Material feeder

A feeding device and feeding device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of easy-wear belts, insufficient height, blocked buckets, etc., to reduce material accumulation, ensure normal work, and reduce input The effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

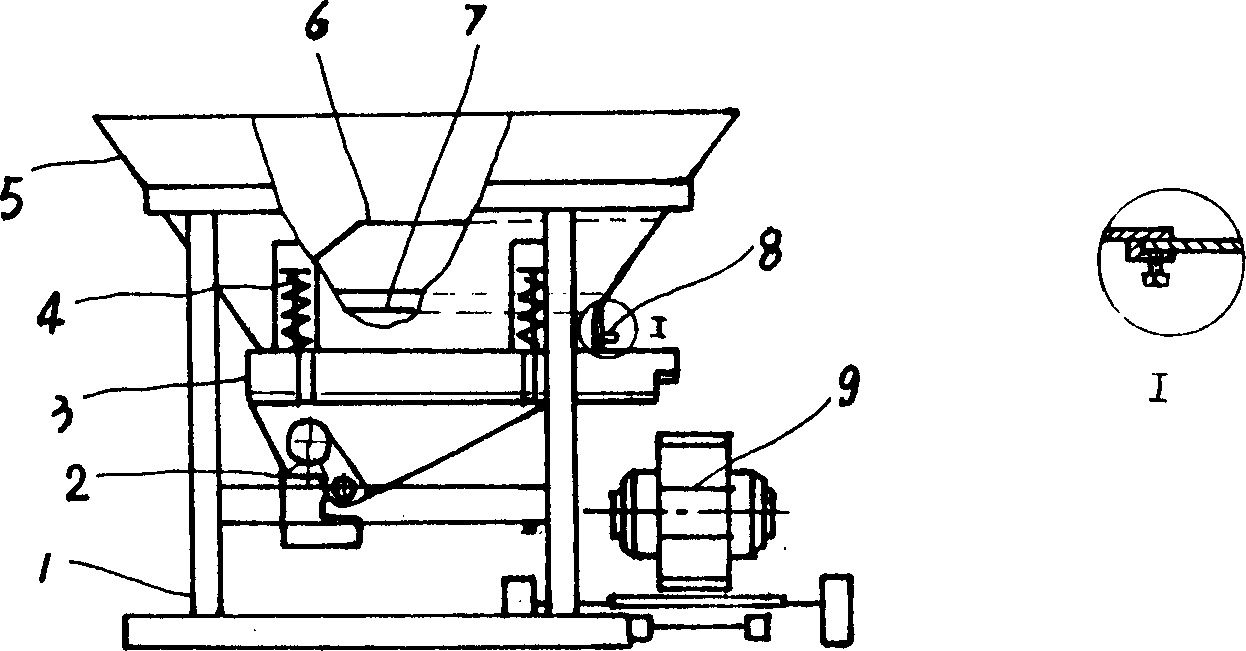

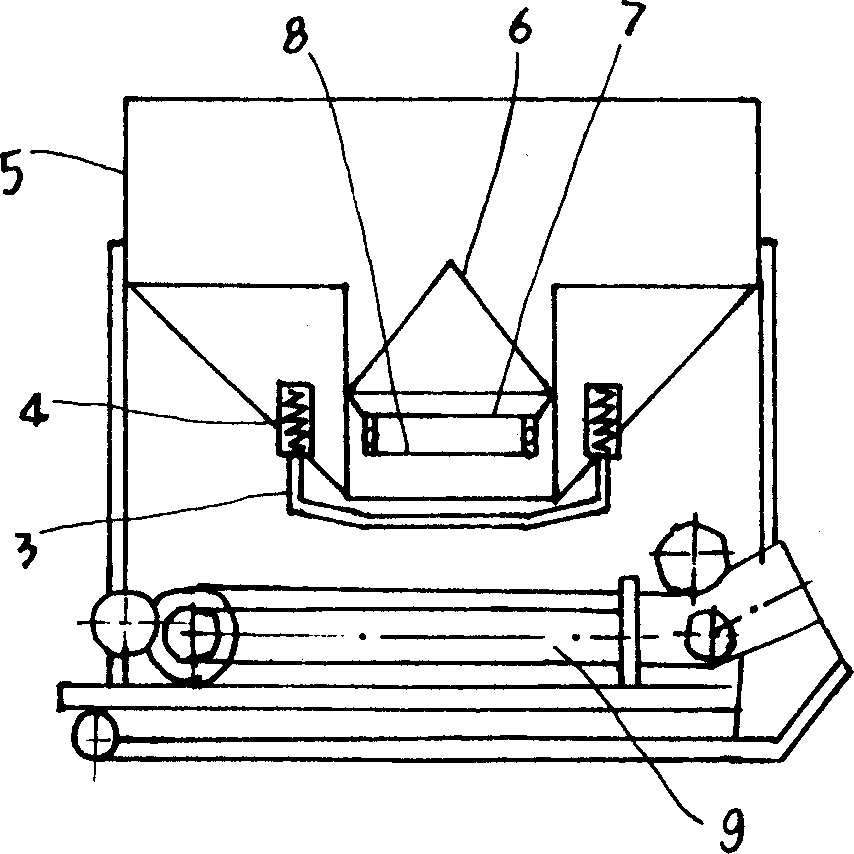

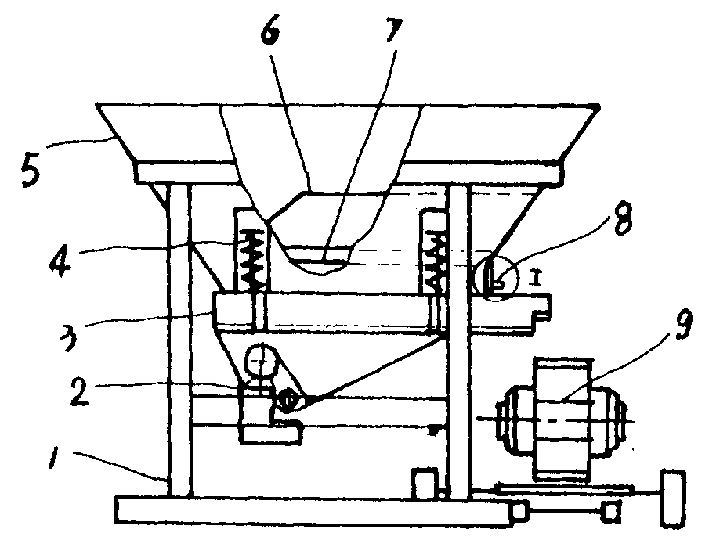

[0008] The present invention will be further described and illustrated below in conjunction with accompanying drawing, by figure 1 , 2 The feeding device is given, which includes a support frame 1 and a hopper 5 installed on it, and a large-inclination corrugated sidewall conveyor 9 installed on the side end of the support frame 1, in order to reduce the warehouse pressure, and set in the hopper 5 There is a material stopper 6, that is, the inwardly inclined material flow direction is controlled by the material stopper skirt 7 at the bottom of the material stopper 6 body, which can not only resist the material flow pressure in all directions, but also redistribute the falling point of the material. The bottom of the hopper 5 is provided with a suspended feeding device. The suspended feeding device is composed of a feeding trough 3, and a fixedly installed driver 2 is flexibly connected to the bottom of the feeding trough. The springs arranged symmetrically on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com