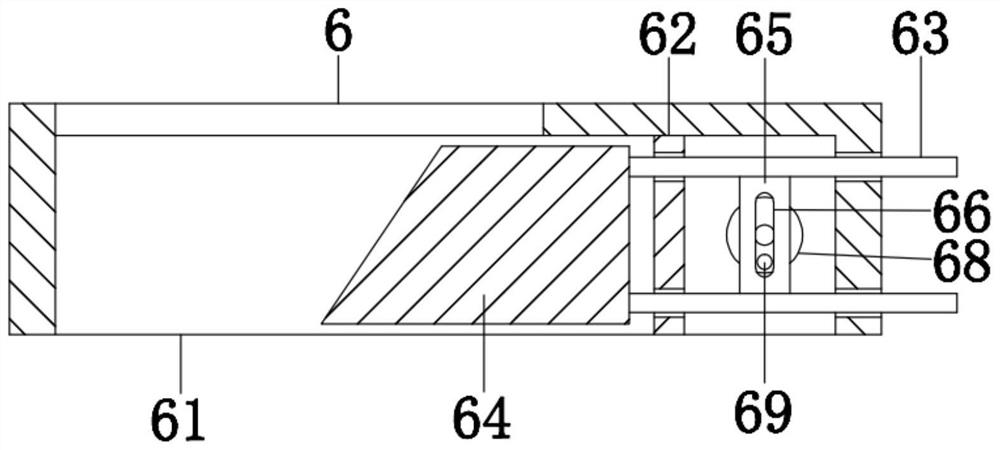

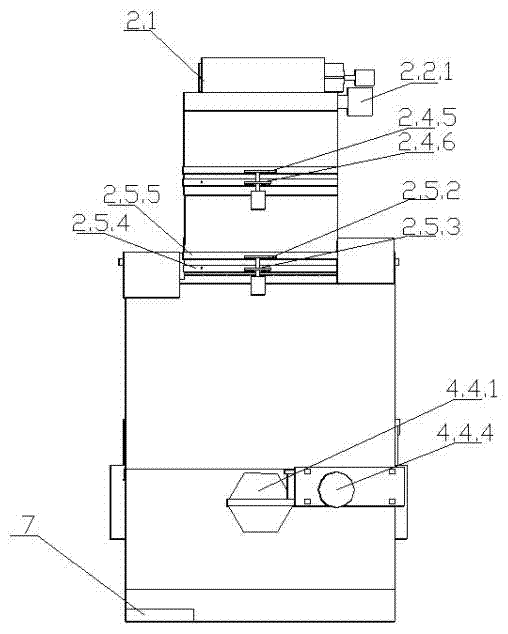

Powder material metering and conveying device of mixing plant and control method of powder material metering and conveying device

InactiveCN102615711AControl the feeding amountGuaranteed delivery speedControl apparatusSold ingredients supply apparatusEngineeringScrew conveyor

The invention discloses a powder material metering and conveying device of a mixing plant and a control method of the powder material metering and conveying device. The powder material metering and conveying device of the mixing plant comprises a material storage bin, a screw conveyer, a feed regulating valve, a metering hopper and a control part, wherein the screw conveyer is provided with a material inlet and a material outlet and the material inlet is connected with the material storage bin; the feed regulating valve is provided with an input end and an output end and the input end is connected with the material outlet; the metering hopper is connected with the output end; and the control part is connected with the feed regulating valve and the metering hopper and is used for receiving the metering signal of the metering hopper and controlling the feed regulating valve to adjust feed caliber. The powder material metering and conveying device of the mixing plant and the control method of the powder material metering and conveying device have the advantages that the powder materials can be rapidly conveyed, the working efficiency is high and the metering accuracy is high.

Owner:SANY HEAVY IND CO LTD (CN)

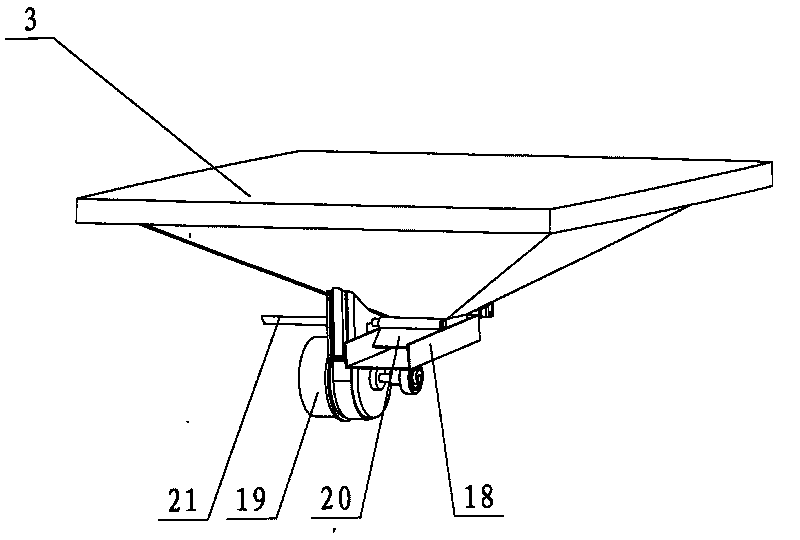

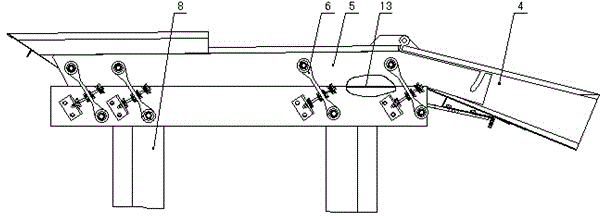

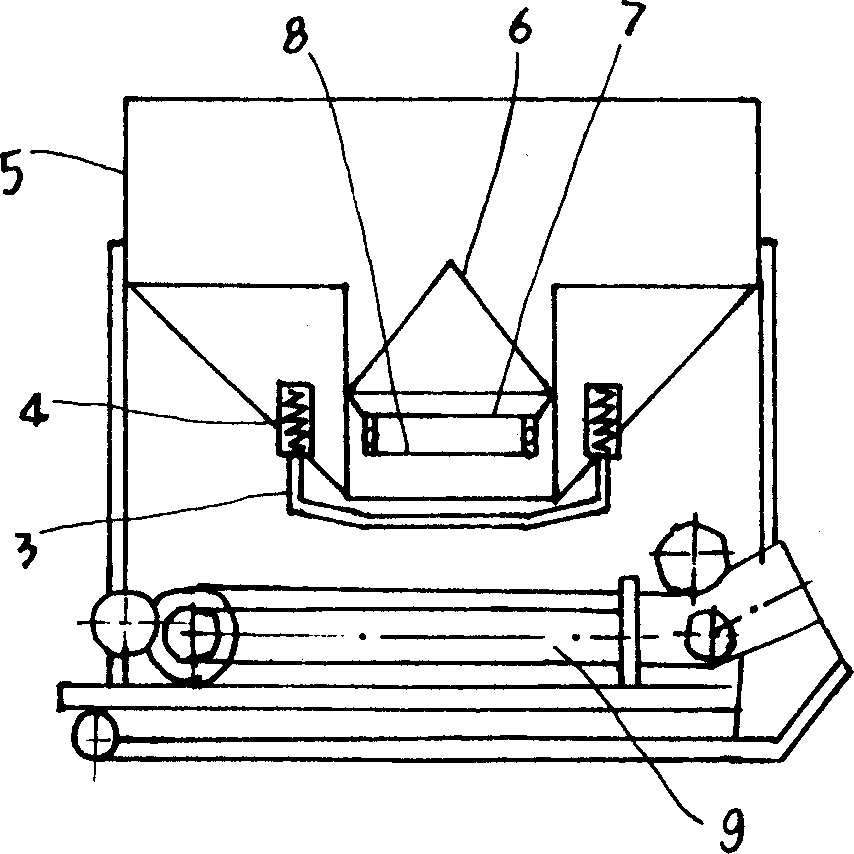

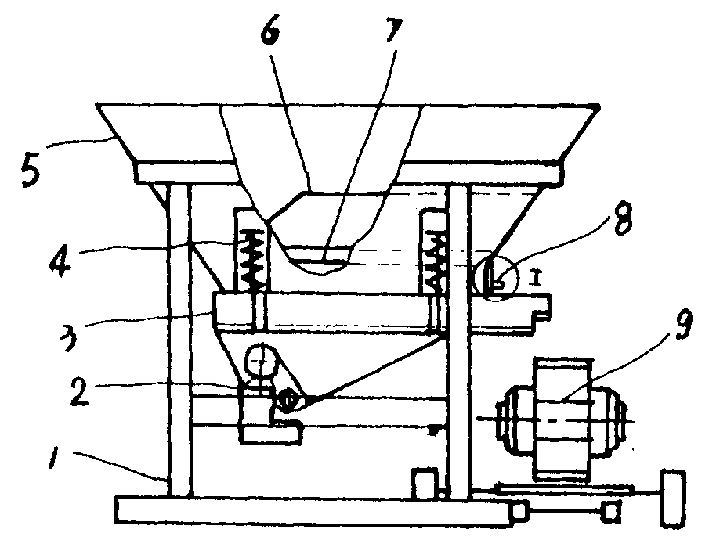

Feeding unit for corn huskers

The invention relates to the technical field of corn husking equipment and discloses a feeding unit for corn huskers. The feeding unit comprises a feed bucket, a belt conveying mechanism, a frame and a reducer. A conveying trough is provided below the belt conveying mechanism and connected with a frame through a plurality of support arms. A joint of each support arm and the frame is provided with a pressure spring. The conveying trough is connected with a rocking vibrator mounted on the frame; the discharge end of the conveying trough is connected with the feed end of a chute. A small guide plate and a large guide plate both in pyramid shapes are disposed at intervals within the chute. The discharge end of the chute is connected with a main unit of the corn husker. The feeding unit has the advantages that harvested corn ears disorderly entering the feed bucket are neatly arranged with ends facing forward and enter the main unit of the corn husker one by one, the corn ears are avoided blocking an entry of the main unit, the corn ears can be completely husked in the corn husker, operating efficiency of the corn husker is improved, fewer scattered kernels are damaged, and optimal husking is achieved.

