Texturing and cleaning process method of polysilicon wafer

A technology for polycrystalline silicon wafers and silicon wafers, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of difficult control of product quality, increase production costs, etc., and achieve remarkable results and improve the effect. , the effect of low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be described in detail below with reference to the accompanying drawings and embodiments.

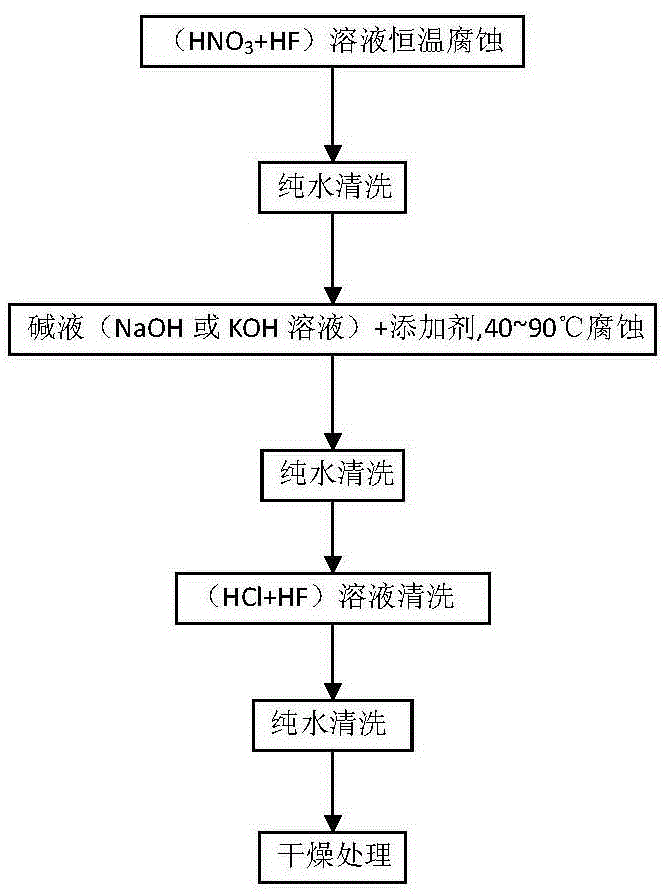

[0019] like figure 1 As shown, the texturing and cleaning process of the polycrystalline silicon wafer proposed by the present invention includes the following steps:

[0020] 1. The silicon wafer is first soaked in a mixed solution of 5-7.5% HF and 35-45% HNO3 with a temperature control of 5-15°C for 0.8-1.5 minutes, and then acid etching is performed to achieve the purpose of preliminary texturing of the silicon wafer. . In this process, according to the consumption of the reaction between the solution and the silicon wafer, a certain amount of HF and HNO3 are replenished in time to ensure the proper ratio of the solution;

[0021] 2. The silicon wafer after acid etching is then cleaned in 10-18MΩ·cm pure water by spraying, soaking or a combination of the two methods, in order to minimize the adhesion of the acid solution on the surface of the silicon wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com