Flute sound tube bundling machine

A flute sound and tube forming technology, which is applied in the field of flute sound tube bundling machine, can solve problems such as delay in process and slow working speed, and achieve the effect of labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

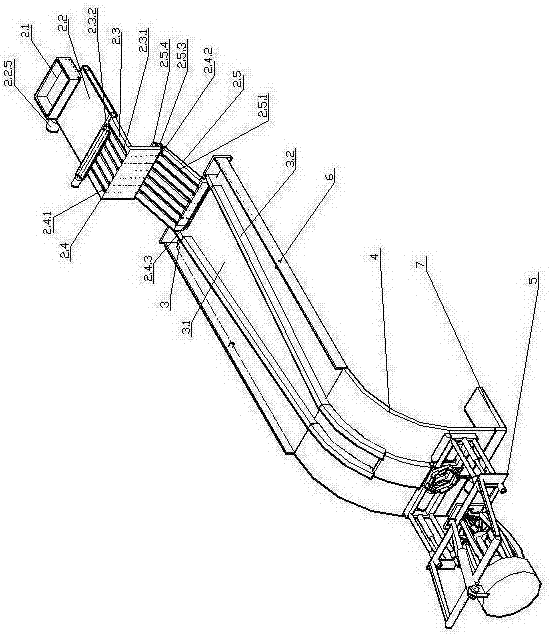

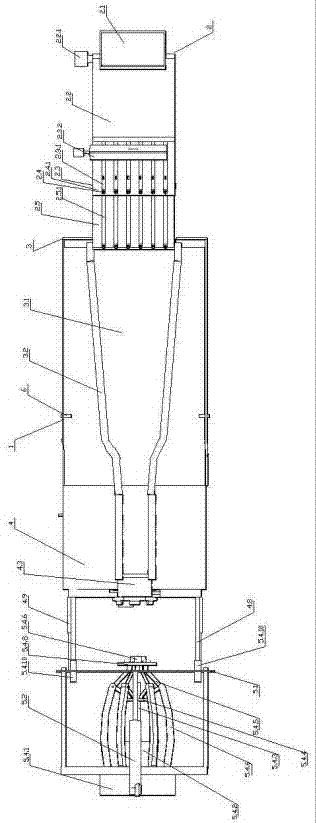

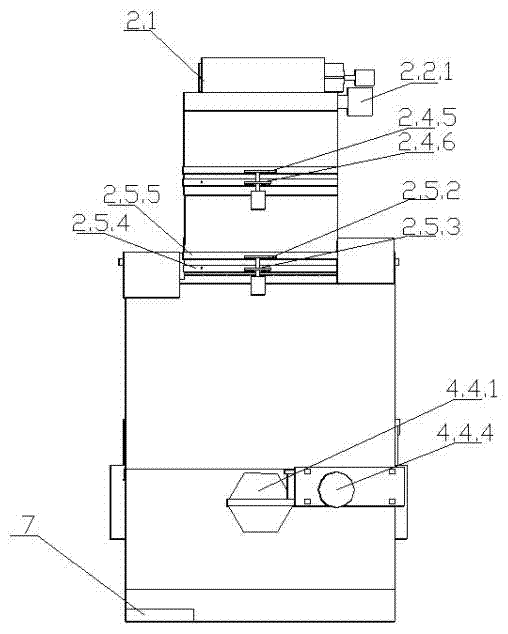

[0020] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0021] Such as Figure 1-2 As shown, the flute tube bundling machine includes a sorting mechanism 2 fixed on the bracket 1, a storage mechanism 3, a shaping mechanism 4 and a binding mechanism 5, wherein the sorting mechanism 2, the storage mechanism 3, the shaping mechanism 4 and the binding mechanism 5 Connect sequentially according to the conveying direction of the flute tube;

[0022]The sorting mechanism 2 includes a material hopper 2.1, a conveyor belt 2.2, a trough plate 2.3, an inverted trough plate 2.4 and a sorting trough plate 2.5, wherein the tail of the material hopper 2.1 is fixed with a conveyor belt 2.2, and the tail of the conveyor belt 2.2 is connected with a trough plate 2.3 , the top of the slot plate 2.3 is provided with a roller baffle plate 2.3.2, the slot plate 2.3 is provided with a plurality of horizontal square slots 2.3.1, the bottom of the square sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com