Owner:JIUQUAN OK SEED MACHINERY

Pneumatic type feeder

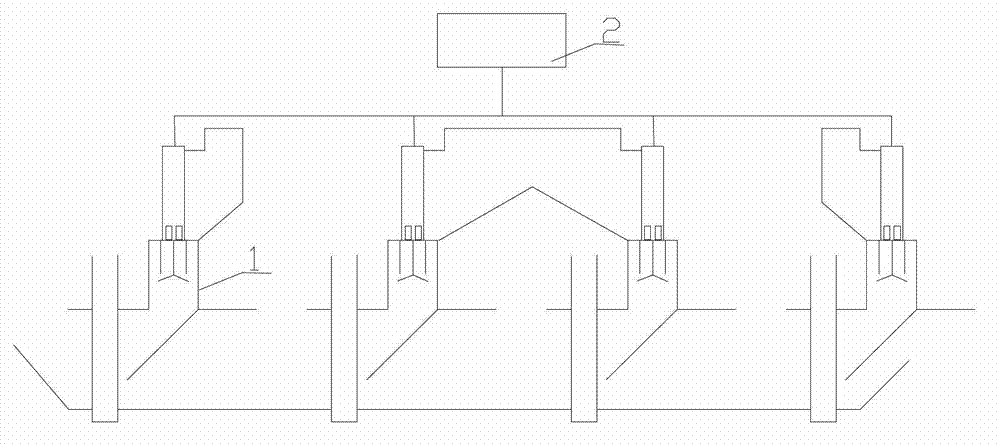

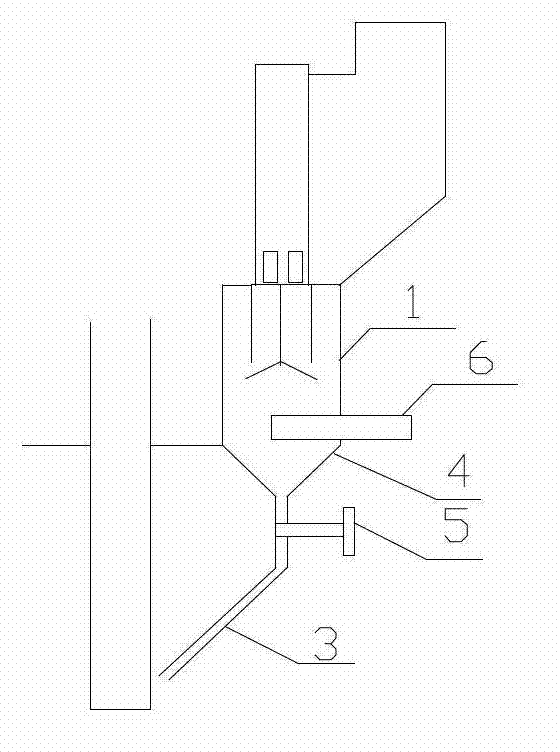

The invention discloses a pneumatic type feeder. The pneumatic type feeder comprises a pneumatic motor (5), a rotary throwing disc (6), a fodder conveying pipe (4), a fodder box (1), a distributor (2), a controller (3), a bracket (7) and a floating body (8); the floating body (8) is installed under the bracket (7) and the pneumatic motor (5) is installed above the bracket (7); the rotary throwing disc (6) is connected with the pneumatic motor (5); one end of the fodder conveying pipe (4) is connected with the pneumatic motor (5) and is communicated with the rotary throwing disc (6), and the other end of the fodder conveying pipe (4) is communicated with the distributor (2); the distributor (2) is installed on a discharge hole of the fodder box (1), the fodder box (1) is equipped with the controller (3), and the controller (3) is connected with the pneumatic motor (5) and the distributor (2). The feeder provided by the invention has the advantages of simple structure, low cost, convenience in installation, high automatic degree, manual work saving, big throwing area and high work efficiency.

Owner:金湖小青青机电设备有限公司

Agricultural cereal spiral falling and drying device

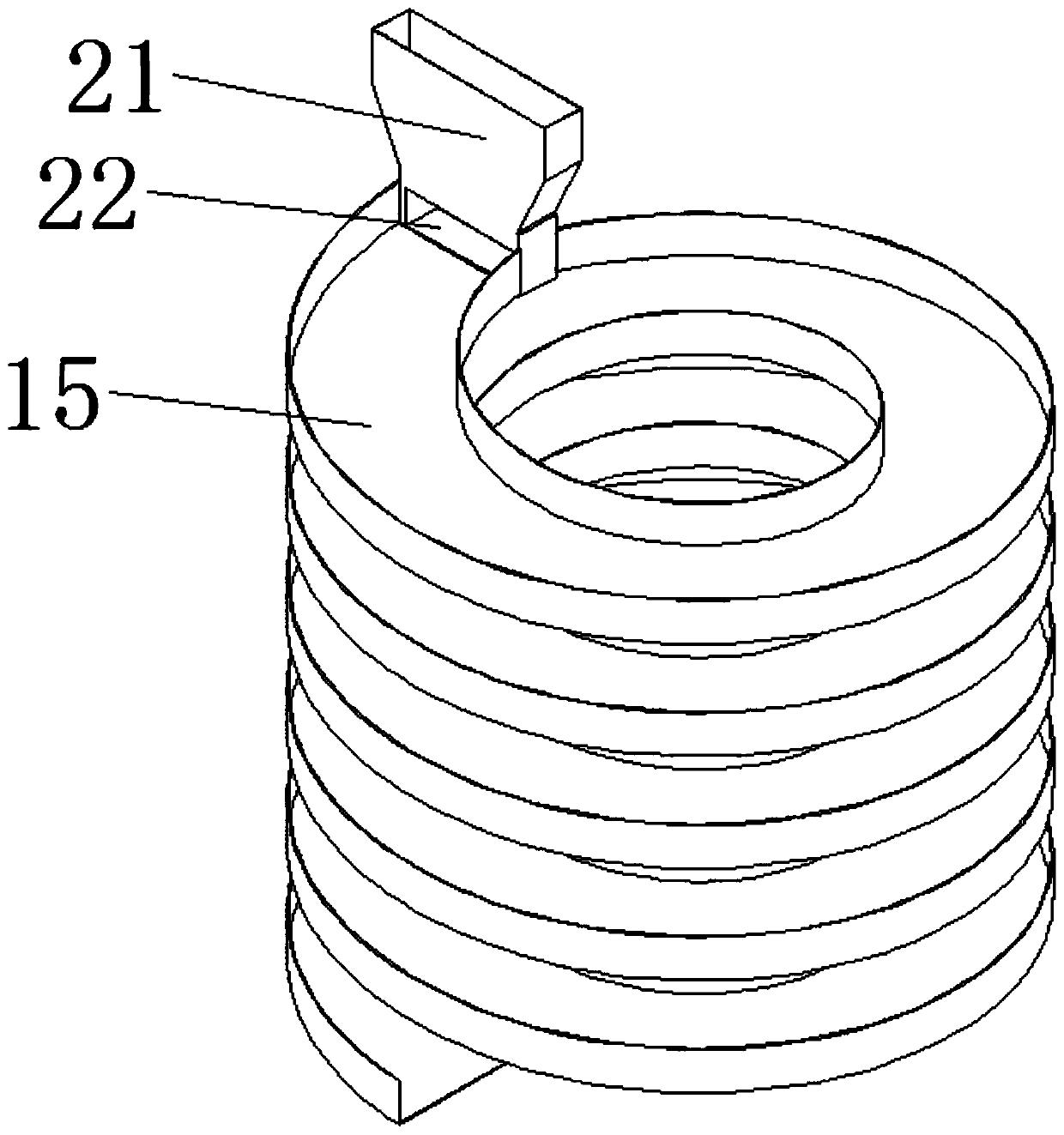

ActiveCN110513995AReduce loadFalling smoothlyDrying gas arrangementsSeed preservation by dryingAgricultural engineeringAgriculture

The invention relates to the field of agriculture, and in particular, discloses an agricultural cereal spiral falling and drying device. The device comprises a shell, a feed hopper, a separation plateand hot air pipes; multiple horizontal stop rollers are uniformly arranged in the connected place of the bottom of the feed hopper with the shell at equal intervals; a horizontal baffle plate capableof being lifted is arranged in the feed hopper; the baffle plate is positioned above the bottom of the feed hopper; multiple stoppers are fixed on the lower surface of the baffle plate; multiple spiral runners are formed under the separation plate in the vertical direction; and the hot air pipes are arranged on the inner wall of the shell corresponding to the spiral runners. Through arrangement of the stop rollers and the stoppers at the bottom of the feed hopper, the unloading quantity can be controlled, so that cereals uniformly enter the feed hopper without blocking meshes, the load of internal equipment is reduced, and smooth falling of the cereals is guaranteed; and the cereals are fully contacted with hot air in the spiral runners for fully drying, and continuously fall down in thespiral runners for drying without needing stop for unloading.

