Pneumatic type feeder

A feeder and pneumatic technology, applied in the field of pneumatic feeders, can solve the problems of high cost of building a feeding table, high labor intensity for feeding, and limited throwing area, and achieves saving feed, high work efficiency, and throwing area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

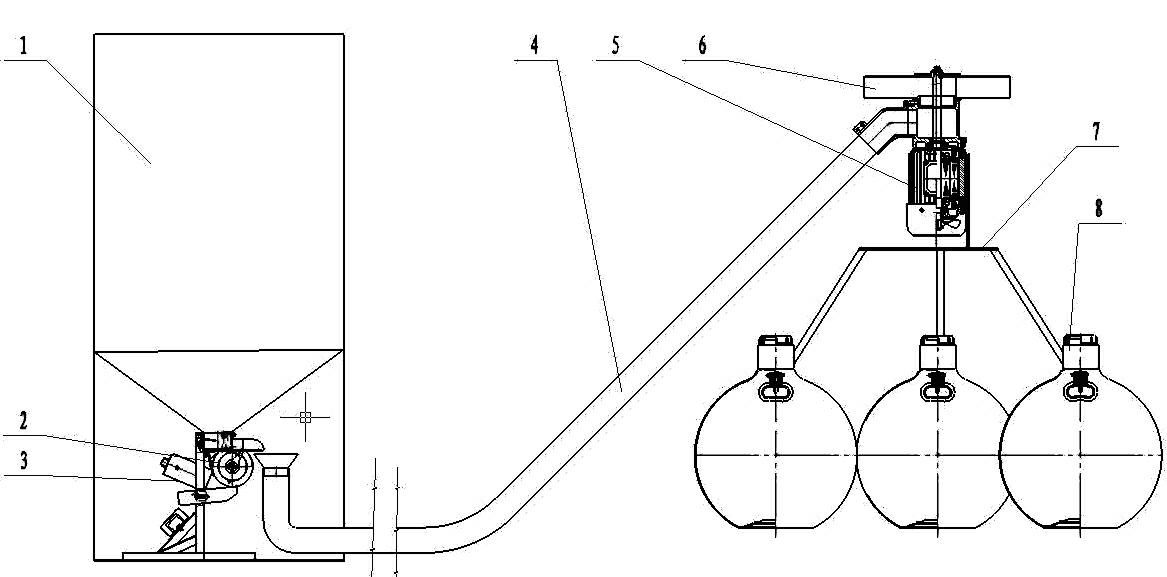

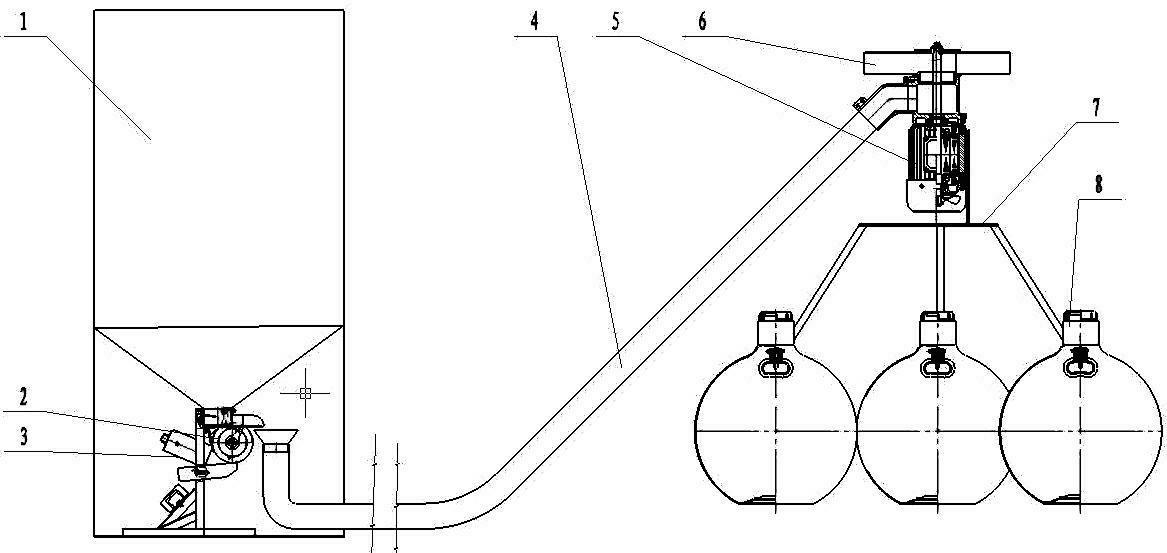

[0012] Such as figure 1 As shown, the pneumatic feeding machine includes a pneumatic motor 5, a rotating throwing tray 6, a feed delivery pipe 4, a material box 1, a feeder 2, a controller 3, a bracket 7 and a floating body 8, and the floating body is installed under the bracket 7 8. Install the air motor 5 above the bracket 7, the rotating throwing disc 6 is connected to the air motor 5, one end of the feed conveying pipe 4 is connected with the air motor 5 and runs through the rotating throwing disc 6, the other end of the feed conveying pipe 4 Through the distributor 2, the distributor 2 is installed at the outlet of the material box 1, and the controller 3 is installed on the material box 1, and the controller 3 is connected to the pneumatic motor 5 and the distributor 2.

[0013] Wherein, the length of the feed conveying pipe 4 is adjusted according to the conveying distance.

[0014] Wherein, the volume of the material box 1 can be set according to the needs of users. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com