Dustproof feeding device for deep processing of forage grass

A feeding device and dust-proof technology, which is applied in the field of dust-proof feeding devices for grass deep processing, and can solve the problems of single function, inability to improve feeding efficiency, lack of mechanism for crushing grass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

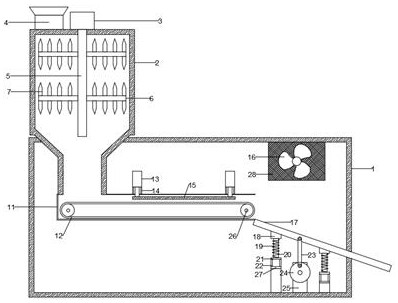

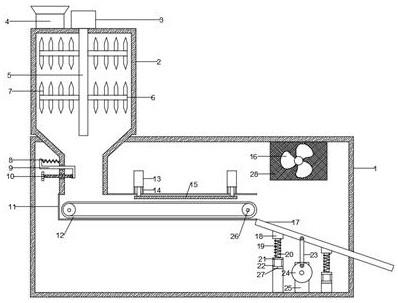

[0020] See Figure 1 ~ 2 In the embodiment of the present invention, a dust-proof feed apparatus for a pasture, including an apparatus main body 1, and a pulverizing mechanism includes a stirring mechanism, which comprises a stirring rod 5, a pulverized blade 7, a feed The port 4 and the pulverizing motor 3, the upper portion of the apparatus main body 1 fixedly provided with a pulverized case 2, and a pulverized motor 3 is fixed at the top, and the top of the pulverizer 2 is also fixedly provided with a feed port 4, which is The rotating portion of the pulverized motor 3 is fixedly attached to the stirring lever 5, the stirring rod 5 extends through the pulverket 2 and the stirring rod 5 away from one end of the pulverized motor 3 to the pulverized case 2, and the shredding tank 2 is opened at the bottom of the discharge opening. ;

[0021] Further, a feed tank 11 is provided below the outlet opening, and the electric push rod 13 is provided with an electric push rod 13 on both si...

Embodiment 2

[0025] See Figure 1 ~ 2 The present embodiment differs from the first embodiment in that the sheet is slid on one side, and the baffle 9 is fixed to the discharge opening and the discharge port. The discharge port is located below the baffle 9 through which is provided with the active shaft 10, which is attached to the baffle 9, and the rotation moving shaft 10 can adjust the position of the baffle 9 at the outlet, which can regulate the grass. The range is controlled to control the speed of the following and the amount of the following.

[0026] The working principle of the present invention is:

[0027] When this device operates, the pasta is supplied from the feed port 4, and the pulverizing motor 3 is applied, the pulverizer 3 is rotated to rotate the stirring rod 5, and the stirring rod 5 rotates the pulverized blade 7 to cut the grass, cutting the grass, cutting After the random fell from the sheet of the discharge opening, the first motor external power supply, the first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com