Owner:西藏瑞华资本管理有限公司

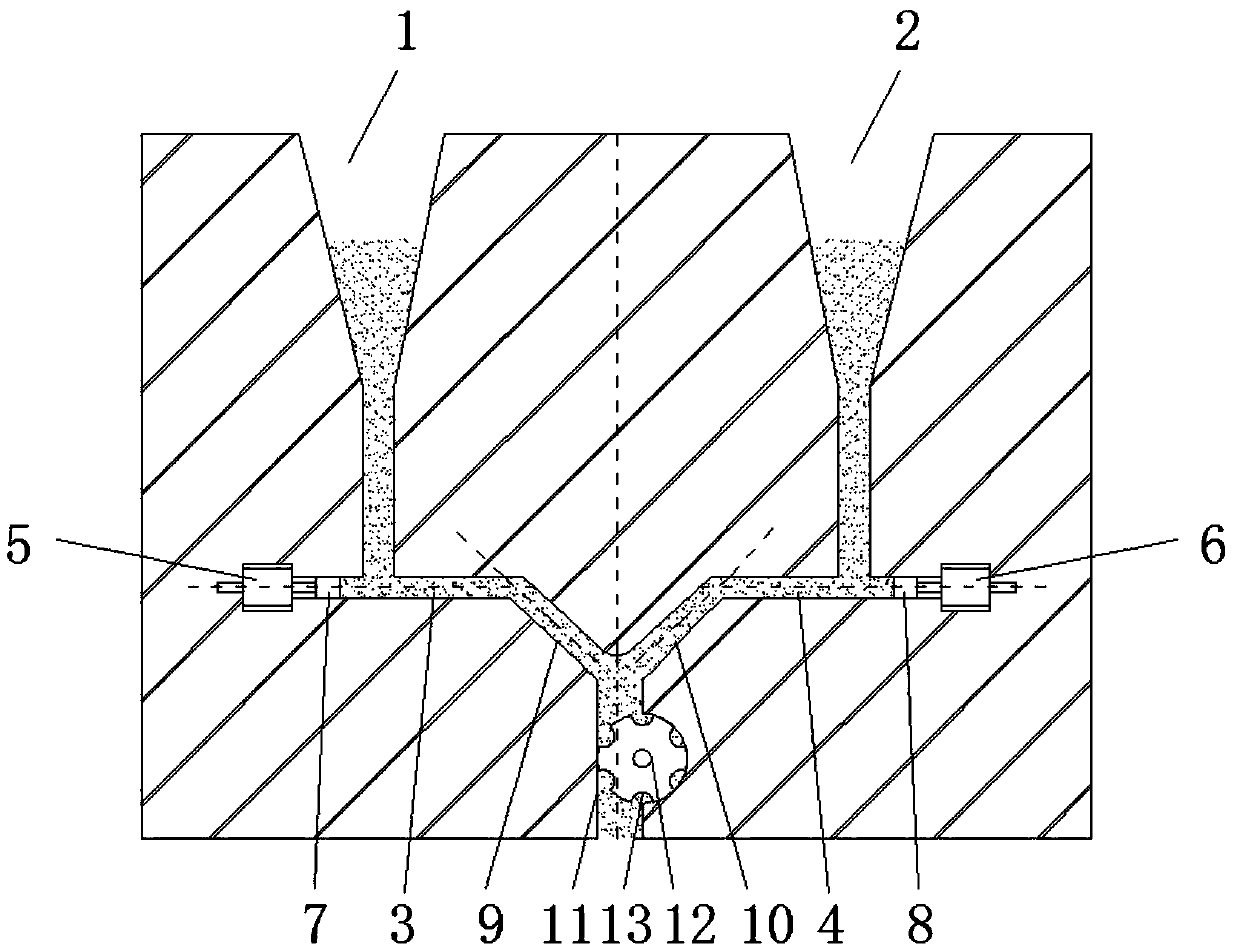

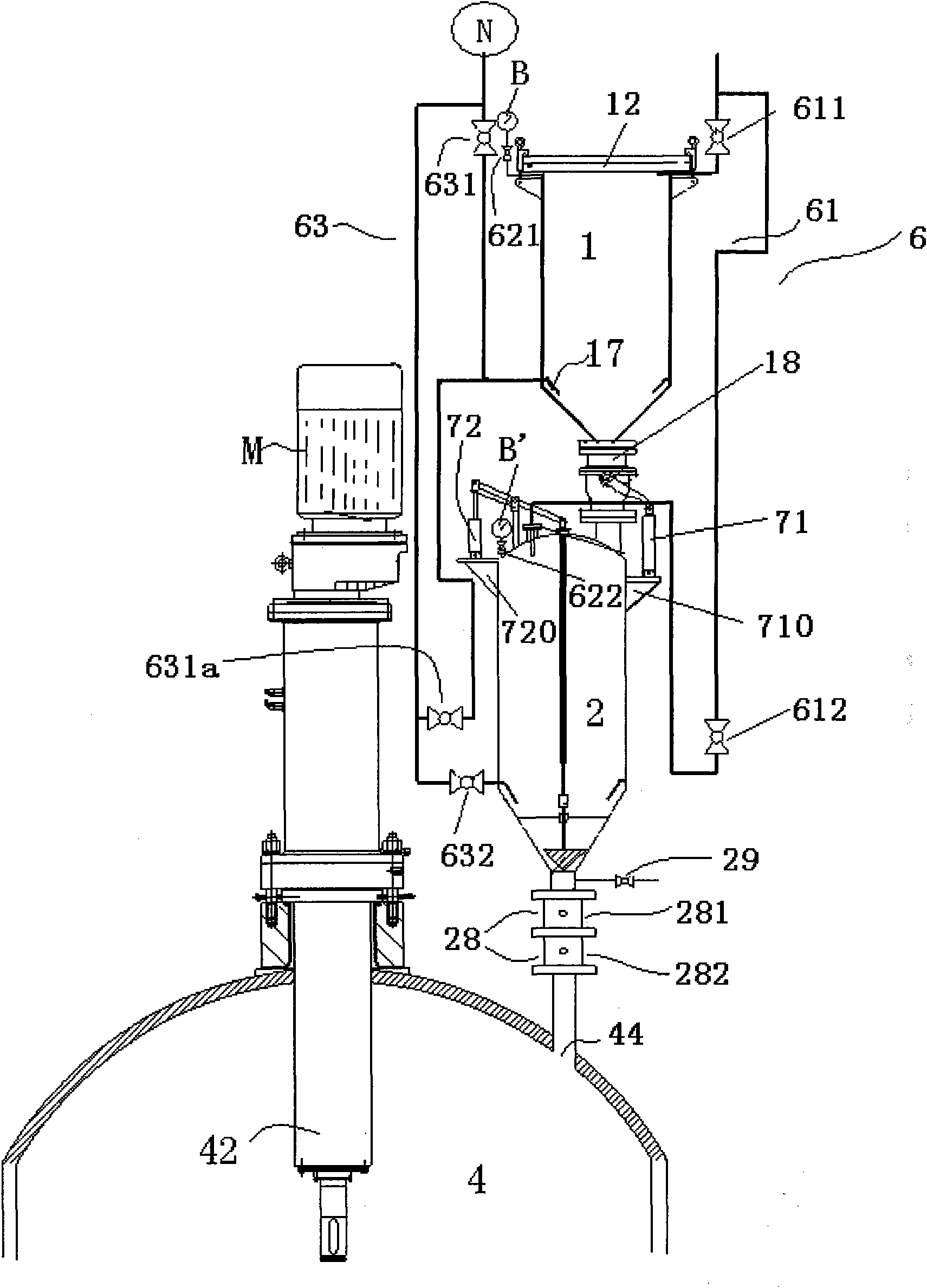

Method for charging and emptying aluminum powder and control system thereof

InactiveCN101850224ADoes not affect feedingSimple processGroup 3/13 element organic compoundsFeed devicesControl systemNitrogen

The invention discloses a method for charging and emptying aluminum powder and a control system thereof, belonging to the field of petrochemical industrial equipment, in particular to a device for charging aluminum powder in production equipment of aluminium ethyl and a control method thereof. In the invention, the control system for charging and emptying the aluminum powder consists of an aluminum powder charging and emptying device and a control unit; the control unit is consists of a nitrogen gas control unit, a pressure detection unit and a vacuum control unit; a first charging valve is used for controlling the opening and closing of the feed opening of a feeder and the inlet point of an emptying device; and a baiting piston unit is used for controlling the opening and closing of a channel between the inlet point of the emptying device and the inlet point of a reactor. Due to the reasonable allocation of the control system for charging and emptying aluminum powder in the invention, a nitrogen displacement tank body and a material transferring tank body can be controlled to be mutually independent, and can work simultaneously without mutual interface so as to optimize th process and improve the industrial efficiency; and compared with the prior art, the method for charging and emptying aluminum powder in the invention is more simple, safer and more reliable, facilitates an operator to master and effectively improves the operating efficiency.

Owner:天津联力化工有限公司

Dustproof feeding device for deep processing of forage grass

InactiveCN113243215AImprove shipping efficiencyGuaranteed efficiencyBalingCuttersAnimal scienceElectric machine

The invention discloses a dustproof feeding device for deep processing of forage grass. The dustproof feeding device comprises a device body, wherein a smashing mechanism is fixedly arranged on one side of the device body, the smashing mechanism comprises a stirring rod, smashing blades, a feeding port and a smashing motor, a smashing box is fixedly arranged at the top of the device body, the smashing motor is fixedly arranged at the top of the smashing box, a rotating part of the smashing motor is fixedly connected with a stirring rod, a discharging opening is formed in the bottom of the smashing box, a feeding box is fixedly arranged below the discharging opening, electric drive pushers are fixedly arranged on the two sides of the feeding box through a plurality of supporting rods which are evenly distributed, the forage grass is fed in from the feeding opening, meanwhile, the smashing motor rotates to drive the stirring rod to rotate, the stirring rod rotates to drive the smashing blades to cut and smash the forage grass, the cut forage grass falls onto a belt in the feeding box from the discharging opening, a first motor rotates to drive a belt wheel to rotate, and the belt wheel rotates to drive the belt to rotate.

Owner:贵州省草地技术试验推广站

Building concrete waste crushing device

InactiveCN111889177AControl the feeding amountFalling smoothlyGrain treatmentsStructural engineeringWaste material

Owner:白良霞

Peanut cleaning and screening machine

PendingCN107321621AControl the feeding amountControl the feeding speedSievingGas current separationElectric machineryStructural engineering

A peanut cleaning and screening machine comprises a machine frame. The upper portion of the machine frame is provided with a feeding hopper and a winnowing device, the middle of the machine frame is provided with a vibration screening device, and a conveying device located at an outlet of the vibration screening device is arranged on the machine frame; and a discharging mechanism is arranged at an outlet of the feeding hopper and comprises a stirring rotating barrel, the outer surface of the stirring rotating barrel is provided with stirring baffles, and the outer edge of each stirring baffle is provided with a fur layer. The vibration screening device comprises a shell, a first screen plate and a second screen plate are arranged in the shell in a spaced mode in the vertical direction, springs are connected between the edge of the first screen plate and the edge of the second screen plate, the rear end of the shell is provided with a first impurity discharging opening, a material discharging opening and a second impurity discharging opening, and the side portion of the shell is provided with a vibration motor. The winnowing device comprises a self-suction fan arranged on the machine frame. The peanut cleaning and screening machine is reliable in working, convenient and fast to operate, good in screening effect, high in working efficiency and capable of effectively removing impurities in peanut materials.

Owner:正阳县豫丰机械有限公司

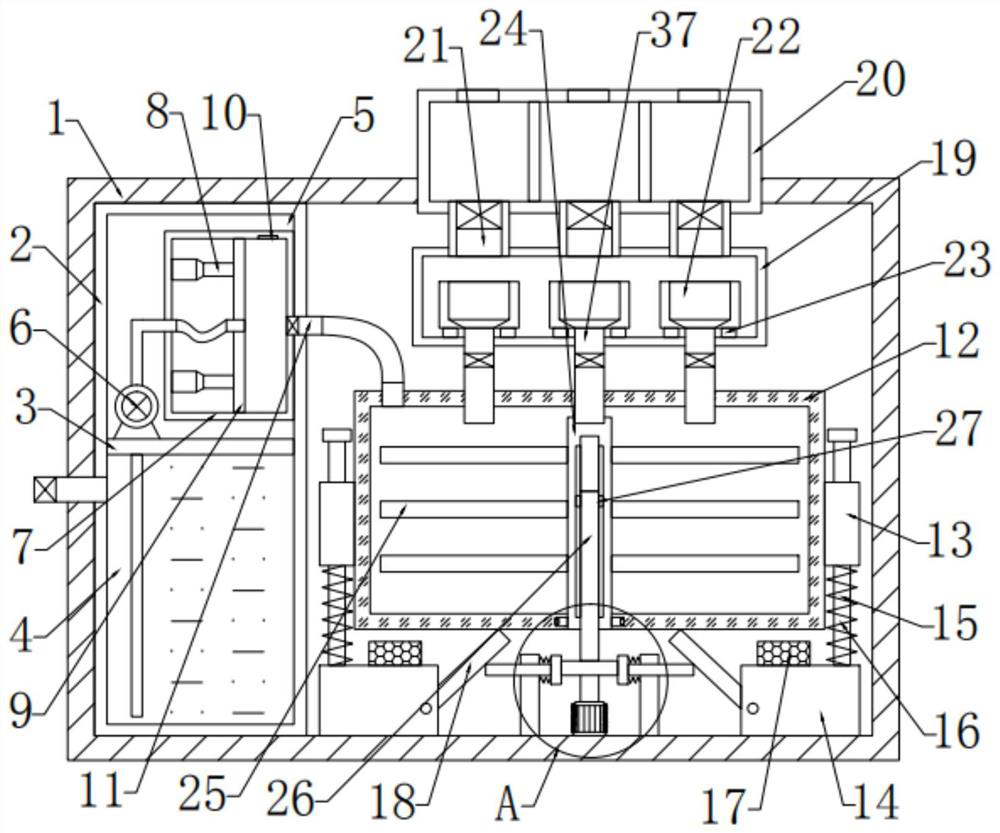

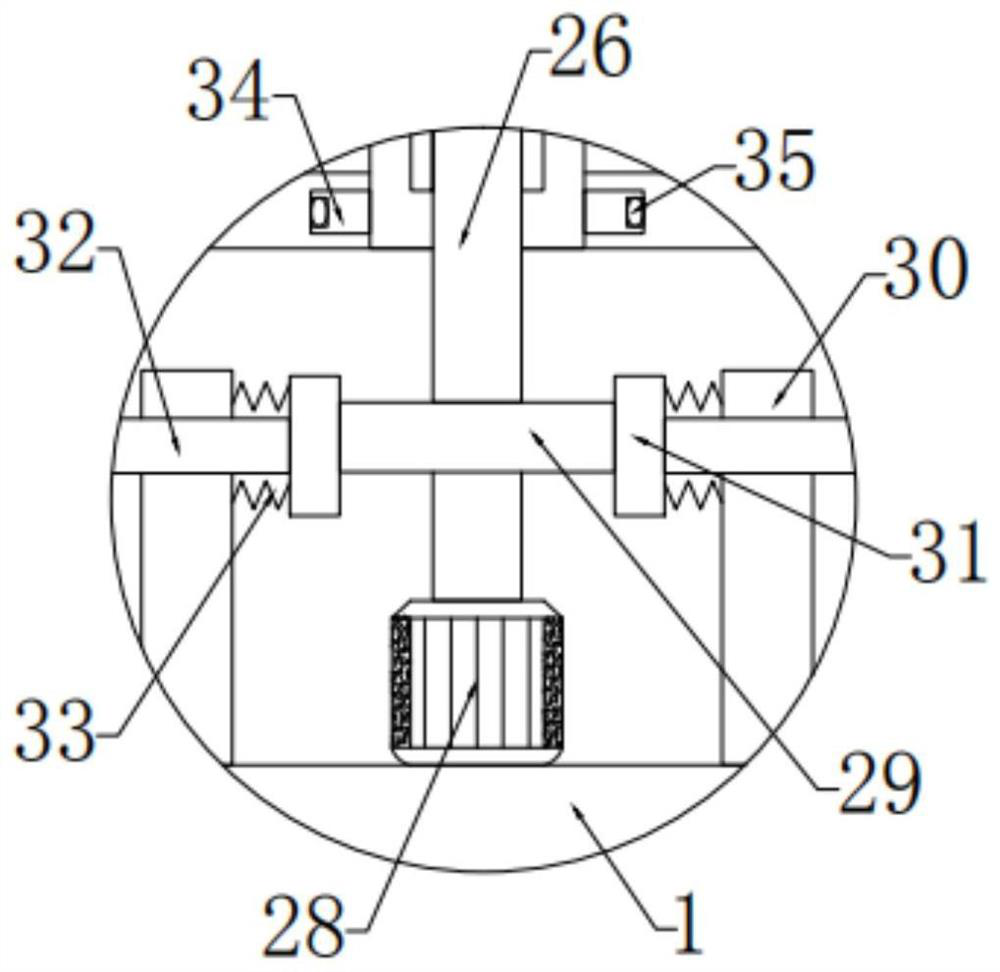

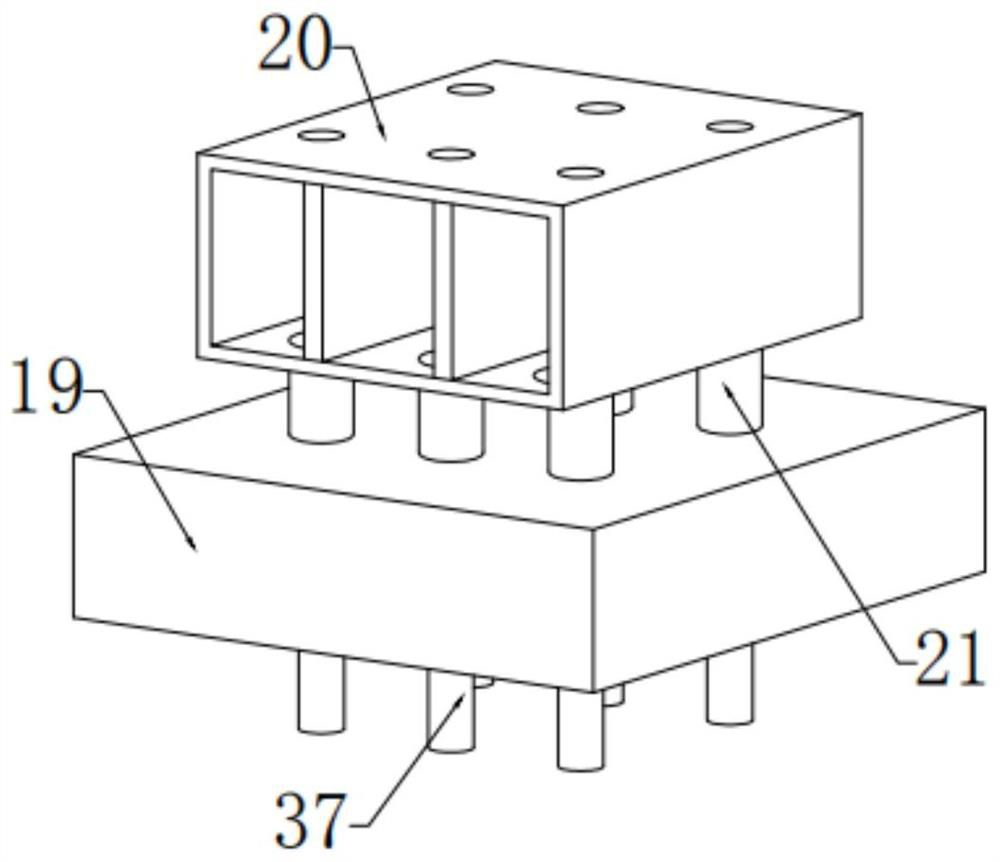

Highly automated fly ash curing device

InactiveCN111745824AGuaranteed stabilityImprove automationDischarging apparatusNon-rotating vibration suppressionEngineeringCement Material

The invention discloses a highly automated fly ash curing device. The highly automated fly ash curing device comprises a bottom plate, a quantitative discharging structure, a chelating agent mixing structure, a chelating structure, a curing structure and an unloading structure. A supporting table is arranged on the left side of the upper surface of the bottom plate, brackets are symmetrically arranged left and right in the middle of the upper surface of the bottom plate, the inner arc-shaped walls of the brackets are fixedly connected to an outer arc-shaped surface of a chelating barrel, L-shaped plates are symmetrically arranged front and back on the right side of the upper surface of the bottom plate, a metering water pump is arranged on the left side of the upper surface of the bottom plate, a water outlet in the right side surface of the metering water pump communicates to a water inlet in the lower end of the left side surface of the chelating barrel through a pipeline, and a conveying pipe is arranged at a discharge position at the lower end of the right side surface of the chelating barrel. The highly automated fly ash curing device can control the discharging amount of materials and further can overturn and chelate the internal materials, so that fly ash is cured to cement and the materials can be air-dried and cured quickly. Influence caused by vibration when equipmentoperates can be further reduced, and the stability of an integral structure is protected.

Owner:江苏西玛环境科技有限公司

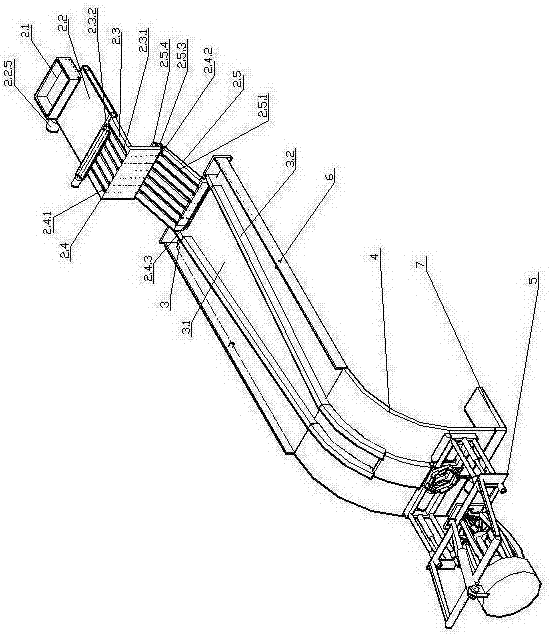

Flute sound tube bundling machine

The invention discloses a flute sound tube bundling machine comprising a bracket, a sorting mechanism, a storage mechanism, a shaping mechanism and a bundling mechanism. The sorting mechanism is composed of a material hopper, a conveyor belt, a trough plate, an inverted trough plate and a sorting trough plate; the storage mechanism comprises an arc surface storage plate, an elastic limiting band and a stroke switch; the shaping mechanism is composed of a shape mould, a push plate, a shaping block, a baffle and a paddling block; and the bundling mechanism comprises a bundling bracket, a third air cylinder and an opening device. A arranged fifth motor and the conveyor belt can control the blanking quantity of a funnel, the arranged elastic limiting band can buffer the capacity of stored materials and tightly presses flute sound cylinders, the shaping mechanism and the bundling mechanism can automatically bundle flute sound tubes into the fixed size, the arranged stroke switch can detect each station, operation of the entire flute sound tube bundling machine is intelligently controlled, a large amount of manual participation is not needed, and labor force is saved.

Owner:林德胜

Material feeder

InactiveCN1403356AReduce the amount of feedReduce material accumulationConveyor partsCoalEngineering

The material feeder includes hopper with supporting frame, front passage with material stop with material stopping skirt plate in the lower part, material flow regulating baffle, suspending feeding unit in the bottom of the hopper and great tilt angle corrugated baffle conveyer. The present invention solves the problem of bin pressure and the material feeder is suitable for use in coal dock or coal yard.

Owner:秦皇岛港务局

Automatic packaging device for drinks packaged in bags and formed by being mixed with water

InactiveCN108216750AImprove packaging efficiencyAccurate measurementLarge containersWrapper twisting/gatheringEngineeringMaterial storage

The invention discloses an automatic packaging device for drinks packaged in bags and formed by being mixed with water. The automatic packaging device comprises a rack, a material storage tank, a discharging mechanism, a packaging bag conveying mechanism, a bag clamping mechanism and a collection box. The discharging mechanism comprises a rotary disc, a first stepping motor and a bagging pipe. Thefirst stepping motor is fixedly mounted on the rack and can drive the rotary disc to rotate. The rotary disc is provided with multiple vertical material storage through holes. A first solenoid valveis arranged at the bottom of each material storage through hole. A discharging pipe is arranged at the bottom of the material storage tank and provided with a second solenoid valve. The rotary disc islocated below the discharging pipe, and in the rotation process of the rotary disc, the bottom of the discharging pipe can directly face all the material storage through holes. The bagging pipe is located below the rotary disc, and in the rotation process of the rotary disc, the upper end of the bagging pipe can directly face all the material storage through holes. According to the automatic packaging device, the discharging quantity is controlled by controlling the discharging time; precise metering can be guaranteed; and materials in all the packaging bags are the same in quantity.

Owner:SHIZONG HONGYING FOOD

Environment-friendly reinforced concrete garbage disposal equipment

InactiveCN109603976AEffective settlementReduce pollutionUsing liquid separation agentGrain treatmentsReinforced concreteEngineering

The invention discloses environment-friendly reinforced concrete garbage disposal equipment which comprises supporting legs, a main rack and a crushing box. The main rack is arranged on the upper sides of the supporting legs. The crushing box is arranged on the upper side of the main rack. A feeding hopper is arranged on the upper side of the crushing box. A water spray pipe is arranged on the upper side of the feeding hopper. The environment-friendly reinforced concrete garbage disposal equipment has the beneficial effects that through the arrangement of the water spray pipe and a spray head,dust generated when building garbage is crushed is effectively settled, and pollution to the environment is reduced; and through the arrangement of a baffle and a hydraulic shaft, the discharging quantity of crushing blocks can be controlled, and a vibration screen is prevented from being blocked.

Owner:GUIZHOU UNIV

Conveying device for mixed metal powder

ActiveCN107900337AAccurate and reliable feedingEnsure stabilityAdditive manufacturing apparatusIncreasing energy efficiencyPistonMixed metal

The invention discloses a conveying device for mixed metal powder and relates to the field of 3D printing. The conveying device for the mixed metal powder comprises a first funnel and a second funnelused for containing the metal powder; the lower end of the first funnel and the lower end of the second funnel are communicated with a first feeding pipe and a second feeding pipe correspondingly; oneend of the first feeding pipe and one end of the second feeding pipe are provide with a first driving system and a second driving system correspondingly; the first feeding pipe and the second feedingpipe are internally provided with a first piston and a second piston correspondingly; the first driving system and the second driving system are connected with the first piston and the second pistoncorrespondingly; the other end of the first feeding pipe and the other end of the second feeding pipe are provided with a first discharging port and a second discharging port correspondingly; the first discharging port and the second discharging port are arranged in opposite directions, and are communicated through a powder leaking pipeline; a powder leaking mechanism is arranged at the outlet position of the powder leaking pipeline; and a plurality of grooves sunken towards the position of the circle center of a rolling wheel are circumferentially distributed in the periphery of the rolling wheel. According to the conveying device for the mixed metal powder, the powder is better saved, and stability of the whole process is guaranteed.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

Feeding control unit

InactiveCN101844055ASignificant advantagesSignificant beneficial effectGroup 3/13 element organic compoundsFeed devicesNitrogen sourceNitrogen gas

The invention discloses a feeding control unit which relates to a control device of aluminum powder feeding equipment in aluminum triethyl production equipment. The feeding control unit consists of a nitrogen control unit, a pressure detection unit and a vacuum control unit, wherein the nitrogen control unit consists of a first nitrogen valve unit and a second nitrogen valve unit; the first nitrogen valve unit is arranged between a nitrogen source and the nitrogen replacing tank body of the feeding device; and the second nitrogen valve is arranged between the nitrogen source and the feed delivery tank body of the feeding device. The invention can independently control different working tanks, and the two tank bodies work at the same time without interfering with each other, thereby optimizing the process and enhancing the industrial efficiency; and the invention has simpler structure, is easier for operators to master, and can effectively improve operating efficiency and equipment safety.

Owner:天津联力化工有限公司

Plastic particle loading device

The invention discloses a plastic particle loading device which comprises a base, wherein a top seat is arranged at the top end of the base and is connected with the base through a support bar; an adding hopper is inlaid in the center position of the bottom end of the top seat; a connecting cylinder is fixedly mounted at the bottom end of the adding hopper; an inner cavity of the connecting cylinder is provided with a blocking plate; the blocking plate is connected with the connecting cylinder through a rotating shaft; the rotating shaft penetrates through an outer wall on the right side of the connecting cylinder; a rotating handle is fixedly mounted at the right end of the rotating shaft; a partition plate is fixedly mounted on the left side of the blocking plate; shaft sleeves are arranged at a joint of the rotating shaft and the connecting cylinder, and a joint of the rotating shaft and the partition plate; a gear is fixedly mounted on the outer wall at the left end of the rotating shaft; a blanking control device is fixedly mounted on the left side of the top end of the inner cavity of the connecting cylinder and comprises a housing. The plastic particle loading device avoids continuous operation of an operator and provides great convenience for the operator, through the coordination of the blocking plate, the rotating shaft, the gear and the blanking control device.

Owner:江苏通发环保科技有限公司

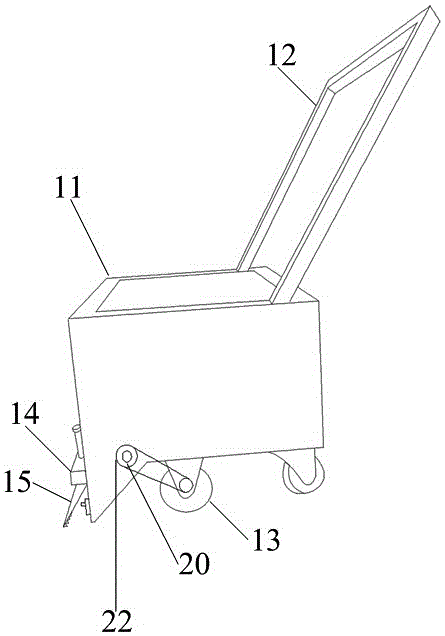

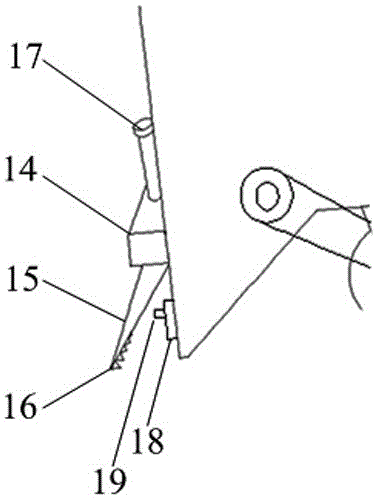

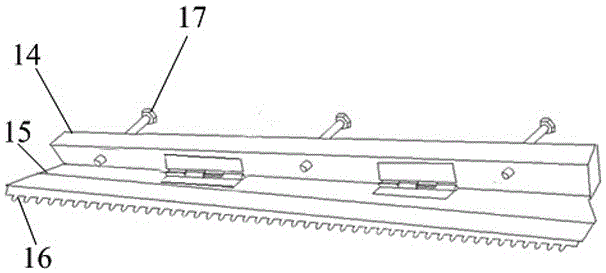

Fluid material lying device

The invention relates to a fluid material lying device. The fluid material lying device comprises a box-type dolly, a walking device, a scraper plate device and a blanking device. The box-type dolly comprises a box body and a push-and-pull section. The walking device is connected with the outer bottom of the box body. The scraper plate device is connected with the box body, and is located at the rear end of the heading direction of the box body. The blanking device is connected with the box body. The scraper plate device comprises a scraper plate fixed strip, a scraper plate adjusting plate, a tooth bar scraper plate and at least two adjusting bolts. The connection relation is as follows: the scraper plate fixed strip is fixedly connected with the outer surface of the box body, the scraper plate fixed strip is in hinge connection with one side of the scraper plate adjusting plate, the tooth bar scraper plate is connected with the other side of the scraper plate adjusting plate, the at least two adjusting bolts are in bolt connection with screw holes in the scraper plate fixed strip, and one end of each of the at least two adjusting bolts is in contact connection with the scraper plate adjusting plate. The used dolly is simple in structure, processing is easy, and labor time is saved. The angle is adjustable, the lying speed is fast, and the effect is good.

Owner:张辉

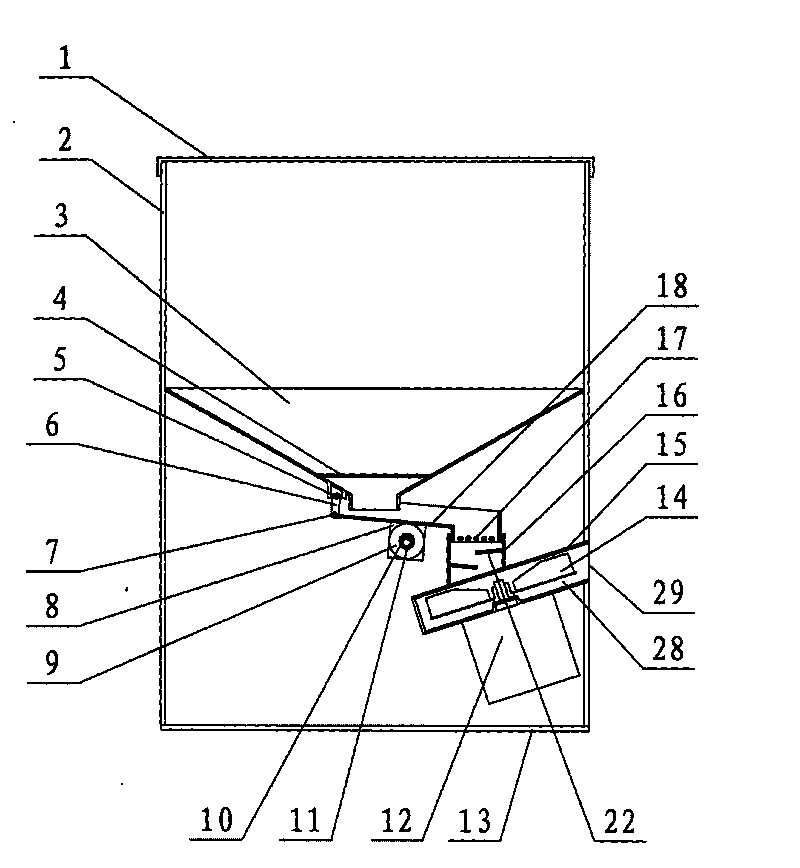

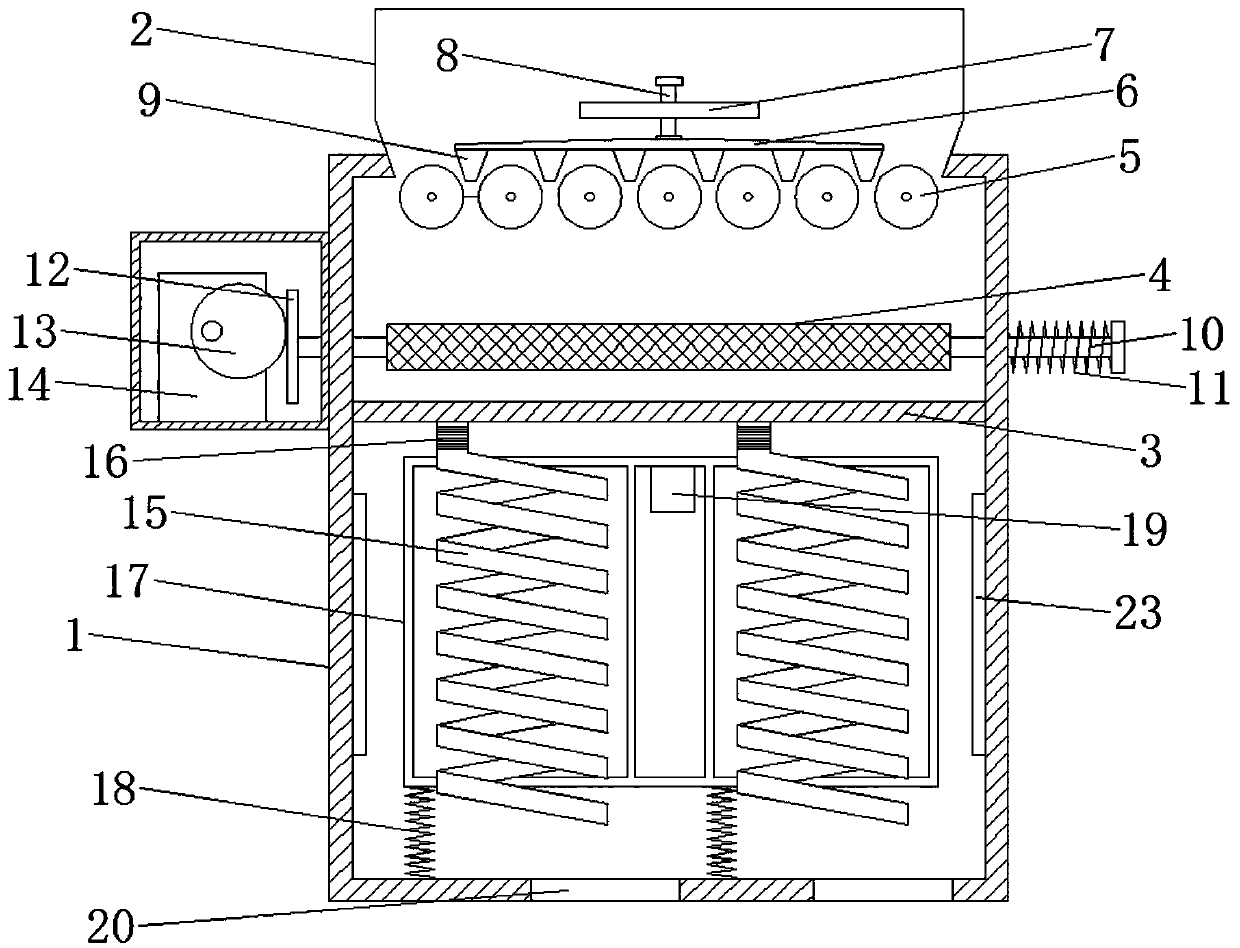

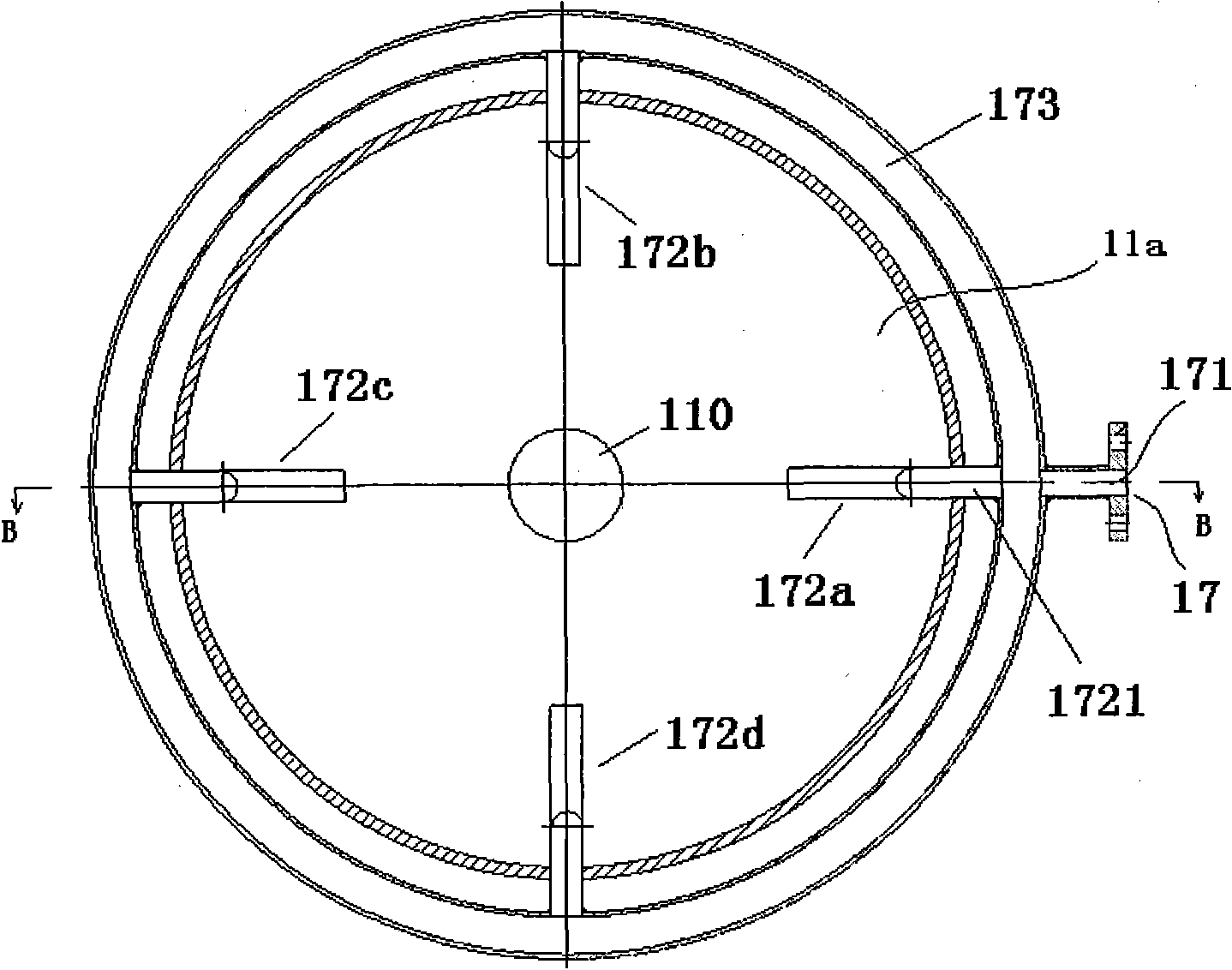

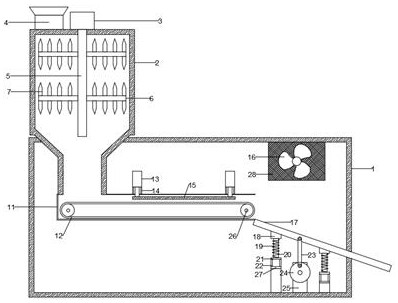

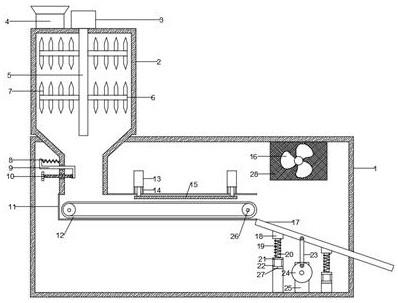

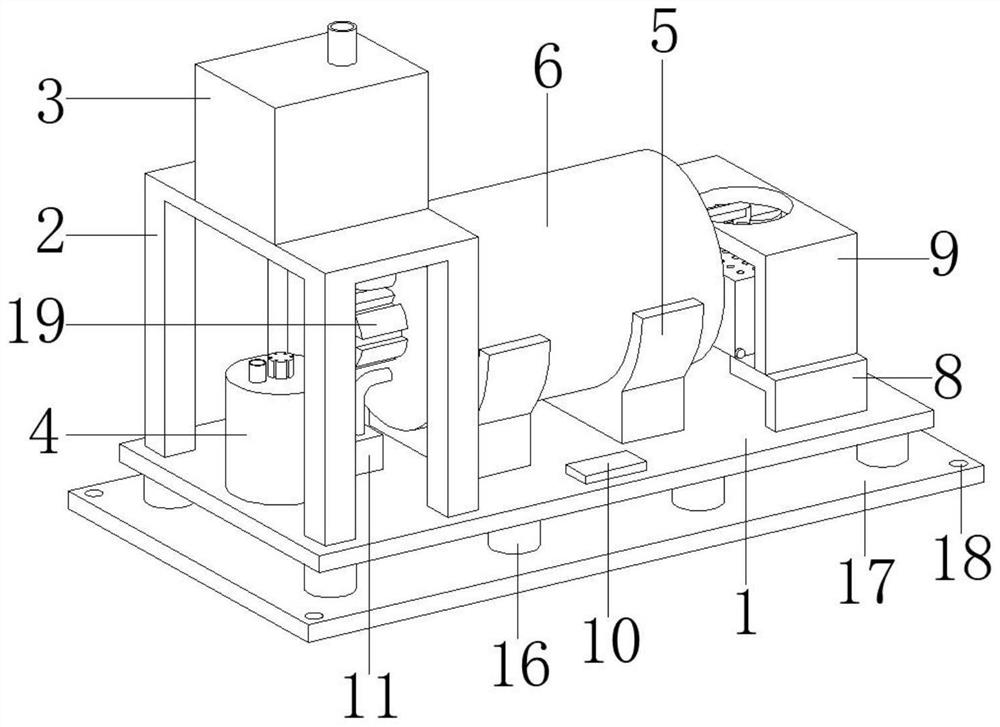

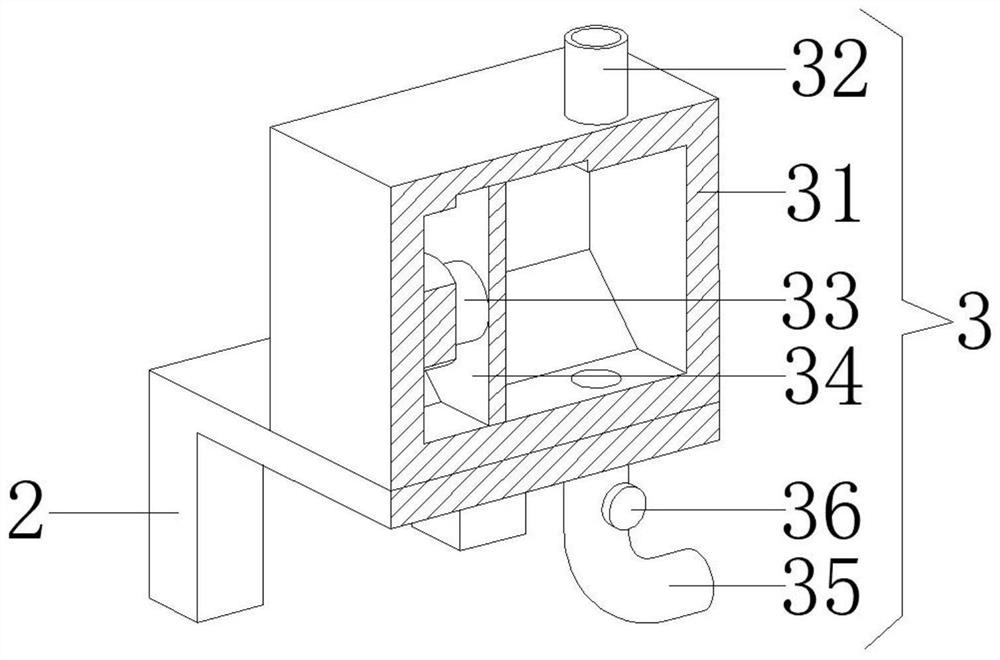

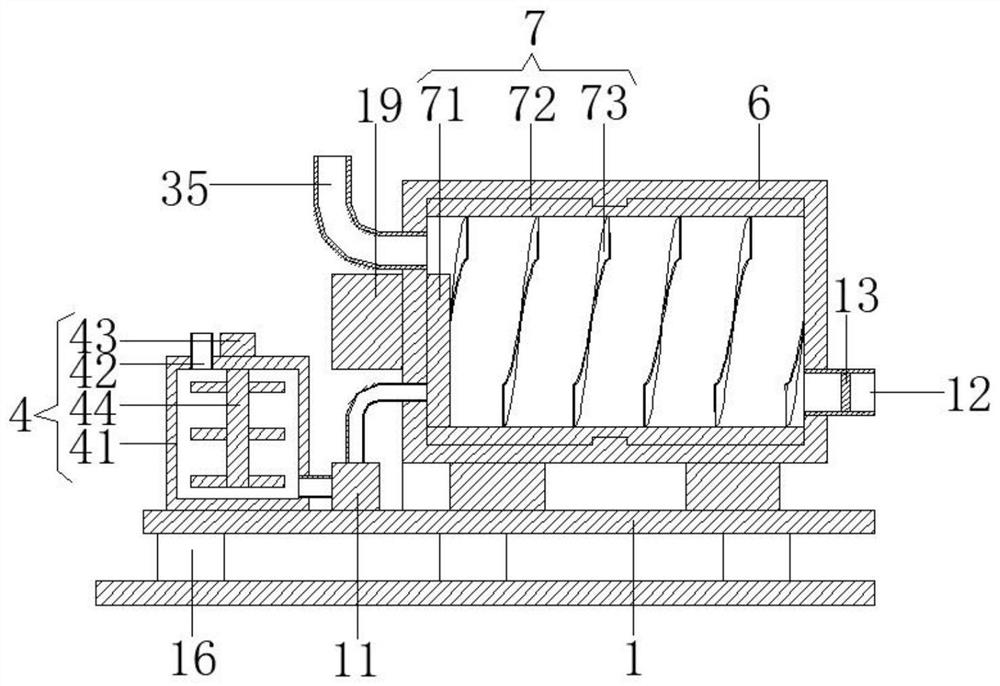

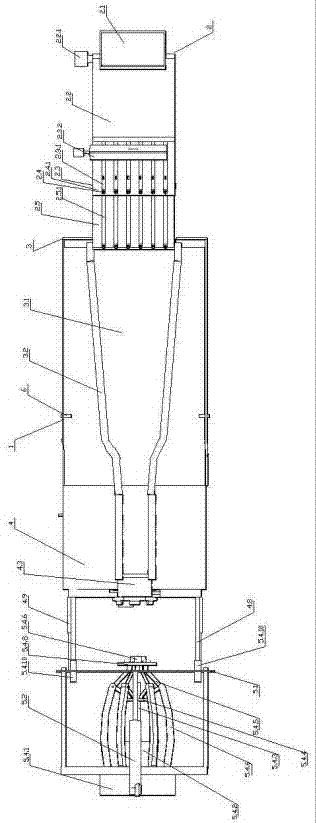

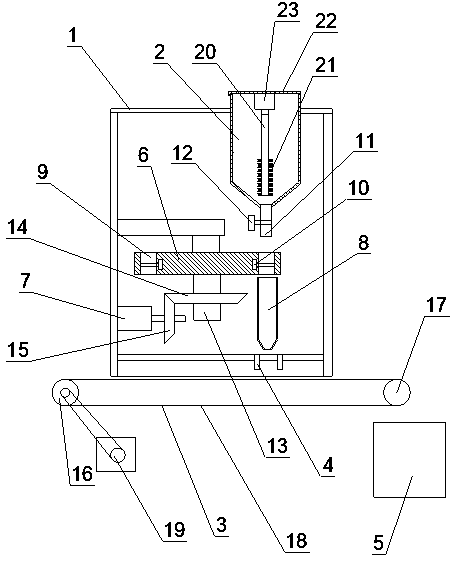

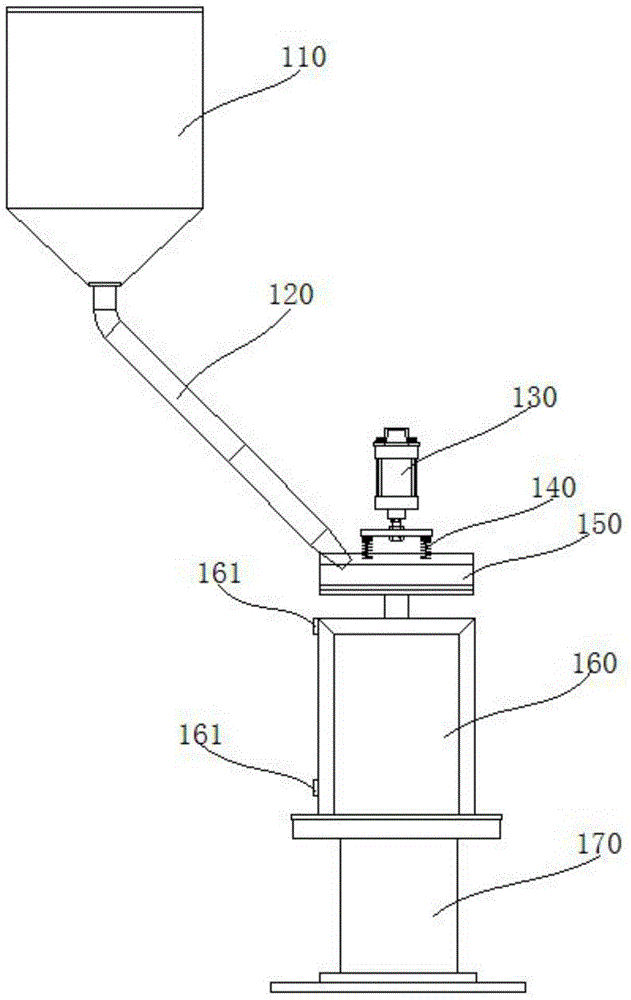

Filling device for activated carbon plate in filtering and absorption device

ActiveCN104147894AUniform dense fillingIncrease productivityDispersed particle separationActivated carbonEngineering

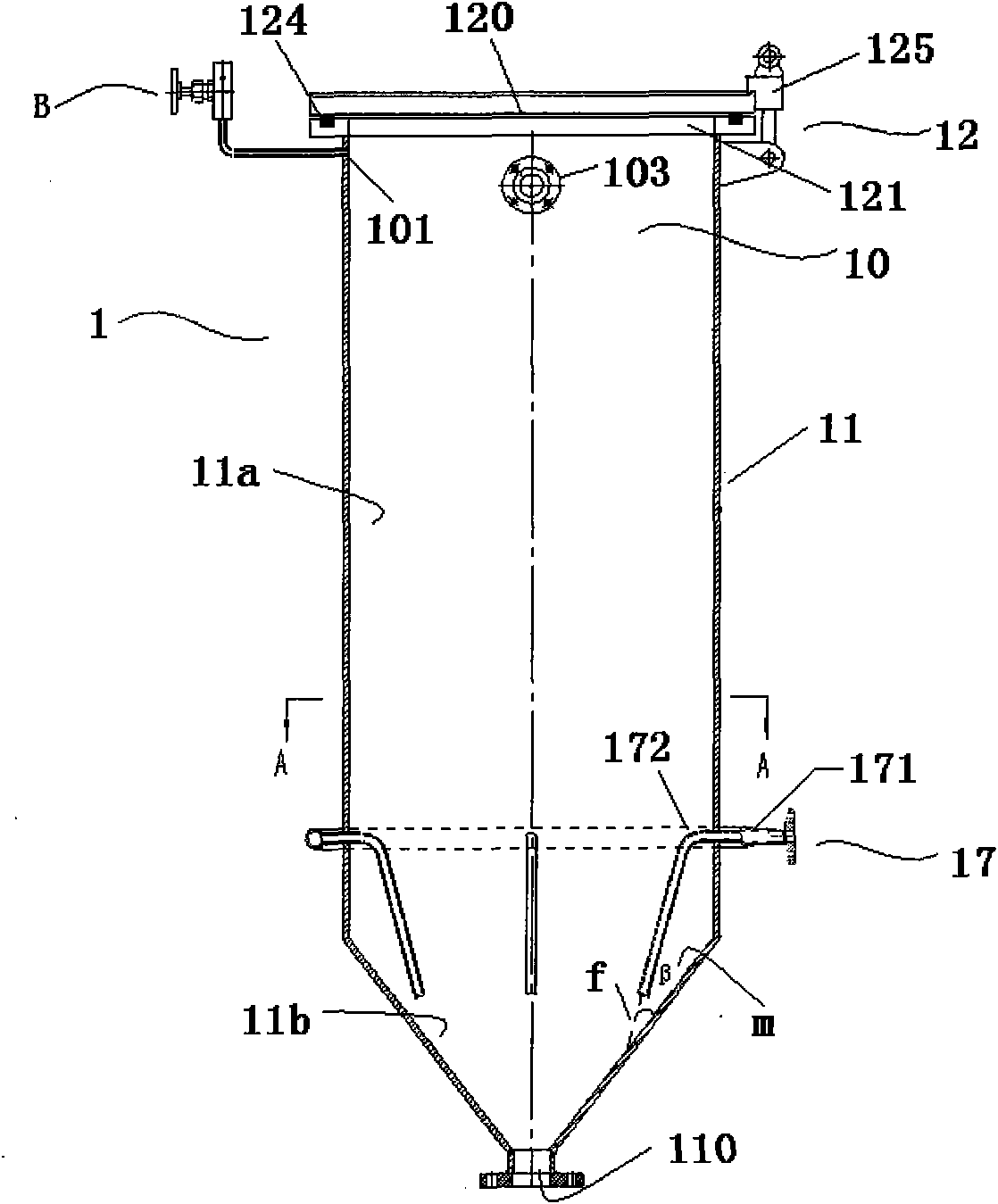

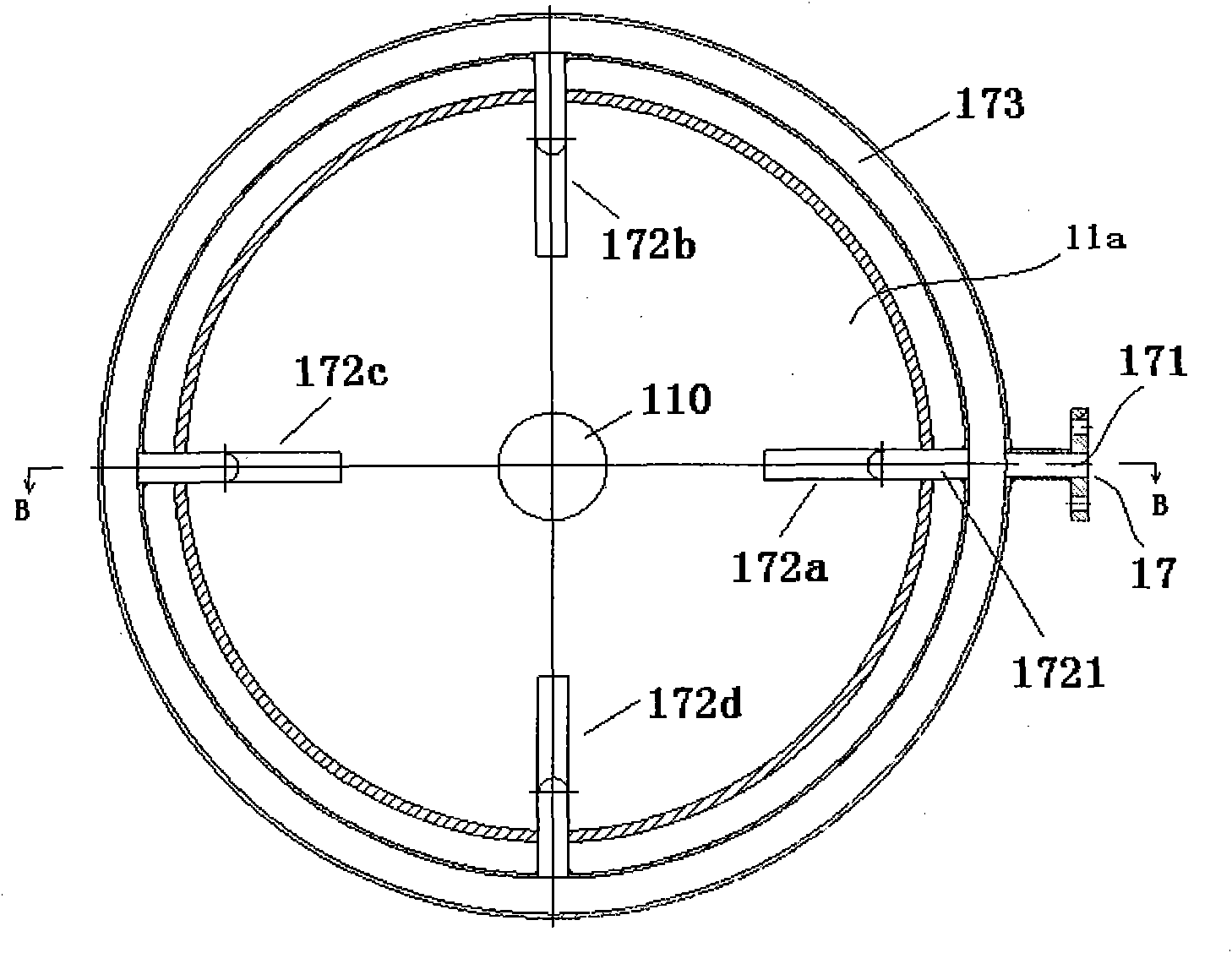

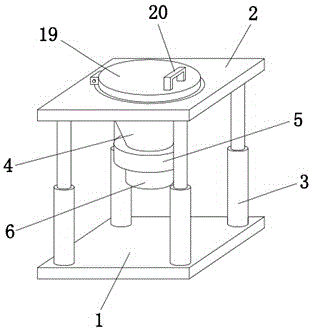

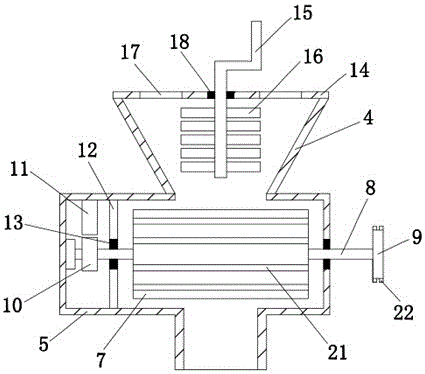

The invention relates to civil defense equipment, and particularly relates to a filling device for an activated carbon plate in a filtering and absorption device. The filling device for the activated carbon plate in the filtering and absorption device comprises a material storage tank (110), a hopper (150), a support frame (160) and a vibration table (170), wherein a feeding pipeline (120) is arranged between the material storage tank (110) and the hopper (150); the hopper (150) is arranged on the support frame (160) in a height adjustable manner; the support frame (160) is arranged on the vibration table (170), and is provided with clamping mechanisms (161); a to-be-filled activated carbon plate is arranged between the vibration table (170) and the hopper (150) and can be clamped by the clamping mechanisms (161). According to the filling device, activated carbon particles and dust are reduced, and the to-be-filled activated carbon plate can be filled with the activated carbon particles in a compact and uniform distribution manner.

Owner:ZHEJIANG SANYI TECH CO LTD

Variable-discourse universe dadaptive fuzzy control method and device for pre-roasted electrolytic aluminium production

The present invention is variable-discourse universe adaptive fuzzy control method and device for pre-roasted electrolytic aluminium production. The device includes voltage detecting unit to detect the voltage variance of electrolytic tank; upper computer to set alumina concentration and perform concentrated control of technological operation and material feeding of the electrolytic tank; electrolytic tank controlling computer to receive the set alumina concentration value from the upper computer, perform variable-discourse universe fuzzy control calculation based on the voltage variance to obtain the current alumina feeding interval time; and executing mechanism to control the alumina feeding amount based on the received alumina feeding interval time.

Owner:BEIJING NORMAL UNIVERSITY

Efficient disinfectant preparation device for animal husbandry

InactiveCN112354442AWell mixedImprove uniformityShaking/oscillating/vibrating mixersTransportation and packagingAnimal scienceElectric machinery

The invention relates to the field of animal husbandry, in particular to an efficient disinfectant preparation device for animal husbandry, which comprises a shell, a mixing box is arranged on the inner side of the shell, a supporting mechanism is arranged between the mixing box and the shell, a discharging mechanism is arranged on the upper side of the mixing box, and a water injection mechanismis arranged on the left side of the discharging mechanism. The motor can drive the outer rod to rotate through the inner rod, the outer rod drives the stirring rod to rotate so that deionized water and a medicament can be fully mixed, the inner rod can drive the outer rod to rotate at the same time, the outer rod drives the cam to rotate so as to push the movable plate to rotate, and the mixing box moves up and down repeatedly under the action of the movable plate and the first spring. By arranging the water injection mechanism, the volume of the deionized water can be accurately controlled, and by arranging the discharging mechanism, the discharging amount of the medicament can be accurately controlled, so that the concentration accuracy of the finally prepared disinfectant is high.

Owner:王凤艳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com